Cargo loading and unloading system of quick-open type side curtain box

A technology of cargo loading and unloading and side curtain boxes, which is applied in loading/unloading, lifting devices, transportation and packaging, etc. It can solve the problems of the last pallet being loaded into the container, the position accuracy is not high enough, and waste of manpower and material resources, etc., to reduce manpower , Improve efficiency and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

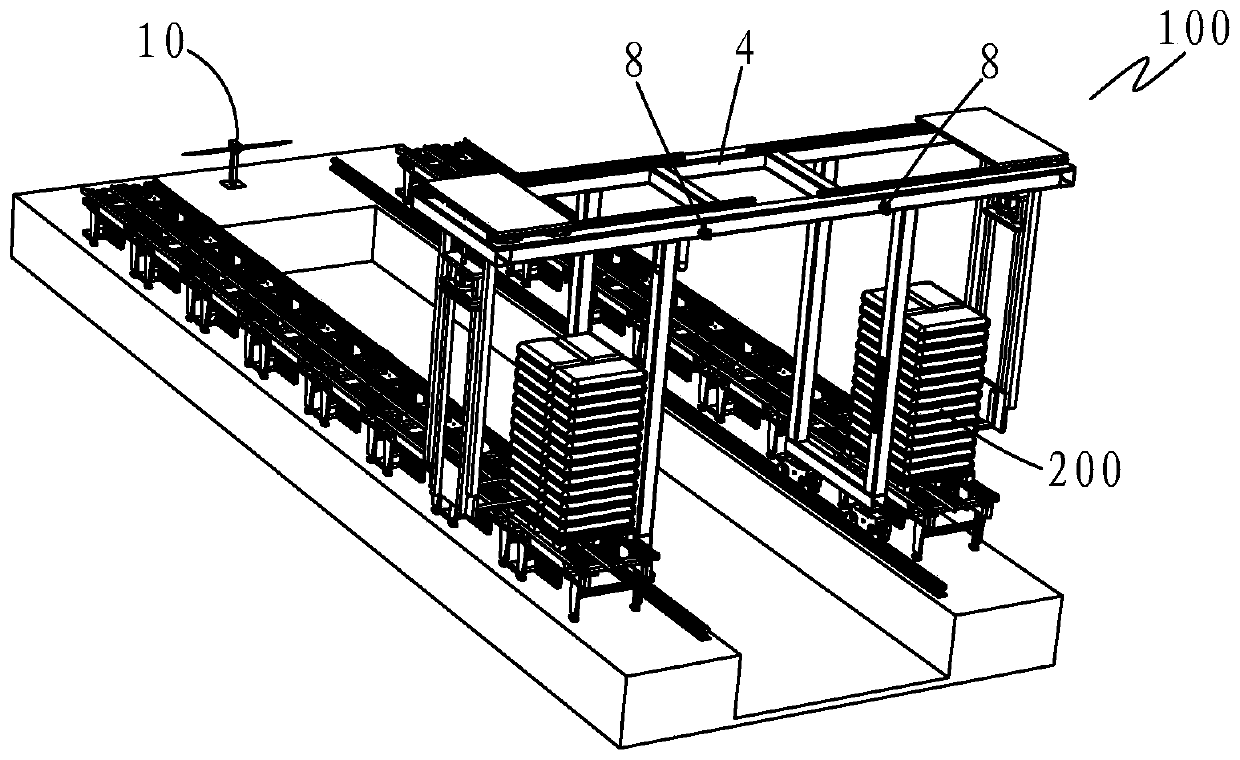

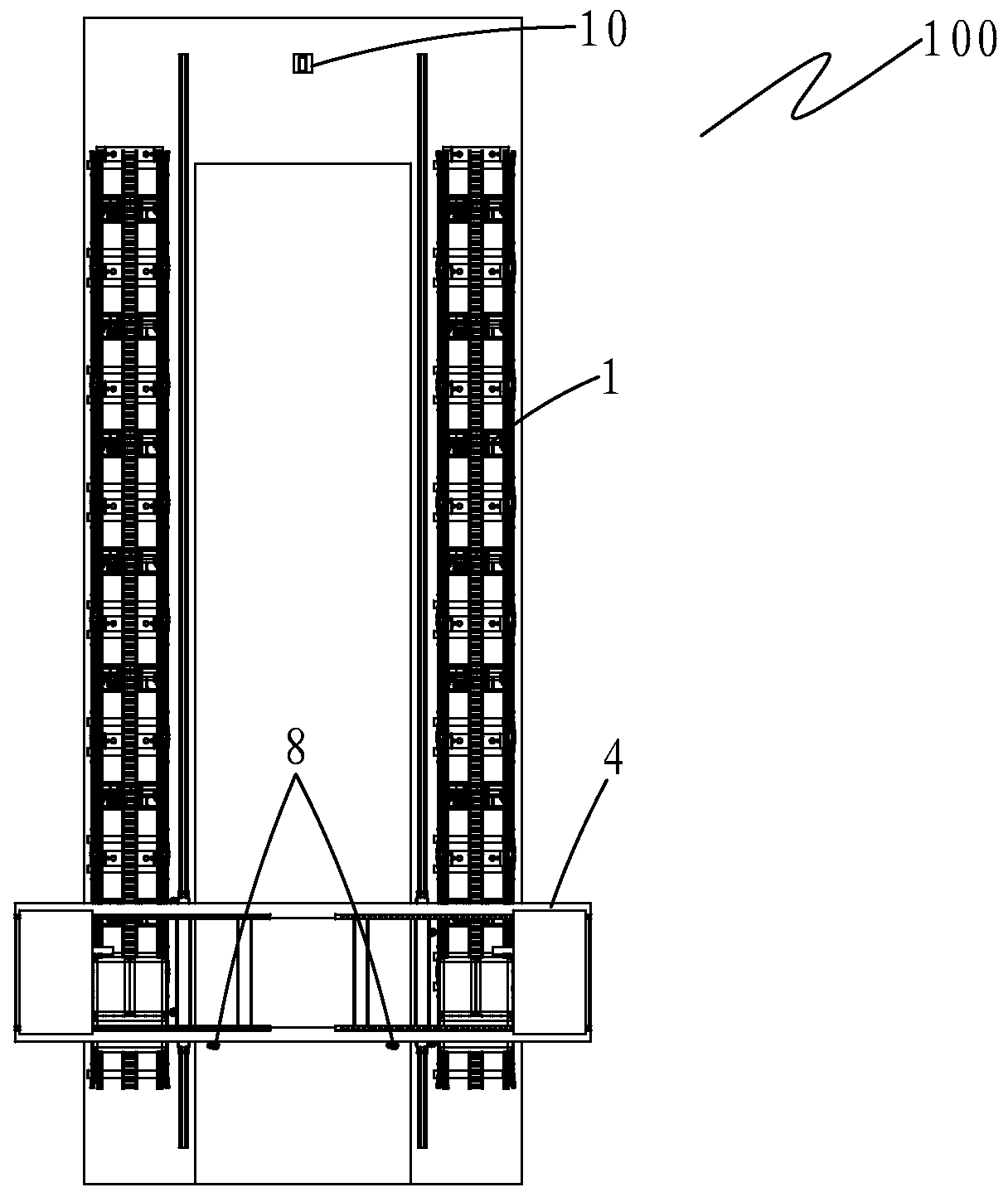

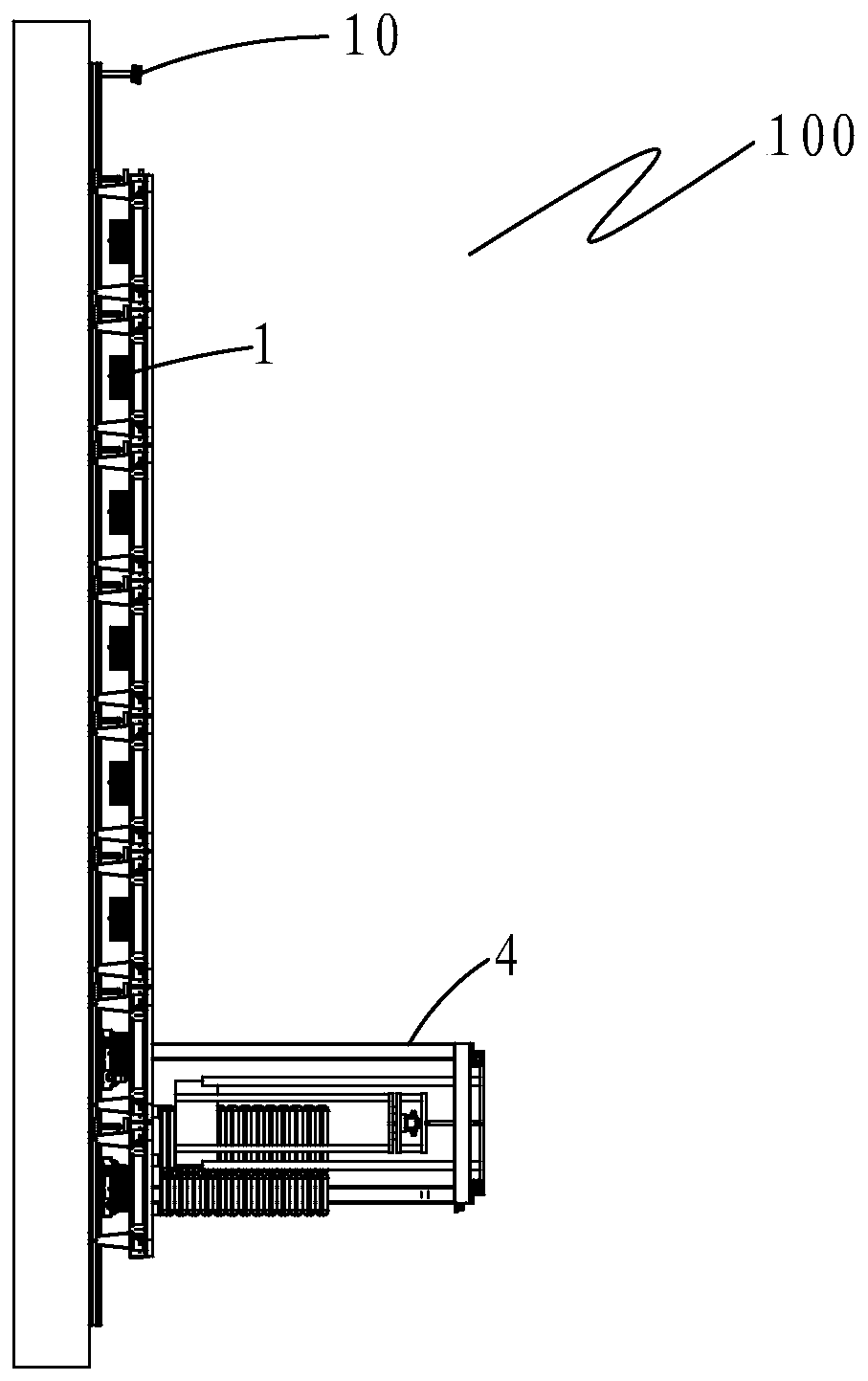

[0092] The present invention provides a cargo handling system 100 for quick-opening side curtain boxes, including:

[0093] The conveying device 1 is arranged in a straight line along the X-axis; the conveying device 1 is used for conveying goods 200 . When loading, the goods 200 can be placed on the conveying device 1 with a forklift, because the conveying device 1 plays the role of transmission, and the position accuracy requirement is lower than that of using a forklift to fork into the container, which is more convenient to operate and reduces the cost of operation. Difficulty; and for the automated storage system, it is also possible to dock the conveying device 1 with the conveying line 300 of the automated storage system, and directly transfer the goods 200 to the conveying device 1 without using a forklift to operate, realizing Automatic docking saves manpower and material resources and improves transmission efficiency. This can be arranged according to the degree of ...

Embodiment 2

[0109] Embodiment 2, on the basis of Embodiment 1, the alarm device 9 is installed on the support frame 4, so that there is no need to add additional supports to install the alarm device 9, while saving the space on the ground and freeing up more space. many locations.

[0110] It also includes a third detection device 10 for collecting vehicle license plates, and the third detection device 10 is communicatively connected to the controller (not shown). The third detection device 10 is used to detect the license plate of the truck, which can be more conveniently applied to the automatic storage system to realize full automation. For example, when in use, the controller is communicatively connected to the control device of the automatic storage system, so that when loading, the license plate of the truck can be detected by the third detection device 100, and then fed back to the controller, the control The controller transmits the license plate to the control device of the auto...

Embodiment 3

[0111] Embodiment 3: It can be adopted on the basis of Embodiment 1 or Embodiment 2. The X-axis sliding module 3 includes

[0112] Wheel base 31, the bottom of the wheel base 31 is provided with a round groove 311, the wheel base 31 is connected to the support frame 4;

[0113] The driving track wheel 32 is rotatably installed in the wheel groove 311, and the rotation axis of the driving track wheel 32 is horizontal and perpendicular to the X axis; for example, symmetrically opened on both sides of the wheel groove 311 Bearing holes, bearings are installed in the bearing holes, and the rotating shaft of the price driving track wheel 32 is embedded in the bearing inner ring.

[0114] The first driving motor 33, the output shaft of the first driving motor 33 is fixedly connected to the driving rail wheel 32, specifically the rotating shaft of the driving rail wheel 32 is fixedly connected to the output shaft of the first driving motor 33 , such as using a shaft coupling for fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com