An automatic loading and unloading carriage

An automatic loading and unloading, carriage technology, applied in the direction of vehicles with elevated loading platforms, vehicles with chain/ring belt, etc., can solve the problem of unsolved loading, can not realize the automatic layering of goods, and the goods cannot be automatically Export and other issues to achieve the effect of improving efficiency, reducing the use of labor, and reducing loading and unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

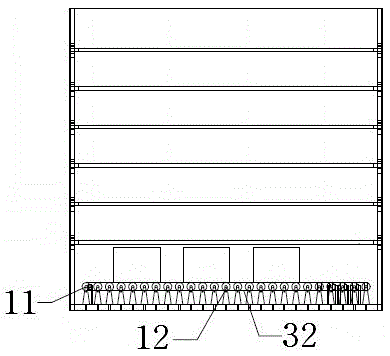

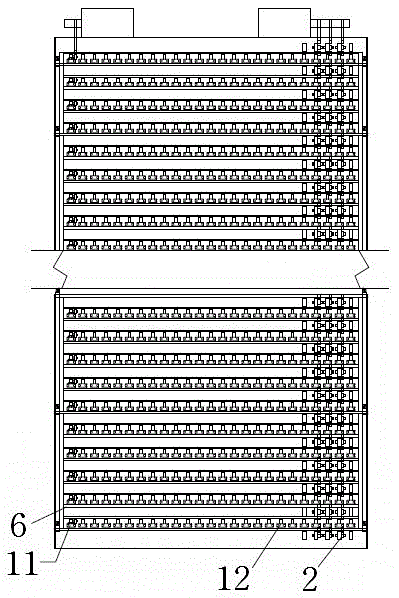

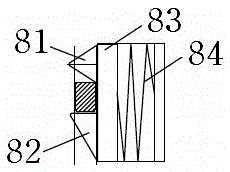

[0034] The bottom of the compartment is arranged with longitudinal and transverse rollers with brackets, and the brackets are connected with the bottom of the compartment by bolts. Horizontal rolling rollers are arranged every 200mm along the longitudinal direction, and a row is arranged every 100mm along the horizontal direction; the longitudinal rolling rollers are arranged on one side of the carriage, interlaced with the horizontal rolling rollers, one every 200mm along the longitudinal direction, and one row is every 100mm along the horizontal direction, a total of 5 rows, of which The three rows in the middle are connected to the motor by chains, and the two rows on the far side are not connected to the motor by chains. The lifting rack 6 is laid on the bottom of the compartment for a six-layer structure frame, and the whole structure frame is stored in the gap between the vertical and horizontal rollers.

Embodiment 2

[0036] 1. When loading the goods into the compartment:

[0037] 1.1 Start the longitudinal motor 92, drive the longitudinal roller 2 through the longitudinal transmission belt 31 to make it rotate longitudinally, put the goods one by one on the longitudinal roller, and the goods will slowly flow into the compartment as the roller rolls. When a row has been filled longitudinally, the transverse motor 91 is started. The transverse motor 91 drives the bevel gear 5 to rotate through the transmission chain 4, and the transmission chain 4 is guided by the chain guide wheel 101 at the bottom of the box. The driving wheel 11 produces lateral rolling, and it drives the lateral driven roller 12 to roll through the lateral transmission belt 32, so that the goods are laterally moved to one side. Reciprocating like this always waits for the goods to cover one deck of the compartment, and stops the transverse motor 91 and the longitudinal motor 92.

[0038]1.2 Hang the hook at the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com