Automatic pallet unloading device

A technology of unloading device and pallet, which is applied in the direction of motor vehicle, loading and unloading vehicle arrangement, loading/unloading, etc. It can solve the problems that the goods cannot be automatically loaded or unloaded, connected, etc., and achieve the effect of reliable and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

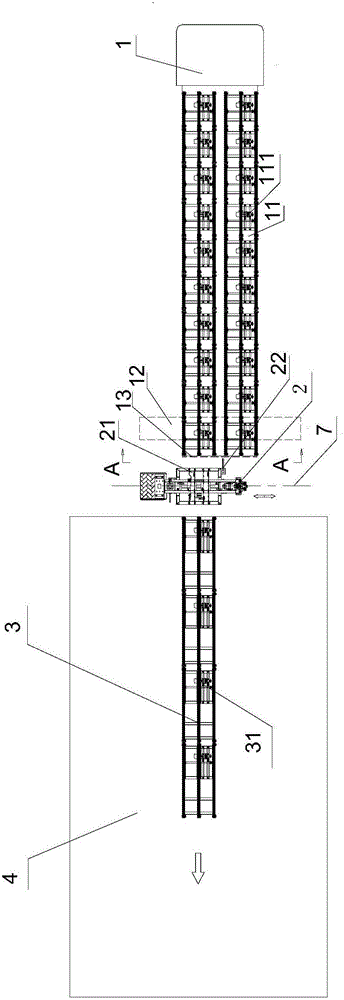

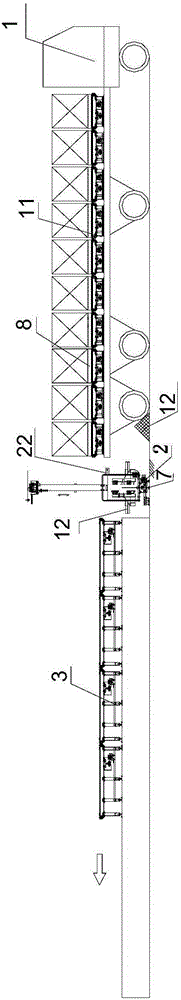

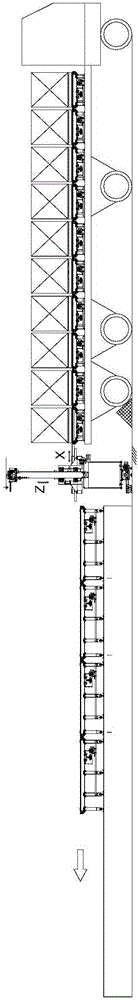

[0039] Further illustrate the present invention below in conjunction with accompanying drawing

[0040] Referring to the attached picture:

[0041] An automatic pallet unloading device according to the present invention includes a truck 1, a stacker 2, an inbound and outbound conveyor unit 3 for transporting goods in a warehouse 4, a first central controller 5 and a second central controller 6, The compartment of the truck 1 is equipped with at least one truck conveying unit 11, and each truck conveying unit 11 is composed of a plurality of independently operating truck conveyors 111, and the truck conveyors 111 are connected to each other in turn to form a truck along the length of the truck. The conveying line arranged in the direction, the control end of each described truck conveyor 111 is connected with the output pin of the first central controller 5; The track 7 is slidably connected, and the fork 21 of the stacker 2 is located on one side of the truck 1; the stacker 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com