Patents

Literature

198 results about "Load carriage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

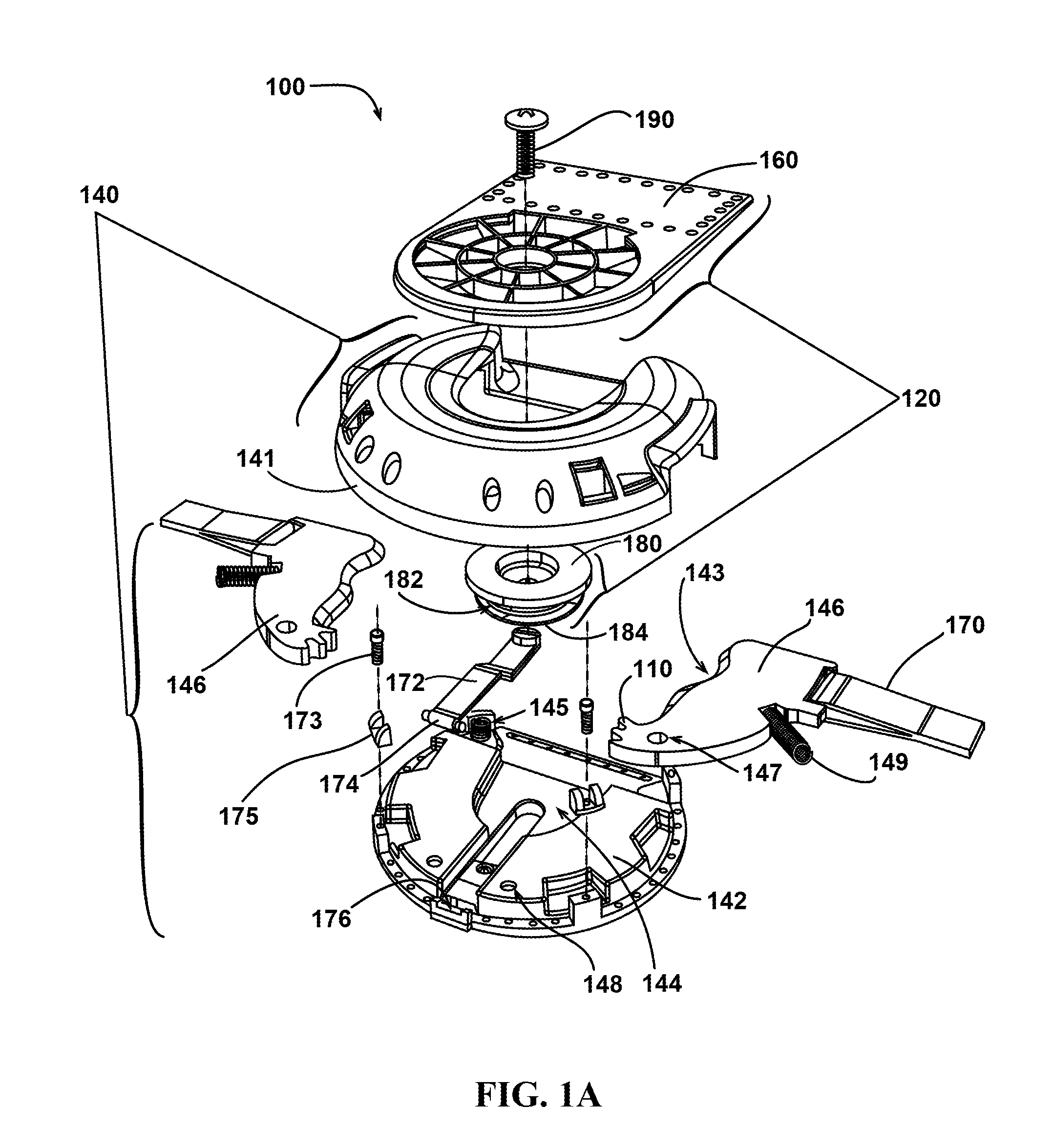

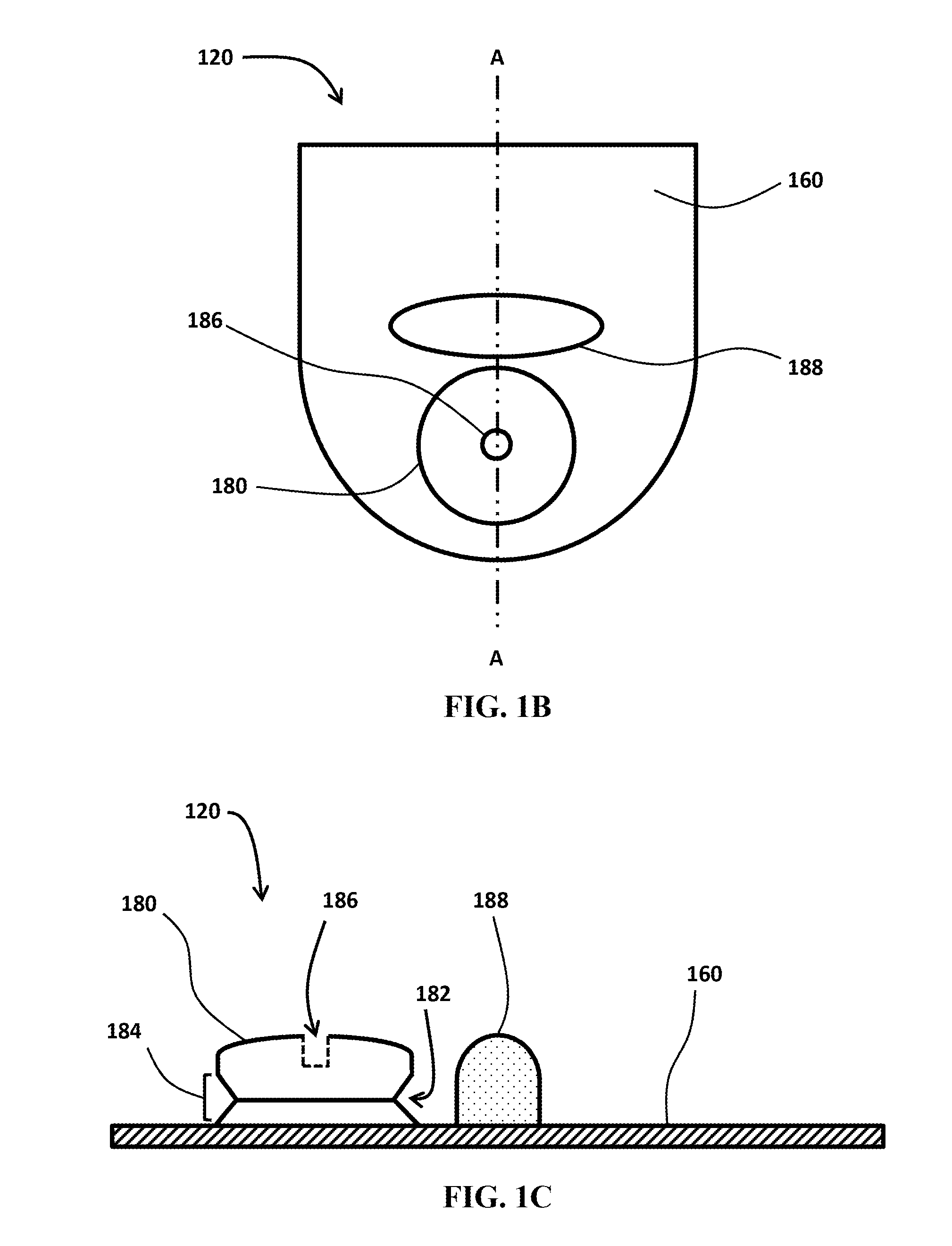

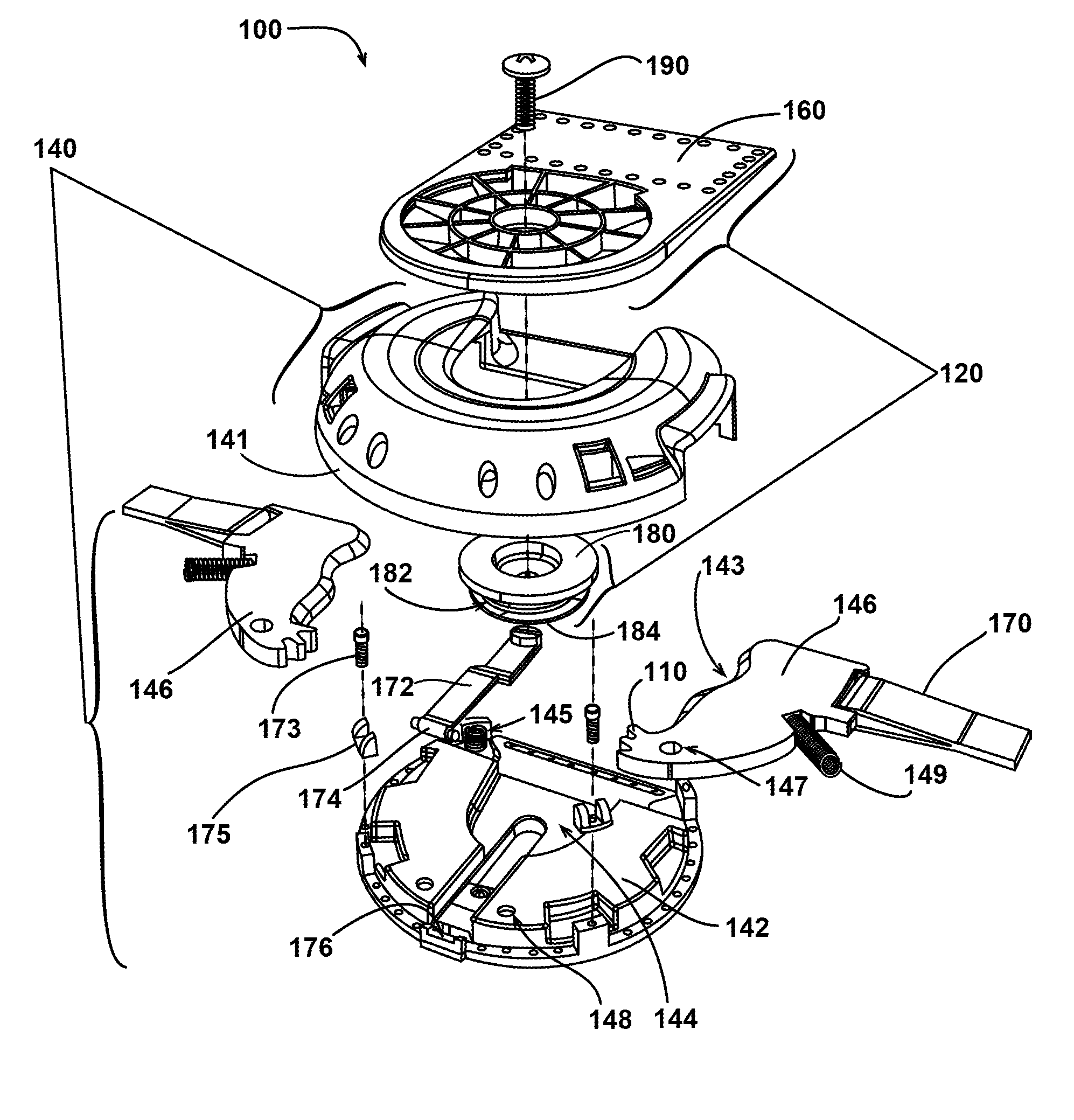

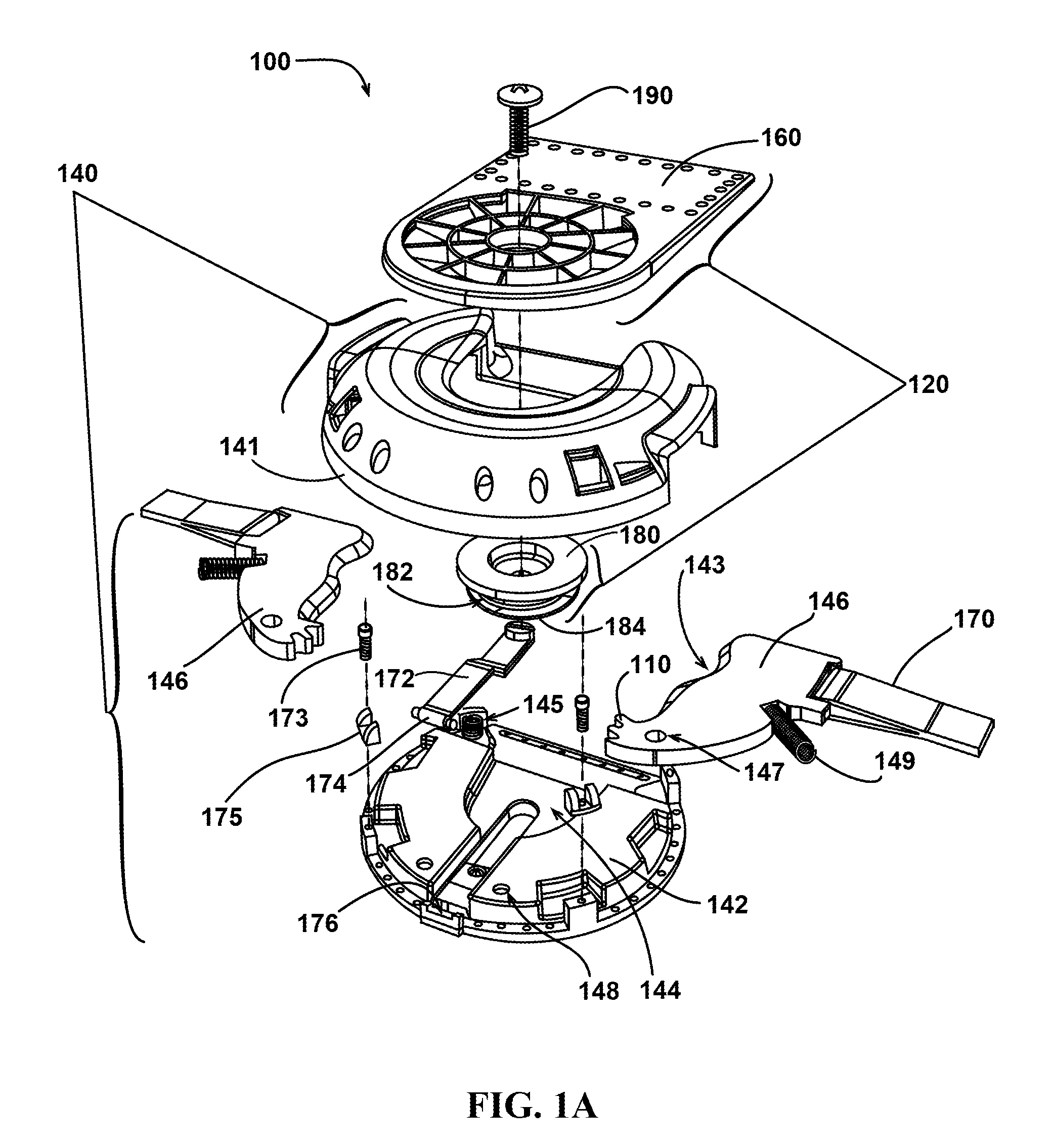

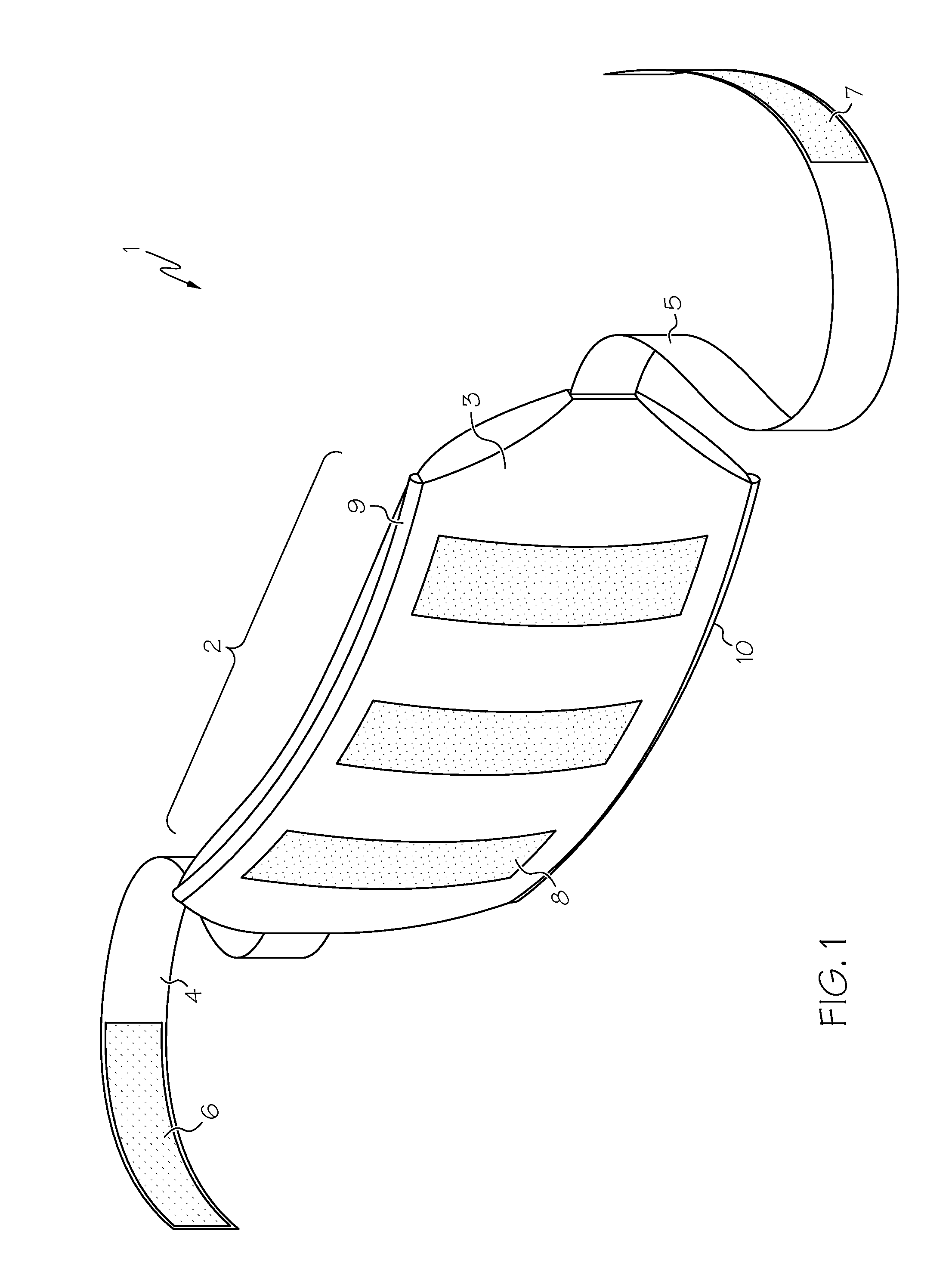

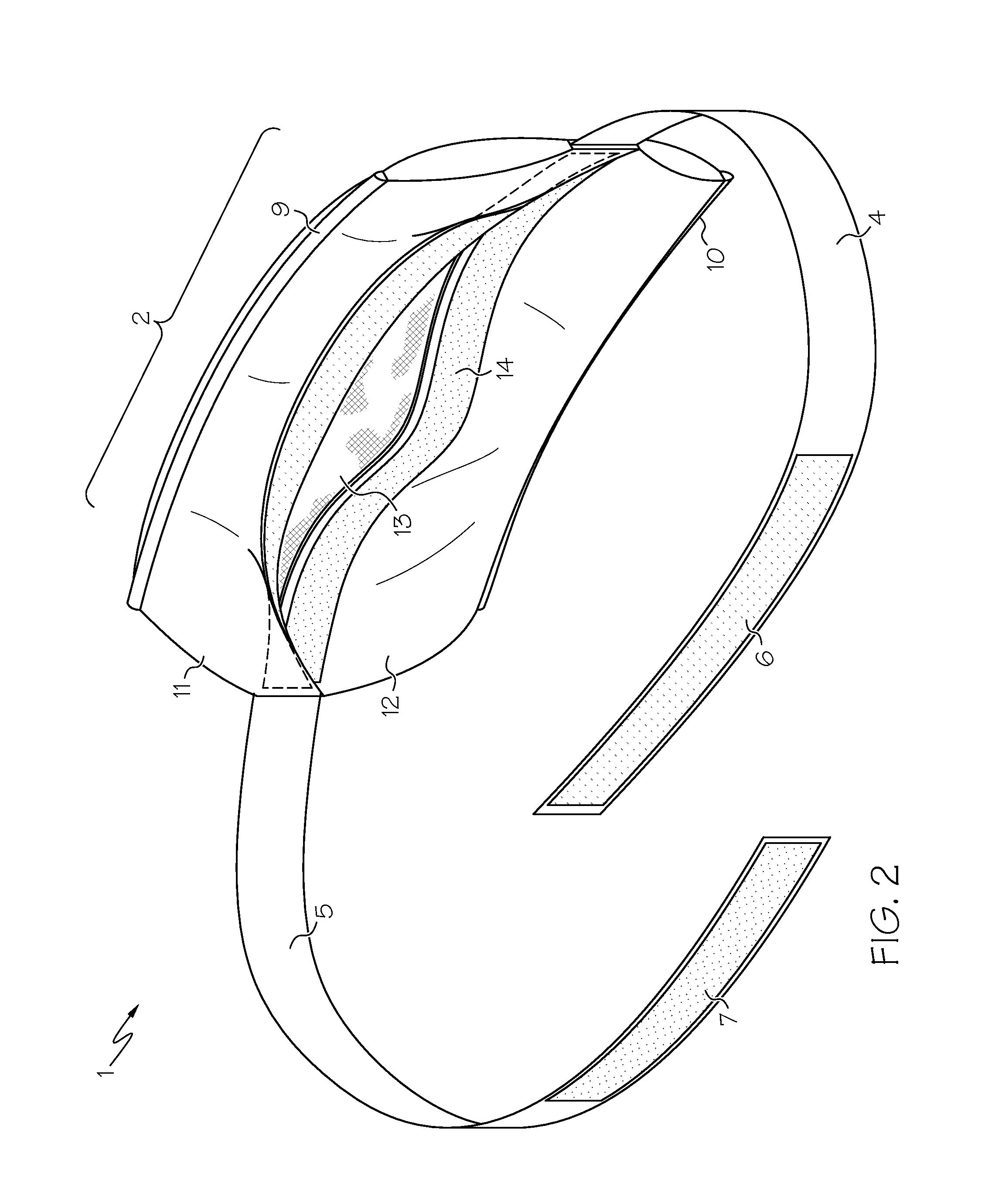

Load carriage connector and system

ActiveUS20130232742A1Rapid demountingFacilitates connection reliabilitySnap fastenersGarment special featuresEngineeringLoad carriage

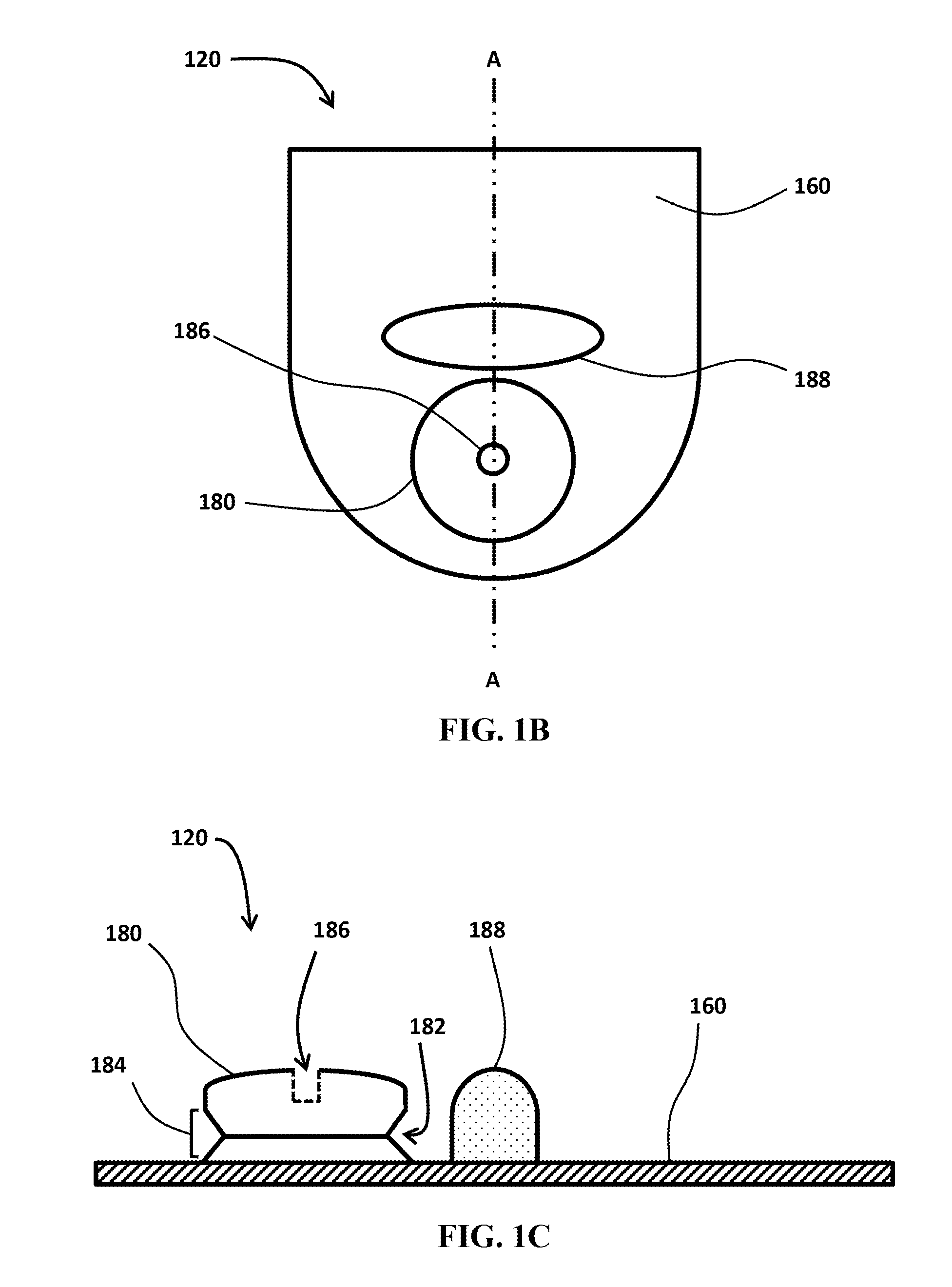

A load carriage connector and system for rapid mounting and demounting of a user-carried load. The connector utilizes two mating halves comprising a male connector half and a female connector half. The connector is configured to allow mating under various angles of approach, allowing the user to reliably couple the system even under conditions in which the user is unable to view the orientation of the connectors. Additionally, the configuration of the connector system allows the user to quickly and efficiently decouple the connector halves, even while under tensile or shear load.

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE SEC OF THE AIR FORCE

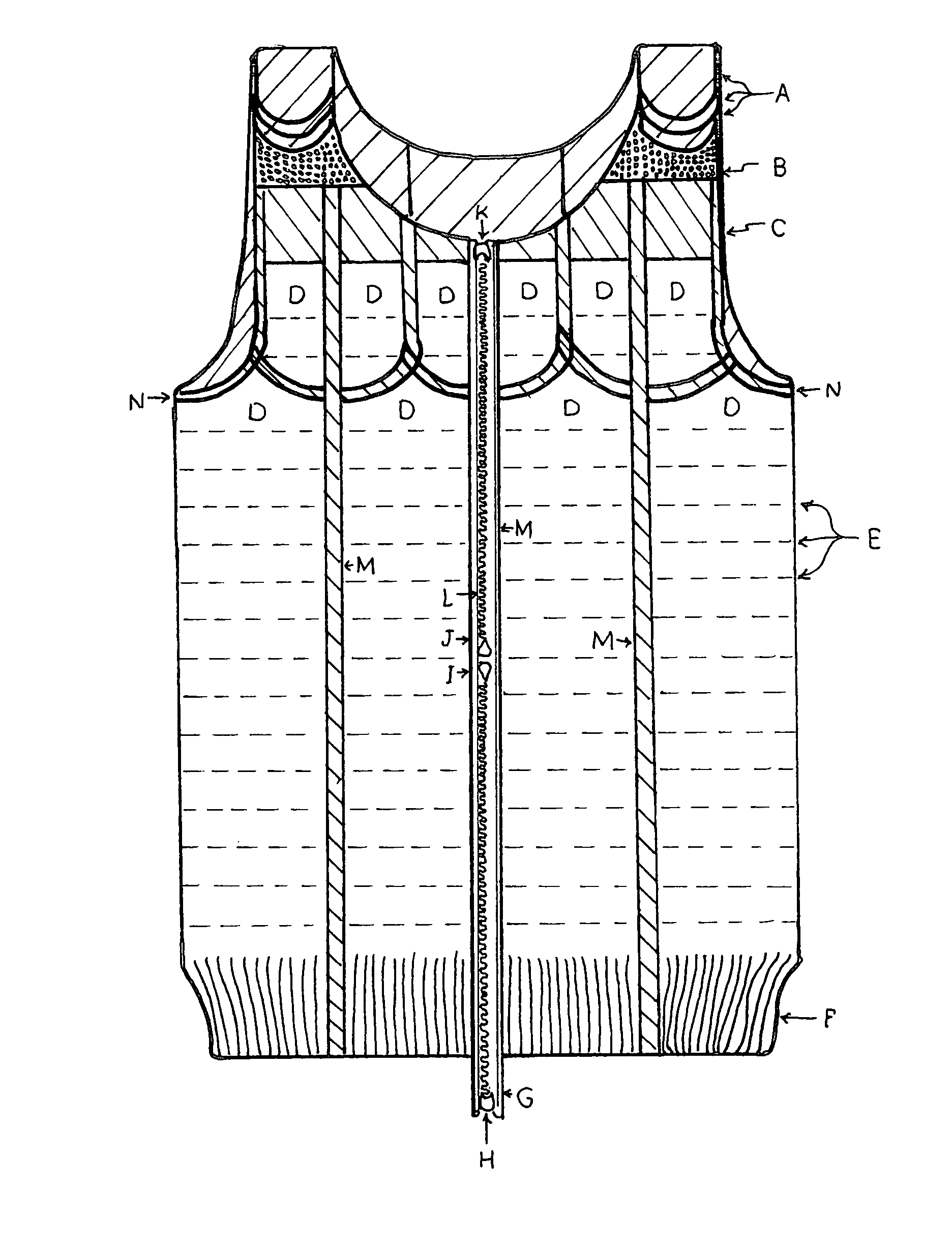

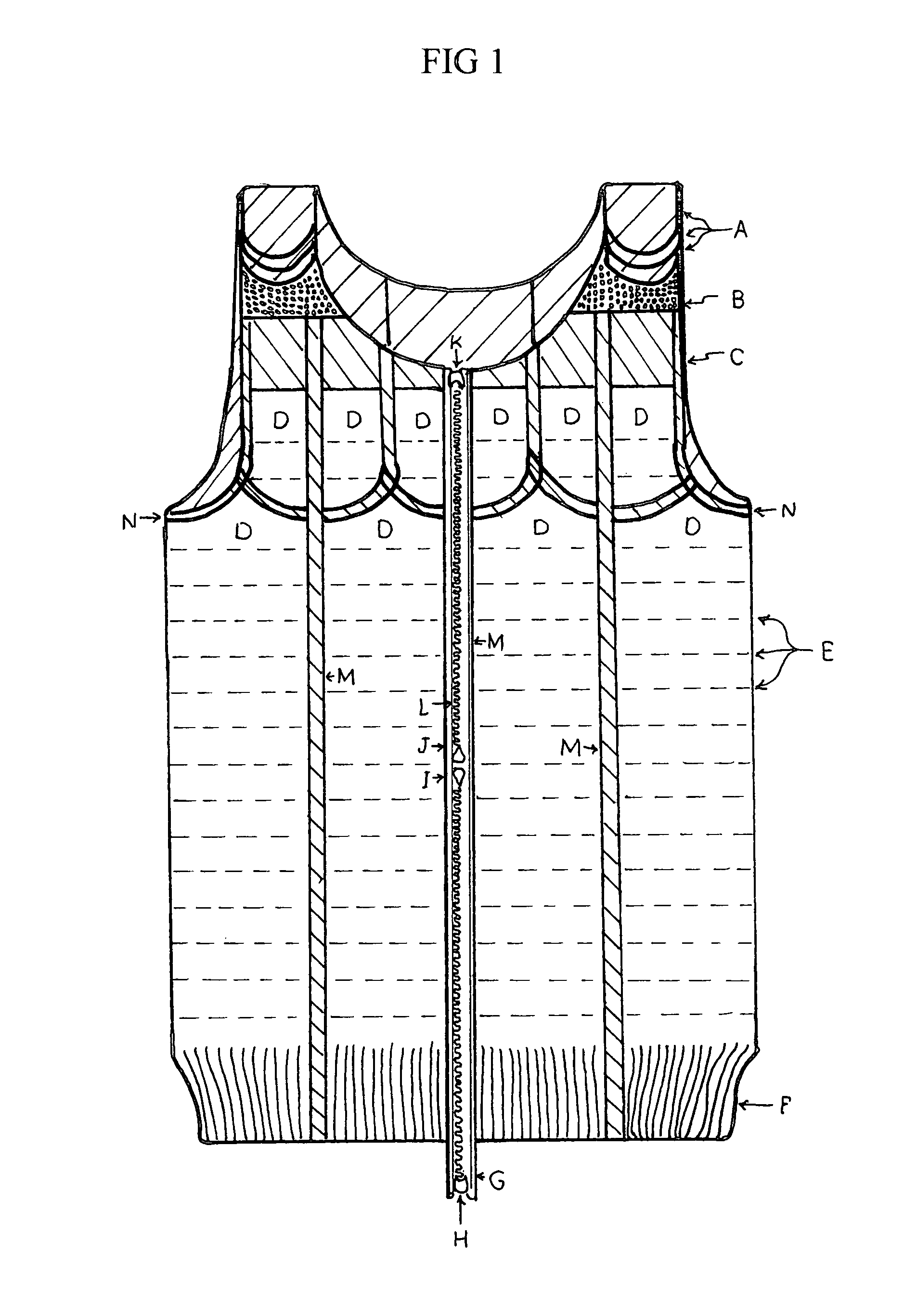

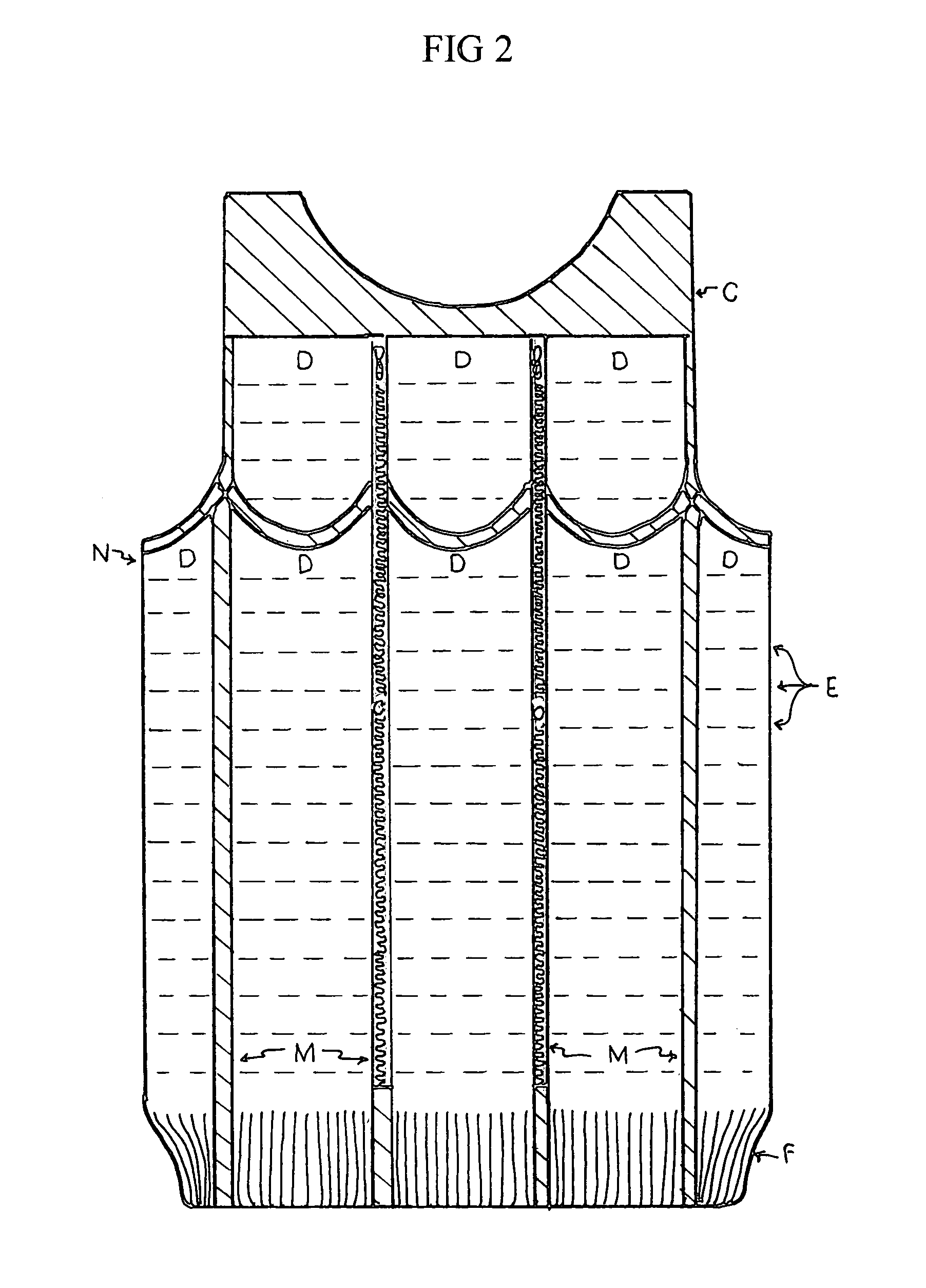

Weaving process for production of a full fashioned woven stretch garment with load carriage capability

InactiveUS7841369B1Easy to useHigher compressive forceJacquardsLoomsPulp and paper industryLoad carriage

A weaving process for constructing weft stretch full fashioned utility garments using a jacquard machine, an electronic loom and highly stretchable elastomeric fill yarns.

Owner:V PARADOX

Load carriage connector and system

ActiveUS8857681B2Rapid demountingQuickly and efficiently decoupleSnap fastenersGarment special featuresEngineeringLoad carriage

A load carriage connector and system for rapid mounting and demounting of a user-carried load. The connector utilizes two mating halves comprising a male connector half and a female connector half. The connector is configured to allow mating under various angles of approach, allowing the user to reliably couple the system even under conditions in which the user is unable to view the orientation of the connectors. Additionally, the configuration of the connector system allows the user to quickly and efficiently decouple the connector halves, even while under tensile or shear load.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

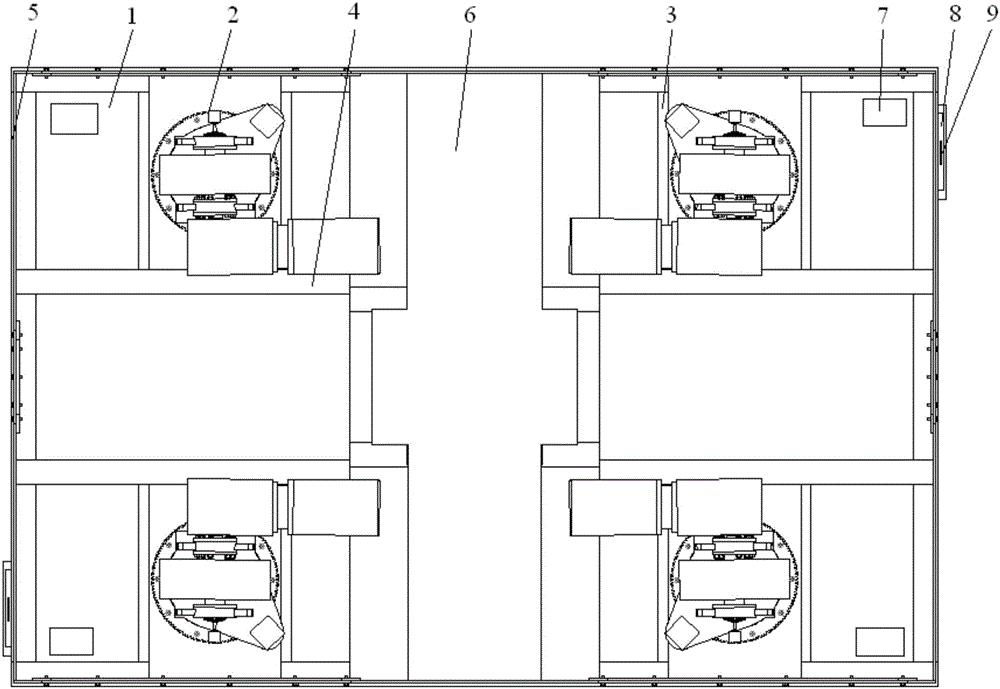

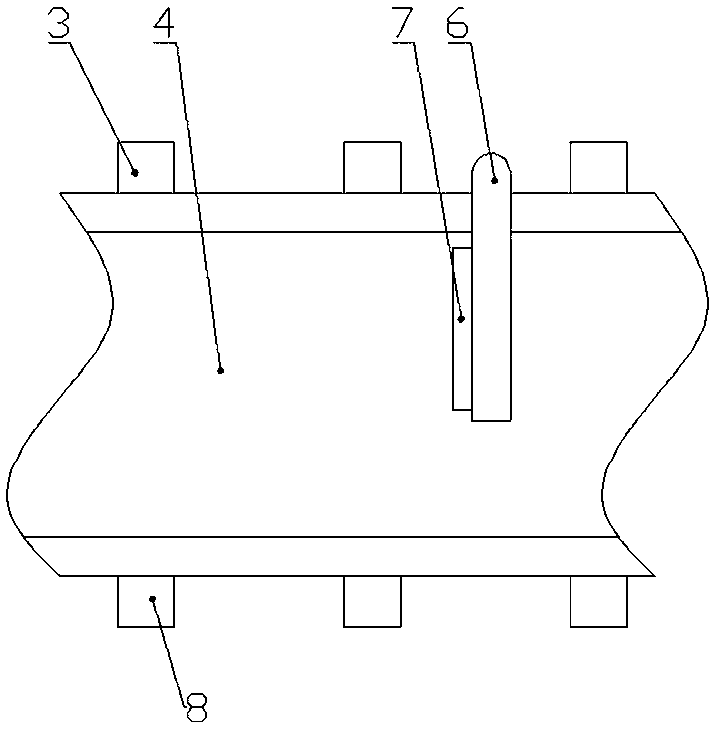

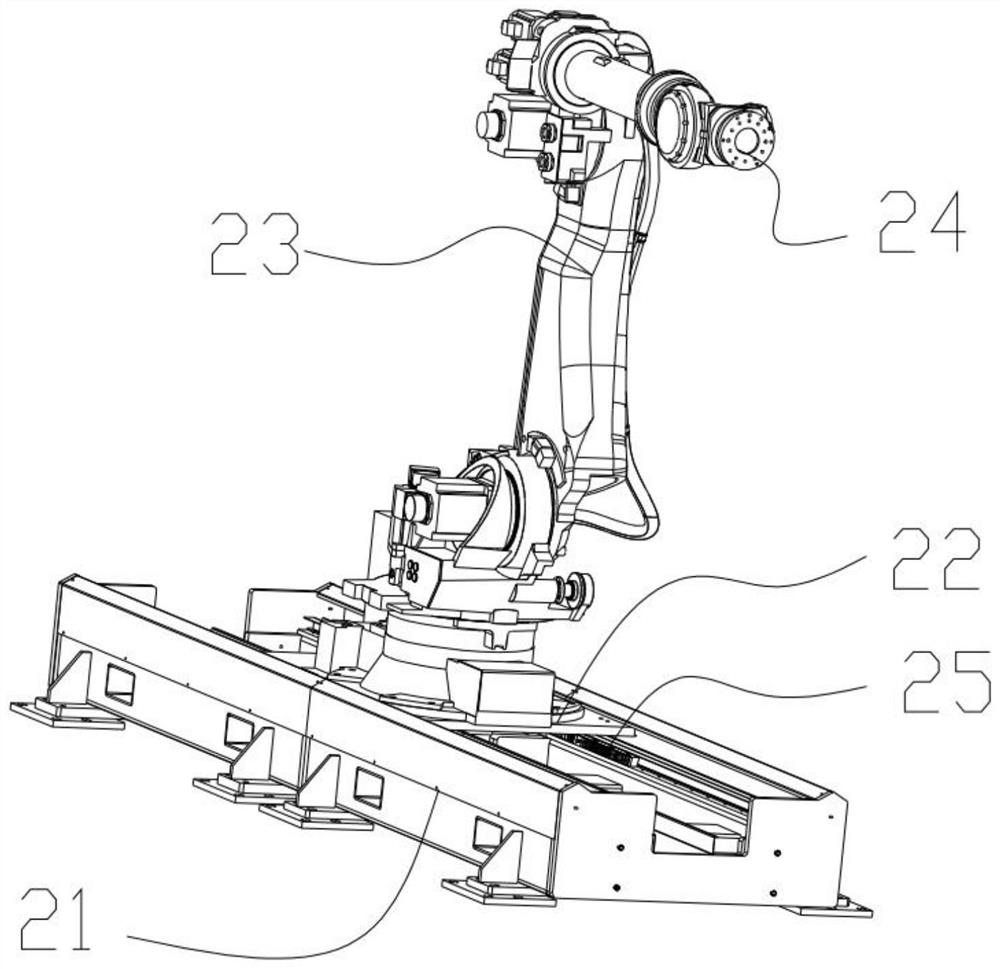

Large heavy-duty unmanned navigation intelligent electric flat carriage with automatic correction function

PendingCN106708045AEasy to controlImprove conveniencePosition/course control in two dimensionsVehiclesElectricityDrive wheel

The invention relates to a large heavy-duty unmanned navigation intelligent electric flat carriage with an automatic correction function. The electric flat carriage comprises a steel load carriage body, four drive wheels set which are arranged at the bottom of the load carriage body, a magnetic navigation sensor, an RFID reader, a power supply and a PLC control box, wherein the magnetic navigation sensor and the RFID reader are arranged on the axle wire of the bottom of the load carriage body, and the power supply and the PLC control box are arranged on the load carriage body. The magnetic navigation sensor and a navigation magnetic stripe laid on the ground of a production workshop are in magnetic induction connection. The RFID reader and a number of RFID electronic tags which are pasted on the navigation magnetic stripe with uniform spacing are in radio frequency communication connection. The magnetic navigation sensor comprises a number of Hall switch sensors, LED indication lamps corresponding to the Hall switch sensors and a control chip. The Hall switch sensors and the LED indication lamps are electrically connected with the control chip. The AGV trolley has the advantages of compact and reliable structure and heavy load, and realizes the functions of self-navigation and automatic correction at the same time through the magnetic navigation sensor.

Owner:YANCHENG INST OF TECH

Dynamic load carriage frame

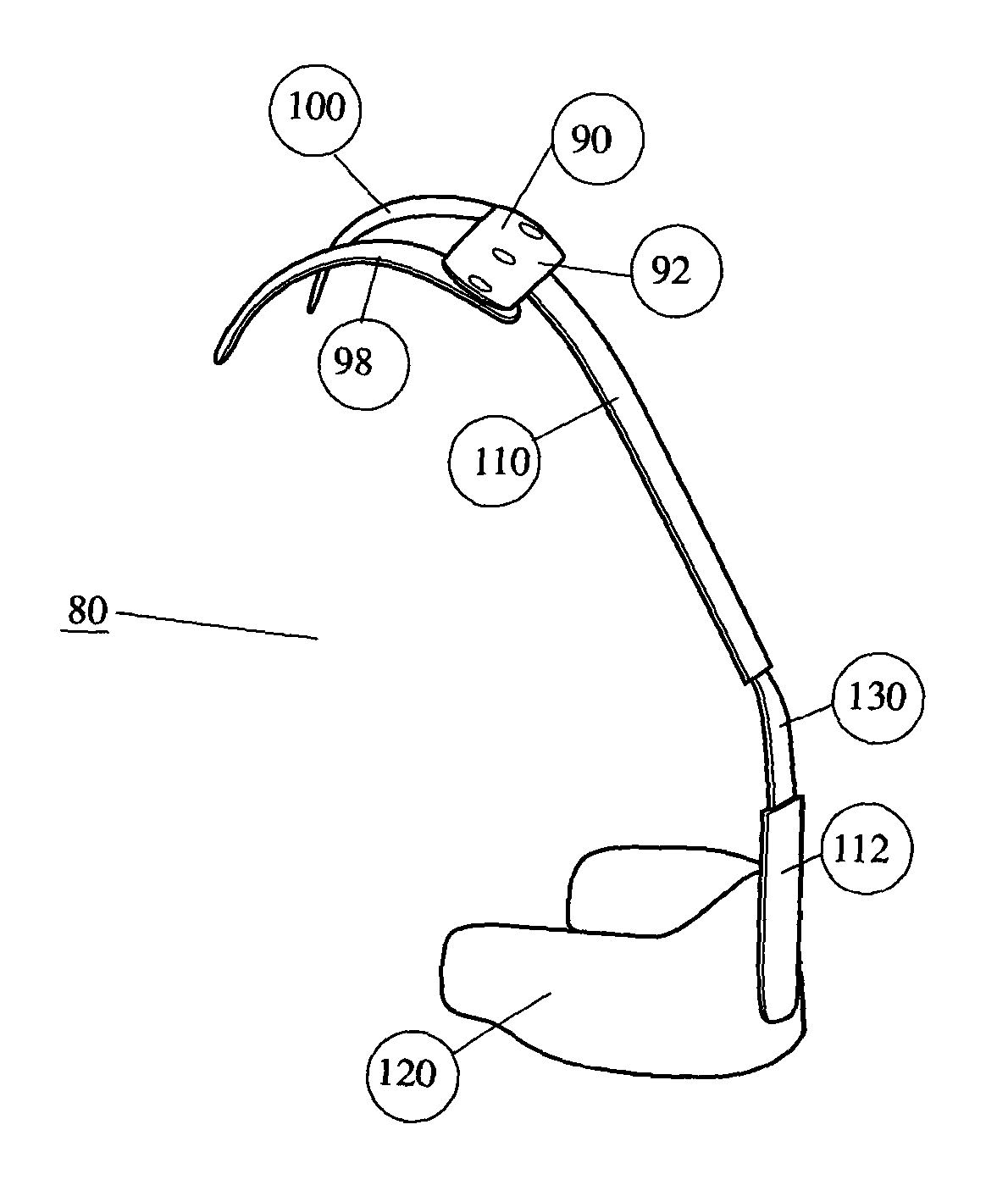

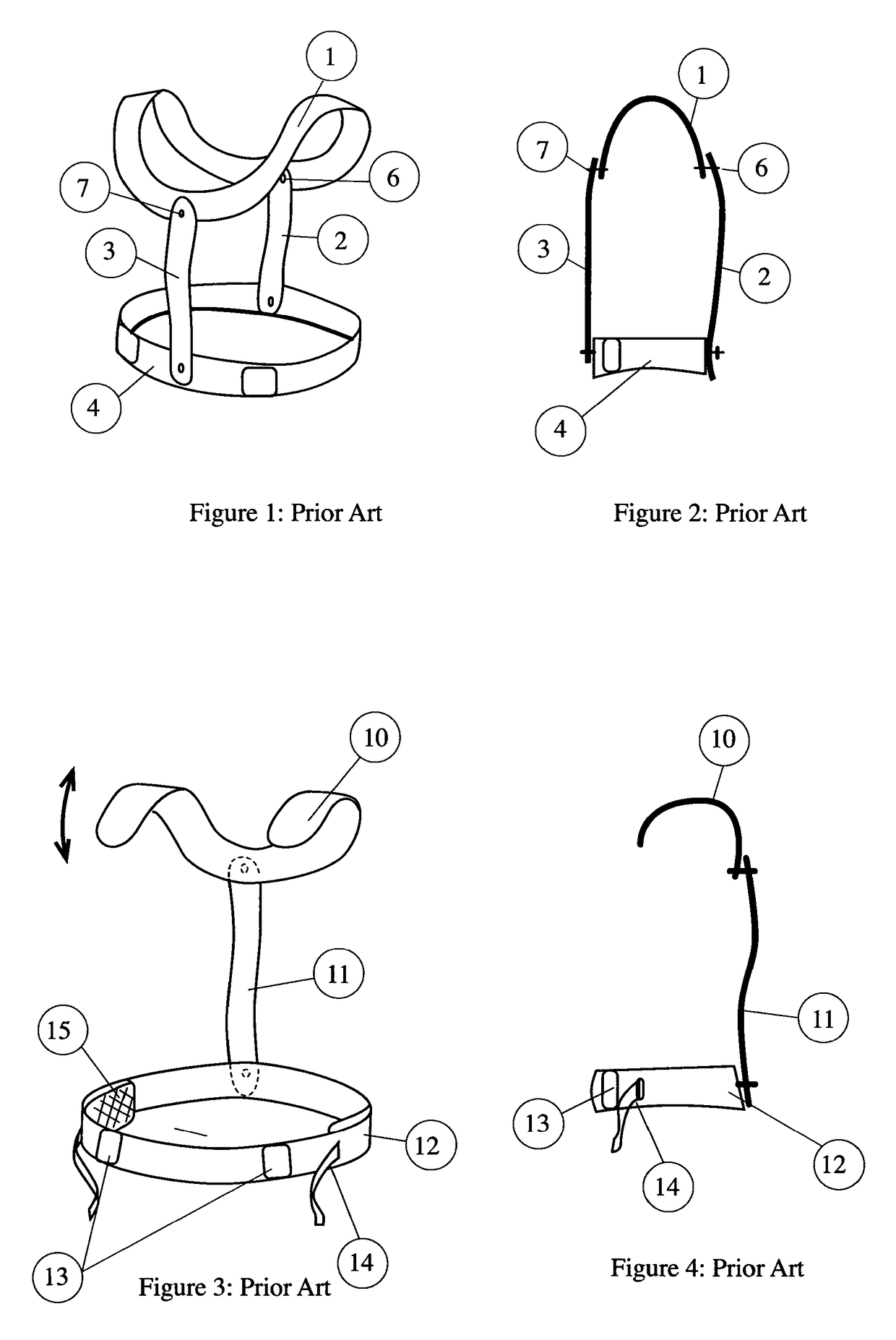

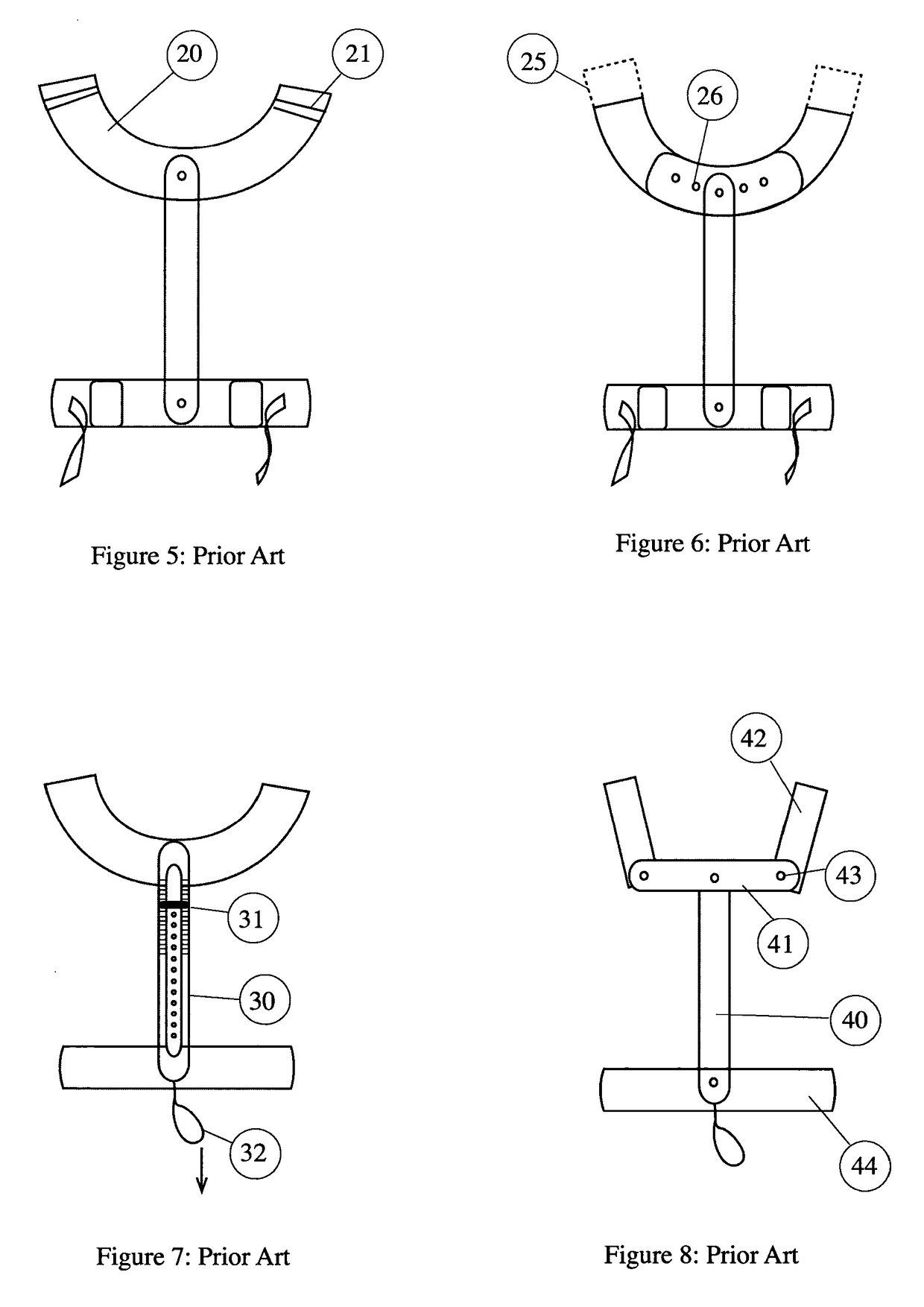

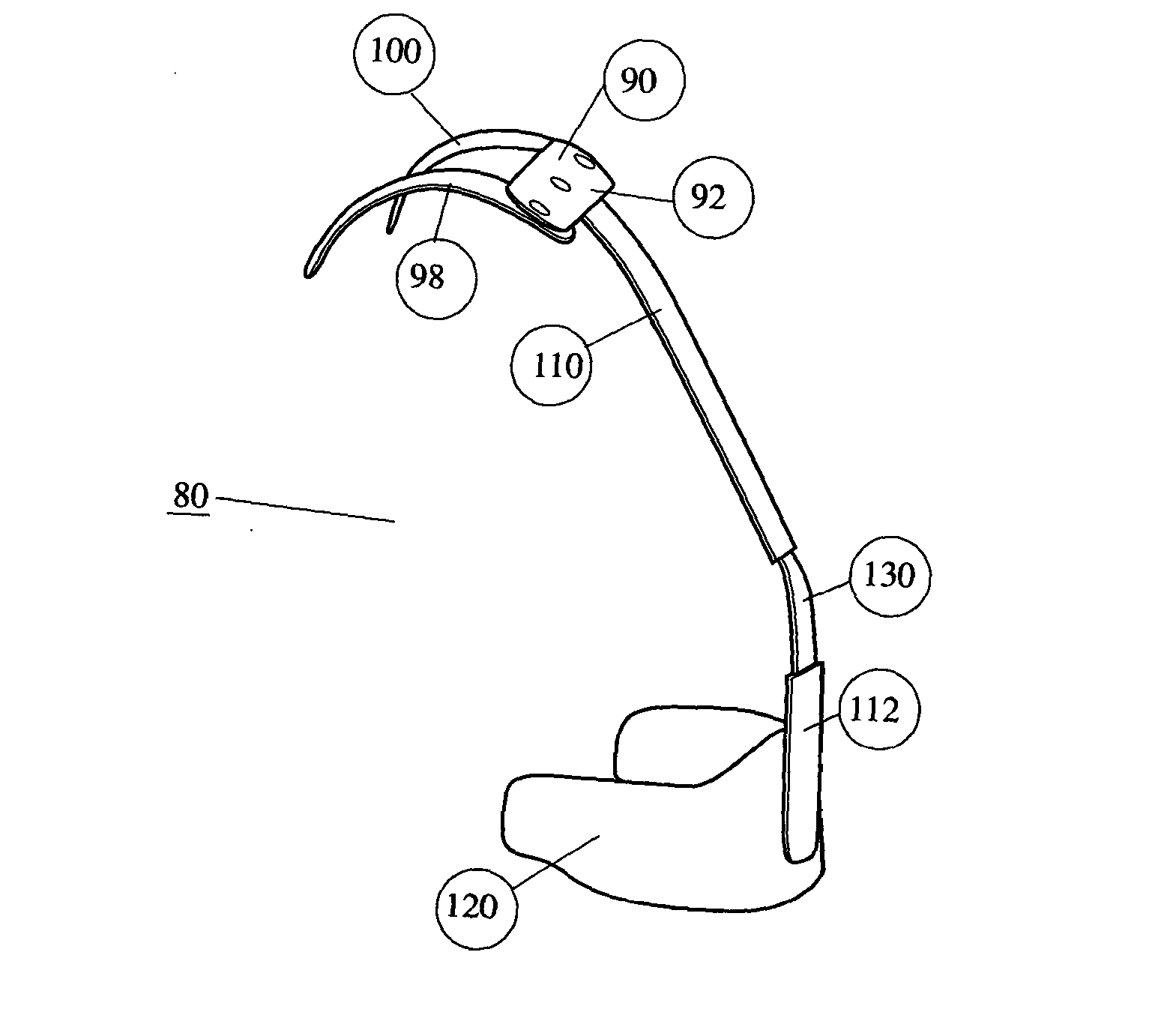

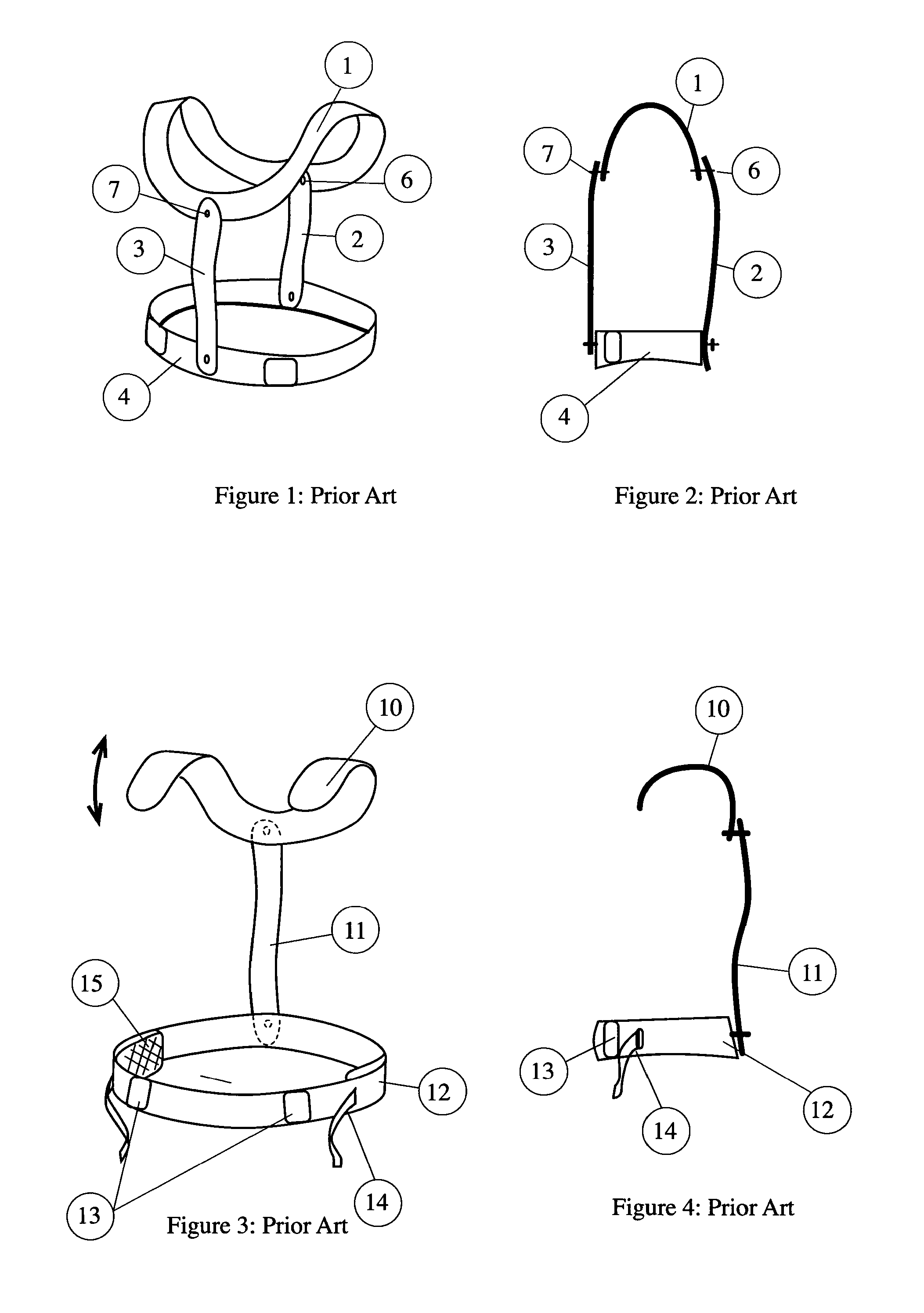

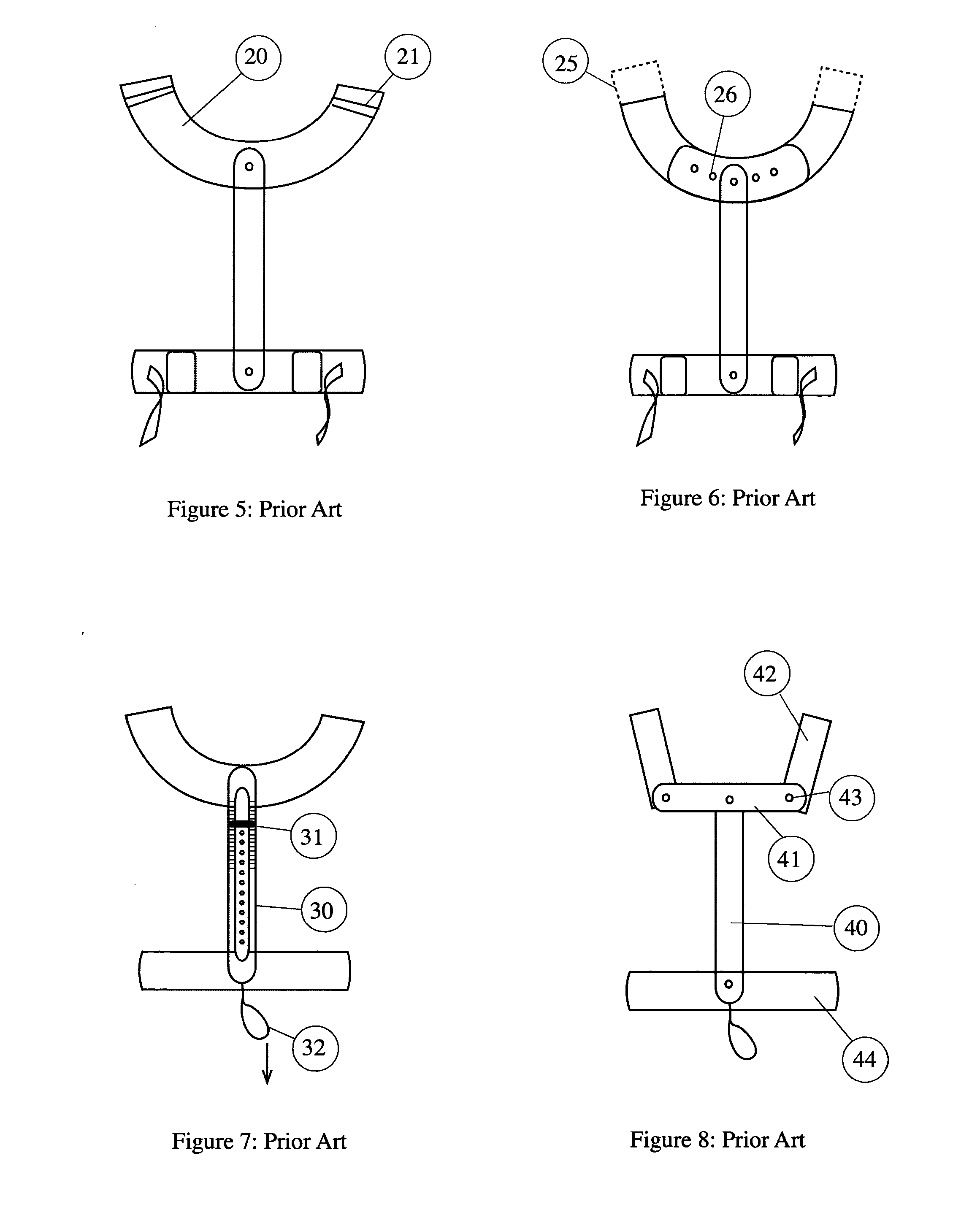

A load carriage frame (80) of FIG. 9 includes a shoulder yoke (90) and a belt (120) separated from the yoke by a multi-element connecting brace (96). The brace is telescopic in nature in that a flexible but rigid tongue (130), extending from a first section, is permitted to slide within a guide on a second section (154), thereby allowing the length of the connecting brace to be altered. The multi-element connecting brace is centrally coupled to the yoke and centrally coupled to the belt and configured to act as a force path by transferring weight that, in use, is loaded onto or through the yoke and into the belt thereby effecting selected weight re-distribution onto the pelvic girdle of a wearer about which the belt, in use, is secured. Additionally, as shown in FIG. 20, a quick release mechanism may further alter the length of the connecting brace by allowing the position of a rotational coupling point to be altered relative to a housing of the quick release mechanism. The quick release mechanism can, in fact, be used with a single piece connecting brace.

Owner:BCB INT

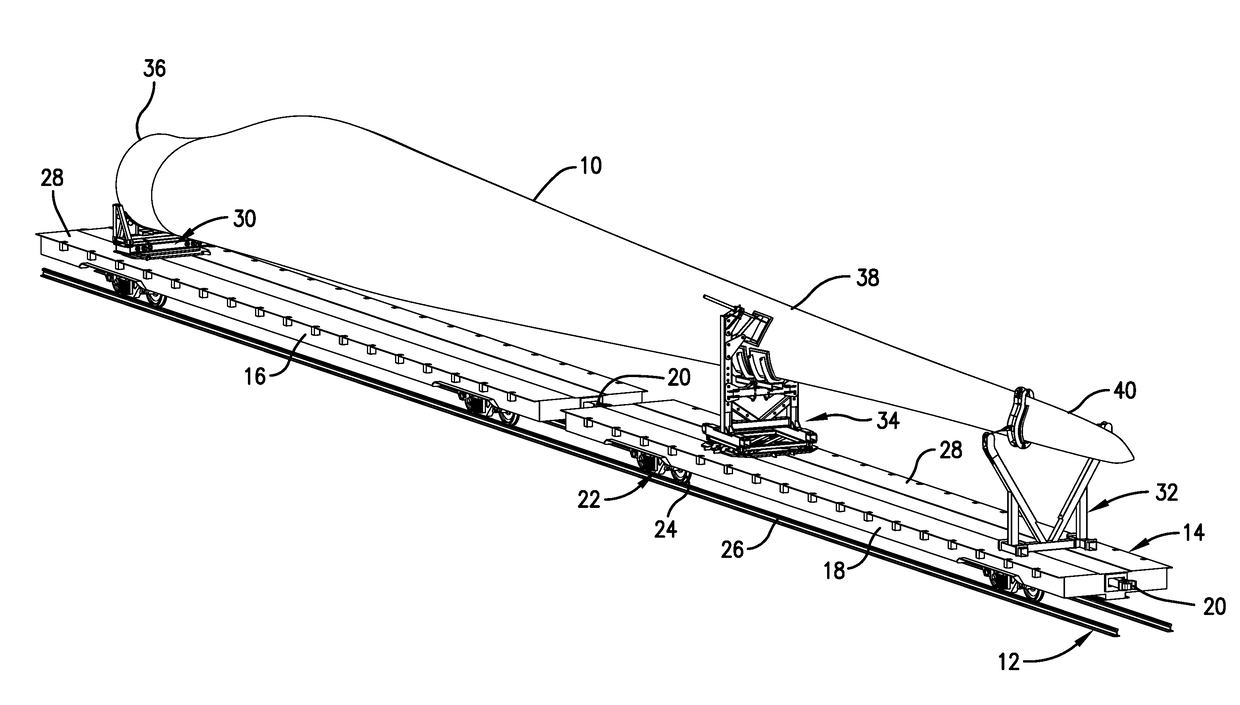

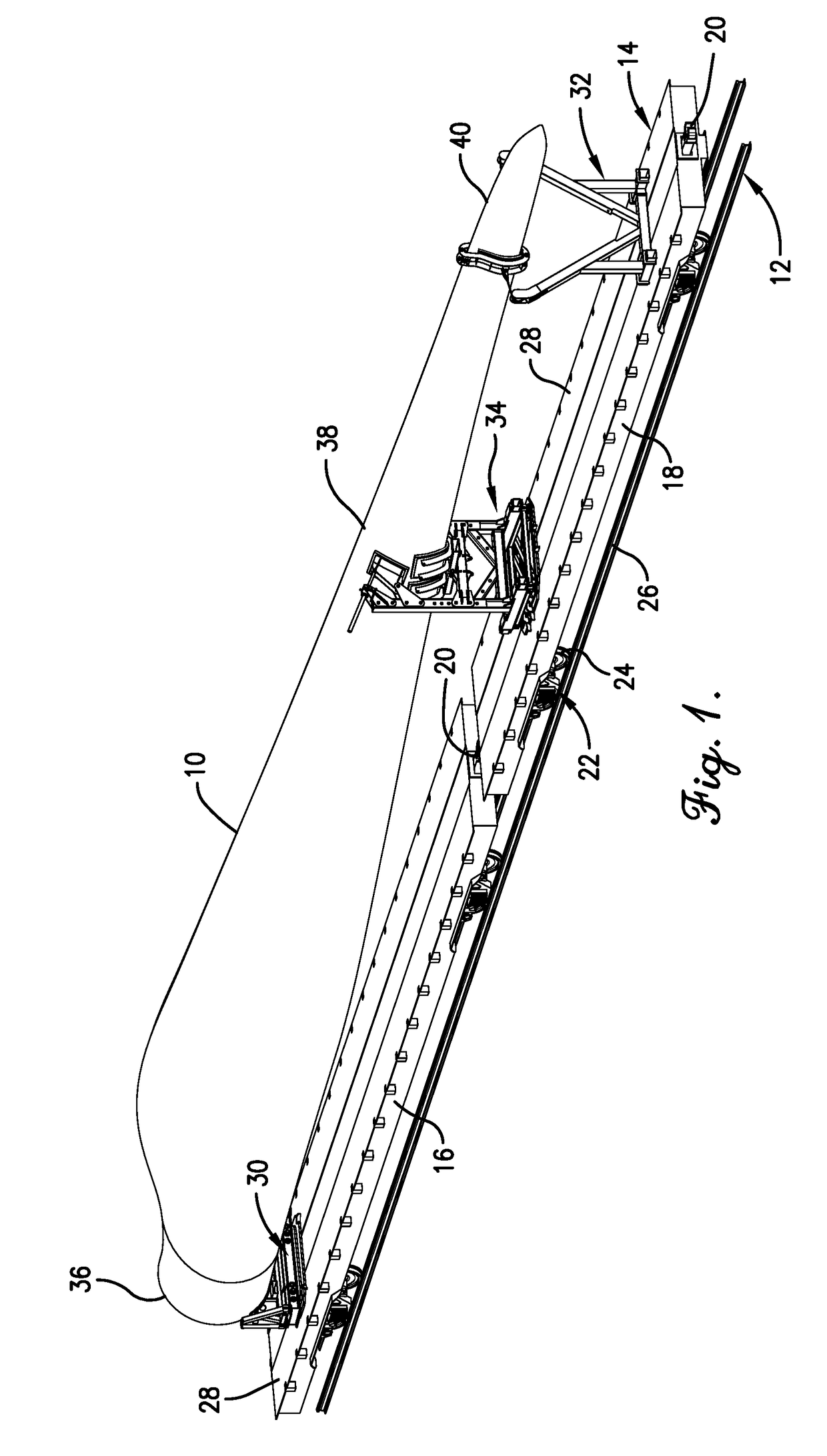

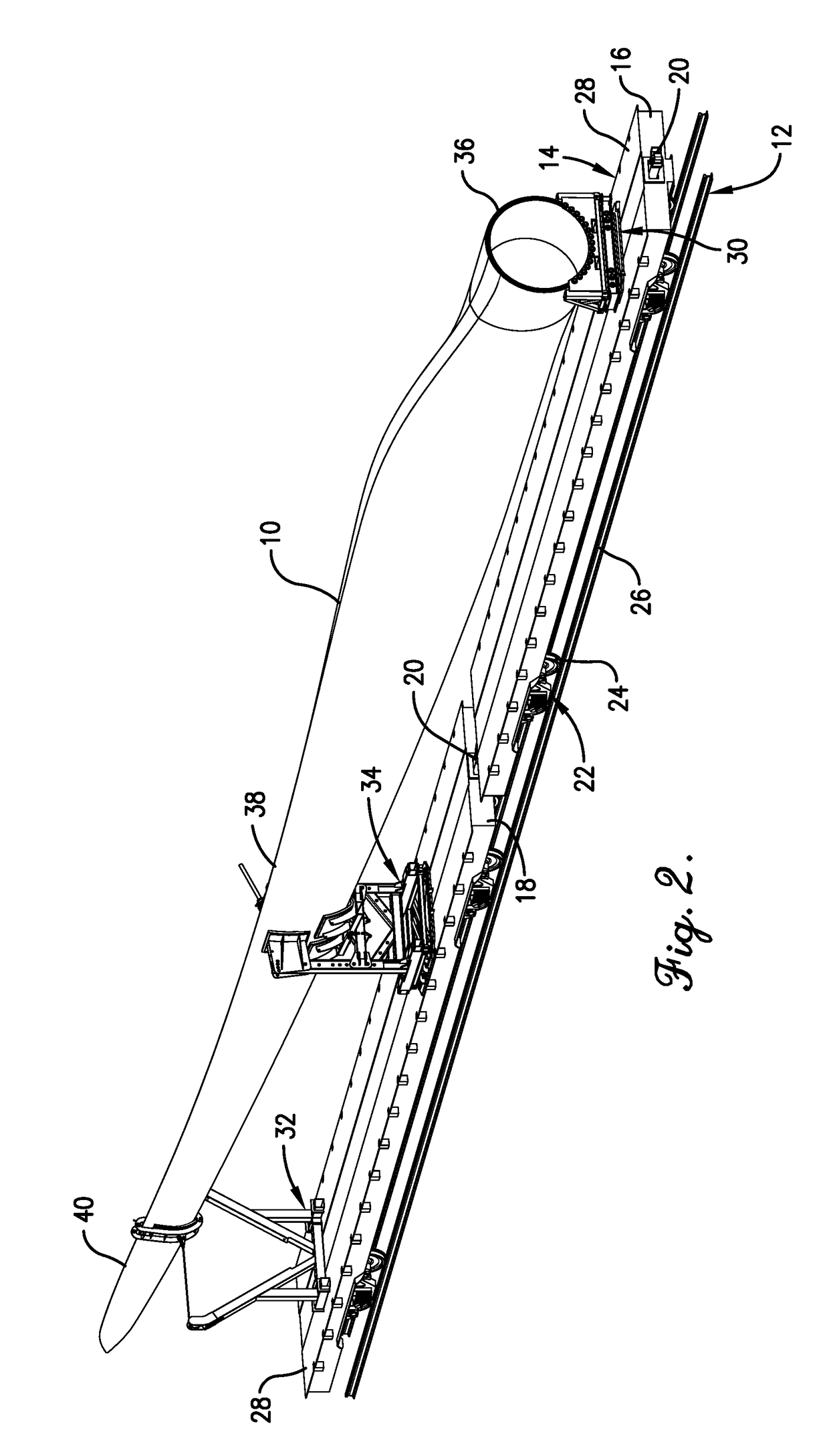

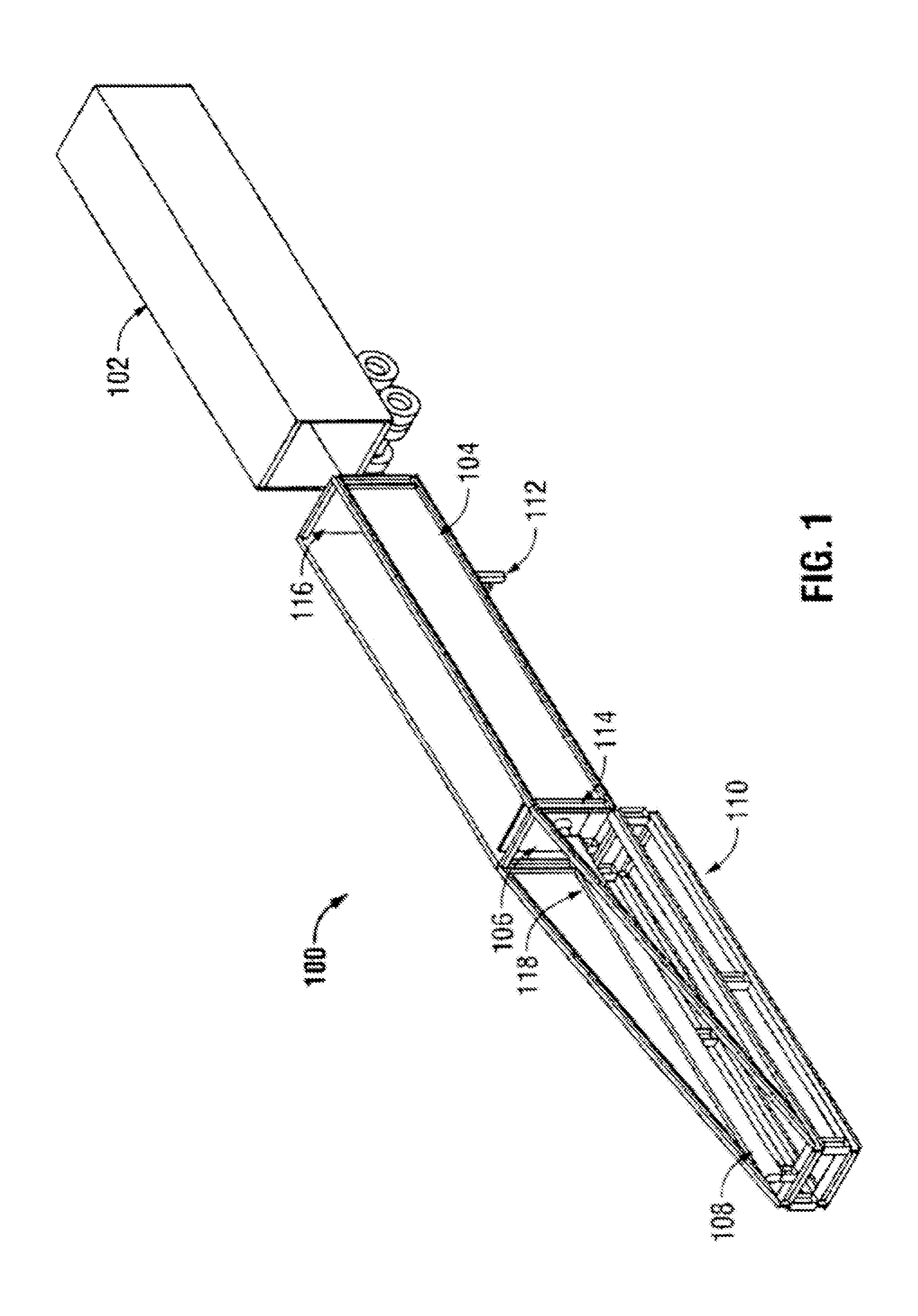

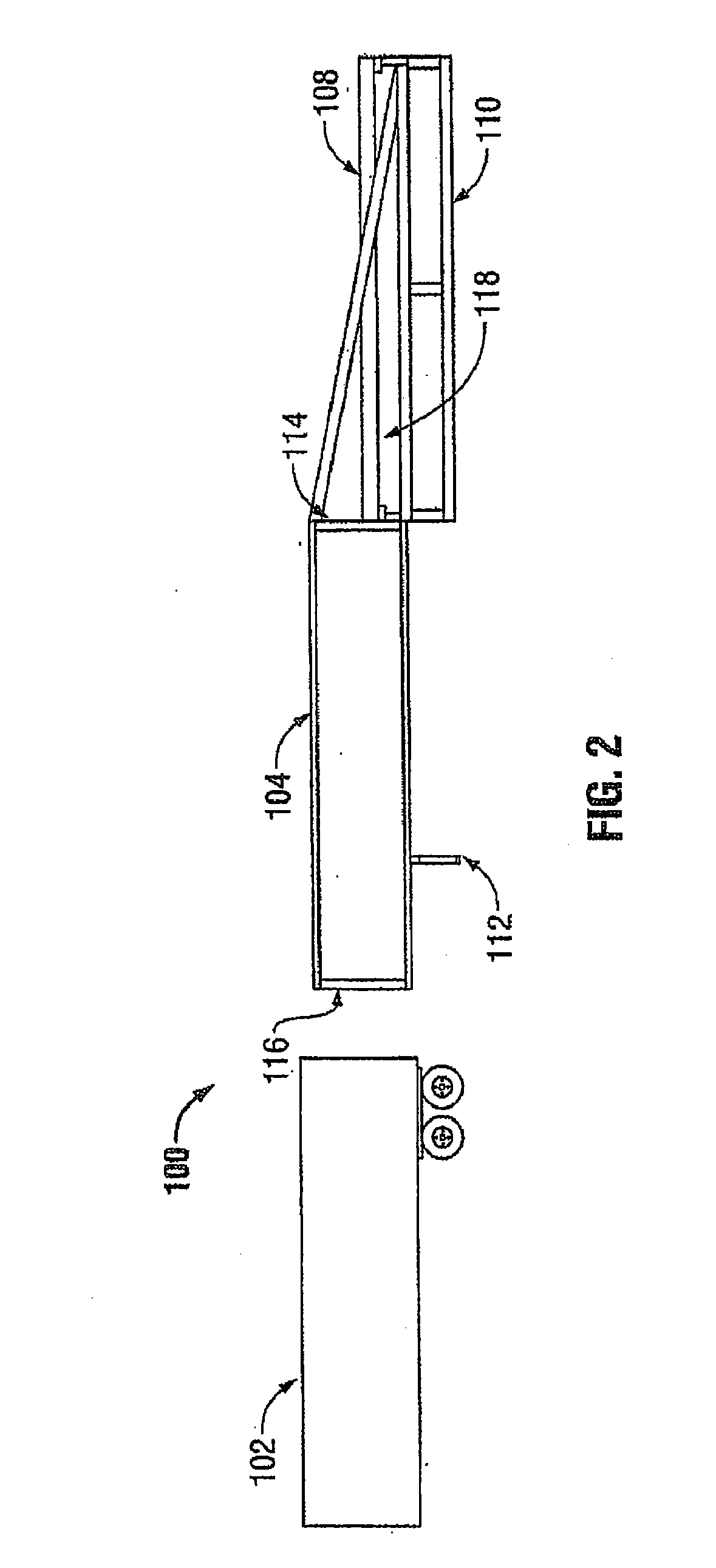

Railcar fixtures for transportation of wind turbine blades and method involving same

ActiveUS20180223811A1Avoid using forceVehicle to carry long loadsLoading/unloading vehicle arrangmentTurbine bladeExtremity Part

A transport system for transporting a wind turbine blade on first and second railcars that serve as load cars. A root end fixture on the first railcar is connected to a root end portion of the wind turbine blade. A mid-frame fixture on the second railcar supports a reinforced midsection of the wind turbine blade using a pair of support saddles. A tip end fixture restrains a tip end portion of the wind turbine blade against lateral movement outside of a preselected range of movement in opposite lateral directions and causing bending of the blade about the mid-frame fixture when the restraint device imparts sufficient restraining force to the tip end portion of the blade.

Owner:MARTIN BENCHER USA LLC

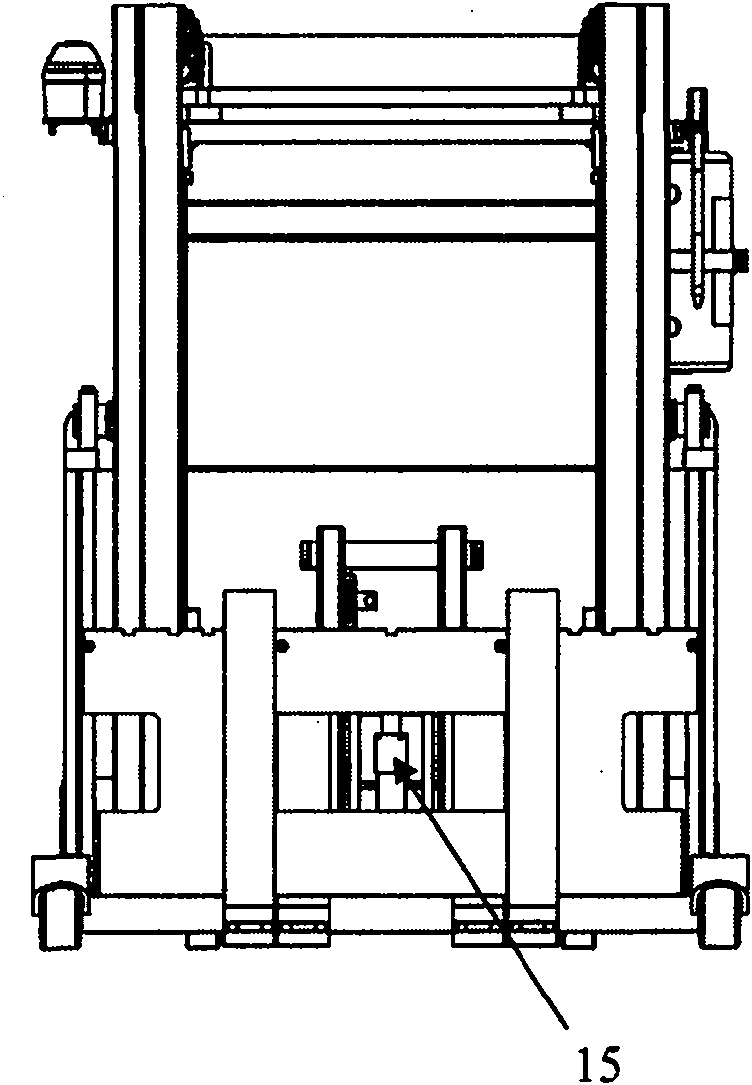

Hydraulic system for double stacker industrial truck

The invention relates to hydraulic system for an double stacker truck comprising a pump for providing hydraulic fluid to the hydraulic system and a first hydraulic lifting cylinder for moving a first load carriage and a second hydraulic lifting cylinder for moving a second load carriage of the truck, the hydraulic lifting system is characterized in a flow divider for dividing the flow of hydraulic fluid between the first and the second hydraulic cylinder and a first directional valve which is arranged open in a first direction for leading hydraulic fluid to the first lifting cylinder or to open in a second direction for leading hydraulic fluid to the second hydraulic cylinder. The invention also relates to a double stacker truck comprising a hydraulic system for moving the load carriages of the truck.

Owner:BT PROD

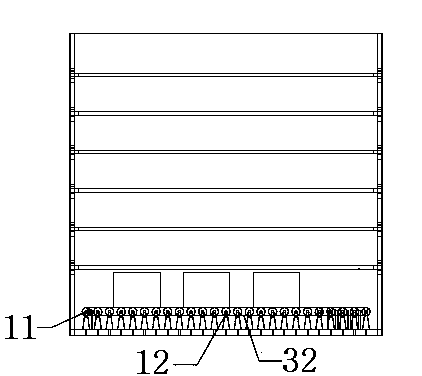

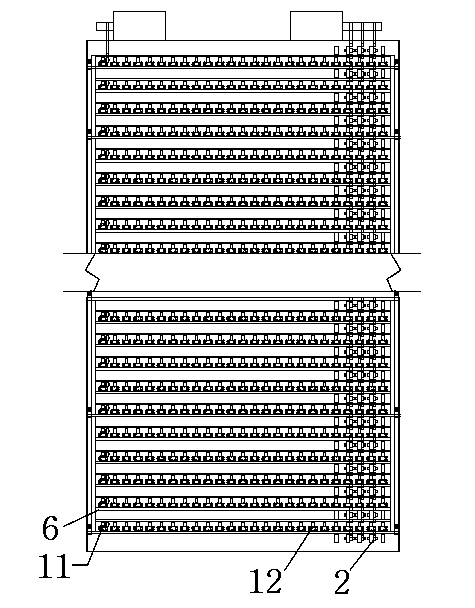

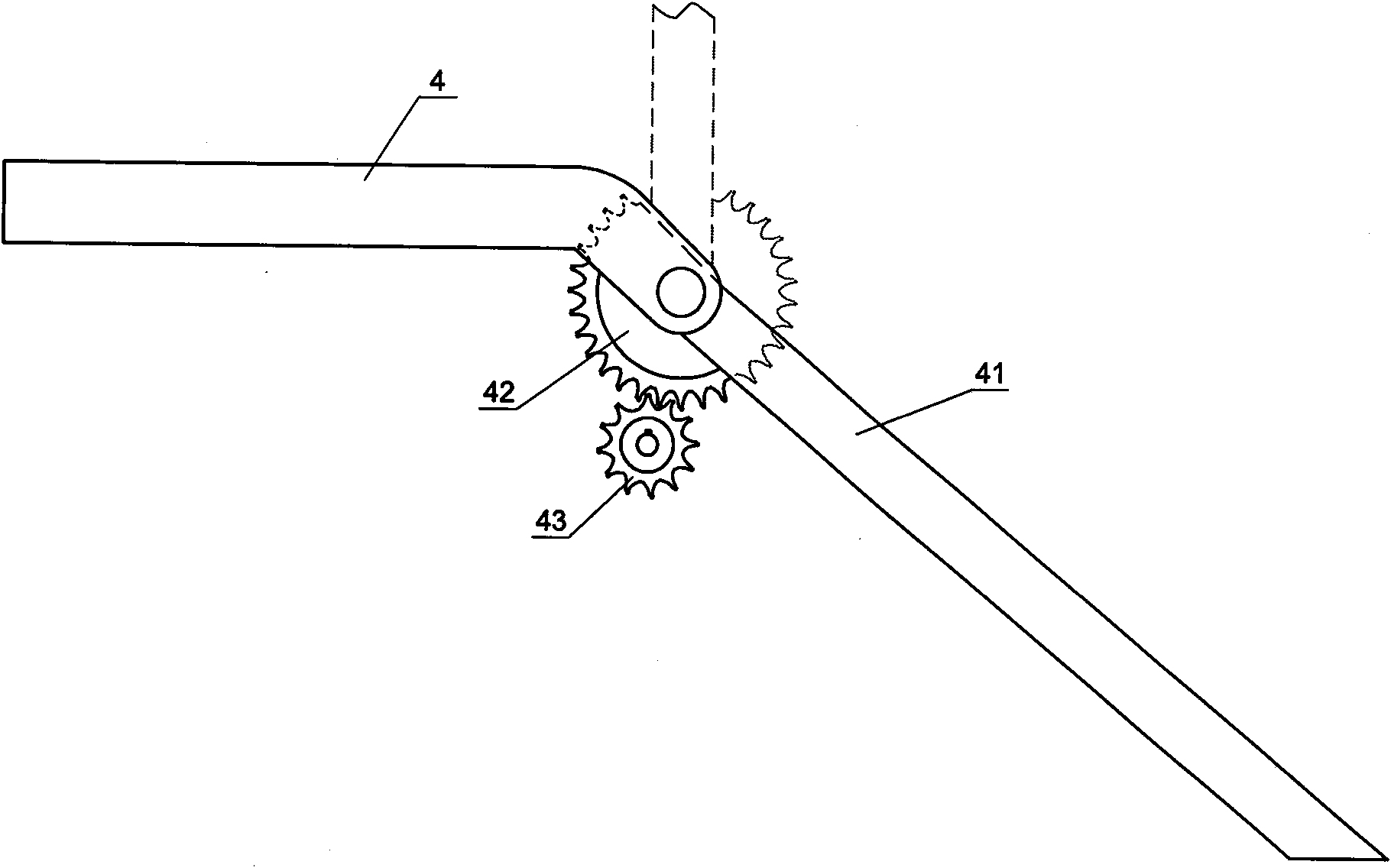

Automatically loaded carriage

InactiveCN103568918ARealize automatic loading and unloadingSave loading and unloading timeVehicle with raised loading platformVehicle with endless chains/beltsDrive wheelEngineering

The invention provides an automatically loaded carriage, which is characterized by comprising a horizontal driving wheel, a horizontal driven wheel, a longitudinal idler wheel, a longitudinal driving belt, a horizontal driving belt, a driving chain, a conical gear, a lifting goods shelf, a rope, a fastening lock, a horizontal motor, a longitudinal motor, a rope motor, a chain guide wheel, a belt guide wheel and a guide groove, wherein the horizontal motor, the longitudinal motor and the rope motor are arranged at the end of the carriage, the horizontal motor drives the conical gear to rotate through the chain, the chain is guided by the chain guide wheel arranged at a box bottom, the conical gear is meshed with the horizontal driving wheel provided with conical gears, and the horizontal driving wheel is connected with a horizontal driven idler wheel through the horizontal driving belt. The device can be matched with a warehouse conveying goods crawler belt for realizing automatically loading goods into a warehouse and unloading the goods from the warehouse; the carriage is more applicable to fragile articles fear of heavy loading, and the carriage structure enables the goods to be placed in a layered manner and to be prevented from being pressed, so that the carriage is particularly suitable for the express industry.

Owner:王延斌

Dynamic load carriage frame

A load carriage frame (80) of FIG. 9 includes a shoulder yoke (90) and a belt (120) separated from the yoke by a multi-element connecting brace (96). The brace is telescopic in nature in that a flexible but rigid tongue (130), extending from a first section, is permitted to slide within a guide on a second section (154), thereby allowing the length of the connecting brace to be altered. The multi-element connecting brace is centrally coupled to the yoke and centrally coupled to the belt and configured to act as a force path by transferring weight that, in use, is loaded onto or through the yoke and into the belt thereby effecting selected weight re-distribution onto the pelvic girdle of a wearer about which the belt, in use, is secured. Additionally, as shown in FIG. 20, a quick release mechanism may further alter the length of the connecting brace by allowing the position of a rotational coupling point to be altered relative to a housing of the quick release mechanism. The quick release mechanism can, in fact, be used with a single piece connecting brace.

Owner:BCB INT

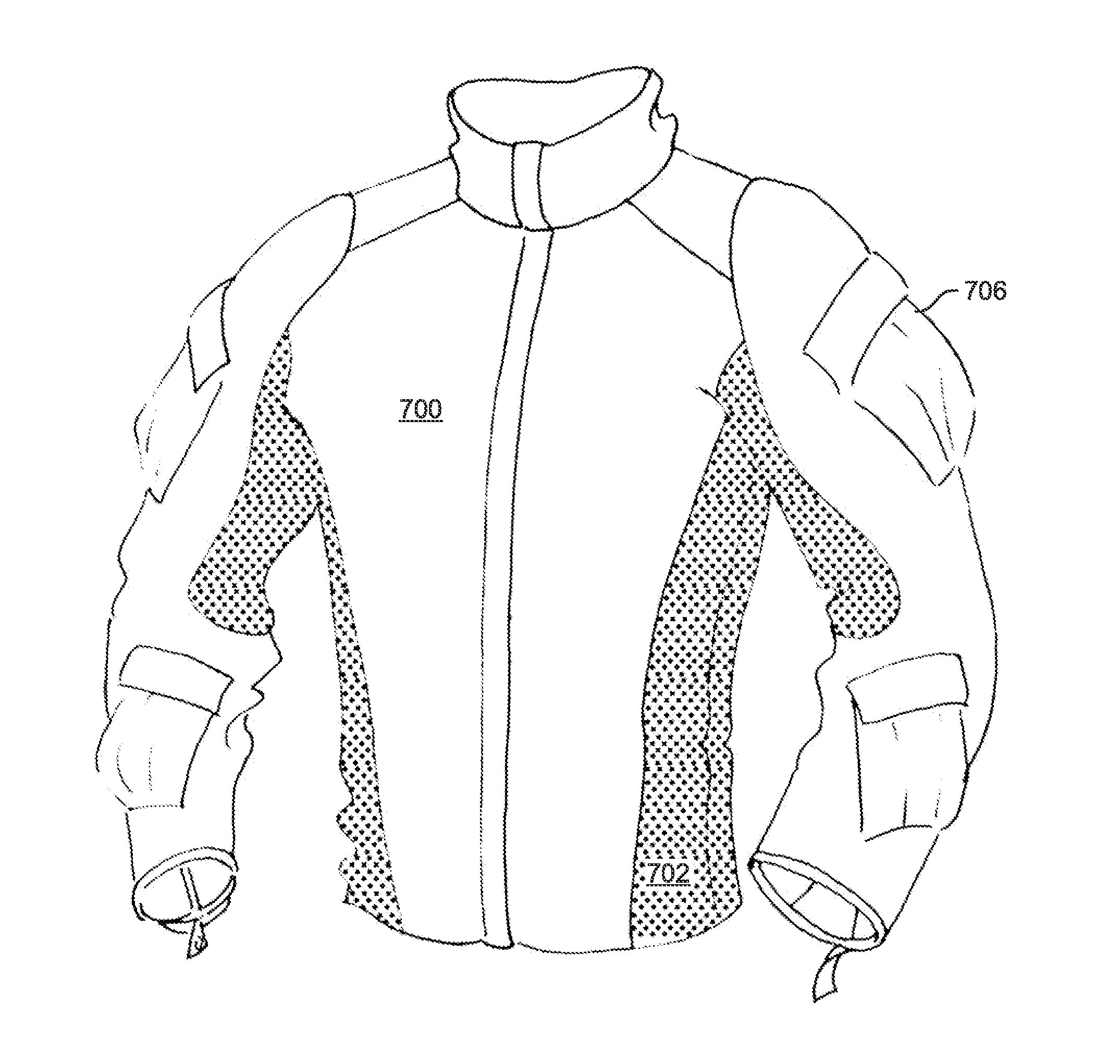

Integrated protective garment ensemble

A protective garment system fabricated from ballistic textiles having a V50 on 2 grain RCC of at least 300 fps as measured by Mil-Spec 662F provides good ballistic and fragmentary protection, and can be worn in lieu of conventional clothing without discomfort to the wearer. Embodiments overcome prior art ballistic fabric limitations by incorporating novel construction, such as plaiting and / or twill or satin weaving, as well as novel yarn selection, to enable comfortable skin contact, and by applying coatings to improve abrasion resistance, UV resistance, and color acceptance. Embodiments incorporate layers of ballistic fabric in critical areas, either by overlapping protective clothing articles, and / or by incorporating multiple layers of protective fabric into an individual protective garment. Embodiments provide good moisture transport for long term comfort. In certain embodiments, substantially all of the garment's mass is protective, including pockets, lapels, load carriage, and any other “folded” features.

Owner:WARWICK MILLS INC

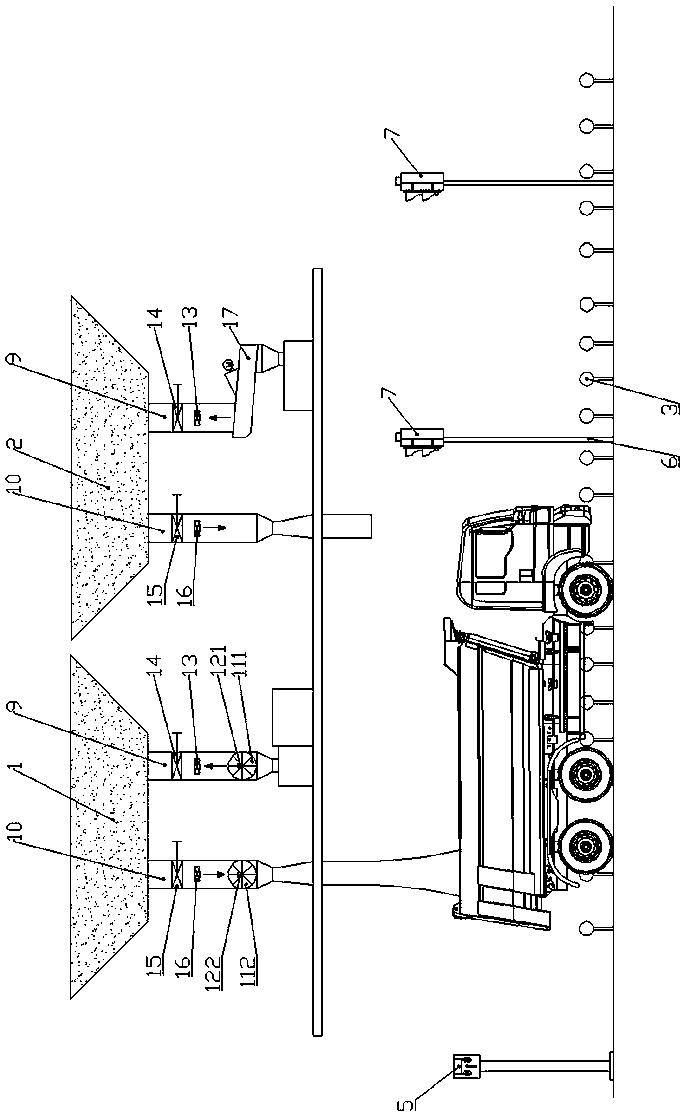

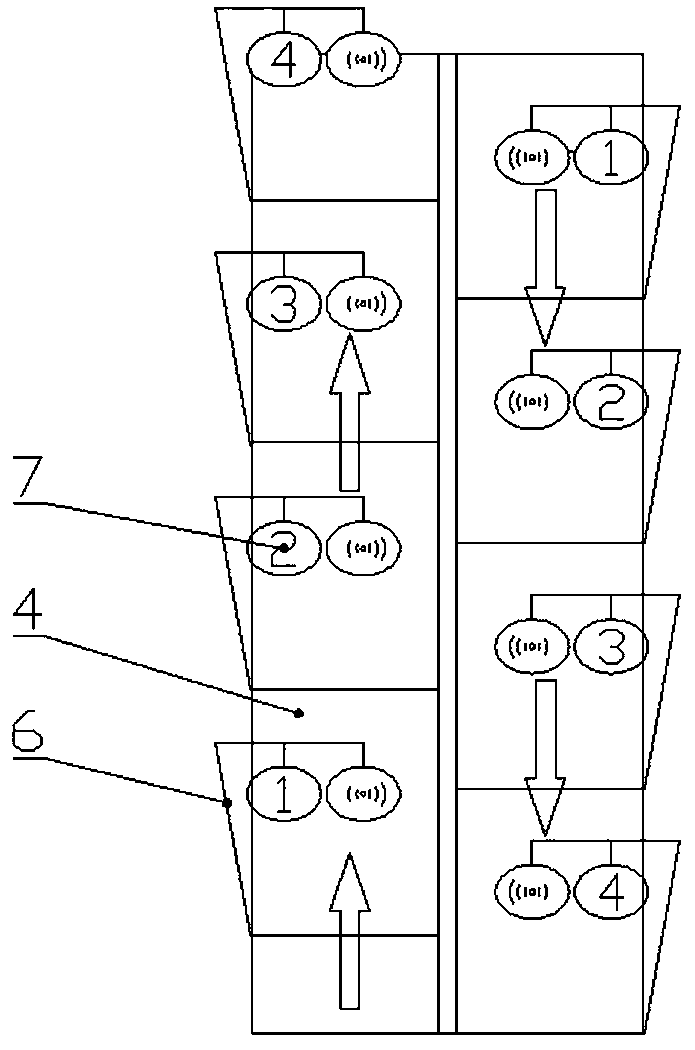

Quantitative loading system and semi-automatic loading method thereof

PendingCN111252572APlay the function of real-time measurementImprove loading efficiencyLoading/unloadingFlow transducerProgrammable logic controller

The invention discloses a quantitative loading system and a semi-automatic loading method thereof, and belong to the technical field of material loading. The quantitative loading system and the semi-automatic loading method thereof solve the technical problems of accurate metering of loading capacity and reduction of workload of personnel. The quantitative loading control system comprises a PLC (programmable logic controller), a display module and an acousto-optic prompt module, IC (integrated circuit) card readers are arranged at initial positions of a plurality of loading areas, an ash siloand a slag silo are arranged above the loading areas at intervals, a cantilever support is arranged between every two adjacent loading areas, a display module and a parking signboard are hung on eachcantilever support, a plurality of sets of laser spotlights are arranged on the side edge of one side of each loading area according to the axle distances of different loading vehicle models, and a laser signal receiving device is arranged at the position, corresponding to the laser spotlight, of one side of the loading area; and each of the ash silo and the slag silo comprises a hopper, a feedingarticulated chute and a discharging articulated chute, and an impeller feeder, a flow sensor and a discharging control valve are mounted on each of the feeding articulated chute and the discharging articulated chute. According to the quantitative loading system and the semi-automatic loading method thereof, the loading efficiency is improved, the manual workload is reduced, and the economic benefit is improved.

Owner:山西菲特电力工程科技股份有限公司

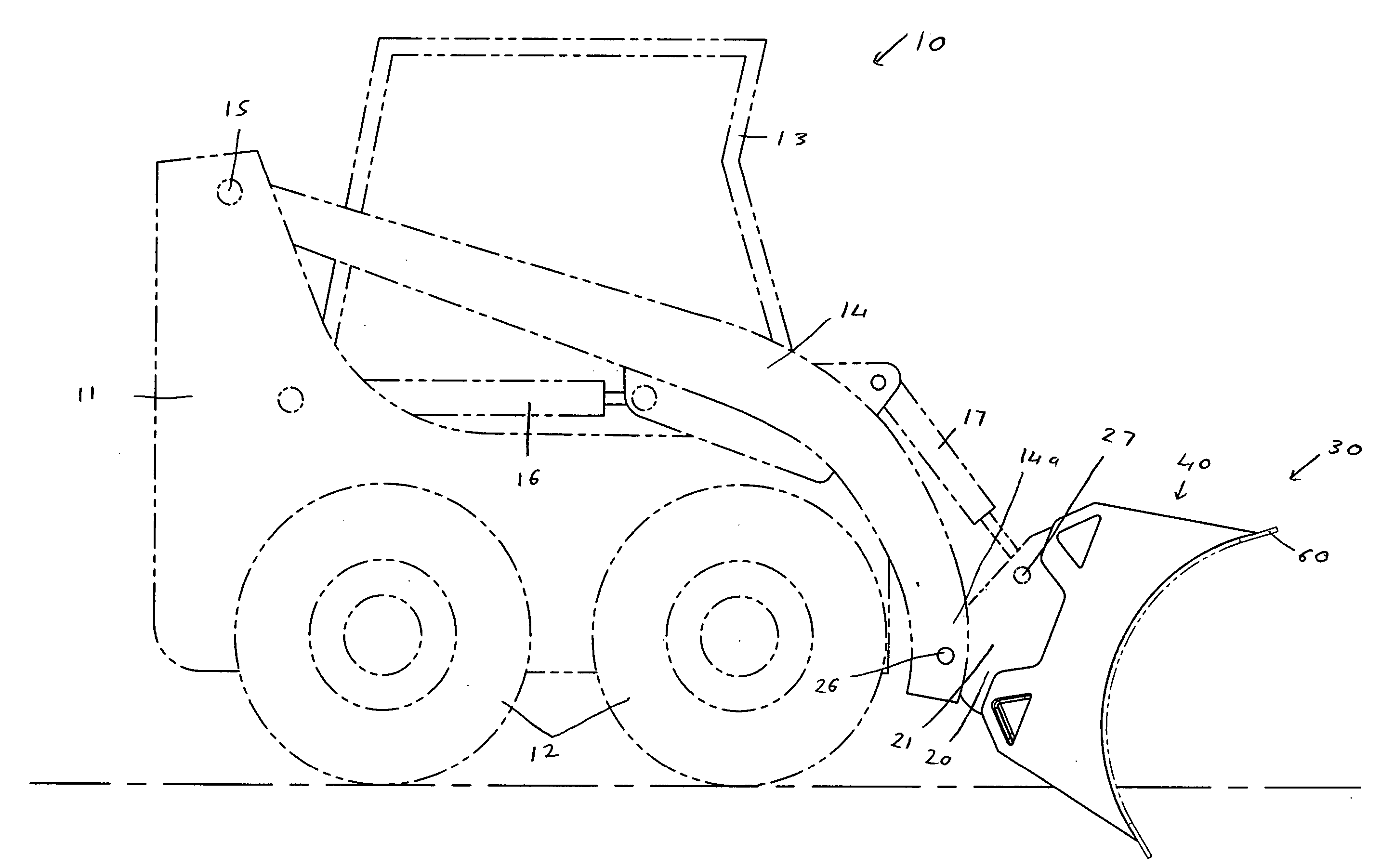

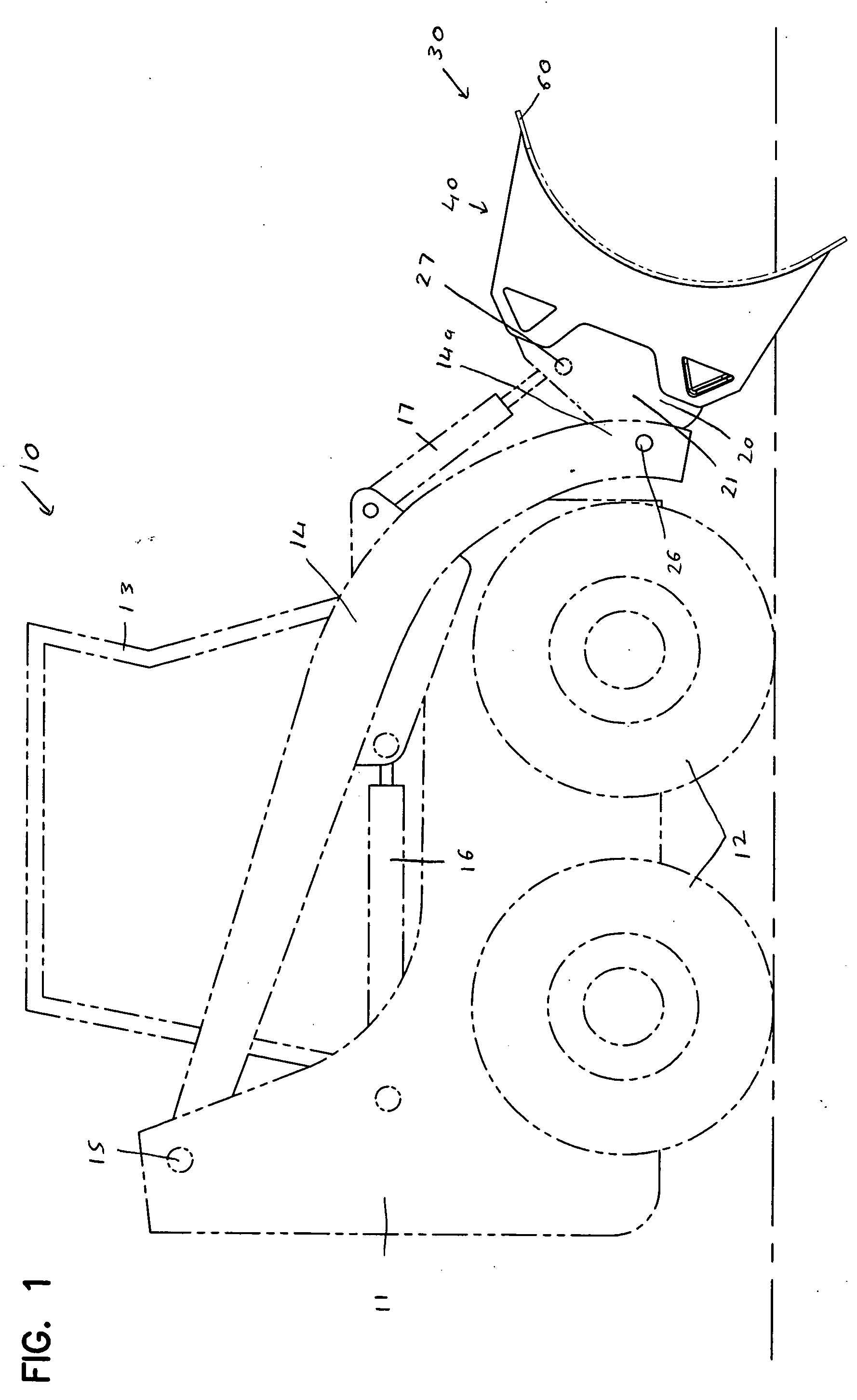

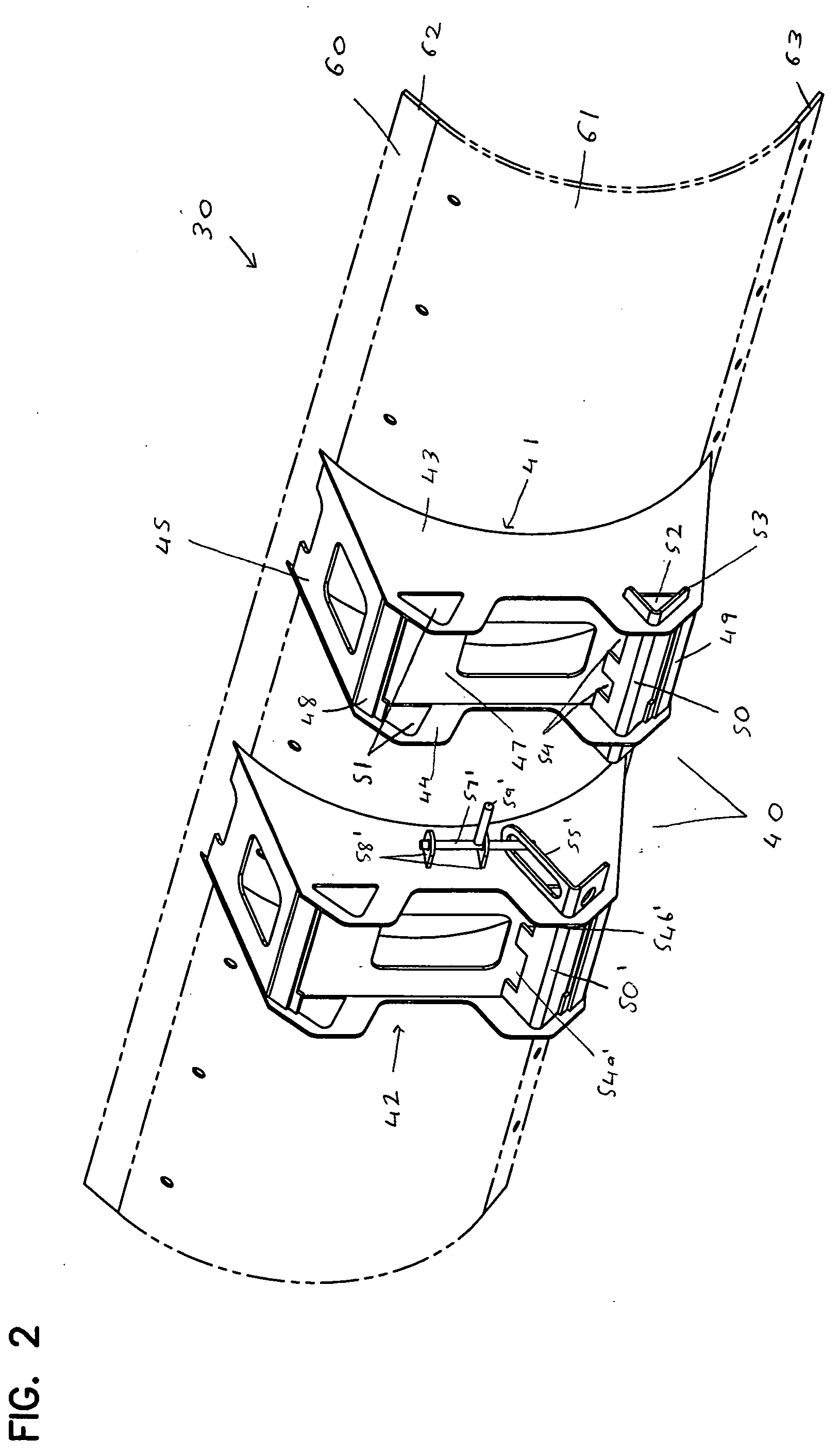

Reversible hitch structure for loader attachments

InactiveUS20060070759A1Mechanical machines/dredgersAgricultural undercarriagesEngineeringMechanical engineering

A hitch structure for mounting attachments to a vehicle such as a skid steer loader is disclosed herein. The hitch structure includes a universal, reversible hitch structure. The hitch structure includes a first end positioned opposite a second end, a fixed locking structure located adjacent each of the first end and the second end, the fixed locking structure constructed for receiving a toe end of an attachment carrier of a loader vehicle. The hitch structure also includes a removable locking structure with a slot for receiving a locking wedge positioned adjacent a heel end of the attachment carrier. The removable locking structure is removably engageable with the hitch structure alternatively adjacent either the first end or the second end of the hitch structure to form a clamping structure with the fixed locking structure located at the opposite end from the removable locking structure for mounting the attachment to the vehicle.

Owner:NTH

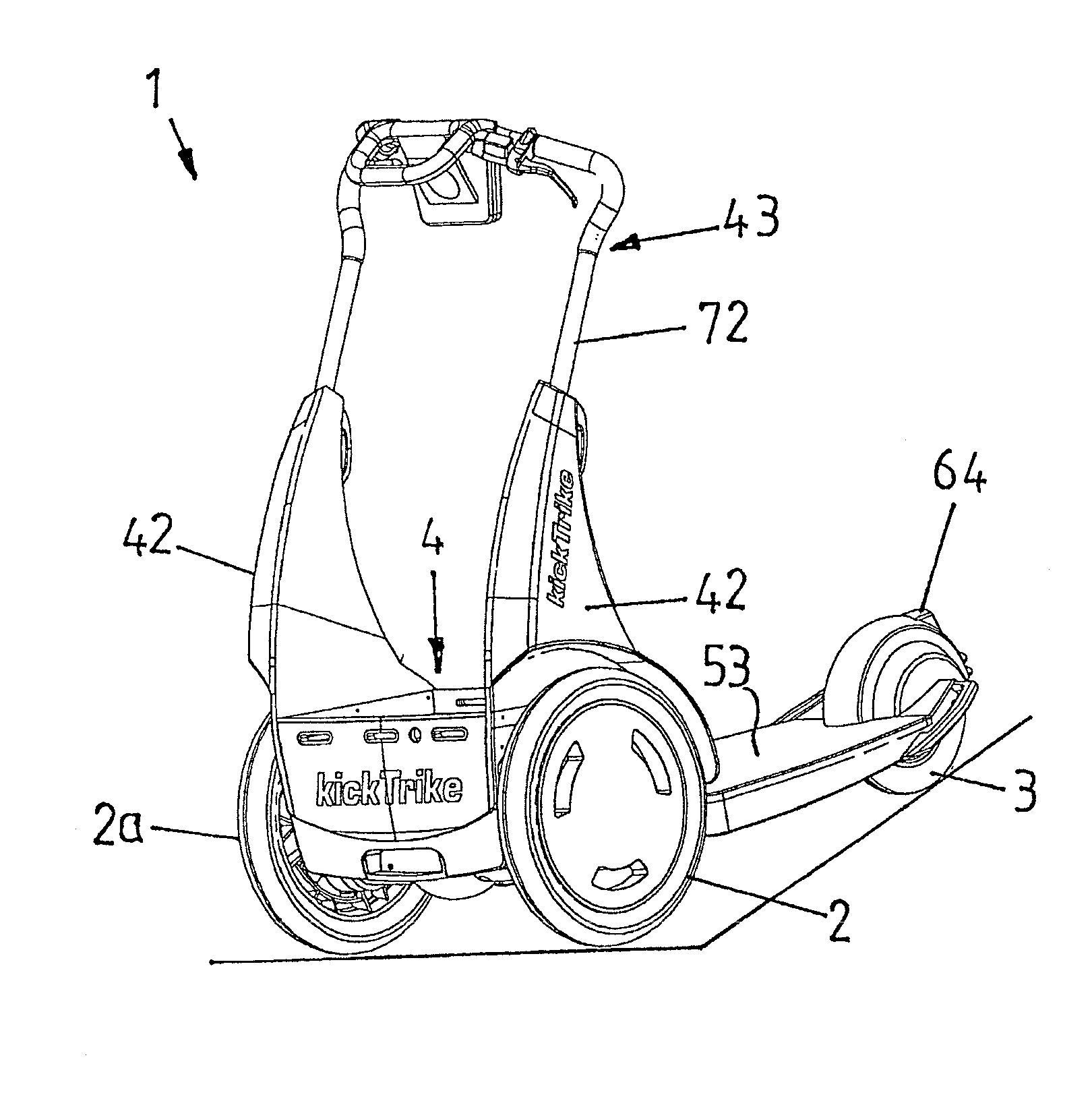

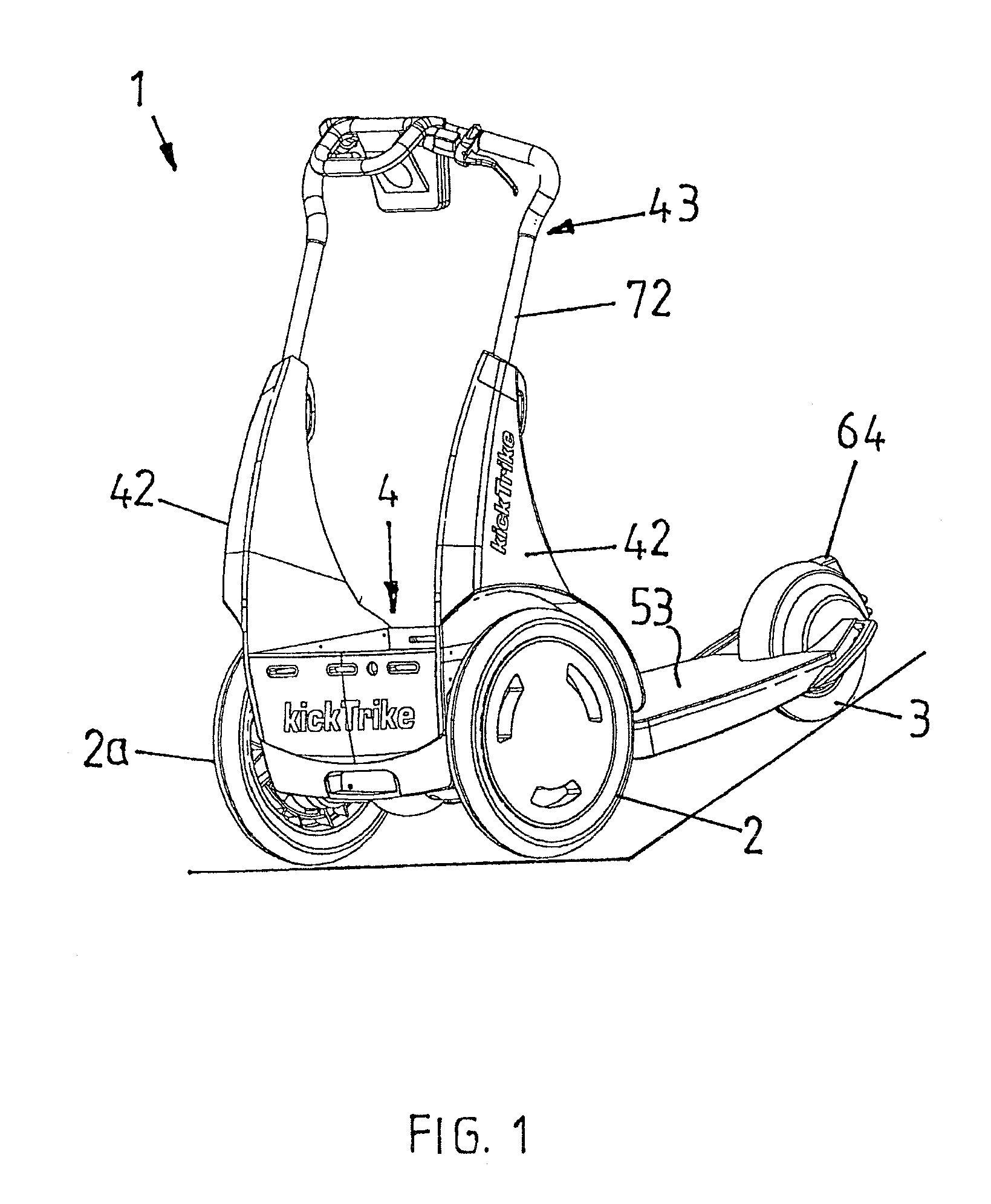

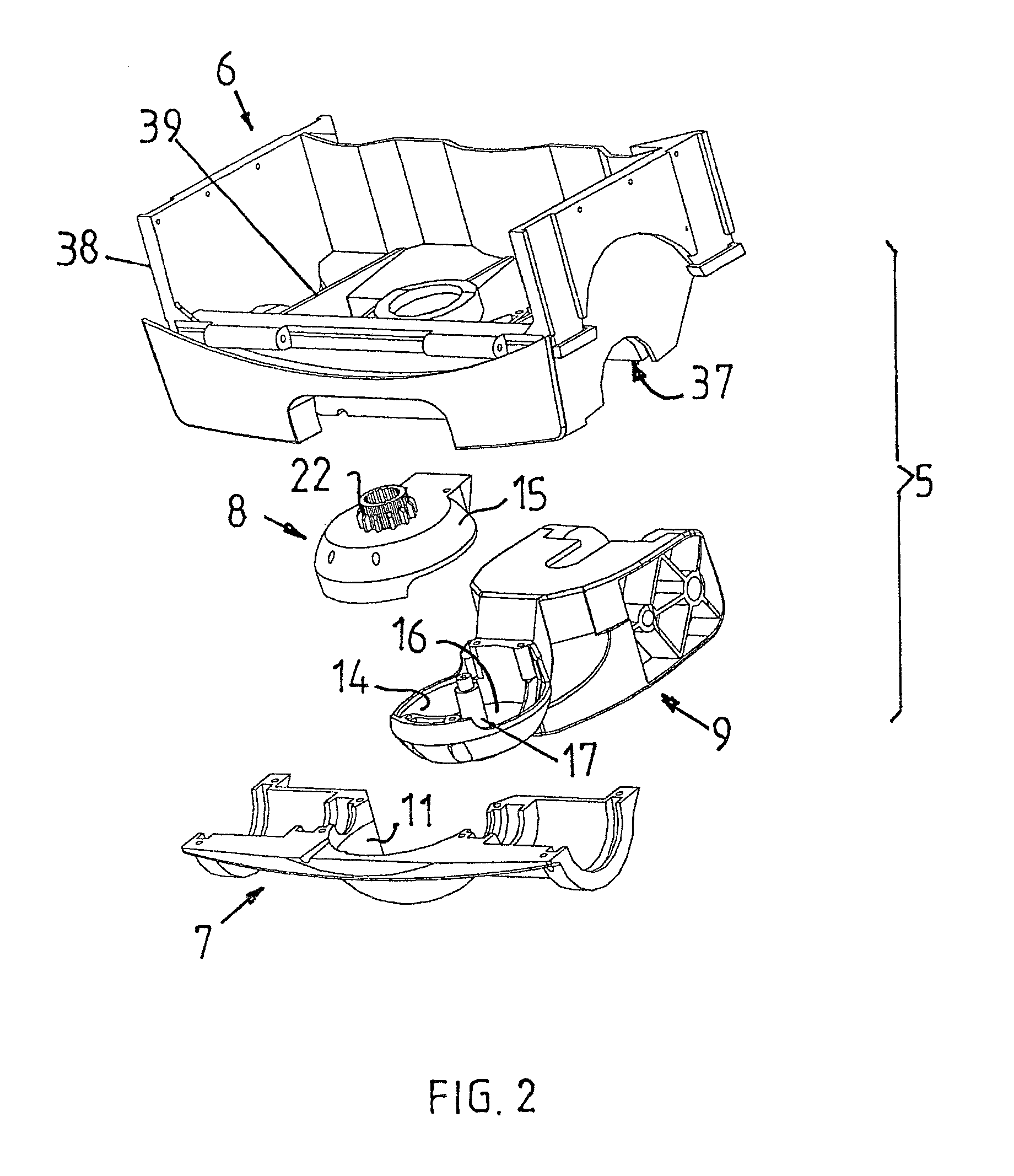

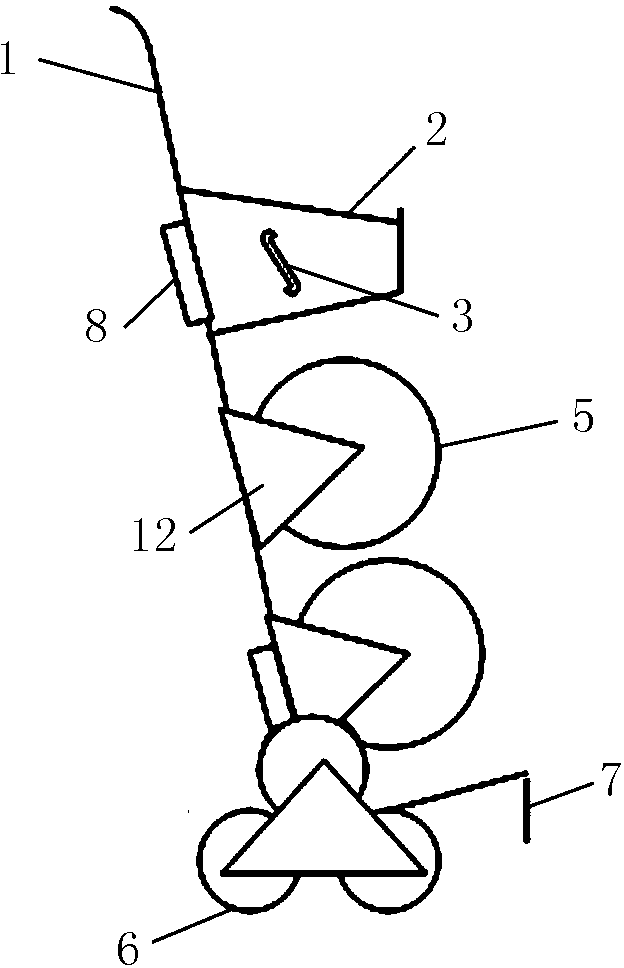

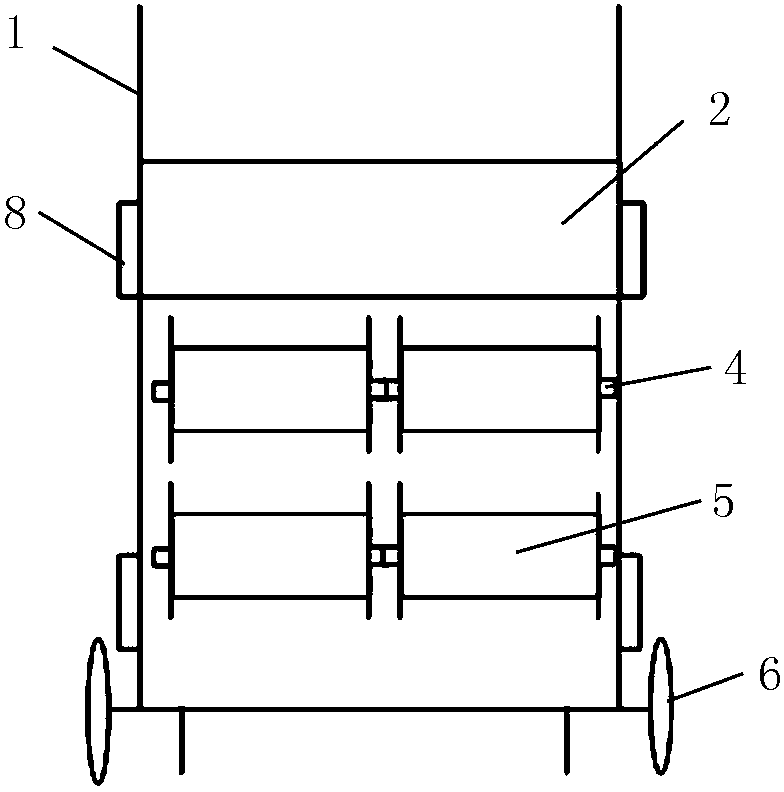

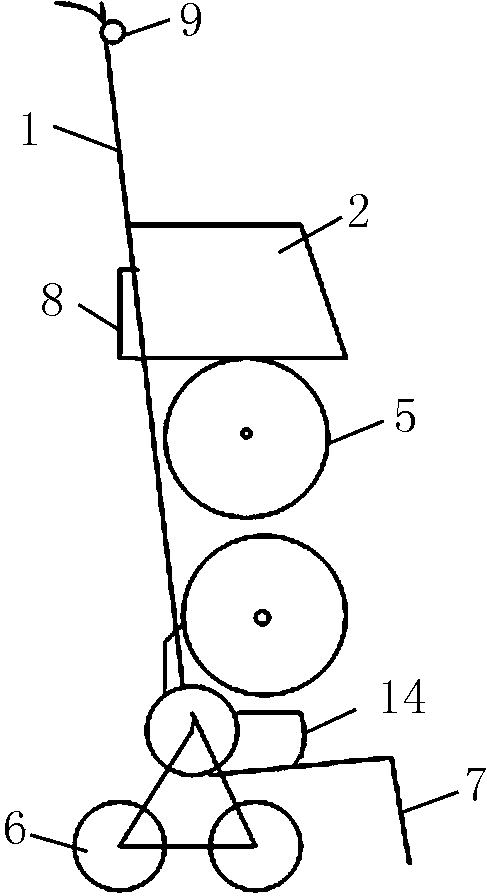

Load and/or transport cart

A transport and load cart in the form of a kick scooter is compact, has a low dead weight and is designed with dimensions that are suitable for transport by train or automobile, and which nonetheless ensures safe transport of bulky and heavy goods together with a person, while improving the handling and reducing the expenditure of force. The longer side of the loading platform is disposed transversely to the travel direction and in a rearwardly inclined and / or displaceable manner relative thereto, and the receiving compartment has a front-side slot for the rechargeable battery.

Owner:CONSTIN

Self-adaptive airport logistics system

ActiveCN112374119AAvoid damageReduce riskStacking articlesDe-stacking articlesTrunk compartmentLogistics management

The invention provides a self-adaptive airport logistics system. The self-adaptive airport logistics system comprises a luggage conveying belt, a stacking manipulator, a composite gripper and a loading parking space; and in order to realizing luggage grabbing and stacking, the self-adaptive airport logistics system adopts the following steps that S1, whether a loading vehicle enters the loading parking space or not is detected; S2, whether a luggage case is conveyed to a preset position on the luggage conveying belt or not is detected; S3, size information and pose information of the luggage case conveyed to the preset position is detected; S4, the stacking position is planned, and a grabbing path of the stacking manipulator is planned; and S5, the composite gripper is controlled to move according to the grabbing path, and the luggage case is grabbed to the stacking position through the composite gripper. The self-adaptive airport logistics system can replace manpower to sort luggage and load and transport the luggage from a departure luggage rotary table to a luggage trailer, the risks of luggage damage and distribution errors are relatively lower, and the labor cost is relativelylower.

Owner:QUANZHOU INST OF EQUIP MFG

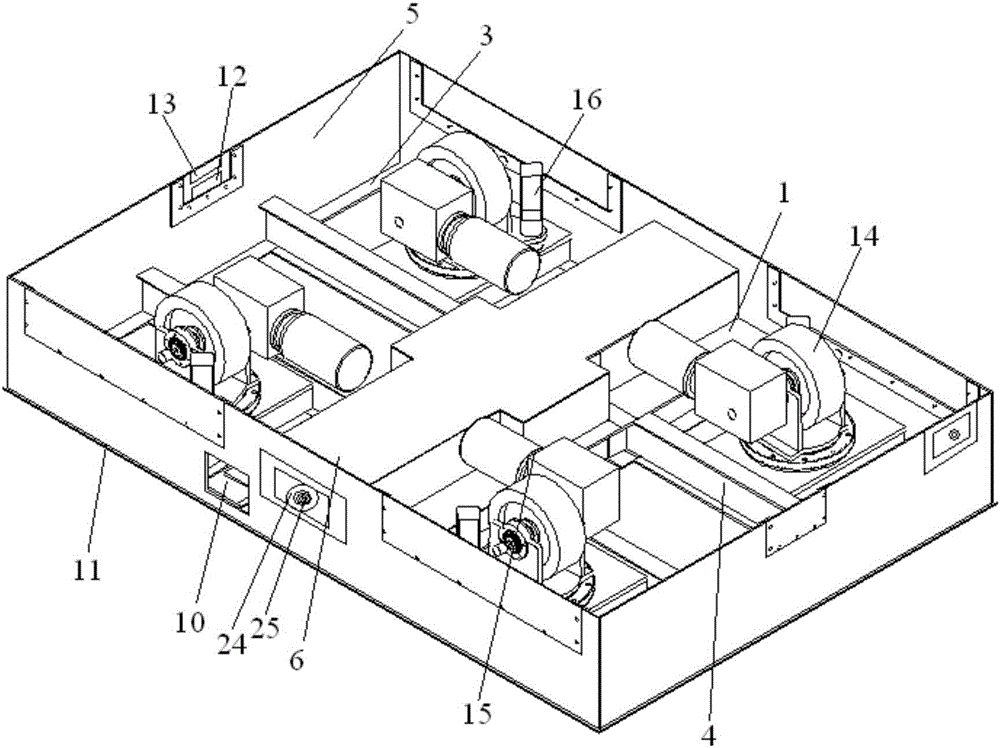

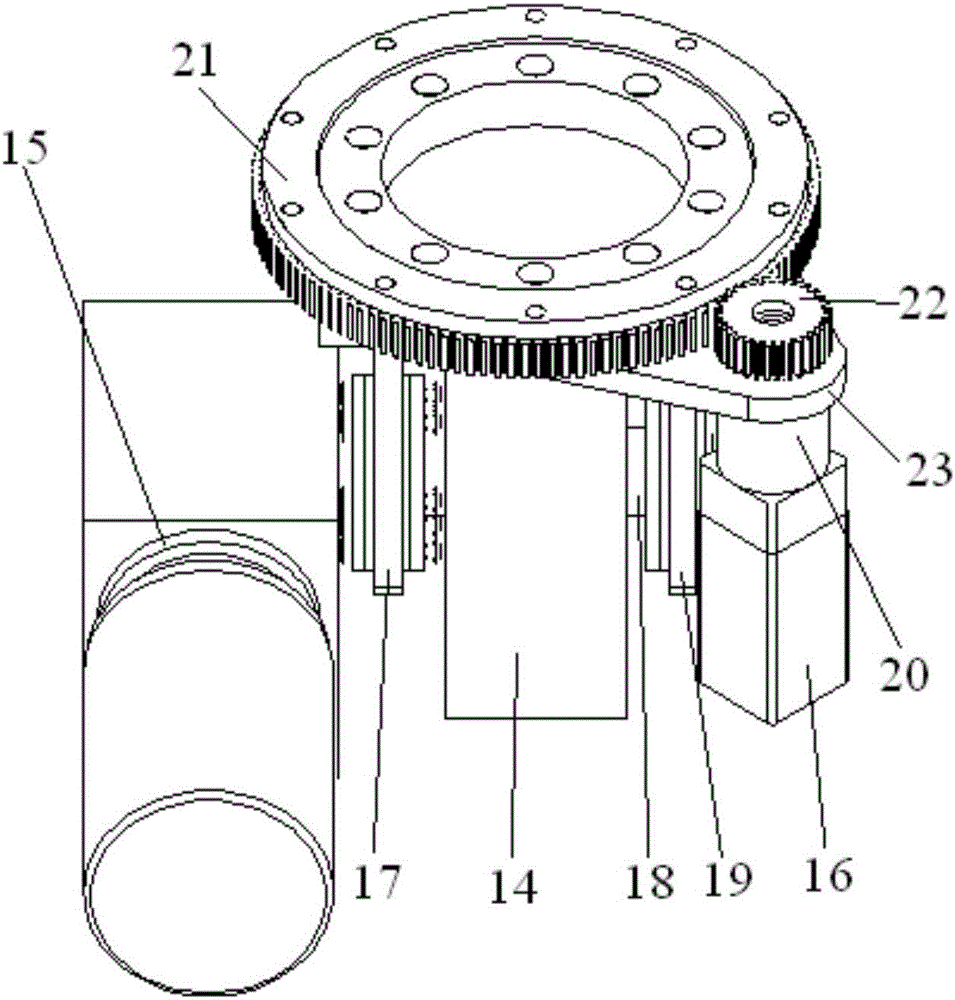

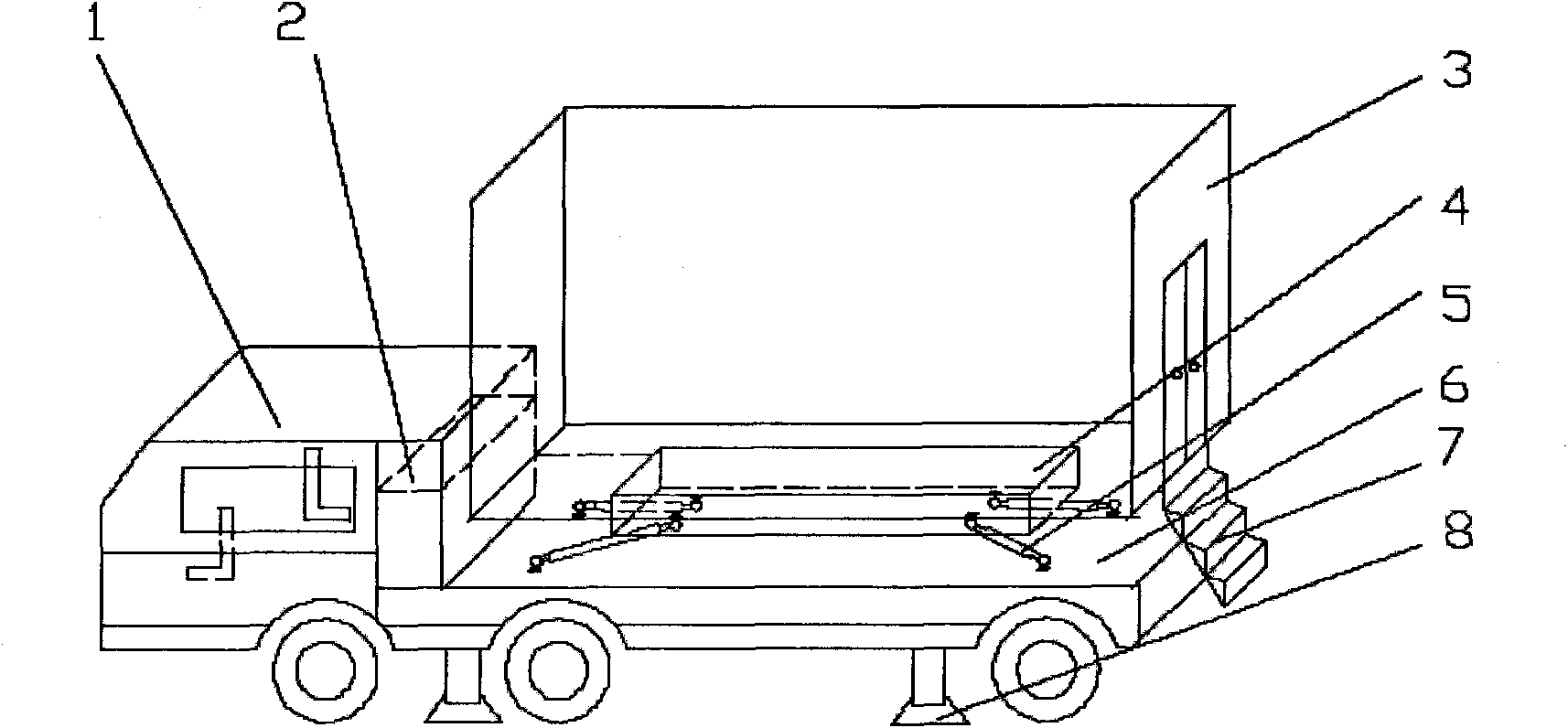

Vehicular earthquake simulator based on 4-RPS (Range Positioning System) space parallel mechanism

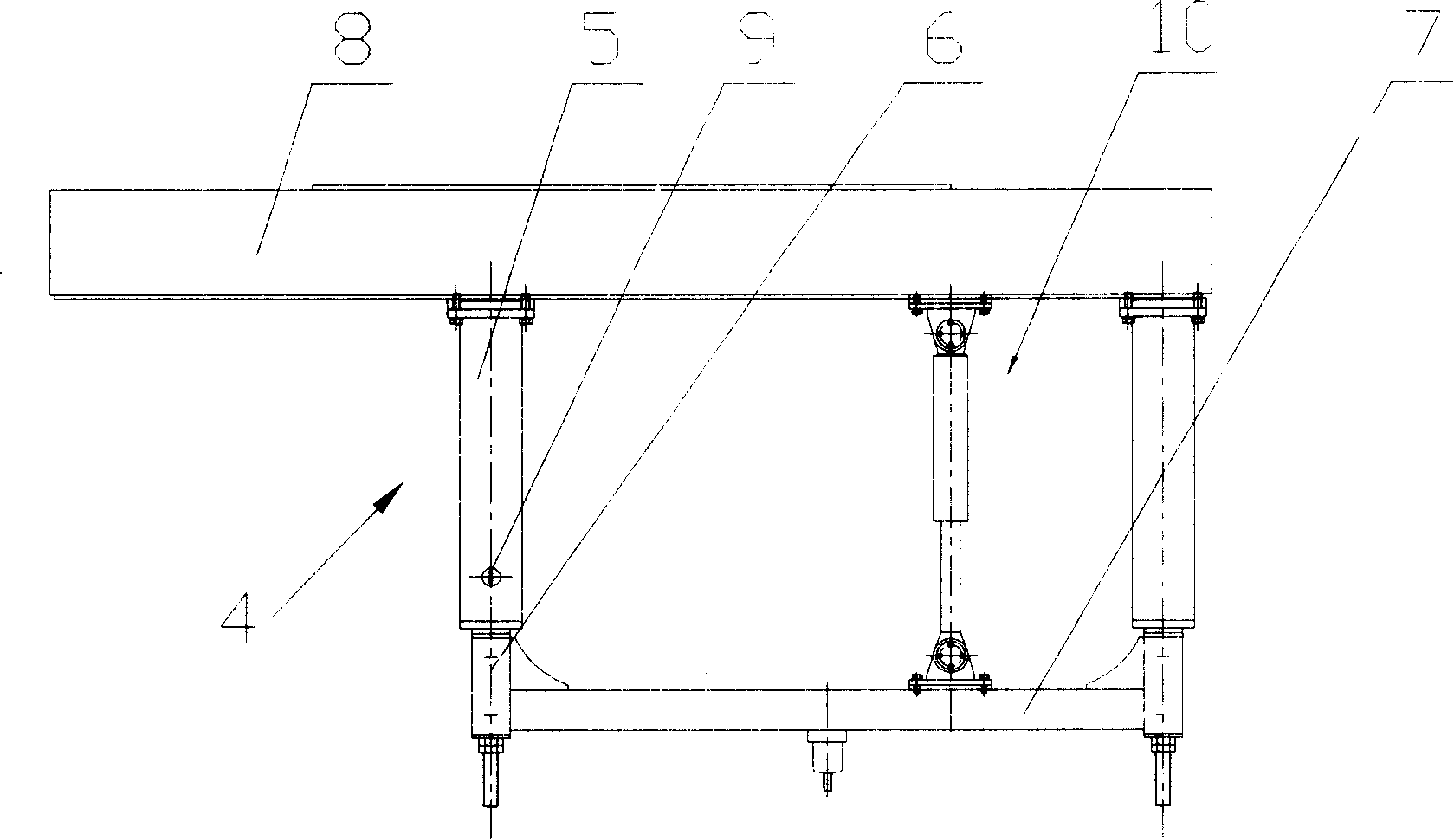

InactiveCN101819727AIngenious structureSimple structureCosmonautic condition simulationsEducational modelsEngineeringLoad carriage

The invention discloses a vehicular earthquake simulator based on a 4-RPS (Range Positioning System) space parallel mechanism. The vehicular earthquake simulator comprises a loading vehicle (1), a control console (2), a simulation room (3) and the 4-RPS space parallel mechanism (5), wherein the rear part of a driving cab of the loading vehicle (1) is provided with the control console (2); the simulation room (3) is installed on a rear vehicle body of the loading vehicle (1) through the 4-RPS space parallel mechanism (5); and the control console (2) is linked with the 4-RPS space parallel mechanism (5) to integrally form the vehicular earthquake simulator. The earthquake simulator is vehicular, simple in structure, flexible and accurate to control, and can be widely used for the floating science popularization of earthquakes in schools and communities.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

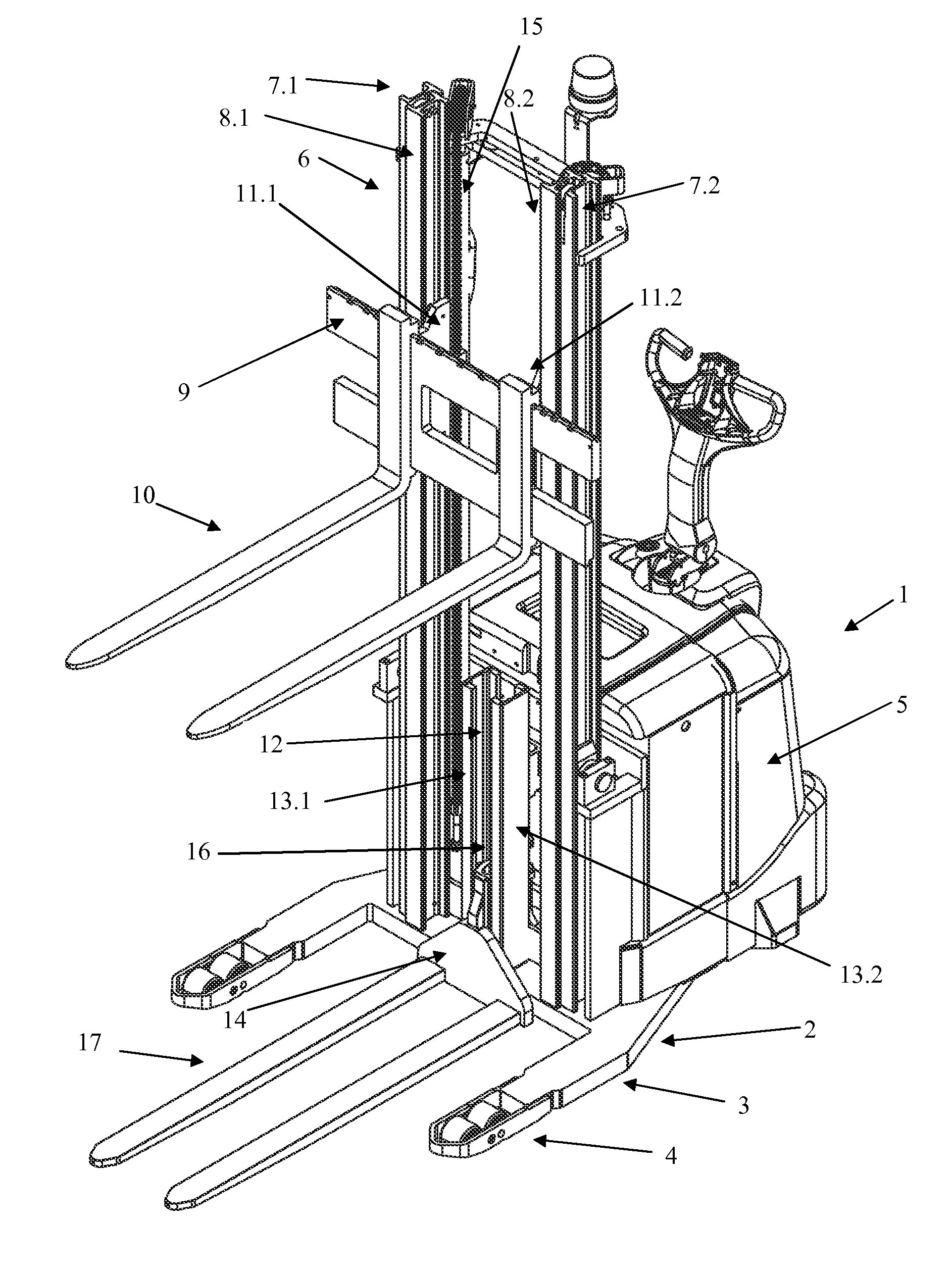

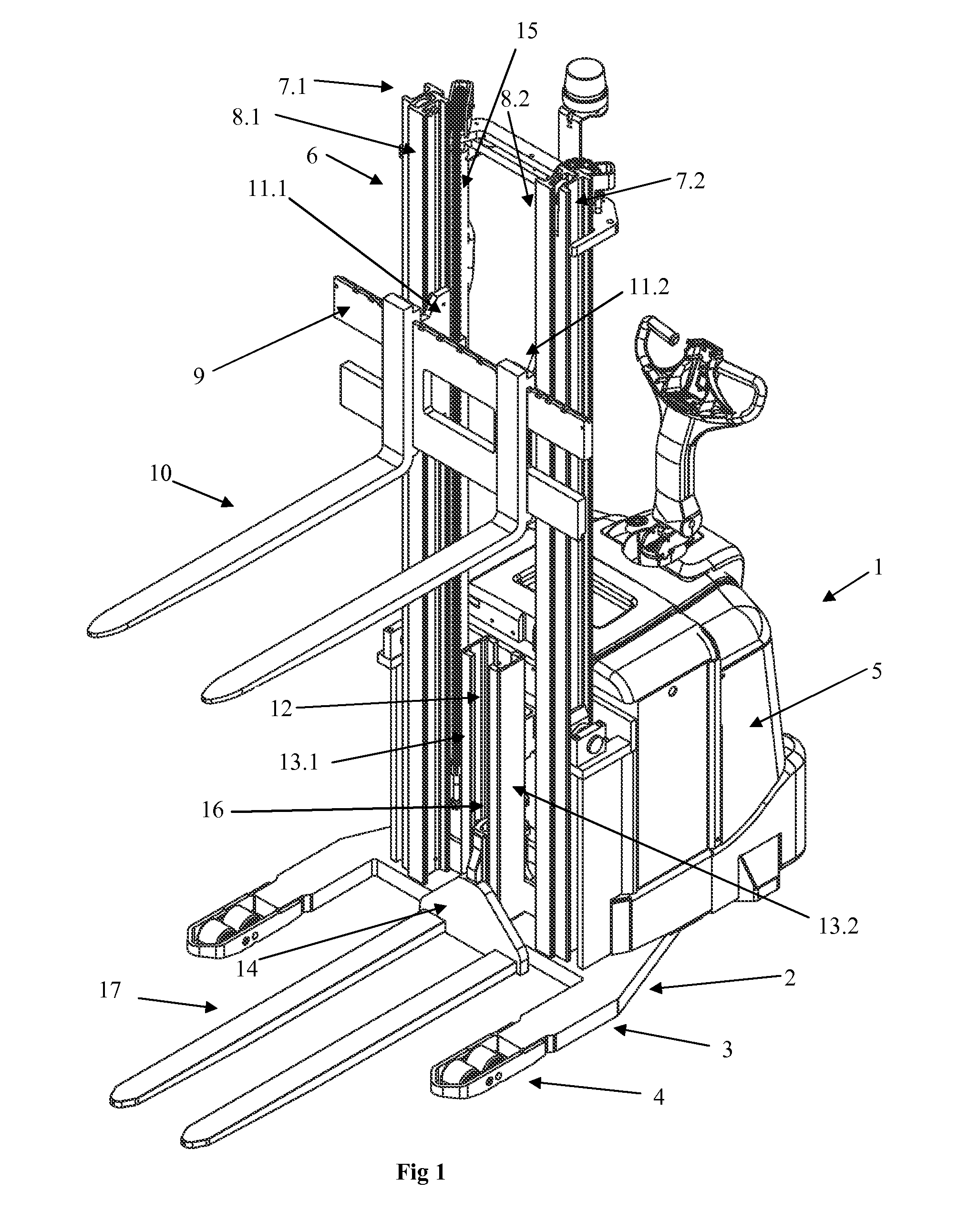

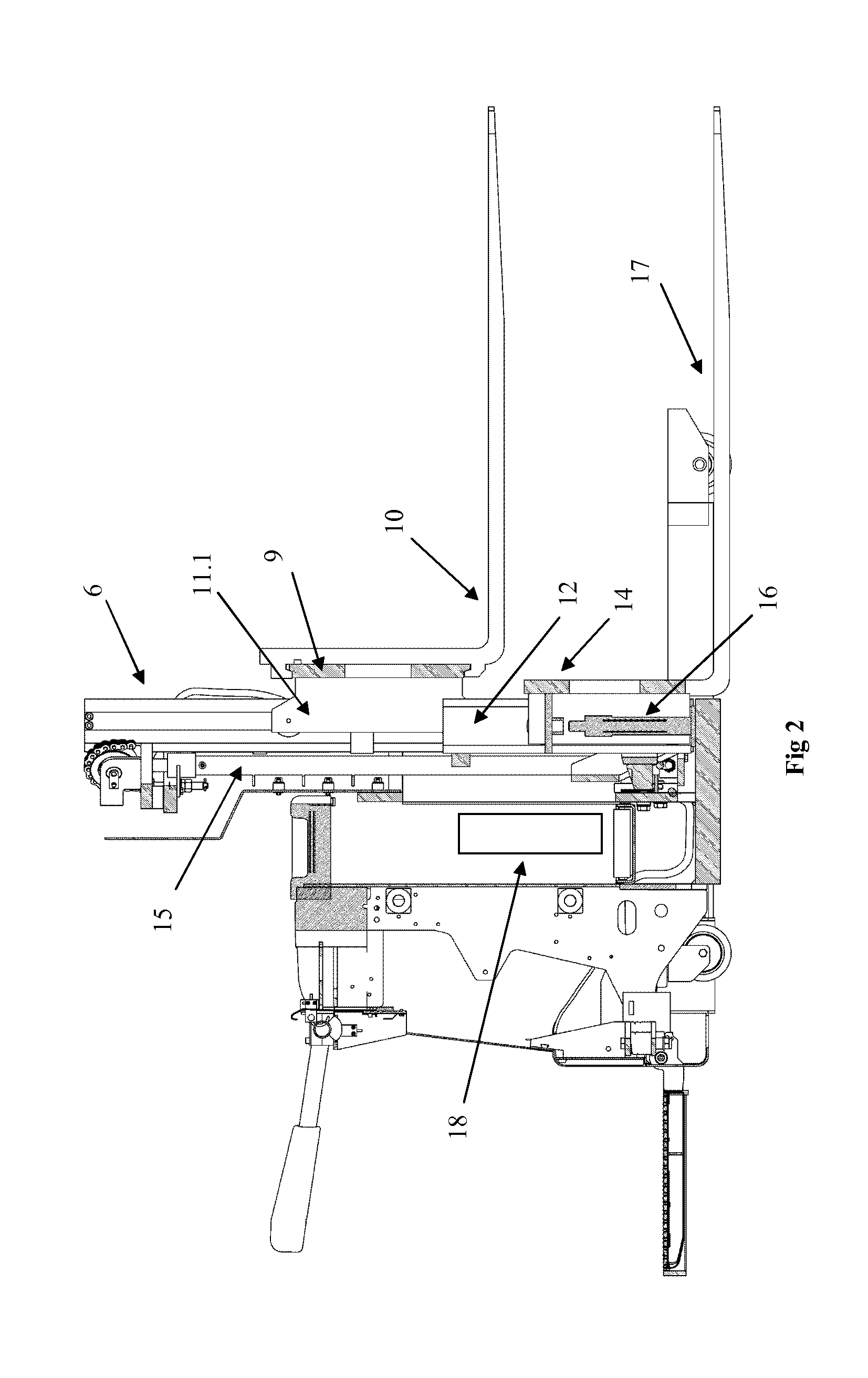

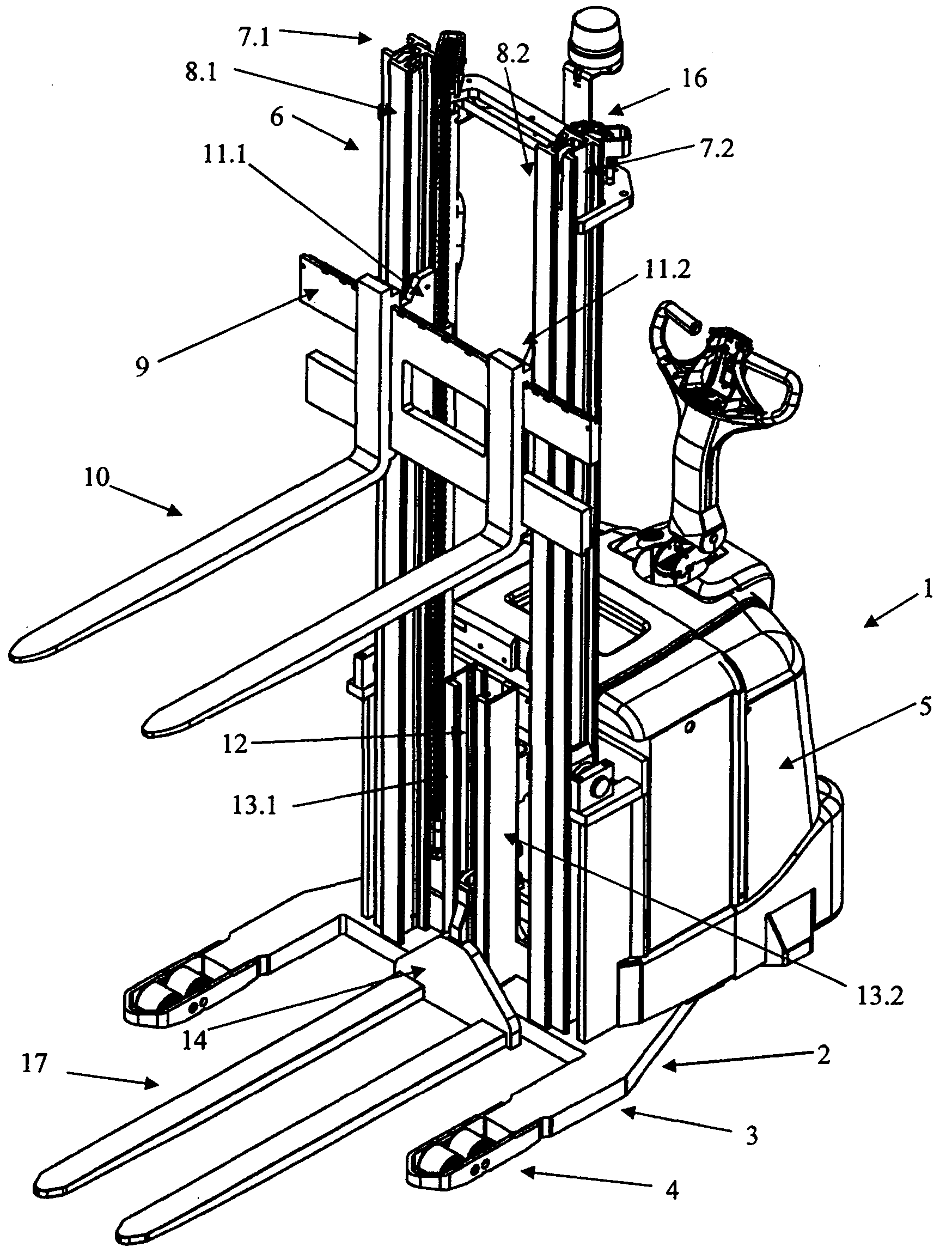

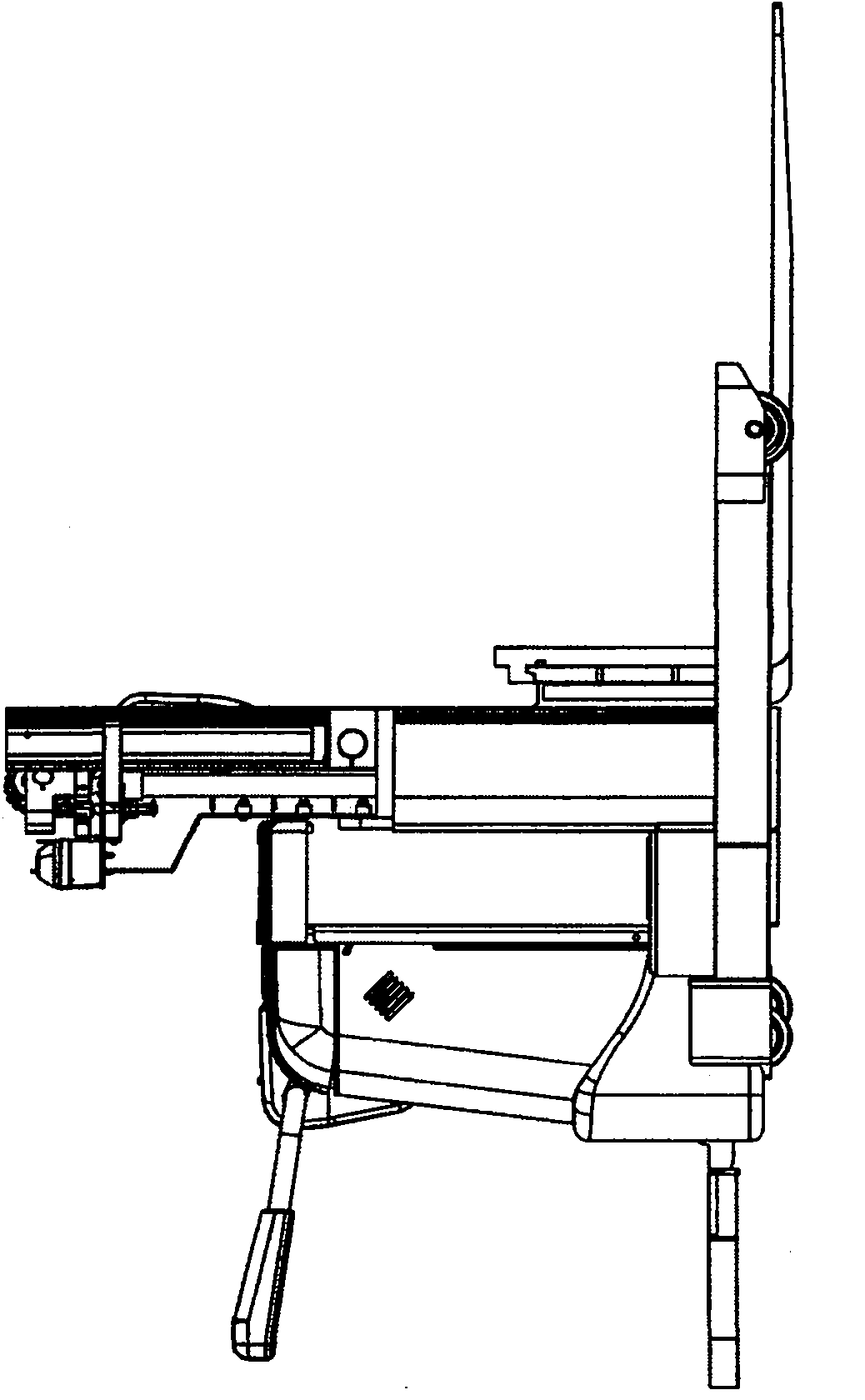

Industrial truck comprising two load carriages

InactiveCN102105385ADeformation MinimizationCan be arranged to lowerLifting devicesEngineeringLoad carriage

The invention relates to an industrial truck (1) comprising a first mast (6) comprising two uprights (7.1; 7.2) and a first and a second load carriage (9; 14) arranged to be independently moved in the vertical direction wherein a second mast (12) is arranged between the uprights (7.1; 7.2) of the first mast and that the first load carriage (9) is arranged to be moved along the first mast (6) and the second load carriage (14) is arranged to be moved along the second mast (12).

Owner:BT PROD

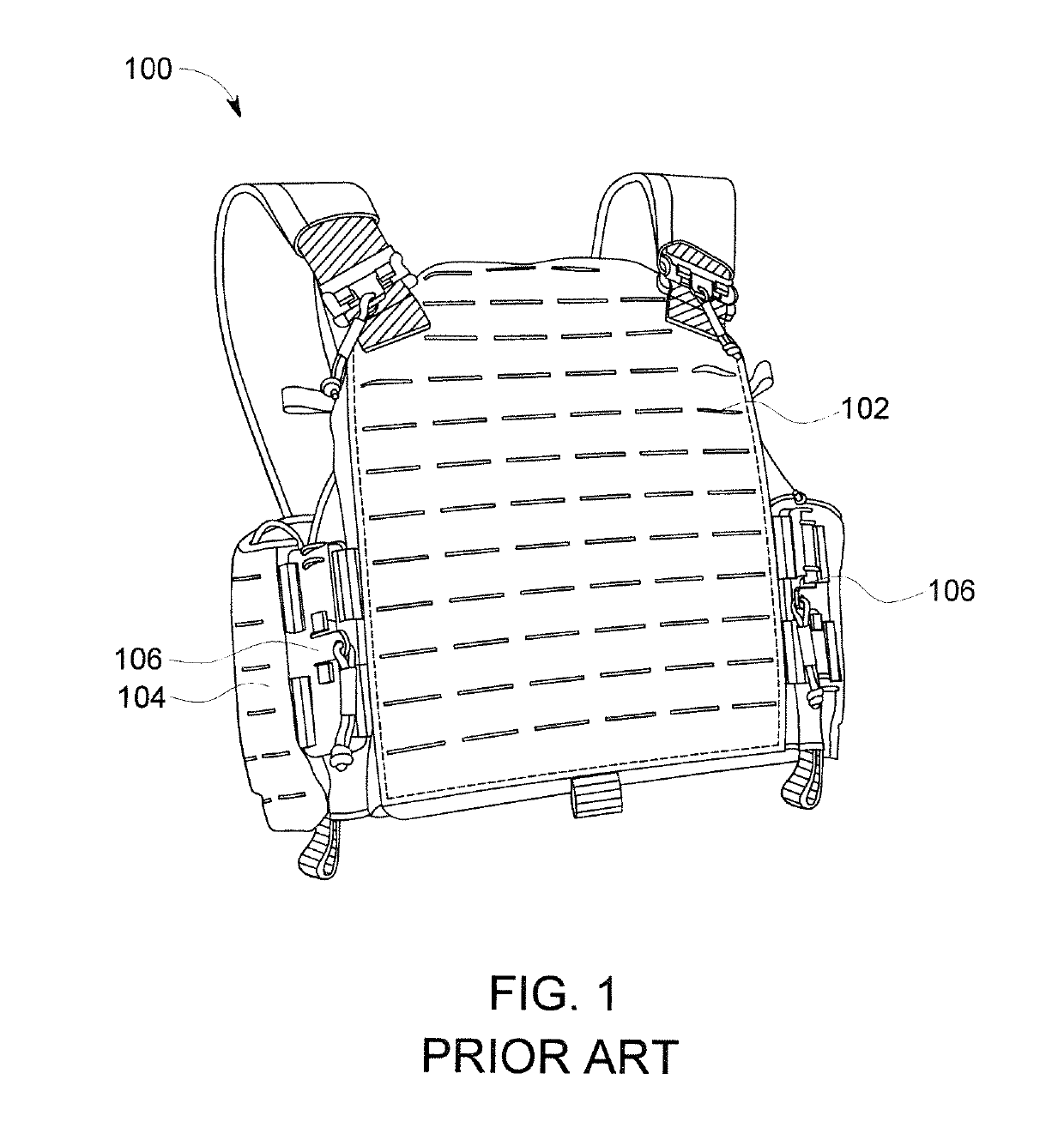

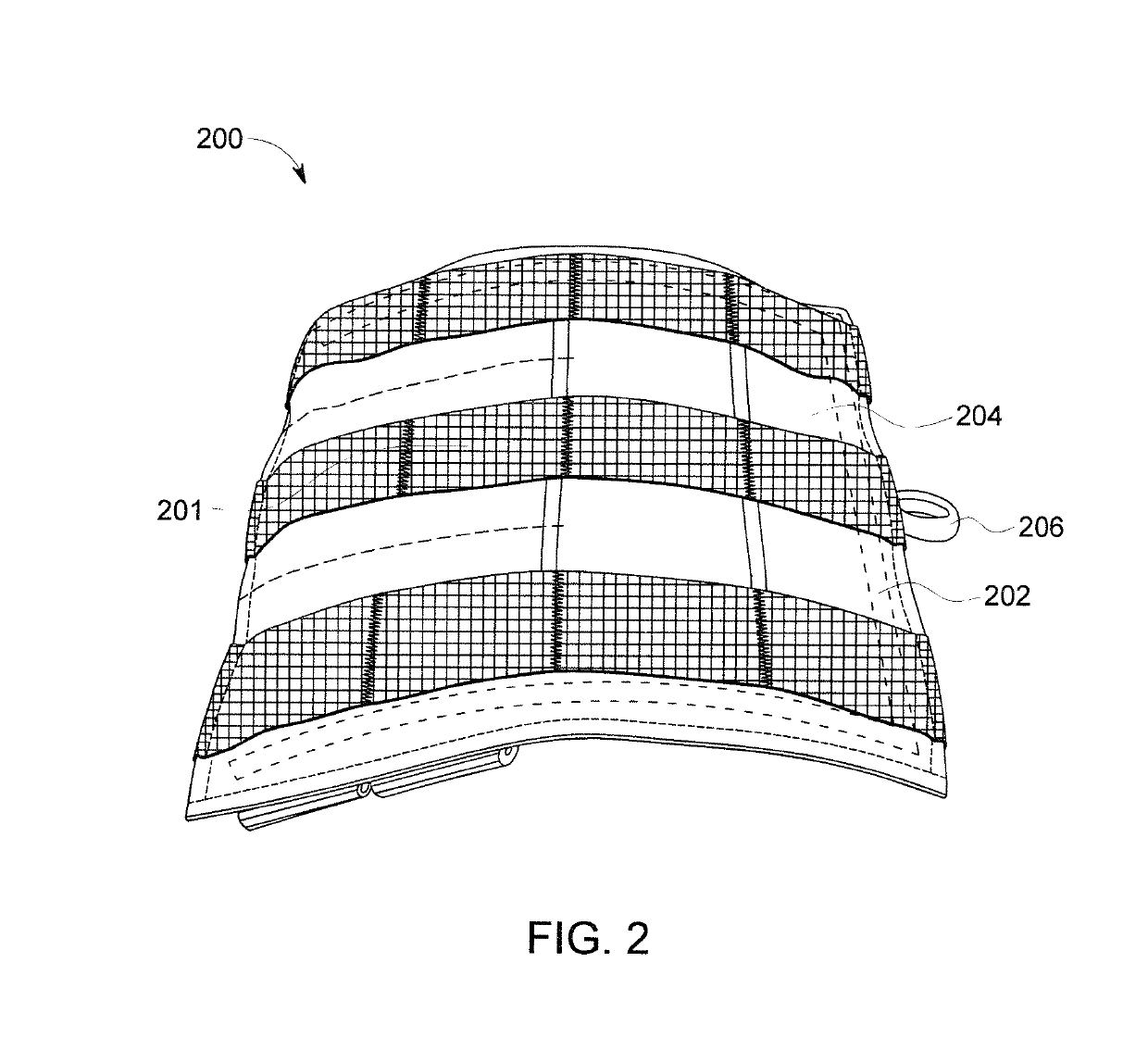

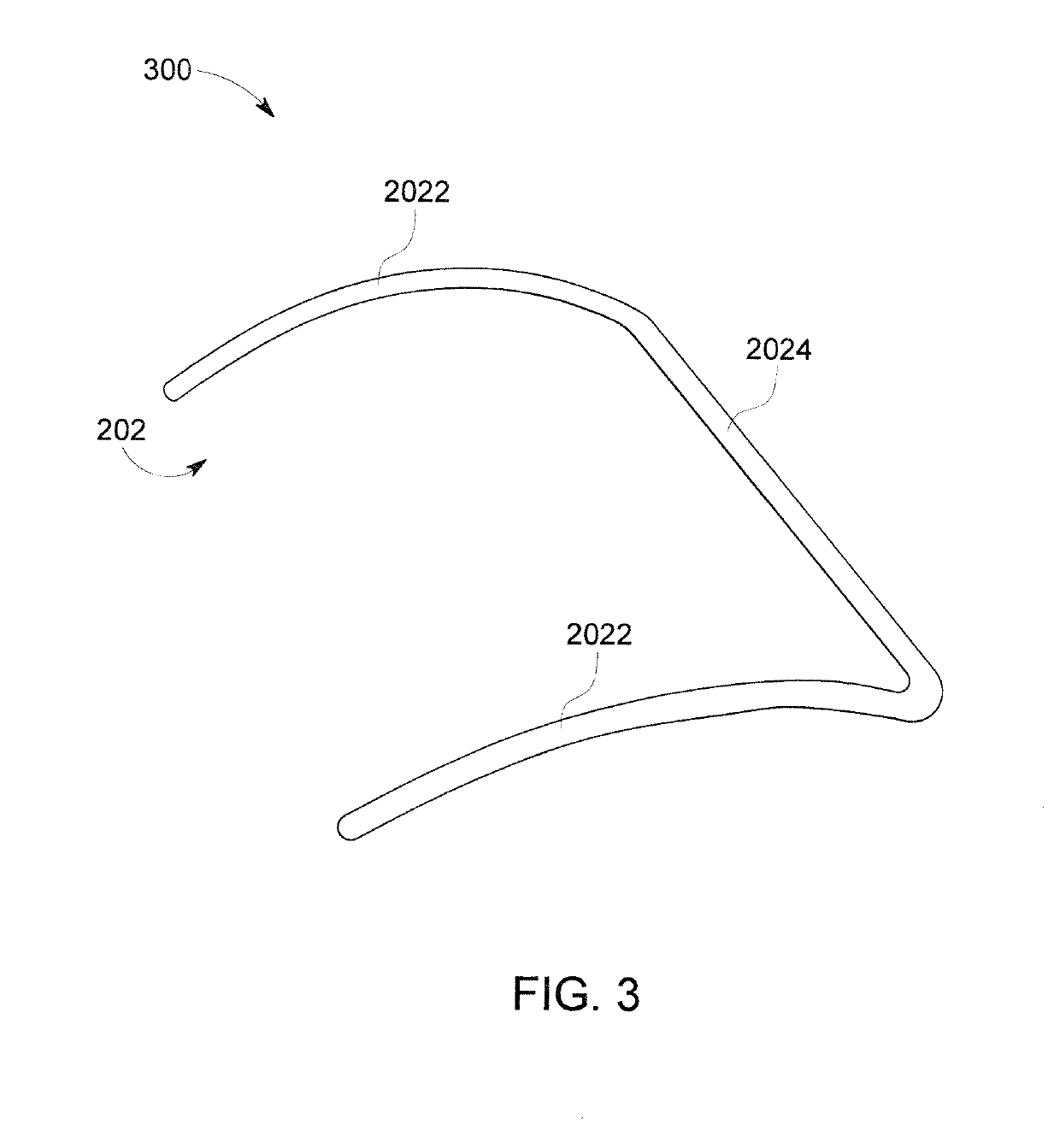

Panel and system for load carriage and protection for tactical and non-tactical garments

Owner:RAINE INC

Ground lead and vehicle for loading safety tools and devices

The invention relates to a ground lead and a vehicle for loading safety tools and devices of the electric and control field. The structure of the vehicle is that a ground lead winding apparatus and a tool accommodating box are arranged on the cart body; multiple sets of ground leads, safety rails, warning boards, insulating rods and safety tools and devices can be simultaneously loaded into the vehicle at a time, can be placed in a classified mode and are convenient to take out for use. The ground leads can be conveniently and fast wound in a manual or electric mode, ground plates can be disassembled and are attractive and tidy when placed down, and therefore working efficiency and standardization level are improved; because wheels are designed in a stair-climbing mode, the vehicle can easily climb stairs and cross roads; because a support is arranged at the bottom of the vehicle, the vehicle is prevented from toppling when being used; furthermore, through the vehicle, operation personnel apply more energy into carrying out electric switching operation, and therefore the probability of faulty operation is reduced.

Owner:STATE GRID CORP OF CHINA +1

Cargo handling system

A cargo handling system for handling cargo in an area of operation is disclosed. The system comprises at least one extendable conveyor having at least one fixed end and at least one movable end and at least one multi-axis means coupled with the extendable conveyor to enable the conveyor to span the entire area of operation. The multi-axis means comprises at least one linear movement means to control the linear movement of the conveyor and at least one pivotable two-axis means to control lateral and vertical movement of the conveyor. Further, the system comprises at least one two-axis loader cart coupled with the extendable conveyor and co-operating with the multi-axis means to minimize cantilever of the extendable conveyor and position the moving end of the conveyor to a desired location and controlling means adapted to control the multi-axis means for automated operation of the extendable conveyor.

Owner:PRECISION AUTOMATION & ROBOTICS INDIA

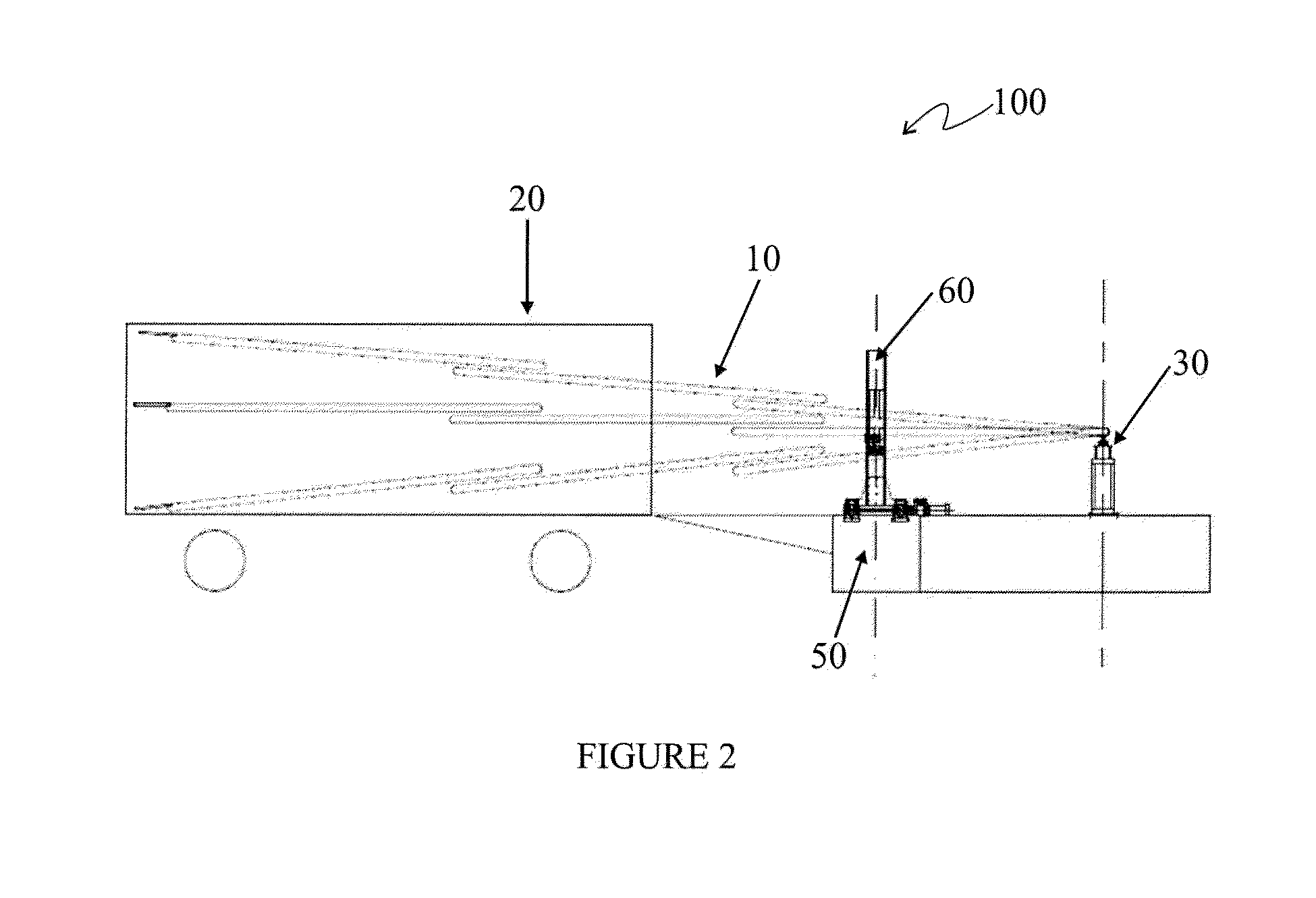

Methods and apparatus for freight container loading

Disclosed are apparatuses and methods for use thereof for loading bulk material into freight containers. One apparatus comprises a hopper configured to receive bulk material that is sized and shaped to be at least partially enclosable by a container to occupy a substantial volume of the container and a ram. The ram comprises a plate and a driver configured to move the plate from a back end of the hopper to an open end of the hopper to expel material into a container. Another apparatus comprises a hopper configured to receive bulk material that is sized and shaped to be at least partially enclosable by a container to occupy a substantial volume of the container and a reciprocating conveyor floor system. Optionally, a chute can be employed in combination with a loader vehicle to quickly and efficiently load bulk material into a container.

Owner:RECYCLING

Self-adaptive control method and warehousing control system applied to intelligent warehousing

ActiveCN112193706AMake parking easierImprove experienceStorage devicesLoading/unloadingControl systemControl engineering

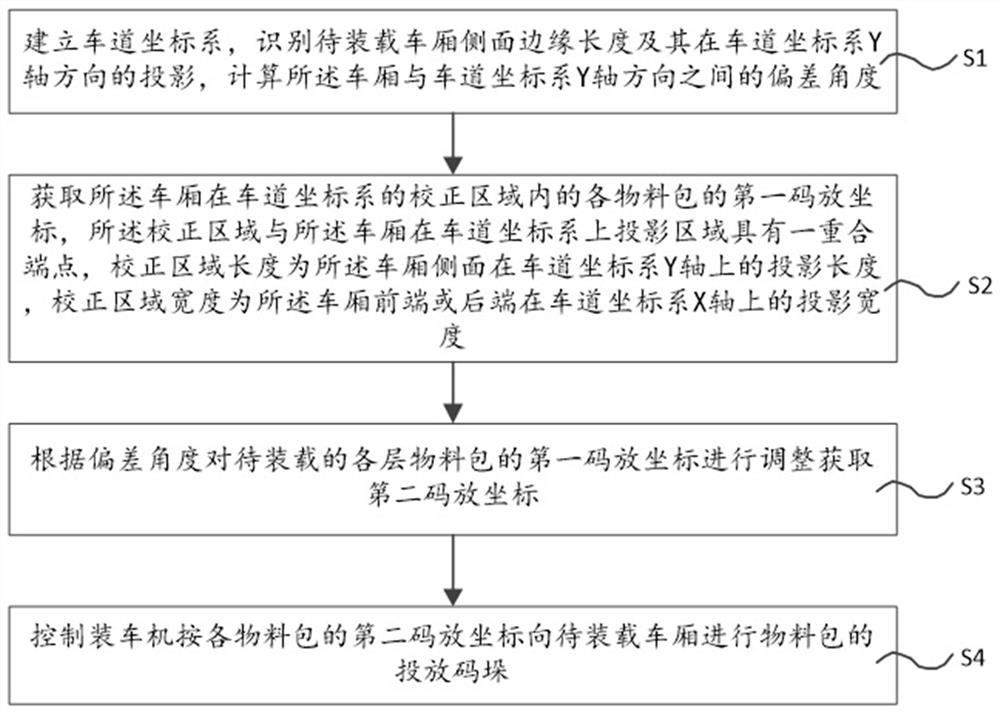

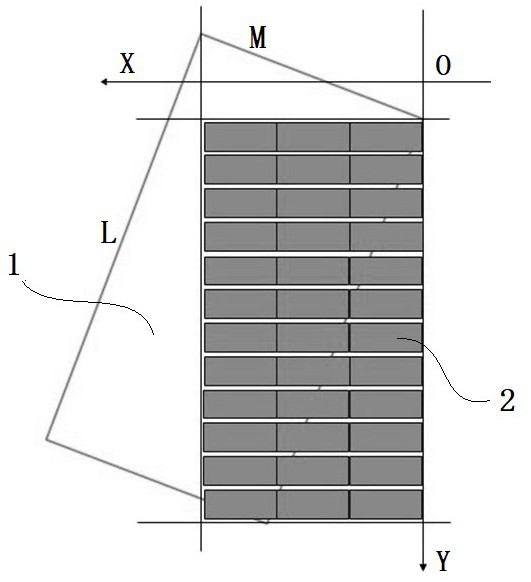

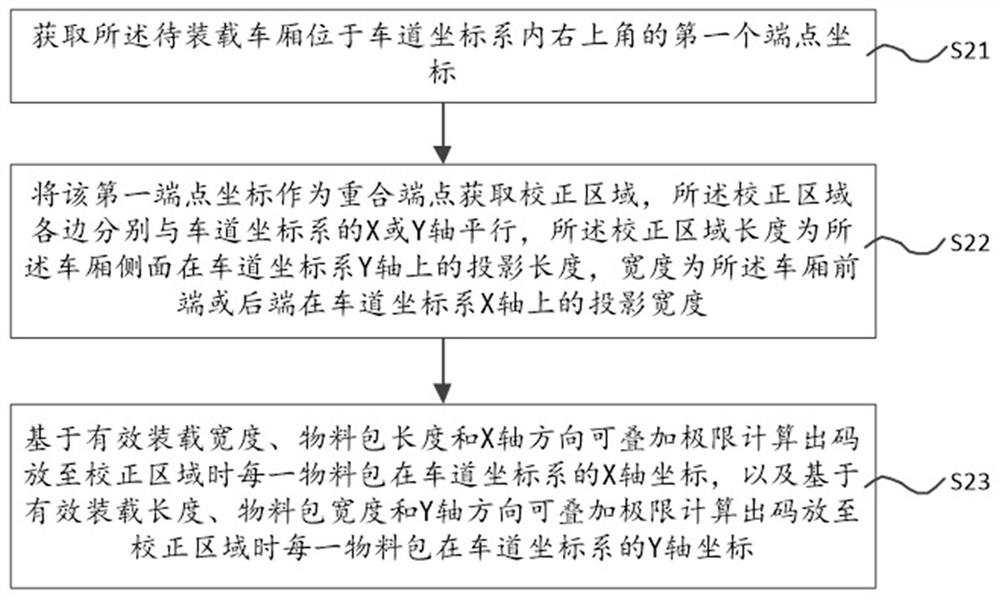

The invention discloses a self-adaptive control method and a warehousing control system applied to intelligent warehousing which are used for controlling a car loader to stack and load material packages. The self-adaptive control method comprise the following steps that a lane coordinate system is established, and the side edge length of a carriage to be loaded and the projection of the carriage to be loaded in the Y-axis direction of the lane coordinate system are identified; a deviation angle between the carriage and the Y-axis direction of the lane coordinate system is calculated; first stacking coordinates of all the material packages of the carriage in a correction area of the lane coordinate system are obtained; the first stacking coordinates of all layers of material packages to beloaded are adjusted according to the deviation angle to obtain second stacking coordinates; and the car loader is controlled to put and stack the material packages into the carriage to be loaded according to the second stacking coordinates of all the material packages. A driver can smoothly complete stacking and loading without adjusting the posture of the vehicle under the condition that the vehicle is parked off tracking, so that the parking difficulty of the driver is reduced, and the loading efficiency is improved.

Owner:MINGDU ZHIYUN (ZHEJIANG) TECH CO LTD

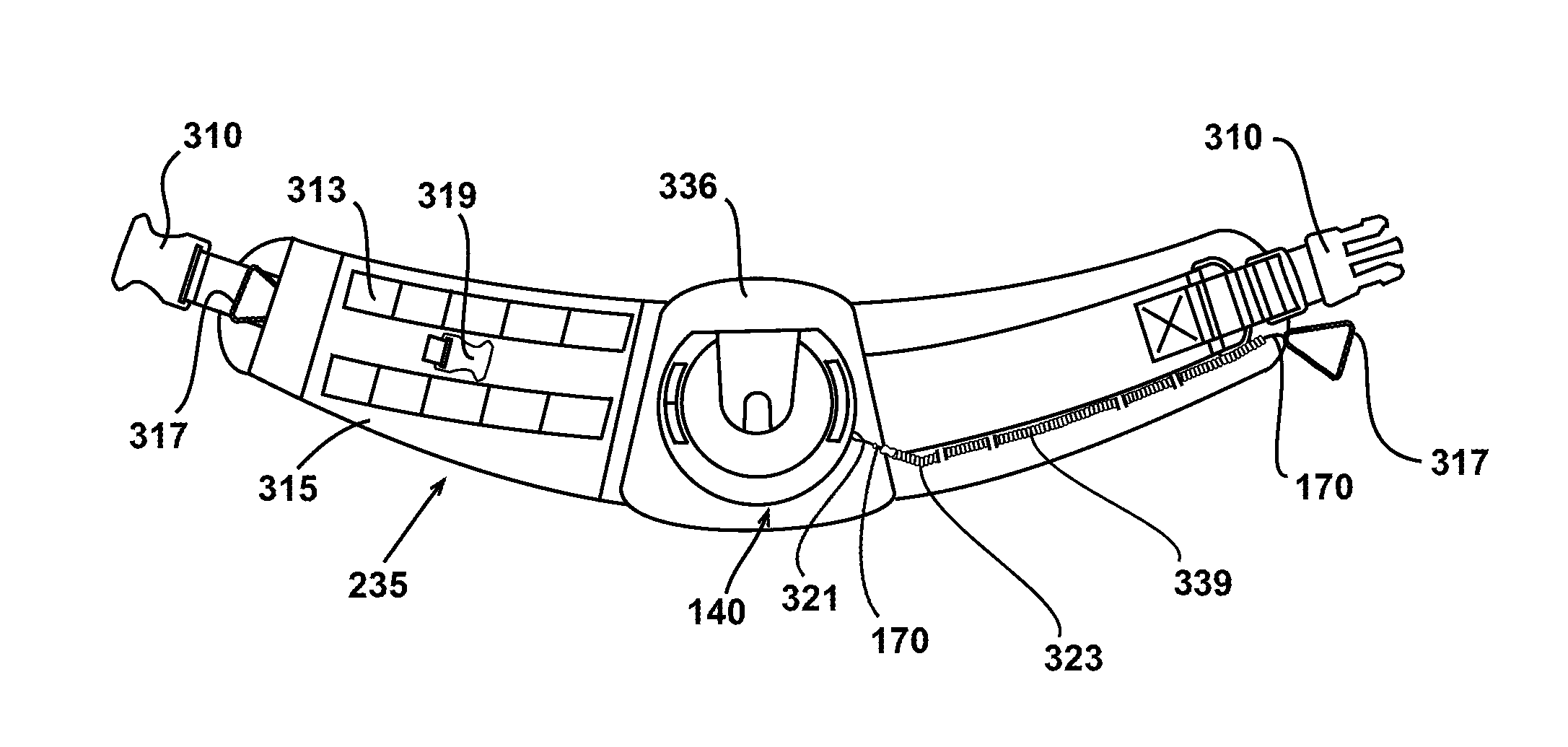

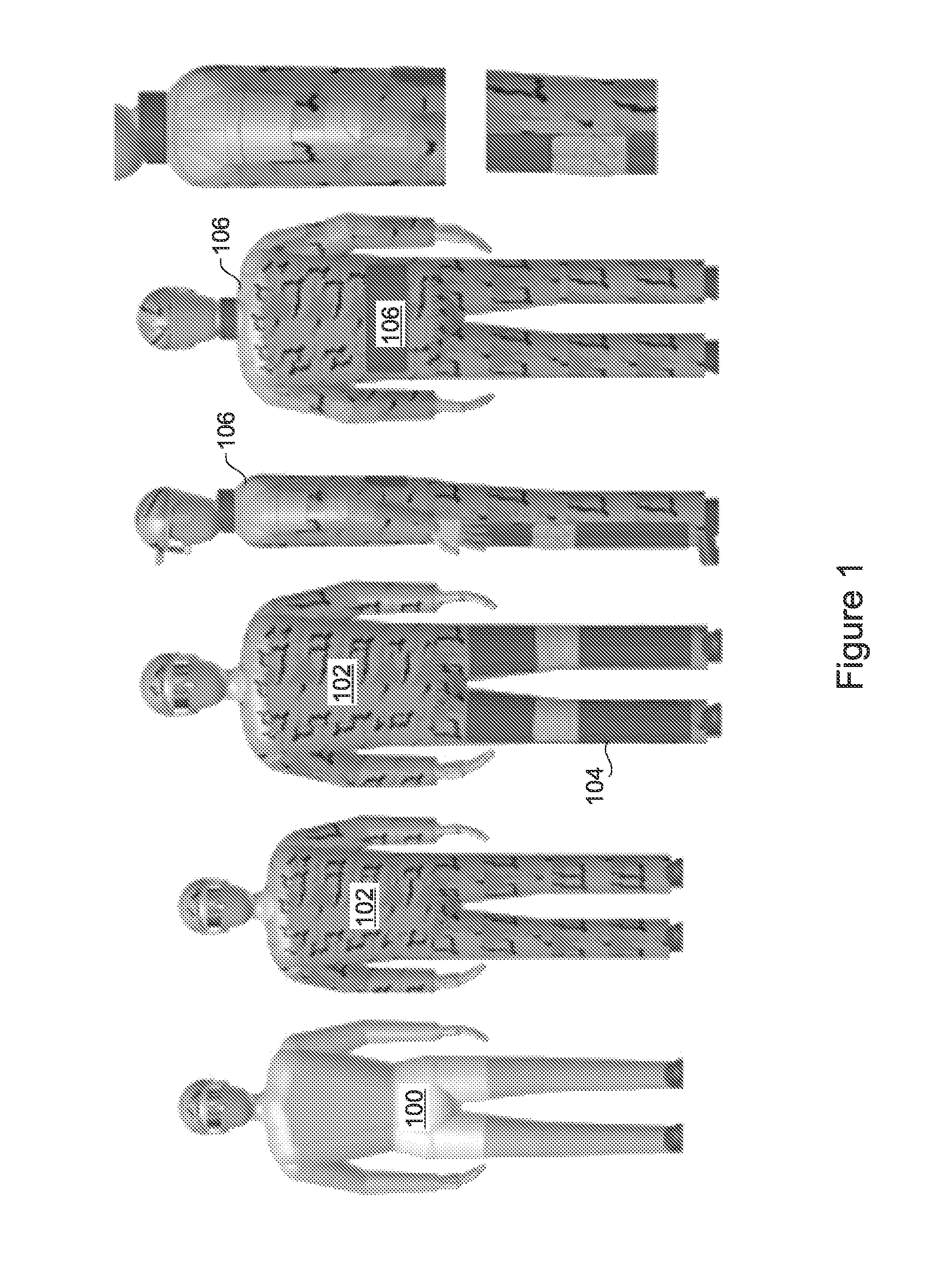

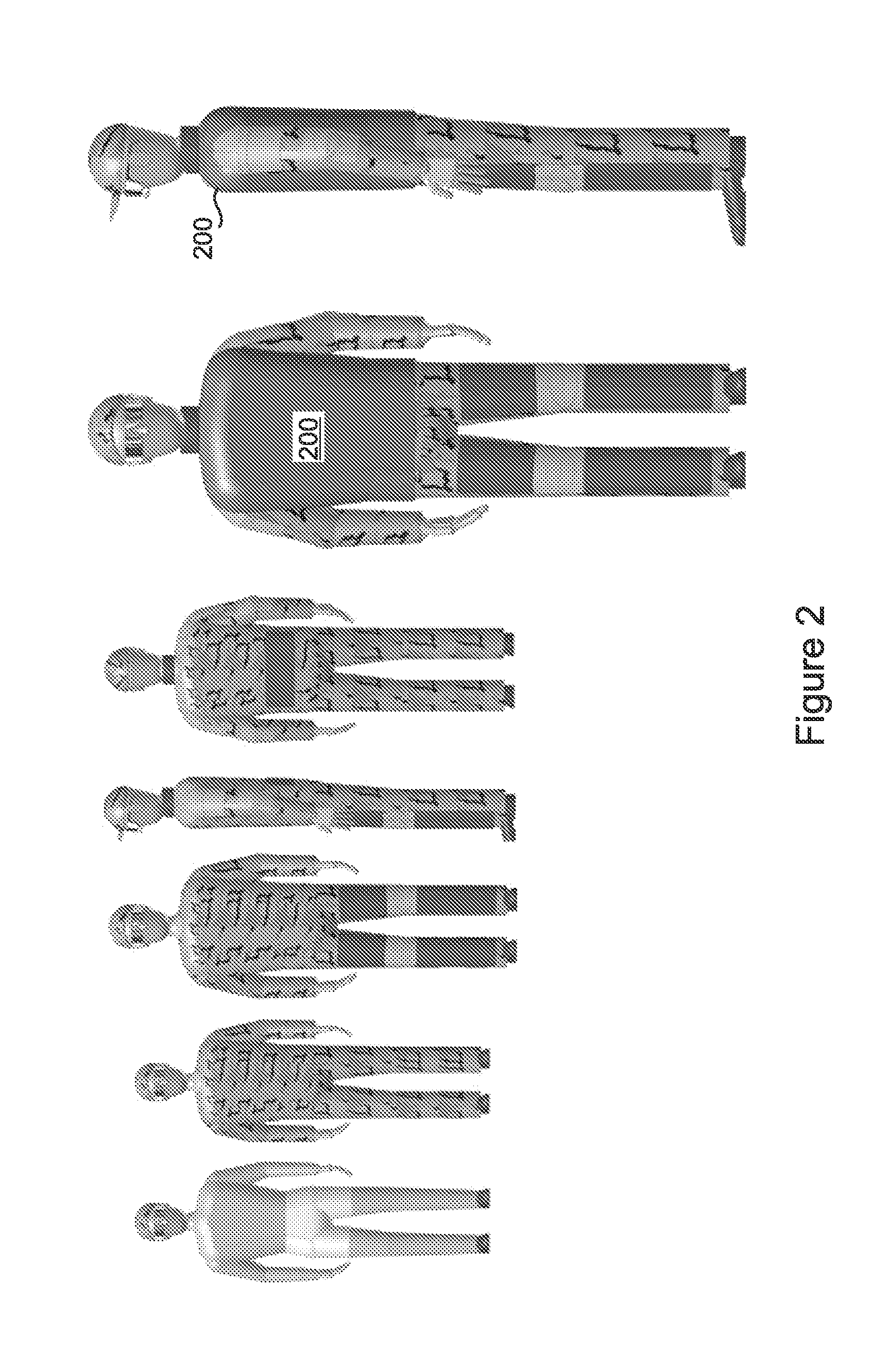

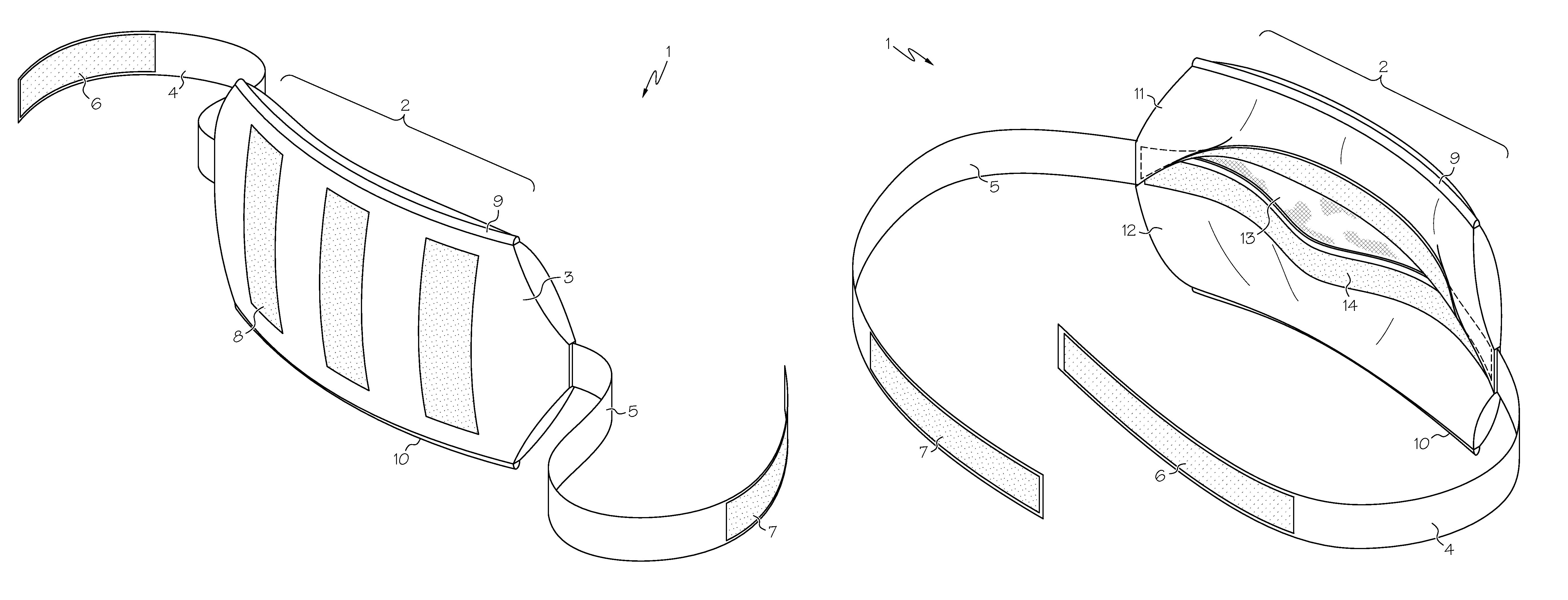

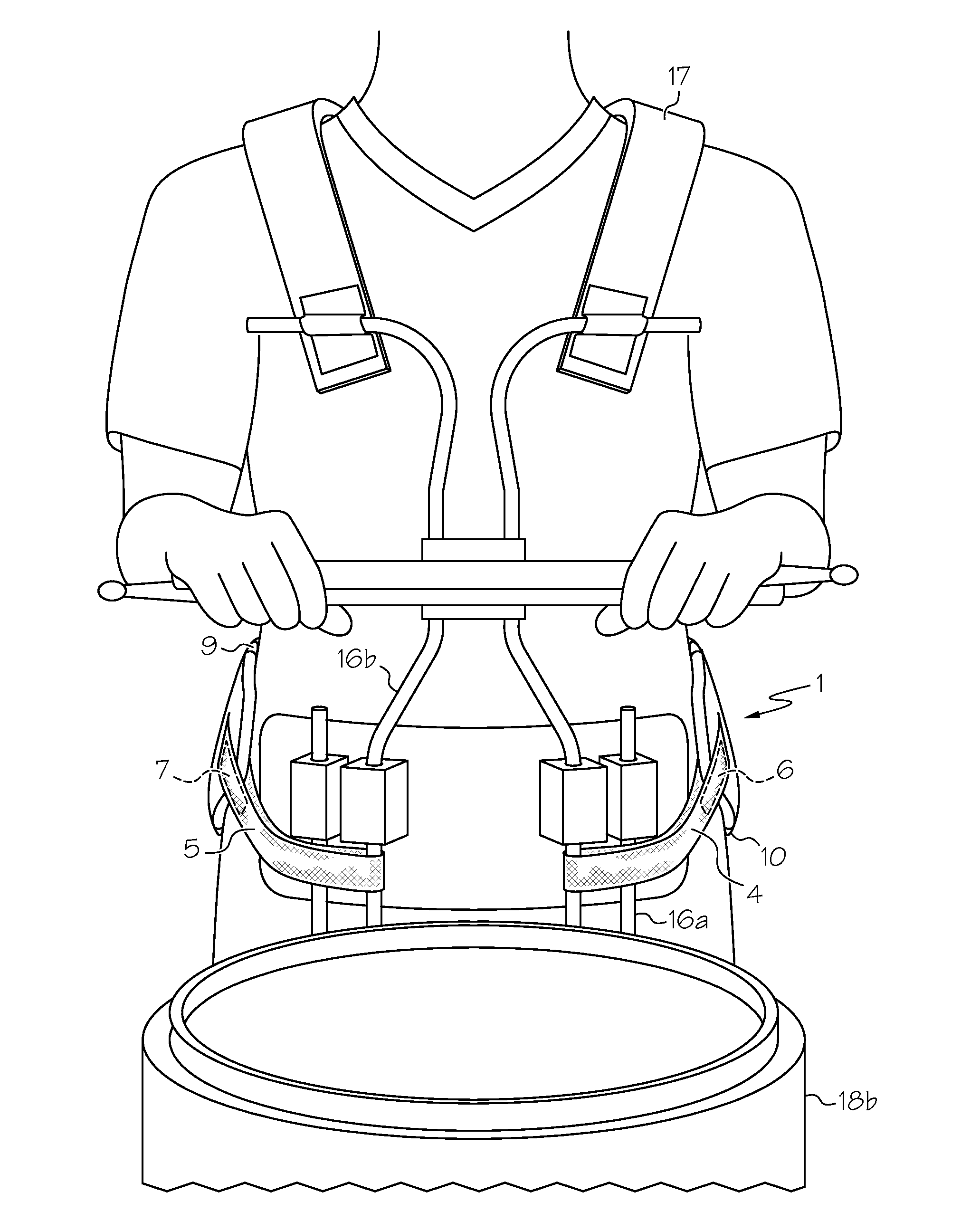

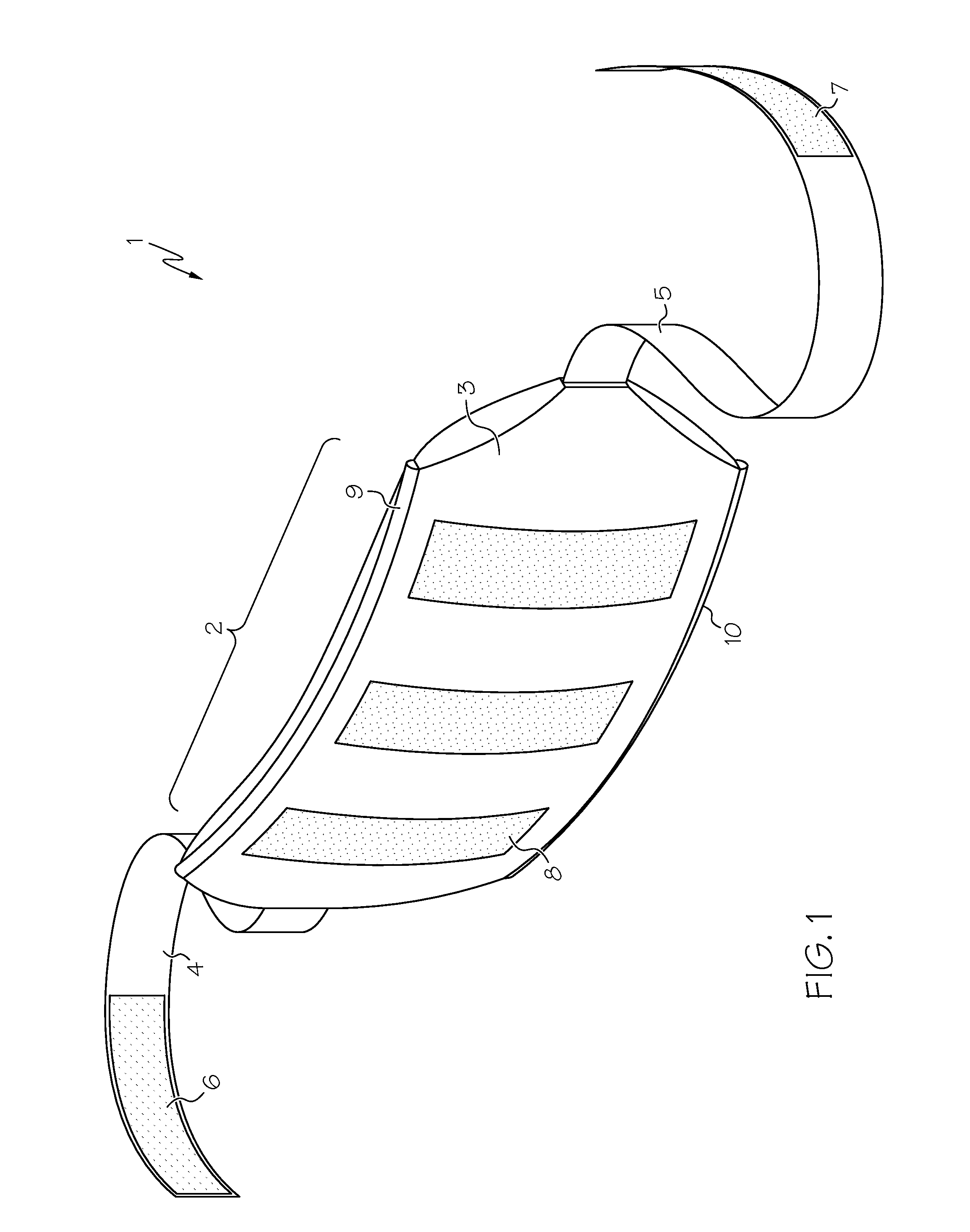

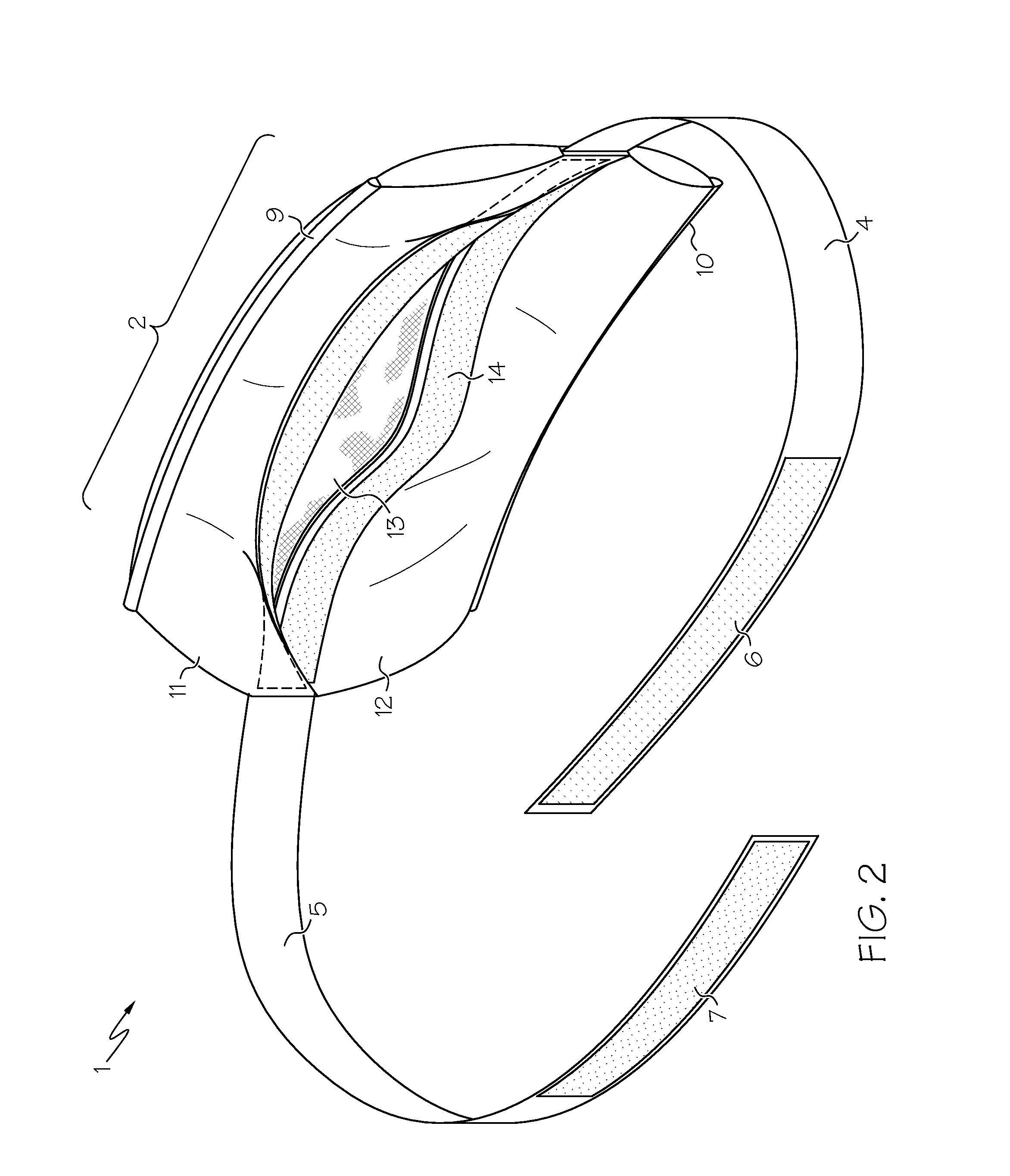

Anterior load carriage stability and mobility support system

ActiveUS9437175B2Provide comfortSturdy structureTravelling sacksPercussion musical instrumentsSupporting systemEngineering

The present invention relates generally to the field of an anterior load carriage stability and mobility support system, and more particularly to marching band equipment and marching drum stability and mobility support belt for a marching drummer in K-12 primary or secondary, a collegiate, a drum and bugle corps or the like. A device capable of providing a support mechanism for the lumbar region of a user's back that allows for load distribution from loads placed anteriorly and inferiorly to the drummer's body. A preferred embodiment of the device includes a large piece and two smaller pieces of neoprene fabric, dual straps sewn along the sides of the belt, removable commercial grade closed cell foam sheets, and two plastic tubing for a sturdy structure with flexibility and versatility, and Velcro® sewn along the straps and on the obverse side of the belt for easy and secure attachment of the straps.

Owner:AUBURN UNIV

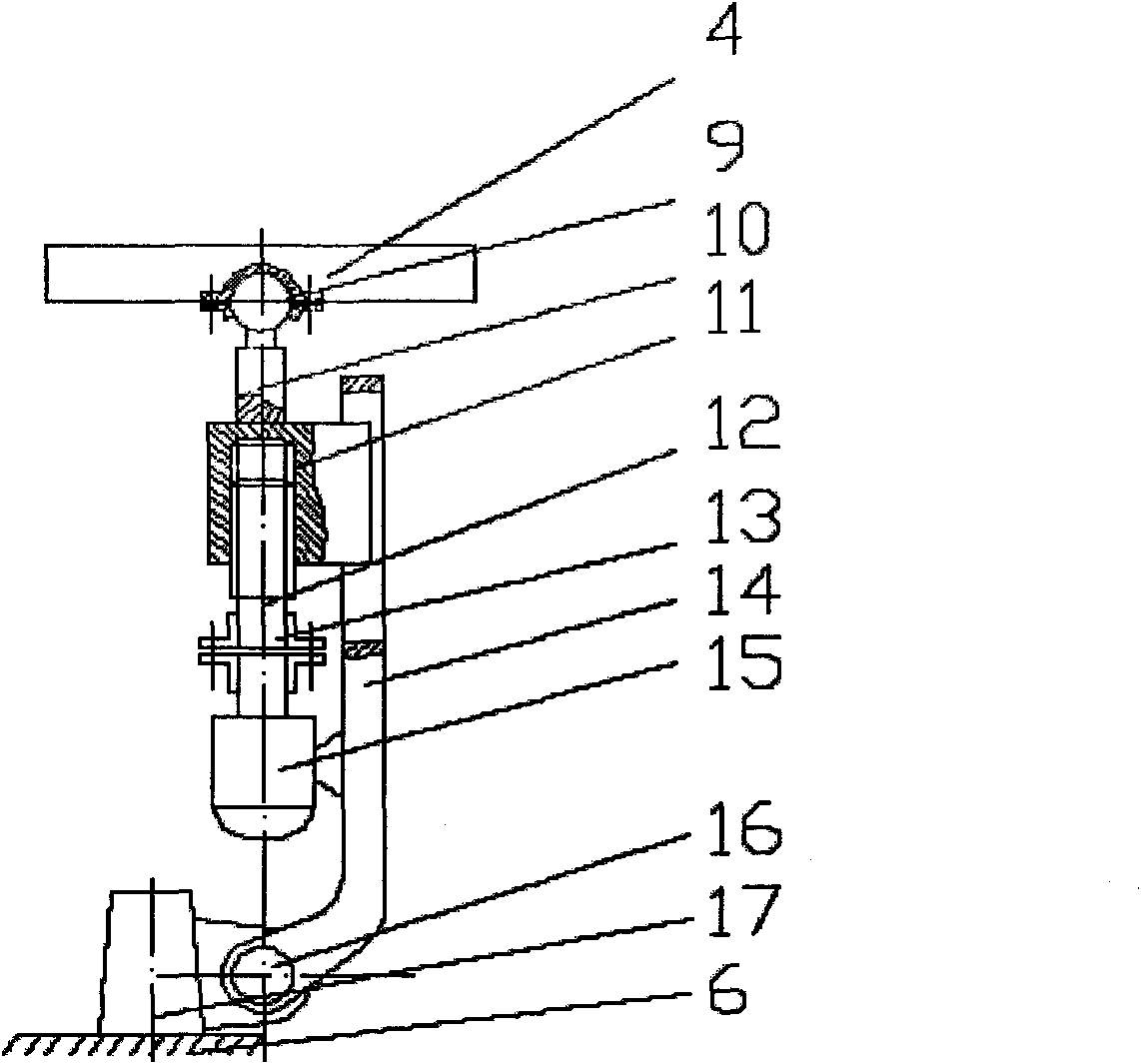

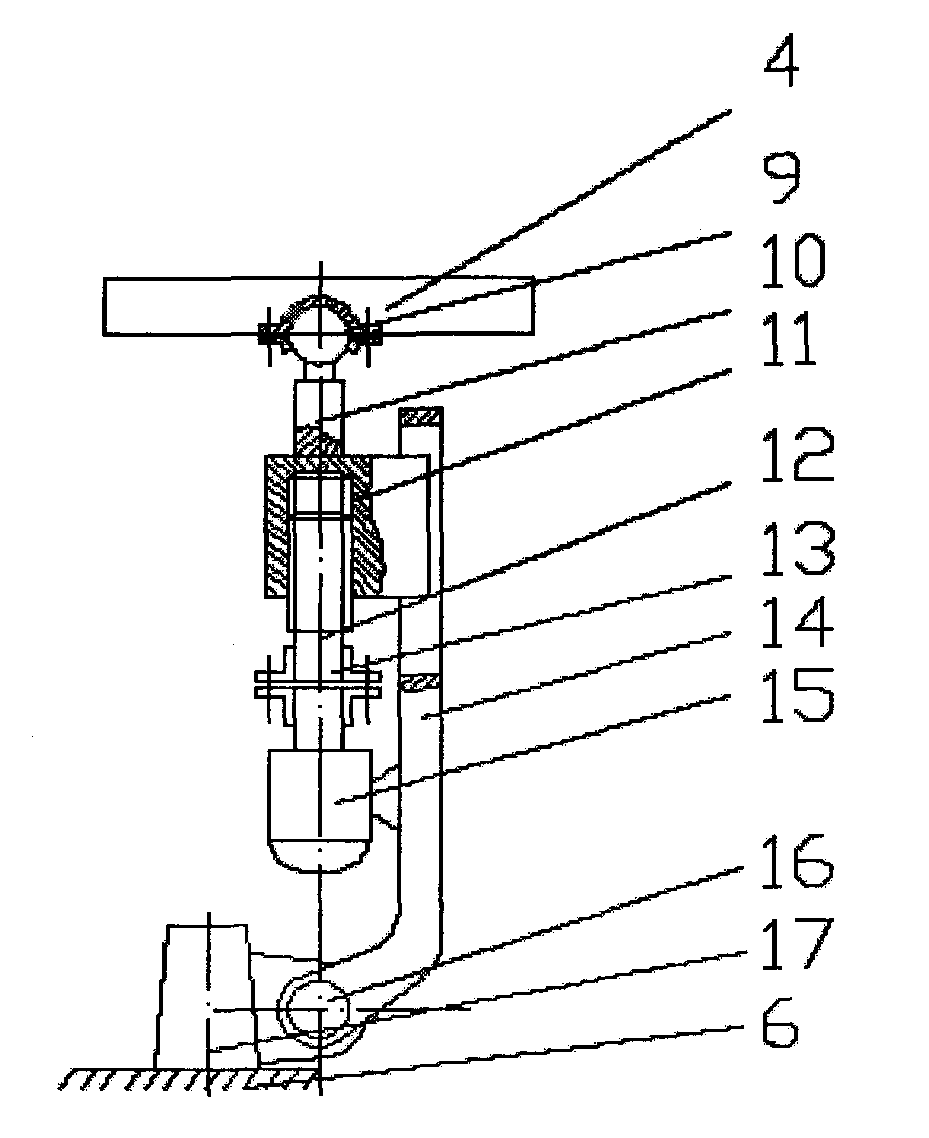

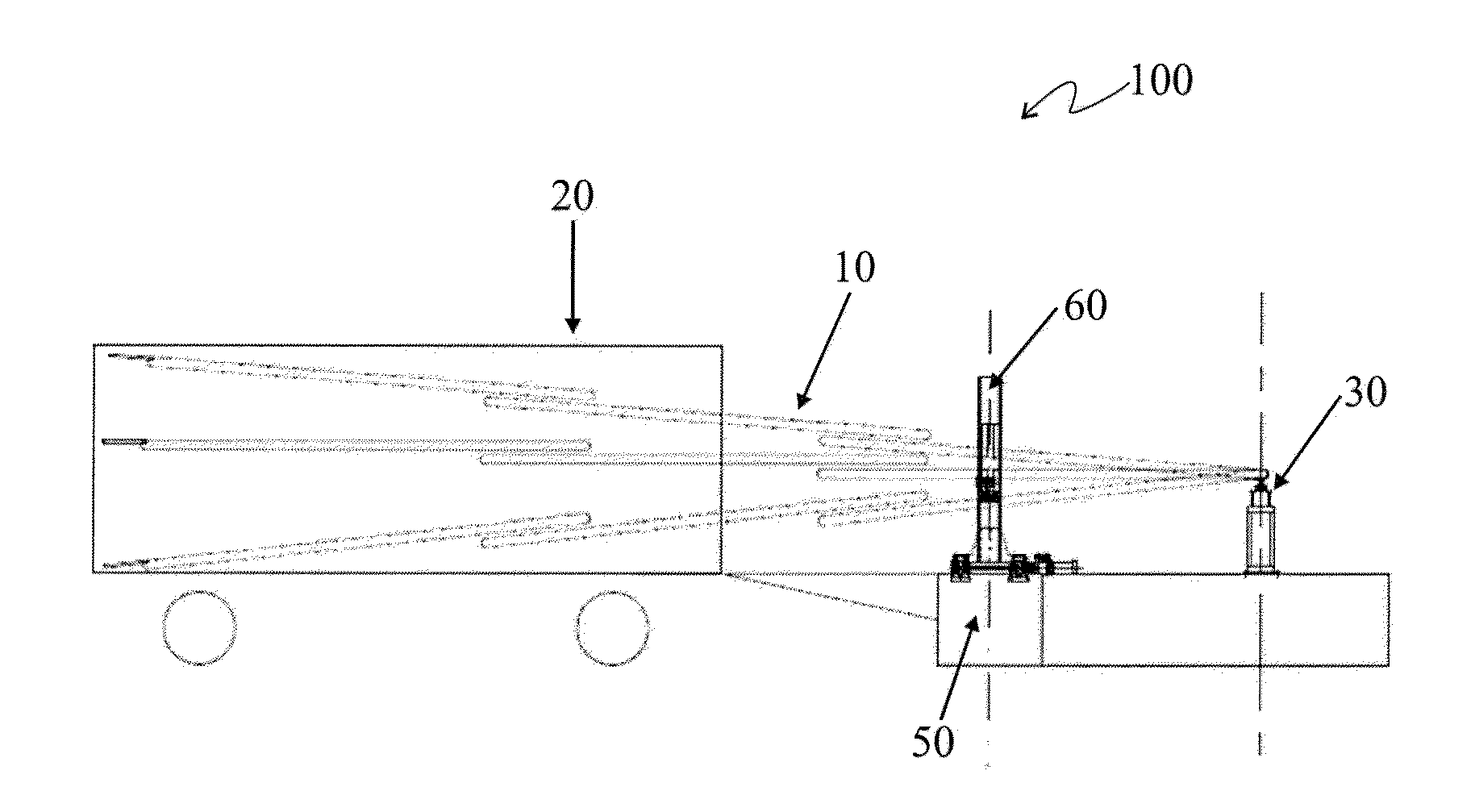

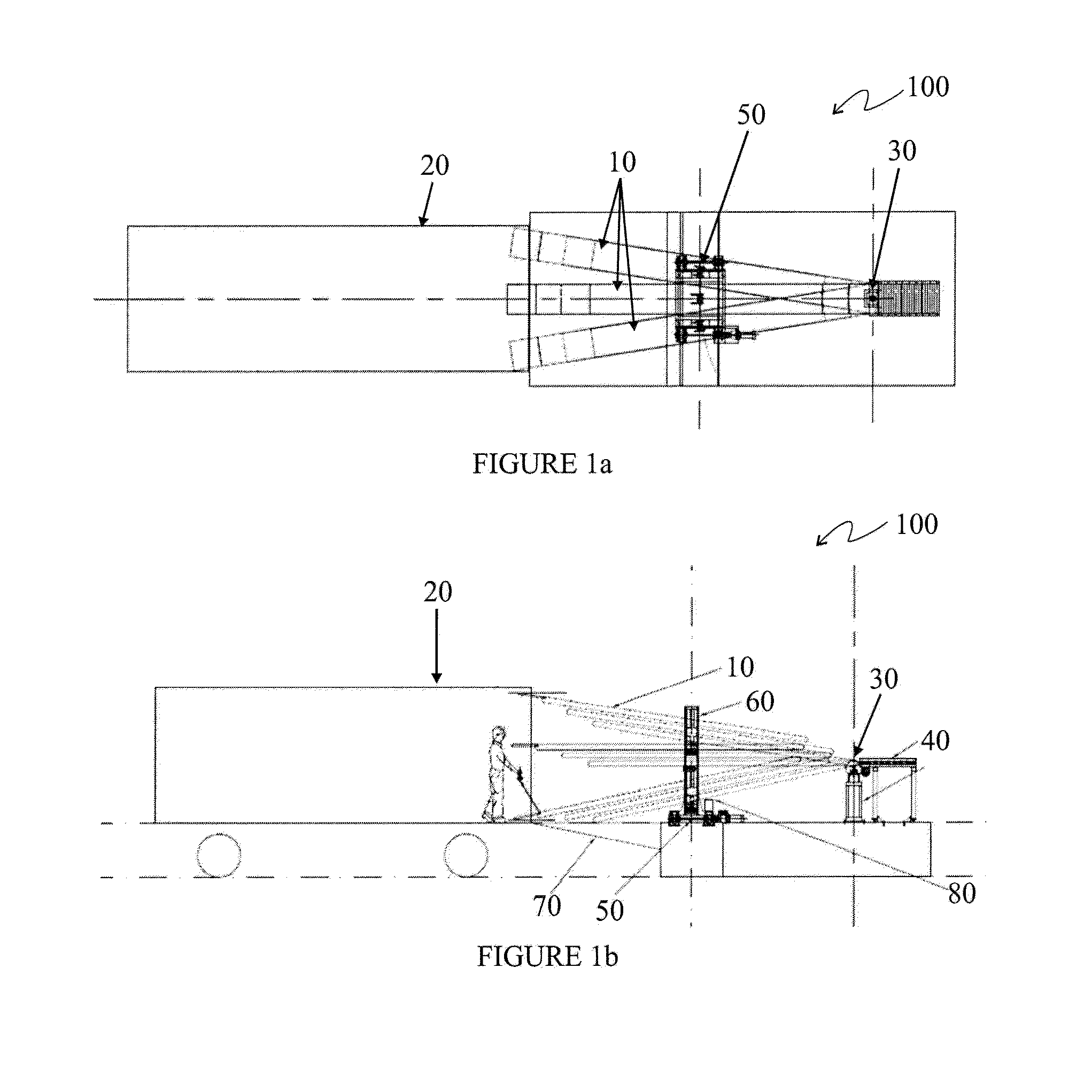

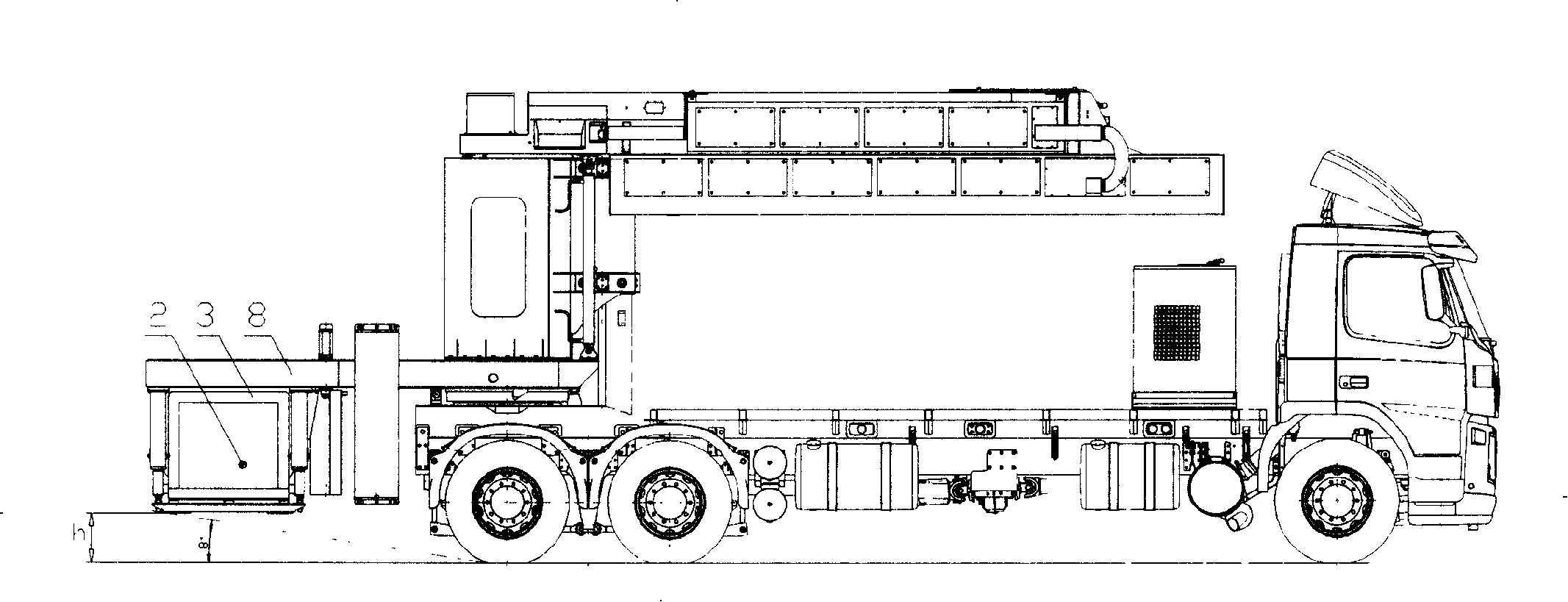

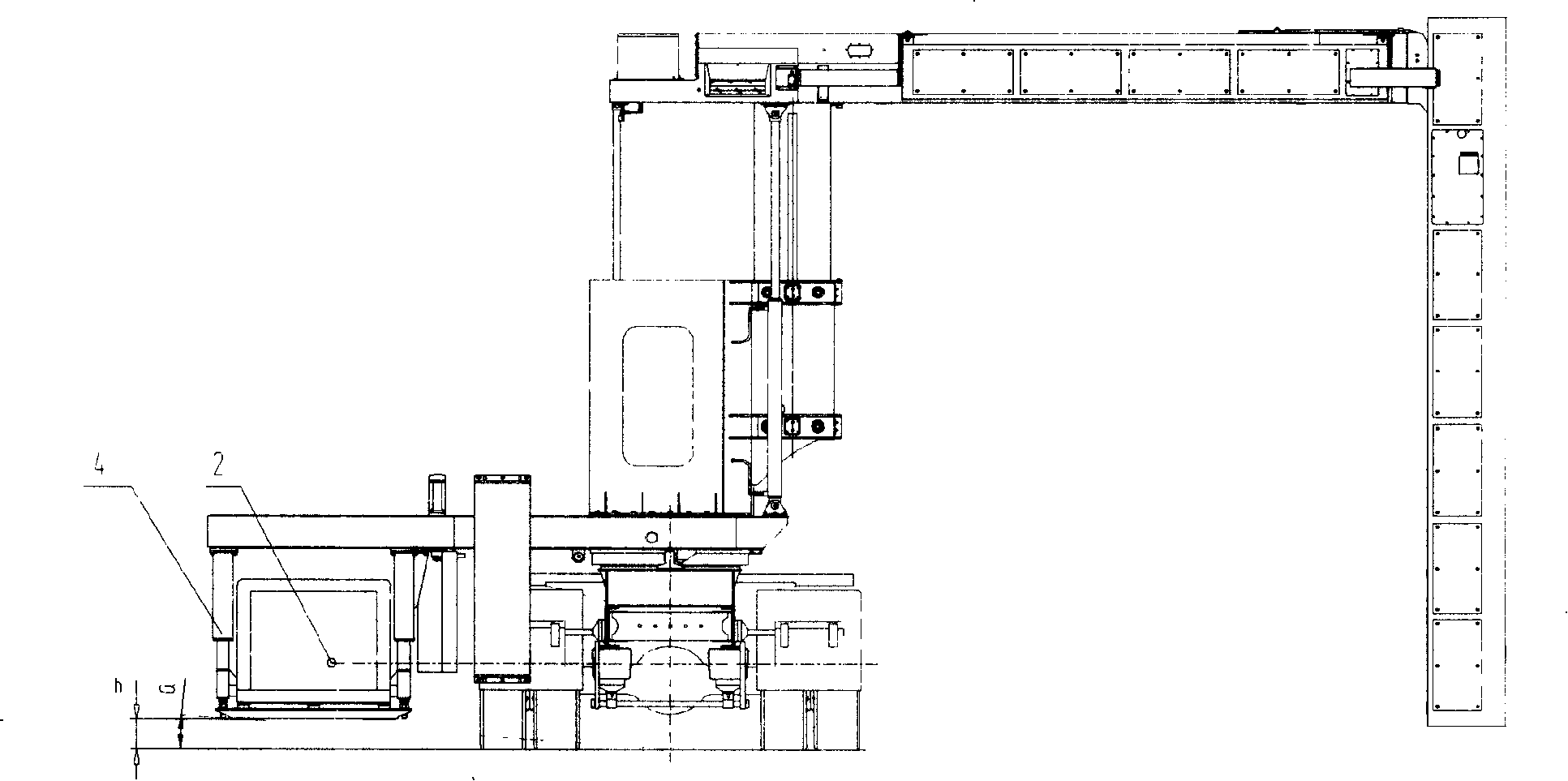

Vehicle mounted type radiation checking system

InactiveCN101210893AHigh target positionIncrease ground clearanceMaterial analysis by transmitting radiationNuclear radiation detectionBlind zoneLoad carriage

The invention relates to a safety monitoring system, more particularly to a vehicle radiation monitoring system with simple structure, convenient operation and small scanning blind zone. The vehicle radiation monitoring system comprises a loading vehicle and an accelerator installed on the loading vehicle, wherein a lifting bracket and a drive device for the lifting bracket are installed on the loading vehicle, and the accelerator is installed on the lifting bracket. The inventive vehicle radiation monitoring system can switch target spots in the loading vehicle between a higher position and a lower position as required through the lifting of the accelerator, so that the invention not only meets the requirements of safety traffic and road regulations, but also can remarkably reduce scanning blind zone. The invention also has the advantages of convenient operation and safe and reliable service.

Owner:NUCTECH CO LTD +1

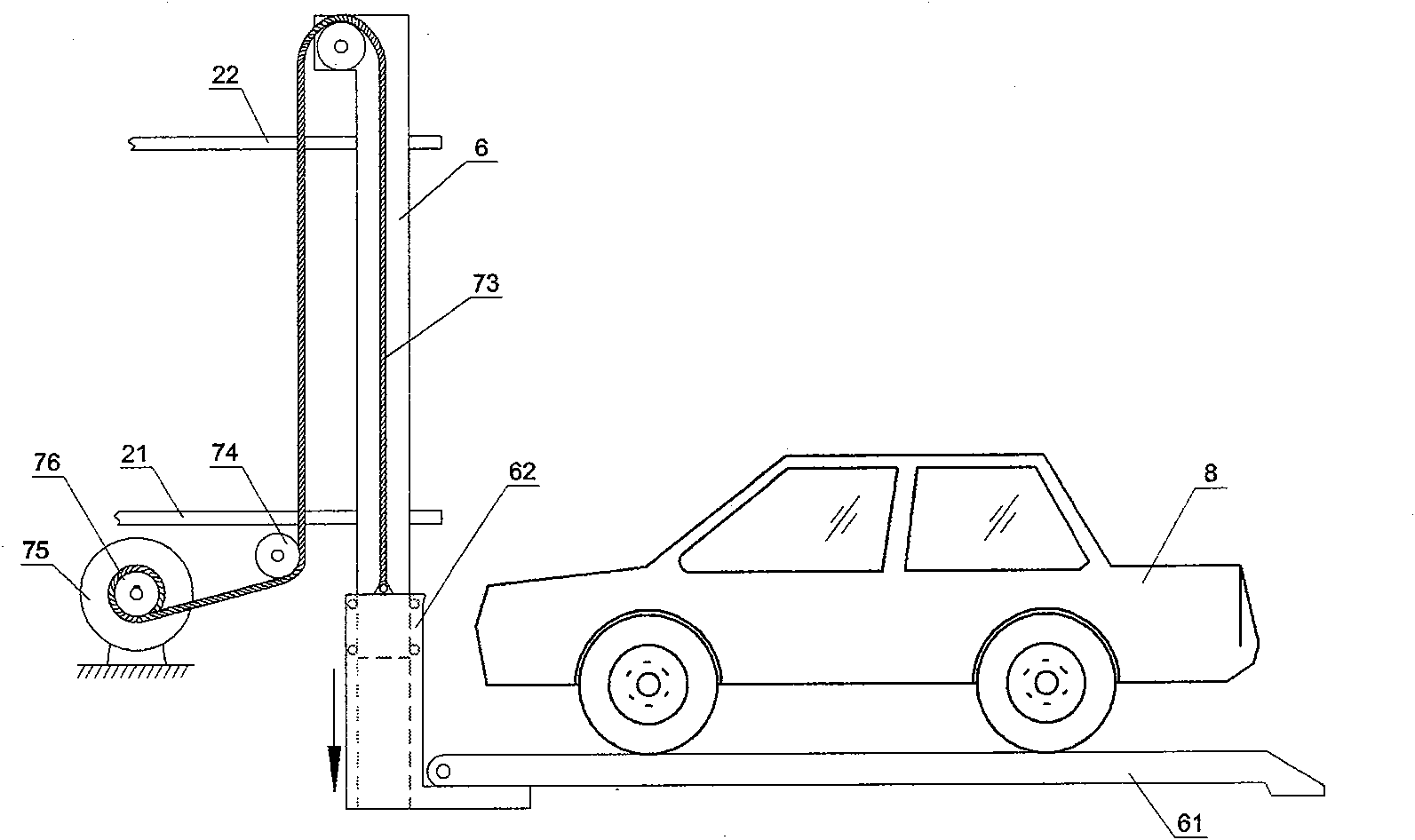

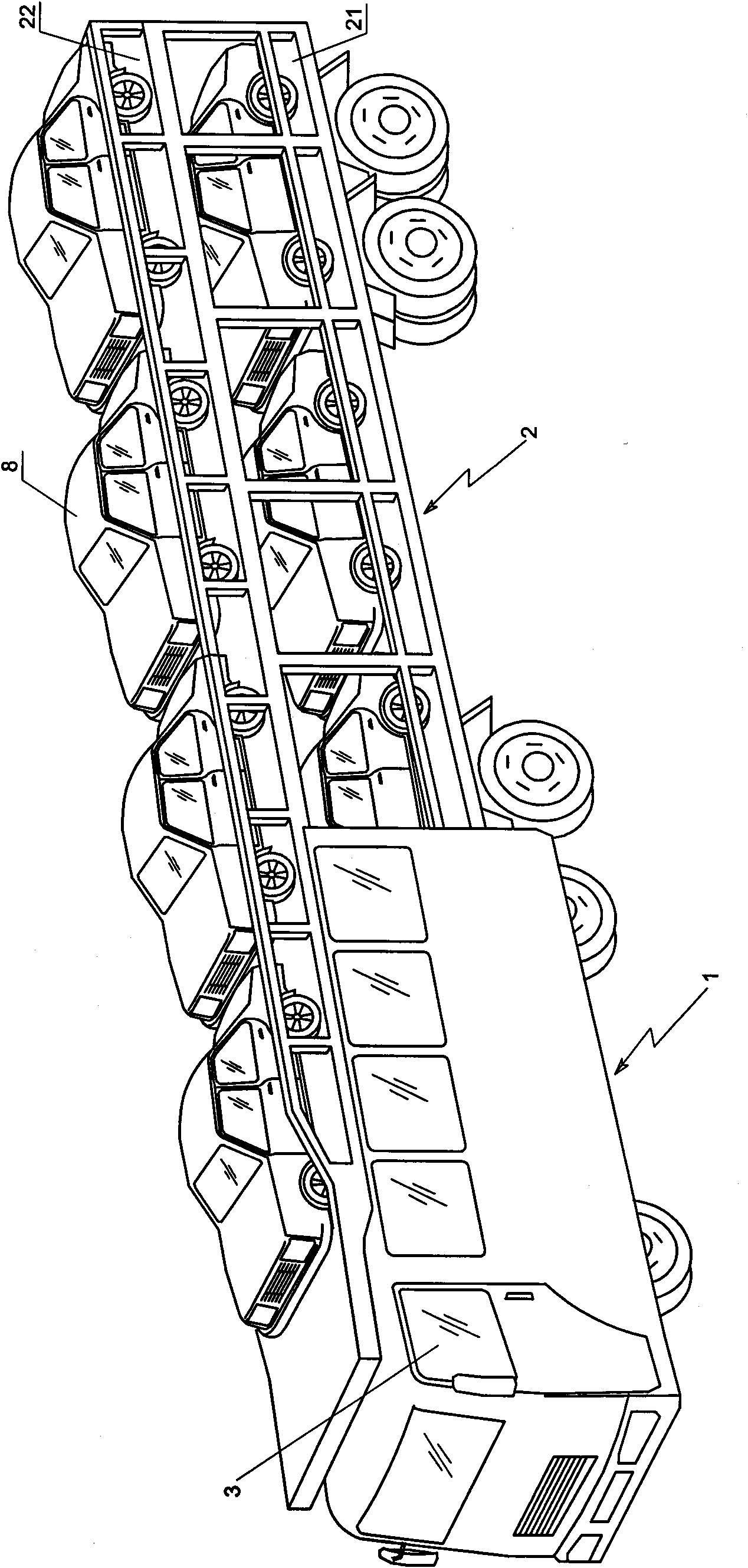

Car carrier

InactiveCN102069743AEasy to carryAvoid fatigueLifting framesItem transportation vehiclesResting timeRest time

The invention relates to a car carrier which comprises a car body, and the car body comprises a passenger carriage and a car-loaded carriage; the car-loaded carriage is respectively provided with stationary fixtures for fixing loaded cars, meanwhile, and the car-loaded carriage is also equipped with a guide device for guiding loaded cars and people to get on and off the car carrier. The car carrier provided by the invention facilitates the carrying of private cars or office cars for long-distance running, so that the long-distance running of the cars is more convenient, and the possibility of occurrence of traffic hazards caused by fatigued non-professional car drivers after long-time driving is prevented; by using the car carrier, the car drivers can get enough rest time, so that the car drivers can keep normal energies for dealing with affairs after arriving at the destination; by using the car carrier, the car can get rest and maintenance, and has no loss because of long-distance running; the car carrier can save the cost of driving; and the car carrier is novel in concept and easy to manufacture or modify, has an ideal application effect and accords with the trend of development, therefore, the car carrier is very beneficial for promotion and implementation.

Owner:HENAN POLYTECHNIC UNIV

Anterior load carriage stability & mobility support system

ActiveUS20150129624A1Guaranteed StrengthVariable placementTravelling sacksPercussion musical instrumentsSupporting systemEngineering

The present invention relates generally to the field of an anterior load carriage stability and mobility support system, and more particularly to marching and equipment and marching drum stability and mobility support belt for a marching drummer in K-12 primary or secondary, a collegiate, a drum and bugle corps or the like. A device capable of providing a support mechanism for the lumbar region of a user's back that allows for load distribution from loads placed anteriorly and inferiorly to the drummer's body. A preferred embodiment of the device includes a large piece and two smaller pieces of neoprene fabric, dual straps sewn along the sides of the belt, removable commercial grade closed cell foam sheets, and two plastic tubing for a sturdy structure with flexibility and versatility, and Velcro® sewn along the straps and on the obverse side of the belt for easy and secure attachment of the straps.

Owner:AUBURN UNIV

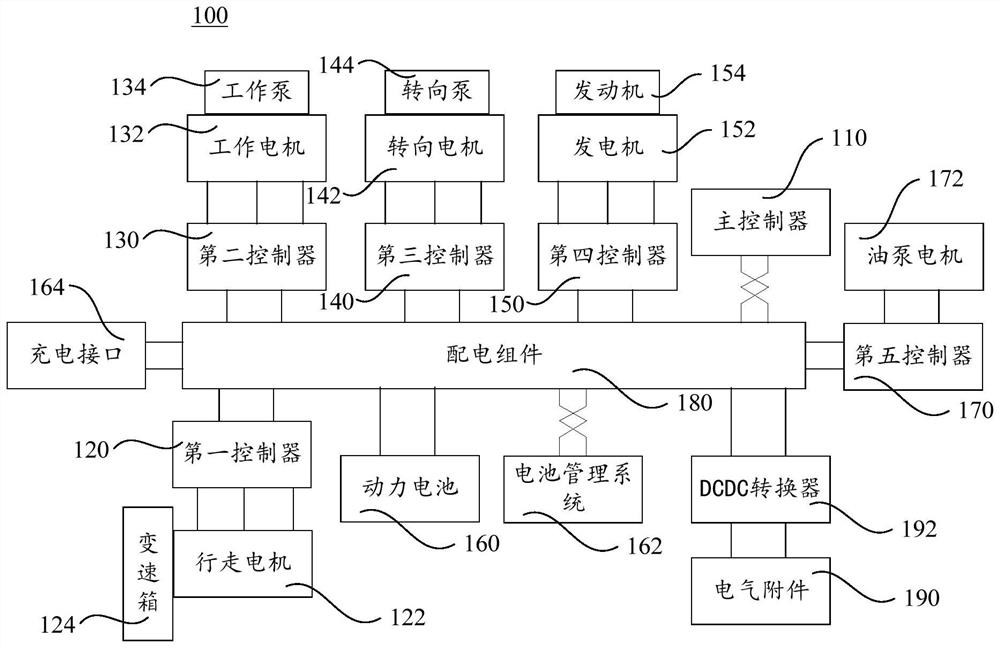

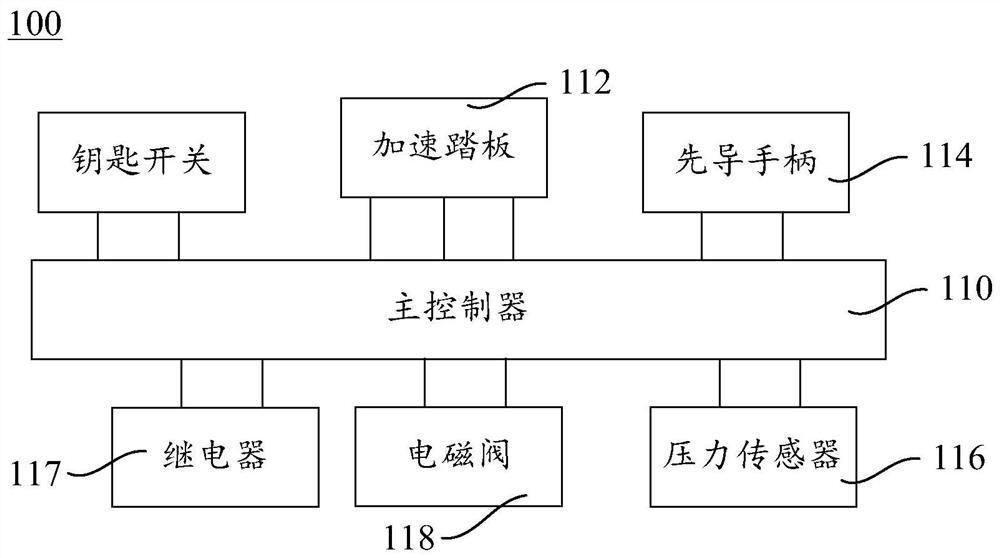

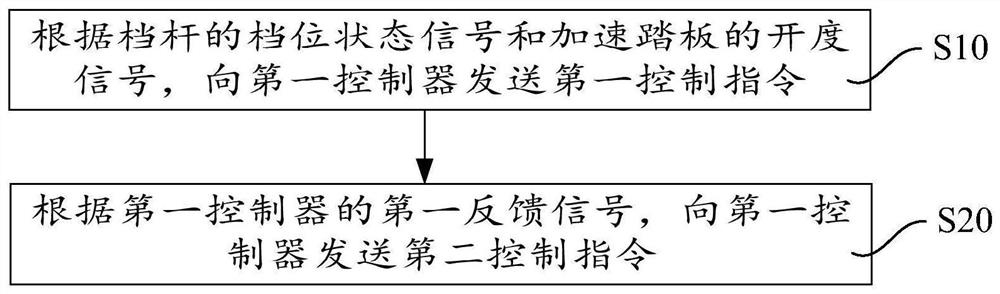

Electric loader power control device and control method thereof

PendingCN112411664AAvoid issues such as wasteRealize the control functionSoil-shifting machines/dredgersControl engineeringElectric machinery

The invention discloses an electric loader power control device and a control method thereof, and relates to the technical field of loading vehicles. The electric loader power control device comprisesa main controller, a first controller, a second controller and a third controller, wherein the first controller, the second controller and the third controller are respectively connected with the main controller through CAN buses. The first controller is connected with a walking motor and used for controlling the output power of the walking motor according to the control instruction of the main controller. The second controller is connected with a working motor and is used for controlling the output power of the working motor according to the control instruction of the main controller. The third controller is connected with a steering motor and is used for controlling the output power of the steering motor according to the control instruction of the main controller. Environmental pollution can be reduced, and the energy utilization rate during hydraulic control is increased.

Owner:ENSIGN HEAVY IND

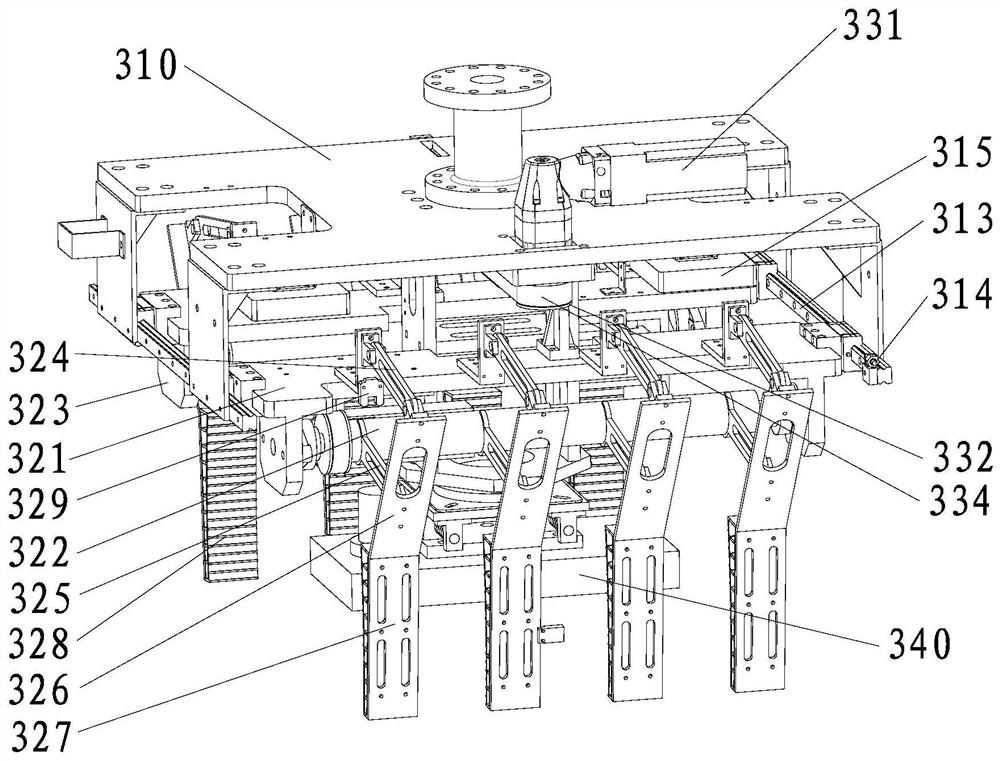

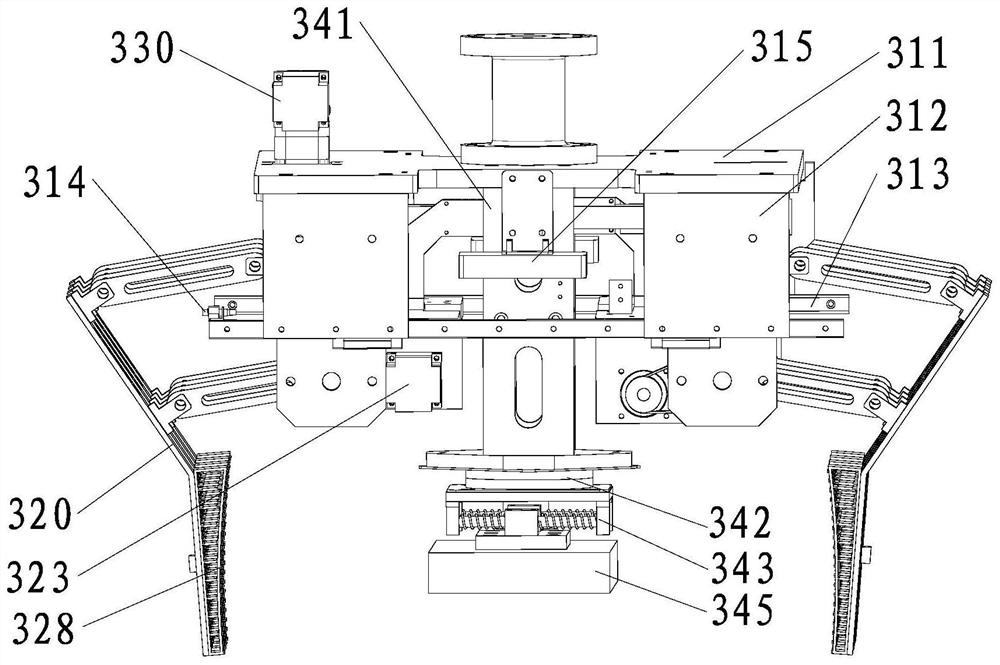

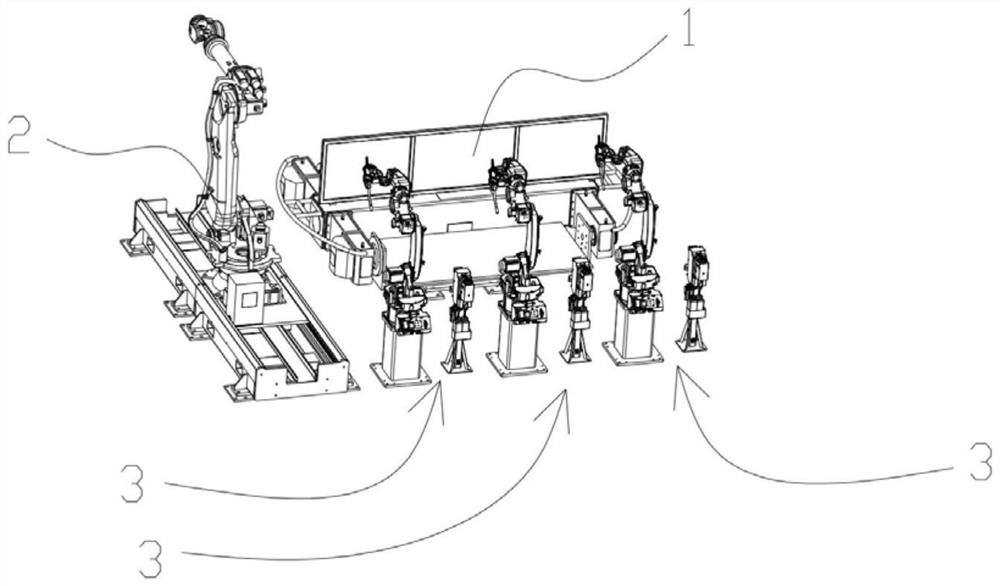

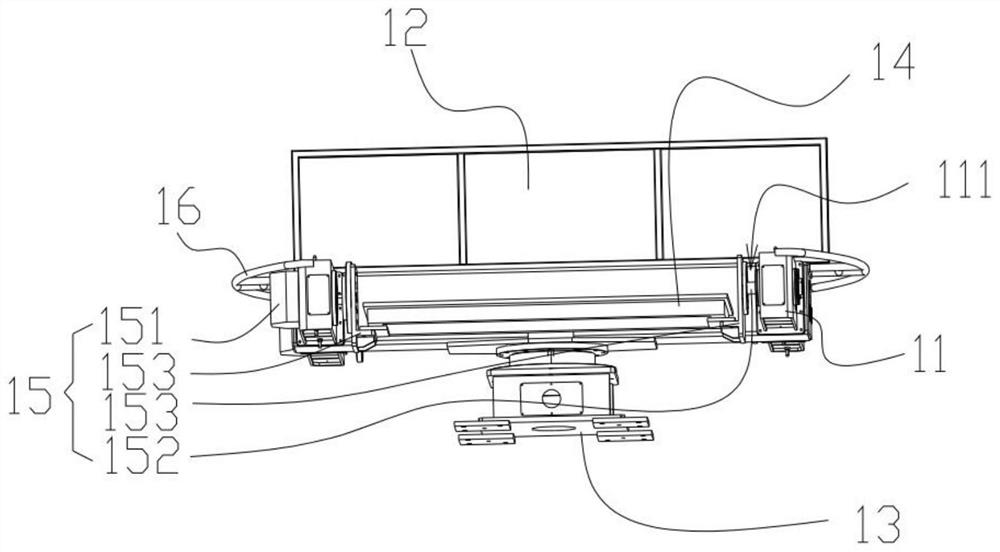

Frame welding device

InactiveCN111843326AImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention relates to the technical field of welding, and particularly relates to a frame welding device. The frame welding device comprises a loading mechanism used for loading a frame, a feedingmechanism used for feeding the frame to the loading mechanism, and a welding mechanism used for welding the frame on the loading mechanism, wherein the loading mechanism comprises a base, a baffle anda horizontal rotating mechanism; carrying plates are arranged on the two sides of the base correspondingly; the baffle is arranged on the base and positioned between the two carrying plates; the horizontal rotating mechanism is arranged at the bottom of the base and used for driving the base to rotate horizontally; the base is further provided with two overturning mechanisms; and the two overturning mechanisms are used for driving the two carrying plates to overturn so that an included angle can be formed between each carrying plate and the horizontal plane. According to the frame welding device, the two carrying plates are arranged and matched with the horizontal rotating mechanism and the overturning mechanisms, so that when the frame on one carrying plate is welded, the feeding mechanism can conduct discharging on the frame on the other carrying plate, a new frame component to be welded is placed, and thus the working efficiency is improved.

Owner:东莞市科泰汽车检夹具有限公司

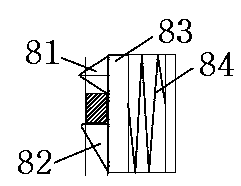

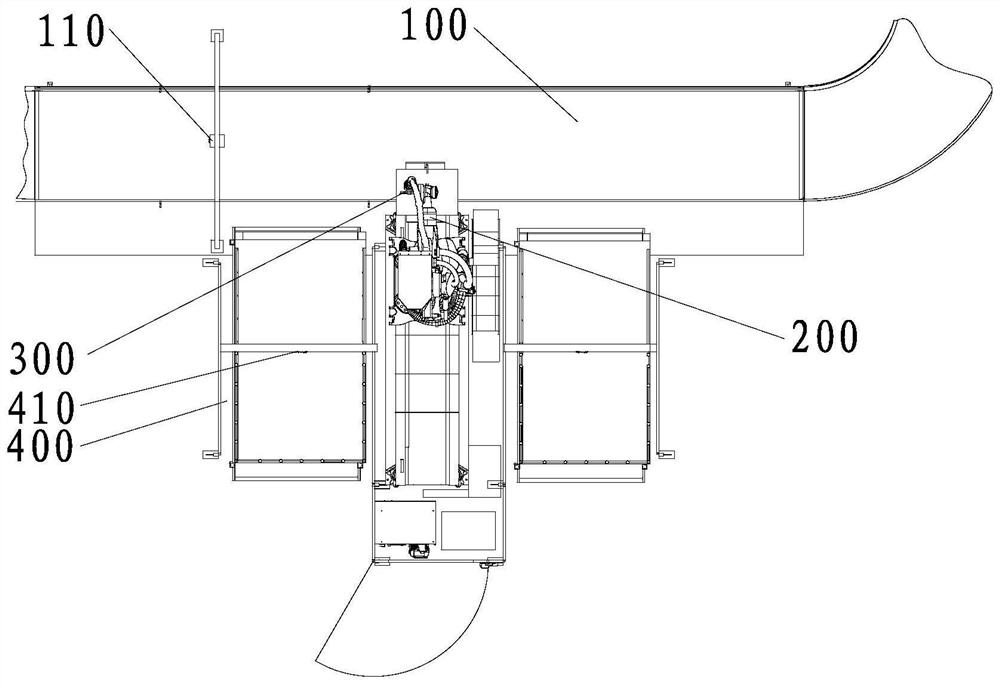

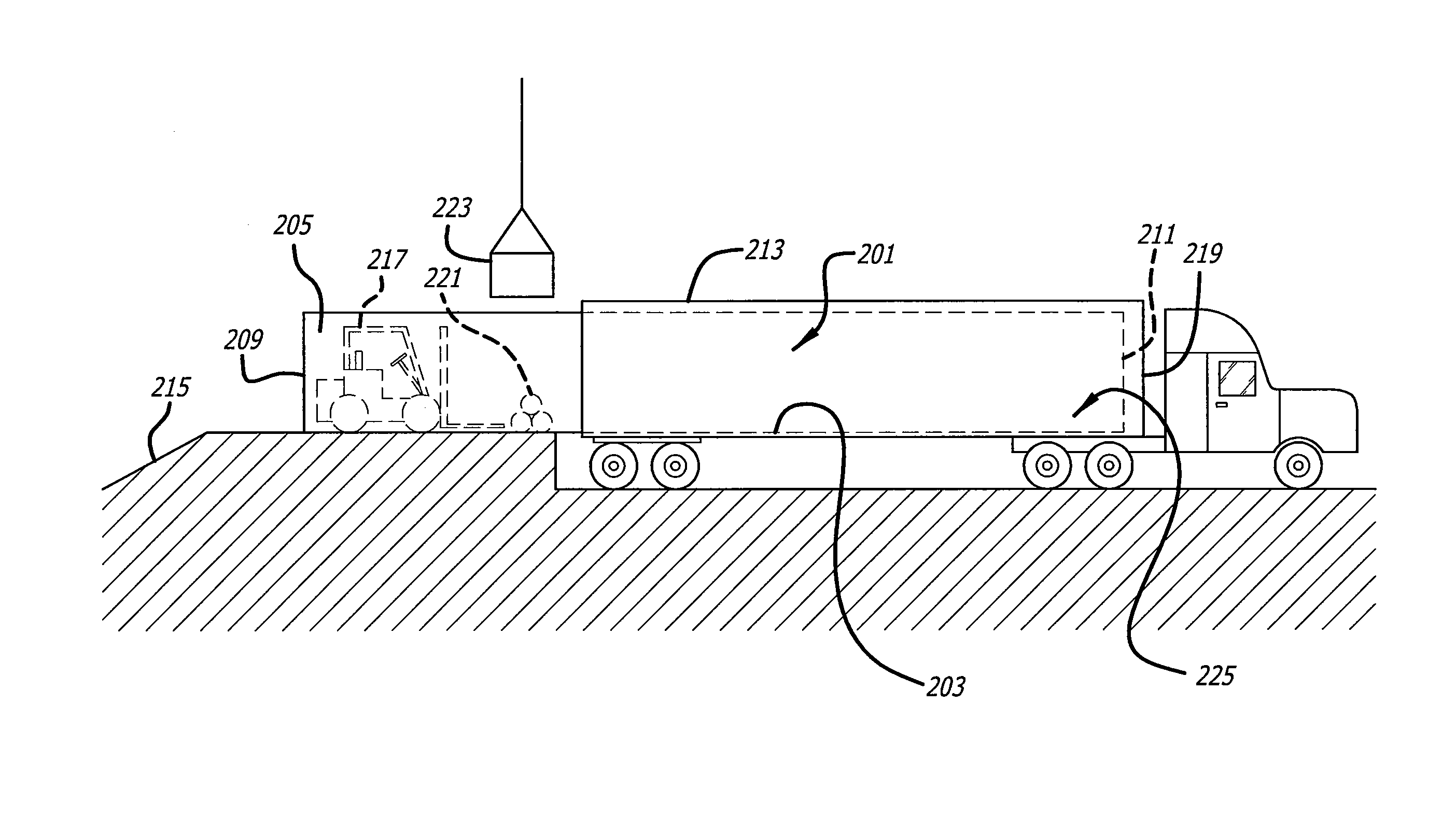

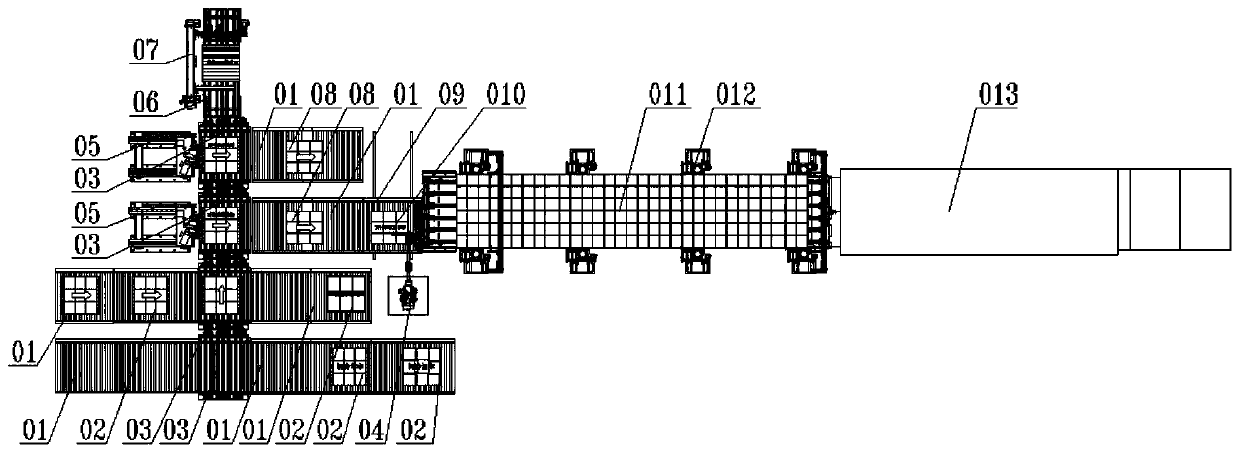

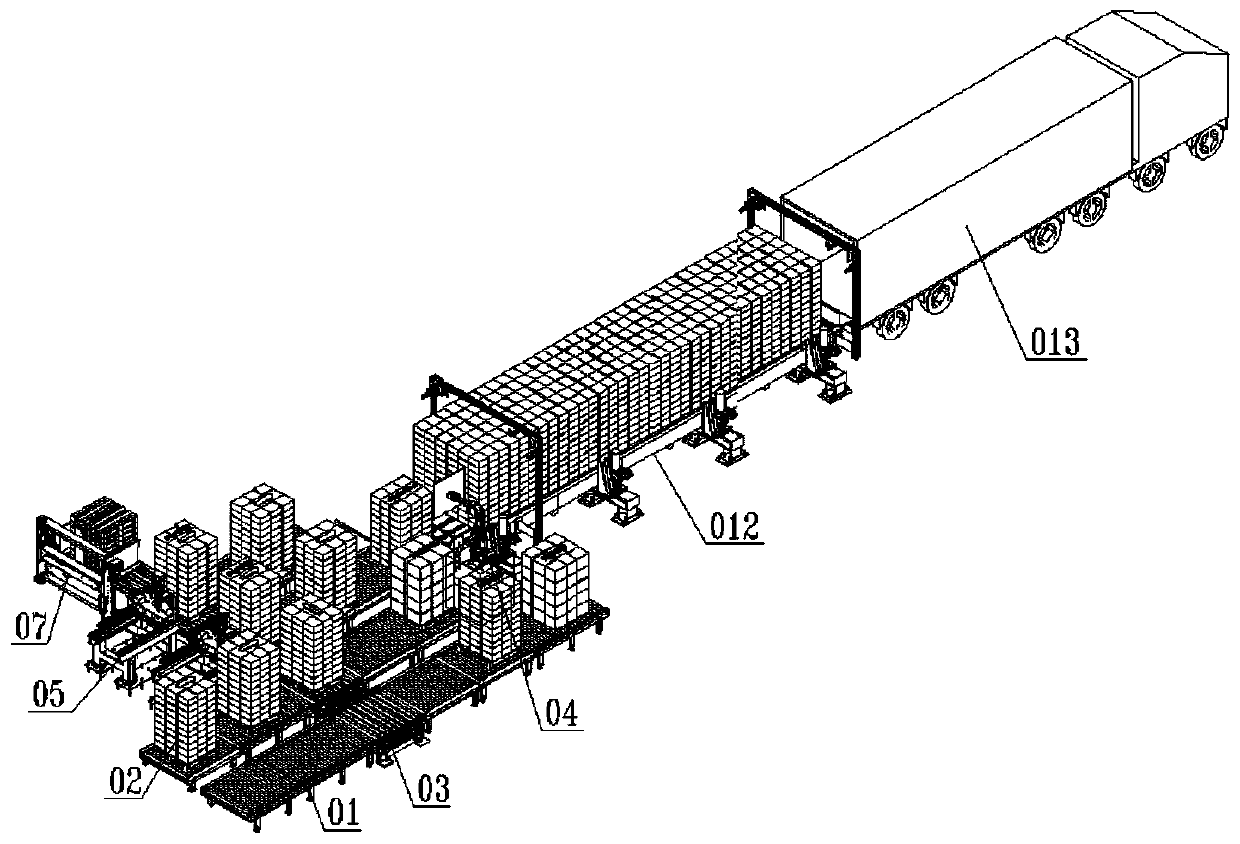

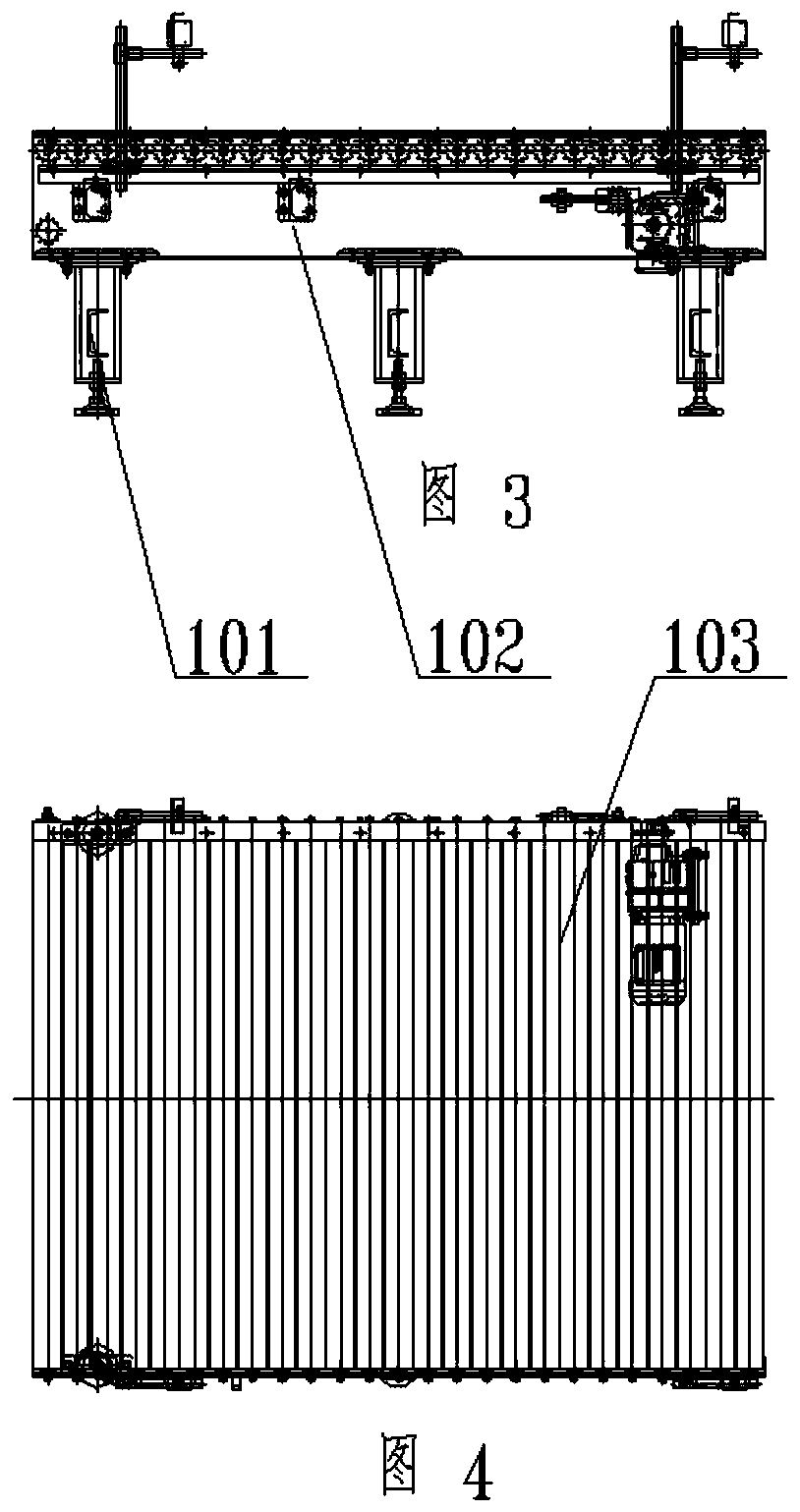

Full-automatic material preparing and car loading system and car loading method

PendingCN111003537ARealize automatic separationRealize automatic recyclingStacking articlesDe-stacking articlesLoad carriageChain link

The invention relates to a full-automatic material preparing and car loading system and a car loading method. The full-automatic material preparing and car loading system comprises a roller conveyingdevice, a combined conveying device, an automatic material supplementing device, a tray separating device, a chain conveying device, a tray recovering device, a movable docking device, an automatic car loading device, a compartment and a car guiding and limiting device. The roller conveying device is used for conveying trays loaded with stacked materials to the tray separating device; the tray separating device is used for separating the trays and the stacked materials of the trays loaded with the stacked materials; a robot stacking device is used for increasing or decreasing the supplementarymaterials for materials to be stacked, enabling the length, the width and the height of the cross section of the stacked materials to meet the cross section requirement of the compartment, and conveying the finished stacked materials the automatic car loading device; and the automatic car loading device is used for combining, sorting and arranging the sorted stacked materials for the second time,enabling the arranged stacked materials to meet the length and width requirements of the compartment, and conveying the whole sorting and arranged stacked materials into the compartment at a time.

Owner:中轻长泰(长沙)智能科技股份有限公司

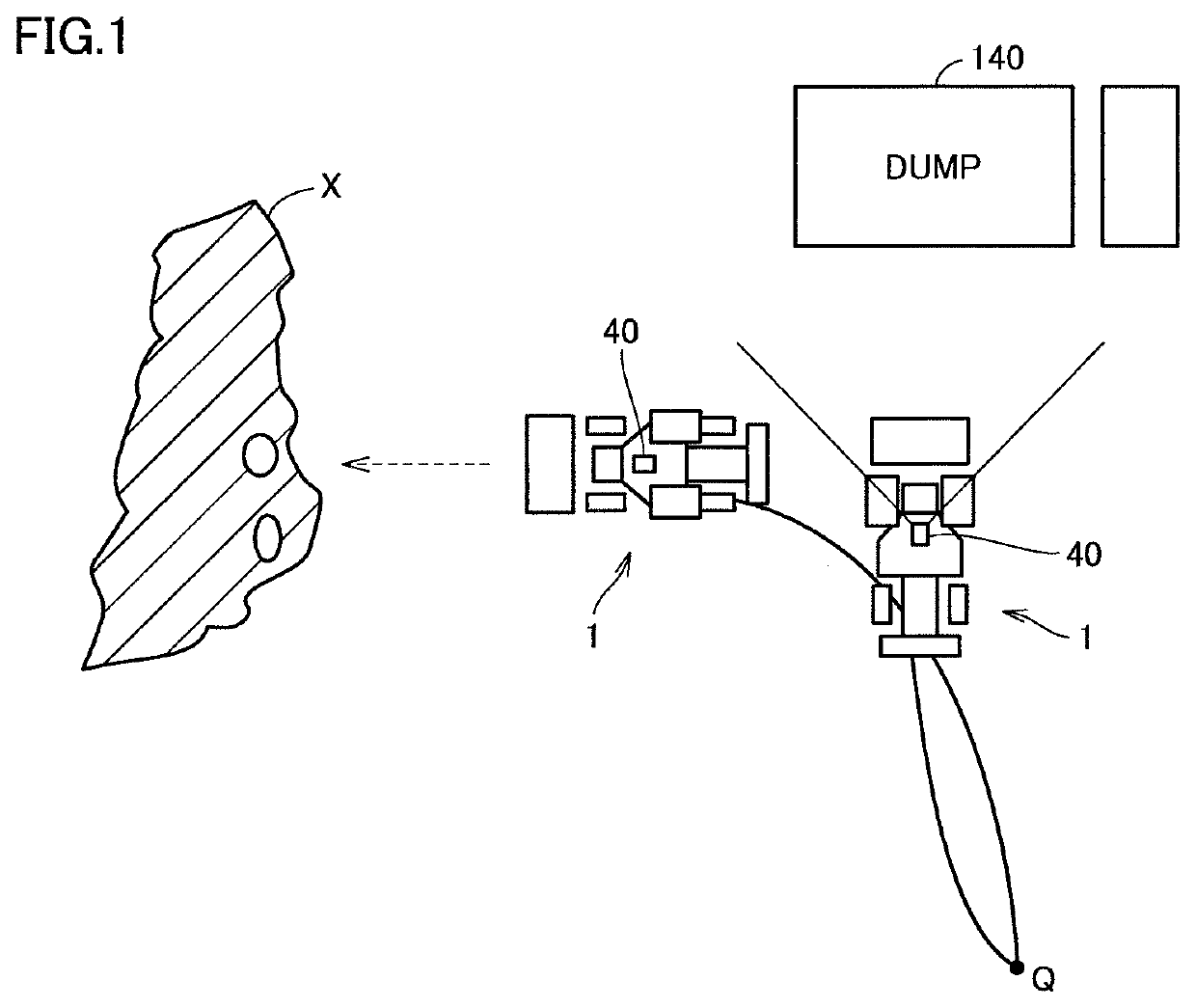

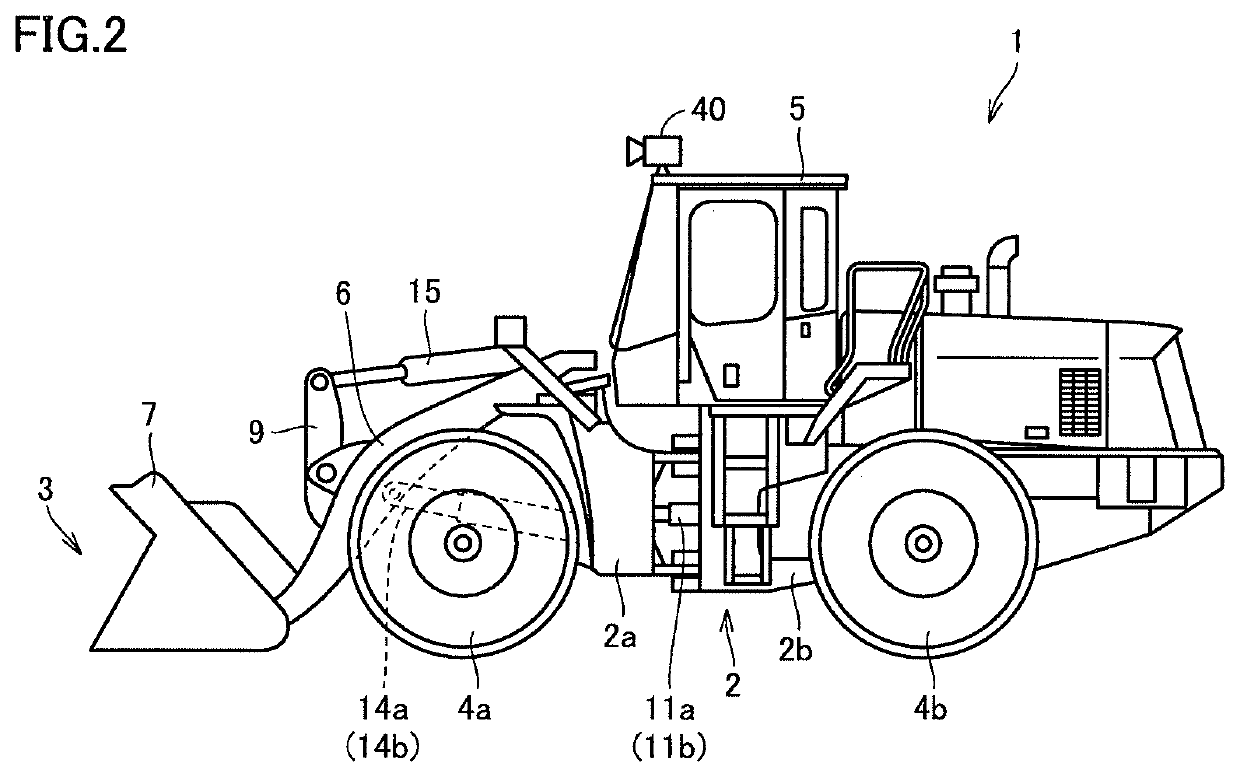

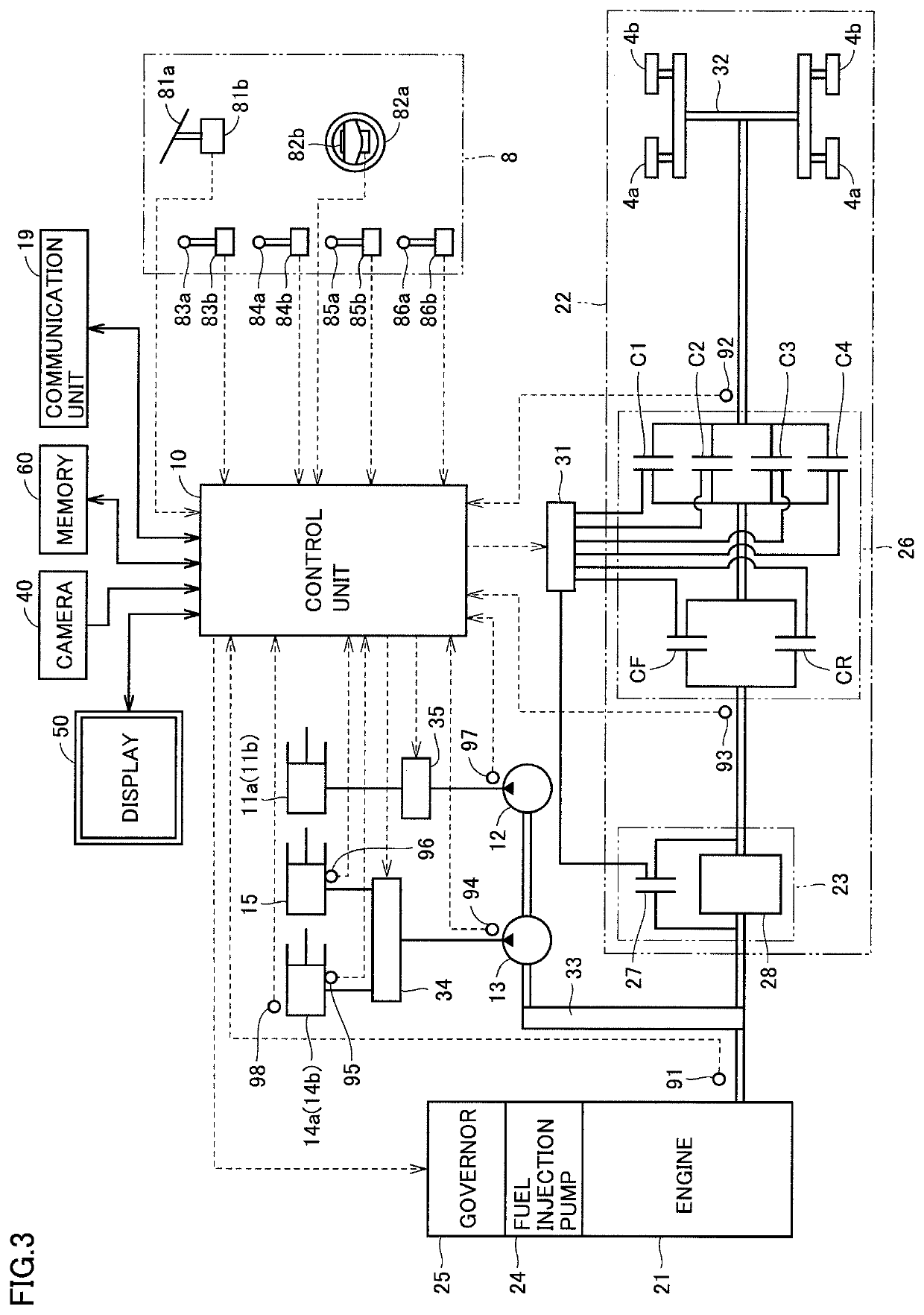

Control system for work vehicle, control method thereof, and method of controlling work vehicle

ActiveUS10704228B2Simplify workMechanical machines/dredgersVehicle componentsControl systemControl engineering

A control system for a work vehicle includes a position determination unit which determines a position of loading on a loaded vehicle based on a state of loading on the loaded vehicle, a display, and a representation control unit which has the display show loading guidance corresponding to the position of loading determined by the position determination unit for a laterally viewed loaded vehicle.

Owner:KOMATSU LTD

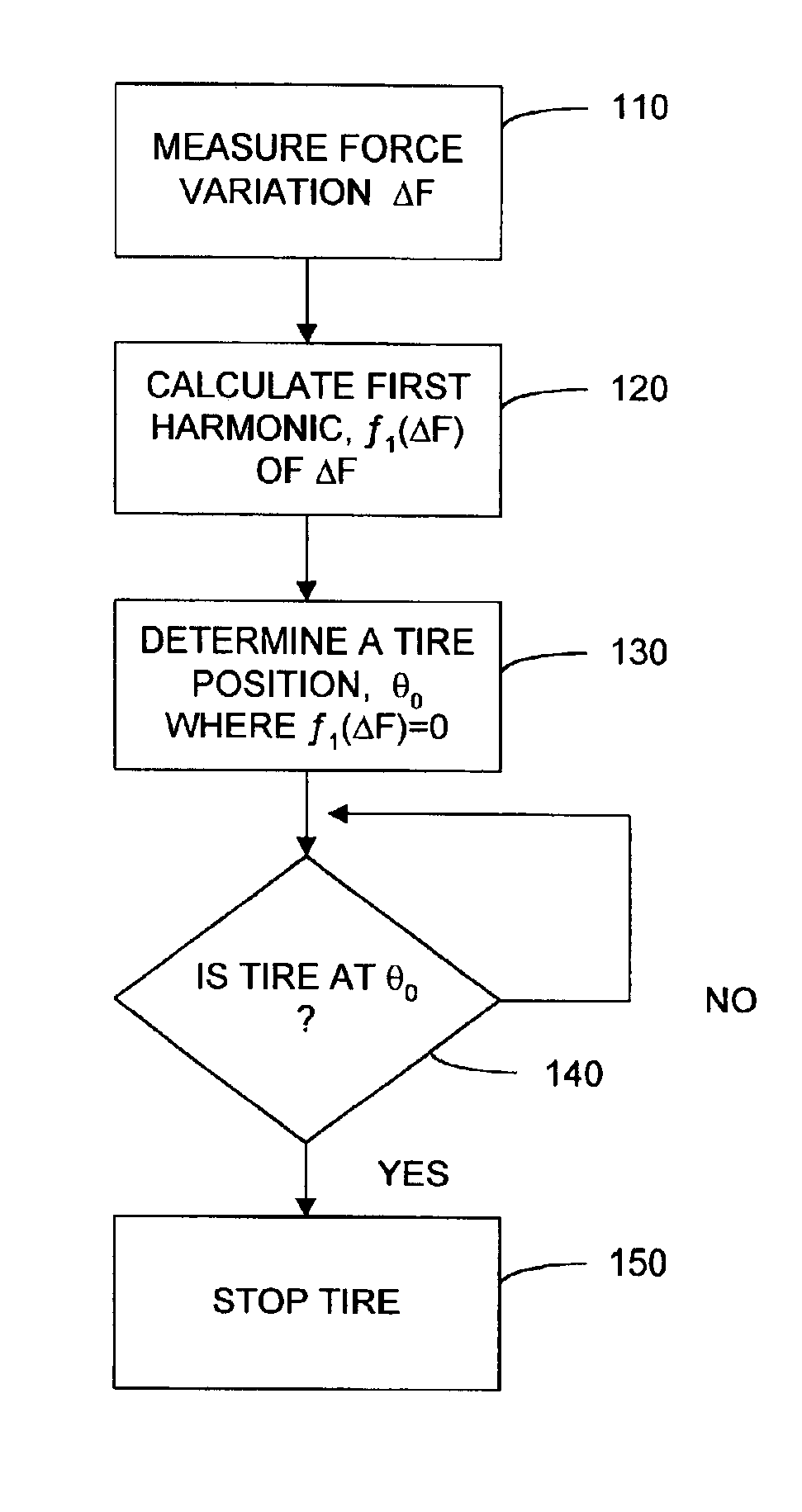

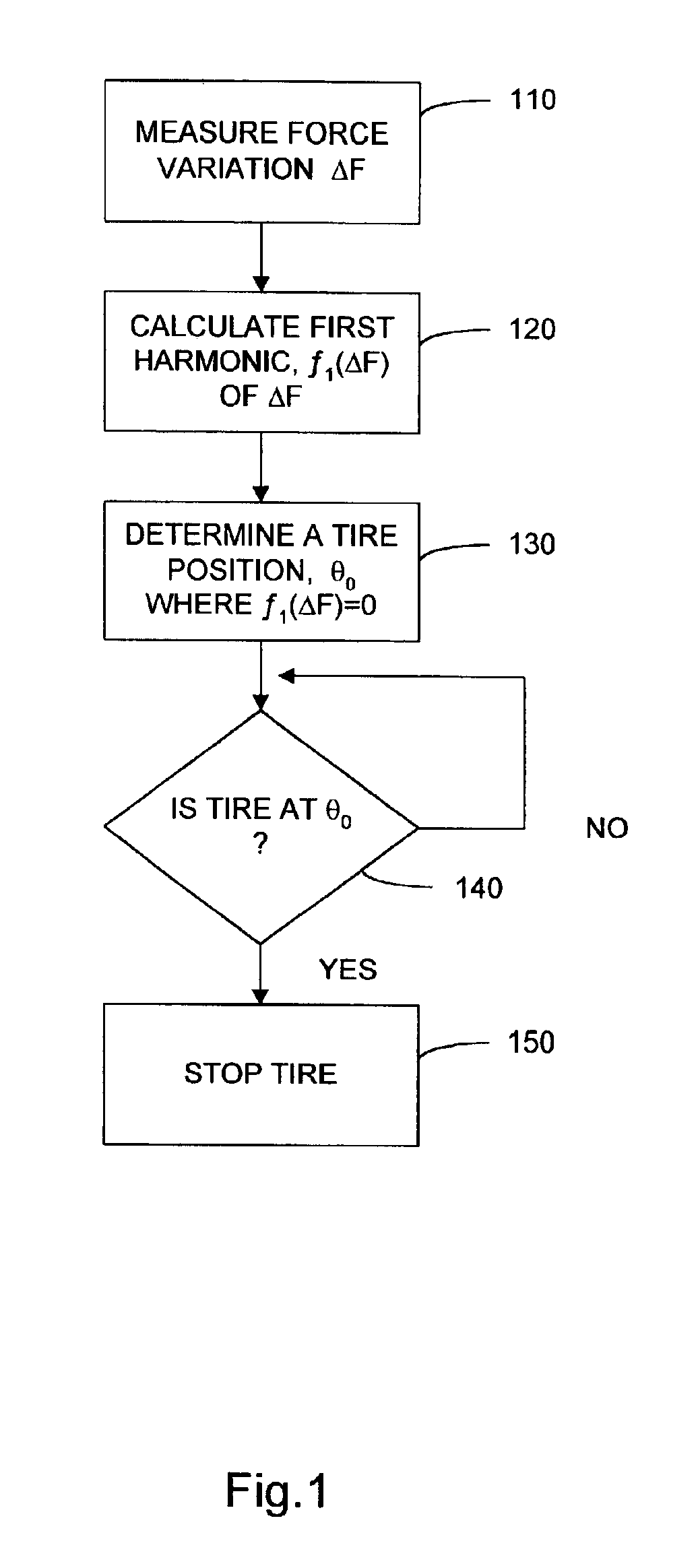

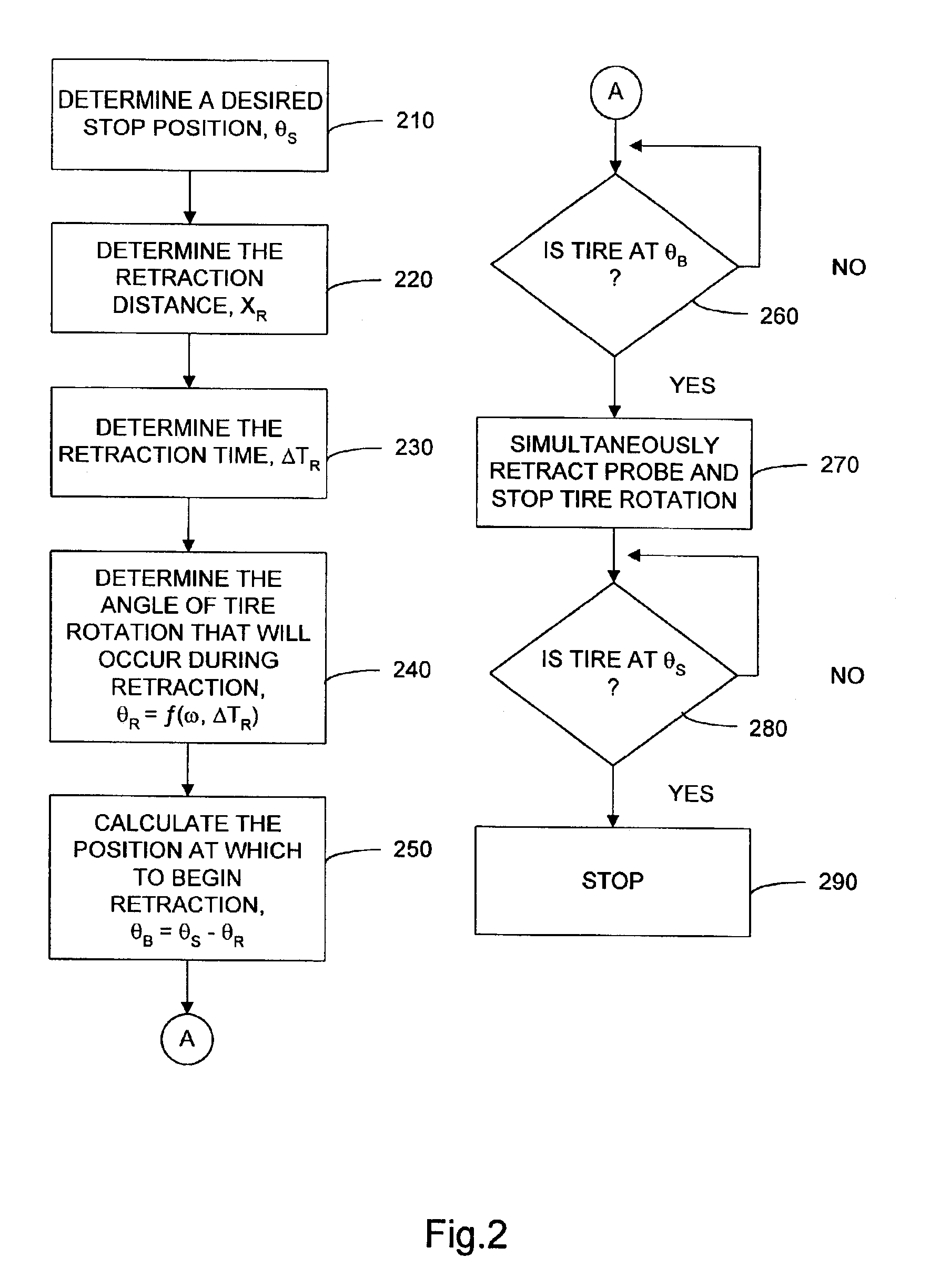

Tire uniformity testing

InactiveUS6915684B2Minimize impactGood repeatabilityStatic/dynamic balance measurementRoads maintainenceTire uniformityTire rotation

A method and apparatus for testing tires in a repeatable manner. Testing steps are performed in a manner that minimizes impact on the tire characteristics being measured. In one aspect, tire rotation reversal is performed at a zero crossing of a first harmonic of radial load variation exerted on a load carriage by the tire. In another aspect, load carriage retraction is performed so that the tire is unloaded when the tire stops rotating.

Owner:MICRO POISE MEASUREMENT SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com