Porous carbon material and preparation method thereof and supercapacitor

A technology of porous carbon materials and potassium bicarbonate, applied in hybrid capacitor electrodes, chemical instruments and methods, carbon compounds, etc., can solve the problems of waste of activators and failure to maximize the activation effect of activators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] (1) Preparation of two-electrode organic capacitor electrodes: activated carbon (80wt%), Super P (10wt%, as a conductive agent) and a binder shared by CMC and SBR (10wt%, CMC:SBR=1:2) The three samples were stirred in deionized water until uniform, coated on aluminum foil with a spatula, and dried overnight in a vacuum oven at 60°C. Gained pole pieces were cut into discs with a diameter of 12 mm, and were further dried and put into a glove box for subsequent use.

[0037] (2) Assembling two-electrode organic capacitors: the button cell uses a CR2032 button cell shell, and a lithium sheet with a diameter of 16 mm is used as the counter electrode. Using propylene carbonate (PC) dissolved in 1mol / L TEATFB as the electrolyte, and Celgard 2300PP / PE / PP three-layer microporous composite membrane as the diaphragm, the positive and negative electrode sheets and the diaphragm were stacked and assembled, and then punched and sealed. All assembly procedures were performed in a dry g...

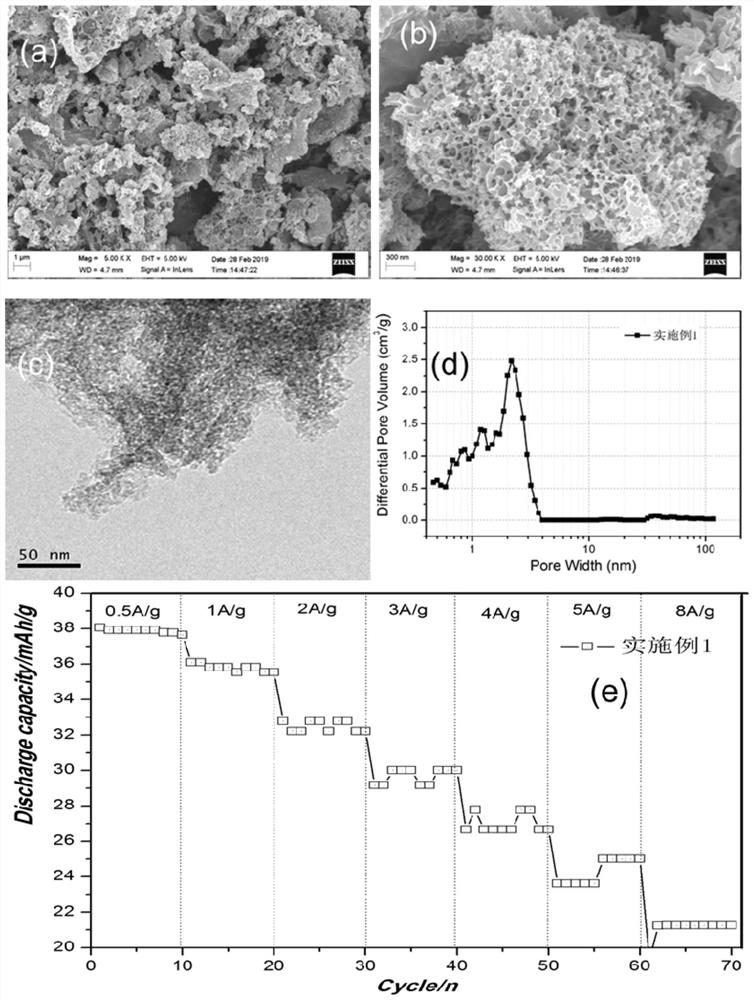

Embodiment 1

[0040] An embodiment of the preparation method of the porous carbon material described in the present invention, the preparation method of the porous carbon material described in this embodiment comprises the following steps:

[0041] (1) Immerse 100g of macroporous acrylic adsorbent resin in dilute hydrochloric acid, filter after soaking for a period of time, then add it to 400mL of cobalt chloride aqueous solution with a concentration of 0.2mol / L, stir for 2 hours, and then put it in an 80°C water bath for stirring Evaporate to dryness, and continue to dry in an 80°C blast drying oven for 12 hours to obtain a resin that adsorbs cobalt ions; after drying, pass through a 200-mesh sieve;

[0042] (2) Dissolve 50g of calcium hydroxide in 800mL of deionized water to form a calcium hydroxide solution, add the product obtained in step (1) and 100g of potassium bicarbonate into the calcium hydroxide solution, put into an 80°C oil bath and stir to evaporate, and wait After the mixtur...

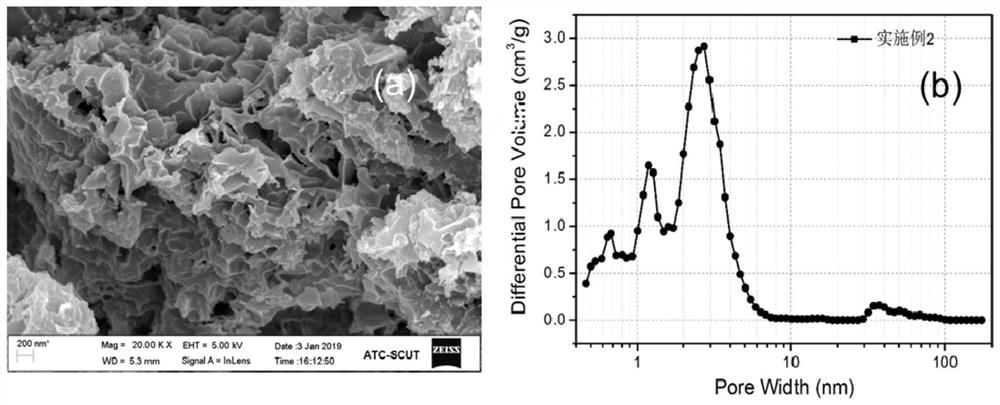

Embodiment 2

[0047] An embodiment of the preparation method of the porous carbon material described in the present invention, the preparation method of the porous carbon material described in this embodiment comprises the following steps:

[0048] (1) Immerse 100g of the pretreated macroporous acrylic adsorbent resin in dilute hydrochloric acid, filter after soaking for a period of time, then add it to 400mL of cobalt chloride aqueous solution with a concentration of 0.2mol / L, stir for 2 hours and put Stir in a water bath at 80°C and evaporate to dryness, then continue to dry in an 80°C blast drying oven for 12 hours to obtain a resin that adsorbs cobalt ions; pass through a 200-mesh sieve after drying;

[0049] (2) Dissolve 100g of calcium hydroxide in 800mL of deionized water to form a calcium hydroxide solution, add the product obtained in step (1) and 100g of potassium bicarbonate into the calcium hydroxide solution, put into an 80°C oil bath and stir to evaporate, and wait After the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com