Coiled material folding device

A folding device and coil technology, which is applied in the directions of winding strips, folding thin materials, transportation and packaging, etc., can solve the problems of high cost, inability to meet the automation level of production lines, low efficiency, etc., and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

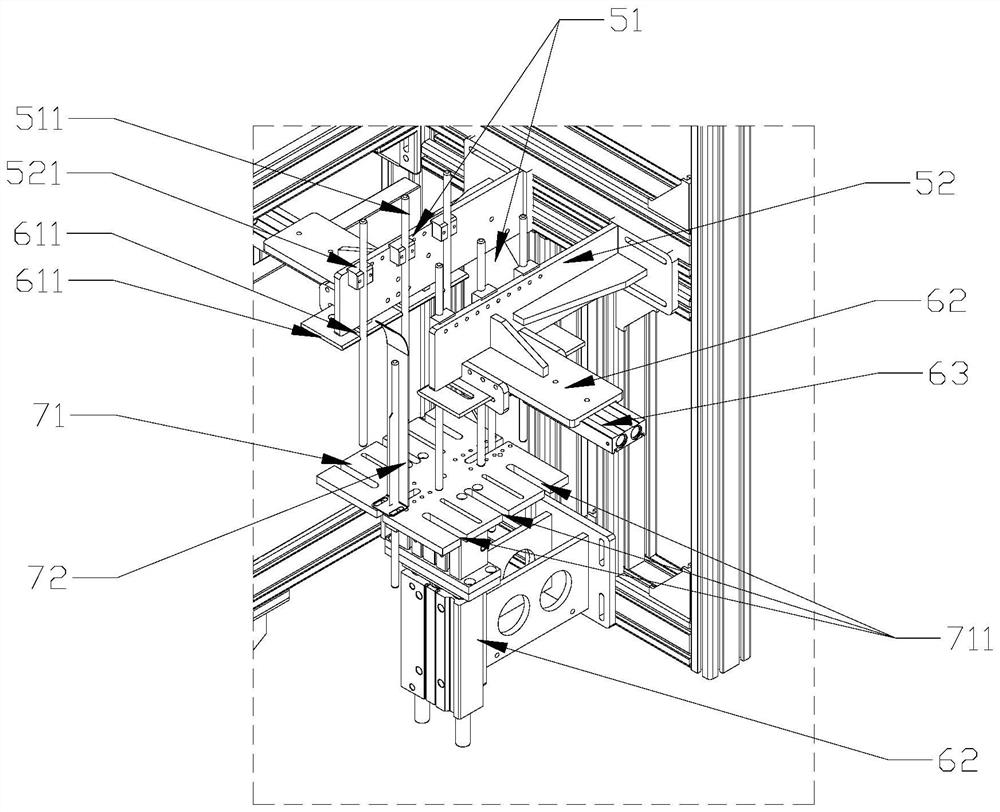

[0033] Such as Figure 4 In the crease mechanism shown, there are two die-cutting rollers 411, the two die-cutting rollers 411 are arranged in parallel, and the two die-cutting rollers 411 rotate in the same direction; the die-cutting rollers 411 include the first roller drum, the first roller shaft for installing the first roller, the outer circumferences of the two first rollers are tangent, the first U-shaped groove and the second U-shaped groove are provided on the first roller, and the first U-shaped groove is provided on the first roller. One U-shaped groove and the second U-shaped groove are arranged axially symmetrically, and one side of the first U-shaped groove and one side of the second U-shaped groove are all provided with a right-angle groove 4113, and the first U-shaped groove is filled with Rubber 4111, the second U-shaped groove is equipped with a cutter 4112. In this embodiment, the cutter head of the cutter 4112 protrudes from the outer circumference of the ...

Embodiment 3

[0036] Described collection jig 7 comprises base plate 71, side plate 72, and the bottom of described base plate 71 is connected with the output end of cylinder 62, and described side plate 72 is installed on the front and back ends of base plate 71 top, and the both sides of described base plate 71 Each is provided with a third groove 711 for the guide rod 511 to pass through, and the third groove 711 is adapted to the shape of the guide rod 511 . The front and rear ends of the base plate 71 have a plurality of threaded holes, the side plate 72 is an L-shaped structure, and the bottom of the side plate 72 is connected with the threaded holes, so that when the coil size changes, the installation of the side plate 72 can be adjusted. The location is enough, and the collection of multi-size coils can be realized. At the same time, the design of the third groove 711, on the one hand, can cooperate with the side plate 72 to collect materials; When the coil size changes, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com