Full-automatic packing method and device capable of achieving brick stacking and reserving forklift holes

A forklift hole, fully automatic technology, applied in the direction of building materials packaging, transportation and packaging, packaging item types, etc., can solve the problems of brick stacks that cannot be directly transported by forklifts, unsafe transportation, and high transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

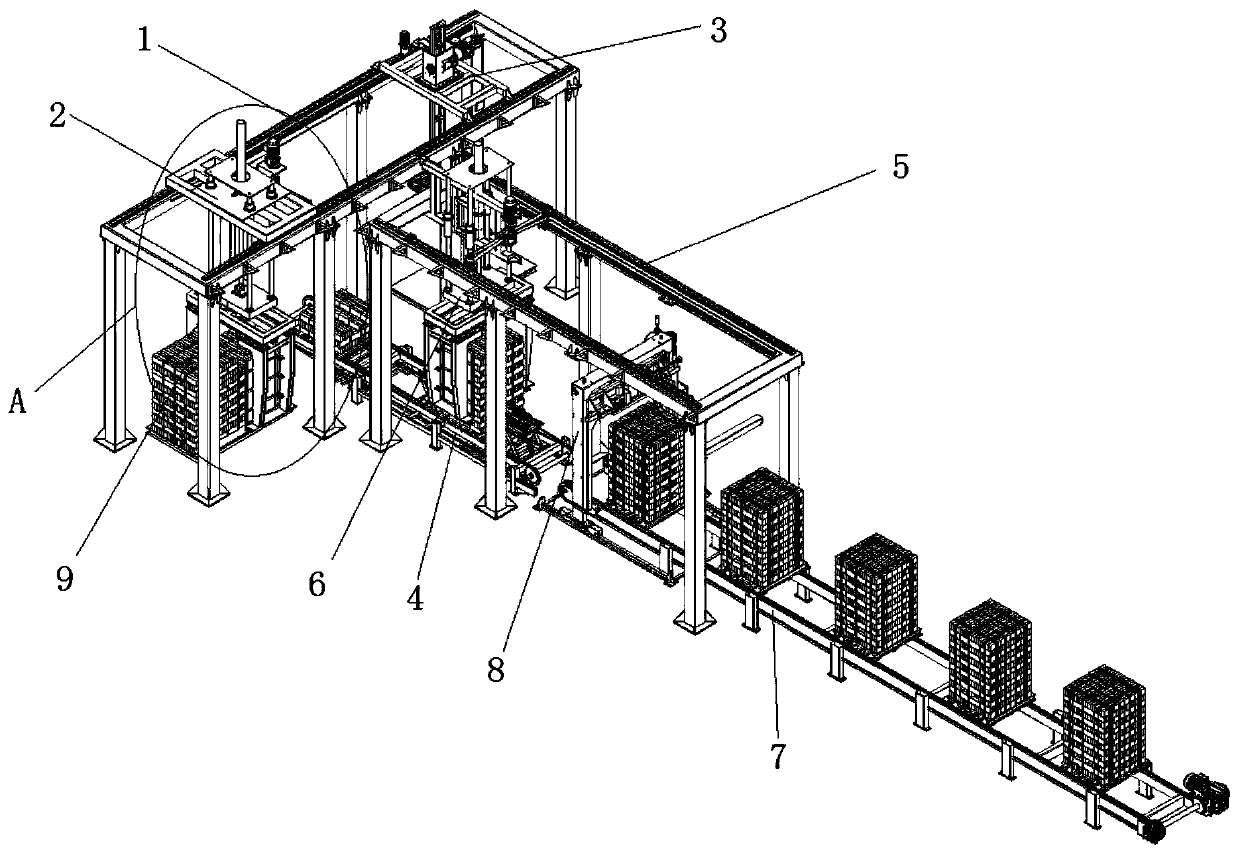

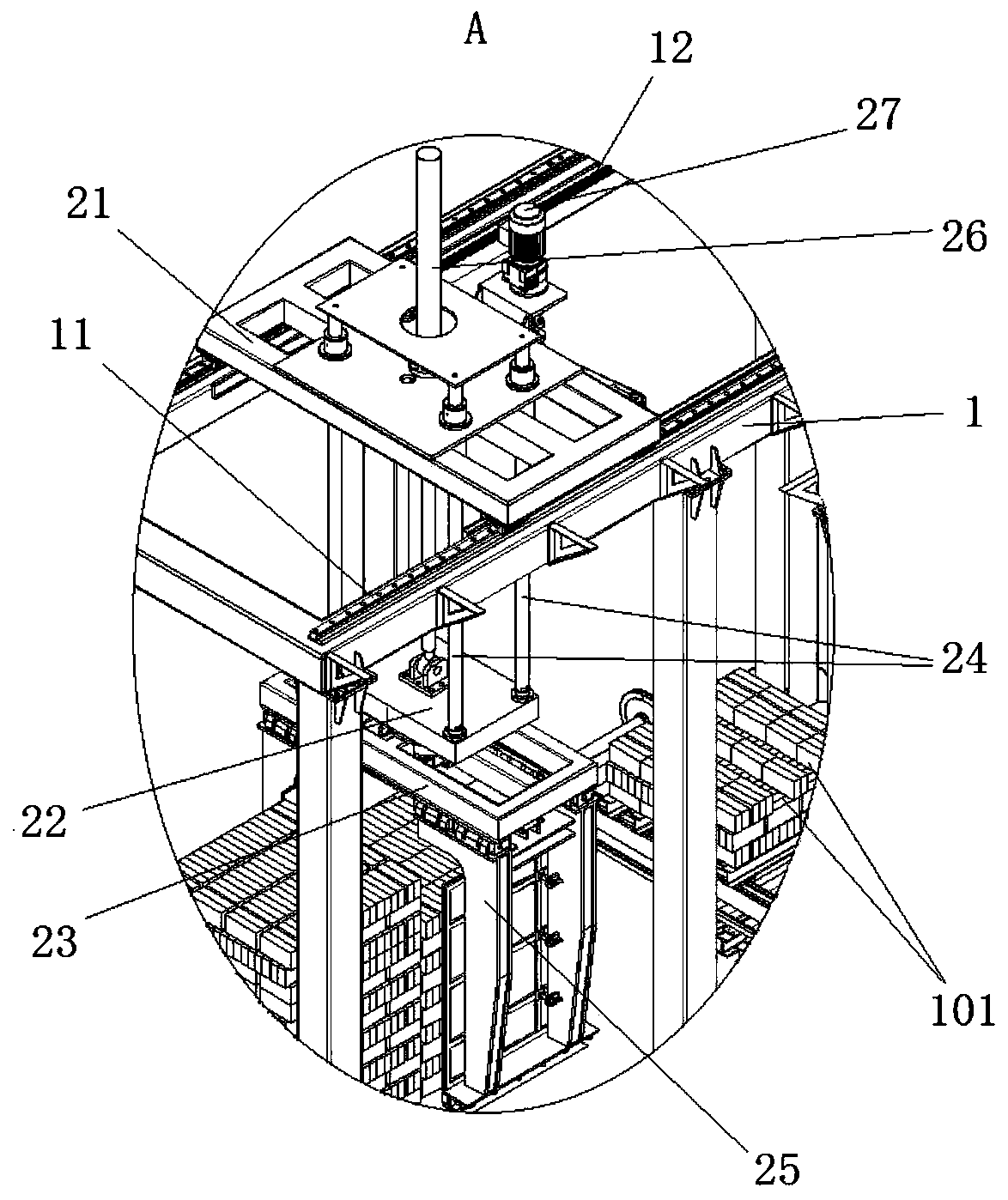

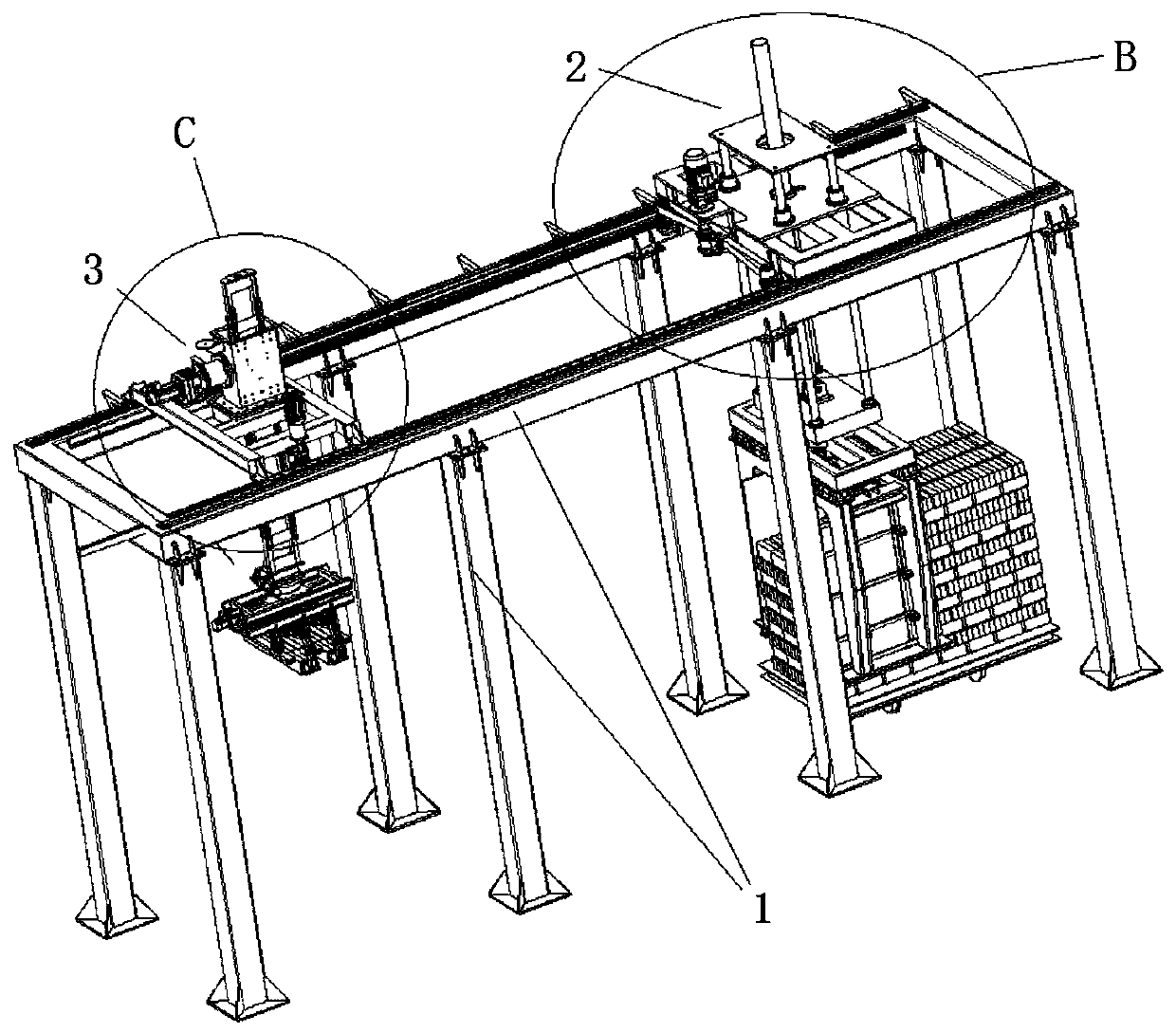

[0034] A kind of embodiment of the fully automatic packaging equipment that can reserve forklift hole brick stack of the present invention, as Figure 1-Figure 13As shown, it includes a longitudinal support 1, on which a first grabbing fixture 2 and a second grabbing fixture 3 are installed along a longitudinal guide, and a first conveying device 4 whose transportation direction extends in a transverse direction is arranged below the longitudinal support 1 In this embodiment, the conveying direction of the first conveying device 4 is the transverse direction, and the direction horizontally perpendicular to the conveying direction of the first conveying device is the longitudinal direction. The first grabbing jig 2 includes a first mounting frame guided and installed on the longitudinal support 1 , and a first driving mechanism for driving the guiding action of the first grabbing jig is provided between the first mounting bracket and the longitudinal bracket. Two first clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com