Patents

Literature

39results about How to "Realize palletizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

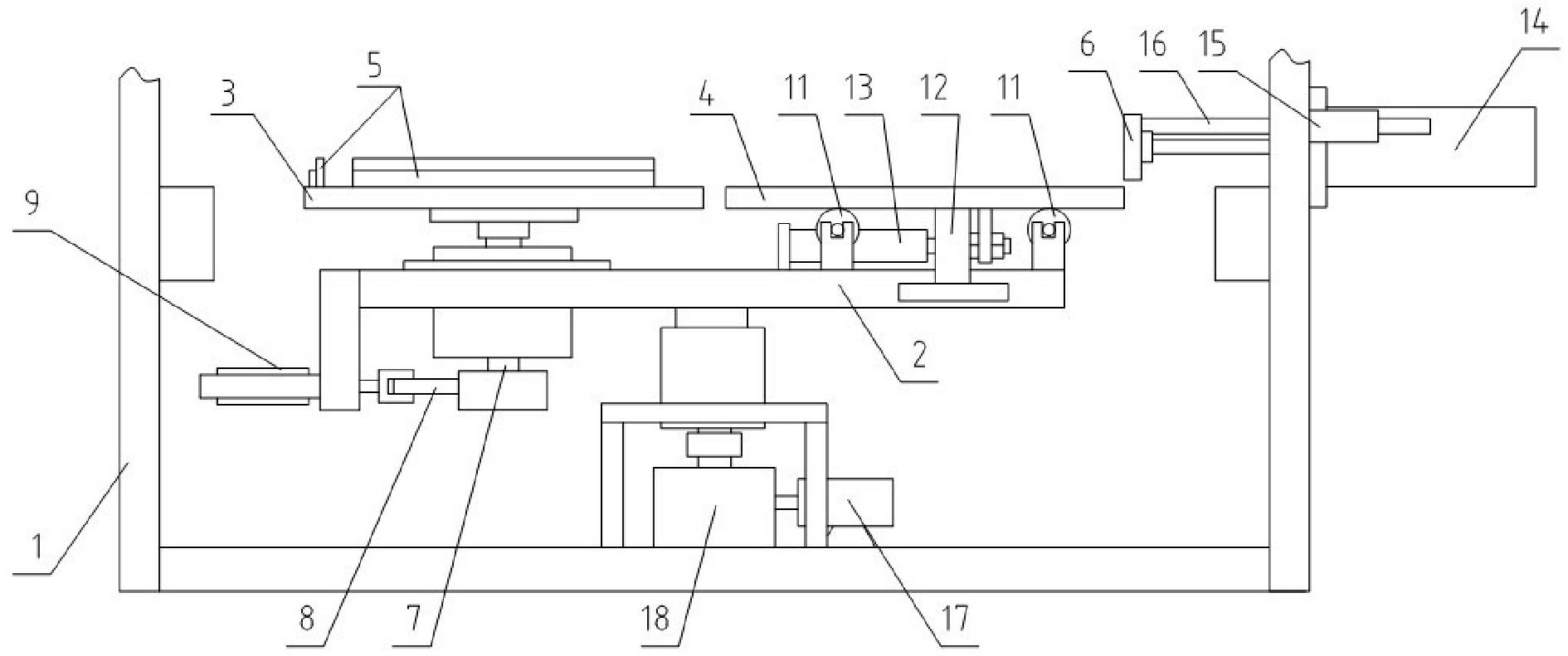

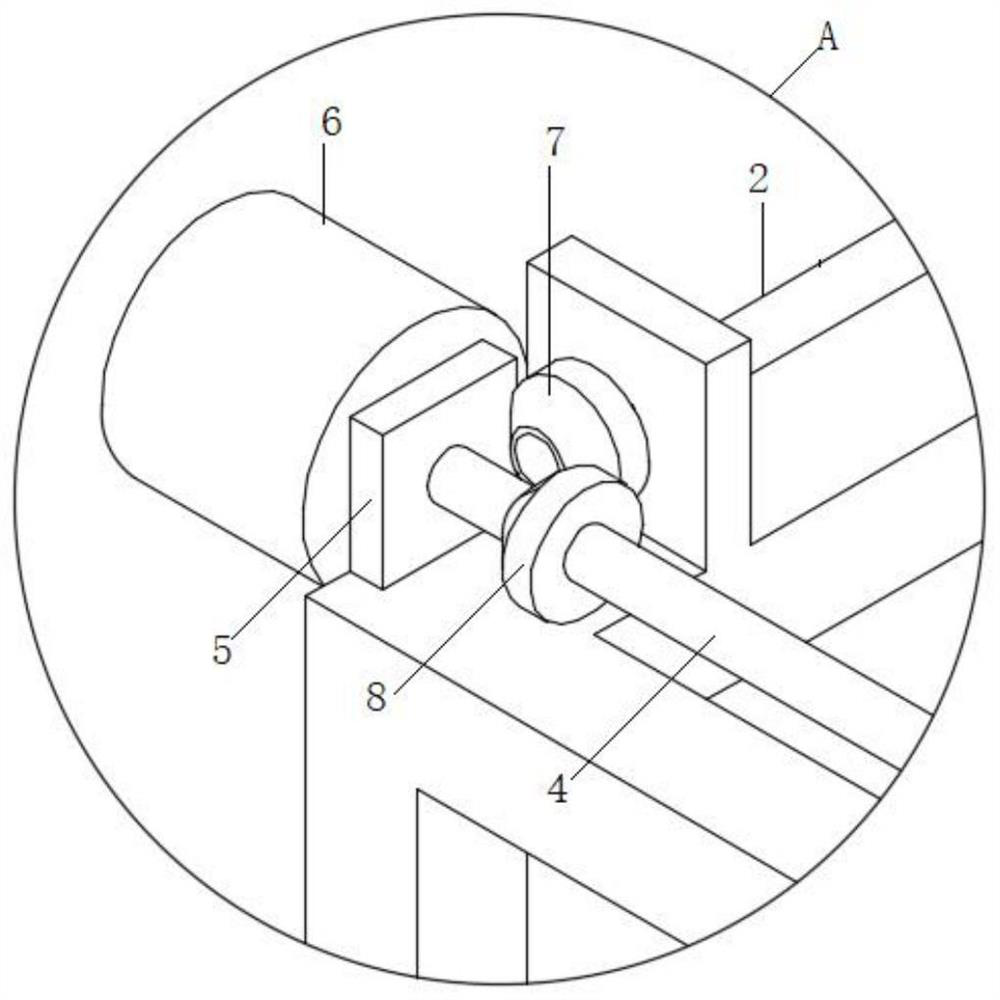

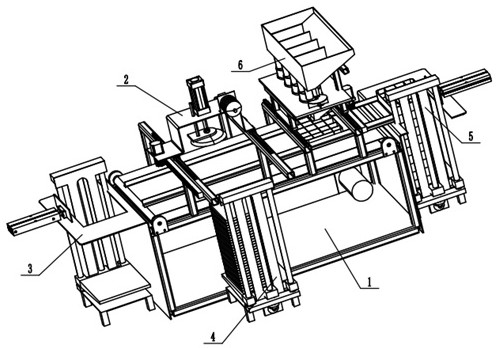

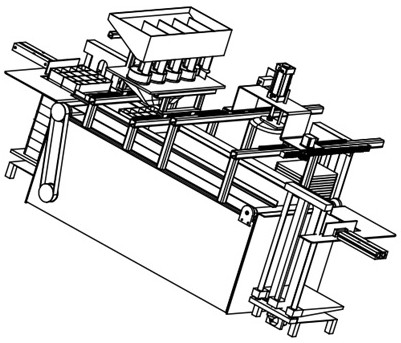

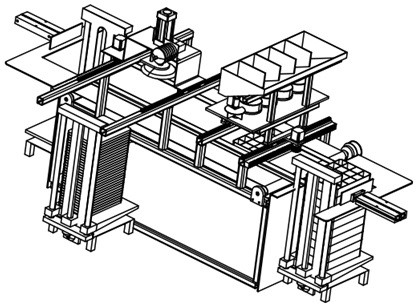

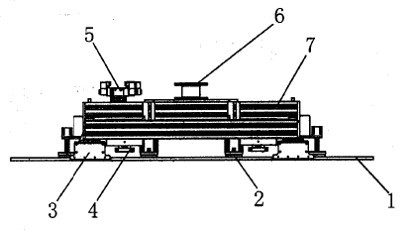

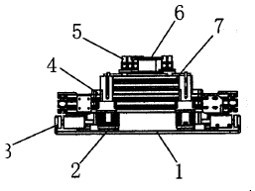

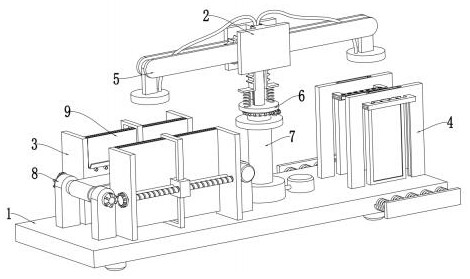

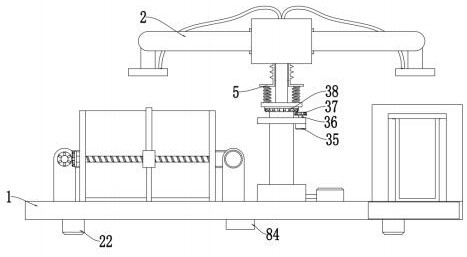

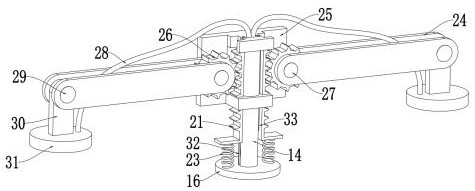

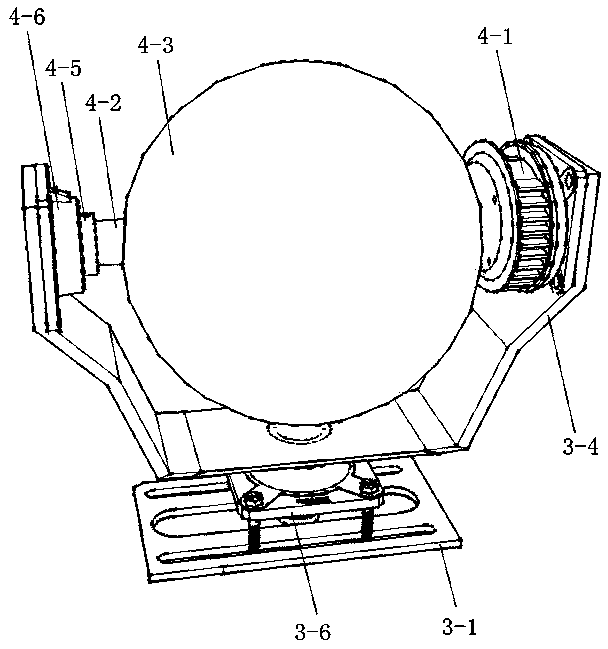

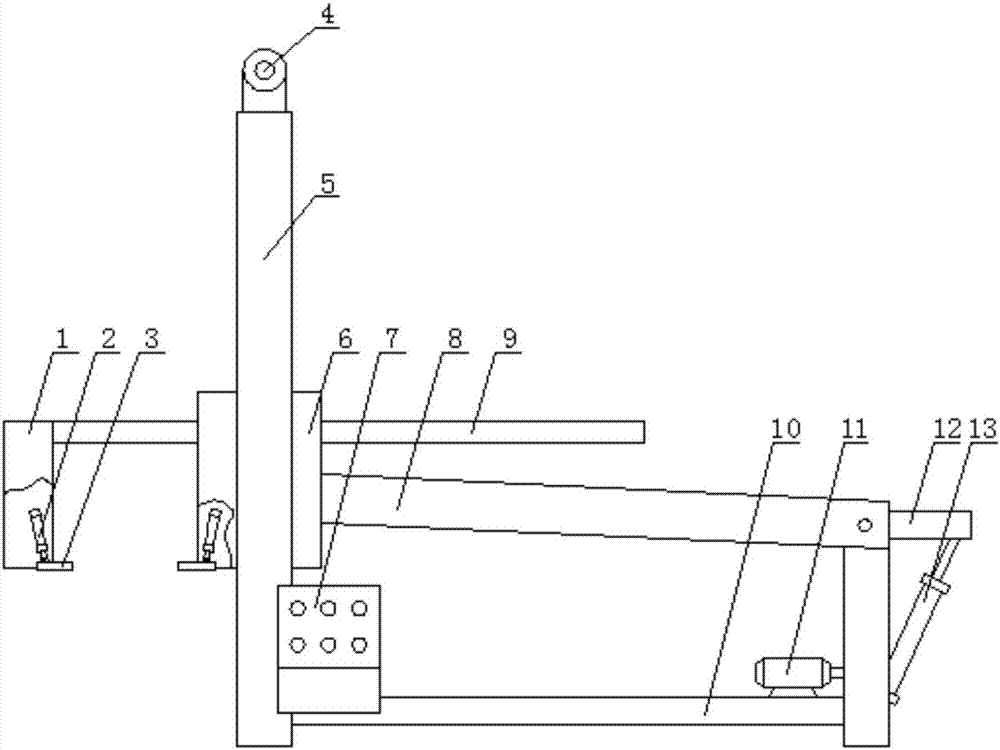

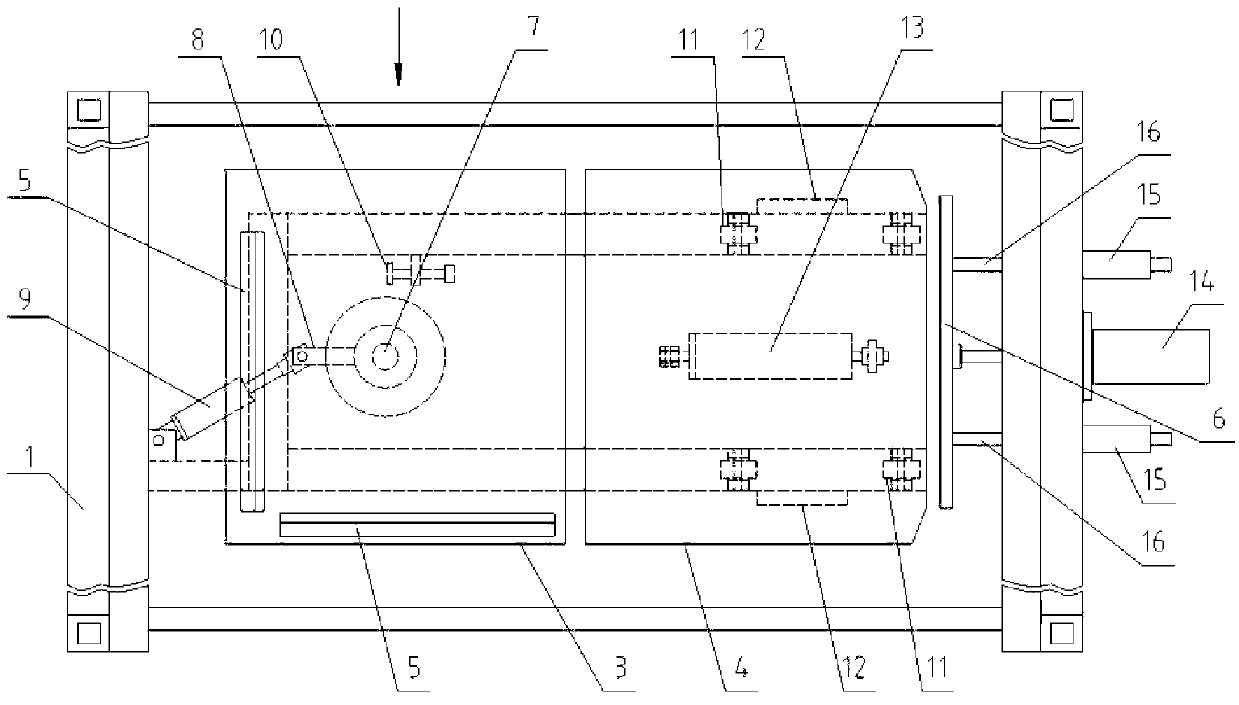

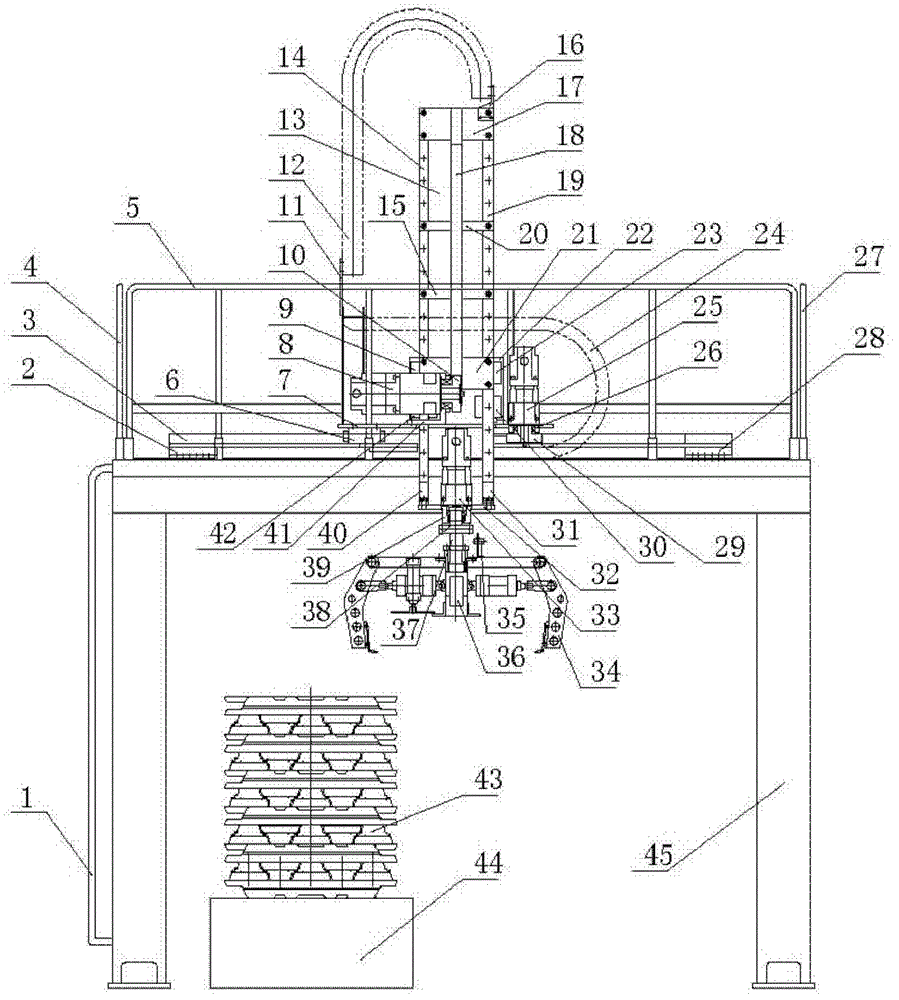

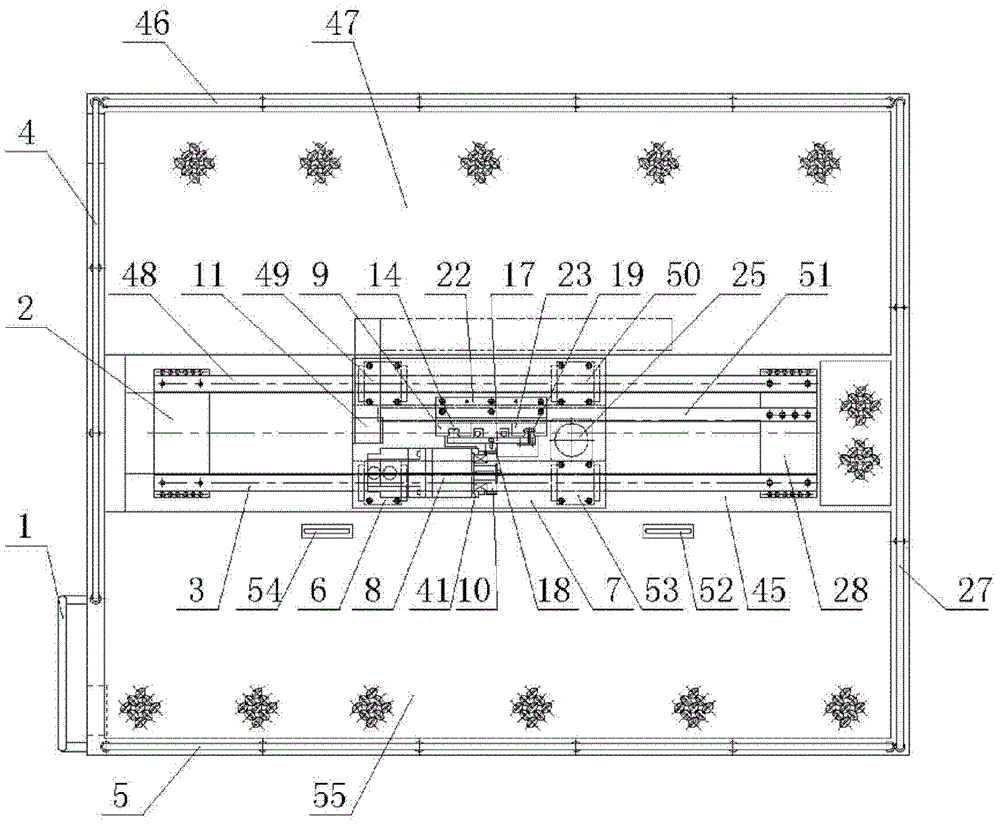

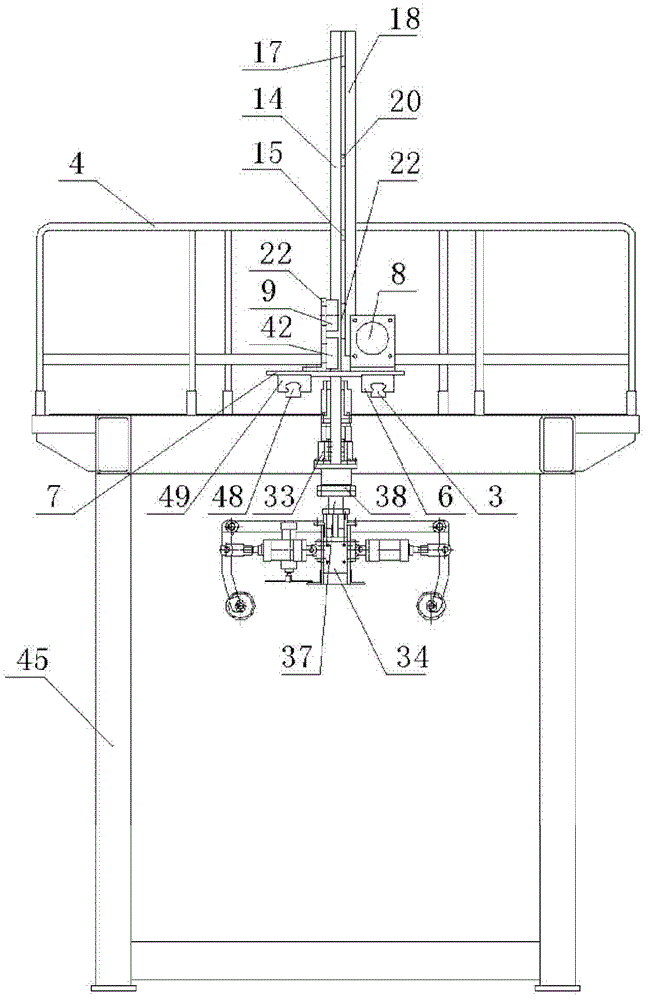

Brick stacking mechanism for automatic stacker

InactiveCN102491100AReduce labor intensityImprove labor efficiencyStacking articlesDe-stacking articlesEngineeringHorizontal translation

The invention discloses a brick stacking mechanism for an automatic stacker. The brick stacking mechanism comprises a chassis fixedly connected with the automatic stacker, a rotary table driven by a power device to rotate horizontally is connected with the chassis in a rotating manner, a rotary support plate and a translation support plate which are arranged horizontally side by side are connected with the rotary table, the rotary support plate is driven to rotate horizontally by a rotation power device arranged on the rotary table, the translation support plate is driven by a translation power device arranged on the rotary table to do horizontal translation to get close to or depart from the rotary support plate, a baffle arranged vertically is arranged on the outer side of the rotary support plate, a baffle arranged horizontally is fixedly arranged on the front side of the rotary support plate, a backlash push plate which is arranged on the outer side of the translation support plate is connected with the chassis in a sliding manner and is driven by a backlash power device arranged on the chassis. The brick stacking mechanism can be used for quickly rearranging building bricks so that the bricks meet stacking requirement; therefore the labor intensity of workers is reduced and the working efficiency of the workers is improved.

Owner:丁来臻

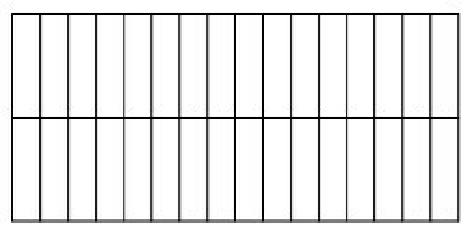

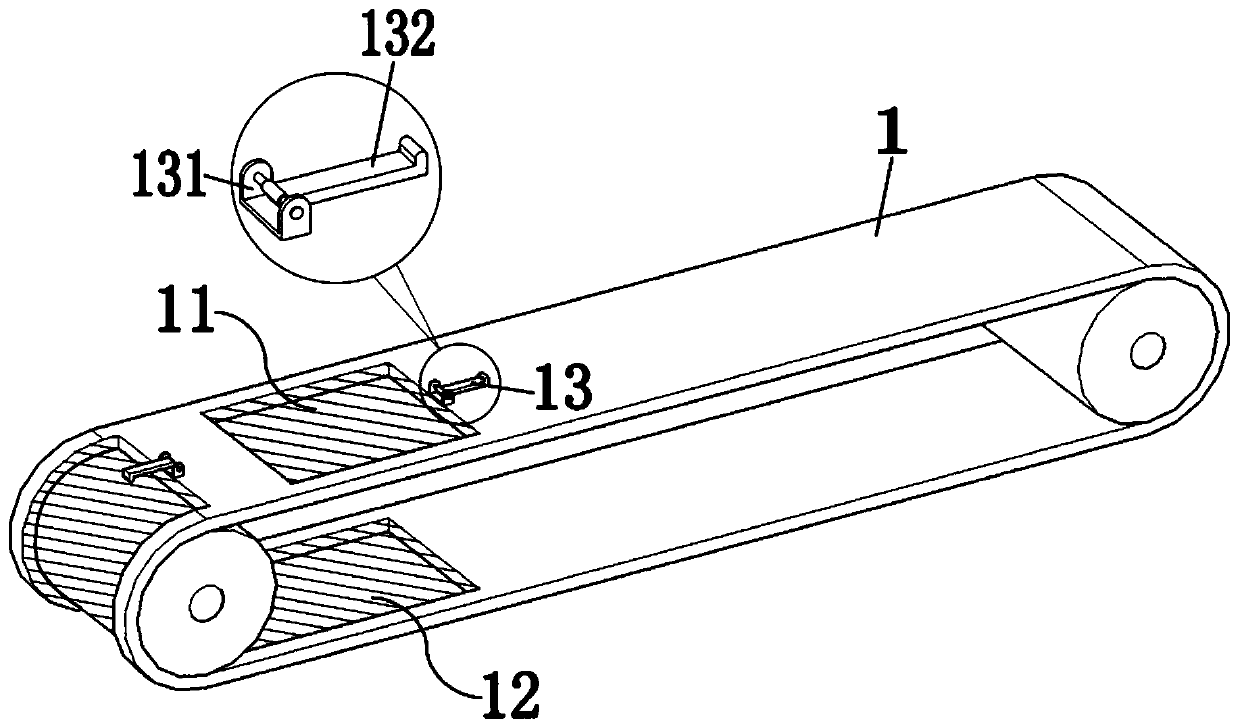

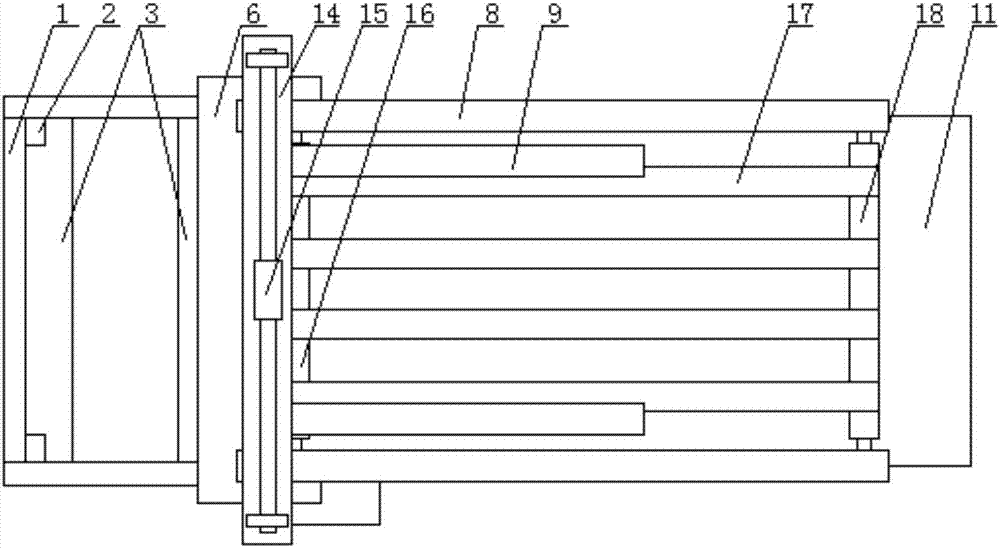

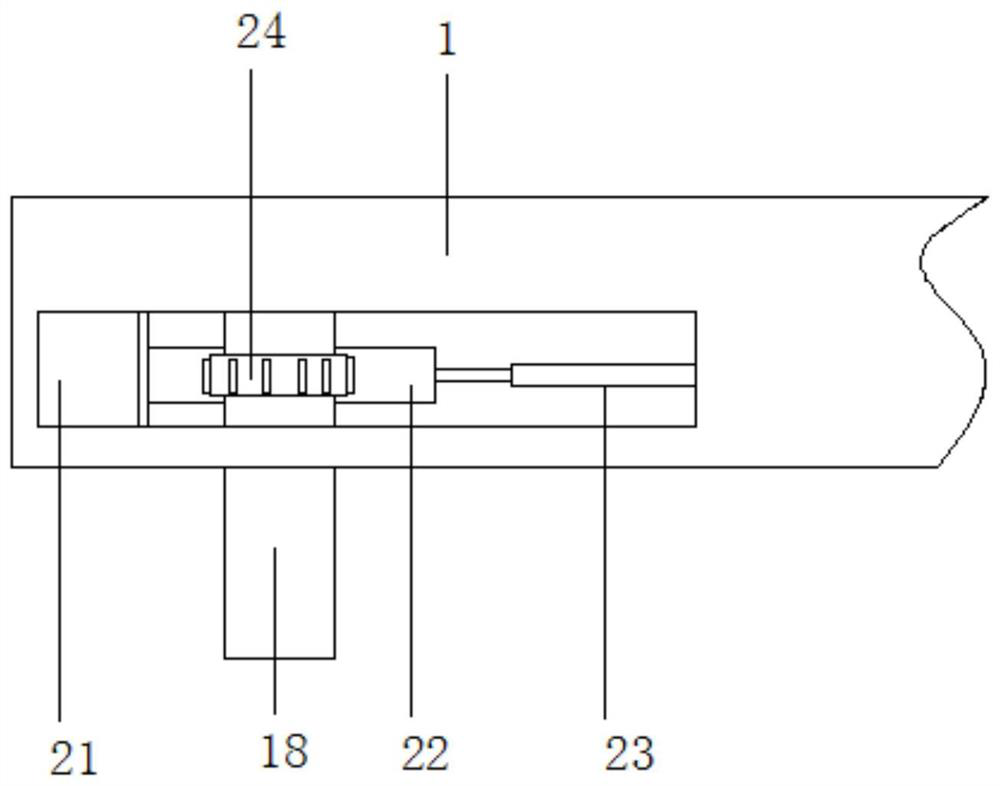

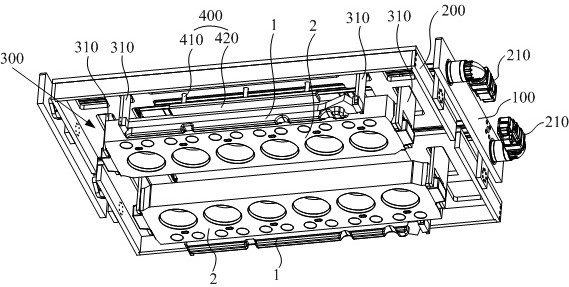

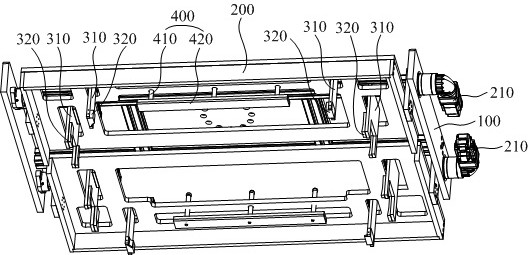

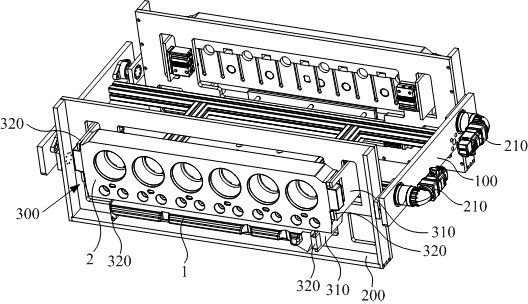

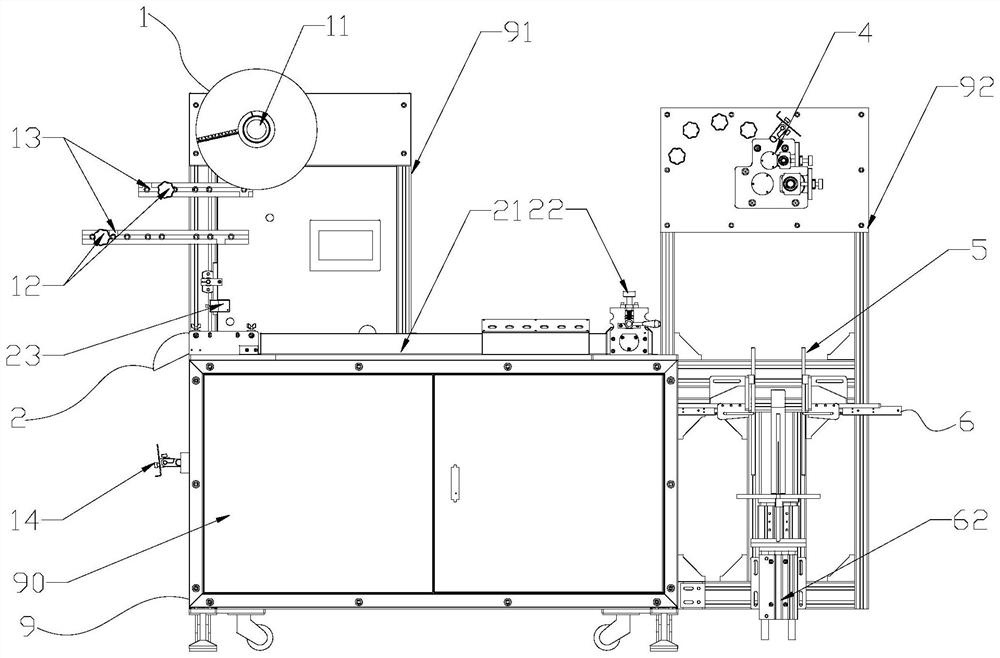

Reciprocating type plastic bag conveying device

ActiveCN111232723ARealize palletizingNo slidingBag making operationsPaper-makingStructural engineeringIndustrial engineering

The invention relates to a plastic bag conveying device for stacking and carrying sheet-shaped plastic bags discharged in sequence. The plastic bag conveying device comprises an output belt, an inputbelt, a first bearing shell body, a baffle, a sliding way, a bottom plate, a second bearing shell body and a bag storage box, wherein the input belt, the first bearing shell body, the baffle and the sliding way are arranged above the output belt, the second bearing shell body is arranged in the output belt in a surrounding mode, and the second bearing shell body and the bag storage box are arranged below the output belt. According to the plastic bag conveying device, under the condition that discharging action of the plastic bags is not interrupted through the first bearing shell body and thebaffle, the plastic bags are stacked and conveyed in the second bearing shell body according to the set number, deviation, so that sliding and deformation of the plastic bags are avoided, and accordingly the plastic bags stacked according to the set number can be stably conveyed; and meanwhile, the baffle, the first bearing shell body and the second bearing shell body can work at the same time through the output belt, so that the overall integration degree is high, complexity is reduced, and equipment reliability is improved.

Owner:泰州海达塑胶包装有限公司

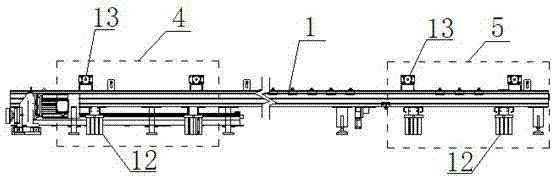

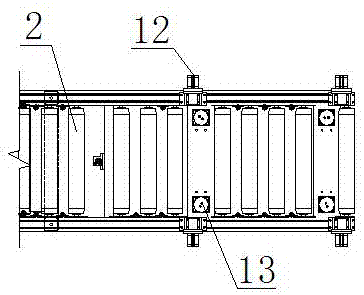

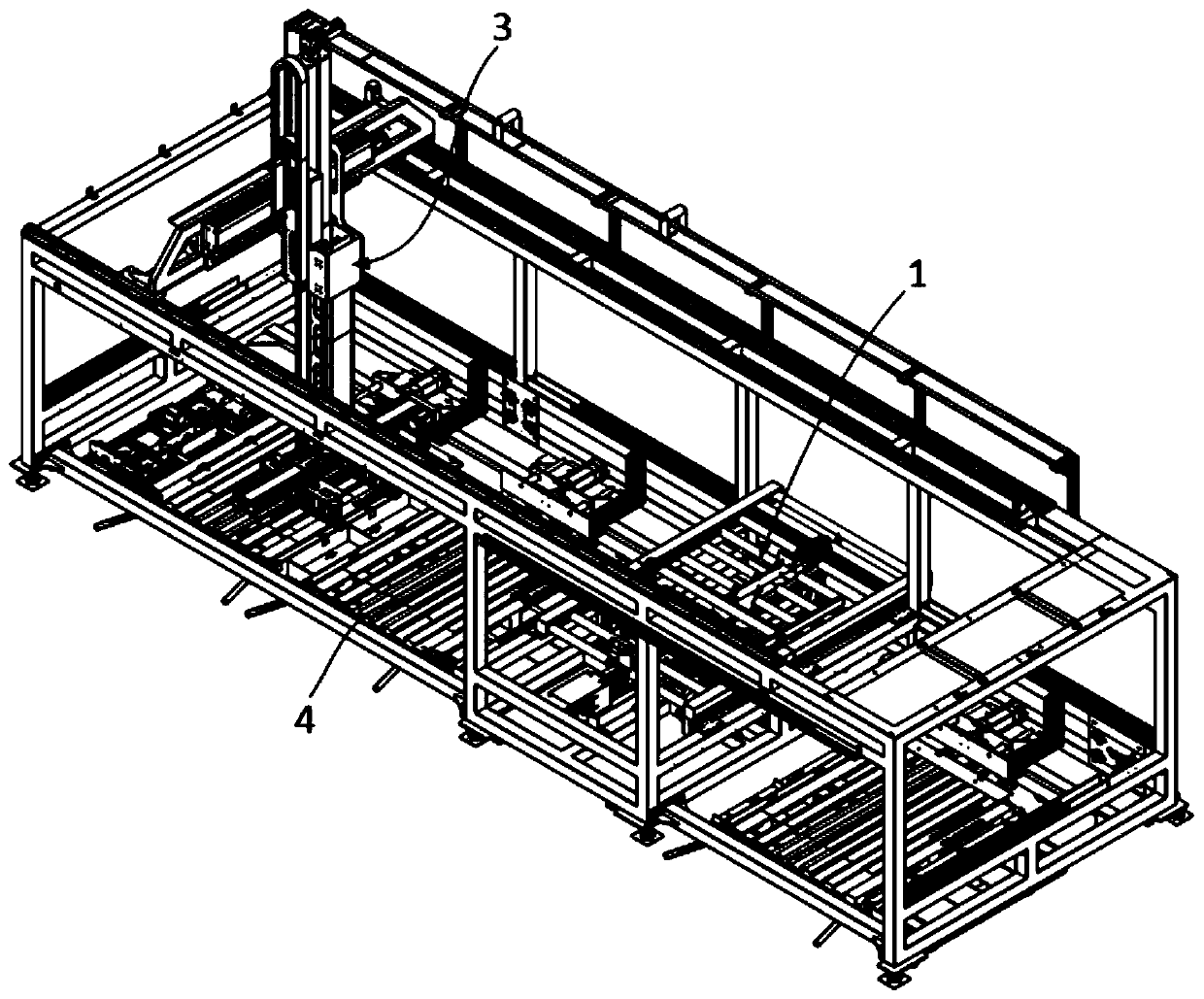

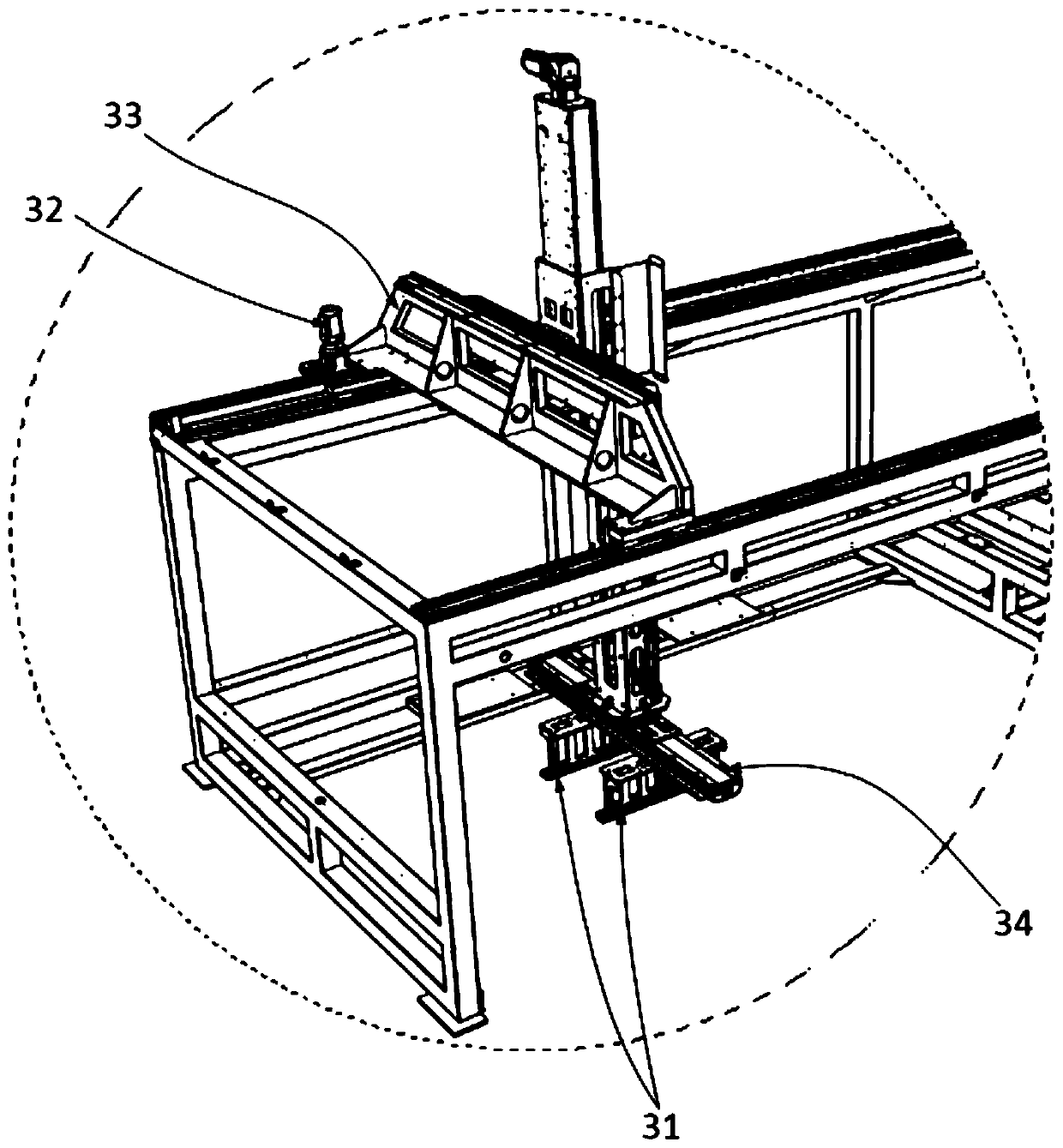

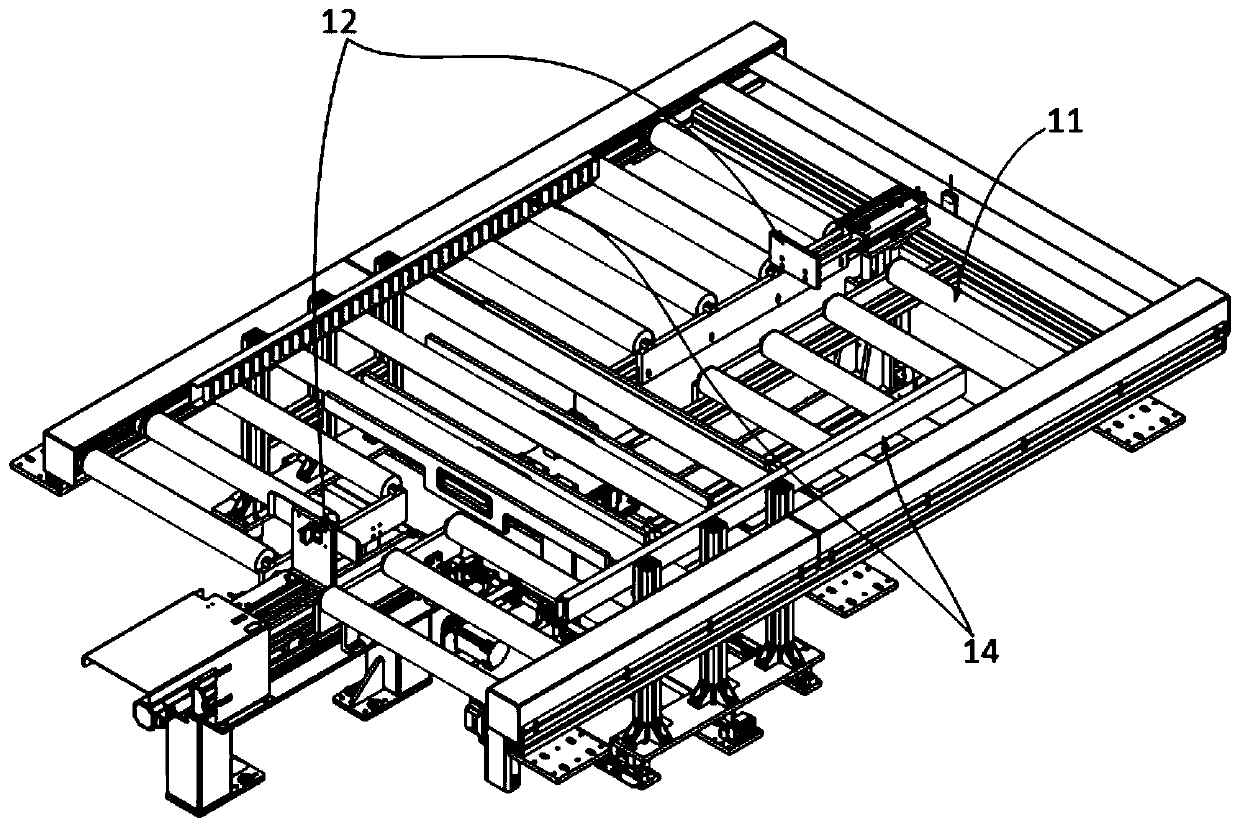

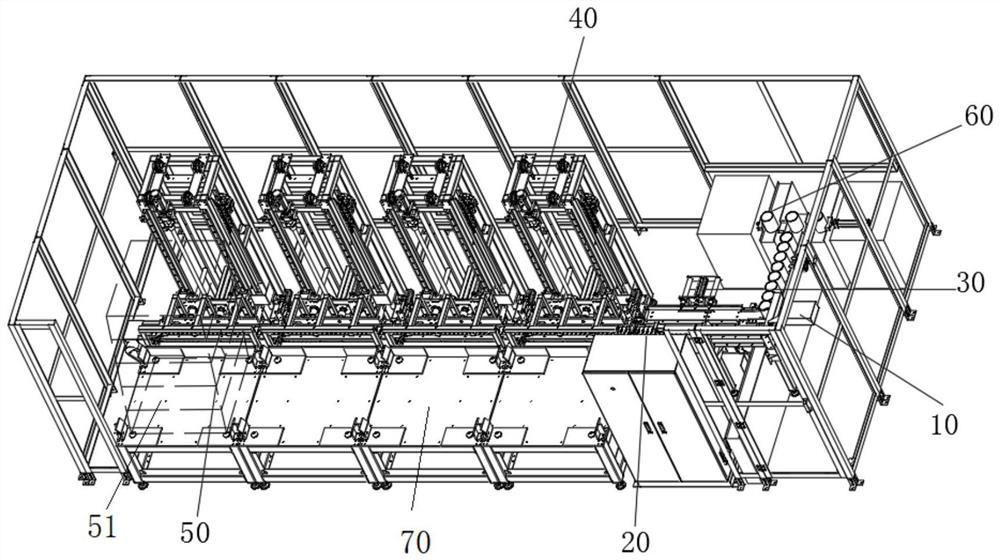

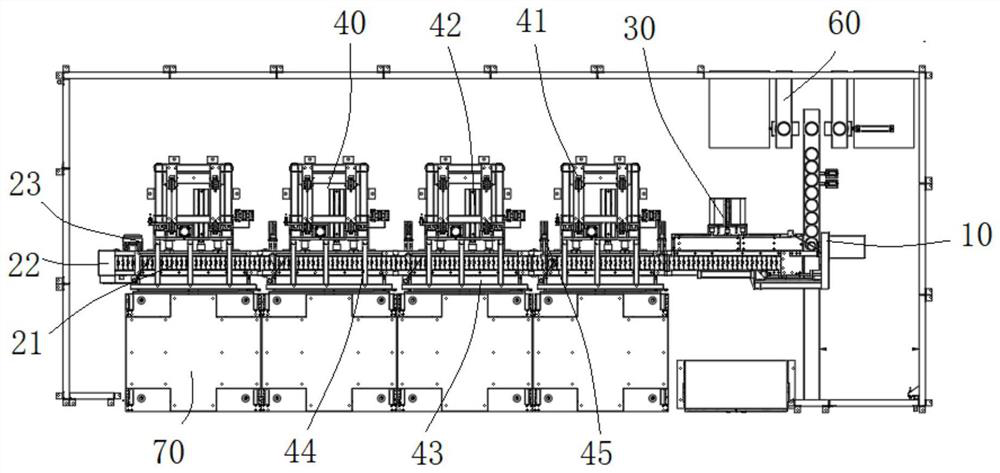

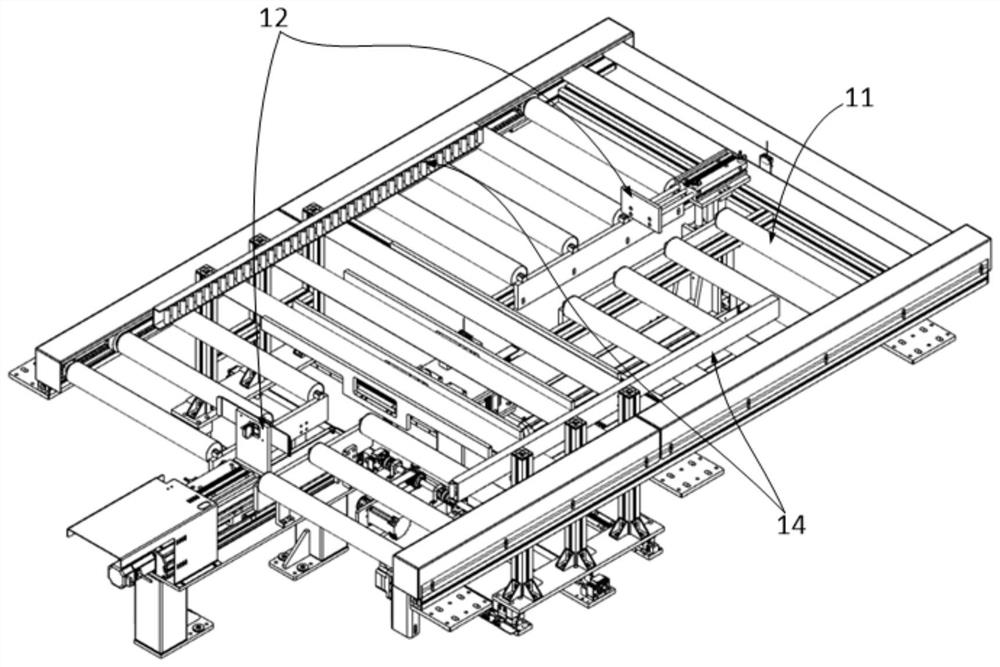

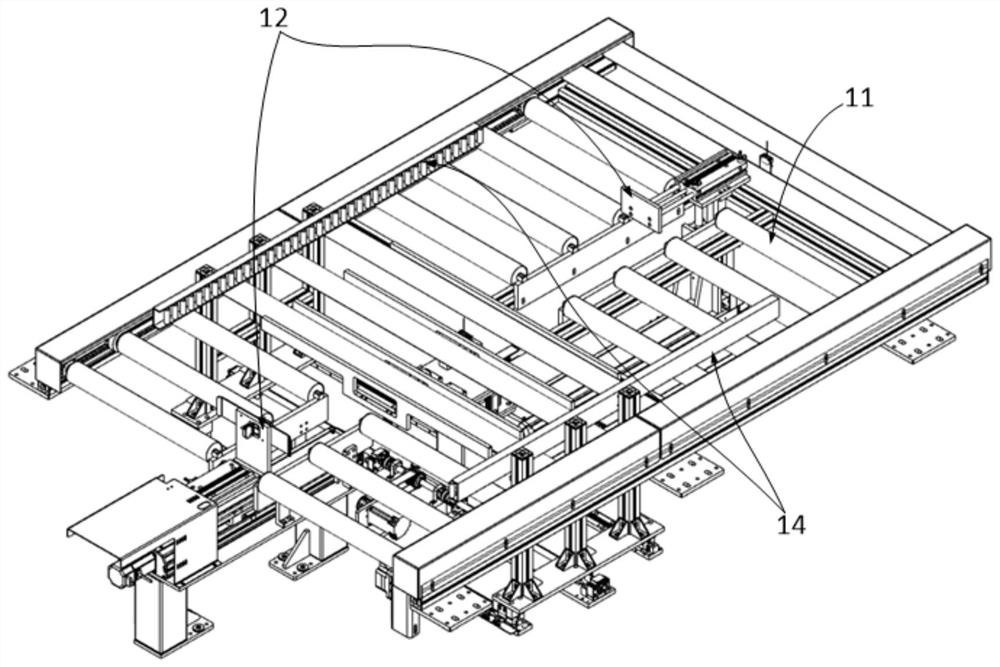

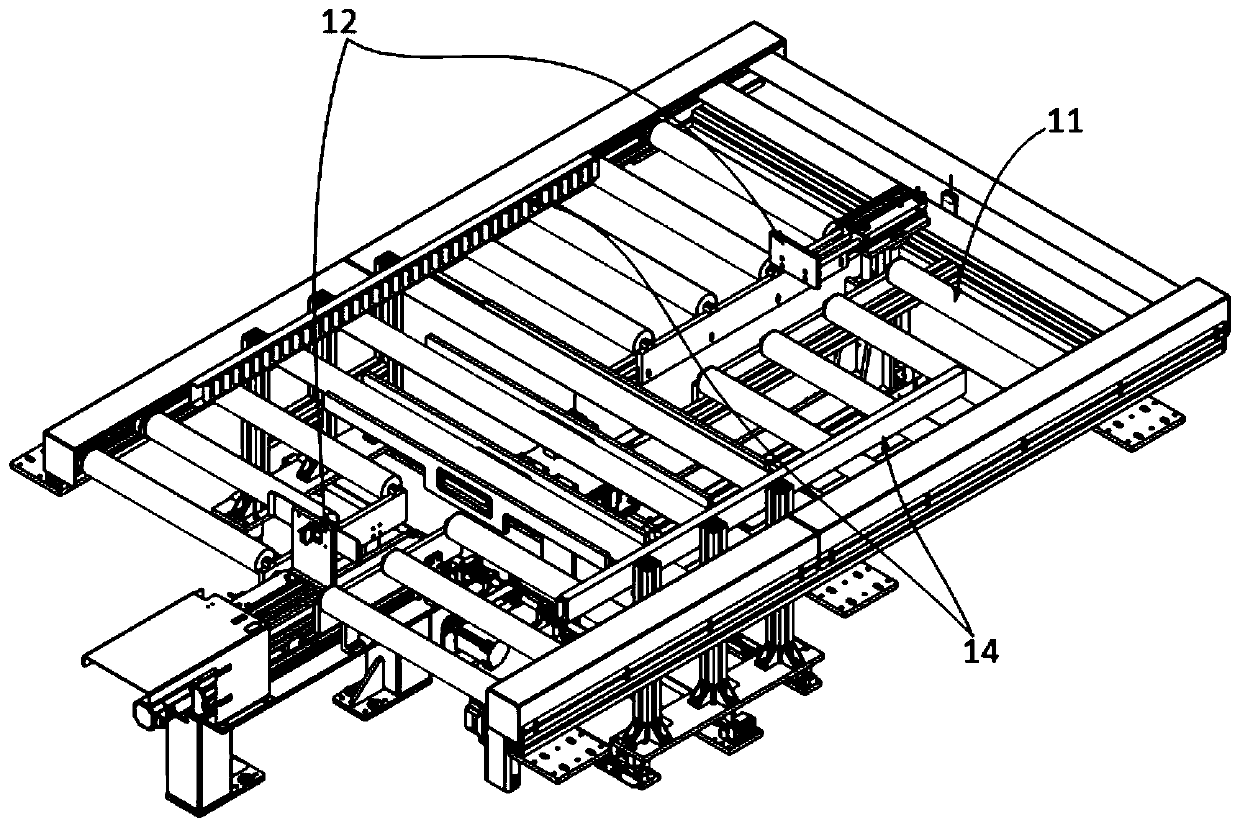

Automatic pallet unstacking and stacking roller conveying line and conveying method

ActiveCN108002055ACompact and reasonable structureReduce manufacturing costStacking articlesDe-stacking articlesProduction lineEngineering

The invention discloses an automatic pallet unstacking and stacking roller conveying line and a conveying method. The automatic pallet unstacking and stacking roller conveying line comprises a push mechanism and a non-power conveying line. The non-power conveying line comprises a track composed of rollers and a support. An unstacking mechanism is arranged at one end of the non-power conveying line. A stacking mechanism is arranged at the other end of the non-power conveying line. By means of the device, a brand-new conveying mode is provided, firstly the whole production line is filled with product pallets, products are put on the pallets and conveyed without manual push and rotating of the power rollers, a power device is mounted at the starting end of the whole conveying line and used for pushing the product pallets, and the products are conveyed through mutual push of the pallets; when the empty pallets are conveyed to the tail end of the conveying line, an automatic stacking deviceis mounted at the tail end of the conveying line, and the pallets can be stacked in piles; when the stacked pallets reach a certain numerical value, the pallets are conveyed to the front end of the conveying line through trolleys, the pallets are pushed to the conveying line one by one through the automatic unstacking device at the front end of the conveying line and the power device, and cycle use of the pallets is achieved; and by means of the manner, the labor intensity can be lowered, the production cost is reduced, the use efficiency is improved as well, and the pallets can be unstackedand stacked automatically.

Owner:山东泰开箱变有限公司

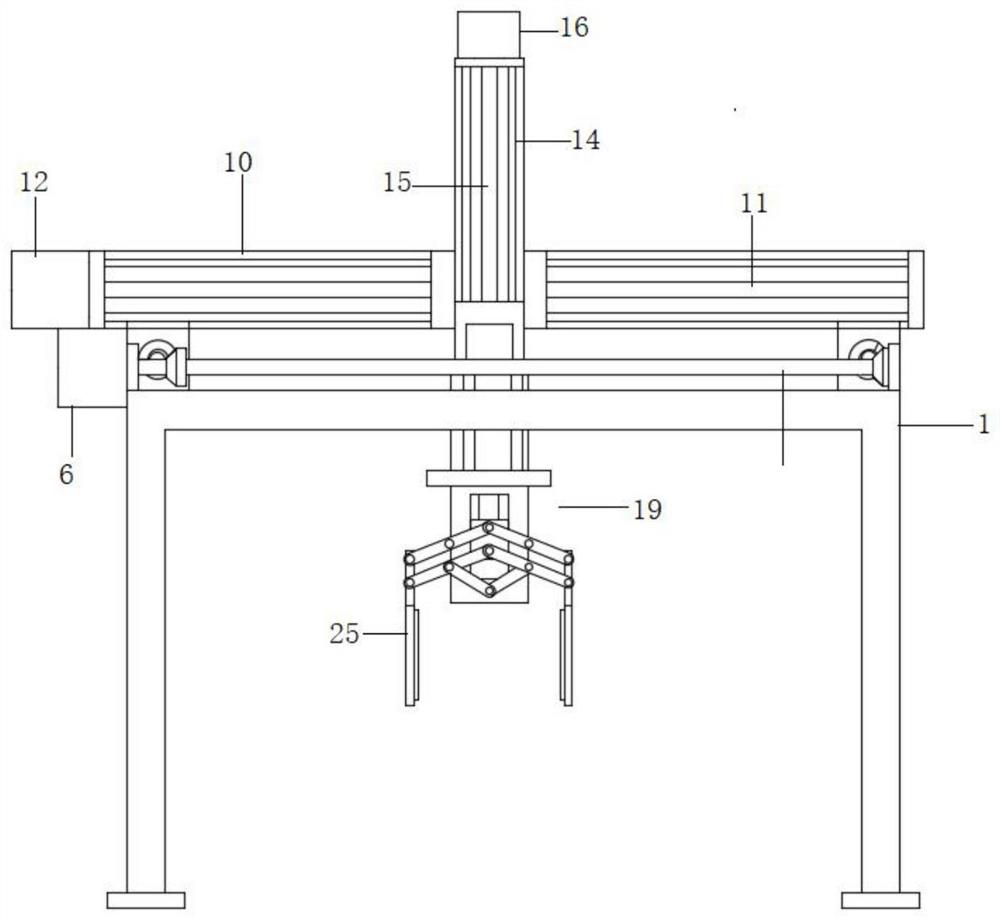

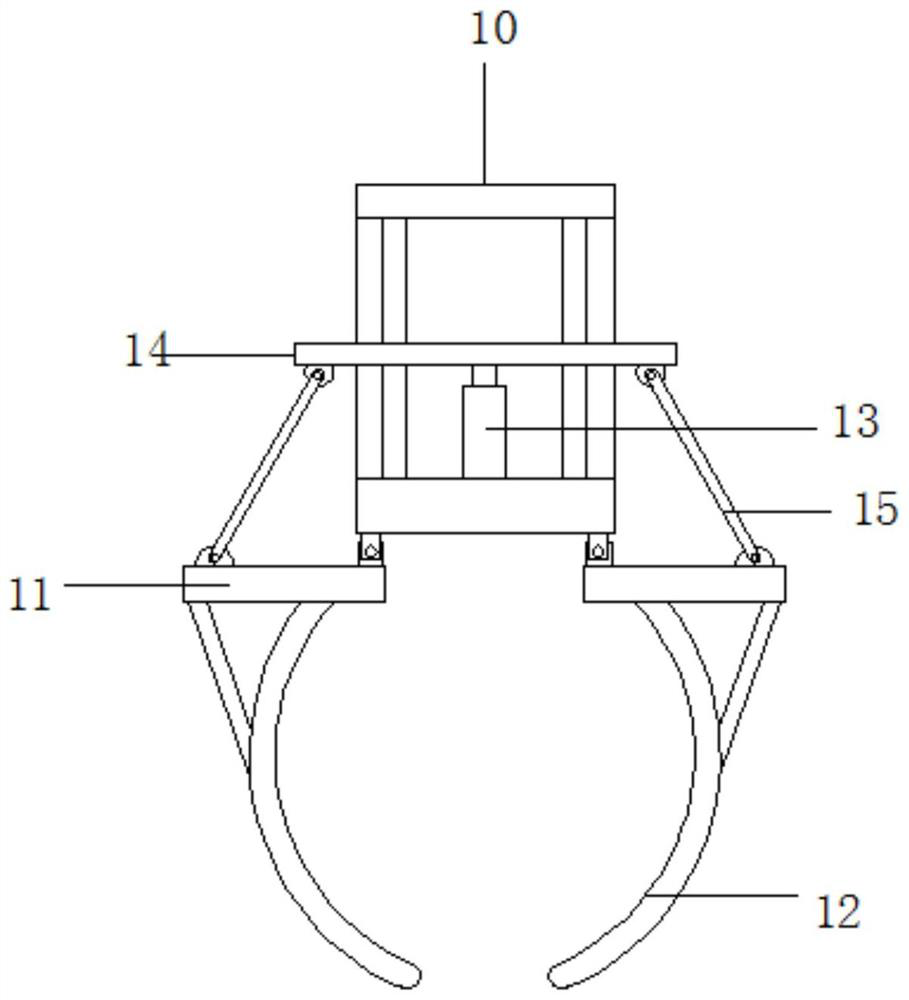

Automatic stacking machine based on storage battery production

InactiveCN113335919ARealize palletizingImprove palletizing efficiencyStacking articlesConveyor partsElectric machineGear wheel

The invention discloses an automatic stacking machine based on storage battery production, and relates to the technical field of automatic equipment. The automatic stacking machine comprises a rack, wherein a pair of first lead screws is symmetrically and fixedly connected to the rack; a rotating shaft is fixedly connected to one end of the rack; a first motor is connected to one end of the rotating shaft; a first gear is fixedly connected to one end of each first lead screw; a second gear is fixedly connected to the rotating shaft; first sliding blocks are connected to the first lead screws in a threaded mode; a first driving mechanism is fixedly connected between the two first sliding blocks; a vertical second driving mechanism is fixedly connected to the first driving mechanism; and a grabbing assembly is fixedly connected to the second driving mechanism. According to the automatic stacking machine, through cooperation of the first driving mechanism and the second driving mechanism, the grabbing assembly can move in the transverse direction, the longitudinal direction and the vertical direction, so that stacking of storage batteries is achieved, and the stacking efficiency of the storage batteries is improved.

Owner:ANHUI HONGDA ELECTRICAL SOURCE

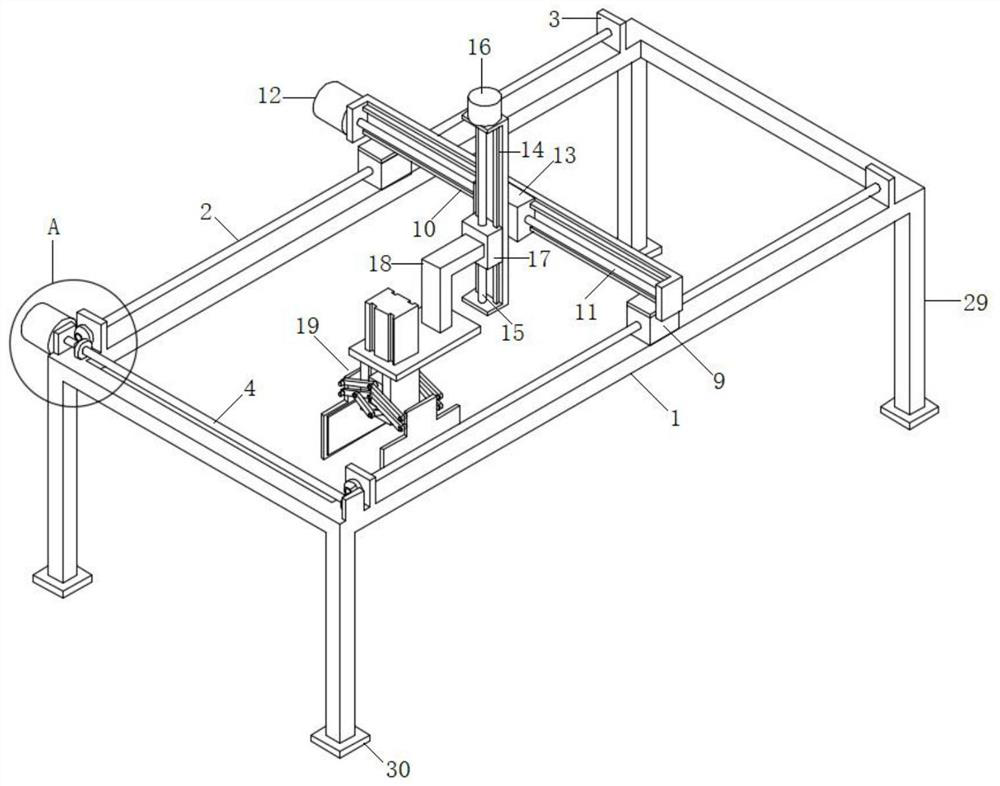

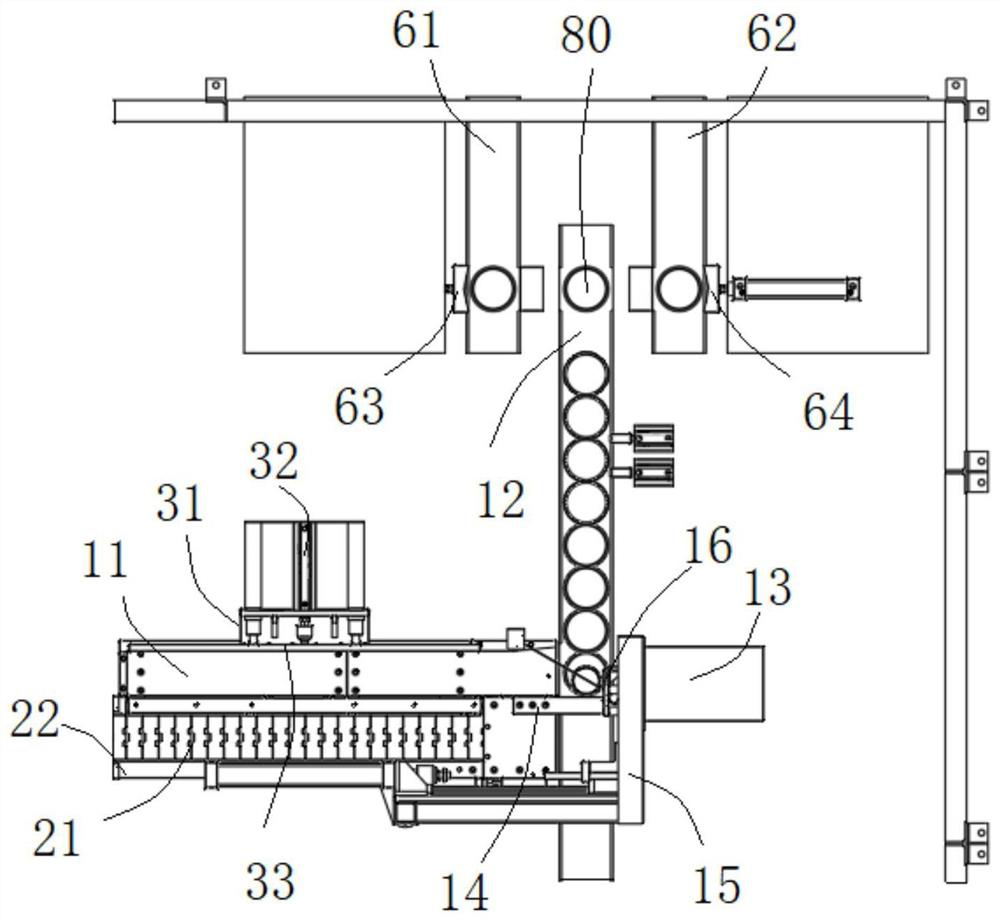

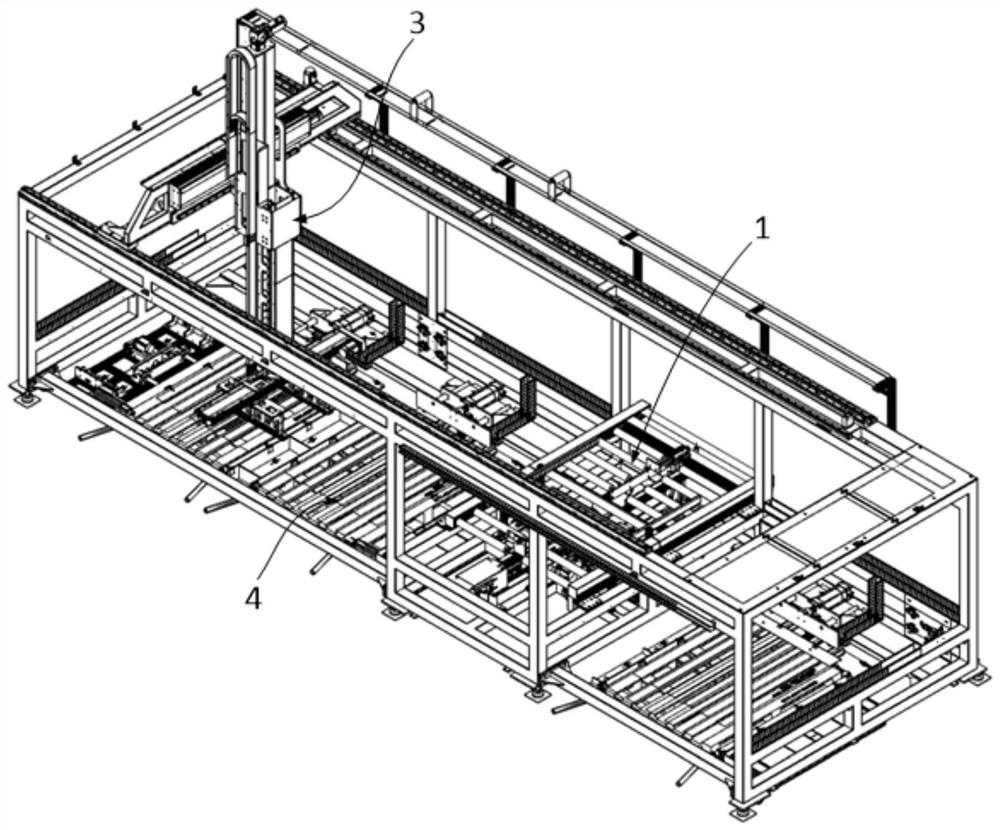

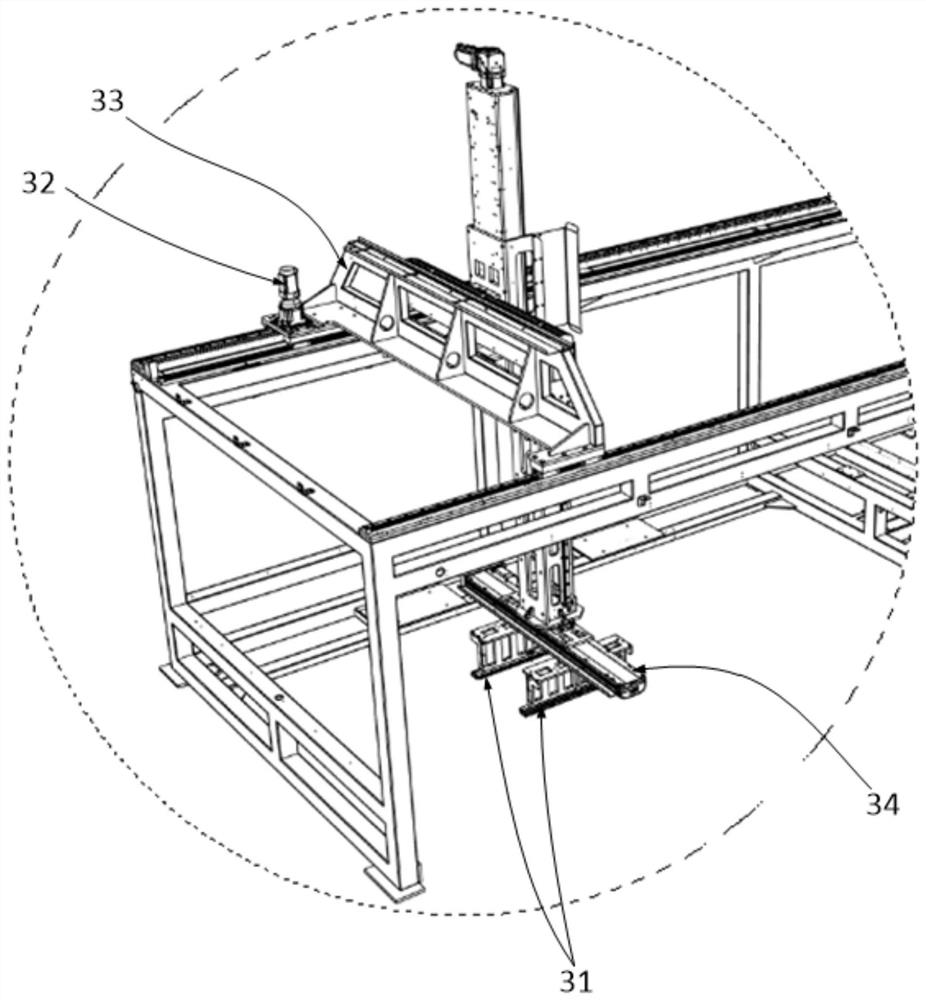

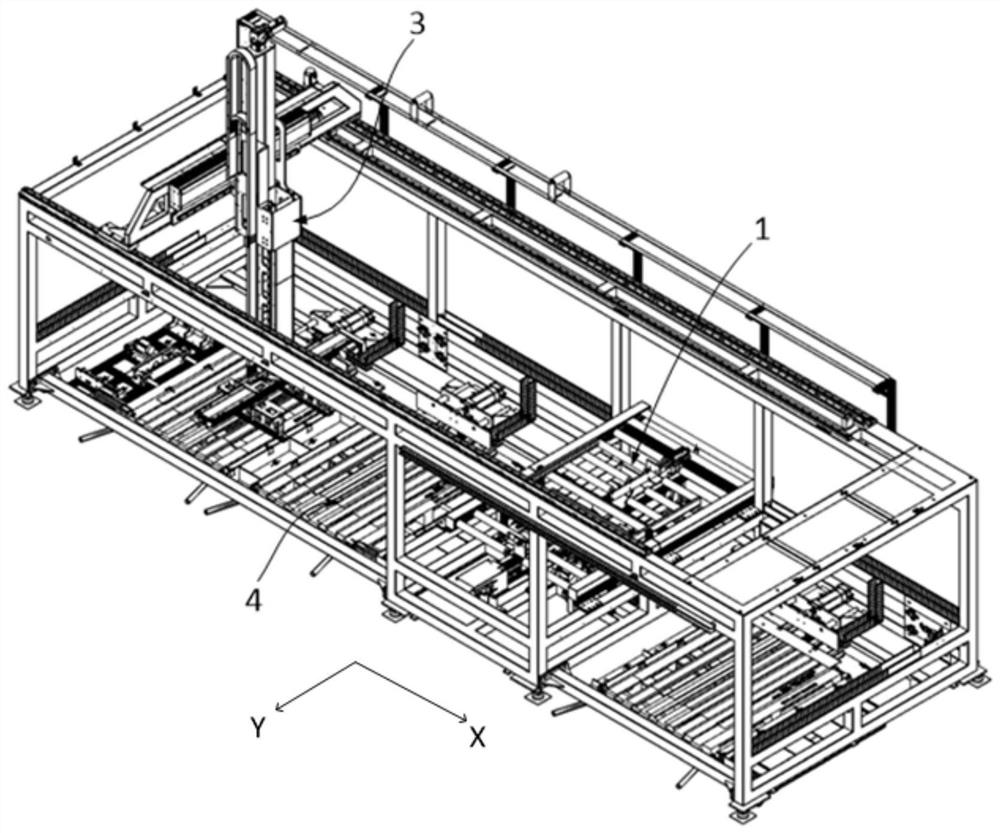

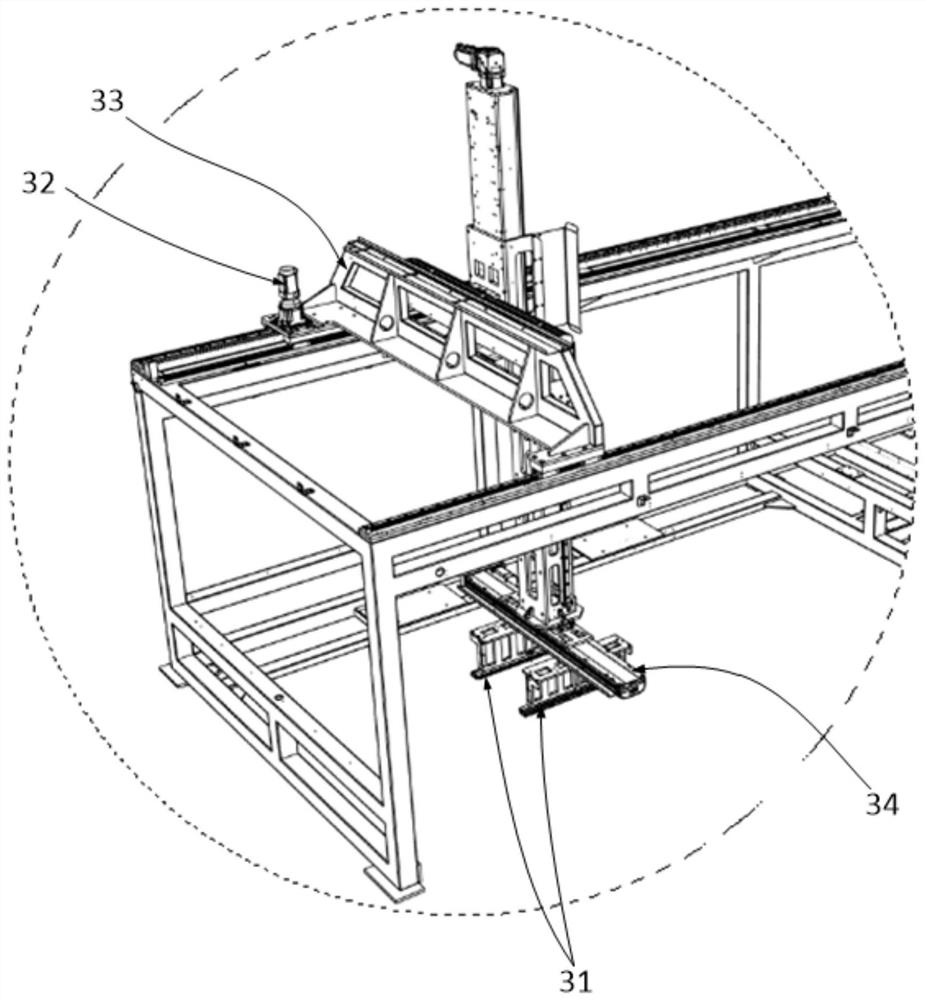

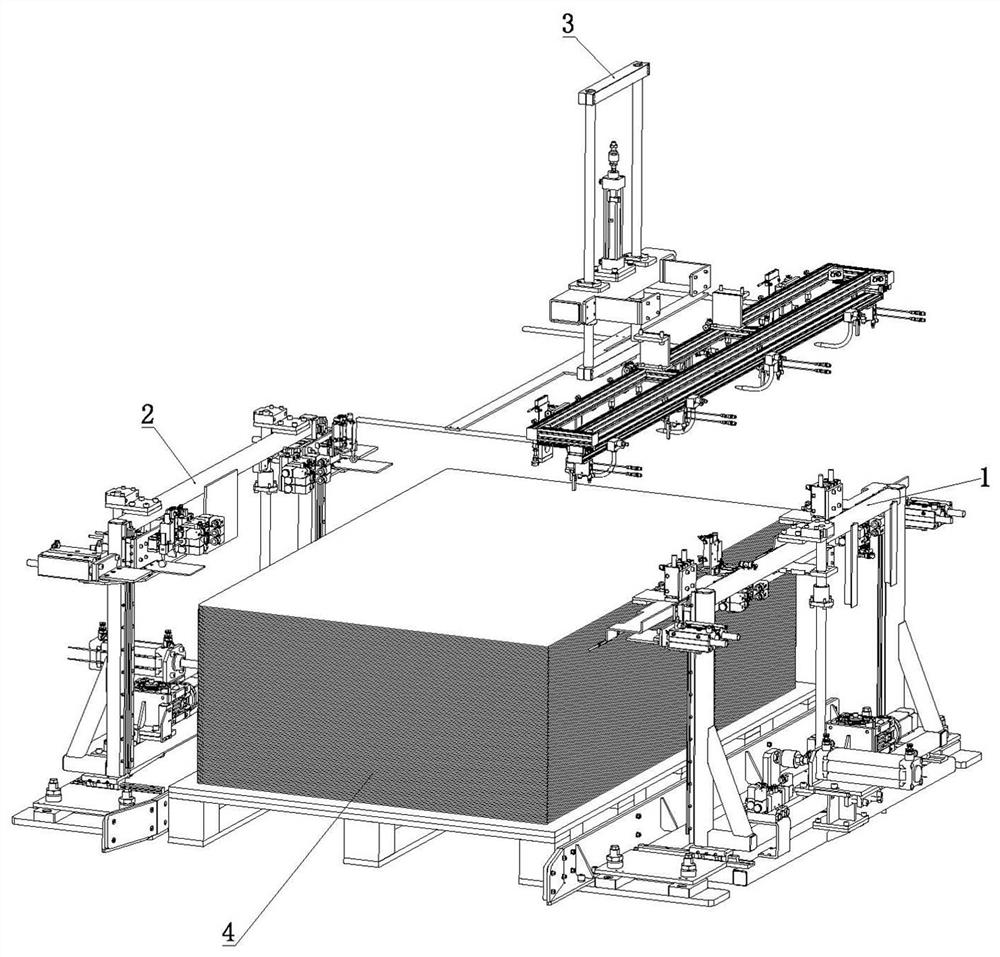

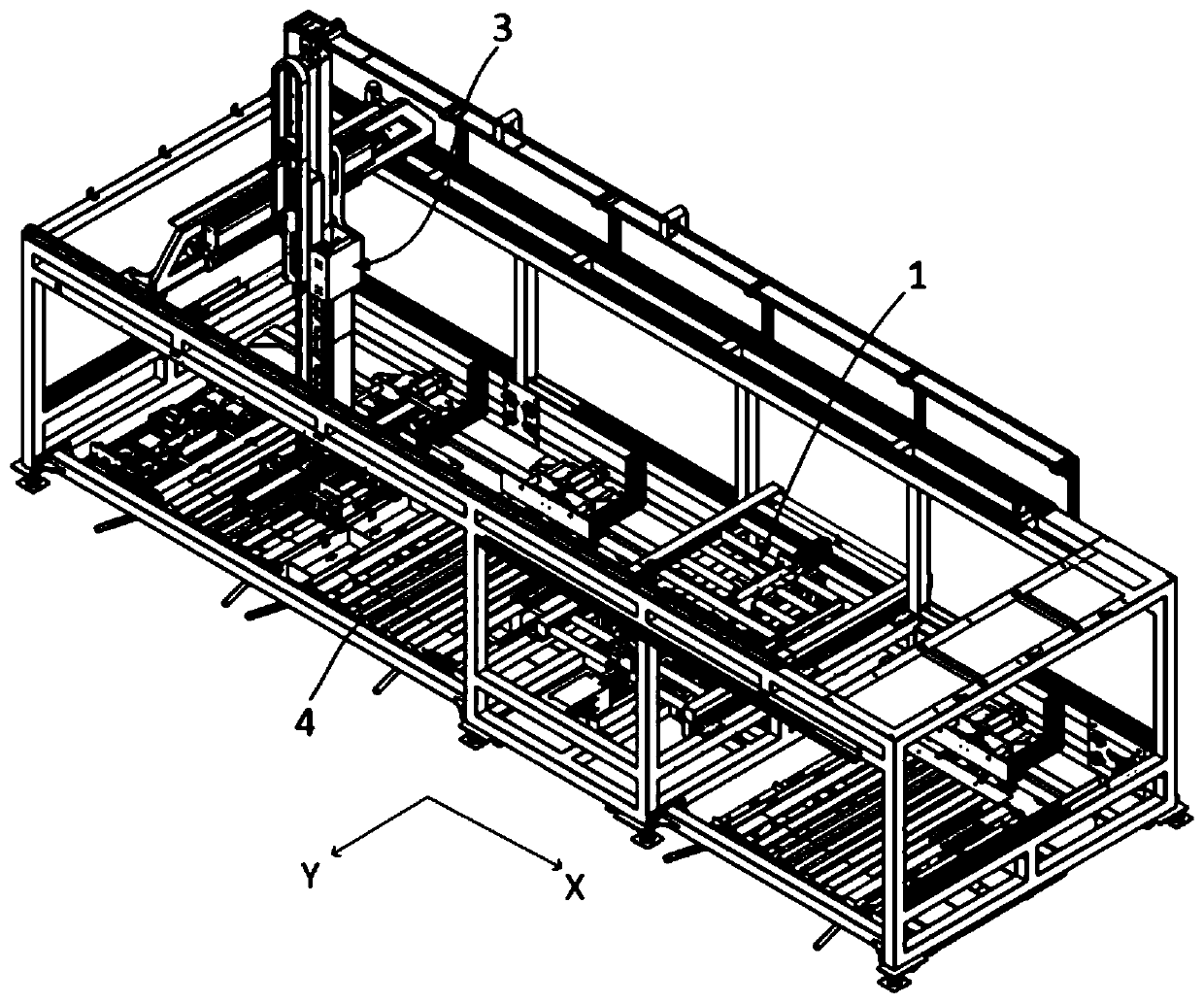

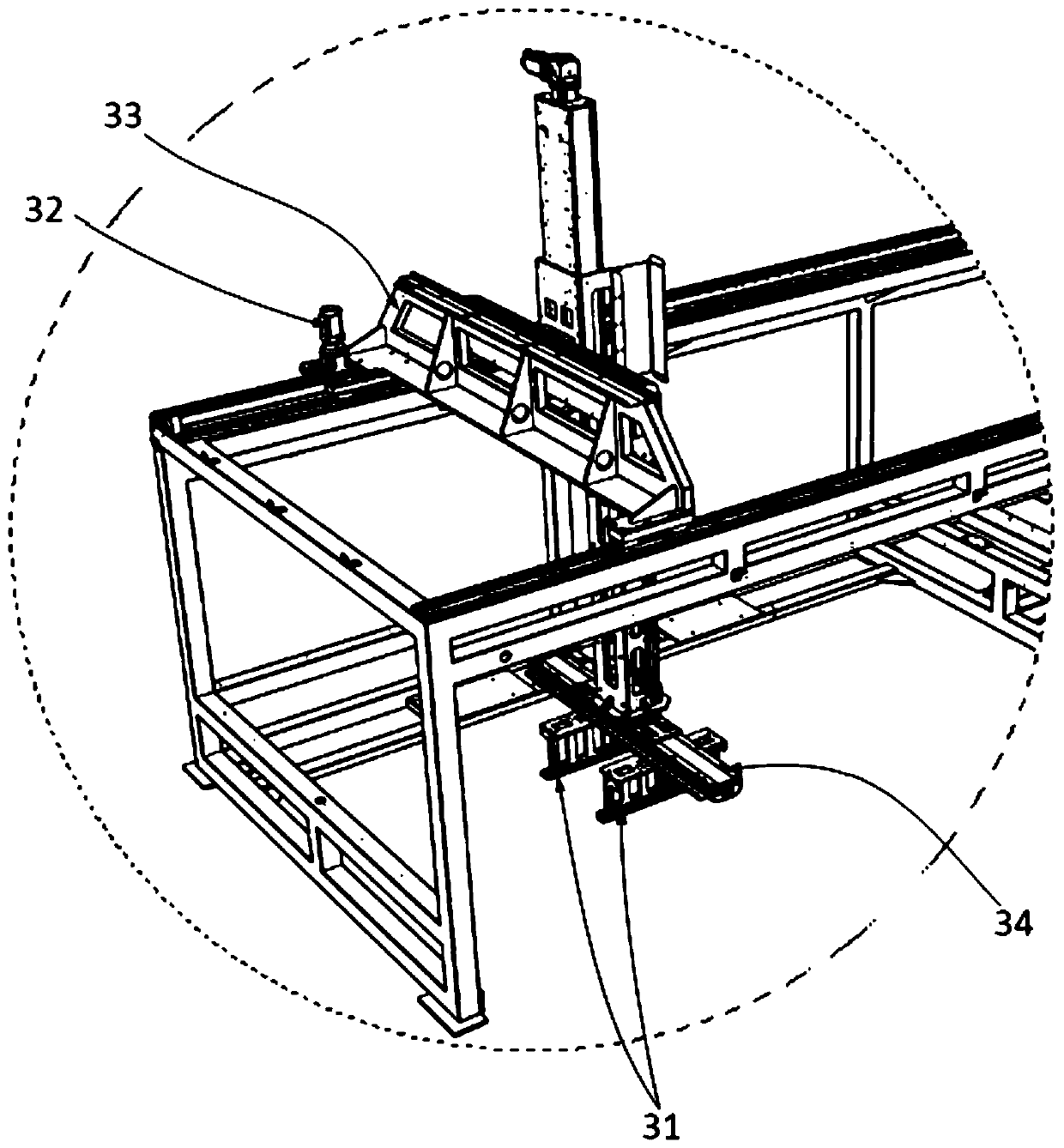

Automatic stacking and palletizing device

ActiveCN110589501AIncrease the difficultyReduce complexityStacking articlesDe-stacking articlesEngineeringFixed position

The invention relates to an automatic stacking and palletizing device. The automatic stacking and palletizing device comprises a frame, a supplied material roller line, a grabbing conveying mechanismand a pallet, wherein the supplied material roller line is used for receiving material boxes and comprises a conveying line support, a plurality of rollers arranged between the two ends of the conveying line support, a pair of first push plates positioned at the two ends of the conveying line support and a pair of second push plates positioned at the two sides of the conveying line support; the material box can be switched in the X direction and the Y direction; the grabbing conveying mechanism is connected to the frame and can perform triaxial movement; the lower end of the grabbing conveyingmechanism is provided with a grabbing part for grabbing the material boxes; and the pallet is arranged below the frame and used for bearing the stacked material boxes. The material boxes can be positioned on the periphery once before mechanical arms grab the material boxes, so that each material box is at a fixed position, the difficulty of grabbing the material boxes by the mechanical arms is greatly reduced, and the complexity of a control program is reduced as well.

Owner:SUZHOU JINGLAI OPTO CO LTD

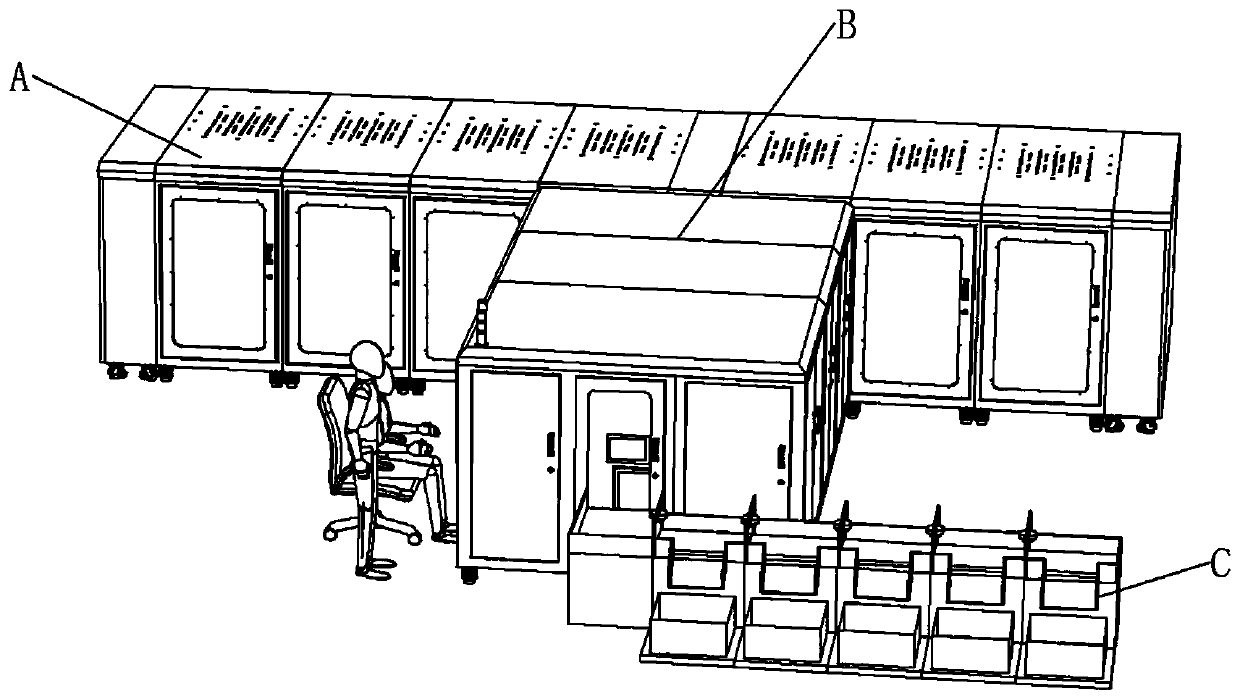

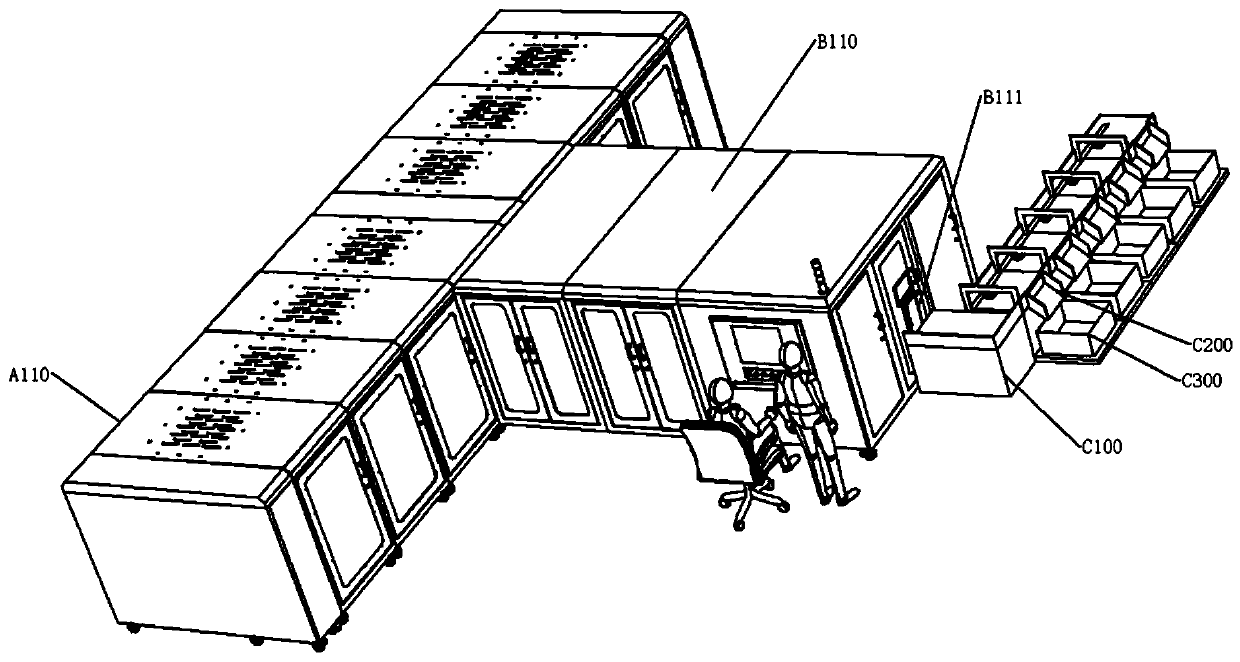

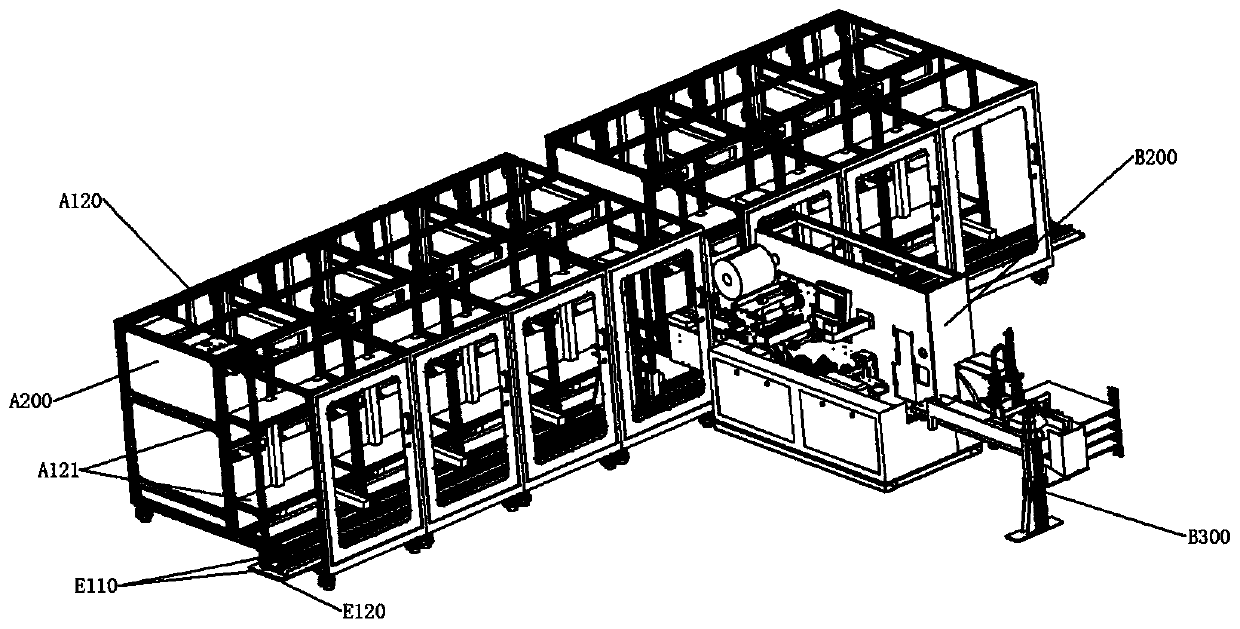

Mechanical arm and multi-currency distribution line applying same

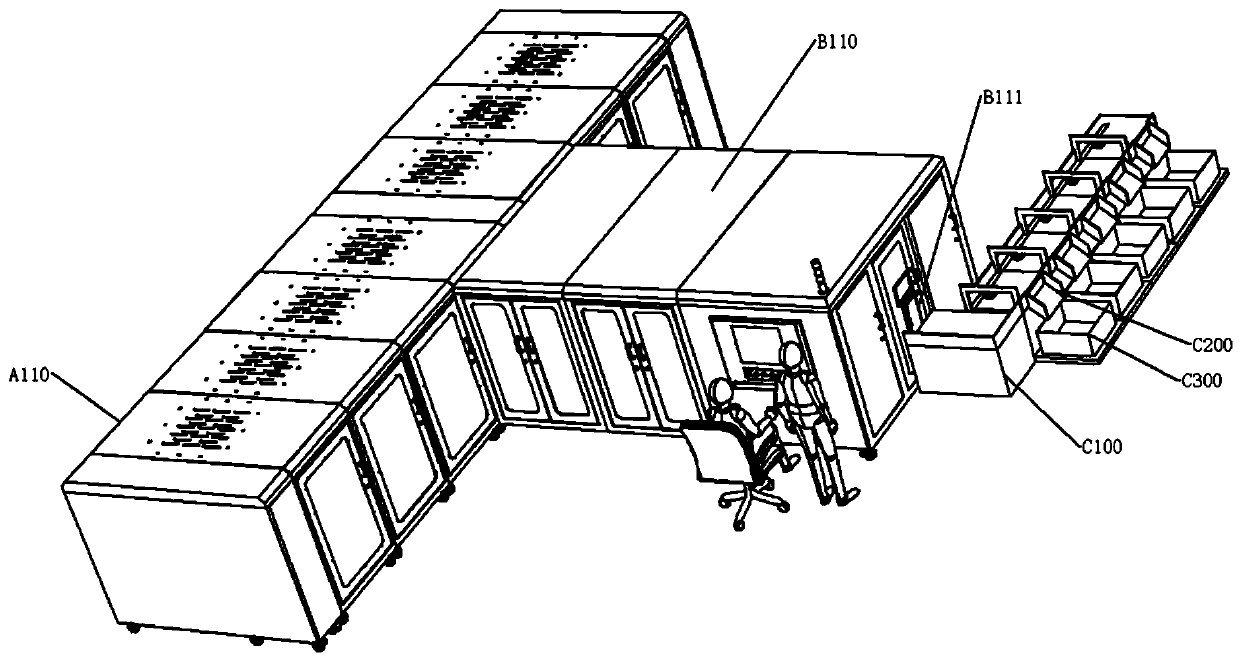

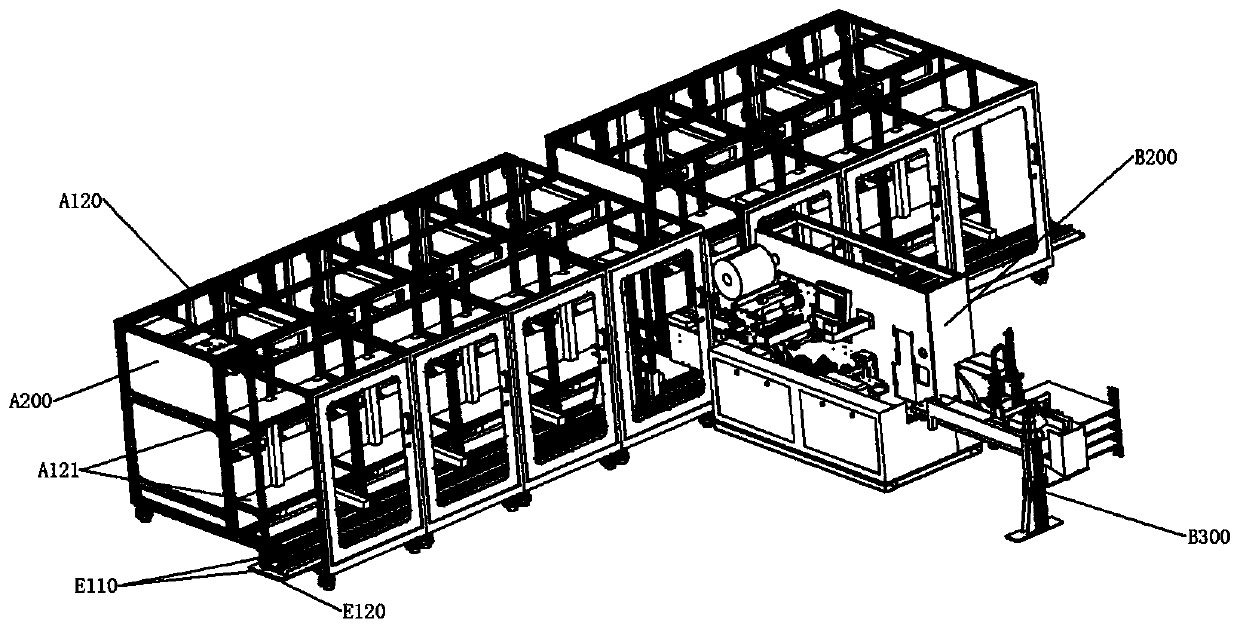

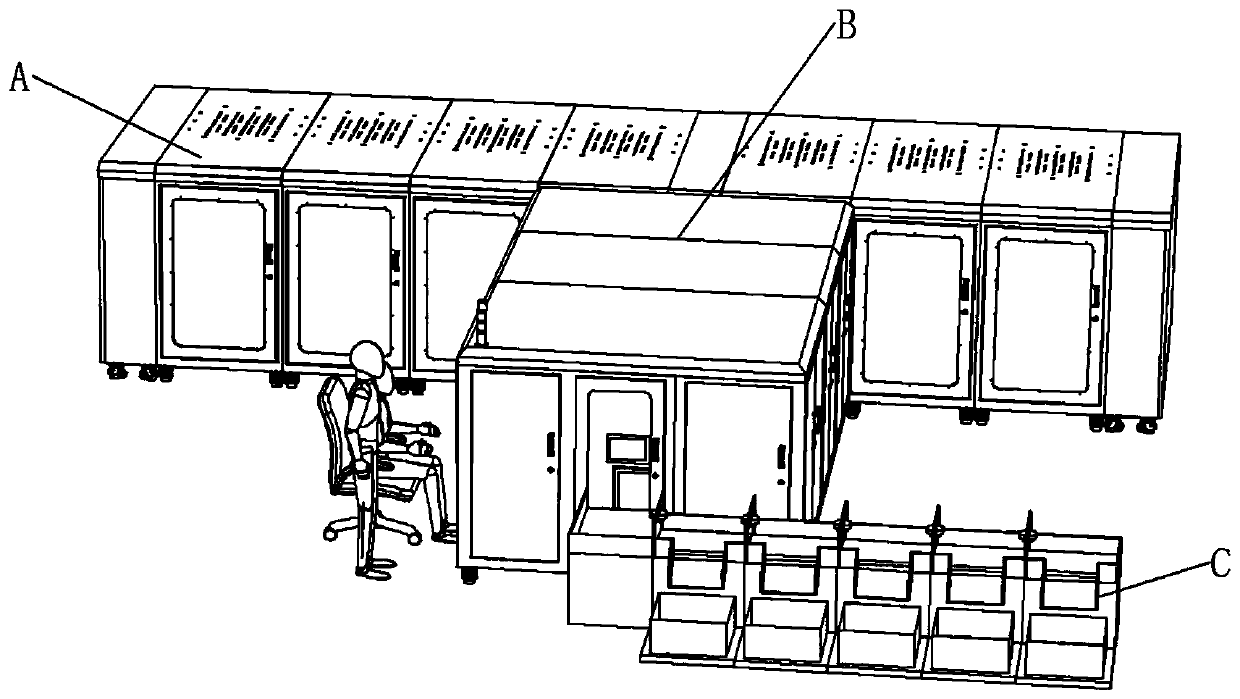

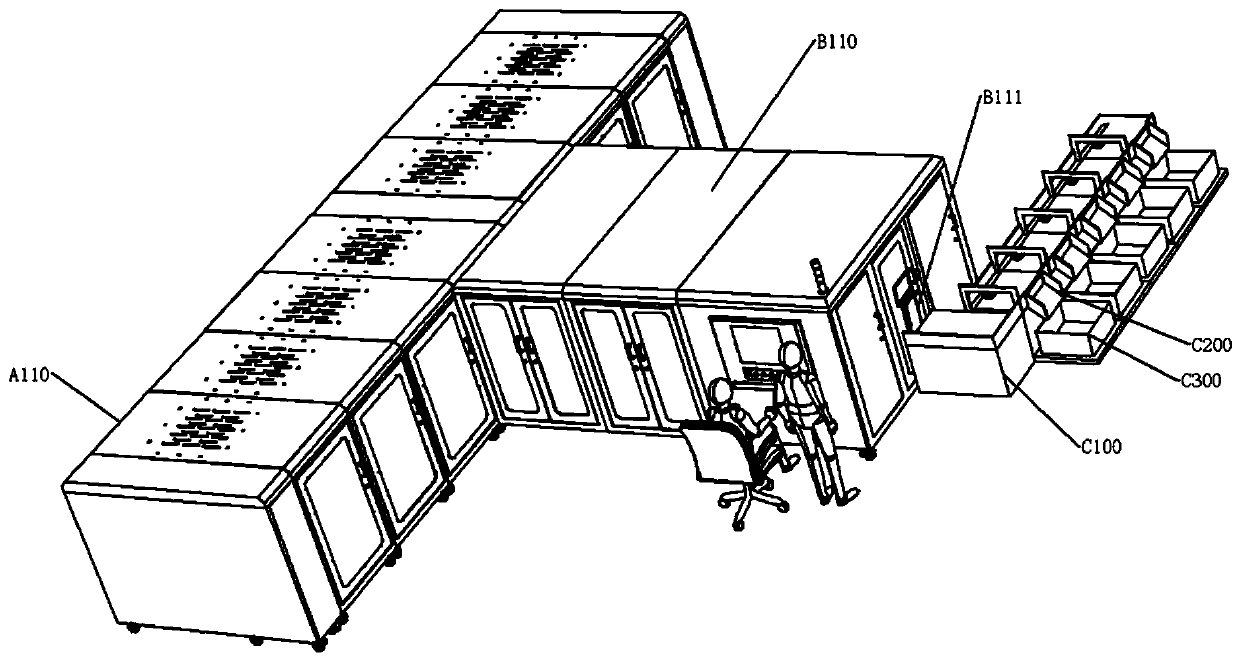

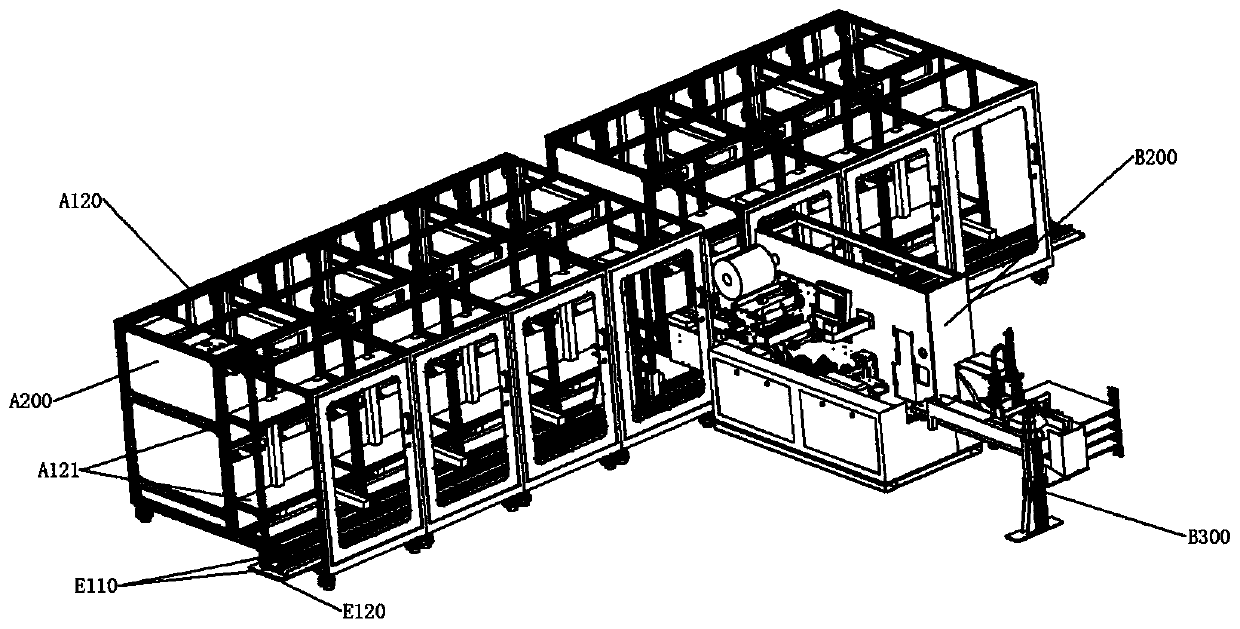

PendingCN110606313AImprove banknote distribution efficiencyReduce human errorStorage devicesConveyor partsPlastic packagingEngineering

The invention discloses a mechanical arm and a multi-currency distribution line applying the same. The multi-currency distribution line comprises a machine core module, a plastic packaging module, a sorting line and the mechanical arm; the machine core module is used for storing paper currency and outputting the currency into currency receiving hoppers according to system instructions; the mechanical arm is used for conveying the currency in the currency receiving hoppers into a plastic packaging feeding mechanism of the plastic packaging module; a plastic packaging machine performs plastic packaging on the stacked currency and then outputs the currency to a stacking mechanism; the stacking mechanism stacks same types of the currency and then outputs the currency from a currency outlet onto a sorting conveying mechanism of the sorting line; and the side surface of the sorting conveying mechanism communicates with sorting frames through inclined sorting plates. According to the line, array type machine cores are arranged and are used for storing different currency respectively, and then the currency output by the different machine cores is conveyed by the mechanical arm to the plastic packaging module for plastic packaging and then is conveyed to the sorting line, so that currency distribution, packaging and sorting are completed in one step, the currency distribution efficiencycan be greatly improved, and the artificial errors caused by manual operation can be reduced to the maximum extent.

Owner:WEIRONG TECH CO LTD

Small green orange gift case packaging machine

PendingCN111907736APrevent the gift box from being damagedFalling smoothlySolid materialPackaging fruits/vegetablesElectric machineryDrive motor

A small green orange gift case packaging machine comprises a frame supporting mechanism, a sucking mechanism, a finished product arranging mechanism, a case cover placing mechanism, a gift case placing mechanism and a feeding mechanism, wherein the sucking mechanism is used for sucking and buckling customized case covers; the finished product arranging mechanism is used for arranging and stackingfinished products; the gift case placing mechanism is placed on the front end face of a box body, and pushes customized gift cases; and the case cover placing mechanism and the sucking mechanism are matched in use, and the case cover placing mechanism lifts the customized case covers to the height where the the sucking mechanism can suck the customized case covers. According to the packaging machine, a case cover driving motor drives a conical wheel on a lead screw at the bottom end of a case cover conveying frame, then a lead screw sliding plate of the case cover conveying frame conveys the customized case covers upwards, an electric motor drives a gear A to make a support slide on long sliding rods, the moving position of a suction cup is adjusted, and the customized case covers sucked by the suction cup are pressed on the customized gift cases through stretching and retracting of an air cylinder.

Owner:陈虎

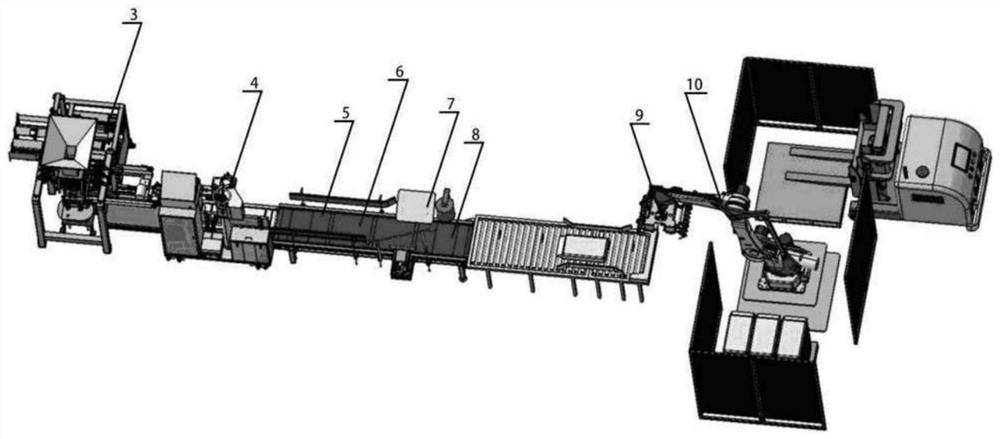

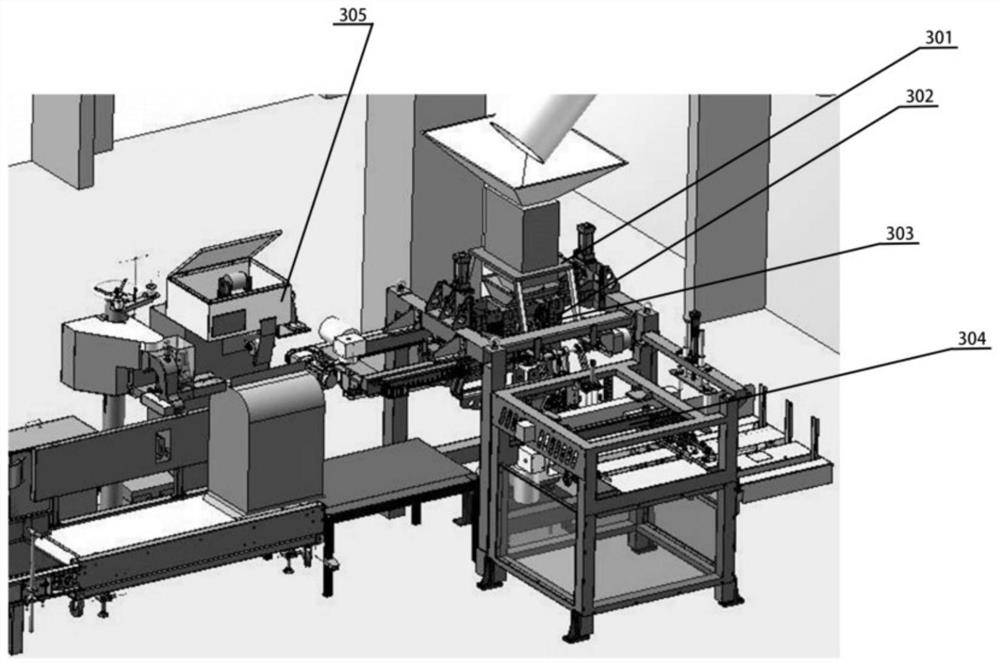

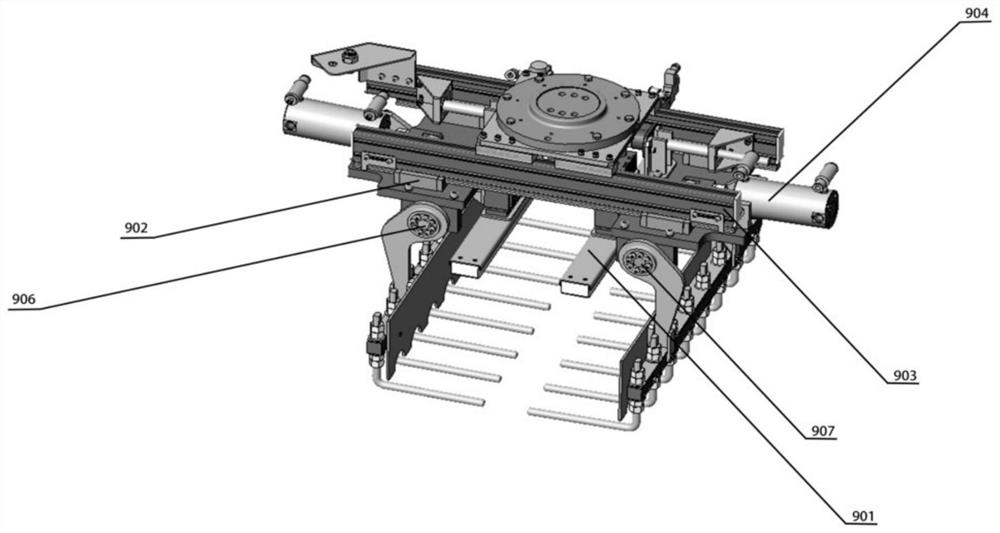

Full-automatic stacking robot system and using method

InactiveCN113306798AImplement packagingRealize palletizingWrapper twisting/gatheringStacking articlesRobotic systemsProcess engineering

The invention discloses a full-automatic packaging and stacking robot system and a using method, and relates to the technical field of packaging machine equipment. The system is composed of a packaging system and a stacking robot system. The packaging system comprises an automatic edge folding and bag sewing mechanism, a bag-to-bag conveying mechanism, a horizontal conveying mechanism, a shaping conveying mechanism, a bag pressing conveying mechanism and a code spraying conveying mechanism. The stacking robot system comprises a robot gripper and a stacking robot. According to the full-automatic packaging and stacking robot system and the using method, the packaging system and the stacking robot system are tightly matched so that the granular material bagging, sealing, stacking and packaging tasks can be completed, the production safety can be greatly improved, the manpower requirement of an enterprise in the product production process is reduced, the granular material bagging, stacking and packaging automation level and the production efficiency are improved, the storage area is saved, and the economic benefits are improved.

Owner:安徽华宇机械制造有限公司 +1

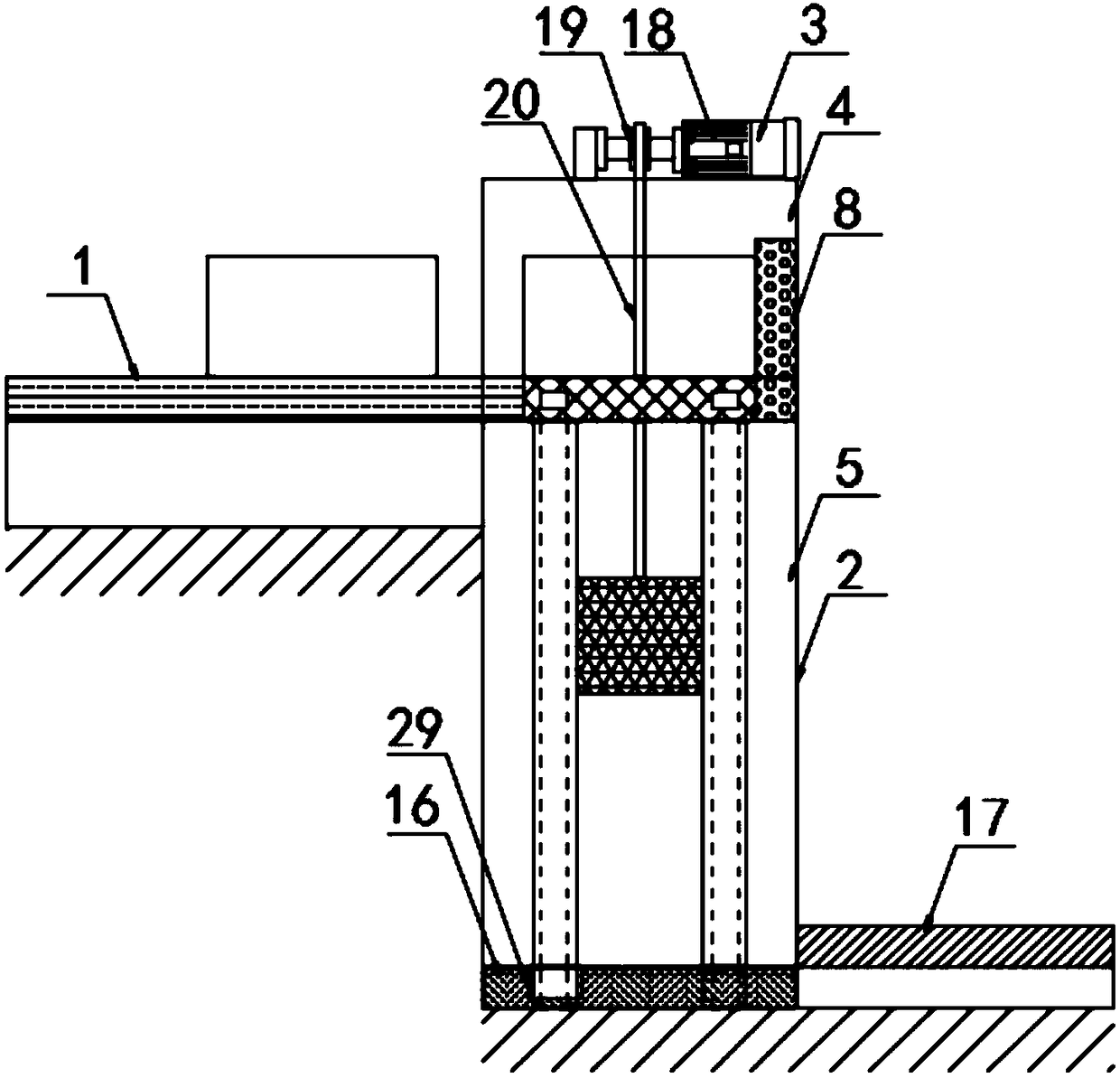

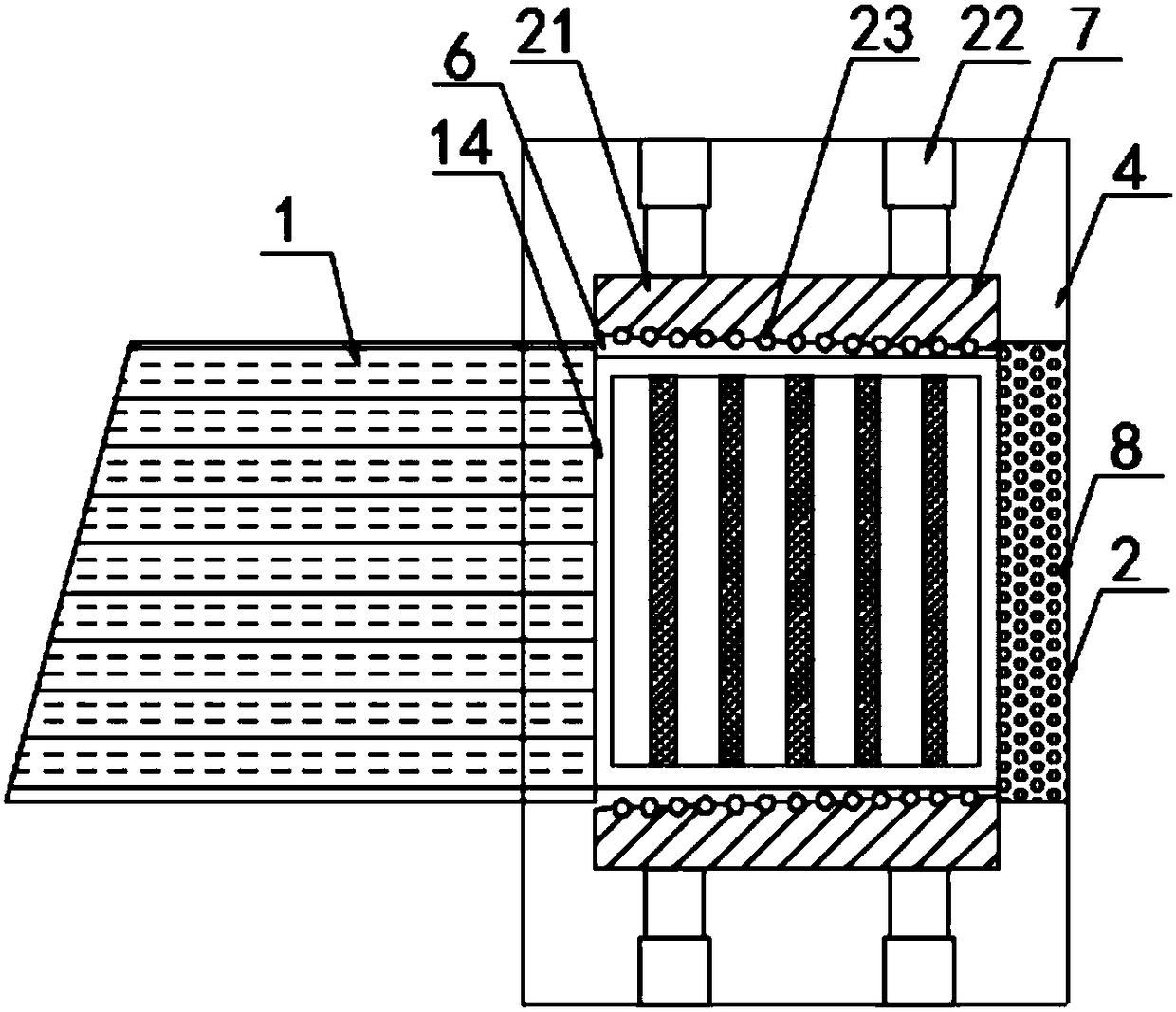

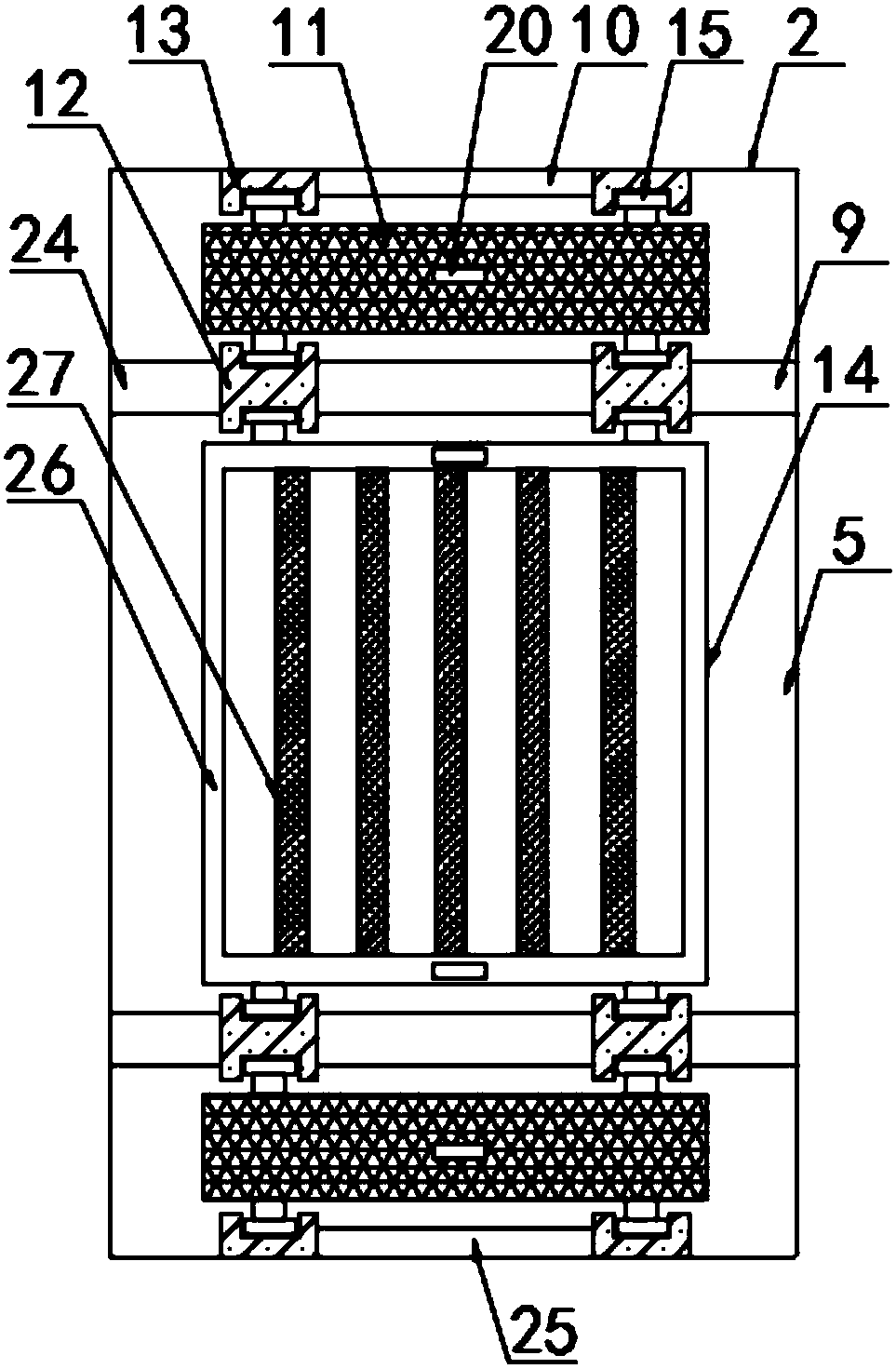

Automatic stacking device for inorganic fireproof expanded perlite insulation boards

The invention discloses an automatic stacking device for inorganic fireproof expanded perlite insulation boards. The automatic stacking device comprises a feeding conveyor belt, a load bearing shell is arranged on one side of the feeding conveyor belt, and a driving device is arranged at the top of the load bearing shell. The load bearing shell is internally provided with an upper material cavityand a lower material cavity, and the lower material cavity is disposed at the bottom of the upper material cavity. A through hole is formed between the upper material cavity and the lower material cavity. A limiting device and a cushion pad are disposed in the upper material cavity, and a first support frame group and a second support frame group are fixedly disposed in the lower material cavity.The second support frame group is disposed on the outer side of the first support frame group, and a counterweight block is arranged between the first support frame group and the second support framegroup. The first support frame group is provided with bi-directional guide rails, and the second support frame group is provided with unidirectional guide rails. Through the arrangement of the drivingdevice, no need for lifting materials for stacking work like a conventional stacking device is achieved; and the workload of the driving device can be reduced through the arrangement of the counterweight block, and energy consumption is reduced.

Owner:马鞍山市金韩防水保温工程股份有限公司

Ceramic large plate tile stacking device

PendingCN111731844AAutomatic palletizingRealize palletizingDischarging arrangementConveyorsCeramic industryComposite material

The invention provides a ceramic large plate tile stacking device. The ceramic large plate tile stacking device comprises a rack, a tile clamping mechanism arranged on the rack for clamping ceramic large plate tiles, a tile adsorbing mechanism arranged on the rack for adsorbing the ceramic large plate tiles, a tile pushing mechanism arranged on the rack for pushing the released ceramic large platetiles to be stacked when the tile adsorbing mechanism and the tile clamping mechanism release the ceramic large plate tiles, and a lifting and turning-over mechanism for driving the rack to ascend, descend and turn over. According to the ceramic large plate tile stacking device, the labor intensity of staff can be greatly reduced, and the automation degree of ceramic industry equipment is increased.

Owner:MONALISA GRP CO LTD

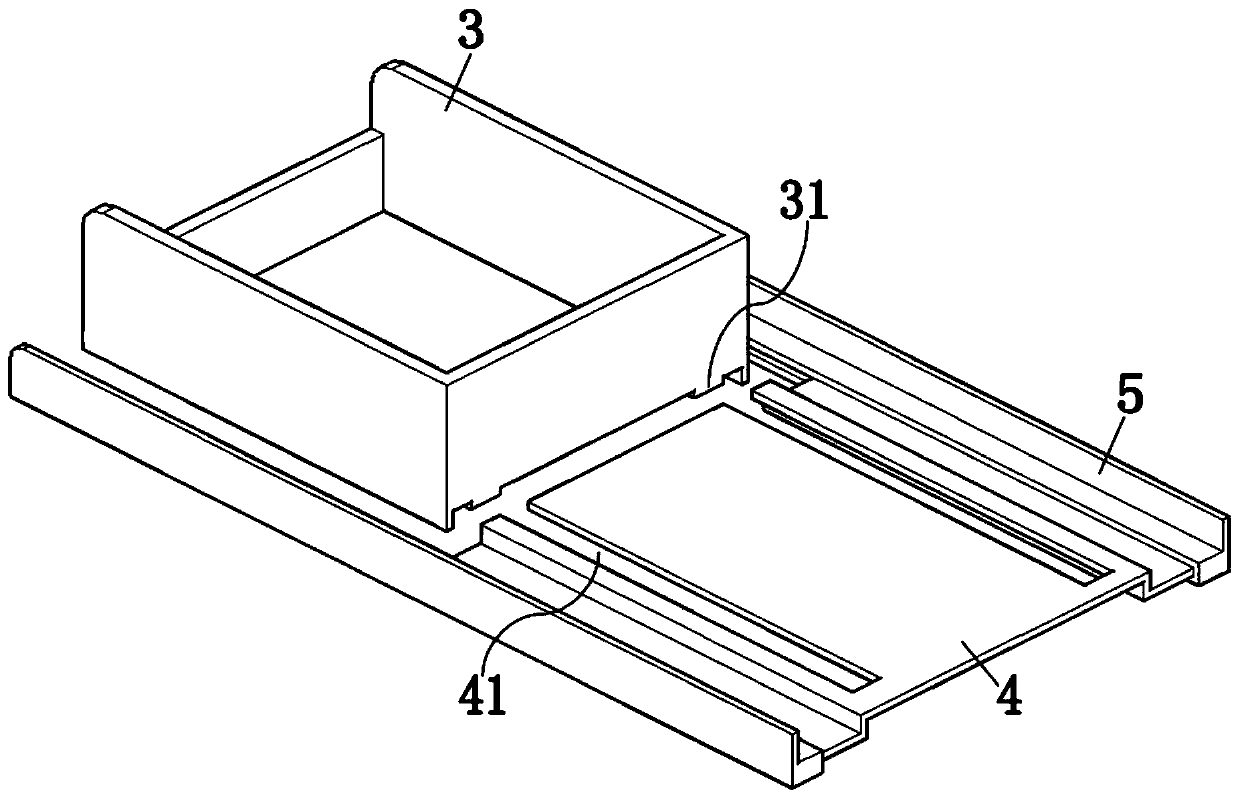

Automatic stacking and material collecting equipment

The invention discloses automatic stacking and material collecting equipment which comprises a material collecting assembly, a conveying assembly, a feeding assembly, a material pushing assembly and a material frame. The material collecting assembly is used for sequentially collecting and arranging a certain number of materials into material groups; the conveying assembly is used for conveying the material groups; the feeding assembly is used for pushing the material groups gathered on the material collecting assembly to the conveying assembly to be conveyed; the material frame is provided with at least one supporting plate in the height direction of the material frame, at least one material group is stacked on each supporting plate, and the material pushing assembly is used for pushing the material groups on the conveying assembly onto the material frame. According to the automatic stacking and material collecting equipment, a row of materials are collected through a feeding conveying belt, a material collecting platform and a material collecting air cylinder, the row of materials are integrally pushed onto the conveying belt through the feeding assembly, finally, the row of materials are pushed onto the material frame through the material pushing assembly with a lifting mechanism, and stacking of multiple layers of material groups on the material frame is achieved.

Owner:ANQING TP GOETZE LINER

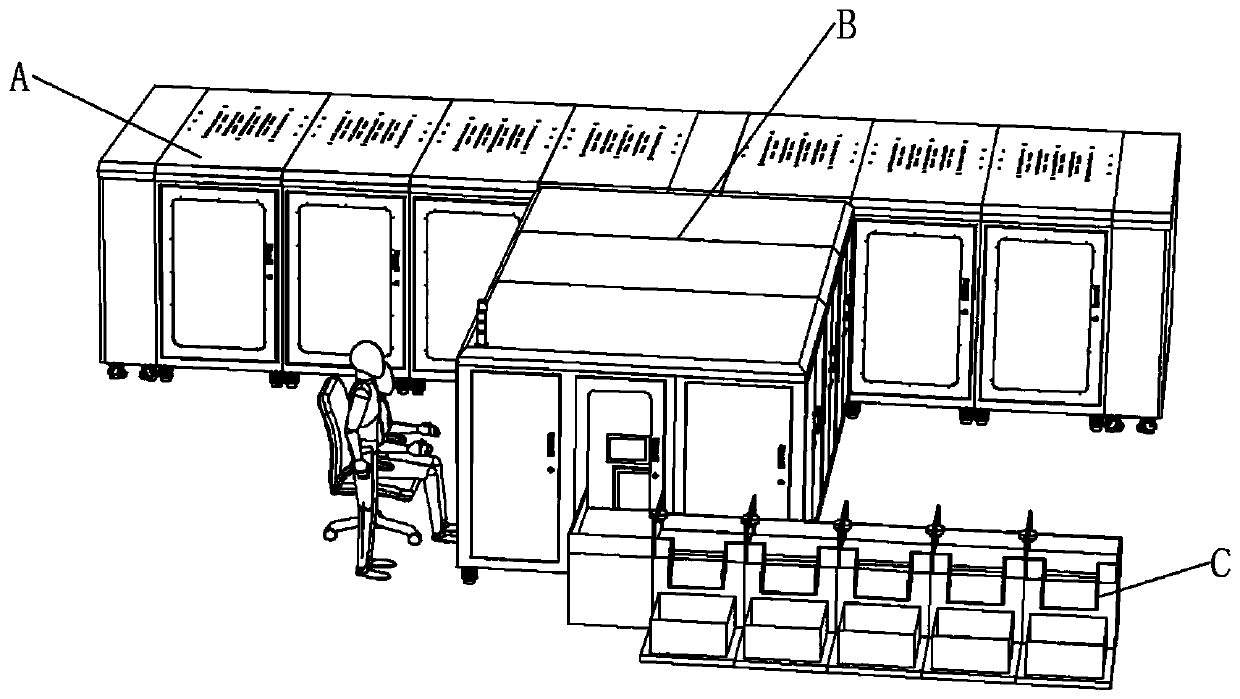

Machine core and multi-currency distribution assembly line thereof

PendingCN110626696AImprove banknote distribution efficiencyReduce human errorPaper-money handling devicesPaper article packagingPlastic packagingComputer module

The invention discloses a machine core and a multi-currency distribution assembly line thereof. The multi-currency distribution assembly line comprises a machine core module, a plastic package module,a sorting assembly line and a mechanical arm. The machine core module is used for storing paper currency and outputting the paper currency to a currency receiving hopper of the module according to the system instruction, the mechanical arm is used for conveying the paper currency in the currency receiving hopper to a plastic package feeding mechanism of the plastic package module, a plastic package machine carries out plastic packaging on the stacked paper currency and then outputs the paper currency to a stacking mechanism, the stacking mechanism stacks the same kind of the paper currency and outputs the paper currency to a sorting conveying mechanism of a sorting assembly line from a currency outlet, and the side face of the sorting conveying mechanism communicates with a sorting framethrough a sorting inclined plate. Due to the array type machine core, each machine core body stores different kinds of paper currency, the mechanical arm conveys the paper currency output by the different machine core bodies to the plastic package module to be subjected to plastic packaging, then the paper currency is conveyed to the sorting assembly line, currency distribution, packaging and sorting are further finished, the currency distribution efficiency is greatly improved, and the manual errors brought by manual operation can be reduced to the maximum.

Owner:WEIRONG TECH CO LTD

Virtual-reality combined robot education comprehensive practical training room

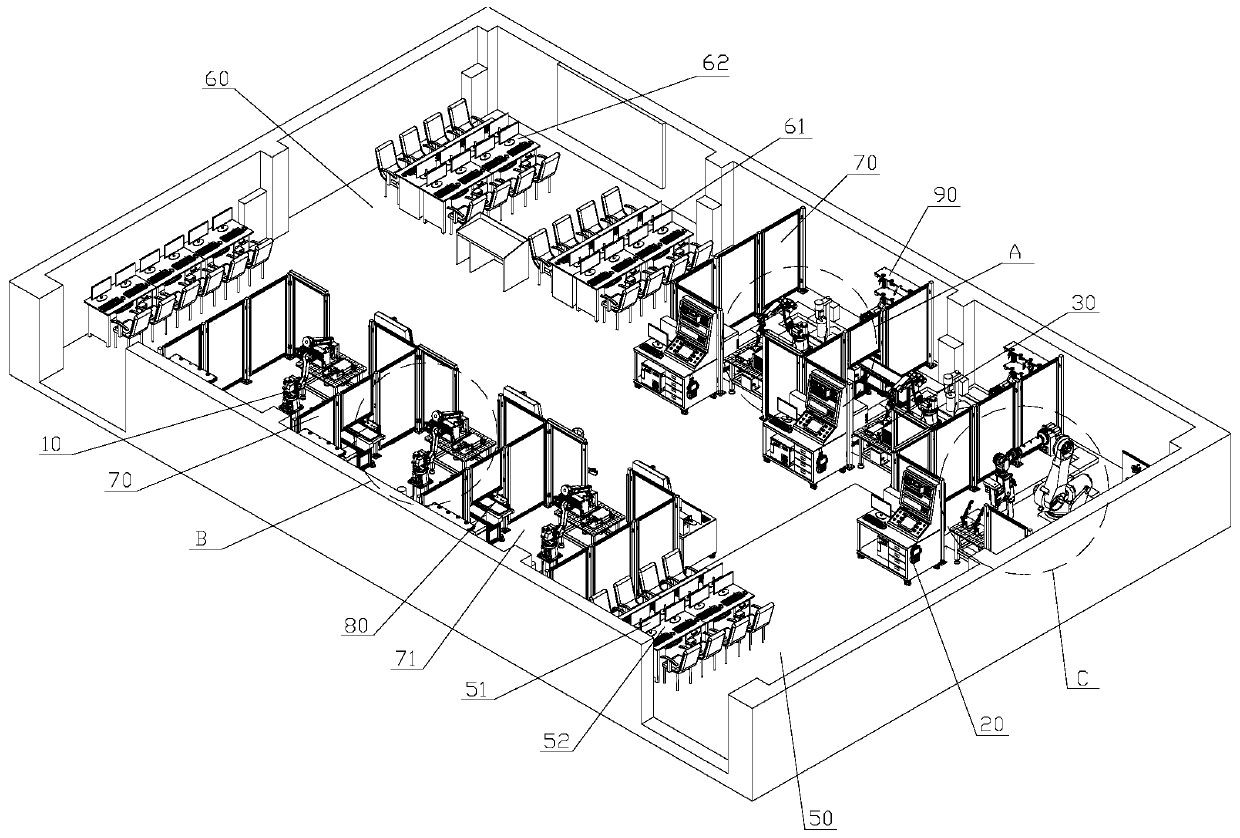

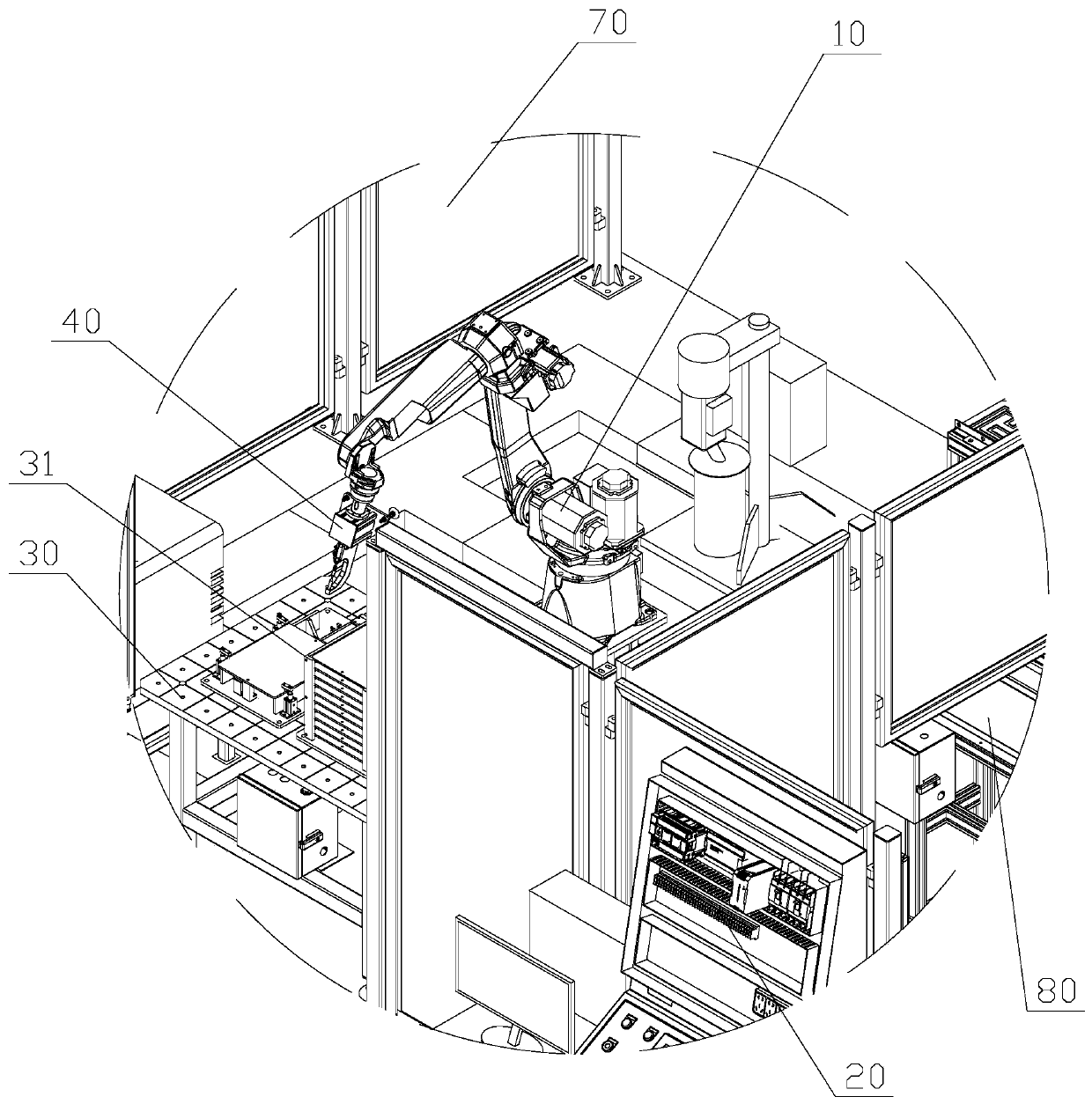

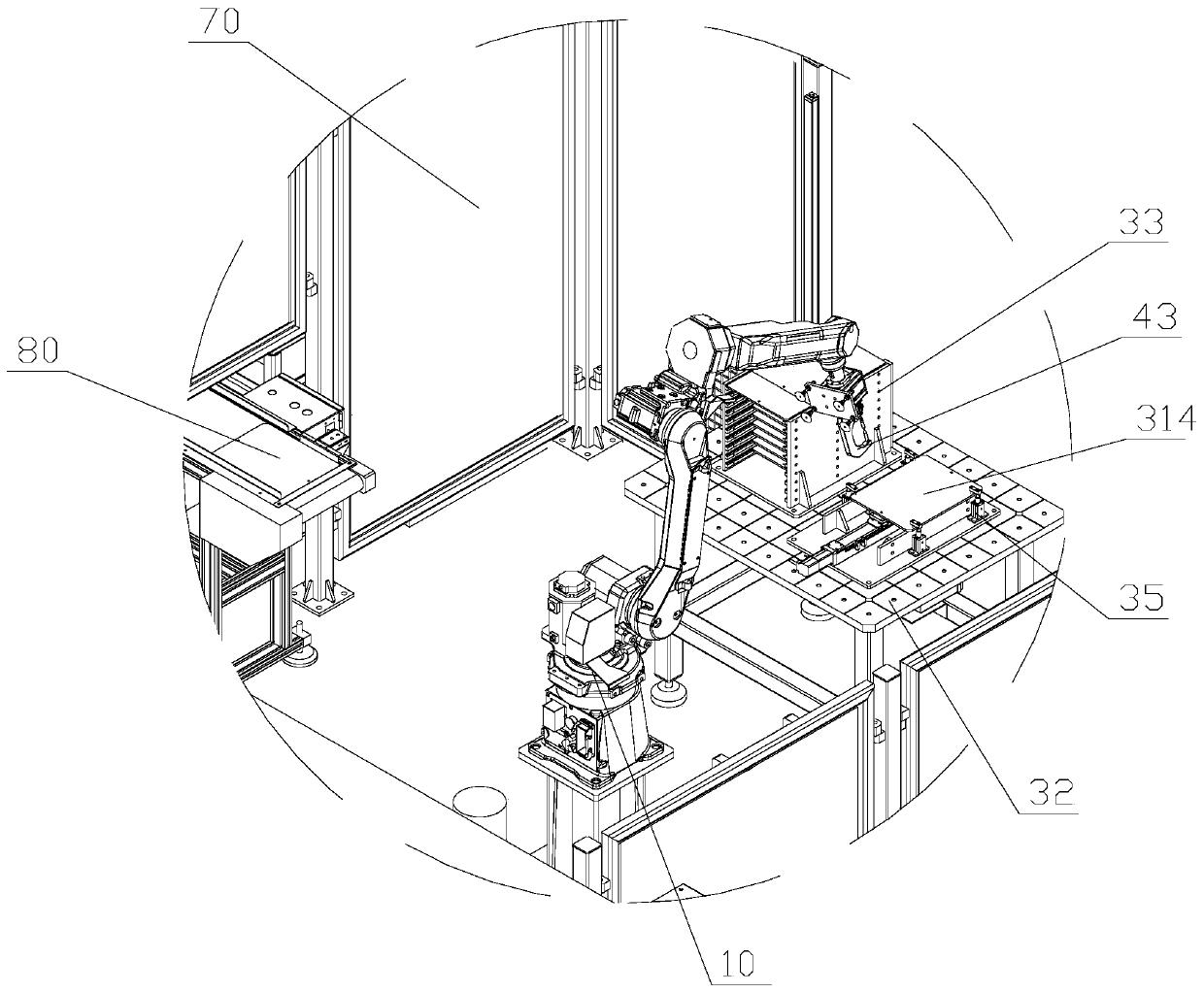

PendingCN110060534AEnsure the safety of life and propertyAvoid safety accidentsCosmonautic condition simulationsEducational modelsSimulationRobot control

Owner:广东省岭南工商第一技师学院 +1

Bernoulli rotary type pneumatic and hydraulic double-control building material stacking device

ActiveCN114314017AImprove bindingThe contradictory technical problem of realizing circular palletizing and stackingCleaningElectrostatic cleaningDust controlPalletizer

The invention discloses a Bernoulli rotary type air pressure and hydraulic pressure double-control building material stacking device which comprises a base, a rotary air control Bernoulli automatic transfer mechanism, an electrostatic dust collection self-cleaning conveying mechanism and a double-magnetic control self-adjusting hydraulic stacking mechanism, and the rotary air control Bernoulli automatic transfer mechanism is arranged in the middle of the upper wall of the base; the electrostatic dust collection self-cleaning conveying mechanism is arranged on the upper wall of the base, the electrostatic dust collection self-cleaning conveying mechanism is arranged on one side of the rotary pneumatic control Bernoulli automatic transfer mechanism, the double-magnetic-control self-adjusting hydraulic stacking mechanism is arranged on the upper wall of the base, and the double-magnetic-control self-adjusting hydraulic stacking mechanism is arranged on the other side of the rotary pneumatic control Bernoulli automatic transfer mechanism. The rotary pneumatic control Bernoulli automatic transfer mechanism comprises a self-adjusting lifting adsorption transfer assembly, a power transmission assembly and an asymmetric rotary pneumatic control assembly. The invention belongs to the field of building material transfer, and particularly relates to a building material stacking device which is easy to operate, capable of automatically achieving grabbing and stacking through pneumatic control and high in efficiency.

Owner:徐州市汇力高强标准件有限公司

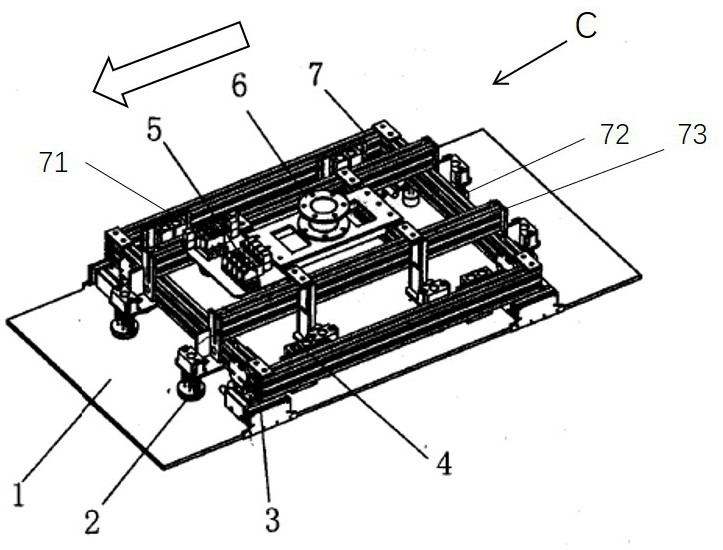

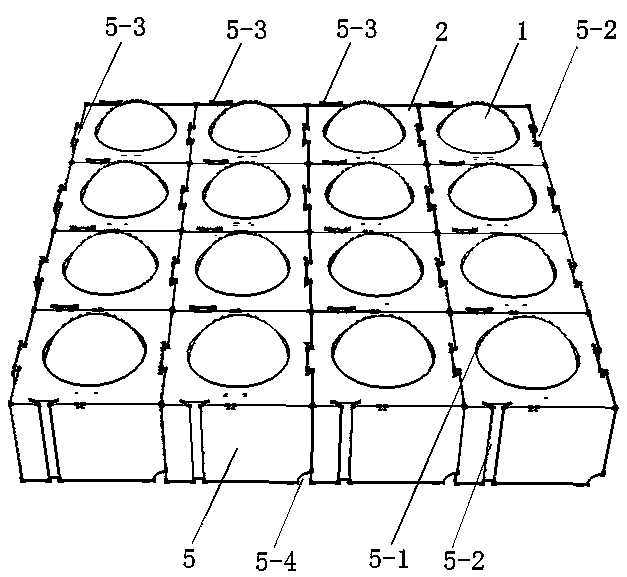

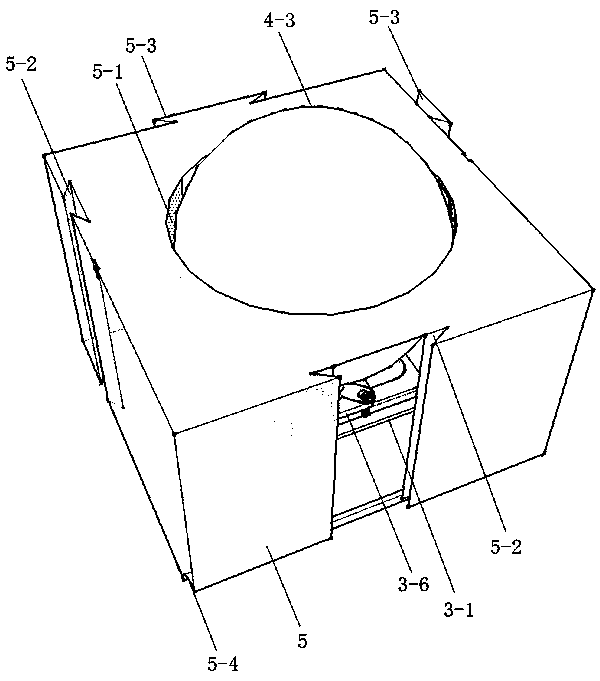

Roller type multifunctional delivery device and control method thereof

ActiveCN109823785ARealize automatic switchingFully automatedControl devices for conveyorsSupporting framesDrive shaftModularity

The invention discloses a roller type multifunctional delivery device and a control method thereof, and solves the technical problems of low automation level and the failure of achieving real-time control and precise control. The device comprises a plurality of driving units, a conveying platform of any shape which is assembled by the driving units, each driving unit comprises a steering mechanismand a rolling mechanism, the steering mechanism comprises a base, a stepping motor with a vertically arranged driving shaft is arranged on the base, the driving shaft of the stepping motor is connected with a rotary supporting frame, the rolling mechanism comprises a long shaft motor which is arranged on the rotary supporting frame, a roller is fixedly arranged on the rotary shaft of the long shaft motor, and each stepping motor and long shaft motor are connected with a power supply and an industrial personal computer through a driving circuit. The multifunctional delivery device has the advantages that the combinations of various shapes can be achieved according to demands, the floor occupation area is small, the flexibility is high, rapid maintenance and replacement can be conducted through a modular design, uninterrupted delivery of materials can be achieved, and the renovation cost is low.

Owner:HENAN UNIVERSITY

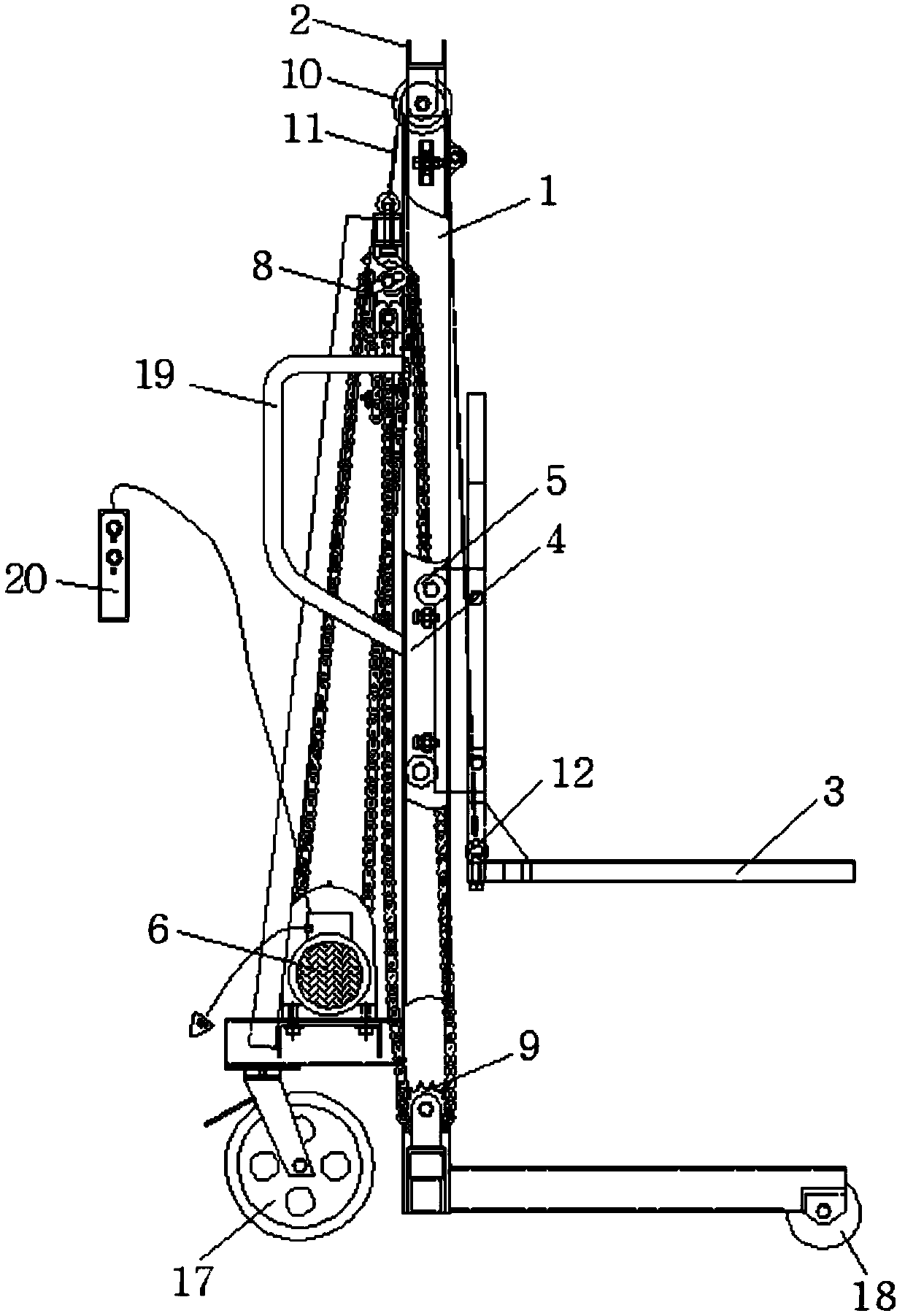

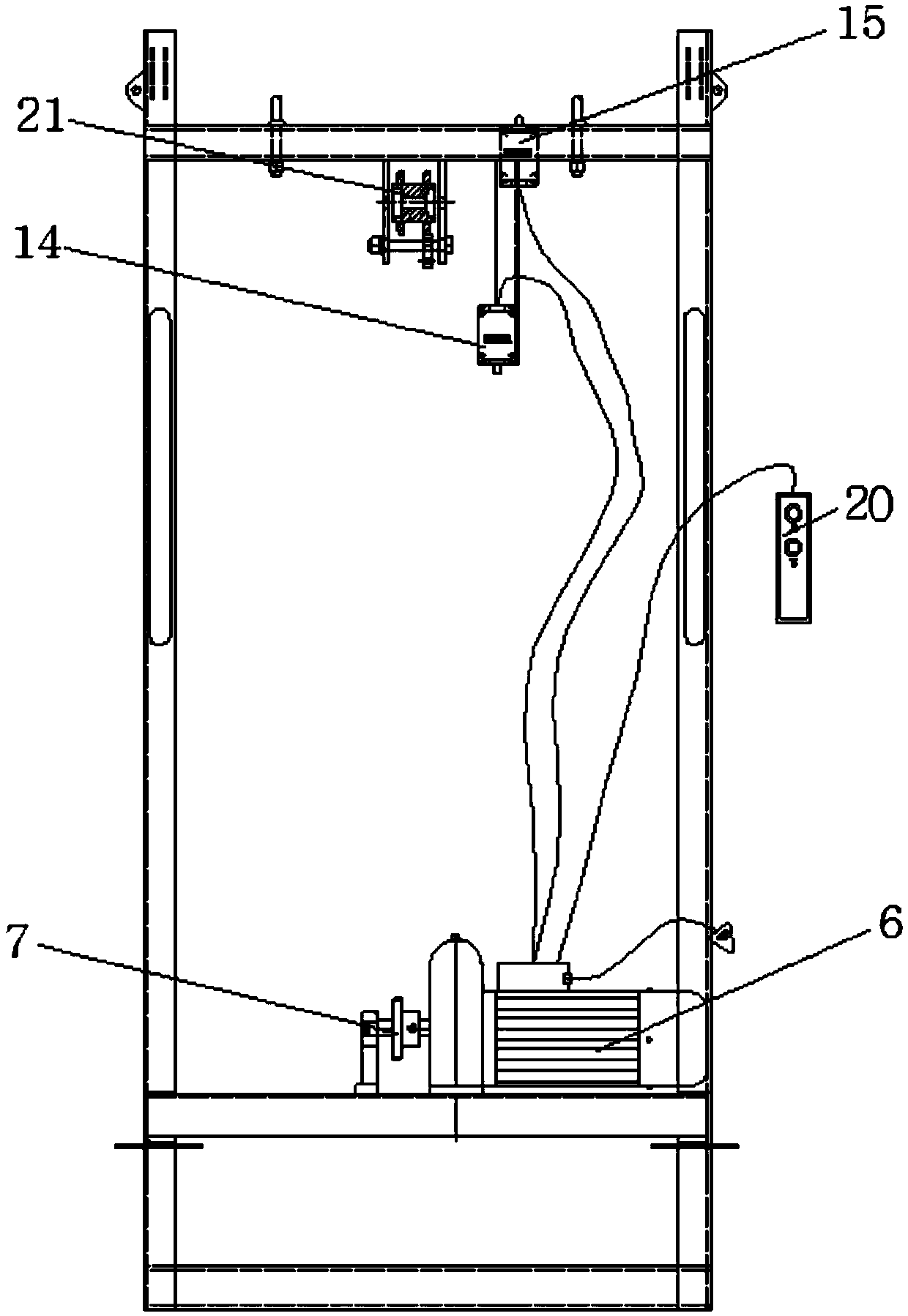

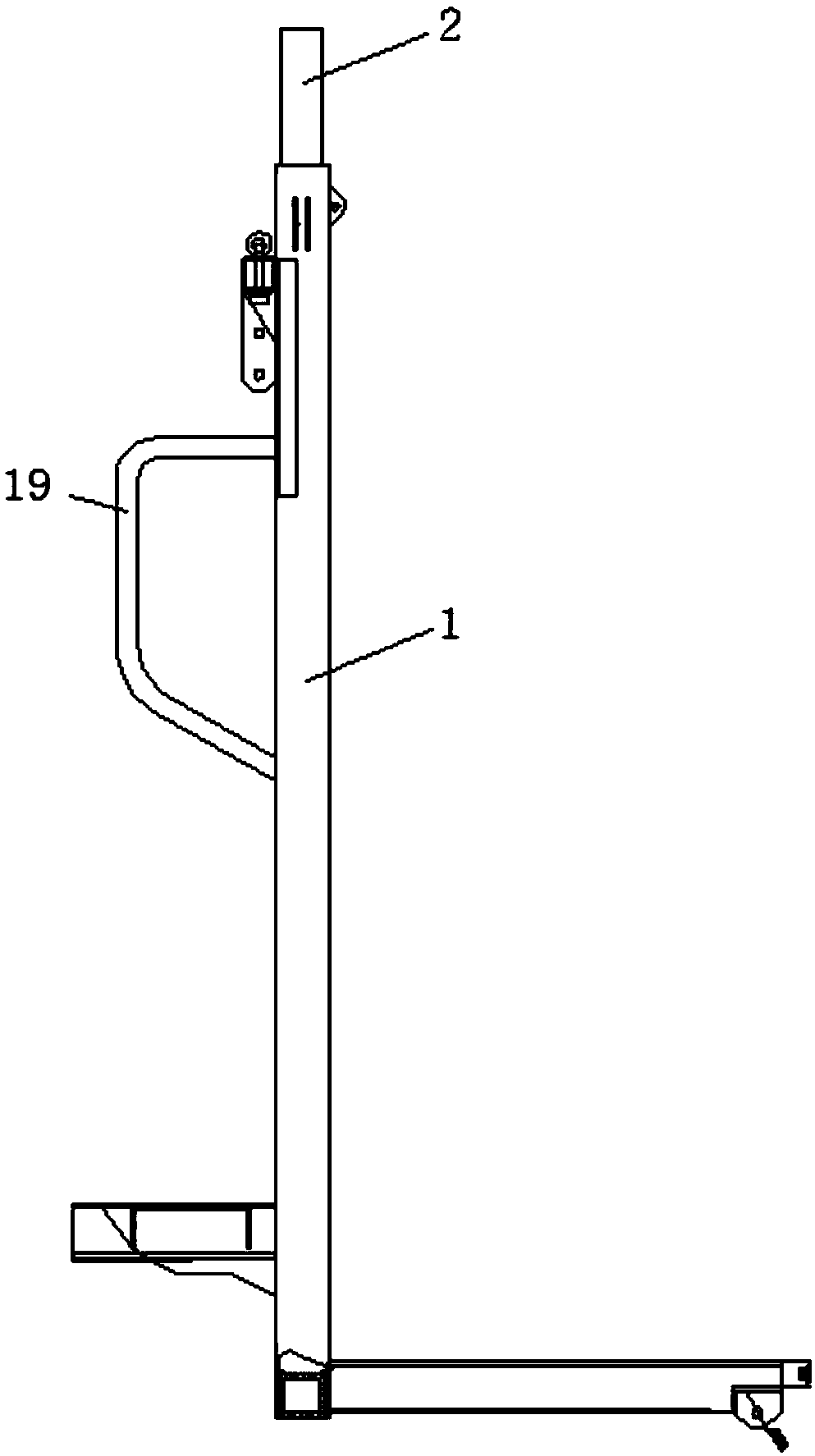

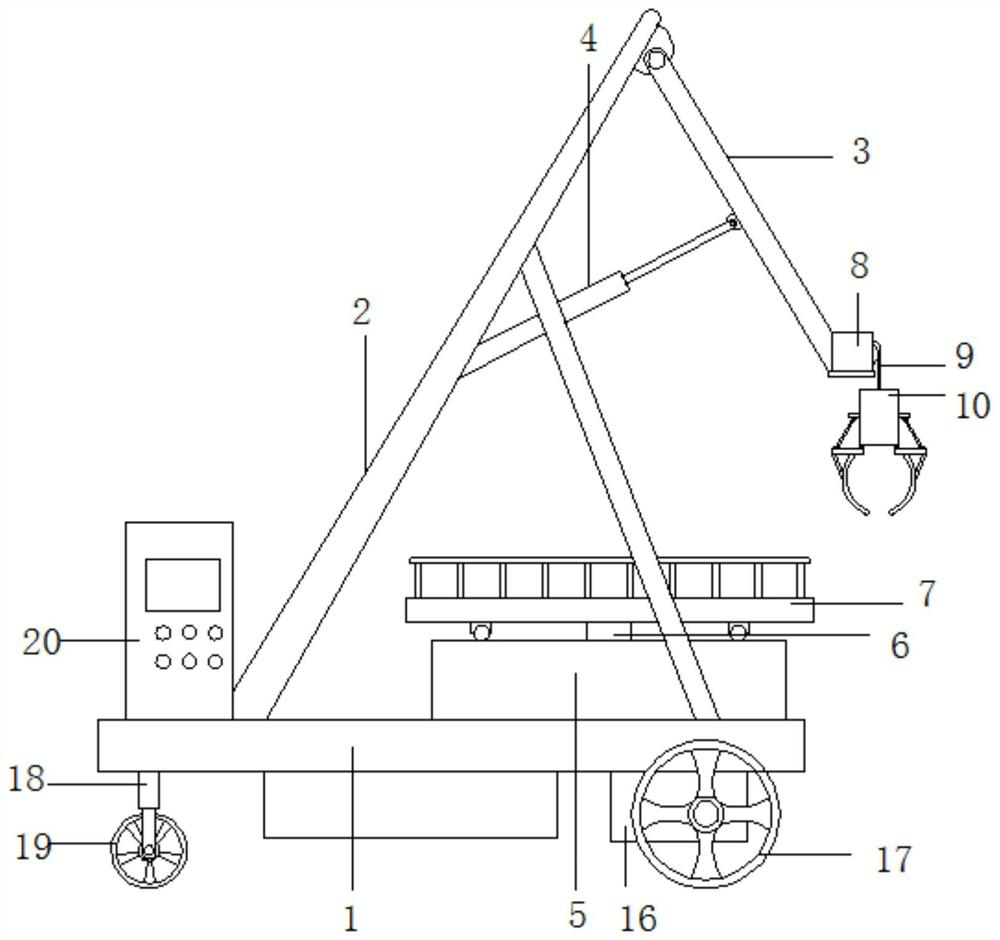

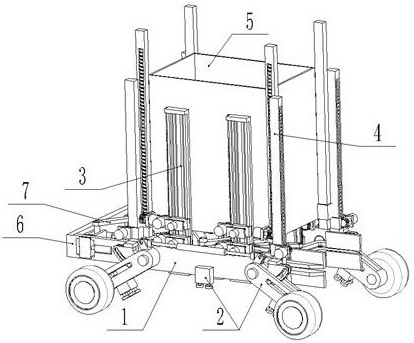

Grain loading and unloading palletizer

PendingCN108033389ARealize palletizingRealize loading and unloadingLifting framesPalletizerWeight lifting

The invention relates to a grain loading and unloading palletizer comprising a rack, a rectangular weight lifting frame and a weight lifting frame hoisting device used for driving the weight lifting frame to rise and fall along vertical sliding rails on brackets on the both sides of the rack; the weight lifting frame is provided with a supporting frame and a supporting frame hoisting device, and the both sides of the supporting frame are fixedly connected to movable sliding frames which are provided with pulleys; and the two opposite inner sides of the weight lifting frame are provided with sliding chutes for installing the pulleys, and the supporting frame hoisting device can be used for driving the supporting frame to rise and fall along the sliding chutes through the pulleys. The grainloading and unloading palletizer provided by the invention is simple in structure, and grain in bags can be quickly lifted for loading and unloading by a lifting motor through a chain and a steel wirerope; the efficiency is high, and the labor intensity of workers is reduced; and the cost is saved.

Owner:安陆市农业机械科学研究院

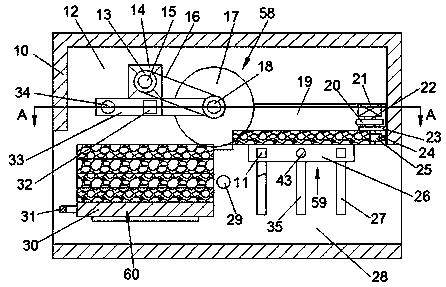

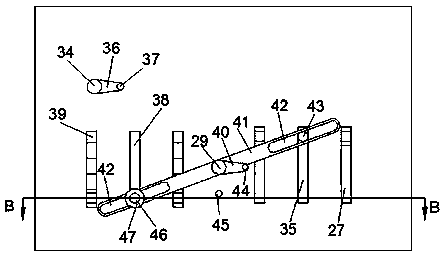

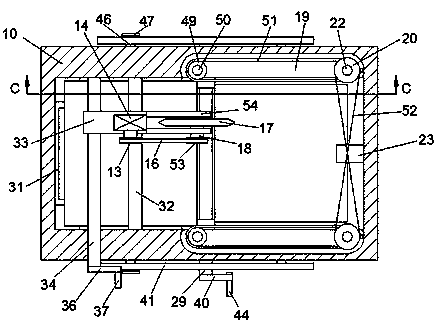

Printing carton automatically receiving and palletizing equipment

InactiveCN107539790ARealize automatic collectionRealize palletizingStacking articlesDe-stacking articlesCartonDrive motor

The invention relates to an automatic receiving and palletizing equipment for printed cartons, which includes a base, a transmission mechanism, a lifting mechanism and a collection mechanism. The transmission mechanism includes a transmission frame, a transmission motor, a driving roller and a driven roller; Gear transmission structure and support frame; collection mechanism includes side baffle, rotating support plate and collection cylinder. The invention is an automatic receiving and palletizing equipment for printed cartons with ingenious design, reasonable structure, convenient use and strong practicability. Mass production.

Owner:天津市宝华机械有限公司

An automatic stacking device

ActiveCN110589501BReduce occupancyAdjust orientationStacking articlesDe-stacking articlesFixed positionIndustrial engineering

Owner:SUZHOU JINGLAI OPTO CO LTD

a stack method

ActiveCN110589502BReduce occupancyAdjust orientationStacking articlesDe-stacking articlesRobot handClassical mechanics

The present application relates to a stacking method, using an automatic stacking device, comprising the steps of: S1: providing a stacking device, the stacking device includes a grabbing conveying mechanism and a pallet; S2: driving the grabbing conveying mechanism to grab The material boxes are stacked on the pallet to form the first material box stack; S3: drive the grasping conveying mechanism to grab the material boxes and stack them on the pallet to form the second material box stack, and between the first material box stack and the second material box stack An active gap of the grasping manipulator is formed between the two stacks of material boxes; S4: push one of the first stack of material boxes and the second stack of material boxes close to the other until they are in close contact with each other. The invention can position the material box once around before the mechanical arm grabs the material box, so that each material box is in a fixed position, which greatly facilitates the difficulty of the subsequent grasping of the material box by the mechanical arm, and can adjust the orientation of the material box. Realize matt-shaped palletizing.

Owner:SUZHOU JINGLAI OPTO CO LTD

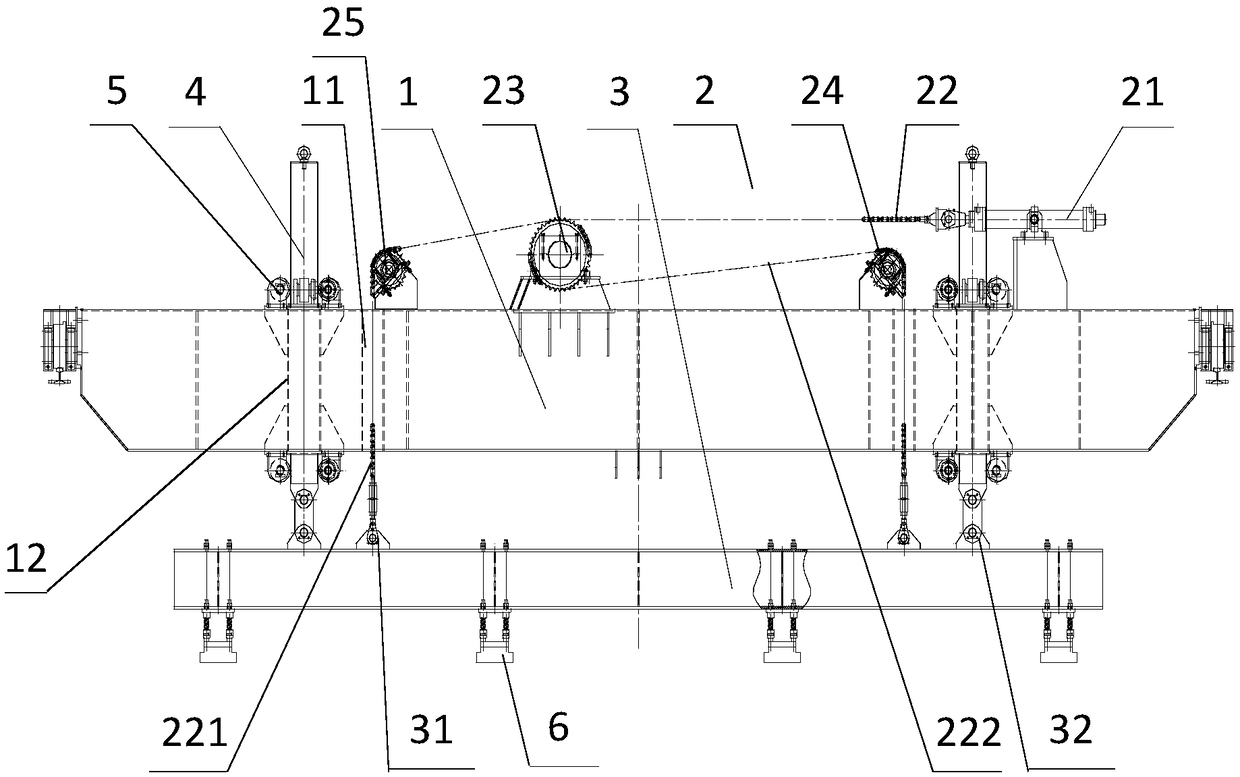

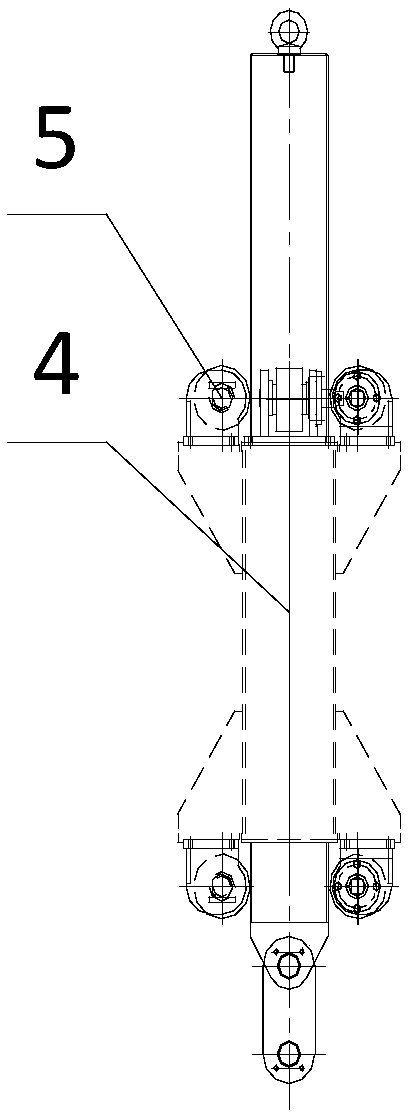

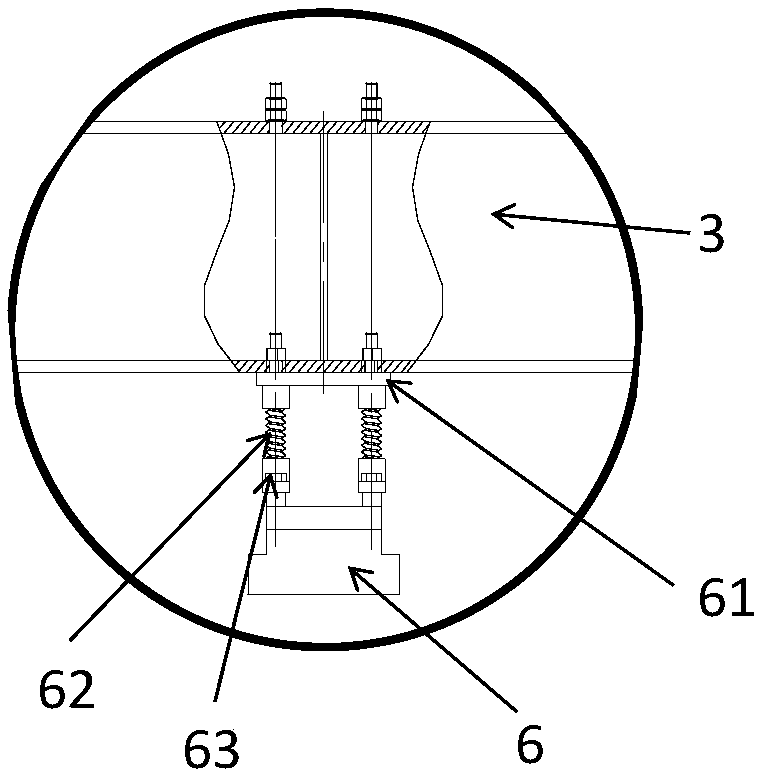

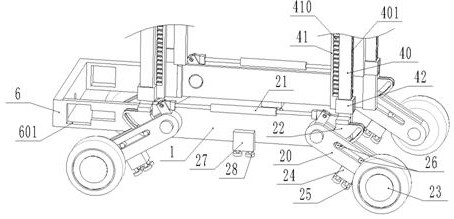

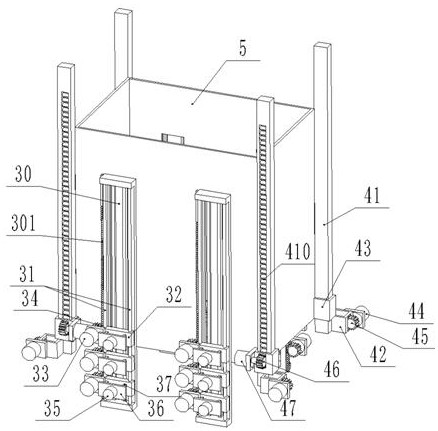

Lifting mechanism of section steel palletizing machine and section steel palletizing machine

PendingCN109051825AGuaranteed outputImprove synchronicityStacking articlesHydraulic cylinderEngineering

The invention provides a lifting mechanism of a section steel palletizing machine and the section steel palletizing machine. The lifting mechanism of the section steel palletizing machine comprises afirst cross-beam and a second cross-beam. The second cross-beam is fixedly arranged on the lower portion of the first cross-beam through a lifting device, and the lifting device comprises a hydrauliccylinder, and the hydraulic cylinder is fixed to one end of the top surface of the first cross-beam, a separation chain wheel is arranged in the middle of the first cross-beam, one end of a double-rowchain is connected to the output end of the hydraulic cylinder, and the double-row chain is divided into a first chain and a second chain after bypassing the separation sprocket, a first chain wheeland a second chain wheel are separately disposed on two sides of the separation chain wheel, the first chain bypasses the first chain wheel, and the end of the first chain penetrates through the firstcross-beam and is hinged to the second cross-beam. The second chain bypasses the second chain wheel, and the end of the second chain penetrates through the first cross-beam and is hinged to the second cross-beam. A plurality of electromagnets capable of attracting the section steel are uniformly disposed on the bottom surface of the second cross-beam in the length direction. The lifting mechanismachieves the lifting and lowering of the electromagnets by the method that the chains and the chain wheels are driven through the hydraulic cylinder, and the synchronization is greatly improved

Owner:中重科技(天津)股份有限公司

Brick stacking mechanism for automatic stacker

InactiveCN102491100BRealize palletizingQuick rearrangeStacking articlesDe-stacking articlesBrickEngineering

The invention discloses a brick stacking mechanism for an automatic stacker. The brick stacking mechanism comprises a chassis fixedly connected with the automatic stacker, a rotary table driven by a power device to rotate horizontally is connected with the chassis in a rotating manner, a rotary support plate and a translation support plate which are arranged horizontally side by side are connected with the rotary table, the rotary support plate is driven to rotate horizontally by a rotation power device arranged on the rotary table, the translation support plate is driven by a translation power device arranged on the rotary table to do horizontal translation to get close to or depart from the rotary support plate, a baffle arranged vertically is arranged on the outer side of the rotary support plate, a baffle arranged horizontally is fixedly arranged on the front side of the rotary support plate, a backlash push plate which is arranged on the outer side of the translation support plate is connected with the chassis in a sliding manner and is driven by a backlash power device arranged on the chassis. The brick stacking mechanism can be used for quickly rearranging building bricks so that the bricks meet stacking requirement; therefore the labor intensity of workers is reduced and the working efficiency of the workers is improved.

Owner:丁来臻

Goods transfer device for zinc sulfate sales

PendingCN113459926ARealize liftingNo need for manual handlingVehicles with cranesMechanical steering gearsSulfate zincWinch

The invention belongs to the technical field of zinc sulfate sales goods transfer, and particularly relates to a goods transfer device forzinc sulfate sales. The transfer device comprises a mounting plate, an inclined rod and a driving table are fixed to the top of the mounting plate, a swing rod is hinged to the top of the inclined rod, an air cylinder is hinged to the inclined rod, a piston rod of the air cylinder is hinged to the swing rod, a rotary shaft is rotatably mounted at the top of the driving table, a placement disc is fixed to the top of the rotary shaft, a winch is mounted at one end of the swing rod, a rope is arranged on the winch, one end of the rope is connected with a positioning block, movable plates are hinged to the two sides of the bottom of the positioning block, arc-shaped plates are fixed to the bottoms of the movable plates, and an adjusting plate is slidably mounted on the positioning block. According to the invention, zinc sulfate hoisting is achieved, manual carrying is not needed, the labor intensity of workers is greatly reduced, stacking, feeding and discharging of objects can be achieved, the transfer efficiency is improved, movement of the device is conveniently controlled, transfer is convenient, and labor is saved.

Owner:PINGXIANG BAOHAI FEED ADDITIVE

Spacing adjustable ceramic tile cutting equipment

InactiveCN111136797ARealize automatic feeding processRealize palletizingDischarging arrangementWorking accessoriesComposite materialCeramic tiles

The invention discloses spacing adjustable ceramic tile cutting equipment. The spacing adjustable ceramic tile cutting equipment comprises a machine body, wherein a cutting cavity is formed in the machine body; a material cavity which is in intercommunication with the cutting cavity is formed in the lower side of the cutting cavity; the left side and right side of the material cavity are in intercommunication with the exterior of the machine body; a cutting device which can be adjusted forwards and backwards is arranged in the cutting cavity; a feeding device for automatically cutting ceramictiles is arranged in the cutting cavity; and a stacking device for stacking the cut ceramic tiles is arranged in the material cavity. Ceramic tiles on a supporting plate I can be driven to move left one by one by a poking block on a chain, and thus, the spacing adjustable ceramic tile cutting equipment realizes the automatic feeding and stacking. The spacing adjustable ceramic tile cutting equipment is easy and simple to operate and low in manufacturing cost, can realize the automatic feeding and stacking of the ceramic tiles, and improves the cutting efficiency and the cutting quality; and the cutting size of the spacing adjustable ceramic tile cutting equipment can be adjusted in a certain range.

Owner:TIANTAI YUNCENG AUTOMATION TECH CO LTD

Paper money receiving hopper and multi-currency distribution assembly line thereof

PendingCN110667918AImprove banknote distribution efficiencyReduce human errorPaper article packagingCoin/currency accepting devicesPalletizerMechanical engineering

The invention discloses a paper money receiving hopper and a multi-currency distribution assembly line thereof. The multi-currency distribution assembly line comprises a machine core module, a plasticpackage module, a sorting assembly line, and a mechanical arm; the machine core module is used for storing paper money and outputting the paper money to the paper money hopper thereof according to asystem instruction, the mechanical arm is used for conveying the paper money in the paper money receiving hopper to a plastic package feeding mechanism of the plastic package module, a plastic packagemachine carries out plastic package on the stacked paper currency and outputs the paper currency to a stacking mechanism, the stacking mechanism stacks the same kind of paper currency, and outputs the stacked paper currency to a sorting conveying mechanism of the sorting assembly line, and the side face of the sorting conveying mechanism communicates with a sorting frame through a sorting inclined plate. Array type machine cores are arranged, each machine core stores the different kinds of paper currency, through the mechanical arm, the paper currency output by the different machine cores isconveyed to the plastic package module to be subjected to plastic package, then, the paper currency is conveyed to the sorting assembly line, currency distribution, packaging and sorting can be finished at one step, the paper currency distribution efficiency is greatly improved, and the manual error brought by manual operation can be reduced in a maximized manner.

Owner:WEIRONG TECH CO LTD

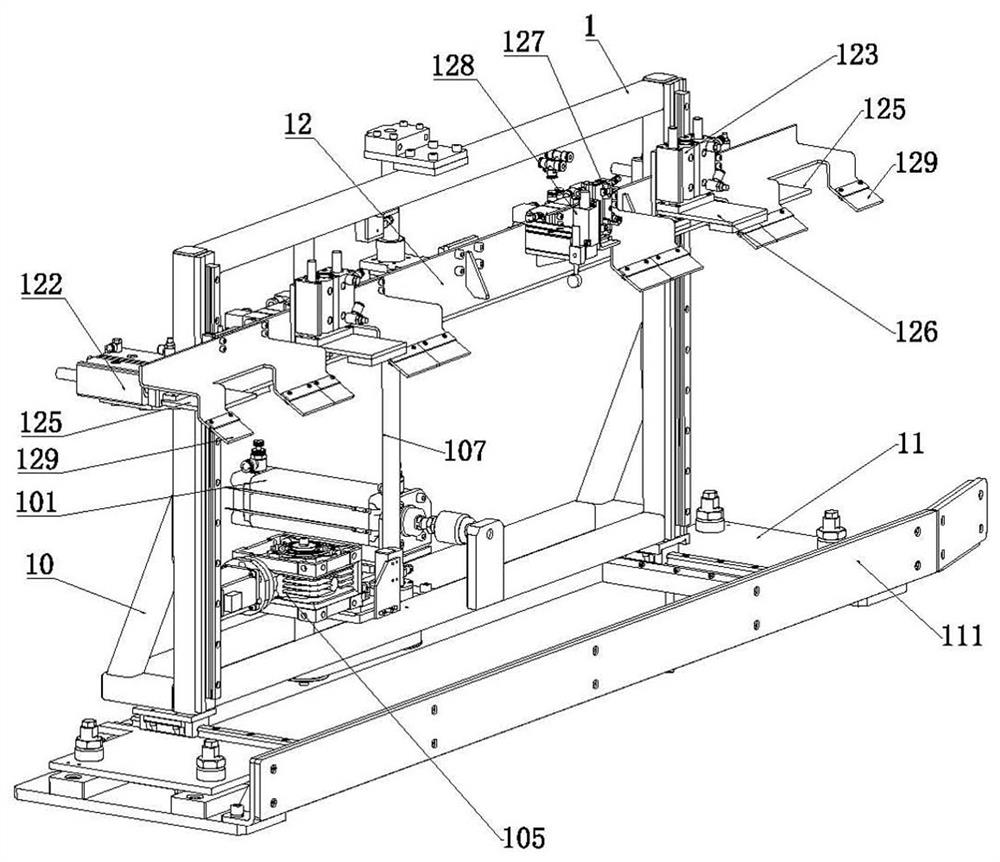

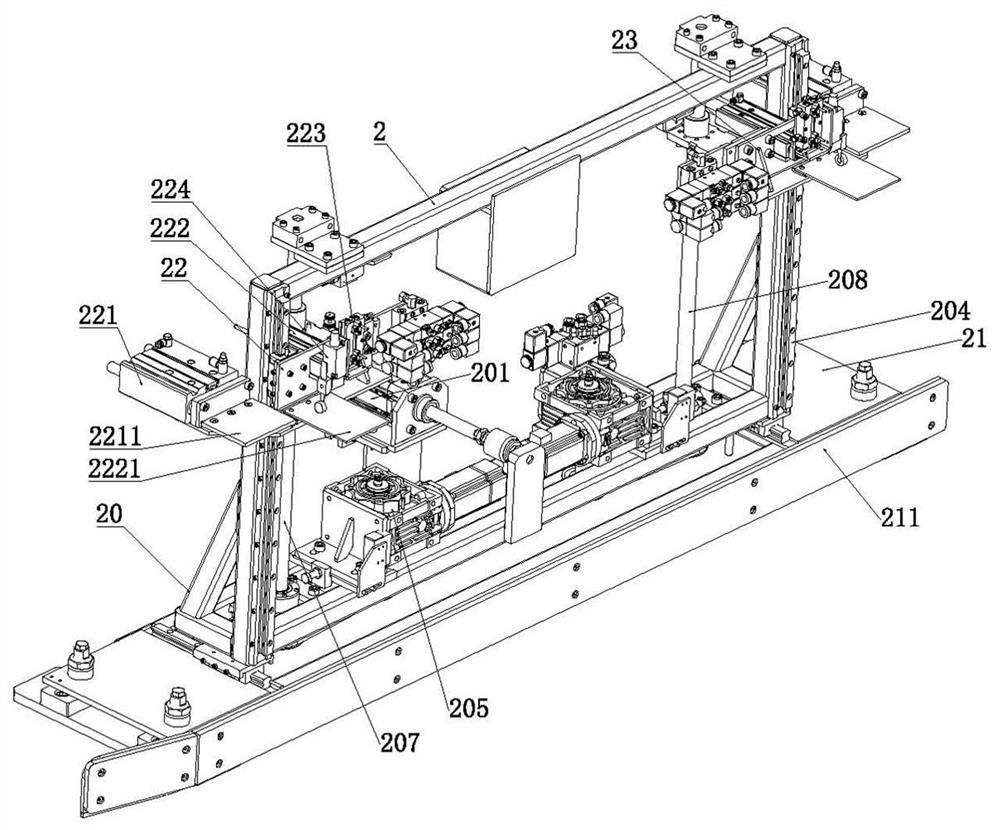

Automatic paper sorting and recycling device for glass stacks

ActiveCN109502395BAchieve recyclingRealize palletizingPile receiversStacking articlesPaperboardStructural engineering

The invention belongs to the technical field of solar cell assembly glass and glass deep processing equipment manufacturing and provides a partitioning paper automatic sorting and recycling device ofa glass stack. The partitioning paper automatic sorting and recycling device of the glass stack is compact in structure and high in automation degree. The partitioning paper automatic sorting and recycling device comprises a paper sorting, separating and stabilizing mechanism at the right side, a paper clamping and separating mechanism on the left side and a paper pick-up clamp device, and is characterized in that the paper sorting, separating and stabilizing mechanism comprises a right fixing frame; a right translation frame is arranged on the right fixing frame through a right translation cylinder; a right lifting frame is arranged on the right translation frame through a right lifting mechanism and is connected with a right travel switch through a right downward moving cylinder; and right normalizing plates are arranged at the two ends of the right lifting frame through right normalizing cylinders; a pressing plate is further arranged on the right lifting frame through a downward pressing air cylinder; and an inclined paper sorting scrubbing brush is further arranged on the right lifting frame.

Owner:YINGKOU JINCHEN MACHINERY

Carrying method applied to cylinder body end cover sand cores

PendingCN113979140ARealize automatic grippingAchieve transshipmentMoulding toolsFoundry mouldsStructural engineeringManufacturing line

The invention discloses a carrying method applied to cylinder body end cover sand cores. The carrying method comprises a clamping procedure, an asbestos pad pasting procedure and a stacking procedure. In the clamping procedure, a sand core carrying jig clamps sand cores conveyed from a production line, and the sand core carrying jig can clamp the sand cores of different sizes at the same time; in the asbestos pad pasting procedure, the sand core carrying jig transfers the clamped sand cores to an asbestos pad pasting station, and the sand core carrying jig drives the sand cores to turn over to a vertical state so that asbestos pad pasting operation can be manually conducted on the sand cores; in the stacking process, according to the stacking mode, the sand core carrying jig transfers the sand cores pasted with the asbestos pads to a stacking station for stacking or transfers the sand cores to a temporary storage station for temporary storage. According to the carrying method, automatic clamping, transferring and stacking of the cylinder body end cover sand cores can be achieved, the working efficiency is improved, and the labor cost is reduced.

Owner:青岛诚广丰自动化工程有限公司

A high-strength manipulator

InactiveCN111470316BStable clampingStable supportMotor depositionStacking articlesDrive wheelDrive by wire

The invention discloses a high-strength mechanical arm which comprises a bottom framework, walking and supporting mechanisms, side clamping mechanisms, a sliding box and a lifting mechanism. The walking and supporting mechanism comprises a first linear drive assembly, an L-shaped swing rod, a sliding and supporting assembly, a drive wheel and a fixed block, wherein a motor is arranged in the drivewheel. The first linear drive assemblies are mounted on the bottom framework. The ends of the short sides of the L-shaped swing rods are rotationally connected with the first linear drive assemblies,and the right angle portions of the L-shaped swing rods are rotationally connected with the bottom framework. The drive wheels with the motors arranged inside are mounted on the end sides of the longsides of the L-shaped swing rods. Mounting grooves and linear kidney holes are formed in the long sides of the L-shaped swing rods. The sliding and supporting assemblies comprise sliding and supporting blocks and limiting pin shafts. According to the high-strength mechanical arm, multiple working functions are achieved, the application range is wide, practicality is high, the manual cost is reduced, and the working efficiency is improved.

Owner:HUNAN BIOLOGICAL & ELECTROMECHANICAL POLYTECHNIC

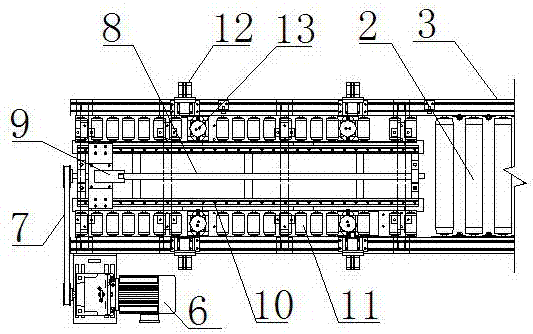

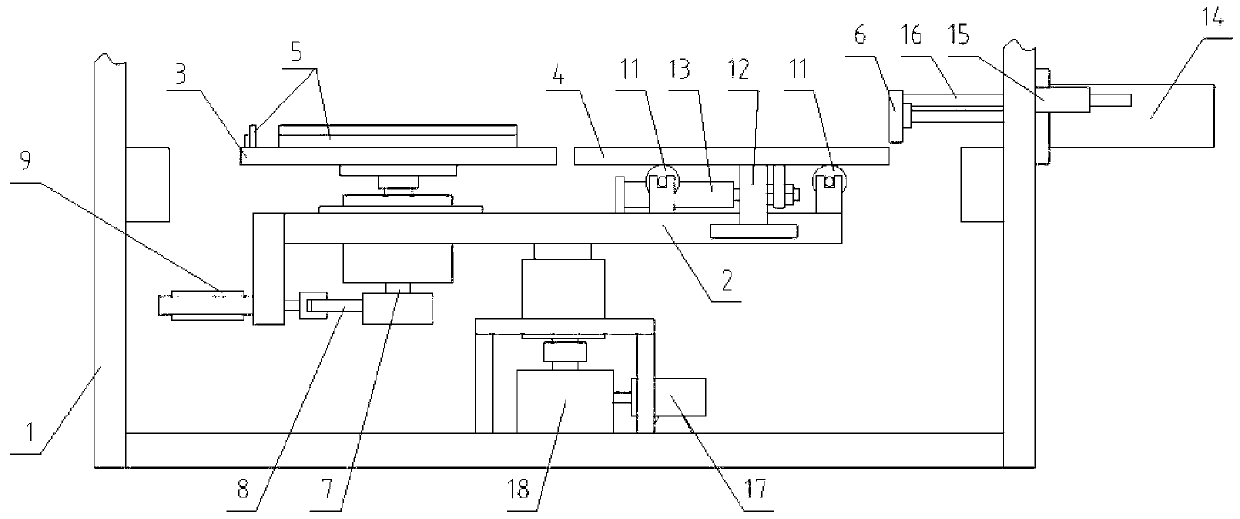

Servo stacking machine used for aluminum ingot on continuous castcontinuous casting production line for aluminum ingots

ActiveCN103286281BEasy palletizingRealize palletizingPig casting plantsIngot casting plantsProduction lineStack machine

A servo stacking machine used on a for an aluminum ingot continuous castcontinuous casting production line for aluminum ingots comprises a movable mechanism and a lifting mechanism, wherein after aluminum ingot layers on a layer conveyor are well arranged, a servo motor (8) acts to drive a lifting mechanism (13) and a clamp (34) to drop to a layer whole-column station; the clamp (34) acts to clamp the whole layer of aluminum ingots; the servo motor (8) acts again to drive the lifting mechanism (13) and the clamp (34) to rise to an initial height; then a servo motor (25) acts to drive the movable mechanism to leftward move to right above a stacking station (44); and then the servo motor (8) acts again to drive the lifting mechanism (13), the clamp (34) and the aluminum ingot layer to drop. After the aluminum ingot layer is contacted with the stacking station (44), a transmission device (35) acts, and the clamp (34) is opened to place the aluminum ingots on the stacking station (44); next, the servo motor (8) acts, the lifting mechanism (13) rises to the initial height, the servo motor (25) acts to drive the clamp (34) to return the initial position, and a first layer of stacking is completed; and for a second layer of stacking, after a servo motor (33) acts to drive the clamp (34) and the second layer of aluminum ingots to rotate for 90 degrees, the second layer of aluminum ingots is placed on a first layer of aluminum ingots, and the stacking of the first layer of aluminum ingots is completed.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

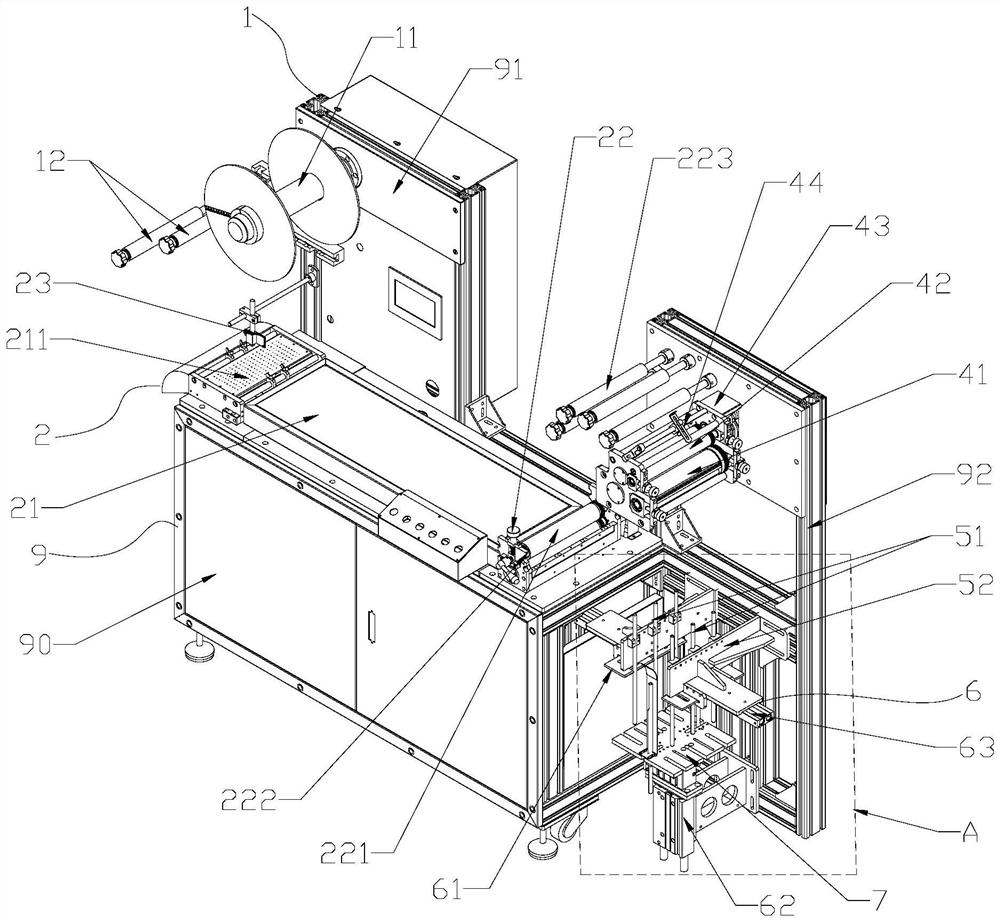

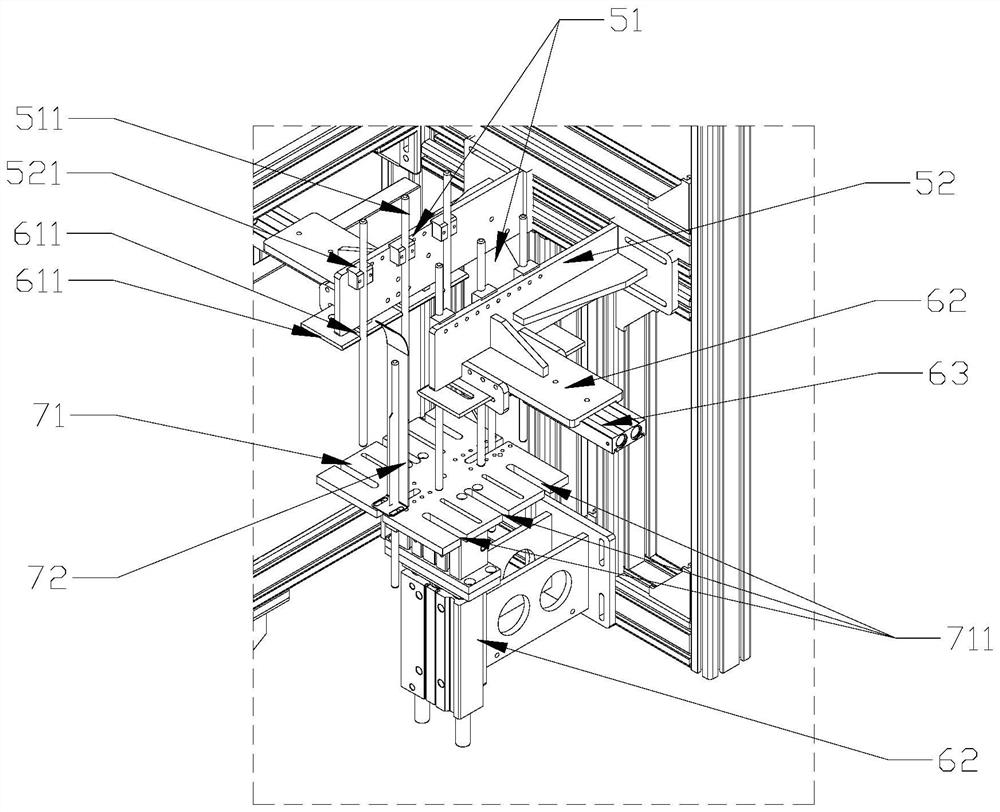

Coiled material folding device

ActiveCN113998501AAchieve foldingRealize palletizingFolding thin materialsWebs handlingEngineeringDie cutting

The invention relates to a coiled material folding device and belongs to the technical field of die cutting. The coiled material folding device comprises a discharging mechanism, a material belt conveying mechanism and a support, wherein the discharging mechanism and the material belt conveying mechanism are both installed on the support. The coiled material folding device further comprises a creasing mechanism, a folding mechanism and a collecting jig, wherein the material belt conveying mechanism is used for conveying a material belt on the discharging mechanism to the creasing mechanism, the creasing mechanism is used for bending the material belt conveyed by the material belt conveying mechanism to form a Z-shaped material belt, the folding mechanism is used for folding the Z-shaped material belt output by the creasing mechanism to the collecting jig, and the folding mechanism is located above the collecting jig. The coiled material folding, stacking and collecting functions are achieved, and the production efficiency can be effectively improved.

Owner:BEIJING ZODNGOC AUTOMATIC TECH

Stacking method

ActiveCN110589502ADifficulty of SimplificationReduce complexityStacking articlesDe-stacking articlesManipulatorFixed position

The invention relates to a stacking method. Automatic stacking equipment is used. The stacking method comprises the steps: S1, the stacking equipment is provided and comprises a grabbing conveying mechanism and a pallet; S2, the grabbing conveying mechanism is driven to grab material boxes, and stack the material boxes on the pallet to form a first material box stack; S3, the grabbing conveying mechanism is driven to grab material boxes and stack the material boxes on the pallet to form a second material box stack, and an activity gap for a grabbing manipulator is formed between the first material box stack and the second material box stack; and S4, one of the first material box stack and the second material box stack is pushed to get close to the other material box stack till the first material box stack and the second material box stack are tightly attached. The material boxes can be peripherally positioned once before the material boxes are grabbed by a mechanical arm, thus all thematerial boxes are located on fixed positions, the subsequent material box grabbing difficulty of the mechanical arm is lowered greatly, the orientation of the material boxes can be adjusted, and Chinese-character-'tian'-shaped stacking is achieved.

Owner:SUZHOU JINGLAI OPTO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com