Reciprocating type plastic bag conveying device

A conveying device, plastic bag technology, applied in transportation and packaging, stack receiving device, packaging, etc., can solve problems such as deformation, plastic bag offset, sliding, etc., achieve a high degree of integration, improve reliability, and reduce complexity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing, set forth more details in the following description so as to fully understand the present invention, but the present invention can be implemented in many other modes different from this description obviously, Those skilled in the art can make similar promotions and deductions based on actual application situations without violating the connotation of the present invention, so the content of this specific embodiment should not limit the protection scope of the present invention.

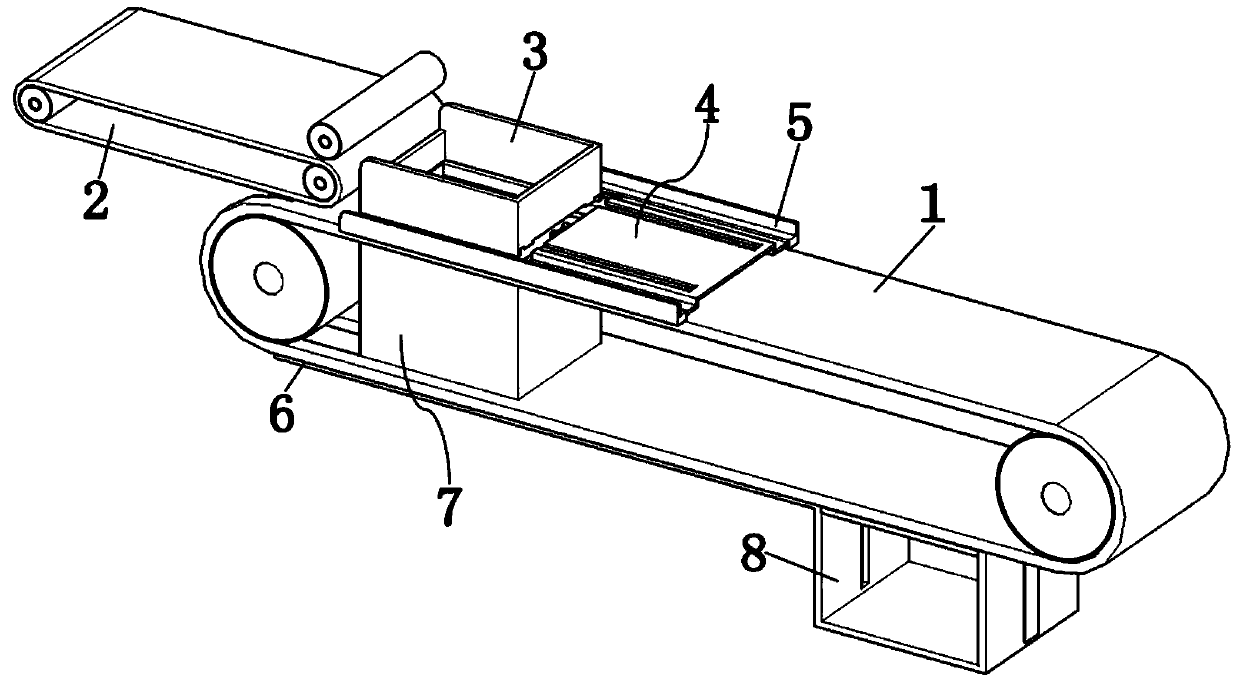

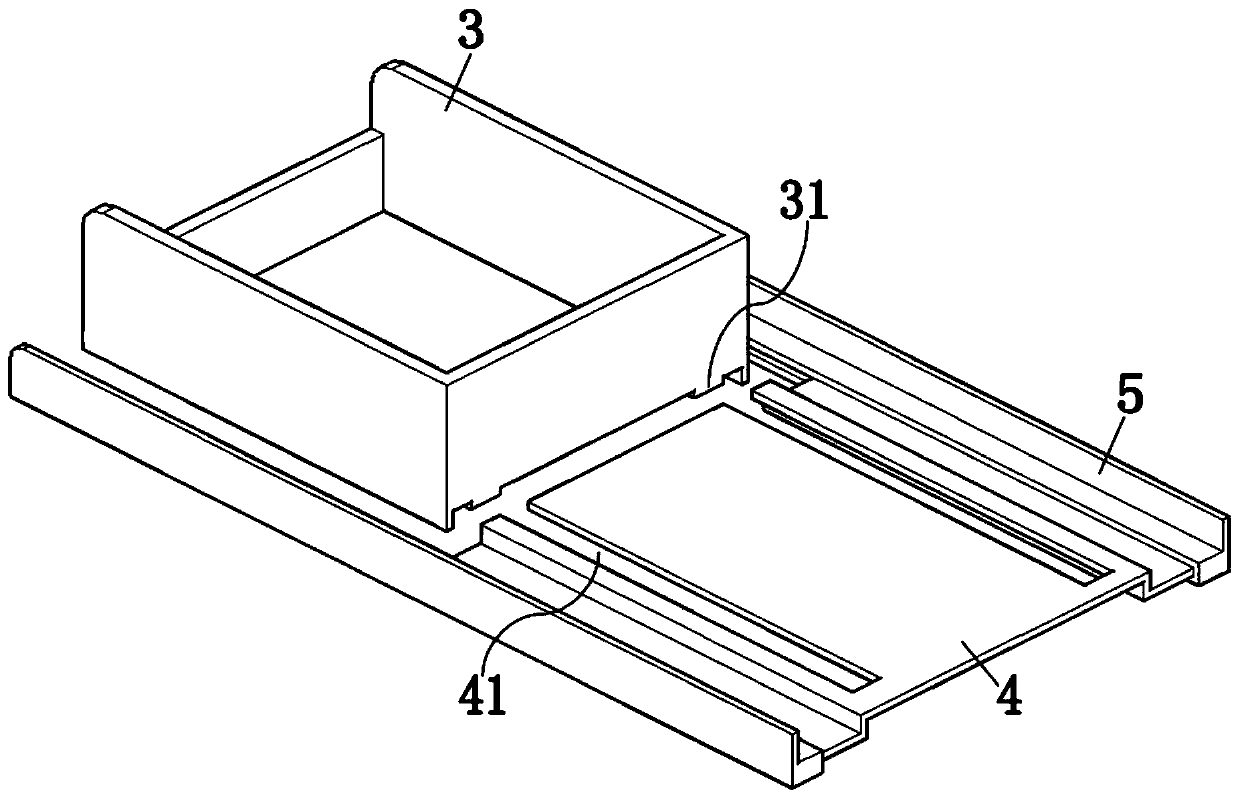

[0034] like figure 1 As shown, the reciprocating plastic bag conveying device includes: an output belt 1, an input belt 2, a housing one 3, a baffle plate 4, a slideway 5, a bottom plate 6, a housing two 7, and a bag storage box 8;

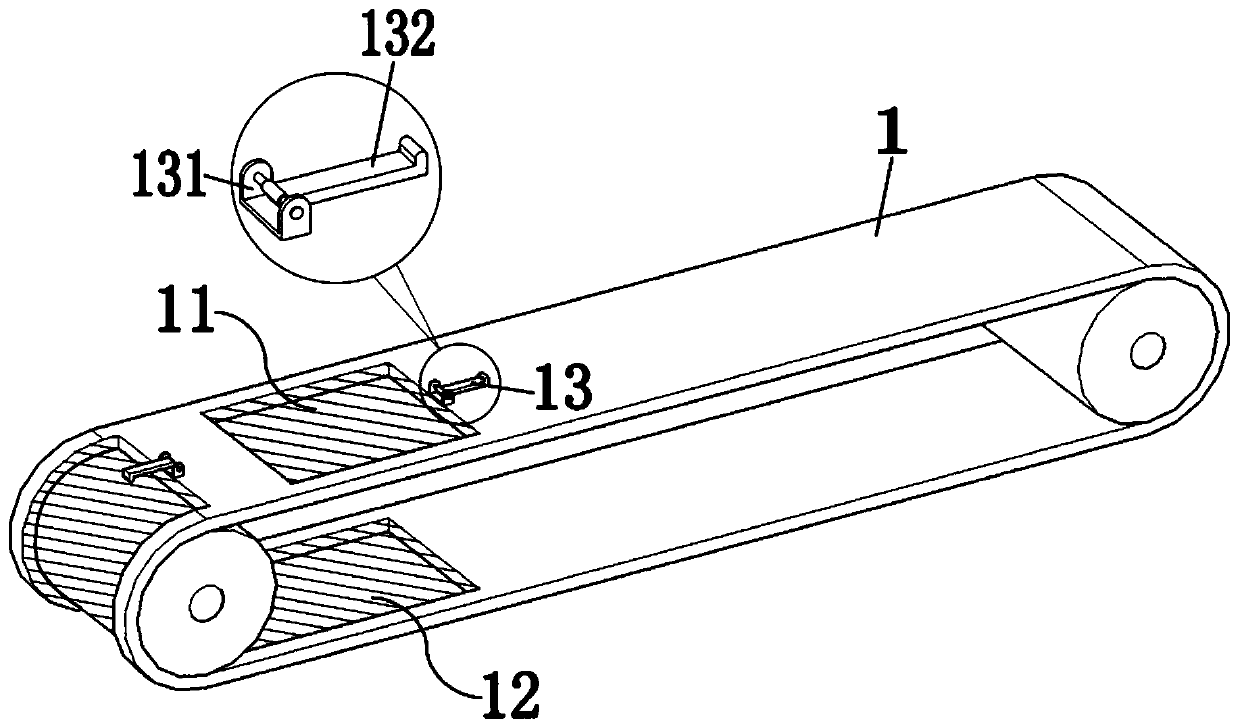

[0035] like figure 2 As shown, the wall of the output belt 1 is provided with a first through opening 11 and a second through opening 12, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com