Continuous tunnel-type dried sweet potato making machine

A technology of dried sweet potato and making machine, which is applied in conveyors, food processing, food science and other directions, can solve the problems of different sizes, irregularities, small sweet potatoes and irregular pores of sweet potatoes that cannot be brushed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

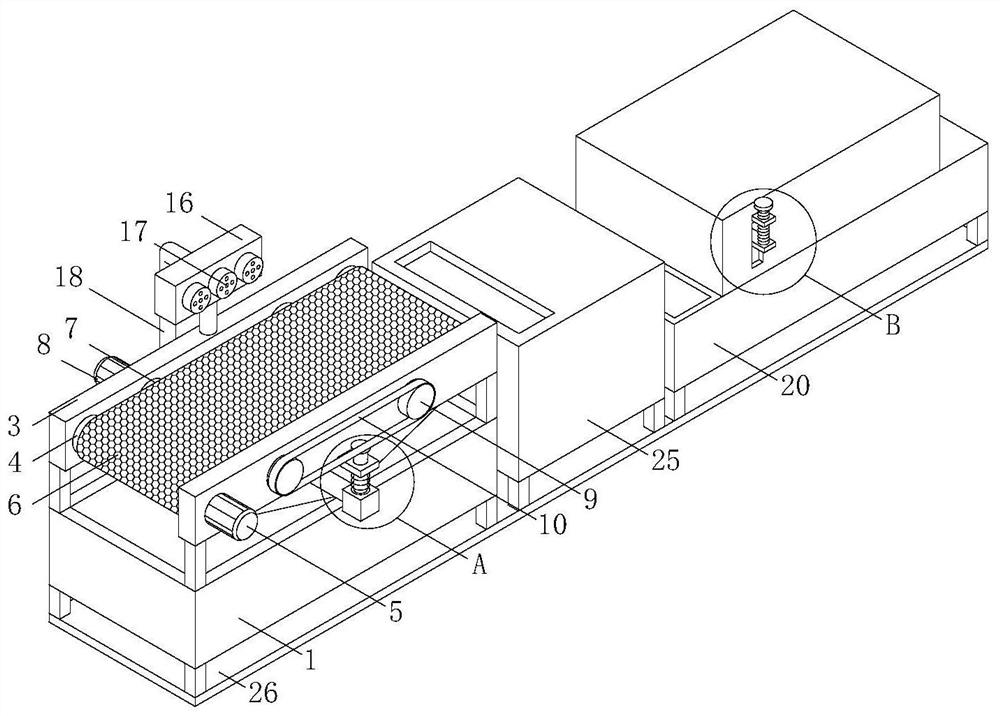

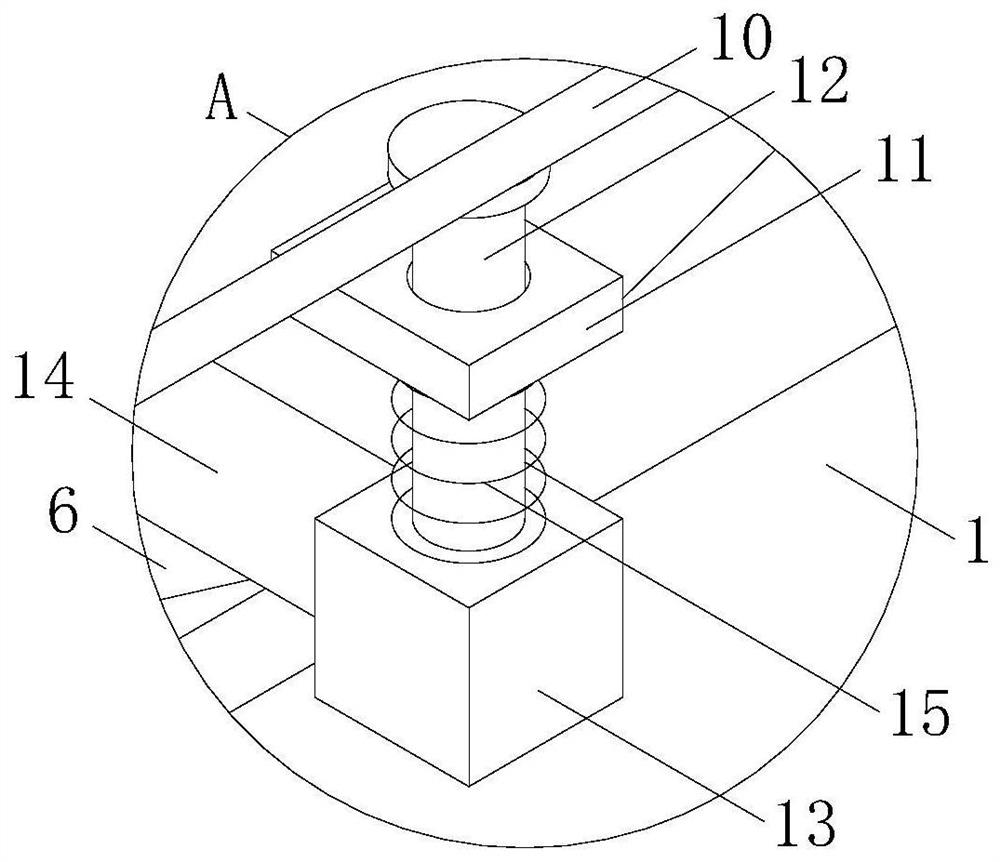

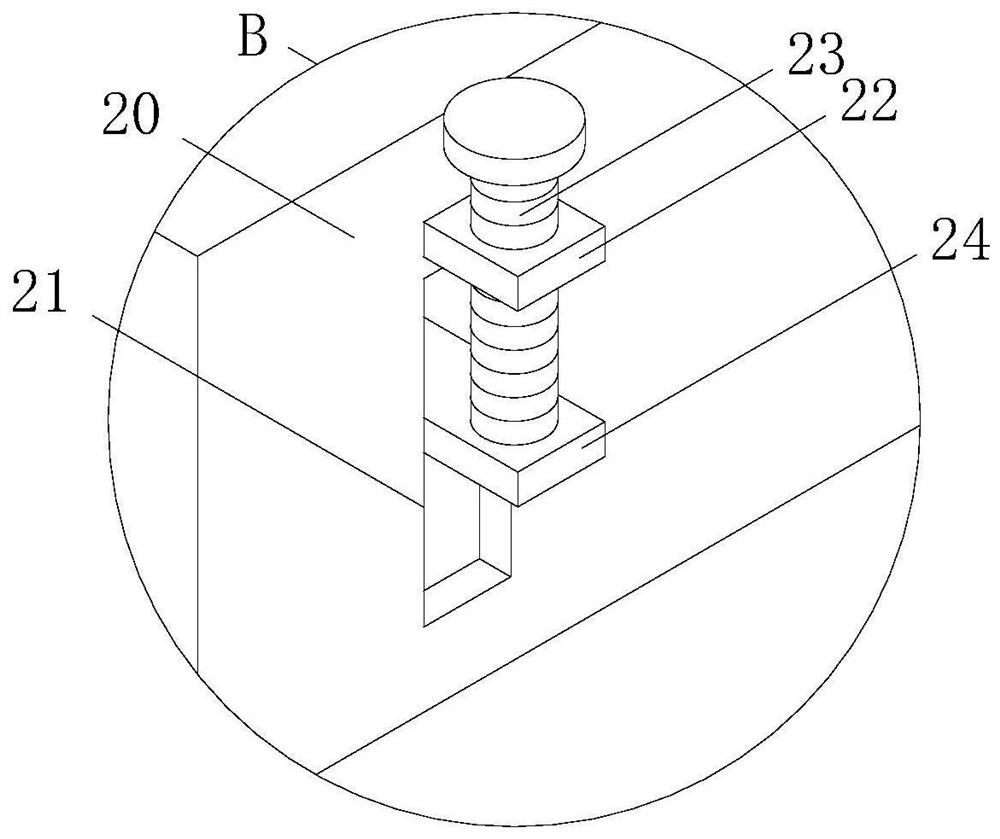

[0026] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Shown, a kind of continuous tunnel type sweet potato drying making machine of the present invention comprises water tank 1, slicer 25, tunnel drying machine 20 and base 26, and tunnel drying machine 20 is CT-C-4 type tunnel drying machine, slices The machine 25 is an XYF-801 type slicer, and the water tank 1, the slicer 25 and the tunnel drying machine 20 are fixedly installed on the top of the base 26 from left to right, and the middle part of the bottom of the water tank 1 is interspersed with a piston 2, and the top of the water tank 1 Both the front and the back are fixedly connected with a connecting frame 3, and a conveying mechanism is arranged between the two connecting frames 3, and the conveying mechanism is composed of two rollers 4, a first motor 5 and a conveying mesh belt 6, and the first motor 5 is 5IK120RGN-CF type deceleration motor, the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com