Self-adaptive airport logistics system

A logistics system and self-adaptive technology, applied in the field of logistics system, can solve the problems of high labor cost, loss, wrong baggage loading, etc., and achieve the effect of good clamping accuracy and firmness, low labor cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

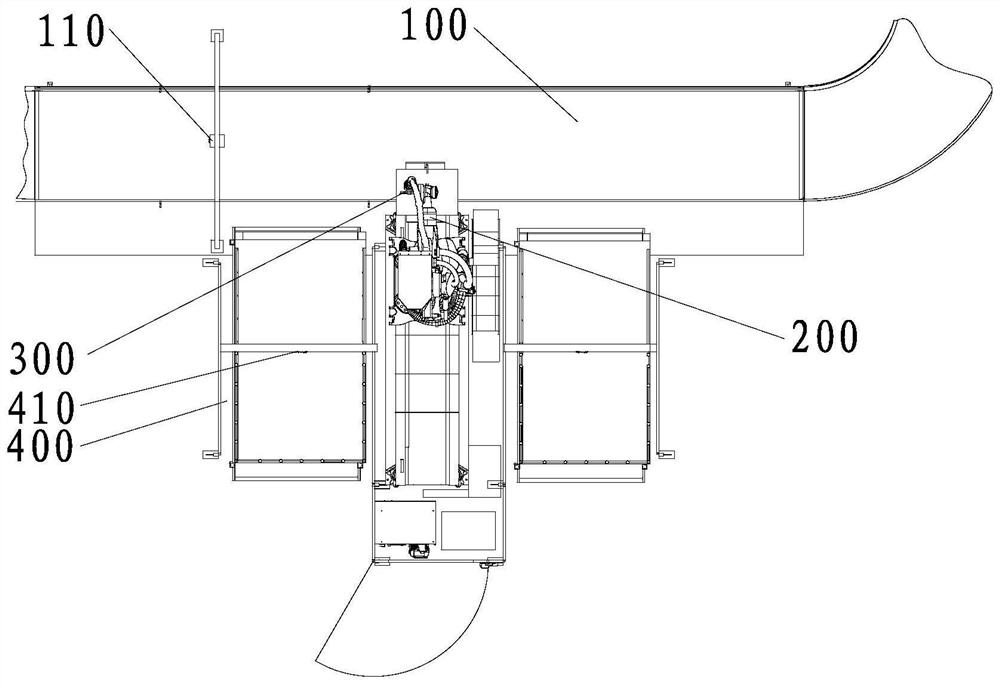

[0059] Such as figure 1 As shown, the present embodiment provides an adaptive airport logistics system, including a luggage conveyor belt 100, a stacking manipulator 200 arranged beside the luggage conveyor belt 100, a composite gripper 300 installed at the end of the stacking manipulator 200, and a stacking manipulator disposed on the stacking manipulator. The loading parking space 400 next to the 300, wherein the baggage conveyor belt 100 is the same as the conventional baggage conveyor belt used for airports, is a rotary endless conveyor belt. The palletizing manipulator 200 is a multi-joint series manipulator directly available on the market, and will not be described in detail here. In addition, a 2D laser sensor 110 is arranged above the luggage conveyor belt 100. The 2D laser sensor 110 includes an industrial camera and a line laser sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com