Patents

Literature

75results about How to "Realize automatic gripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

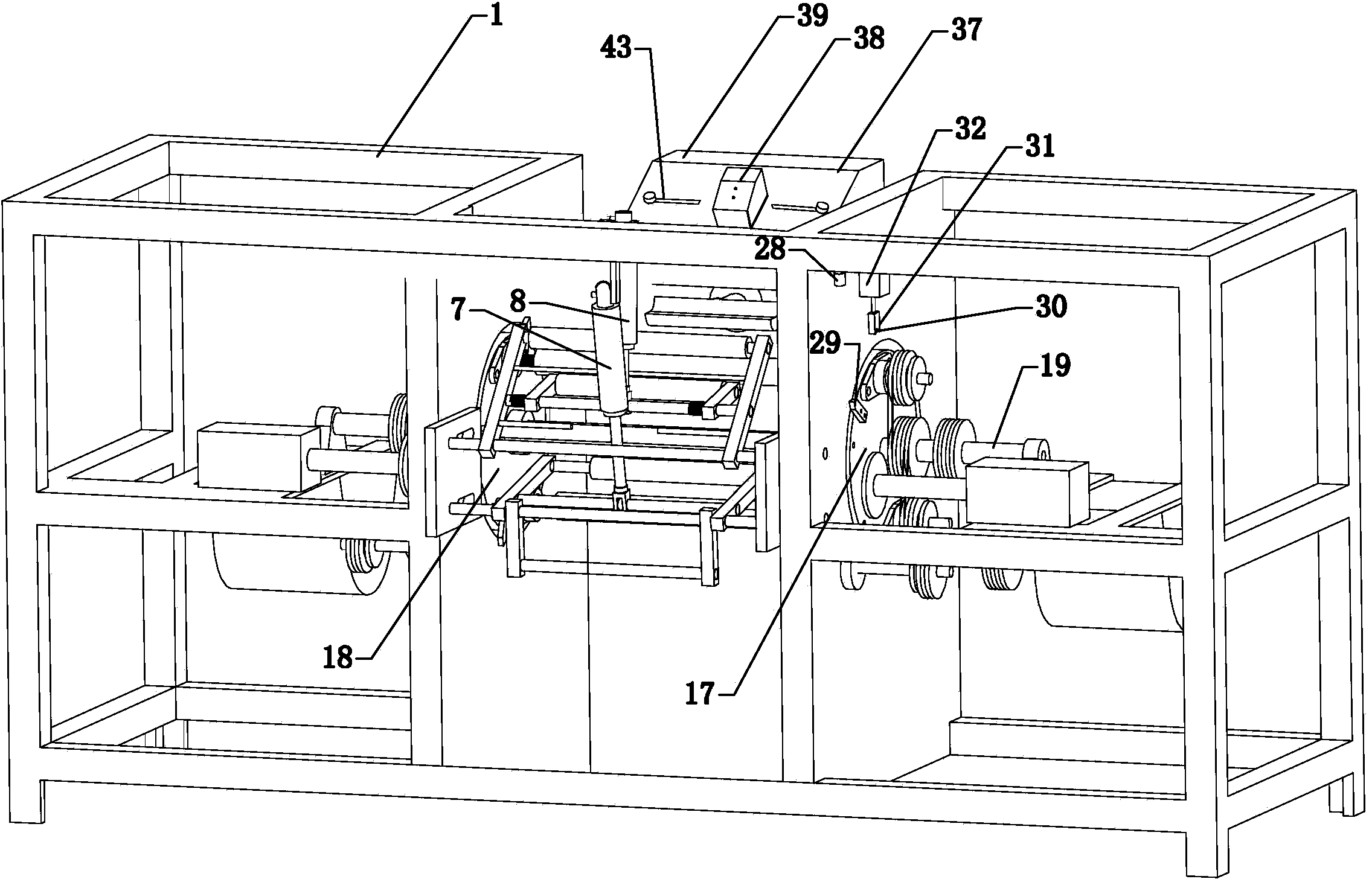

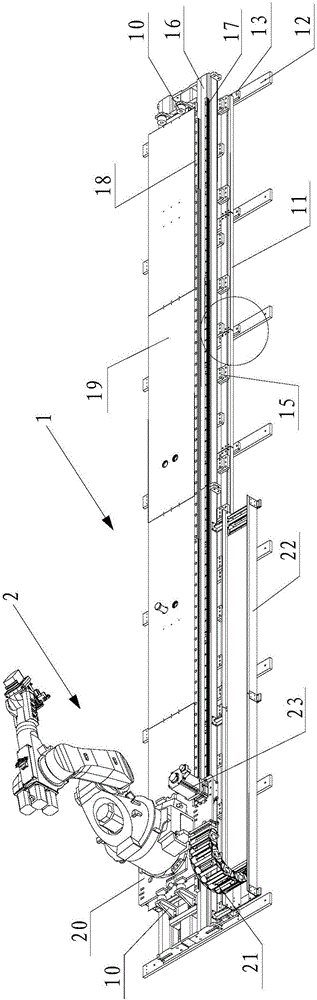

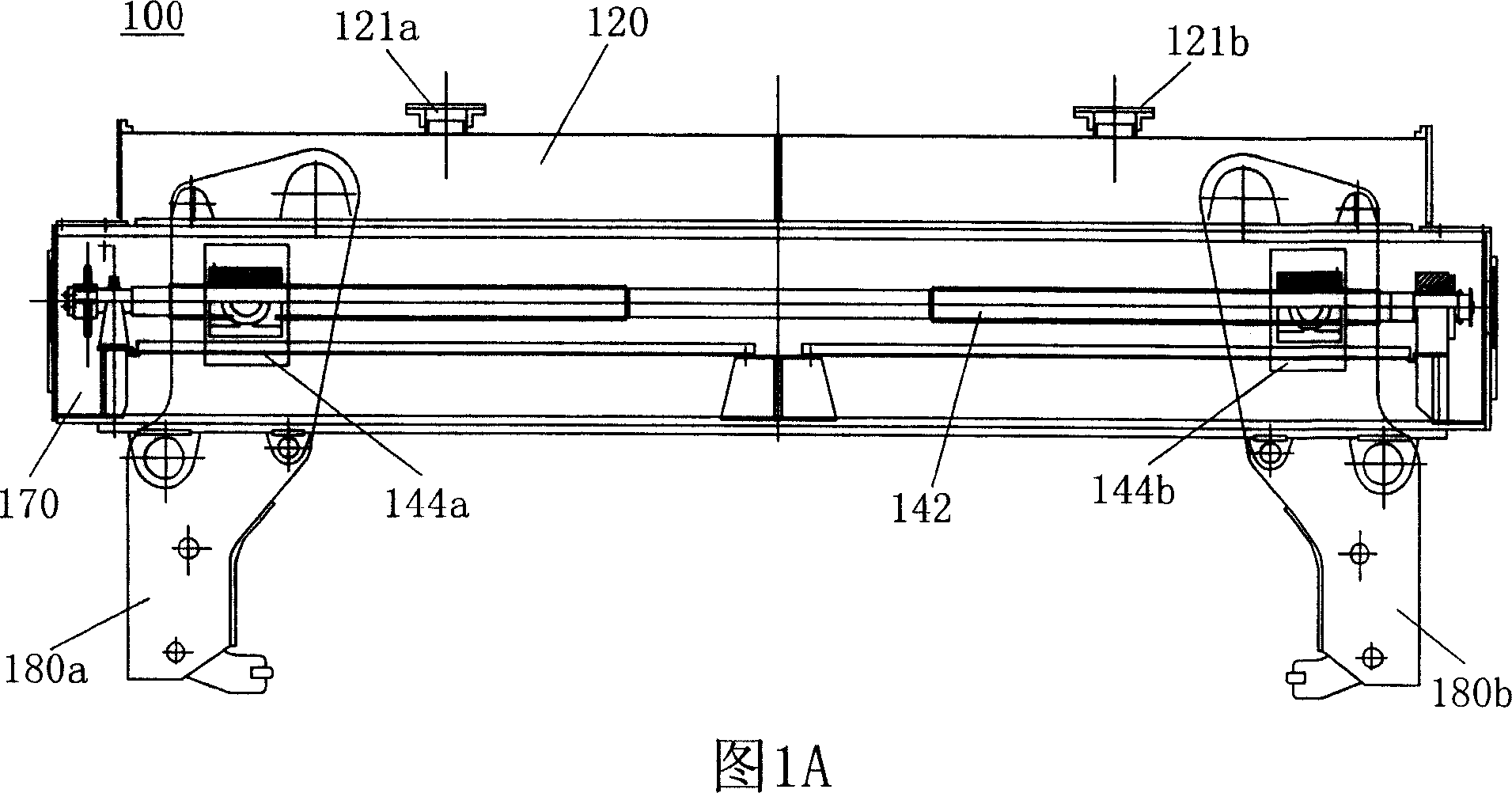

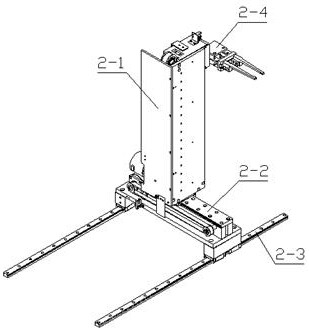

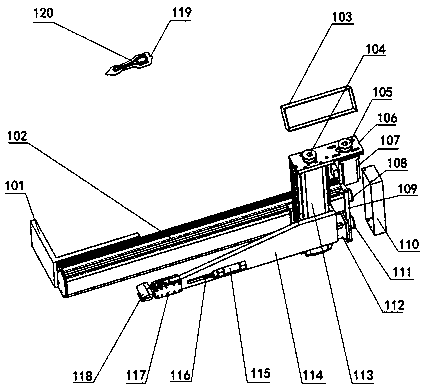

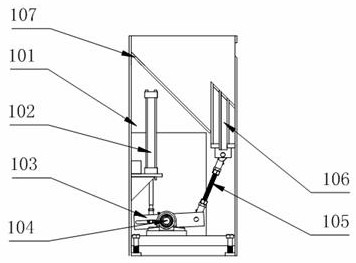

System for storing and fetching multiple drill rods

ActiveCN101988374AImplement automatic storageRealize automatic grippingDrilling rodsDrilling casingsLathe faceplateManipulator

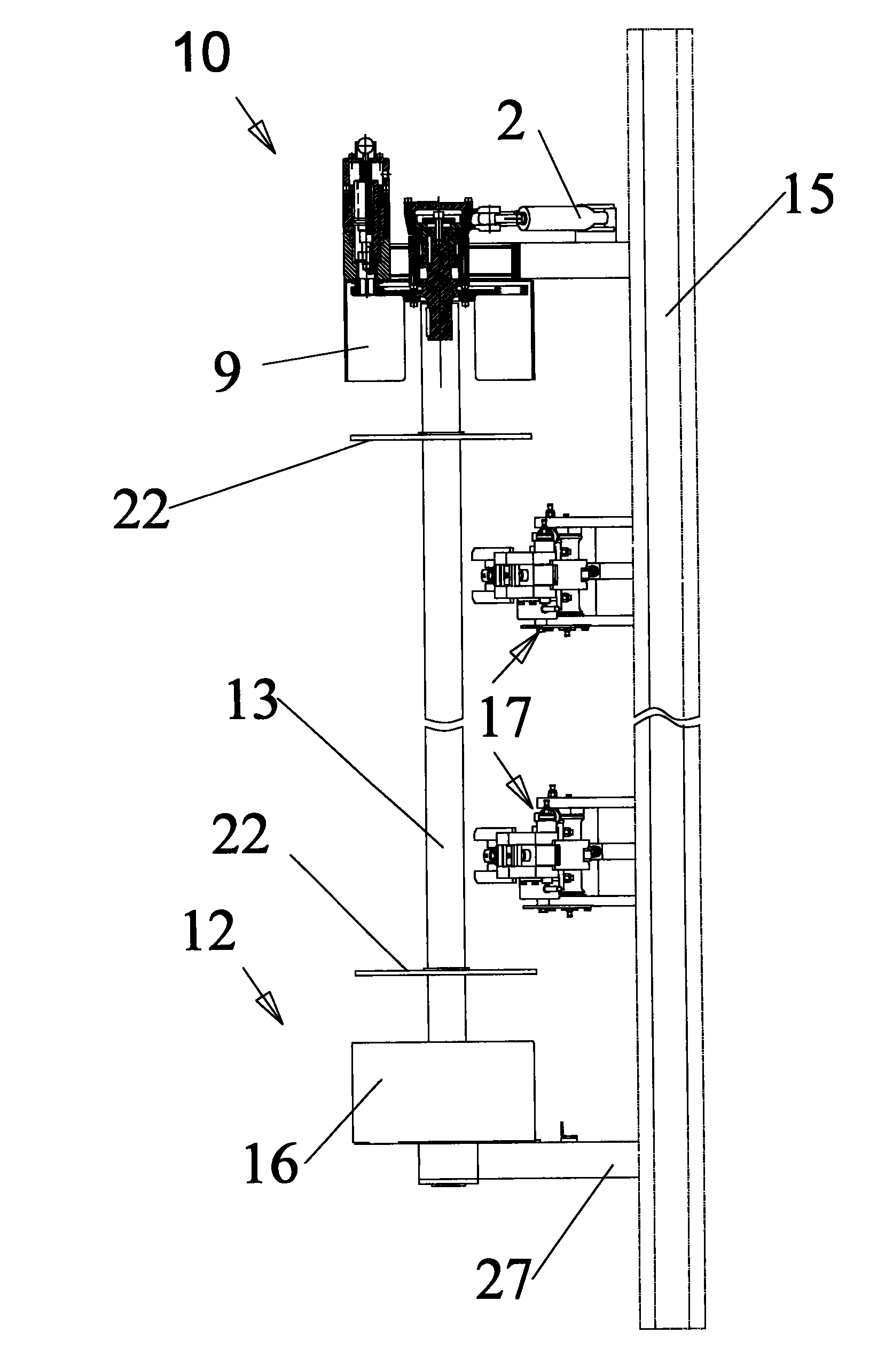

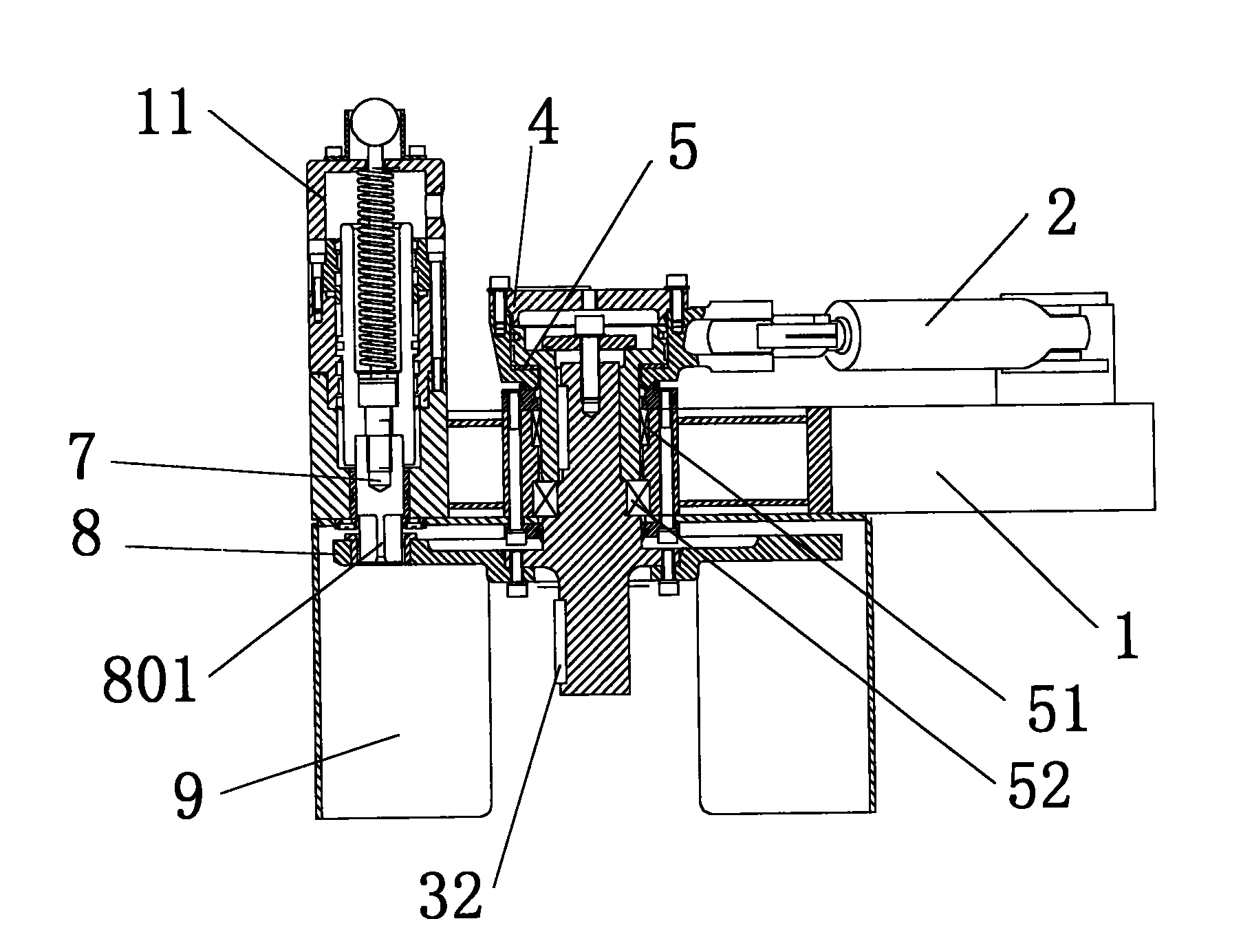

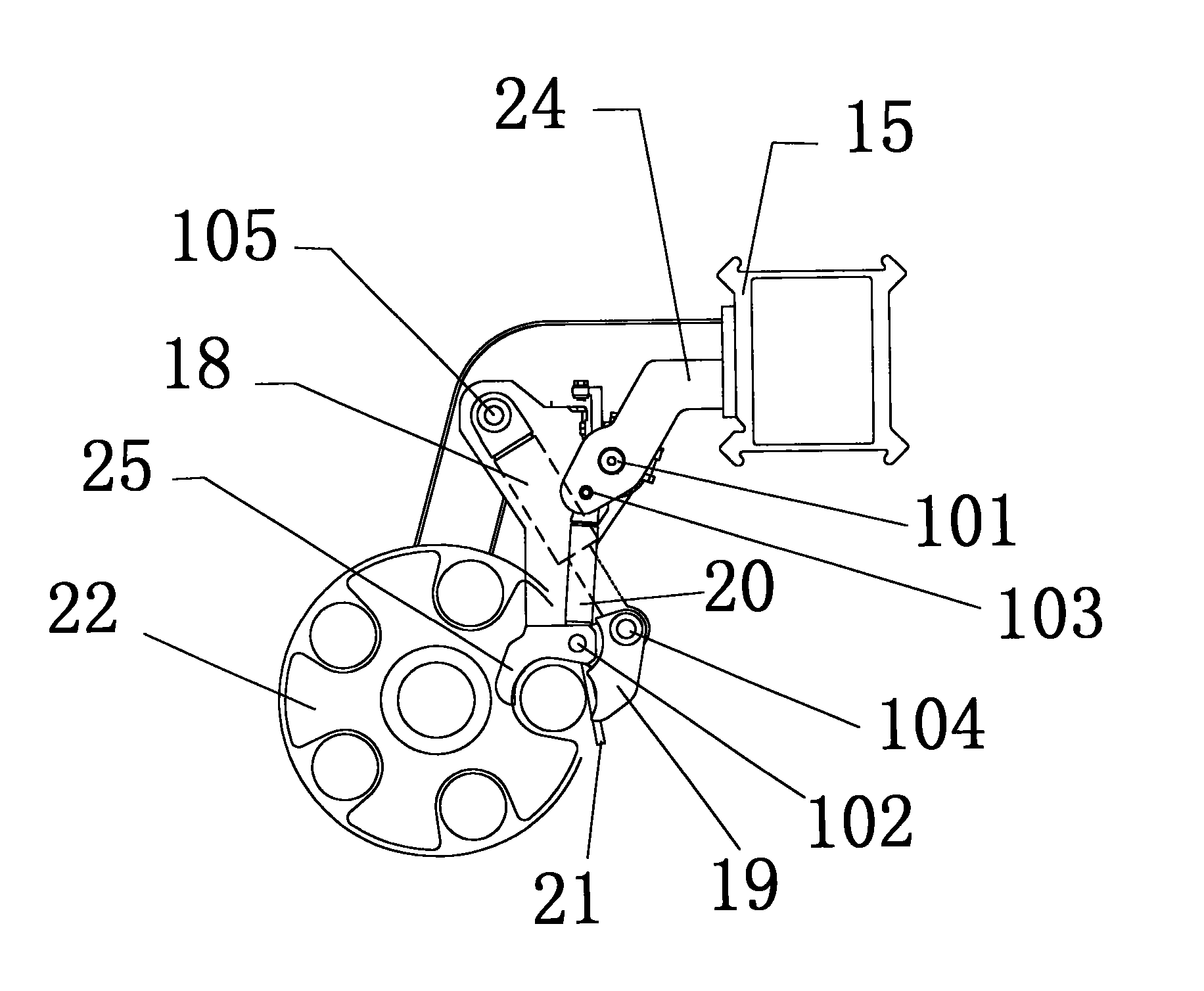

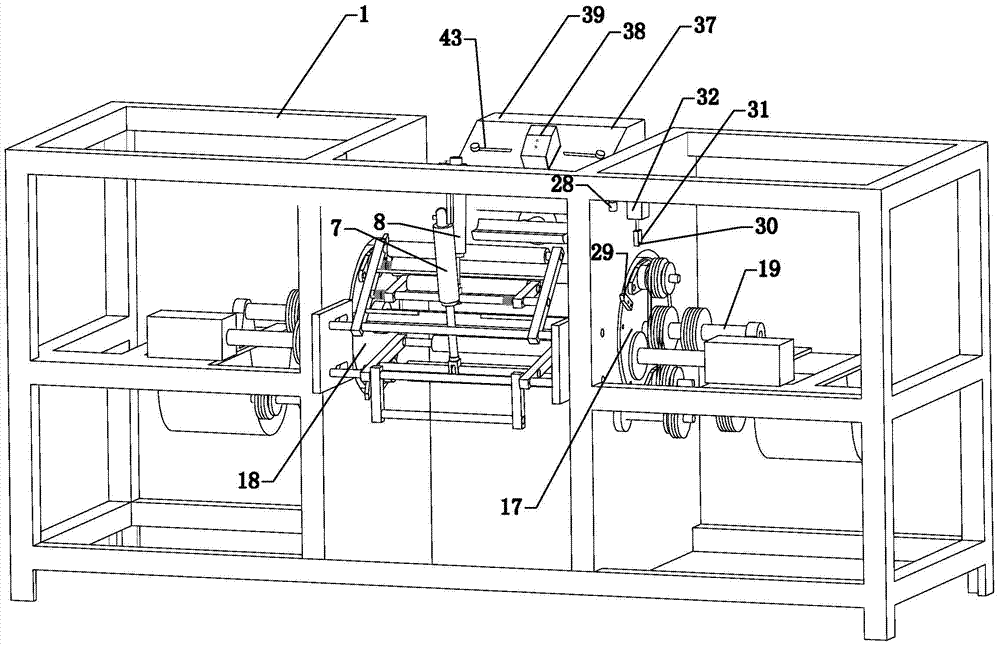

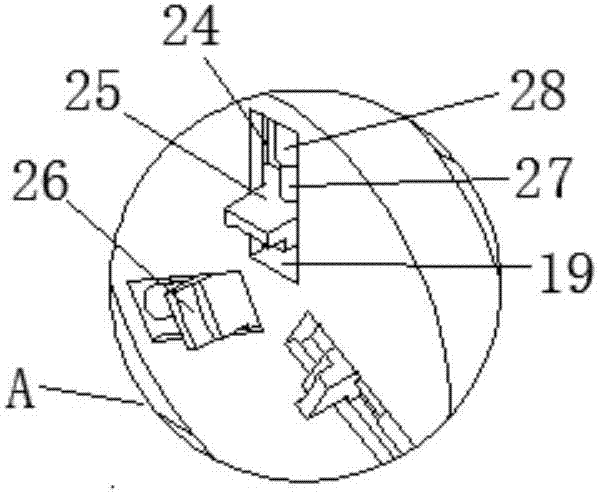

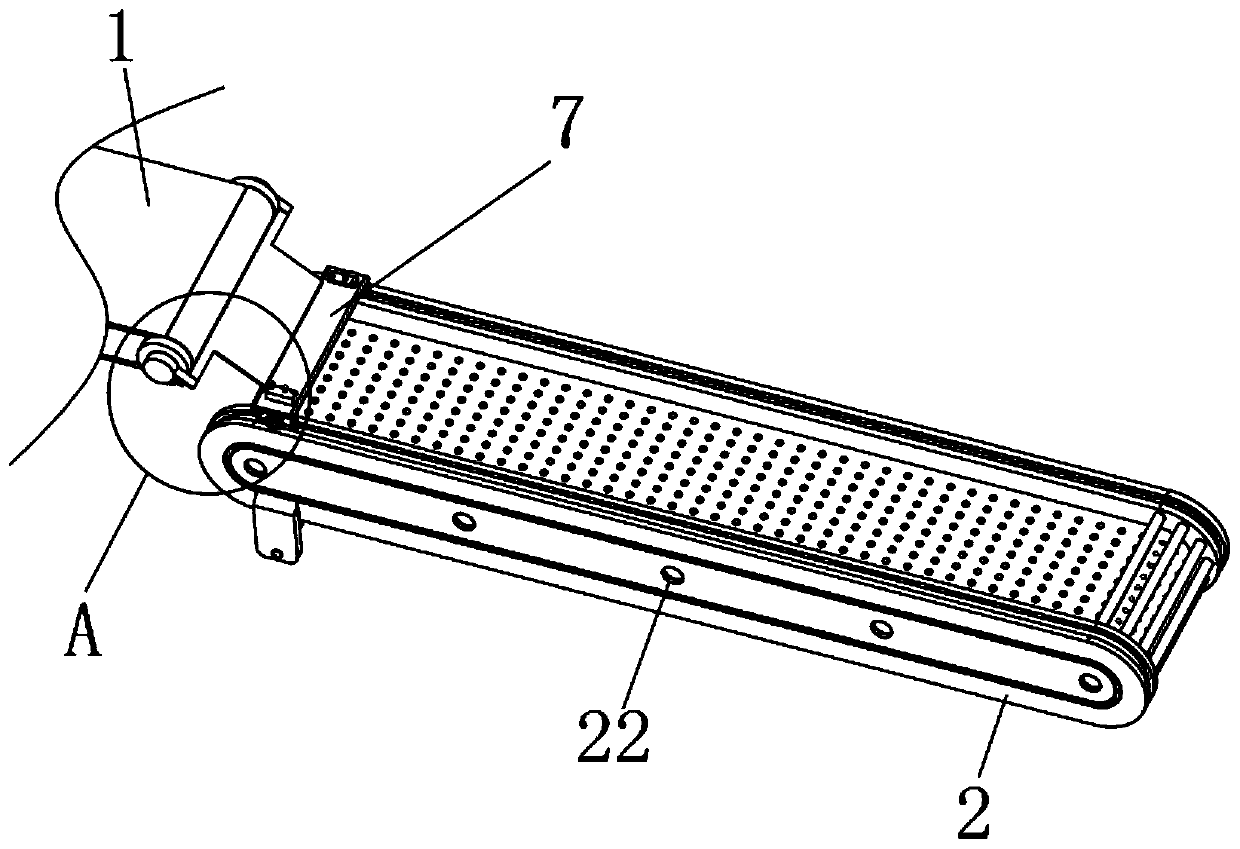

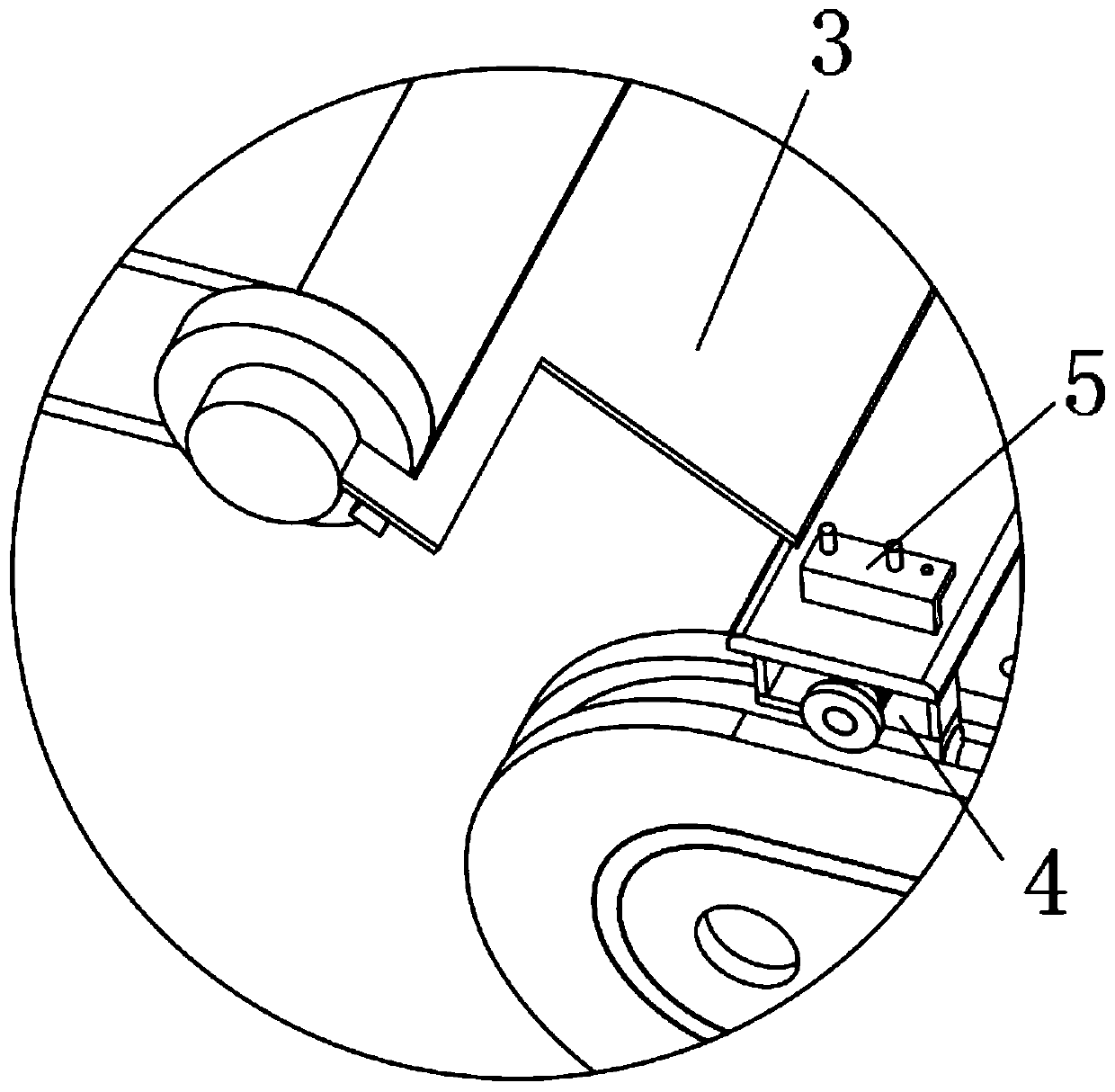

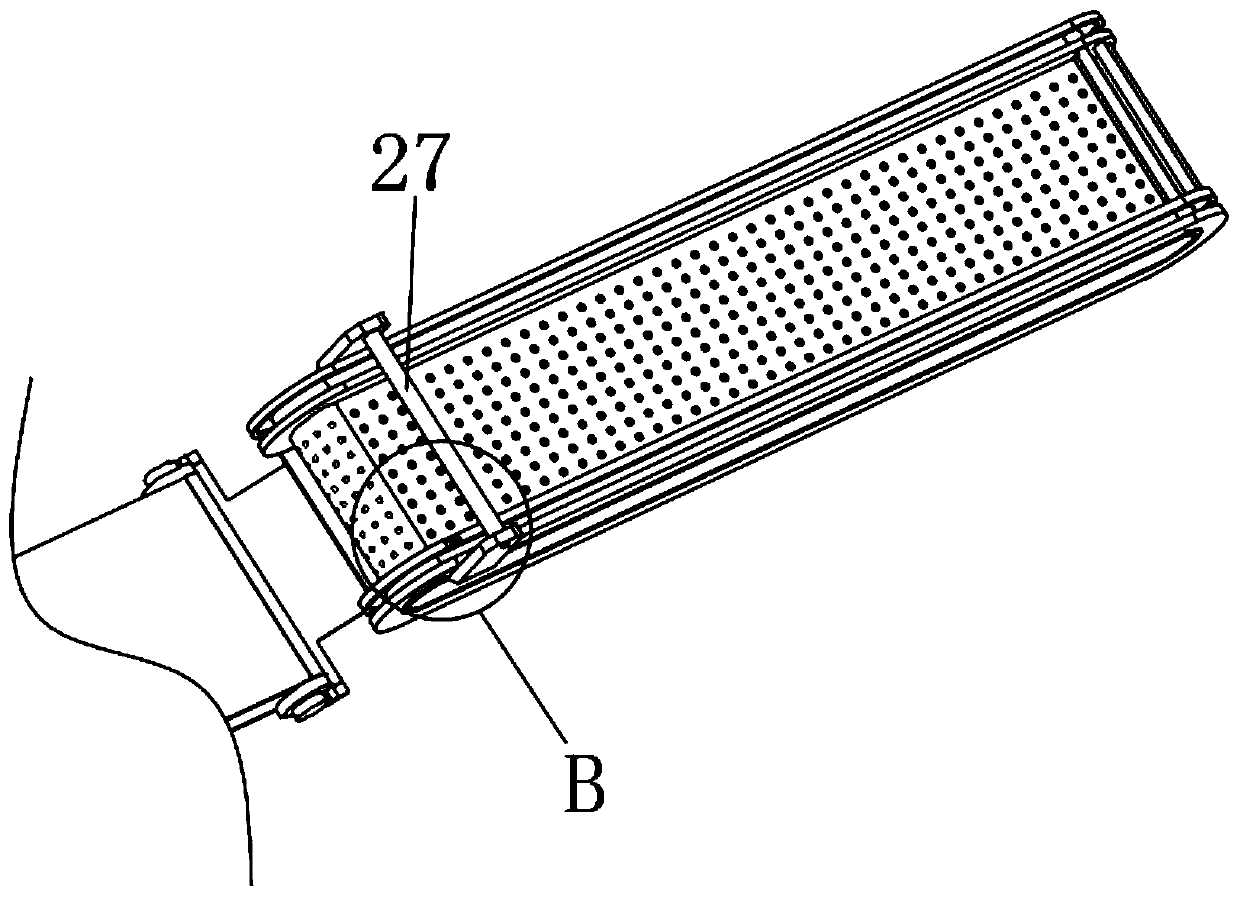

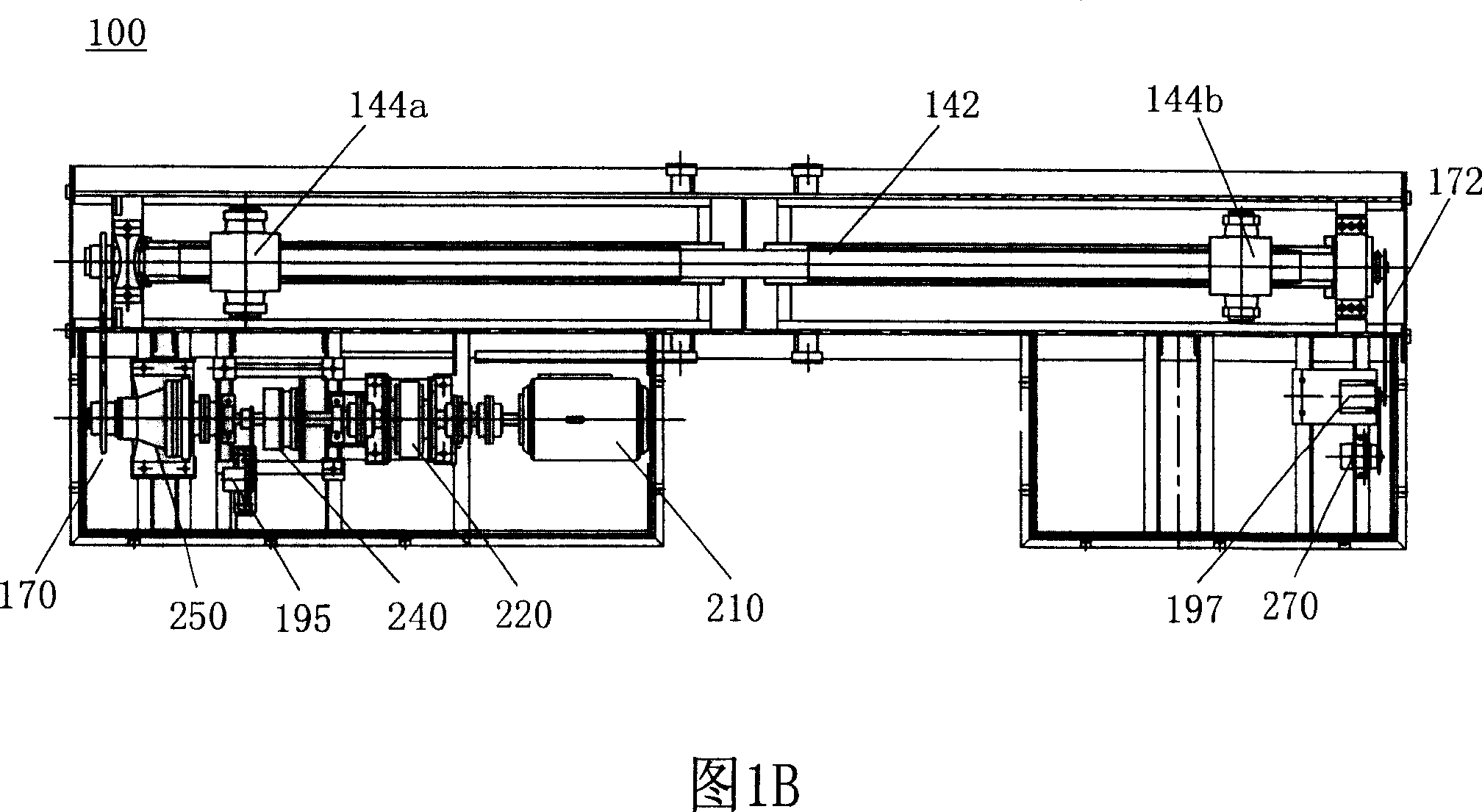

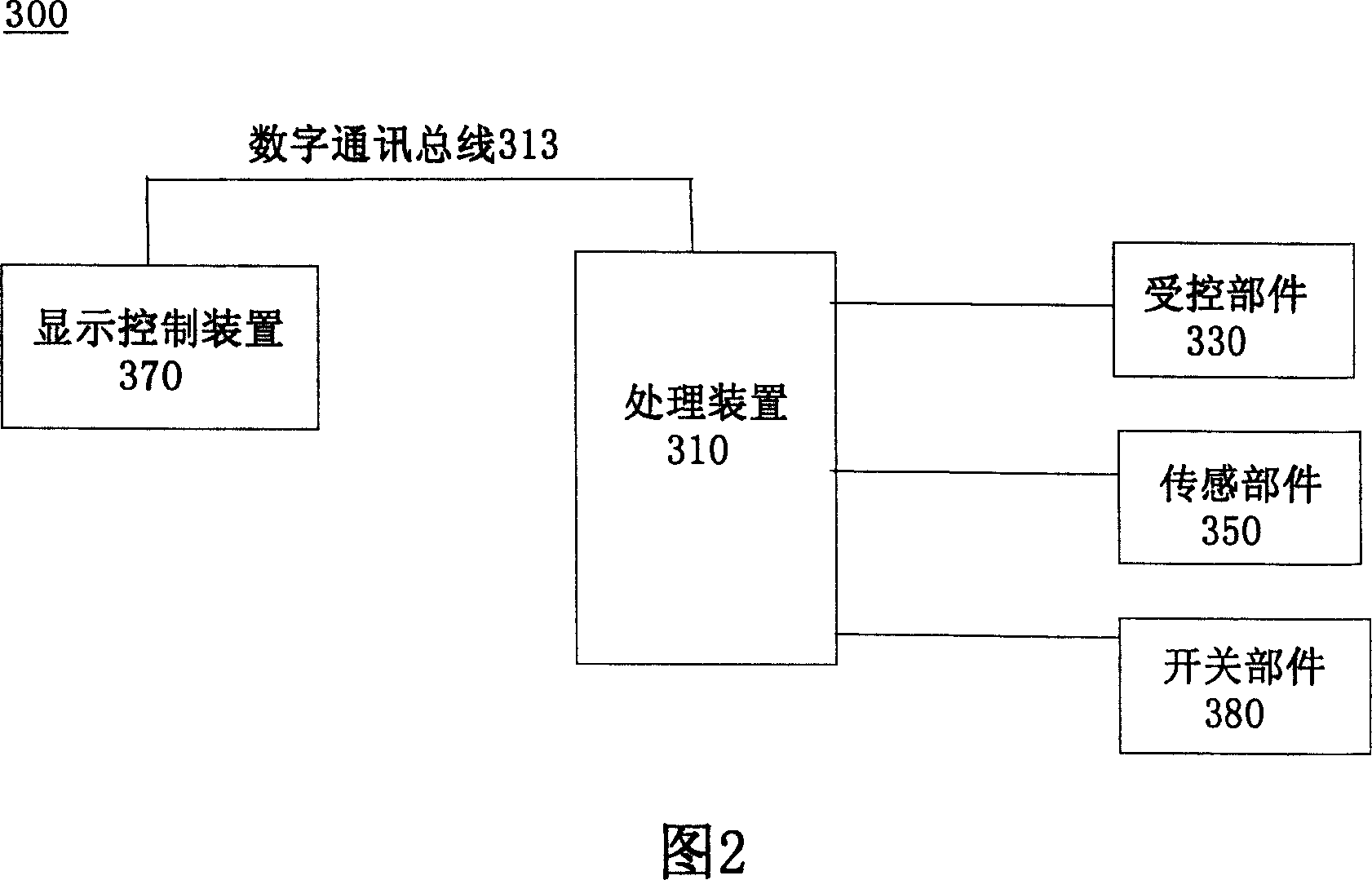

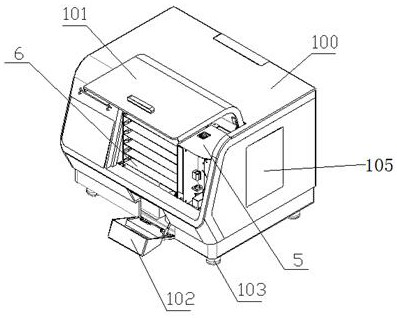

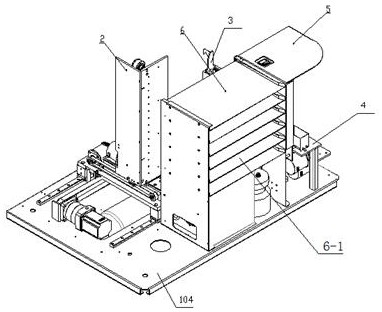

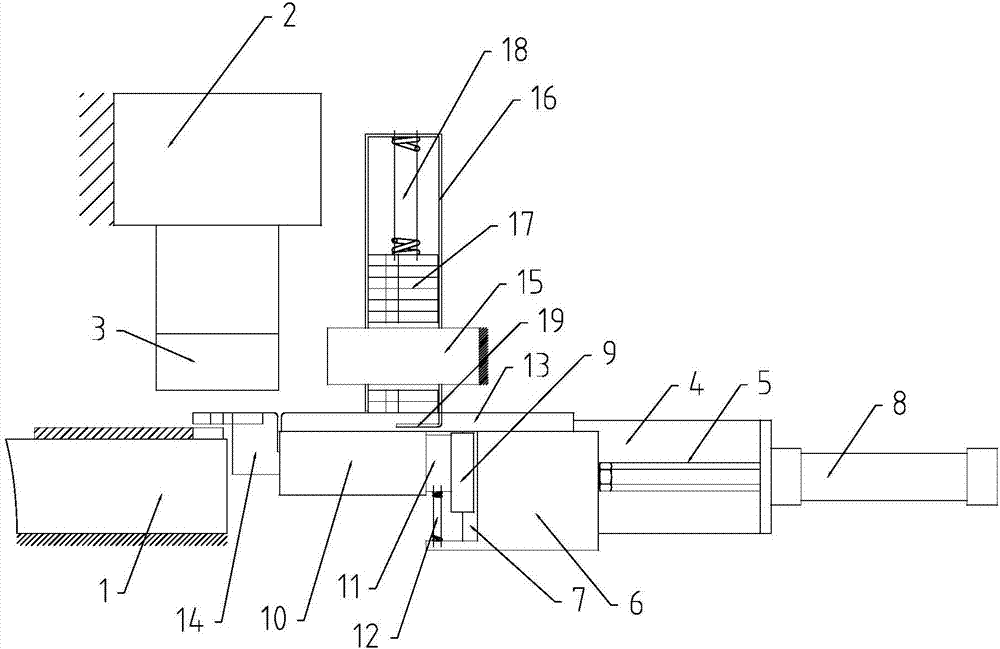

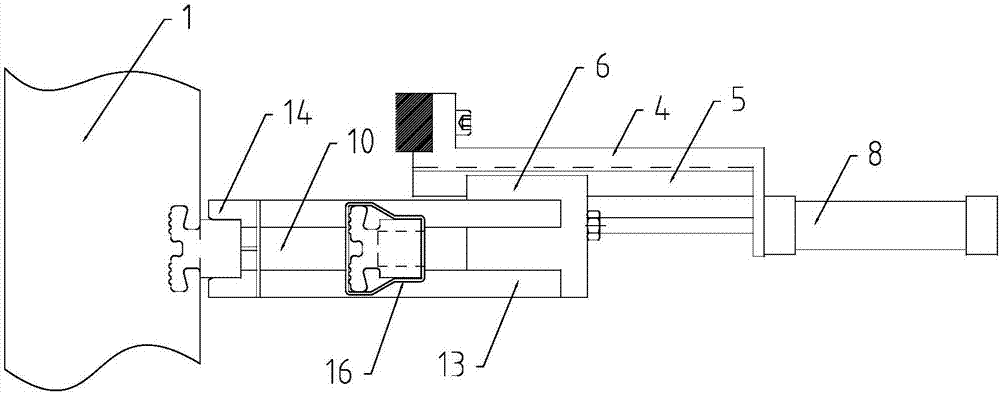

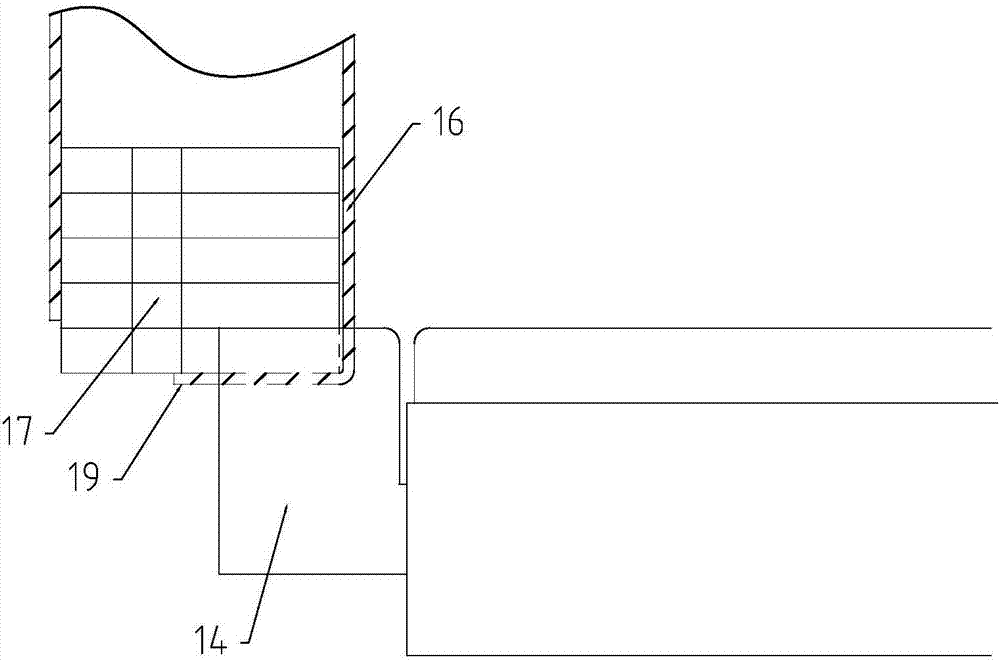

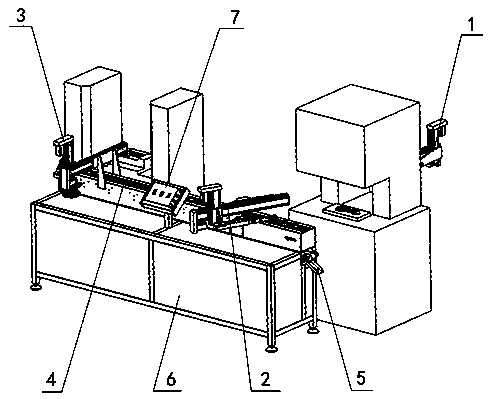

The invention provides a system for storing and fetching multiple drill rods, which comprises a drill rod warehouse, a plurality of manipulators and a pushing beam, wherein the drill rod warehouse is used for storing drill rods; the manipulators are used for clamping the drill rods; the pushing beam is used for installing the drill rod warehouse and the manipulators; the drill rod warehouse comprises a main shaft, an upper bracket and a lower bracket, the main shaft is parallel with the pushing beam and connected with the upper bracket and the lower bracket, the upper part and the lower part of the main shaft are respectively provided with a face plate perpendicular to the main shaft, a plurality of grooves are uniformly arranged at the periphery of each face plate, and the drill rods areclamped in the grooves of the face plates; the upper bracket and the lower bracket are internally and respectively provided with an upper drill rod box and a lower drill rod box used for storing the drill rods, and the upper bracket is also provided with a rotating positioning mechanism; and each manipulator comprises a manipulator seat frame, a swinging arm, a swinging arm oil cylinder, a fixed clamping jaw, a movable clamping jaw and a clamping jaw oil cylinder. Compared with the way of manual mounting and dismounting in the prior art, the invention realizes the storage and the automatic and continuous fetching of the multiple drill rods, reduces the labor intensity, improves the working efficiency and further enhances the operation safety through matching of the drill rod warehouse andthe manipulators.

Owner:ATLAS COPCO (NANJING) CONSTR & MINING EQUIP CO LTD

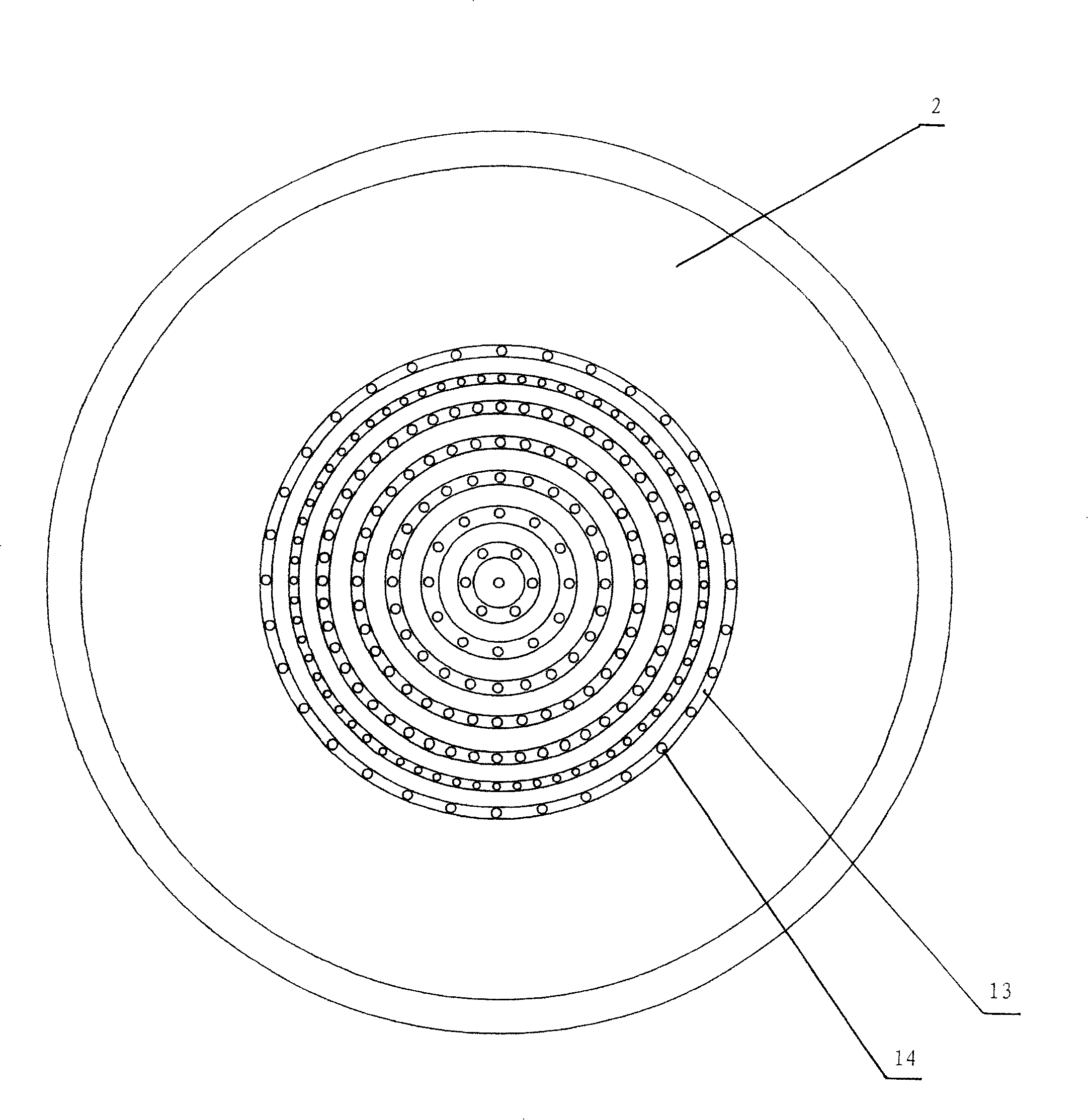

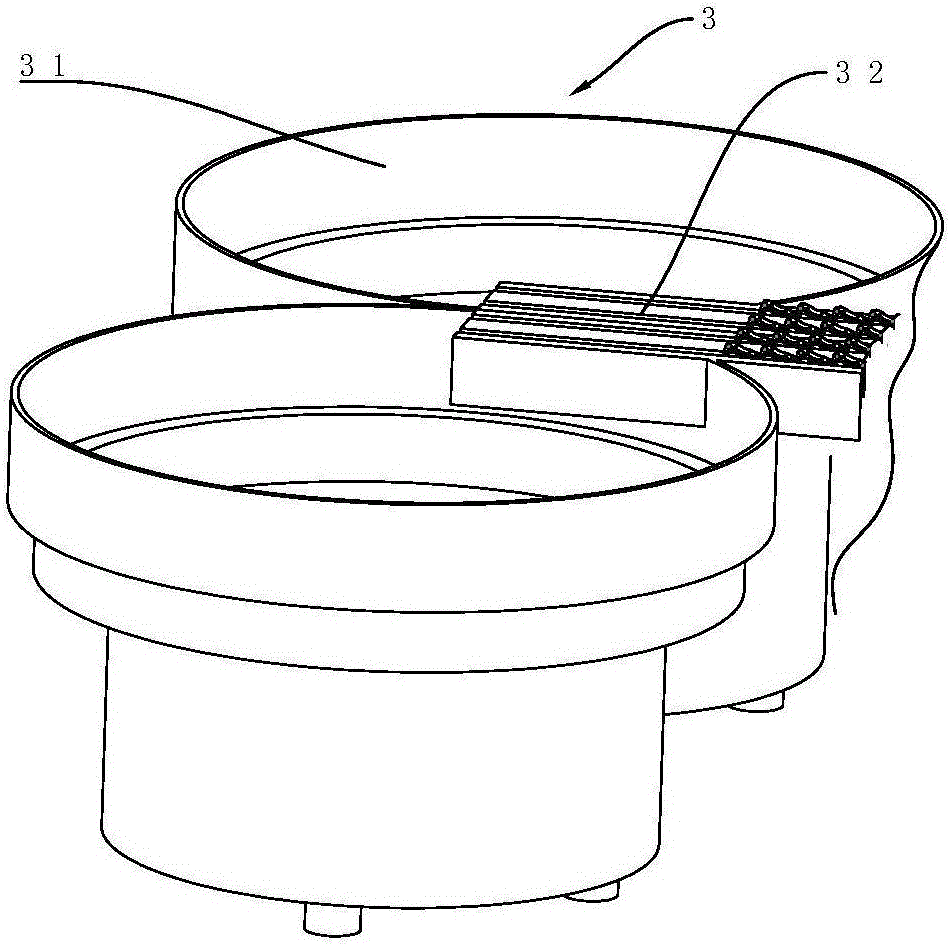

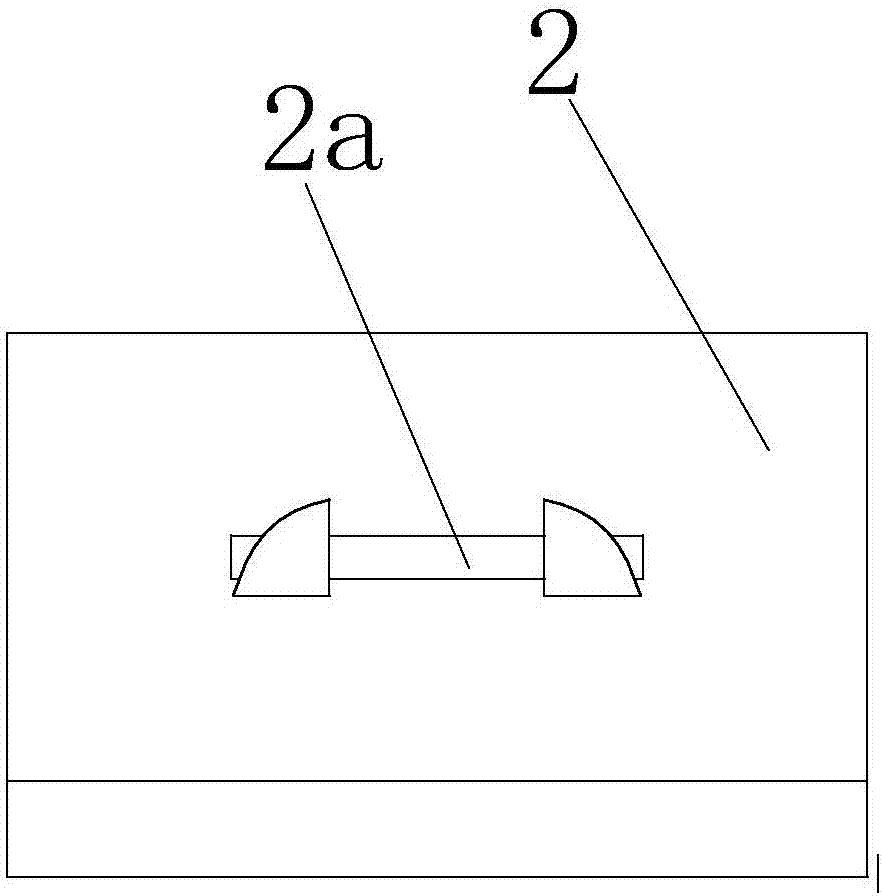

Ring-shaped lead rail of vertical type lathe

InactiveCN101204779AChange suctionGuarantee processing qualityEngine sealsPositioning apparatusEngineeringMachine tool

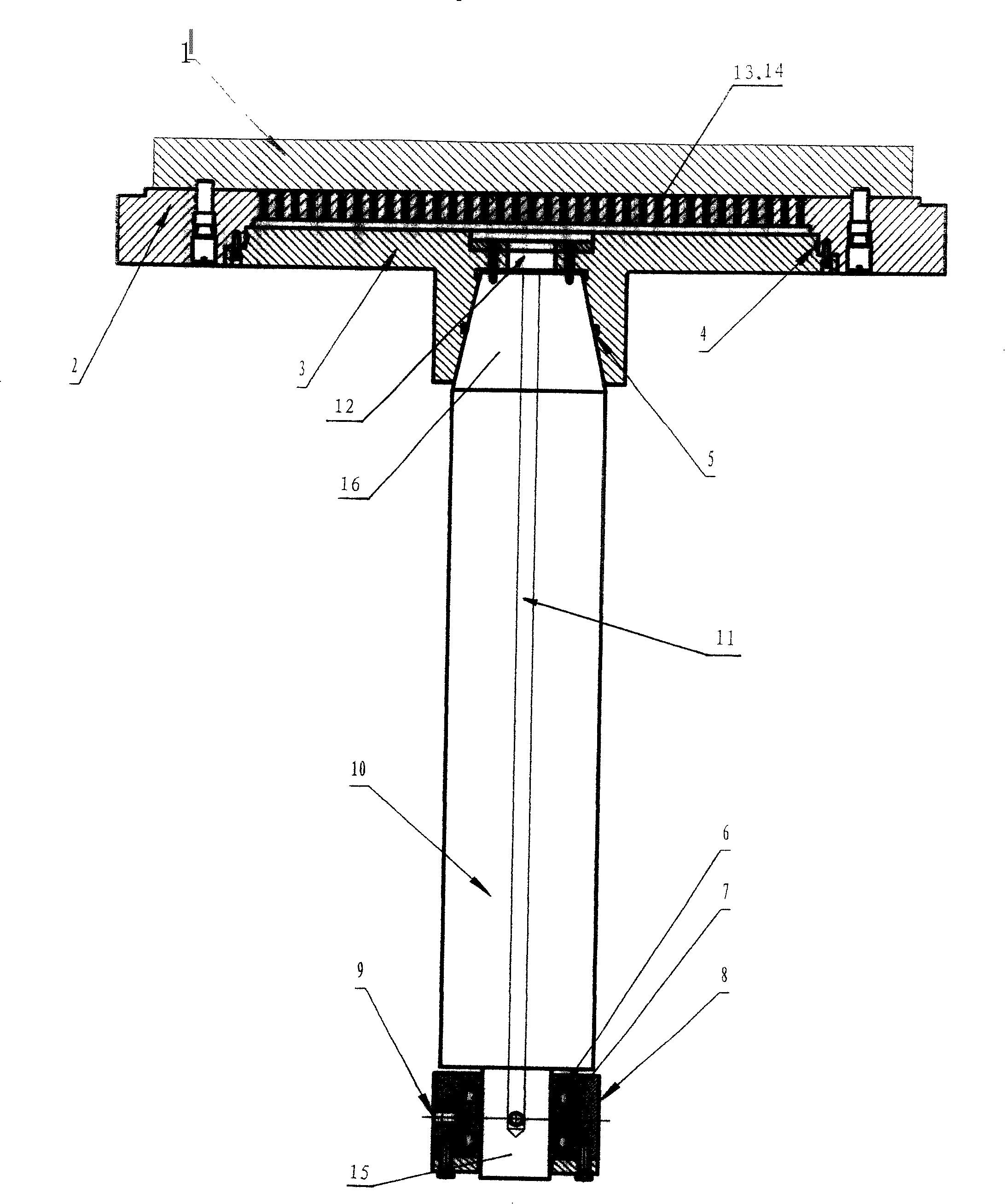

The invention provides a vacuum chuck used for a precision lathe relating to the field of latch frocks. A traditional lathe clamp traditionally adopts a machinery chuck which can generate deformation easily on chuck work-pieces and thin wall work-pieces of precision machining and affect the machining quality. The invention adopts a vacuum system to absorb the machining work-piece, thus avoiding the defects. The tail part of a main shaft of the lathe with a vacuum pipeline is connected with an external vacuum system and the end part of the main shaft of the lathe is provided with the vacuum chuck. The surface of the vacuum chuck is provided with a plurality of air suction openings. The machining work-piece is arranged on the vacuum chuck and is absorbed on the vacuum chuck tightly with the enlarging of the vacuum degree. The work-piece clamping mode ensures the machining quality and improves the automation degree. The invention also has the beneficial effects of simple structure and convenient operation.

Owner:TIANSHUI SPARK MACHINE TOOL

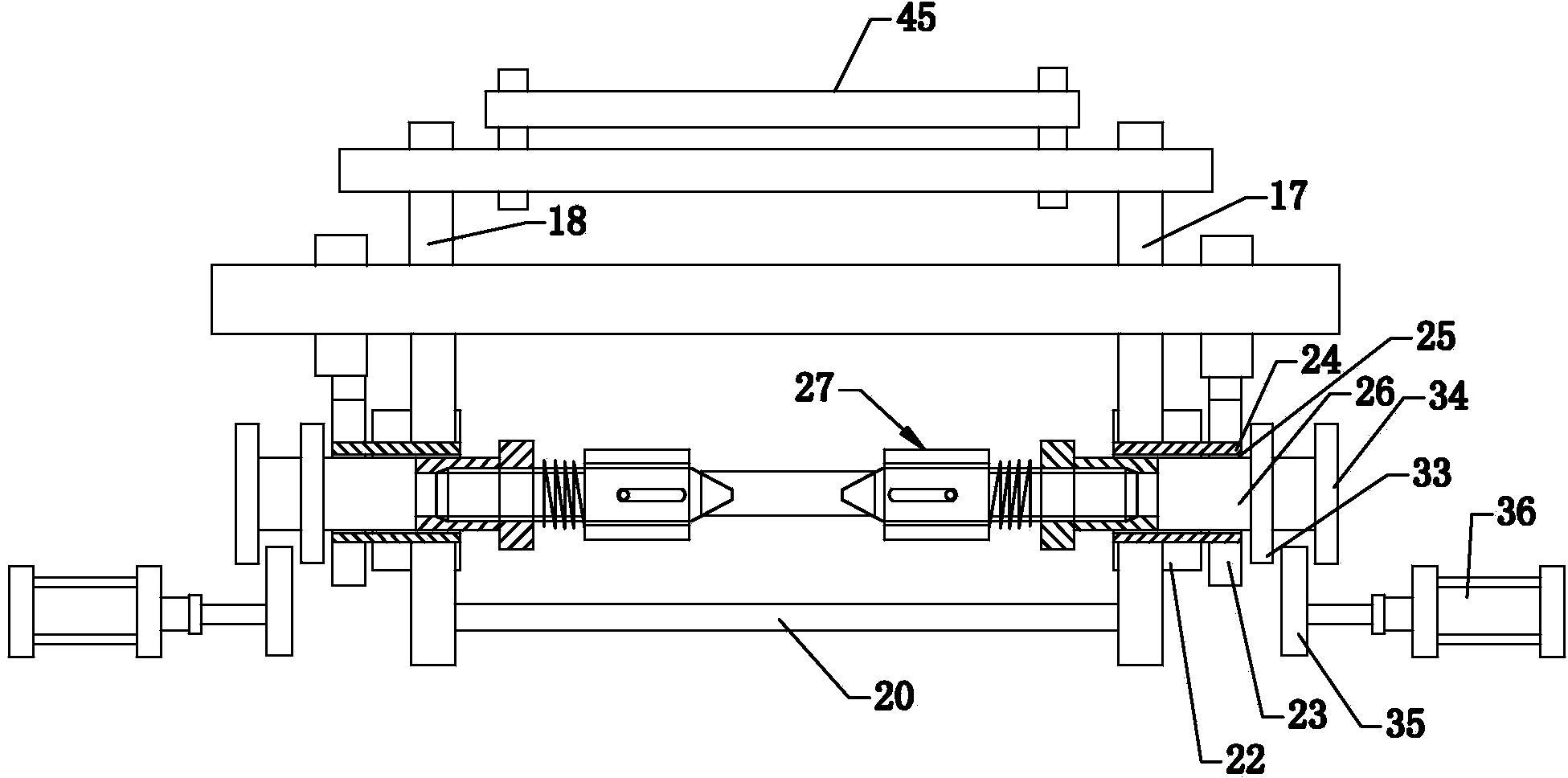

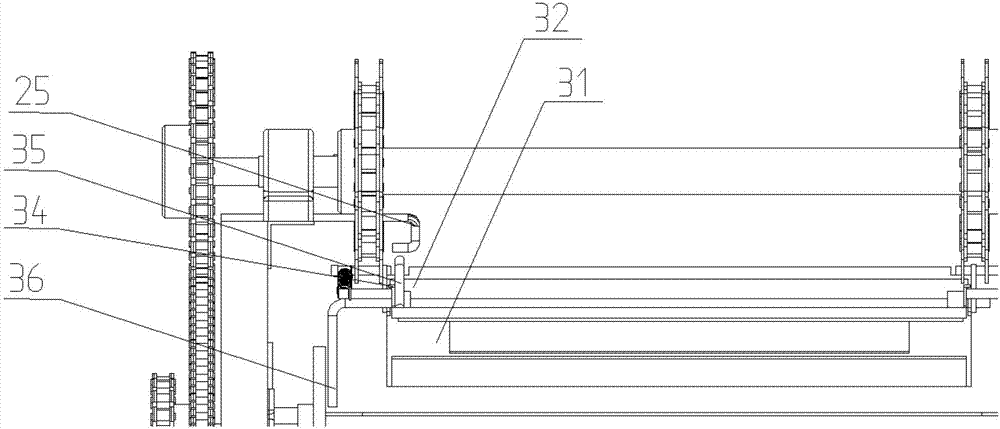

Automatic take-up and reel alternation machine for plastic bags

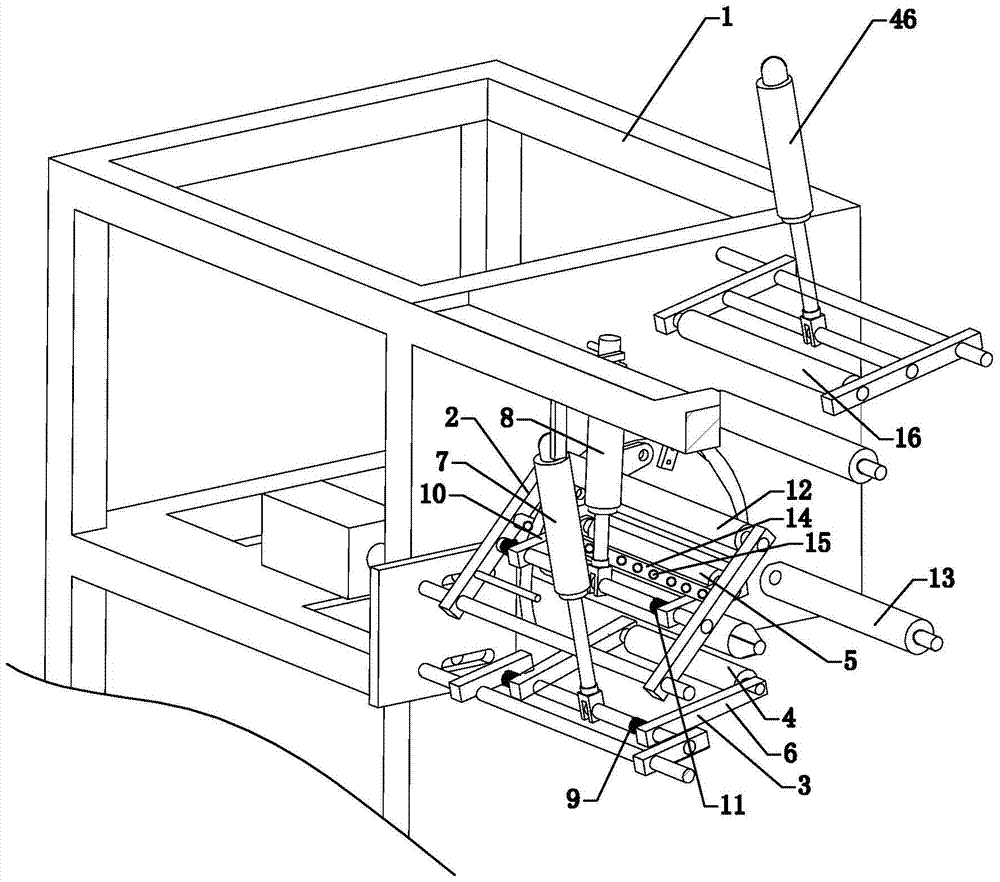

The invention discloses an automatic take-up and reel alternation machine for plastic bags. The automatic take-up and reel alternation machine comprises a machine frame and further comprises a reel-alternating mechanical arm, an overturning mechanism and a clamping mechanism in the conveying direction of plastic bag films. The reel-alternating mechanical arm is used for reel alternation of the plastic bag films and is installed on the machine frame. The overturning mechanism is used for making reels of the plastic bags reach a working position alternately, is installed on the machine frame and is arranged below the reel-alternating mechanical arm. The clamping mechanism is used for clamping and dismantling the reels alternately, is installed on the machine frame and is arranged below the reel-alternating mechanical arm. The automatic take-up and reel alternation machine for the plastic bags is used in cooperation with a bag making machine, realizes automatic take-up and reel alternation of the plastic bag films, is reliable in operation and high in automation degree, lowers the labor intensity of workers, improves the production efficiency of the plastic bag films, and greatly lowers production cost.

Owner:潍坊兴信工程项目管理有限公司

Lithium automatic transmitting and fixing equipment as well as transmitting and fixing process thereof

ActiveCN108750535AImprove teleportation effectShaking will not appearConveyorsGrinding feedersAutomatic controlEngineering

The invention relates to lithium automatic transmitting and fixing equipment as well as a transmitting and fixing process thereof. The lithium automatic transmitting and fixing equipment comprises a supporting bottom plate, supporting columns, a transmitting supporting plate, a transmitting device and a fixing device; a round hole is formed in the middle part of the left end of the transmitting supporting plate; the supporting columns are arranged at the top of the supporting bottom plate uniformly; the transmitting supporting plate is arranged at the top of each supporting column; the transmitting device is arranged at the top of the right end of the transmitting supporting plate; the fixing device is arranged at the top of the left end of the transmitting supporting plate; and the transmitting device comprises a transmitting belt, a limiting mechanism, a transmitting electric sliding block, a transmitting upright column and two transmitting and lamping branched chains. The problems that when the lithium battery needs to be fixed before being polished, the lithium battery cannot be transmitted automatically, omnibearing fixation cannot be conducted when the lithium battery is polished, the lithium battery is waggled when being polished, a negative electrode of the lithium battery needs to be clamped by a special clamp when being polished, the lithium battery cannot be automatically controlled to rotate as well as the placing position of the lithium battery causes deviation are solved.

Owner:领航国创新能源电池技术研究院(北京)有限公司

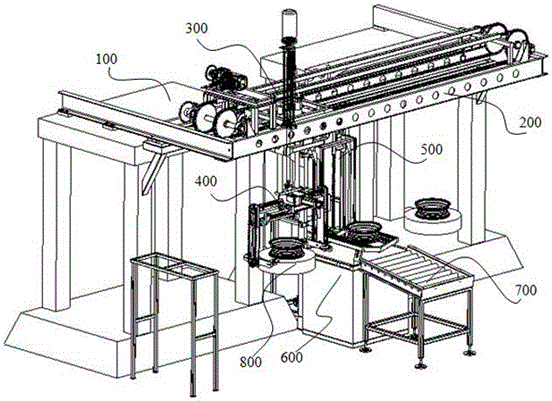

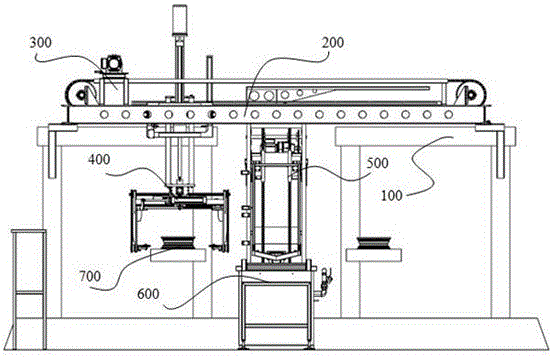

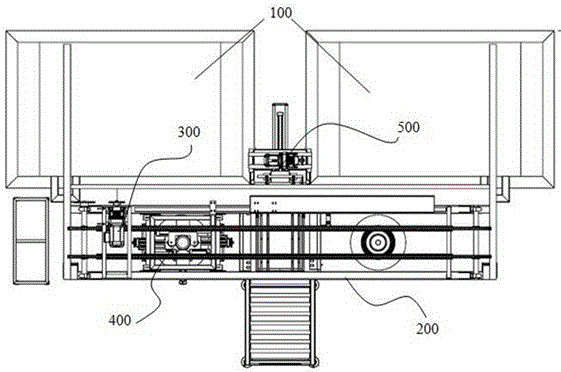

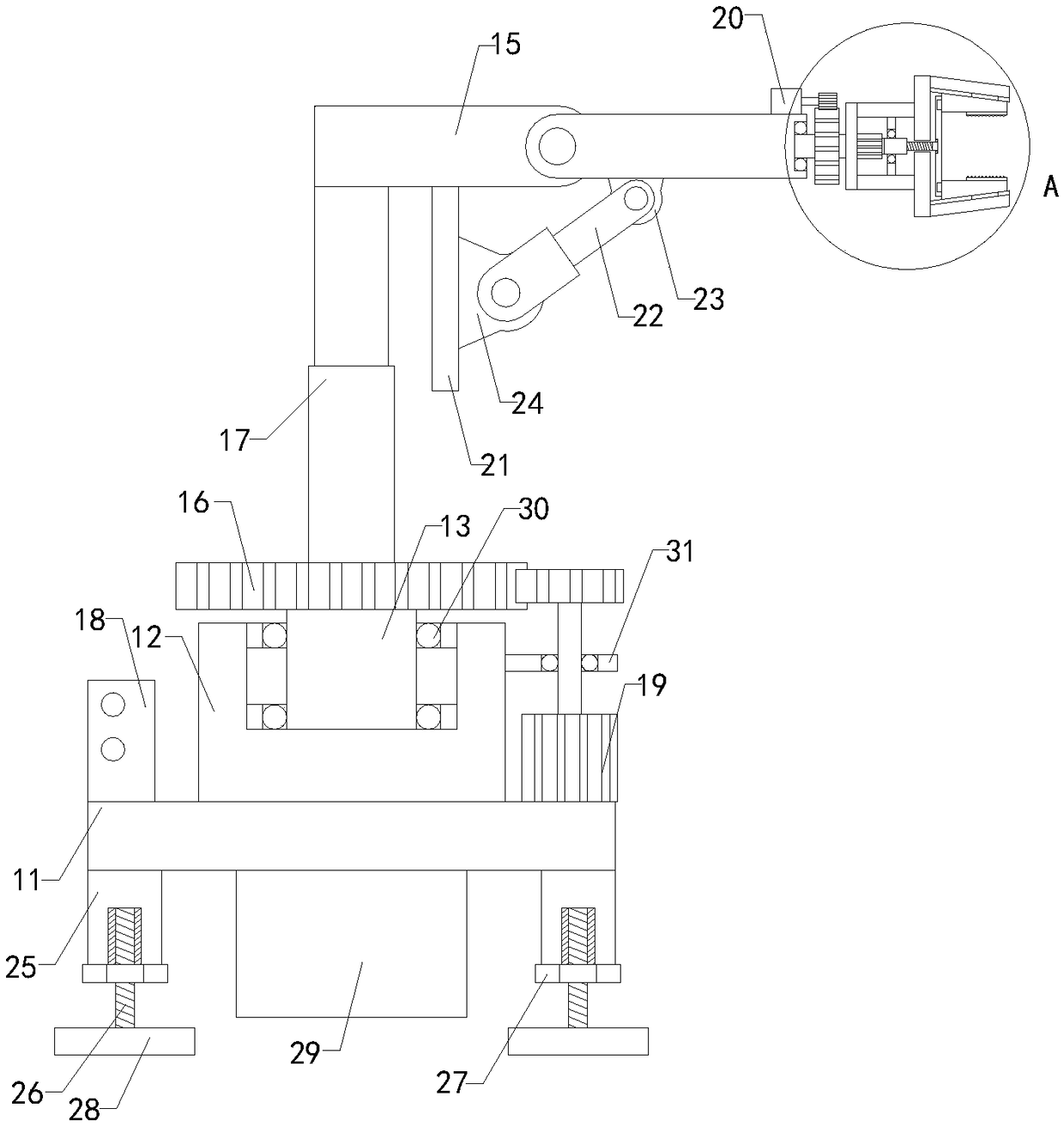

Cooling manipulator of die-casting machine for automobile aluminum alloy hub

The invention provides a cooling manipulator of a die-casting machine for an automobile aluminum alloy hub. The cooling manipulator comprises two supporting seats, a bracket, a transverse driving mechanism, a mechanical grabber, a longitudinal driving mechanism, a cooling water tank and a discharging rack, wherein the two supporting seats are arranged in parallel, and the bracket is mounted on the two parallel supporting seats; the transverse driving mechanism is mounted on the bracket; the mechanical grabber, comprising a moving rack, a first cylinder and a grabber body, is mounted on the transverse driving mechanism and is driven by the transverse driving mechanism to horizontally move; the longitudinal driving mechanism is mounted below the transverse driving mechanism; the cooling water tank is mounted in front of the longitudinal driving mechanism; the discharging rack is mounted at the front side of the cooling water tank. The cooling manipulator of the die-casting machine for the automobile aluminum alloy hub is simple in structure, high in automation degree, and free of manual carrying of the hub casting; the automobile aluminum alloy hub can be automatically clamped, moved, cooled, turned over and discharged in production, so that the automation level of a hub production device can be improved.

Owner:徐州智驾谨行科技有限公司

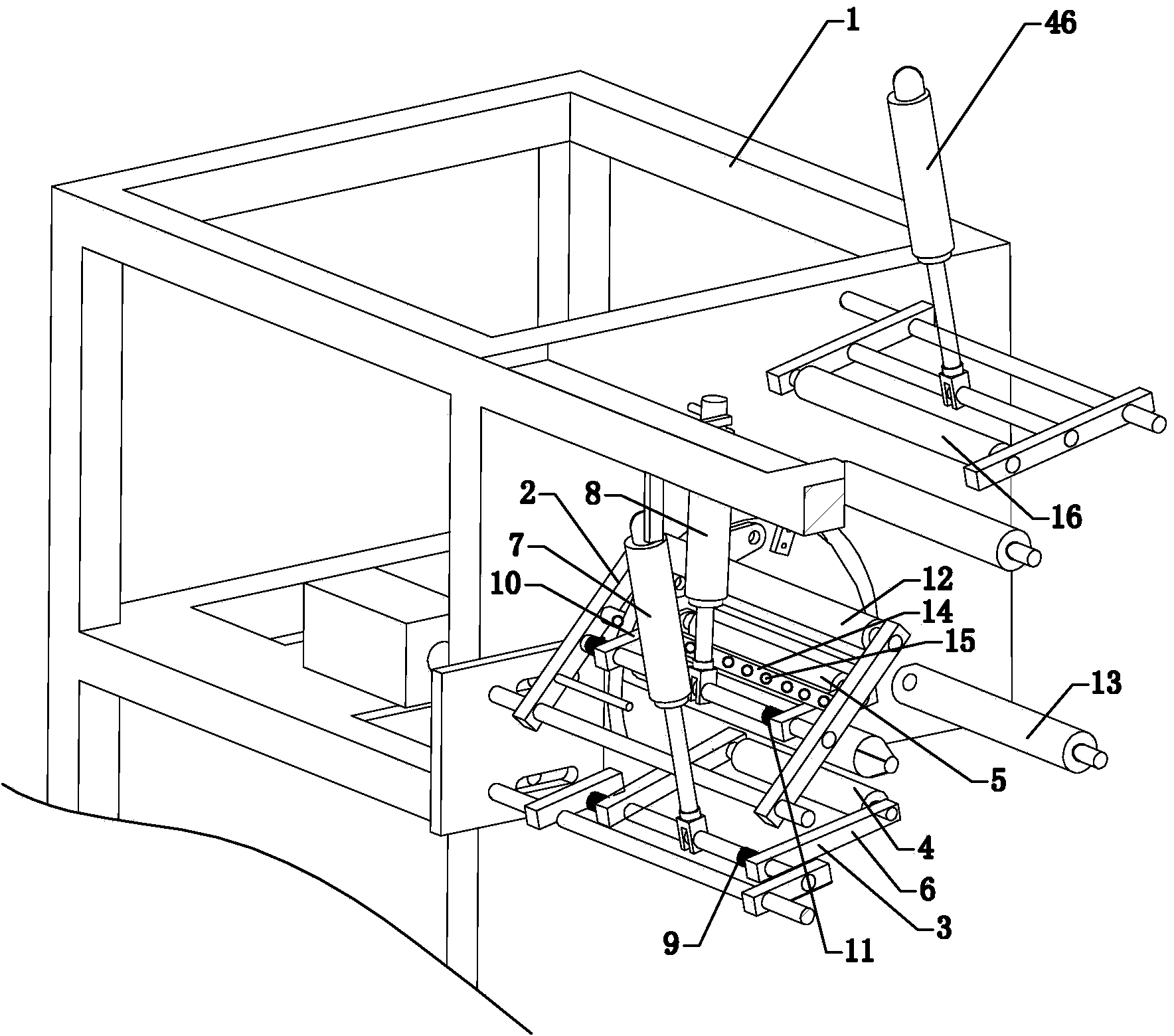

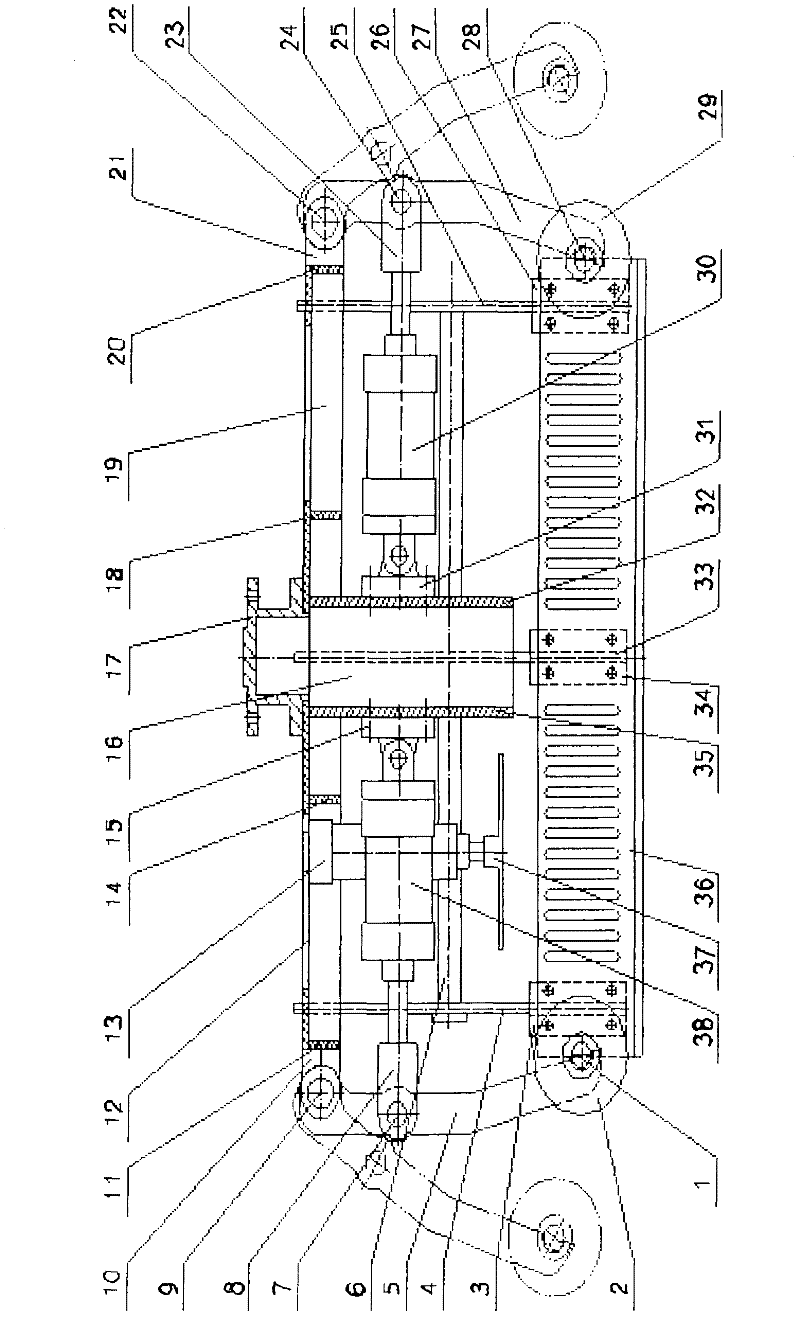

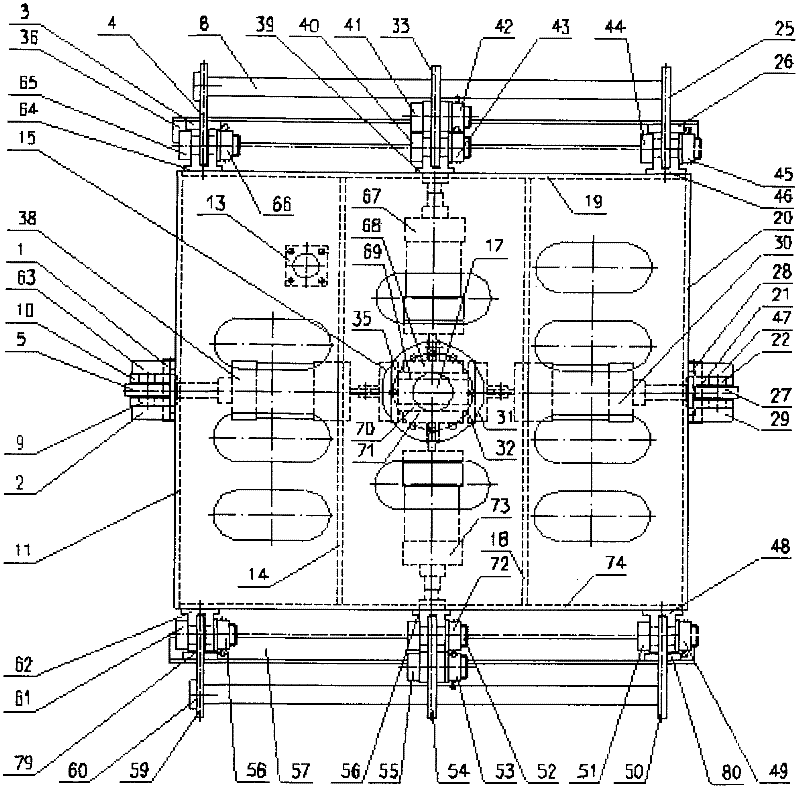

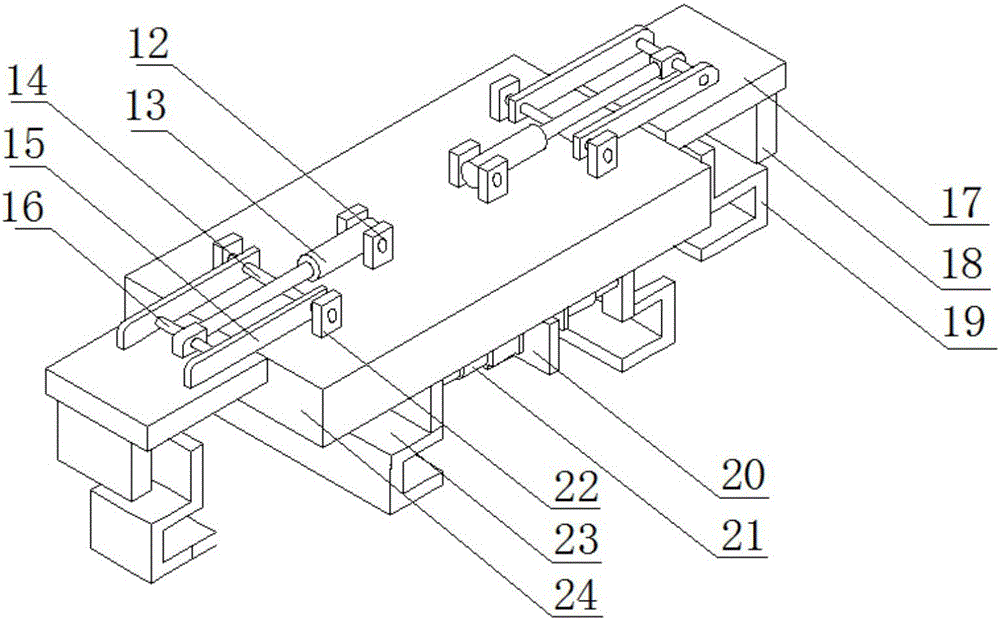

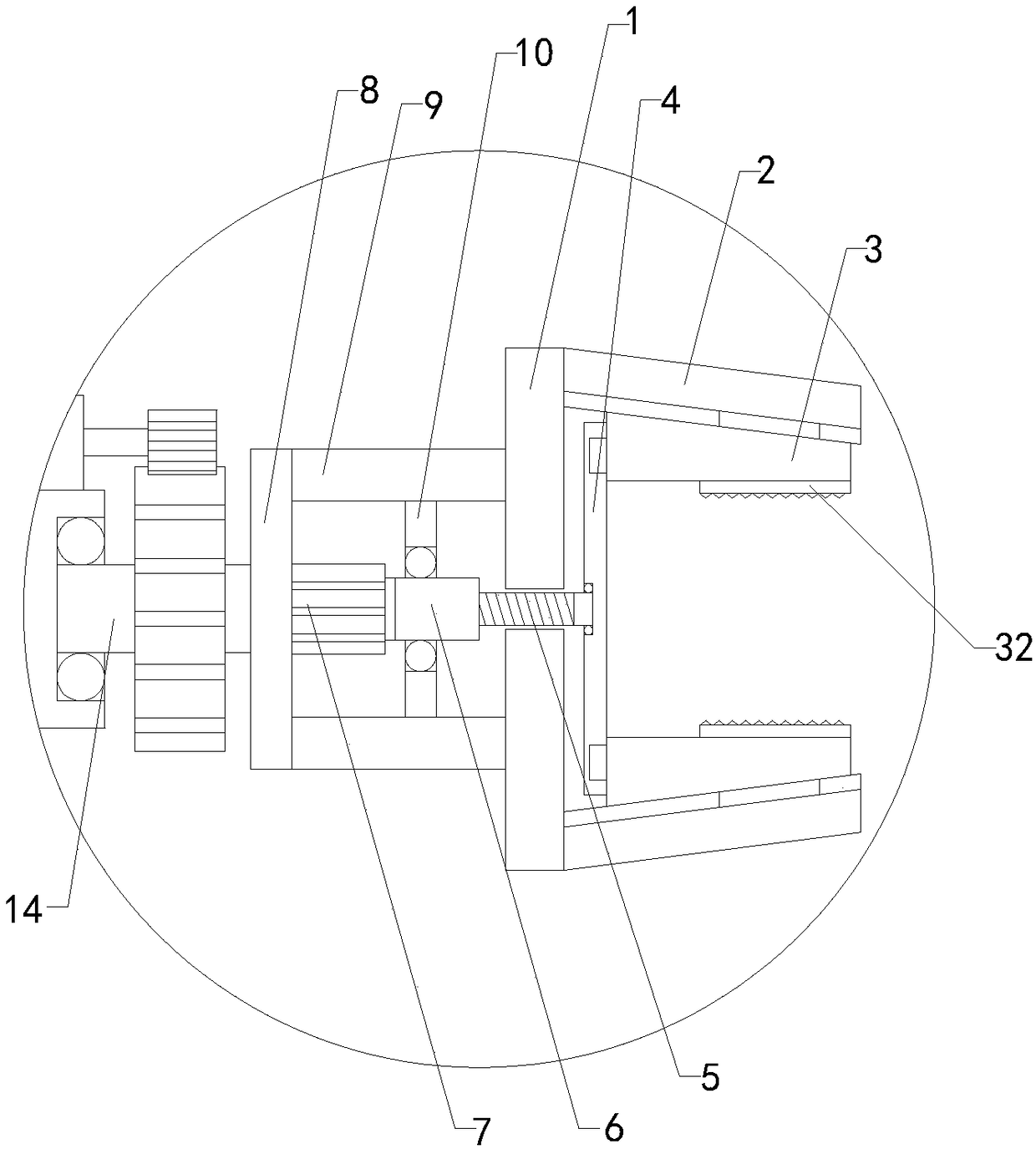

Special fixture used for stacking robot of continuous casting production line of aluminum ingots

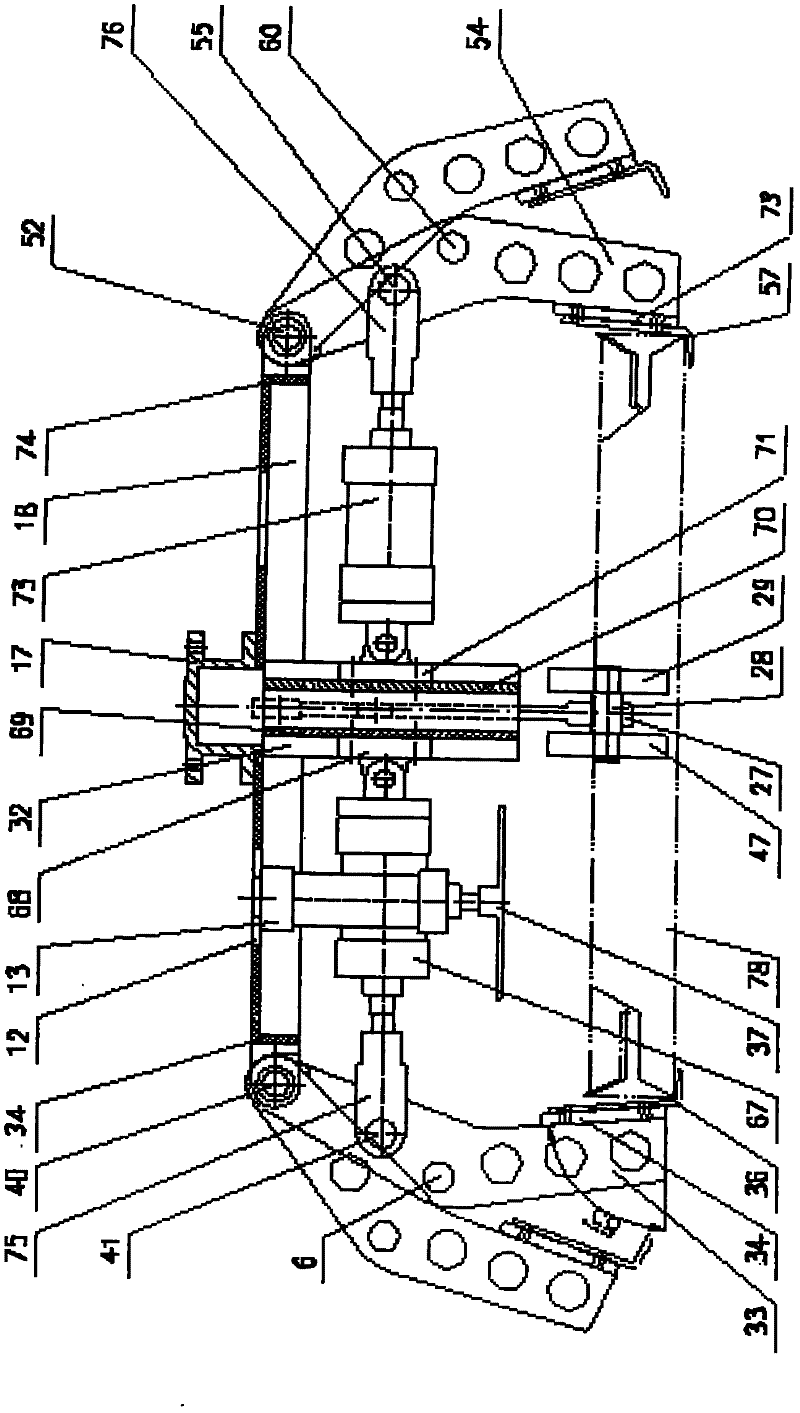

InactiveCN102502276ARealize automatic grippingIncrease productivityGripping headsStacking articlesProduction lineEngineering

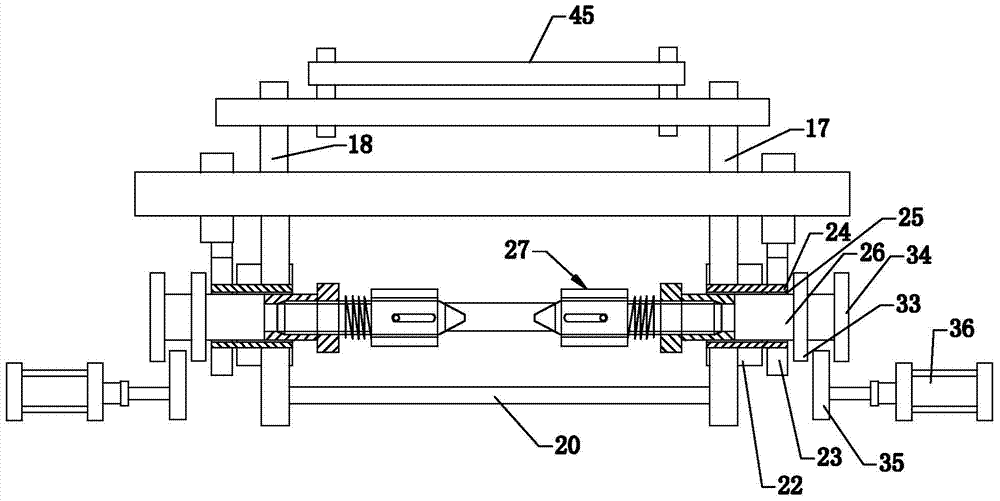

The invention discloses a special fixture used for a stacking robot of a continuous casting production line of aluminum ingots. The special fixture is used for the stacking of molded aluminum ingots on a continuous casting production line of the aluminum ingots. A detecting cylinder (13) is fixed at the lower surface of a sole plate (12); a terminal end of a piston rod of the detecting cylinder (13) is provided with a detection disk (37); the whole fixture is connected with a robot through a connecting base (17); and after the aluminum ingots (78) are well arranged at ingot arrangement stations of a layer conveyor, the special fixture drops to a capturing position under the driving of the stacking robot, front and back clamping claws are closed under the action of a cylinder (73) and a cylinder (73) to clamp each ingot, and left and right ingot supporting claws support aluminum ingots outside an aluminum ingot layer under the action of a cylinder (38) and a cylinder (30).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Sorting robot applied to machining industry

InactiveCN106625587ARealize automatic grippingQuick sortingProgramme-controlled manipulatorSortingEngineeringHigh definition

The invention discloses a sorting robot applied to machining industry. The sorting robot comprises an operation platform, a visual identification device, a clamping device and a transferring and storage device, wherein the upper end of the operation platform is provided with a conveying belt for conveying parts, support rods are arranged at two ends of the conveying belt, a support plate is fixed at the upper ends of the two support rods, the visual identification device is arranged at the lower end of the support plate and comprises a high-definition camera and a flash lamp, a fixing block is arranged on one side of the conveying belt, a robot body is arranged at the upper end of the fixing block, a first fixing rod is arranged at the upper end of one side of the robot body, and a first support arm is arranged at the tail end of the first fixing rod. The sorting robot has the advantages that automatic clamping of appointed parts is achieved by using the visual identification device and the clamping device in a combined manner, automatic storage and transferring are achieved by the transferring and storage device, fast sorting is achieved, manpower cost is lowered, and the sorting robot is suitable for being popularized.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

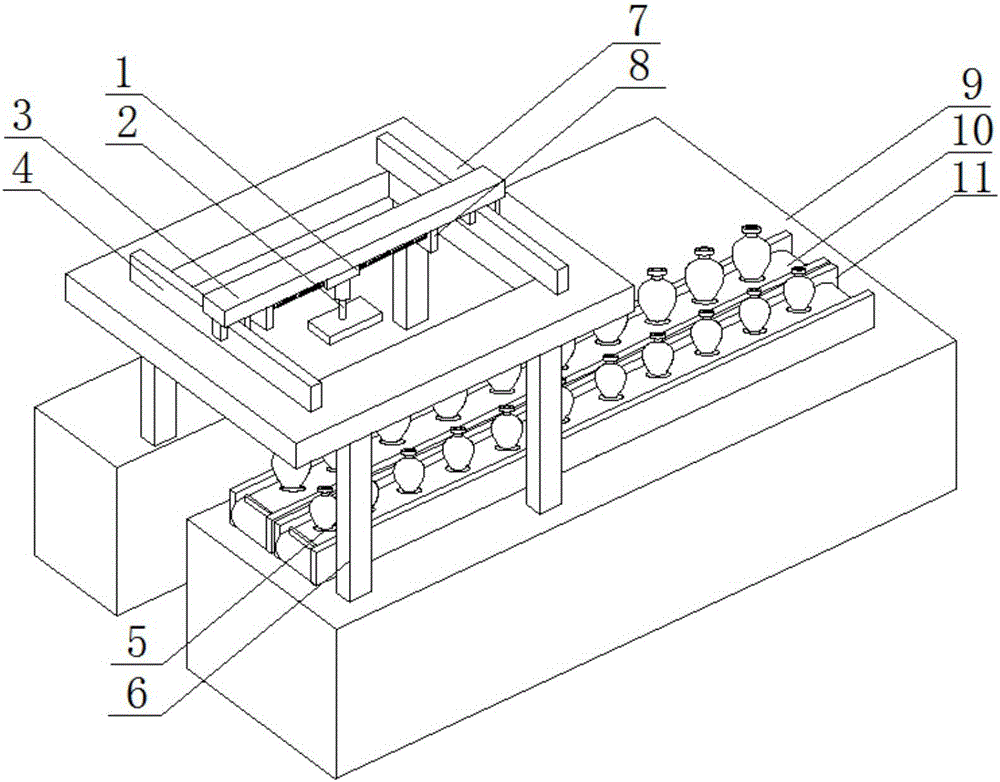

Automatic ceramic wine bottle sorting and conveying device

InactiveCN106348006ARealize automatic grippingSolve the problem of low efficiency of manual sorting and transportationConveyorsConveyor partsEngineering

The invention discloses an automatic ceramic wine bottle sorting and conveying device, which comprises an operation table, wherein a notch is formed in one side of the operation table; two mutually parallel transmission mechanisms are arranged at the upper end of the operation table; baffle plates are arranged at the two sides of the two transmission mechanisms; the upper end of the operation table is provided with four support posts; the upper ends of the support post are provided with placement plates; the middle part of each placement plate is provided with an opening; electric slide rails are arranged on the placement plates positioned at the two sides of the openings. Through the combination of a second telescopic mechanism and a second clamp block and the combination of a first air cylinder and a first clamp block, the automatic clamping on a ceramic wine bottle placement box and a ceramic wine bottle is realized; through the combination of the electric slide rails, a screw rod and a clamping device, the corresponding wine bottle can be selected according to requirements, so that the automatic sorting type clamping is realized; the problem of low conveying efficiency of artificial sorting is solved; the occurrence of unexpected accidents is prevented to a certain degree; the automatic ceramic wine bottle sorting and conveying device is suitable for being popularized.

Owner:CHONGQING YAYU CERAMICS CO LTD

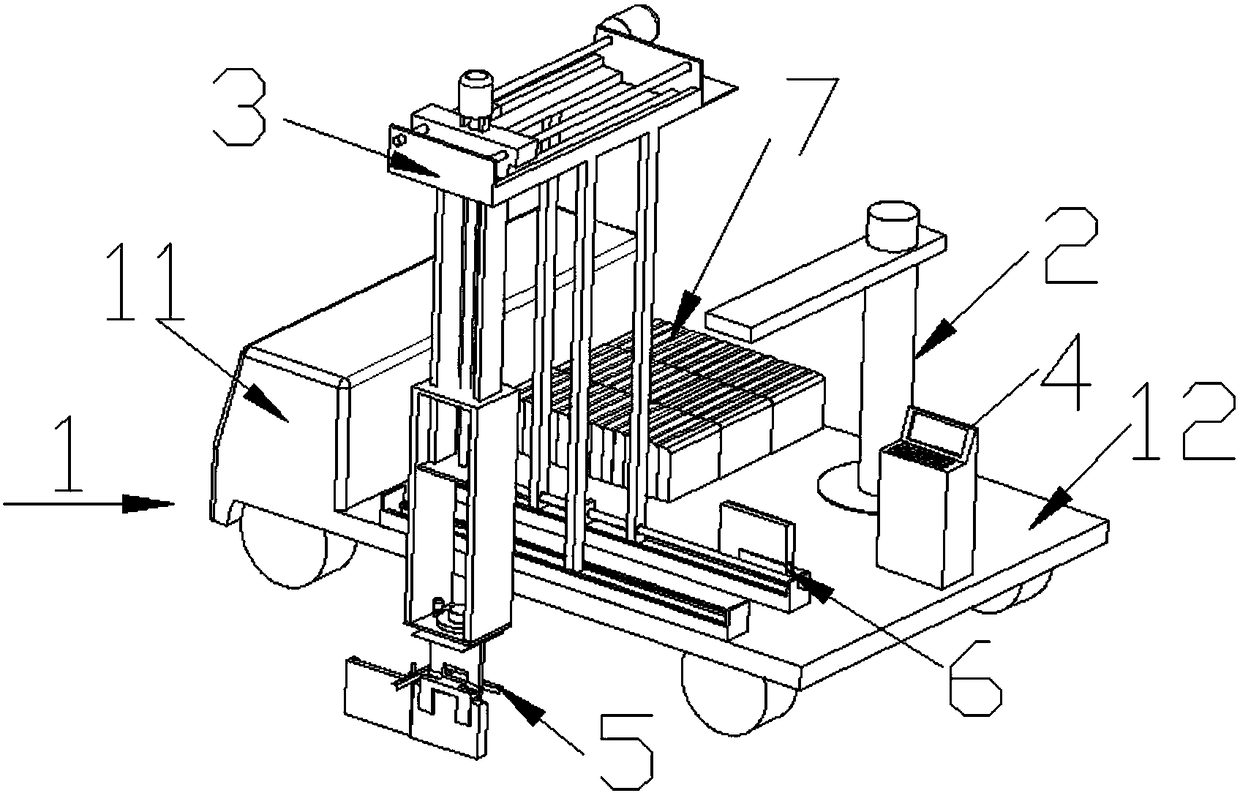

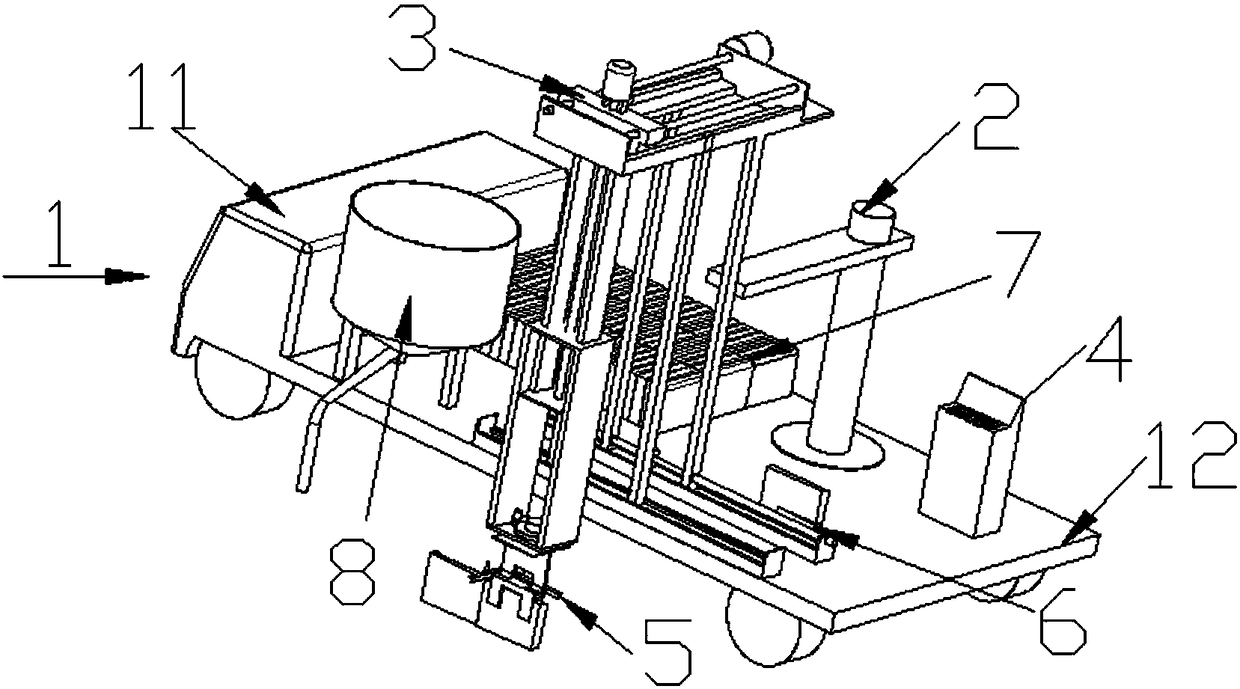

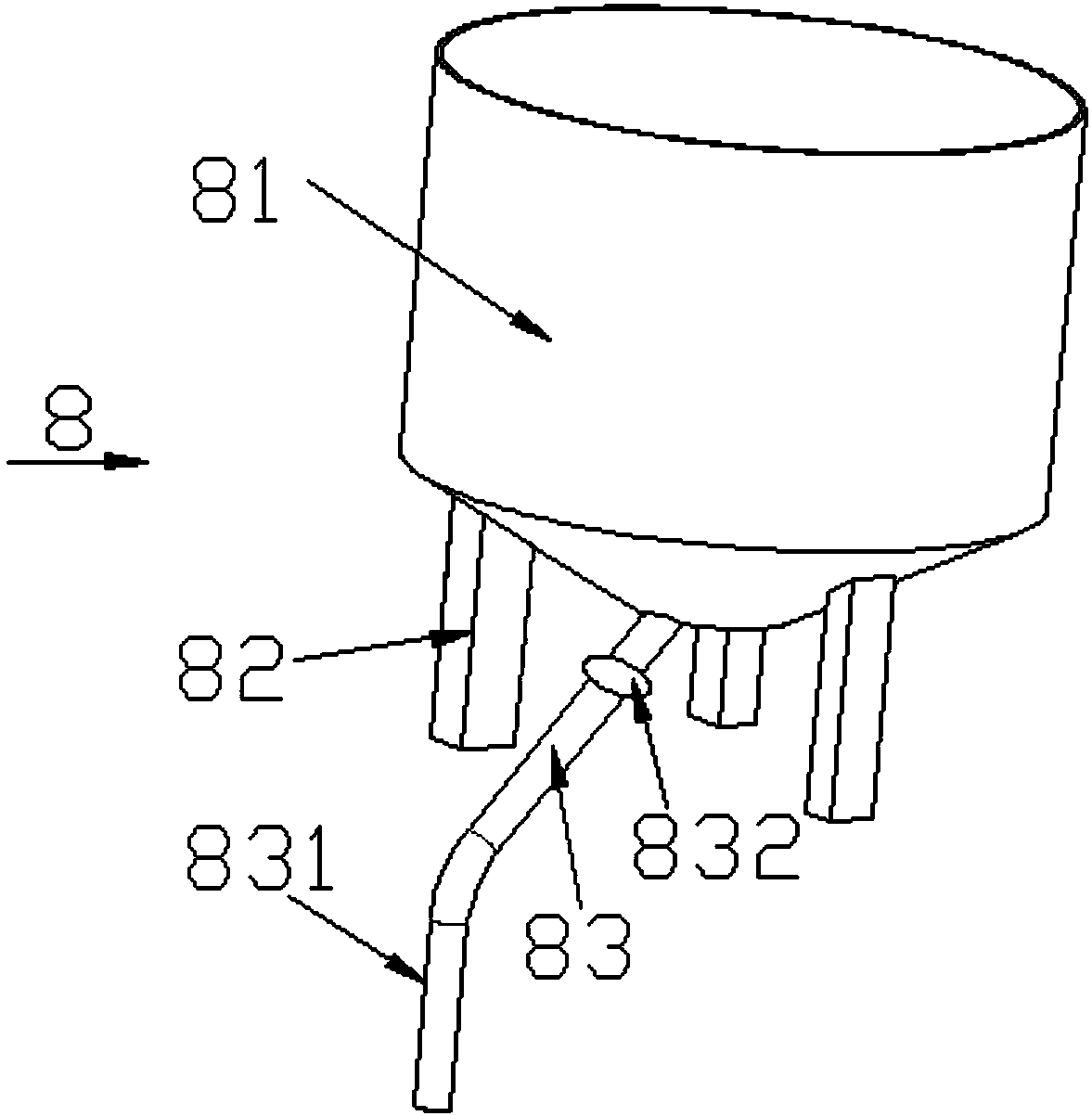

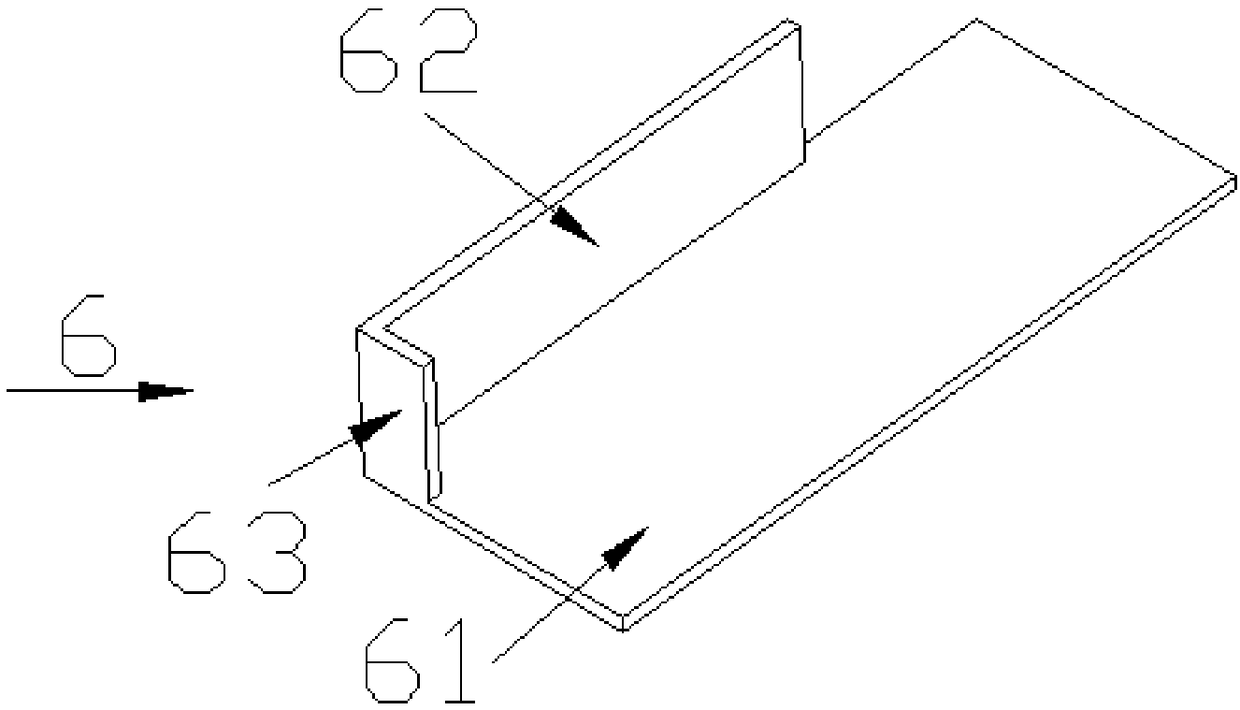

Kerb laying vehicle

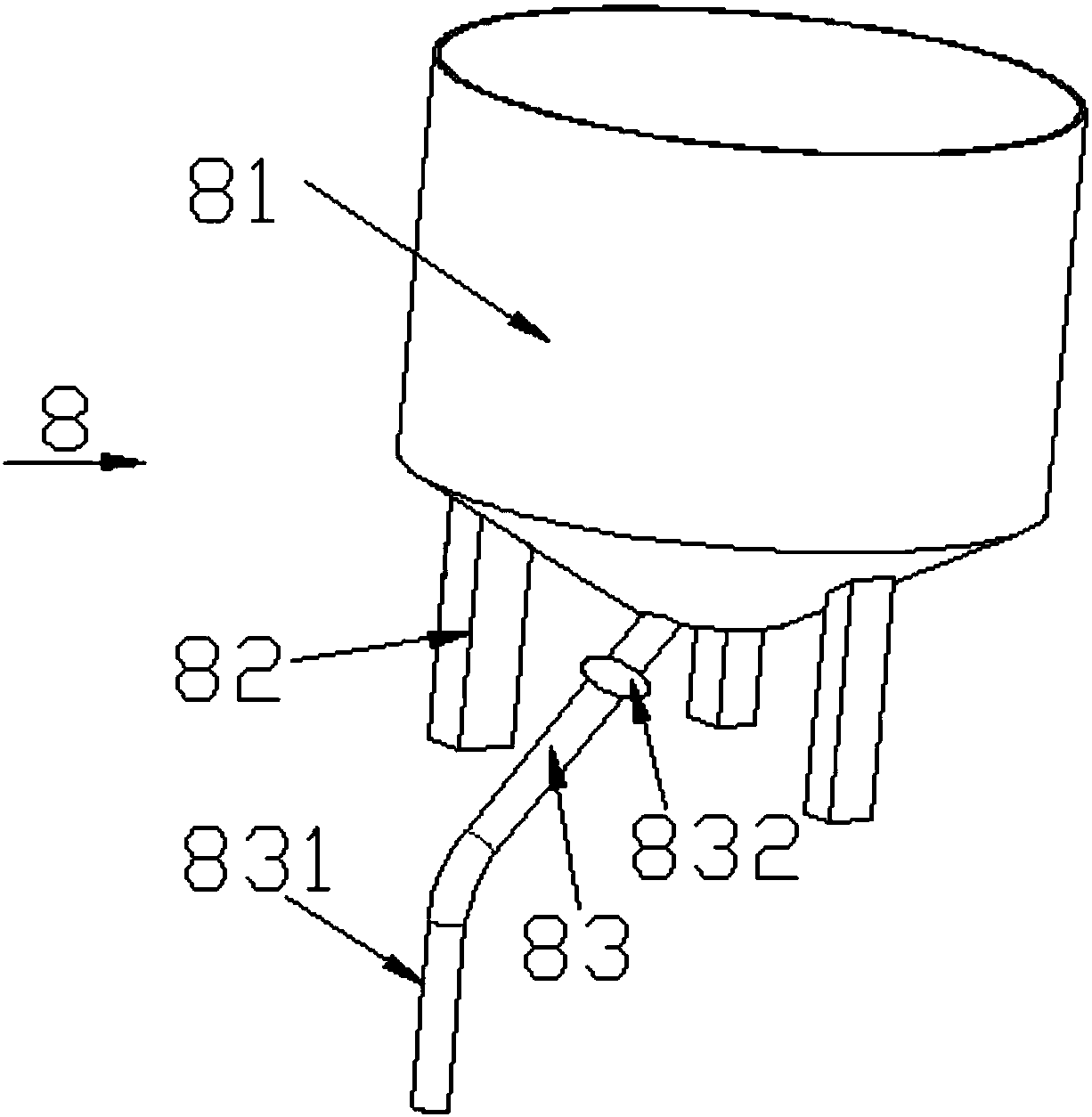

InactiveCN108442216AReduce intermediate handlingImprove laying efficiencyRoads maintainencePoint placementCantilever

The invention relates to the field of decoration construction, in particular to a kerb laying vehicle. The kerb laying vehicle comprises a vehicle assembly, a cantilever crane, a laying device, a control device, an alignment bracket, an original point placement board and kerbs. The kerb carrying step can be omitted to save time; besides, manual work is greatly reduced to save time and labor.

Owner:湖州华科建设工程质量检测有限公司

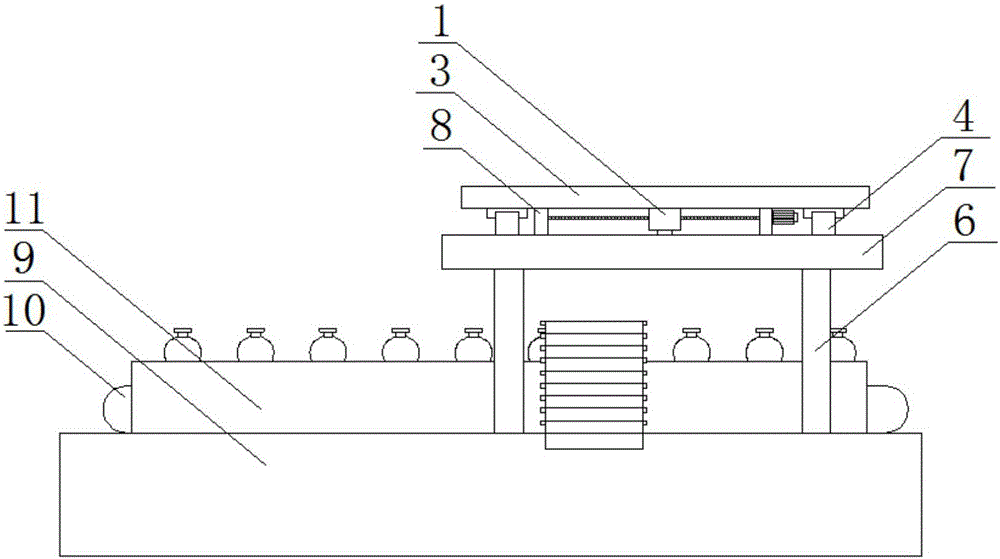

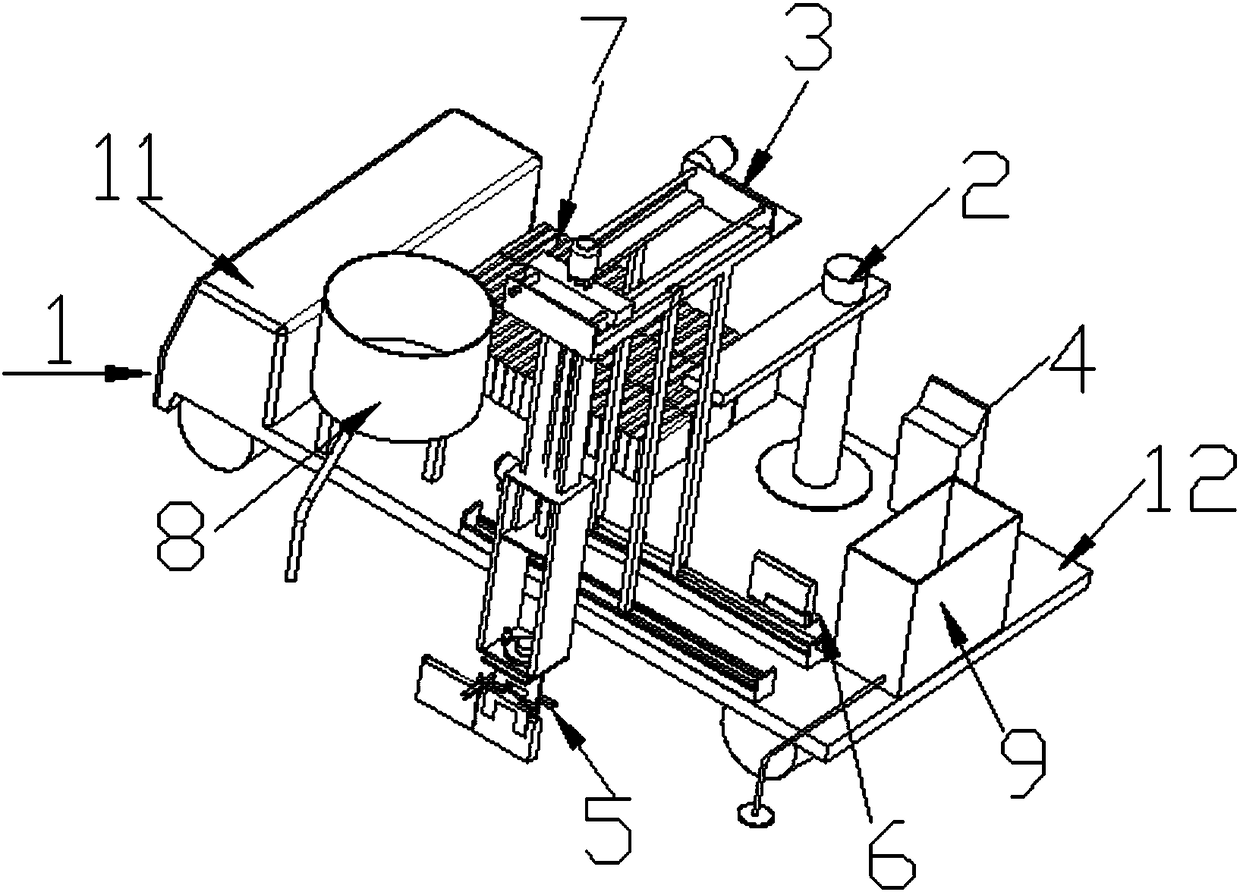

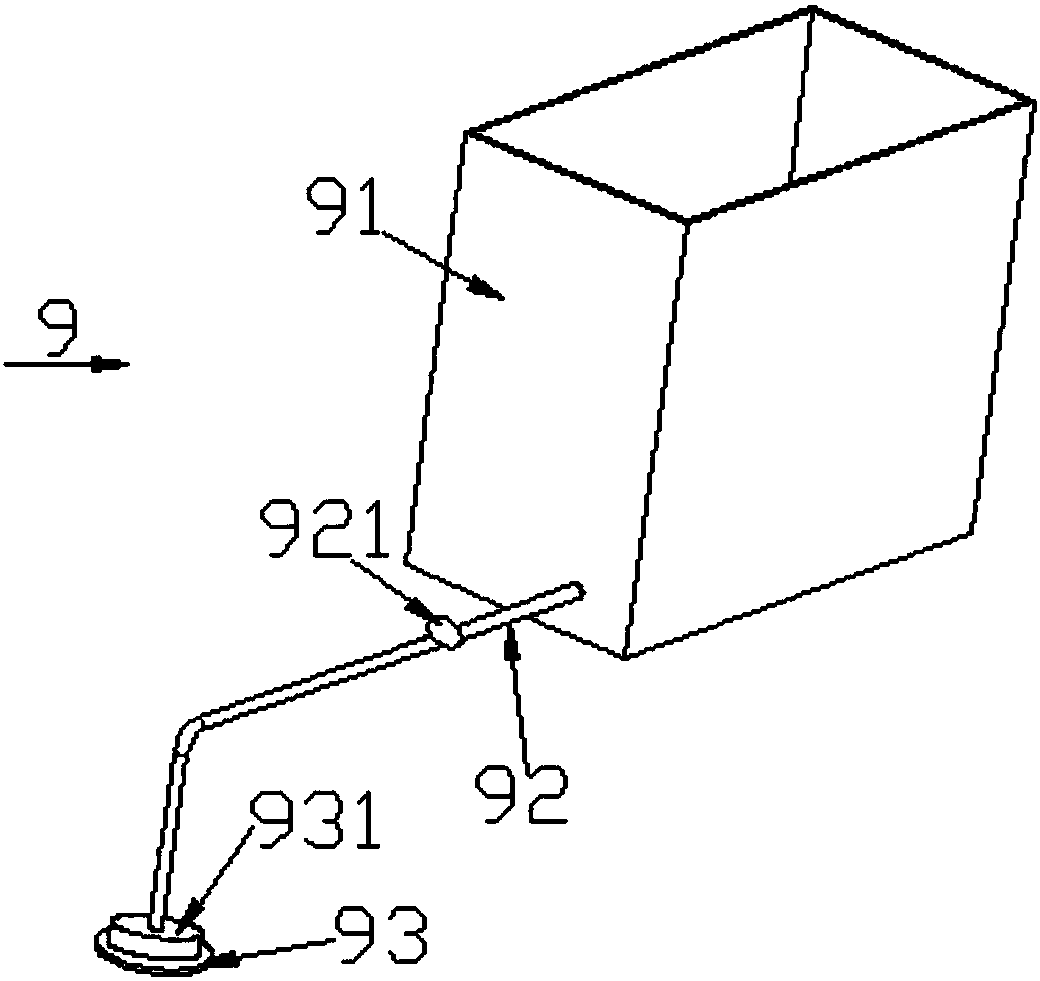

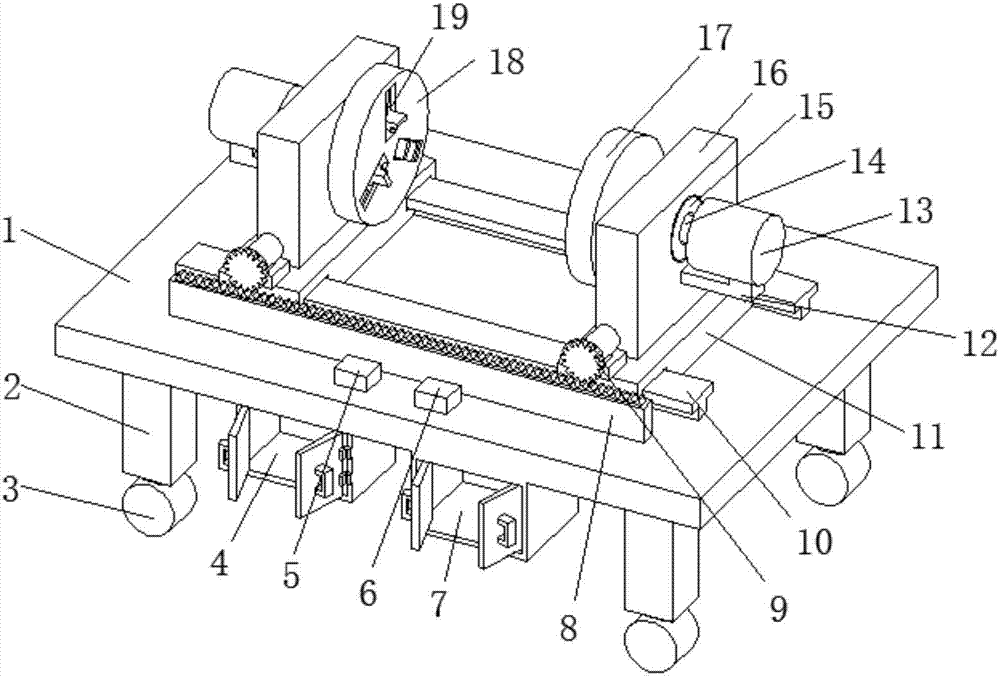

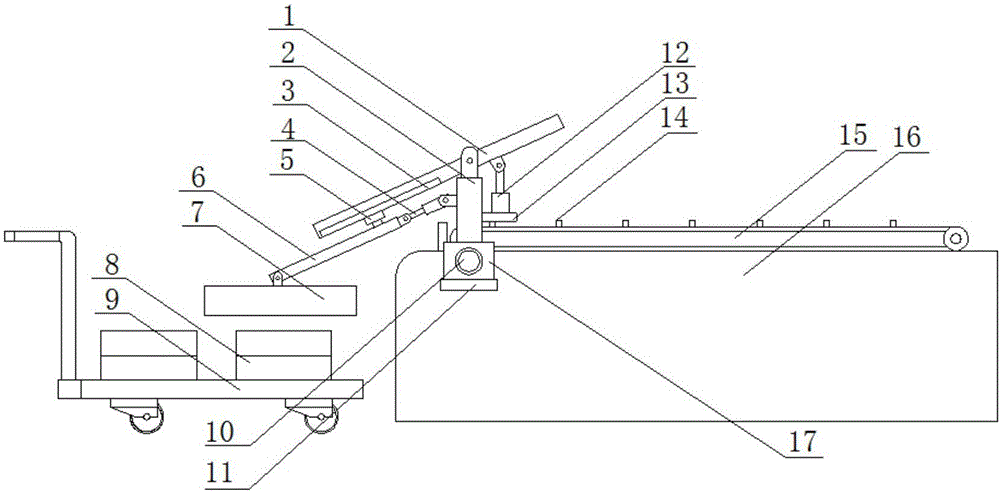

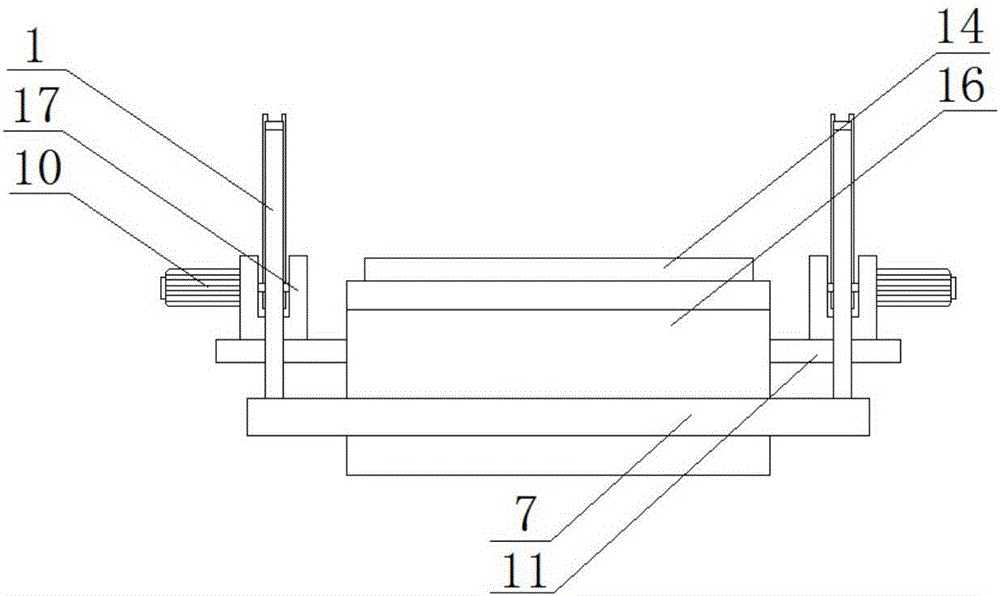

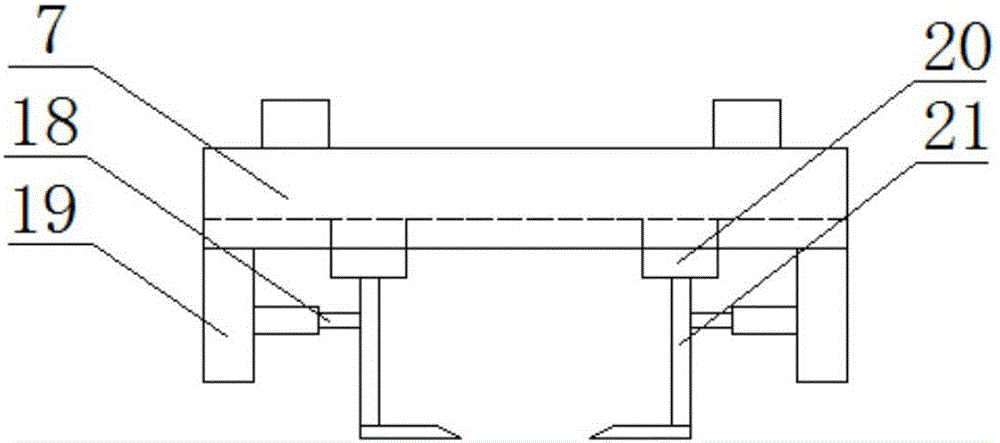

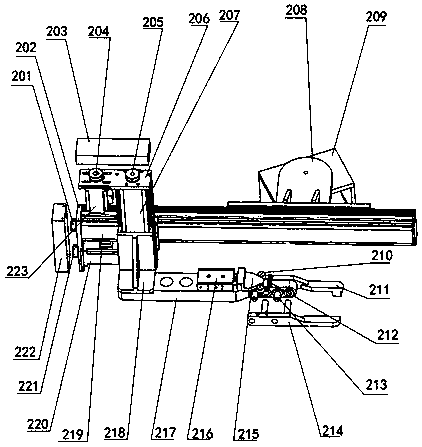

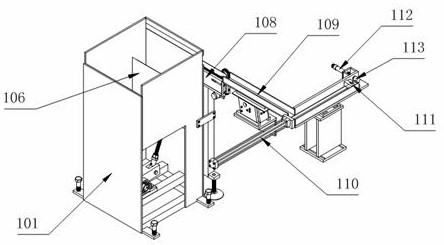

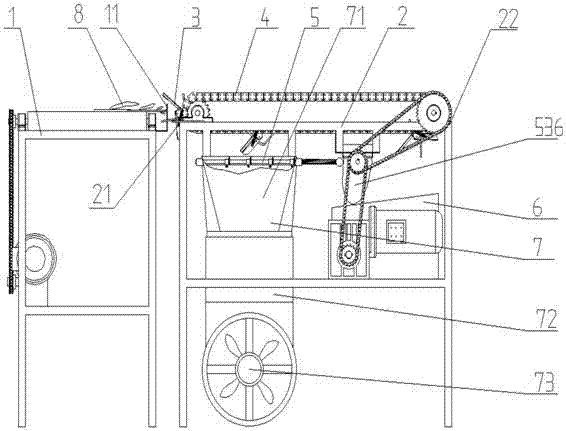

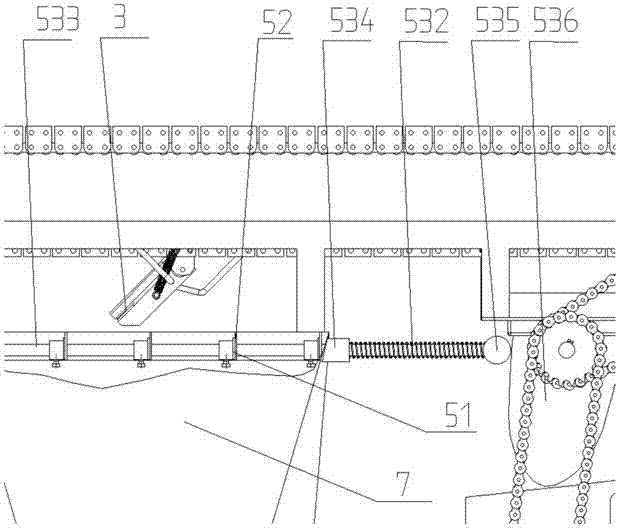

Automatic machining production line for parts of silicone oil clutch of large vehicle

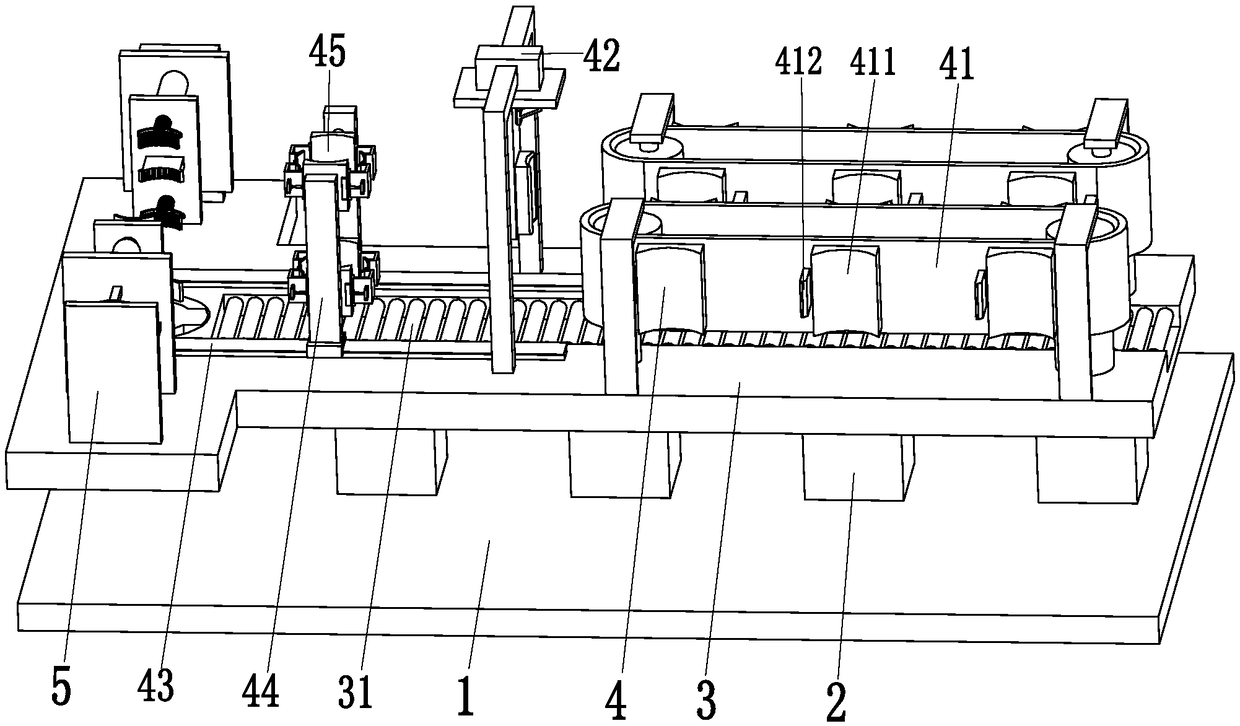

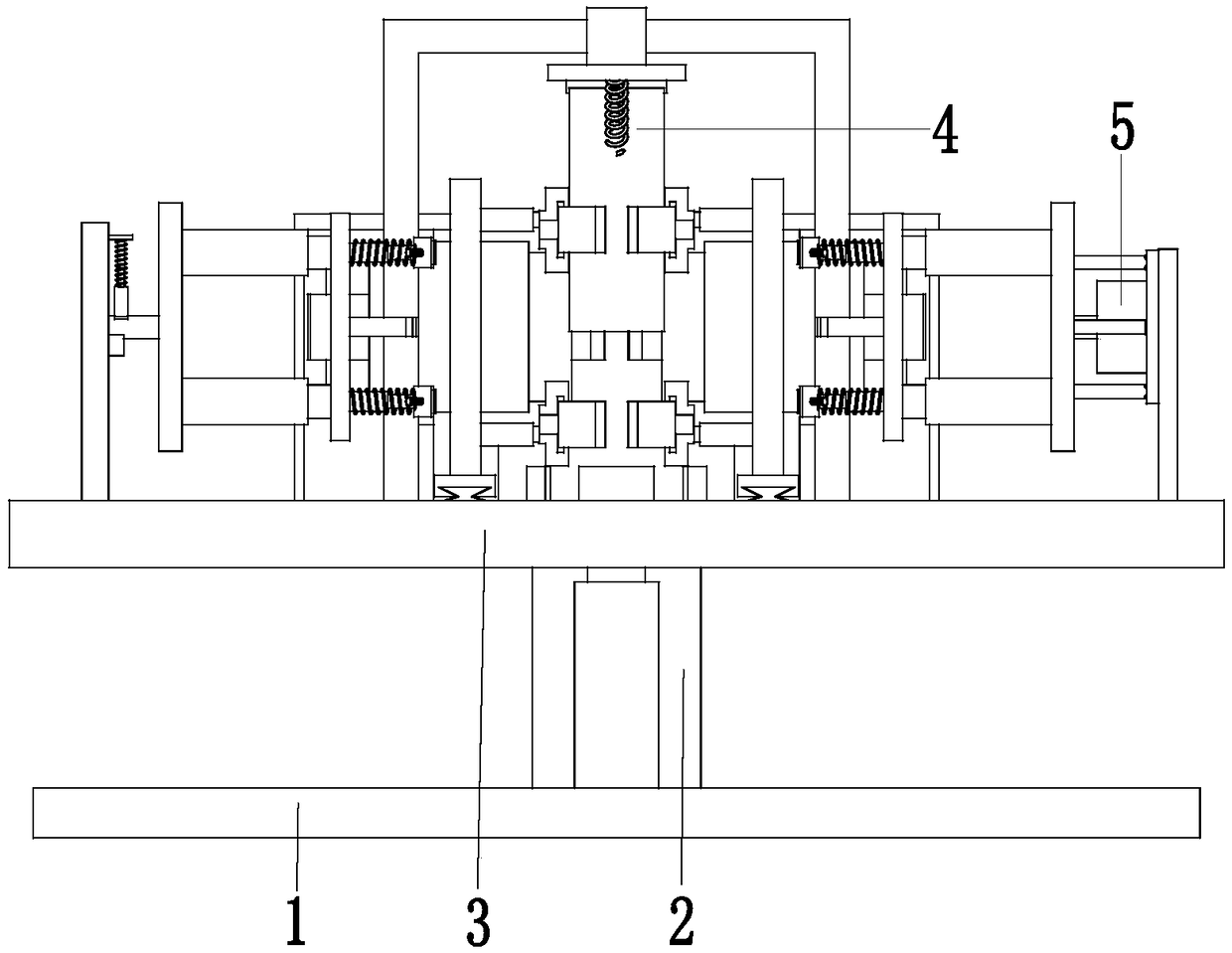

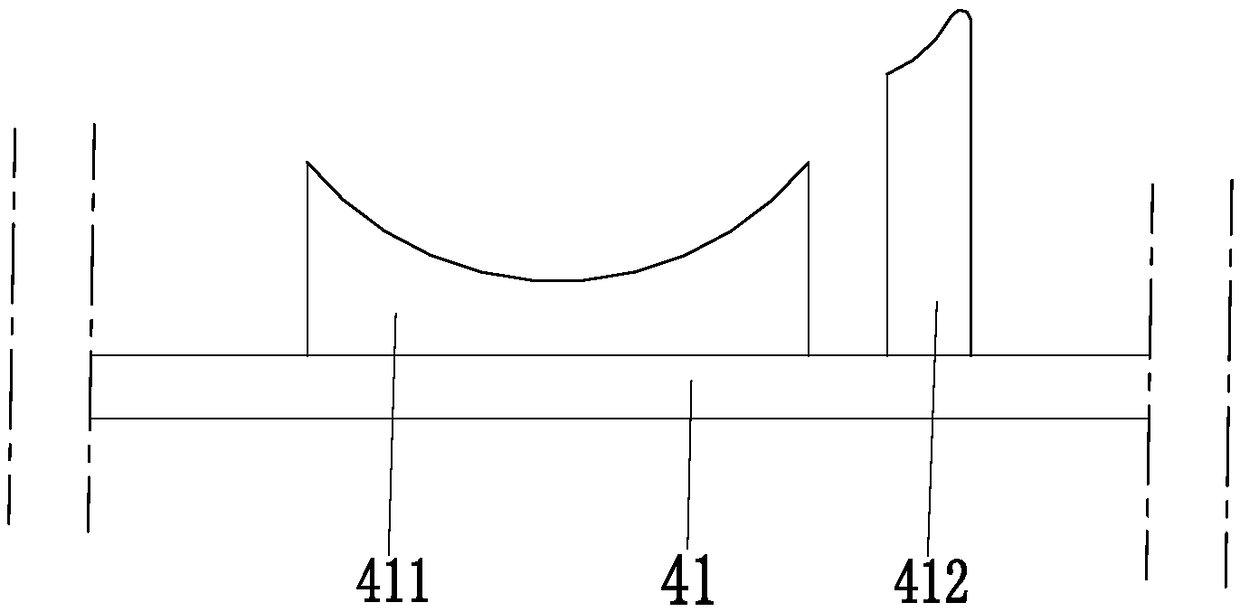

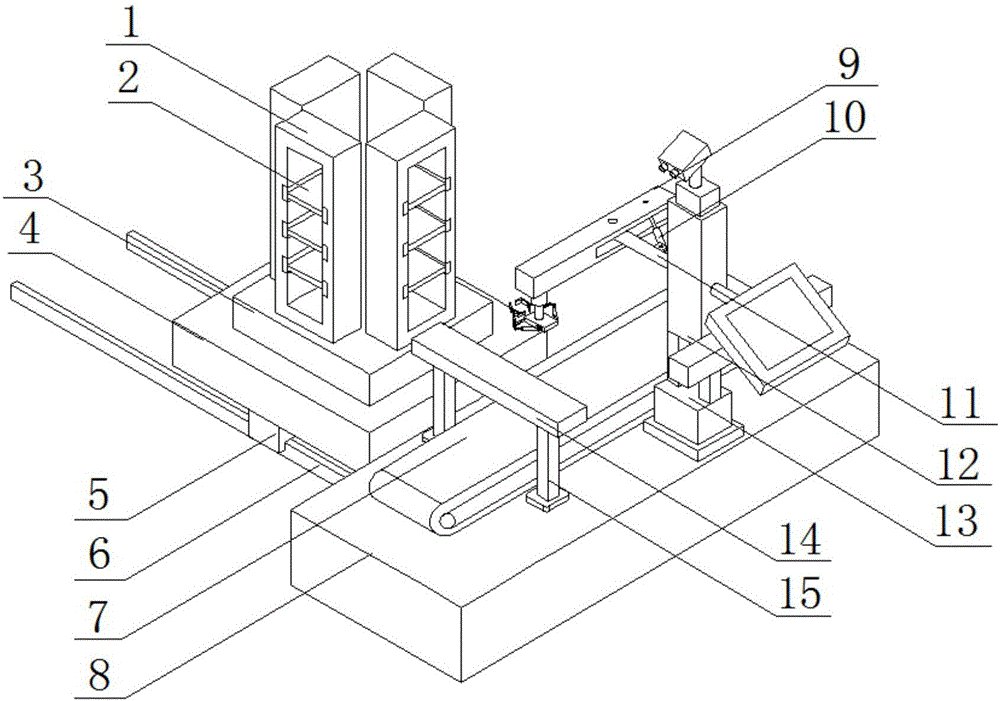

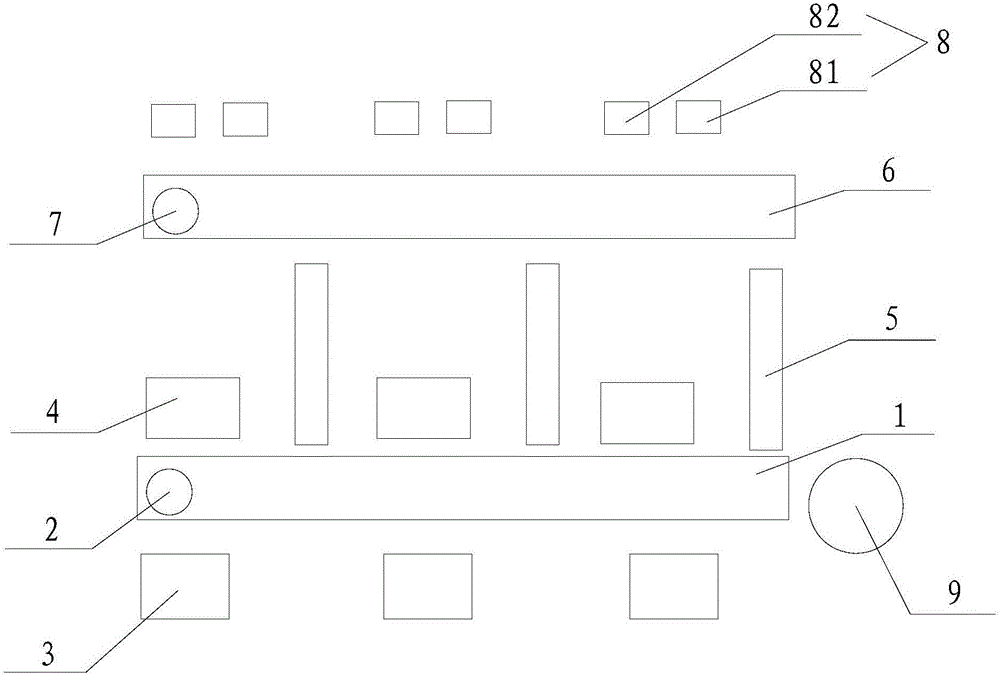

ActiveCN106078228ARealize automatic grippingRealize the processing effectOther manufacturing equipments/toolsMetal working apparatusProduction lineSilicone oil

The invention discloses an automatic machining production line for parts of a silicone oil clutch of a large vehicle. The automatic machining production line comprises a first walking rail assembly, a plurality of storage mechanisms, a plurality of machining centers arranged on the other side of the first walking rail assembly, a plurality of conveying mechanisms perpendicular to the first walking rail assembly, a material taking robot movably mounted on the first walking rail assembly, a second walking rail assembly parallel to the first walking rail assembly and matched with the conveying mechanisms, a plurality of sets of collecting boxes arranged on the other side of the second walking rail assembly, and a discharging robot movably mounted on the second walking rail assembly. The storage mechanisms are located on a straight line parallel to the first walking rail assembly. In this way, automatic clamping, machining and collecting of the silicon oil clutch can be achieved, and production efficiency is improved.

Owner:SUZHOU GETLOON AUTOMATION EQUIP CO LTD

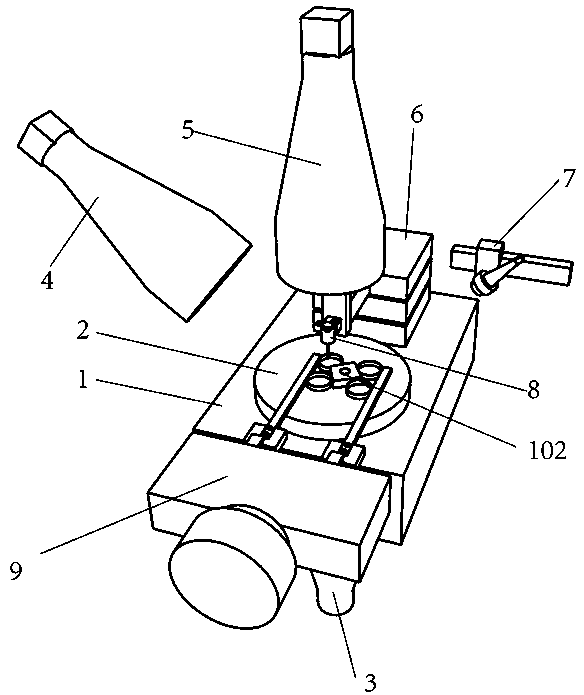

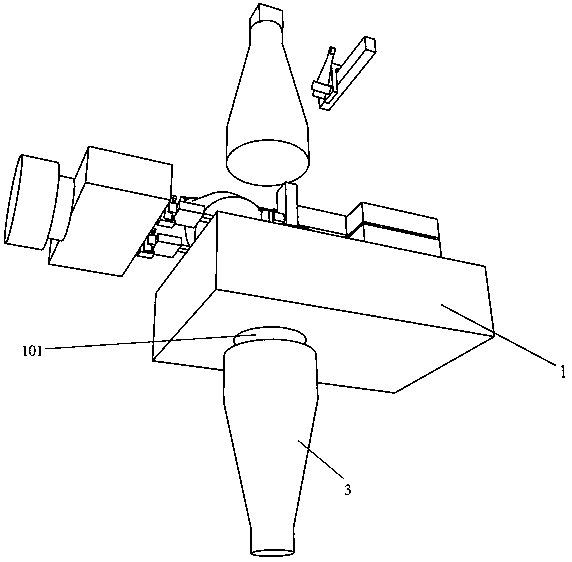

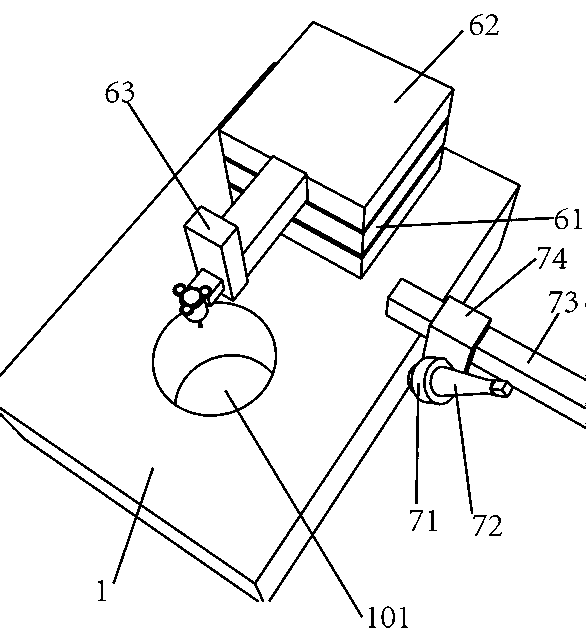

Machine vision and scanning detection device and working method thereof

PendingCN110702008AImprove adaptabilityImprove versatilityUsing optical meansMachine visionEngineering

The invention relates to a machine vision and scanning detection device and a working method thereof. The detection device comprises a detection table, a perspective hole is formed in the detection table in an up-down penetrating manner, a backlight source is erected below the detection table and is opposite to the perspective hole, a transparent platform is fixedly arranged on the upper surface of the detection table right above the perspective hole, a second camera is erected right above the transparent platform, one side of the second camera forms a certain included angle with the second camera and aligns to the transparent platform to erect the first camera, the other side of the second camera forms a certain included angle with the second camera and is aligned with the transparent platform to erect a structured light scanning mechanism, a movable clamp is arranged in front of the detection table, the movable clamp extends to the transparent platform to be used for limiting, a triaxial moving platform is installed at the rear side of the detection table, and a measuring head is fixedly arranged on the Z axis of the triaxial detection table. The machine vision and scanning detection device is reasonable in structure, and the problems that a vision or scanning single detection method is narrow in application range, low in scanning detection efficiency and inconvenient in partclamping, positioning, taking and placing for a long time are solved.

Owner:三明图灵智能科技有限公司

Plastic bag automatic rewinding and changing machine

ActiveCN103754677BIncrease productivityReduce labor intensityWebs handlingWinding machineManipulator

Owner:潍坊兴信工程项目管理有限公司

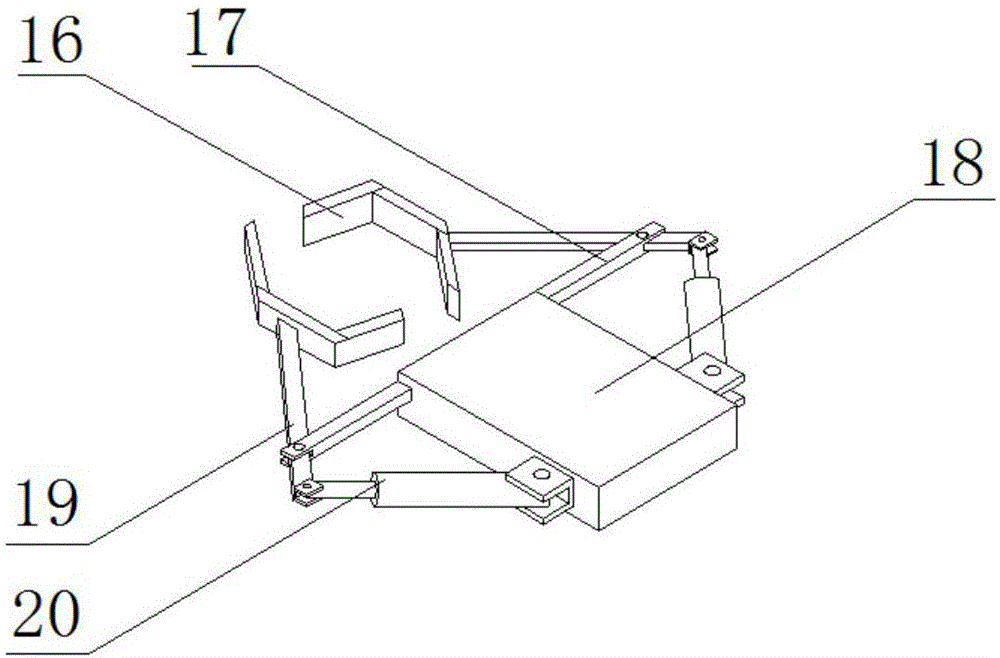

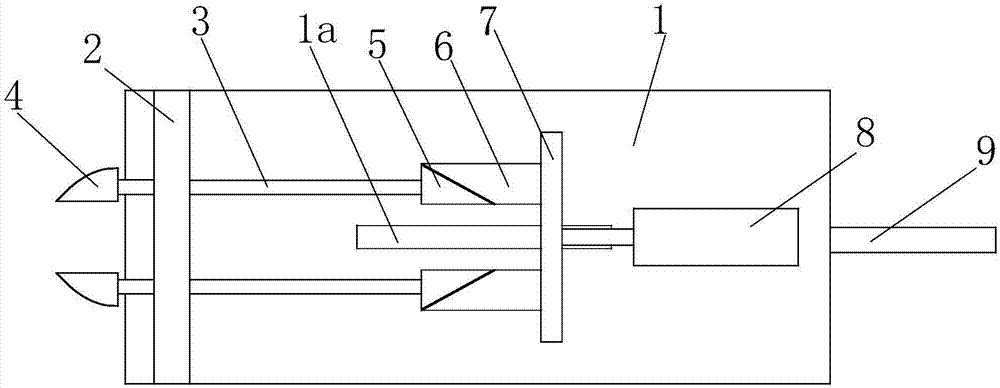

Assembly device of liquid check clips and catheters

PendingCN106078179AAvoid blockingAvoid consumptionMetal working apparatusReciprocating motionAssembly line

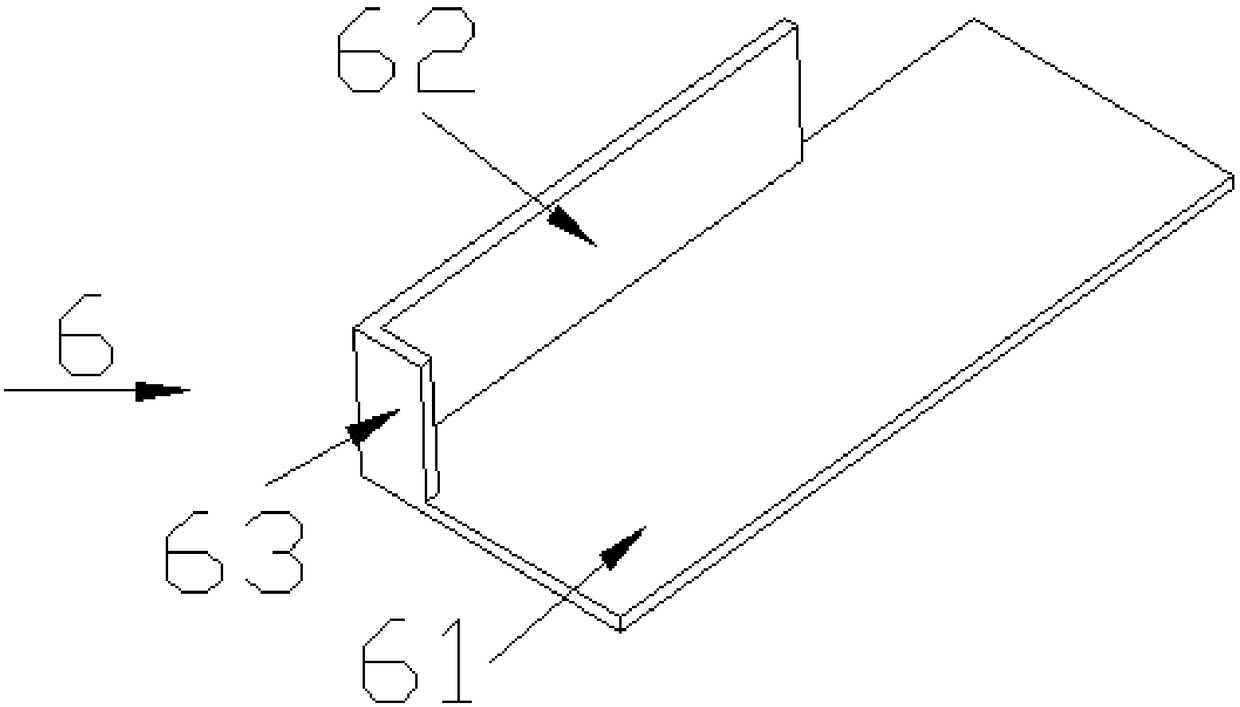

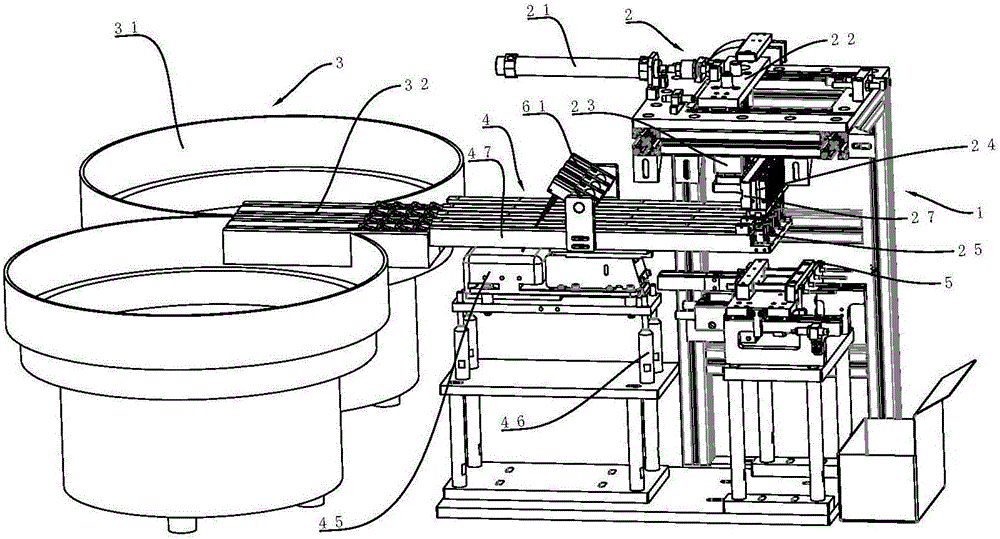

The invention discloses an assembly device of liquid check clips and catheters, and belongs to the technical field of manufacturing equipment of medical instruments. According to assembly devices of the liquid check clips and the catheters in the prior art, the ends of the catheters are worn in the assembly process, the structures of the assembly devices are complex, and the control difficulty is increased. The assembly device comprises a machine frame, a feed mechanism, a taking mechanism, a guide rod mechanism penetrating through the liquid check clips and a pushing mechanism. The taking mechanism comprises a taking and horizontal-moving assembly driving the liquid check clips to horizontally move, a taking and vertically-moving assembly driving the liquid check clips to vertically move, a clamping plate clamping the liquid check clips and a clamping drive assembly driving the clamping plate to do reciprocating motion. The pushing mechanism comprises expanding plates used for driving the liquid check clips to horizontally move and opening-closing drive sources used for driving the expanding plates to do reciprocating motion, and the opening-closing drive sources drive the expanding plates to be inserted into gaps of the liquid check clips. The assembly device is convenient to assembly, simple in structure and reasonable in design and can effectively improve the assembly efficiency.

Owner:梁启明

Multifunctional curb laying truck

The invention relates to the field of decoration construction and particularly to a multifunctional curb laying truck which comprises an automobile assembly, a cantilever crane, a laying device, a control device, an alignment bracket, an original point setting board, curbs, an agitator and a maintenance water-spraying device. The curb laying truck completes concrete laying, curb laying, water spraying maintenance and the like synchronously, not only saves time for laying maintenance but reduces labor force greatly, and achieves the effect of saving both time and labor.

Owner:湖州华科建设工程质量检测有限公司

Kerbstone paving truck with concrete laying function

The invention relates to the field of decoration construction, in particular to a kerbstone laying truck with a concrete laying function. The kerbstone laying truck comprises an automobile assembly, acantilever crane, a paving device, a control device, an alignment bracket, an origin point shelving board, kerbstones and a stirring machine. The kerbstone paving truck has the advantages that transportation steps of the kerbstones can be reduced and the time is saved; in addition, labor force is greatly reduced, time and labor are saved and concrete laying can be synchronously realized before the kerbstones are laid.

Owner:湖州华科建设工程质量检测有限公司

Loading and unloading equipment for automatic warehousing of goods

InactiveCN108584416AAchieve releaseRealize automatic grippingConveyor partsElectric machineryThreaded pipe

The invention relates to the technical field of automatic warehousing accessory devices, in particular to loading and unloading equipment for automatic warehousing of goods. The loading and unloadingequipment can automatically clamp and release, saves manpower, reduces the economical cost, improves the practicality, increases the degree of automation and reduces the using limitation. The loadingand unloading equipment comprises an operating plate, an upper chuck plate, a lower chuck plate, an upper clamping plate, a lower clamping plate, an adjusting plate, a threaded rod, a threaded pipe, an adjustable motor, a left baffle plate, an upper baffle plate, a lower baffle plate and a fixed plate and further comprises a bottom plate, a placement block, a first rotary shaft, a second rotary shaft, a tumbler, a rotary table, a first electric cylinder, a controller, a first gear motor and a second gear motor, wherein the bottom end of the placement block is connected with the top end of thebottom plate; a first placement groove is formed in the top end of the placement block; a lower first placement ball bearing is arranged at the bottom end of the first placement groove; and the adjustable motor, the first gear motor, the second gear motor and the first electric cylinder are electrically connected with the controller.

Owner:苏州奇思汇智能科技有限公司

Electronic product magnetic core clamping device

The invention discloses an electronic product magnetic core clamping device. The device comprises a bottom plate, a first control switch and a second control switch are arranged on one side of the upper surface of the bottom plate, two sliding rails are arranged on the upper surface of the bottom plate at equal intervals, sliding plates are clamped at the left ends and the right ends of the two sliding rails in a sliding mode respectively, support plates are arranged on the upper surfaces of the sliding plates, bearings are clamped in through grooves inside the support plates, a first motor isfixed to one side of one support plate through a first motor fixing base, an input end of the first motor is electrically connected with an output end of the first control switch, an output shaft ofthe first motor is connected with a first rotating shaft through a coupling, and the first rotating shaft penetrates through an inner rings of the bearings. According to the electronic product magnetic core clamping device, use is convenient, magnetic cores of different lengths can be clamped, the two ends are fixed and clamped simultaneously, automatic clamping is achieved, the magnetic cores ofdifferent diameters can be clamped, the device is uses widely, subsequent winding work is facilitated, and the working efficiency is improved.

Owner:珠海美源智科技有限公司

Cloth drying device used after printing processing

ActiveCN110526011ARealize automatic grippingImprove work efficiencyPrinting press partsWebs handlingEngineeringMechanical engineering

The invention discloses a cloth drying device used after printing processing. The device comprises a conveying belt and a guide rail, a material guide plate is arranged at one end of the conveying belt, two groups of guide rails are arranged, and a movable supporting device is arranged on the guide rails. The movable supporting device is connected with an automatic cloth clamping device, and a drying box is connected between the two groups of guide rails. According to the cloth drying device used after printing processing, the printed cloth is guided to a flat plate on the automatic cloth clamping device through the material guide plate, during the continuous propelling process, the printed cloth passes through the area of an infrared sensor, and because the infrared sensor judges whetheran object exists or not through distance measurement, after the object is detected, an electric telescopic rod works to enable the clamping plate to press downwards to clamp the cloth, after the clothis clamped, the movable supporting device can drive the cloth to move on the guide rail, then the hot air blows to the cloth, and a fixing plate is controlled through the detection of the infrared sensor, so that the automatic clamping is realized, and compared with the manual operation, the working efficiency is improved.

Owner:海盐县新艺印刷有限公司

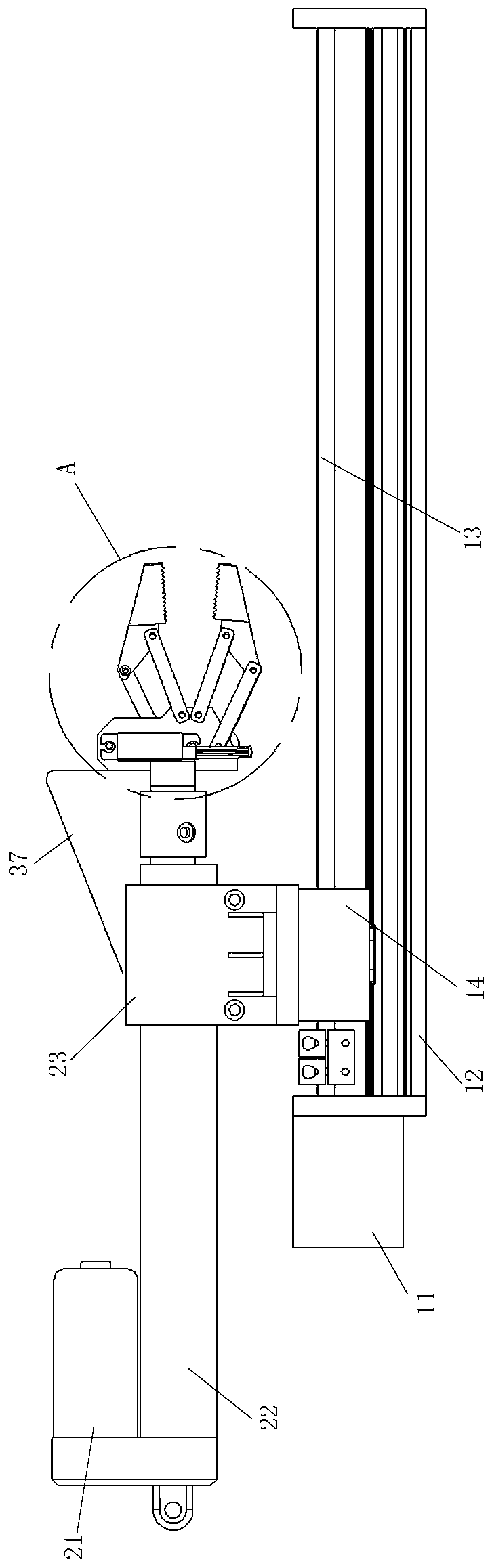

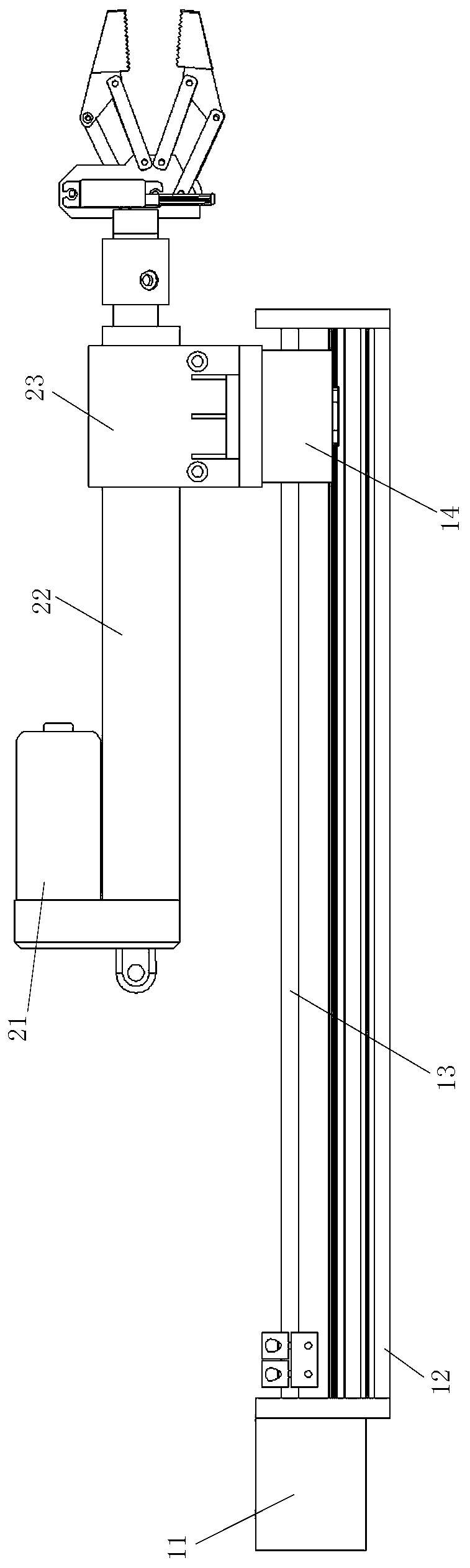

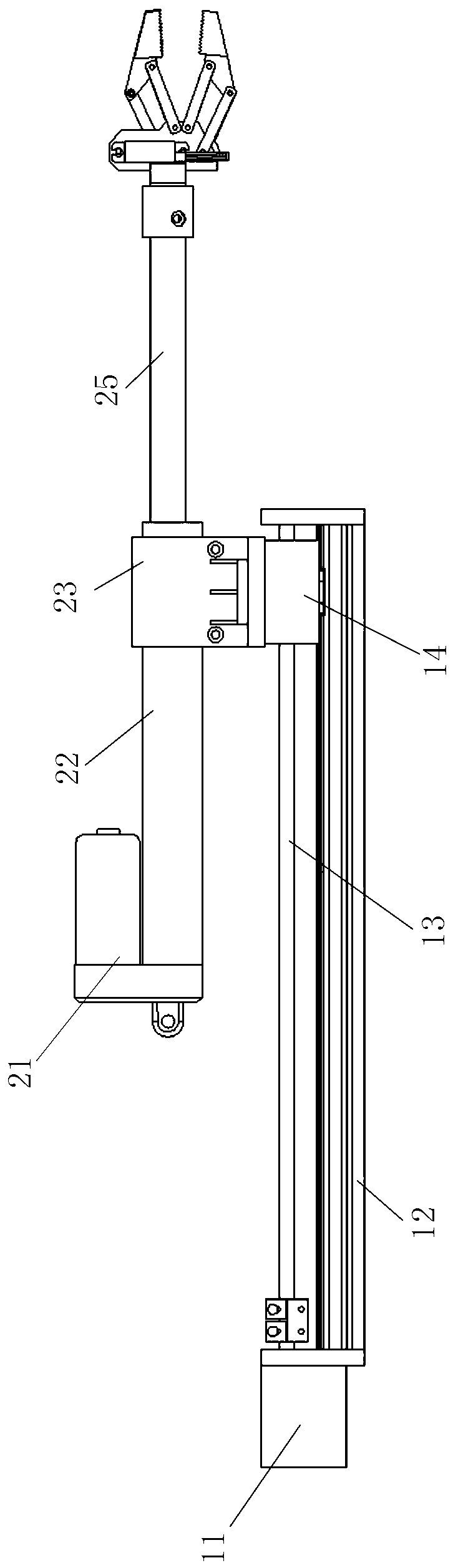

Sport manipulator for smart wardrobe

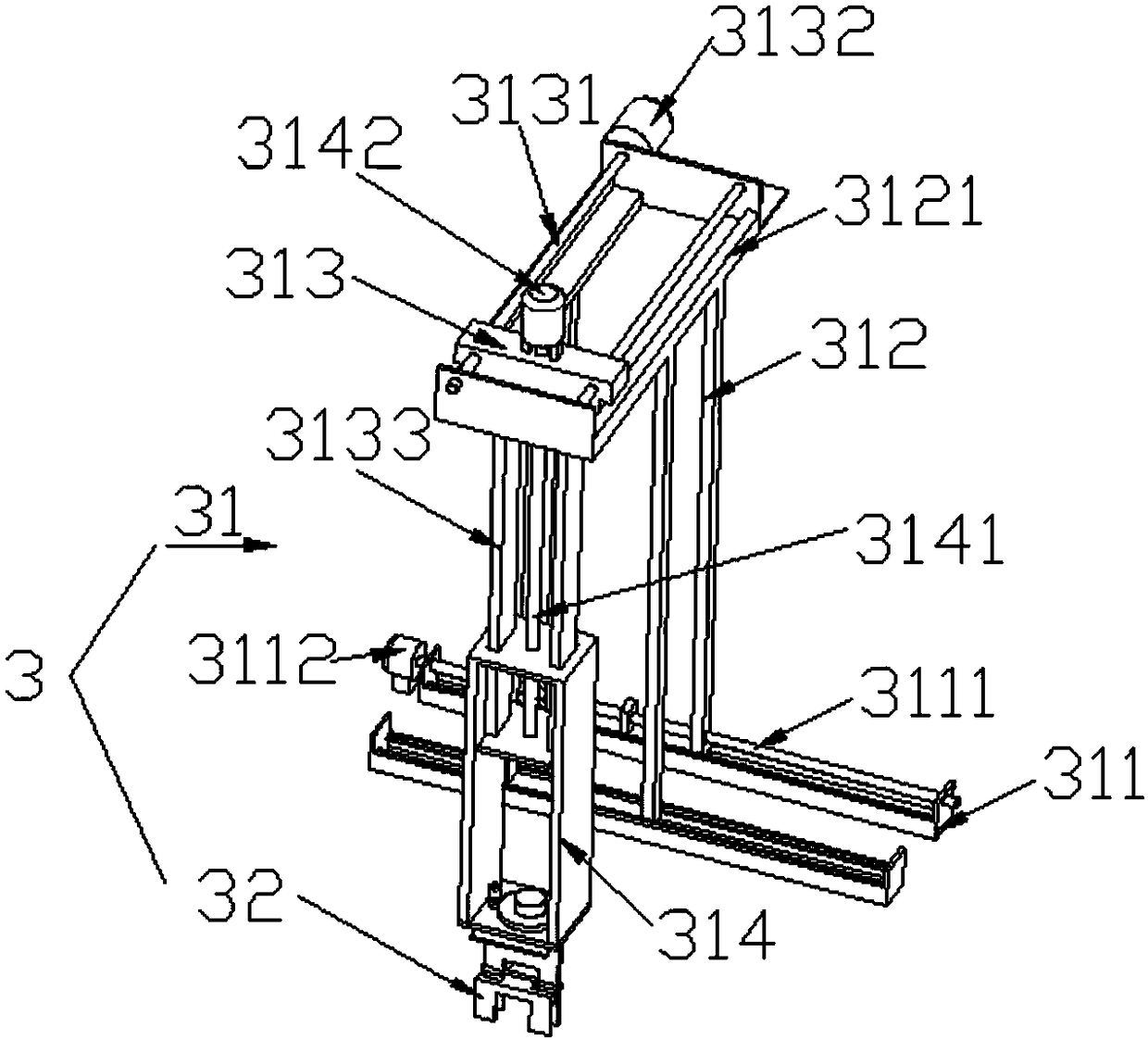

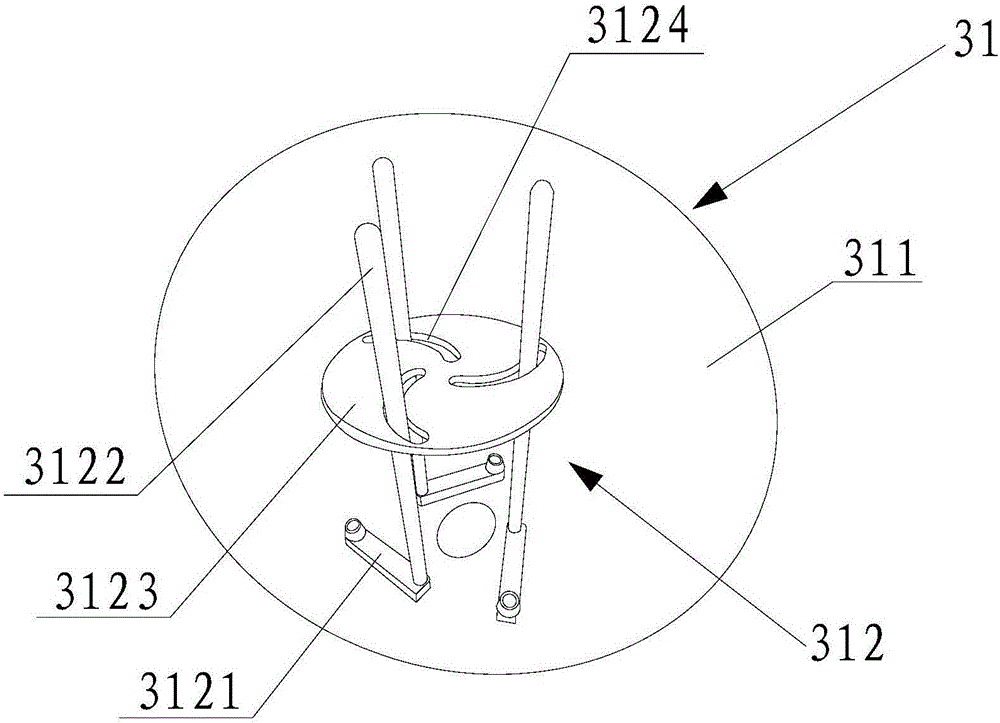

PendingCN109333513AAchieve crawlingSimple structureProgramme-controlled manipulatorManipulatorAerospace engineering

The invention discloses a sport manipulator for a smart wardrobe. The sport manipulator comprises a first-stage propulsion mechanism, a second-stage propulsion mechanism slidably connected to the first-stage propulsion mechanism and a grasping mechanism arranged at one end of the second-stage propulsion mechanism, fixedly connected with the second-stage propulsion mechanism and used for grasping clothes. Through first time of propulsion by the first-stage propulsion mechanism, the grasping mechanism reaches the position of a hanger to clamp the hanger, the second-stage propulsion mechanism realizes second time of propulsion to push the hanger out of the wardrobe, and therefore clothes can be captured with the sport manipulator.

Owner:FOSHAN POLYTECHNIC

Electric pincers

InactiveCN1958427AImprove securityControl process safetyLoad-engaging elementsTransducerElectrical control

An electric gripper is composed of a grip body consisting of a pair of jaws and its opening-closing mechanism with an actuating unit and one or more drive units, and an electric control system consisting of a programmable digital processor, an openness sensor, and an open angle transducer.

Owner:JULI SLING

Slide sealing machine

PendingCN112414823ARealize automatic grippingDispensing to achievePreparing sample for investigationEngineeringMechanical engineering

The invention provides a slide sealing machine, which comprises a rack assembly, a glass slide clamping device, a dyeing frame conveying device, a cover glass conveying device, a dispensing device anda slide airing bracket; the rack assembly is used for mounting the glass slide clamping device, the dyeing frame conveying device, the cover glass conveying device, the dispensing device and the slide airing bracket; the glass slide clamping device is used for automatically clamping the glass slide placed on the slide airing bracket; the dyeing frame conveying device is used for automatically conveying the dyeing frame so as to facilitate dyeing treatment; the cover glass conveying device is used for automatically conveying the cover glass to prepare for dispensing and sealing the glass; andthe dispensing device is used for automatically dispensing and sealing the glass slide on which the cover glass is placed. By arranging the glass slide clamping device, the dyeing frame conveying device, the cover glass conveying device and the dispensing device, automatic clamping and dyeing of the glass slide and automatic conveying and dispensing of the cover glass are achieved, and the automation degree is high.

Owner:长沙亚湘医疗科技有限公司

Full-automatic cloth spreading method

InactiveCN108049009AWear softGood hygroscopicityFabric breaking/softeningWeft knittingYarnShrinkage rate

The invention provides a full-automatic cloth spreading method and belongs to the field of cloth preparation. The method comprises the steps of firstly, preparation of premade cloth, wherein S-twistedcolored yarn of cotton, silk and wool, Z-twisted colored yarn of cotton, silk and wool, a full-automatic cloth spreading machine, a double-sided jacquard machine and an inkjet digital printing machine are prepared; secondly, weaving of the raw materials, wherein the double-sided jacquard machine is used for evenly weaving the S-twisted yarn and the Z-twisted yarn at path intervals according to acertain path number; thirdly, secondary treatment of the raw materials, wherein the full-automatic cloth spreading machine is used for spreading the cloth; fourthly, drying, wool grabbing and wool cutting, wherein shaping with clear water and drying are conducted; fifthly, soft cloth treatment, wherein a machine runs at a certain speed, when a front cloth end reaches the front portion of the machine, the machine is stopped, the front and rear cloth ends are sewn into an annular shape, and then the machine is started and stopped to achieve scutching and cloth discharging; sixthly, printing treatment, wherein the treated cloth is placed on the inkjet digital printing machine for printing; seventhly, rubber blanket pre-shrinking and steaming pre-shrinking, wherein the temperature of a rubberblanket is controlled, the processing speed is controlled, and the horizontal and vertical shrinkage rates of fabric and the patterns and effective width of the fabric are processed and adjusted.

Owner:XINMA ANHUI GARMENT CO LTD

Auxiliary loading device used in ceramic wine bottle production

ActiveCN106364942ARealize automatic grippingReduce harmConveyorsLoading/unloadingWine bottleEngineering

The invention discloses an auxiliary loading device used in ceramic wine bottle production. The auxiliary loading device comprises an operation table. A conveying mechanism is arranged at the upper end of the operation table. First supporting plates are fixed to the two sides of the upper end of the operation table correspondingly. A connecting piece is arranged on each first supporting plate and rotationally connected with a supporting rod. A first drive device is arranged on one side of each connecting piece. An output shaft of each first drive device penetrates the corresponding connecting piece and is fixedly connected with the lower end of the corresponding supporting rod. A fixed plate is hinged to the upper end of each supporting rod. A first sliding groove is formed in one side of the lower end of each fixed plate. A first sliding block is mounted in each first sliding groove. By means of combination of first oil cylinders, second oil cylinders, the fixed plates, clamping devices and the like, automatic clamping on a ceramic wine bottle containing box is achieved, and damage and hurt caused to personnel in the carrying process are reduced; and meanwhile, the labor cost is greatly reduced, the work efficiency is improved, and the auxiliary loading device is suitable for popularization.

Owner:江苏长欣车辆装备有限公司

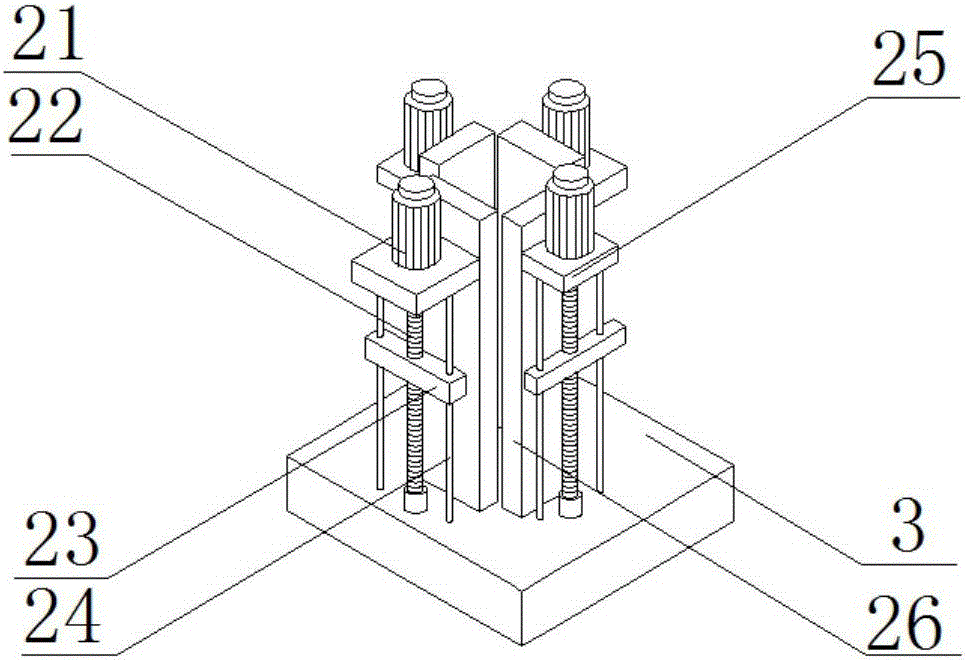

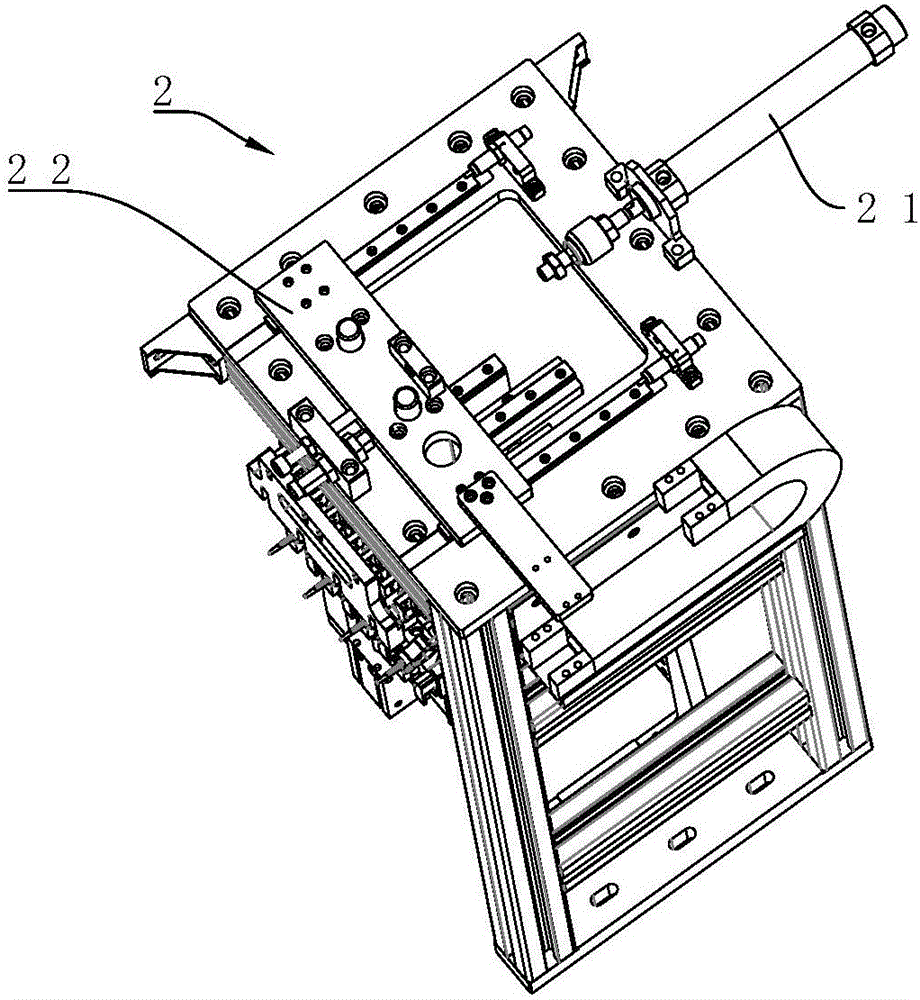

Automatic pressure riveting mechanism for bus duct contact

ActiveCN107052173ARealize automatic grippingRealize pressure rivetingMetal-working feeding devicesPositioning devicesHydraulic cylinderUltimate tensile strength

The invention discloses an automatic pressure riveting mechanism for a bus duct contact. The mechanism comprises a workpiece placement table fixed to an installation frame. A pressure riveting hydraulic cylinder fixedly connected to the installation frame is arranged on the workpiece placement table. The end of a piston rod of the pressure riveting hydraulic cylinder is provided with a pressure riveting head. A guide rail base is arranged on the installation frame and located on one side of the workpiece placement table. The guide rail base is provided with a horizontal guide rail. A horizontal sliding body is movably clamped to the horizontal guide rail. One side of the horizontal sliding body is provided with a vertical guide rail. The guide rail base is provided with a driving air cylinder. A piston rod of the driving air cylinder is connected with the horizontal sliding body. A vertical sliding body is movably clamped to the vertical guide rail. A pneumatic clamping jaw is fixed to the vertical sliding body through a connection block. By the adoption of the structure, structural design is reasonable, automatic clamping and pressure riveting for the contact are achieved, operation is easier and more convenient, the production efficiency is improved, the labor intensity of workers is lowered, and safety is improved.

Owner:SHANDONG GAOJI IND MACHINERY

Automatic screening and conveying device for connection rod machining

PendingCN108747552ARealize automatic grippingGuaranteed uptimeMetal working apparatusManipulatorEngineering

The invention relates to an automatic screening and conveying device for connection rod machining and belongs to the field of mechanical manufacturing. The automatic screening and conveying device forconnection rod machining comprises an automatic mold clamping unit, an automatic feeding unit, a connection rod conveying and screening unit, a residue conveying unit, an automatic discharging unit,a supporting unit and a control unit. The automatic mold clamping unit, the automatic feeding unit, the connection rod conveying and screening unit, the residue conveying unit, the automatic discharging unit and the control unit are all fixedly connected to the supporting unit and supported by the supporting unit. Mechanical arms clamp and take out a connection rod mold from a trimming press, clamp and fetch the connection rod and place the connection rod on a conveying unit, the connection rod is conveyed on the conveying unit, residues are filtered off, the mechanical arms clamp the connection rod to a next station, and qualified products are screened out. The automatic screening and conveying device for connection rod machining has the advantages of being reliable in overall operation,high in automation degree, accurate in locating and stable in conveying process, improving the production efficiency, reducing the labor cost and having high practicability.

Owner:ZHAOQING UNIV

Blanking assembly of rack assembling control system

InactiveCN109590704ARealize automatic grippingHigh degree of automationGripping headsMetal working apparatusBiochemical engineeringCoupling

The invention relates to a blanking assembly of a rack assembling control system. The blanking assembly comprises a supporting table, a translation mechanism, and a material clamping mechanism; the translation mechanism comprises a fixed bottom plate, a supporting column, a first fixing frame, a first motor, a horizontal guiding column, a first screw rod and a first coupling, wherein the fixed bottom plate is arranged on the upper surface of the supporting table, the supporting column is erected on the upper surface of the fixed bottom plate, the first fixing frame is fixed to the top of the supporting column, the first motor is arranged on the side surface of the first fixing frame, the horizontal guiding column which is arranged on the other side surface of the first fixing frame is provided with a walking groove, the first screw rod is rotationally arranged in the horizontal guiding column in a penetrating manner, the first coupling is arranged in the fixing frame and used for connecting the first screw rod and the first motor. Therefore, the automatic clamping of the materials can be realized, and the automation degree and the production efficiency can be improved.

Owner:SUZHOU GETLOON AUTOMATION EQUIP CO LTD

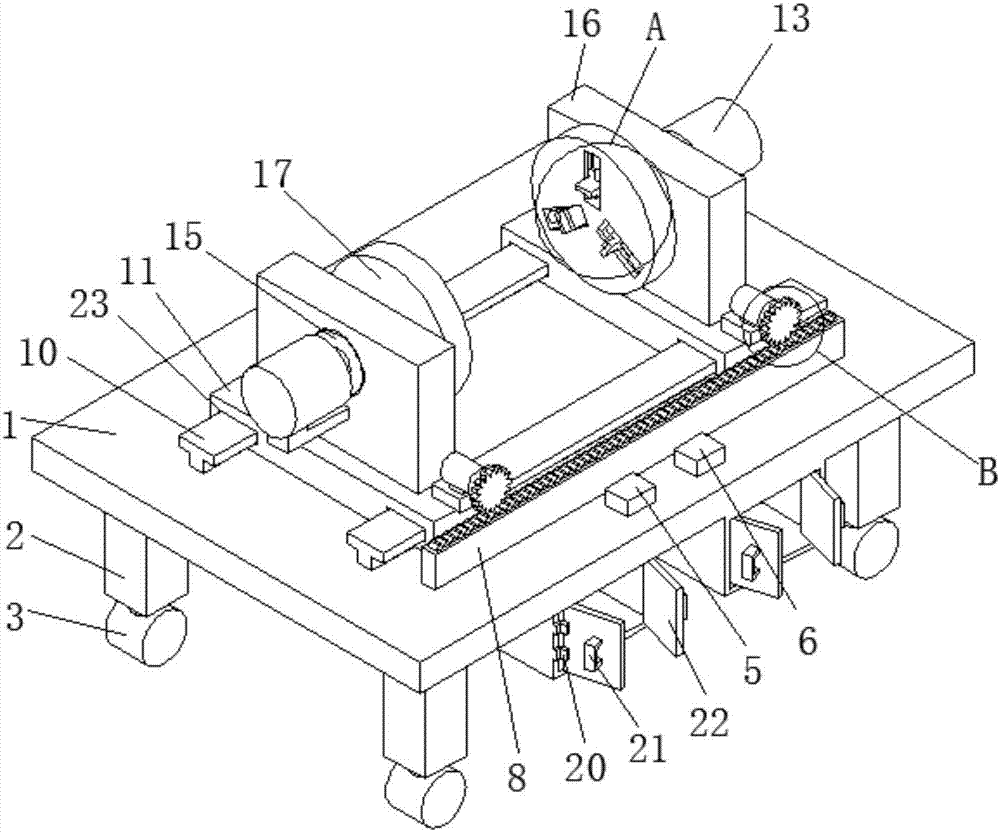

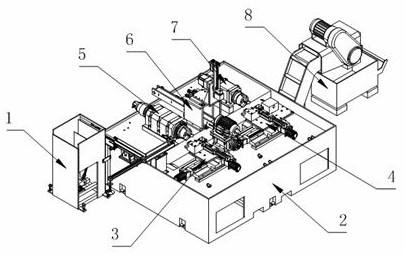

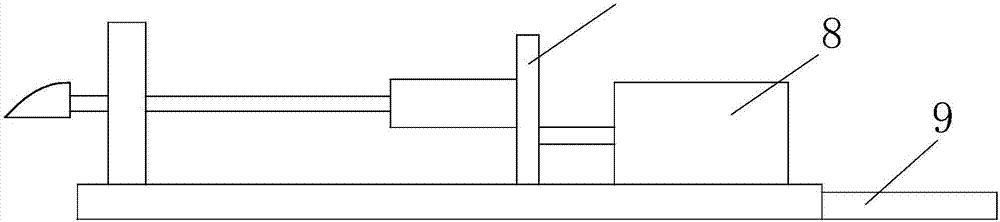

Full-automatic tool jig for precision lathe

ActiveCN112171356ARealize the function of automatic feedingReduce labor intensityMetal working apparatusMachiningWorkbench

The invention discloses a full-automatic tool jig for a precision lathe, and particularly relates to the technical field of lathe machining devices. The full-automatic tool jig comprises an automaticfeeding mechanism. A device working table is arranged beside the automatic feeding mechanism. A rough turning tool rest moving mechanism and a finish turning tool rest moving mechanism are fixedly installed on one side of the upper surface of the device working table. A rough turning spindle module, an automatic material taking and placing mechanism and a finish turning spindle module are fixedlyinstalled on the other side of the upper surface of the device working table. An automatic material collecting mechanism is arranged beside the device working table. According to the full-automatic tool jig for the precision lathe, by arranging the automatic feeding mechanism, the rough turning tool rest moving mechanism, the finish turning tool rest moving mechanism, the rough turning spindle module, the automatic taking and placing mechanism, the finish turning spindle module and the automatic material collecting mechanism, the full-automatic production functions of feeding, machining, material taking and placing, recycling and storing of parts by the device are achieved, the labor intensity of workers is reduced, and the automation degree and the practicability of the device are improved.

Owner:浙江众兴智能科技股份有限公司

Handheld clamping device

InactiveCN107128637AEasy to useRealize automatic grippingManual conveyance devicesRight trapezoidEngineering

Owner:台聪

Air-suction type vegetable stem leaf removal device

ActiveCN107280045ARealize automatic feeding processRealize automatic grippingFood treatmentEngineeringMechanical engineering

Owner:HUAZHONG AGRI UNIV

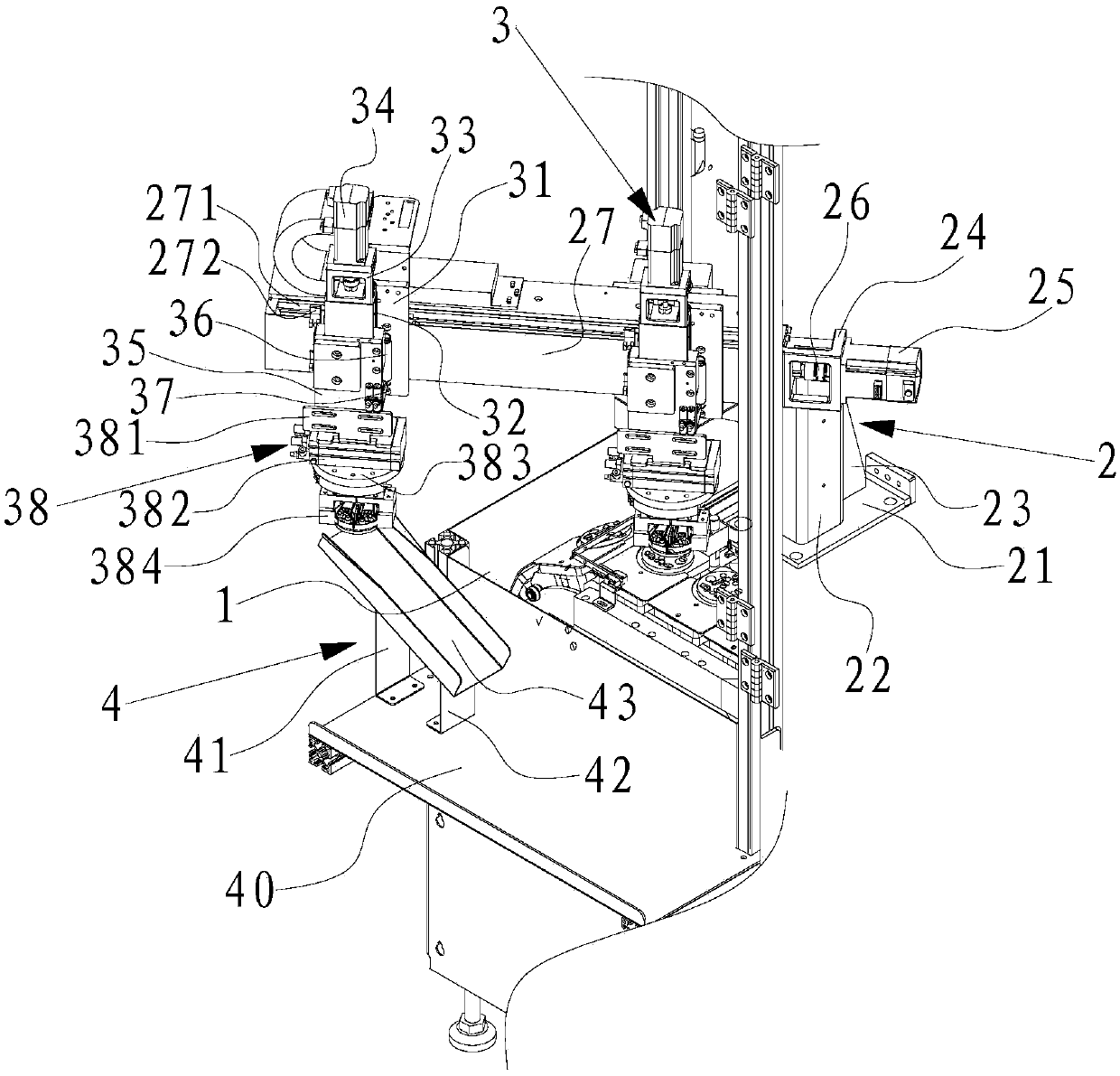

Apparatus for polishing aviation precision forging blade front trailing edge contour

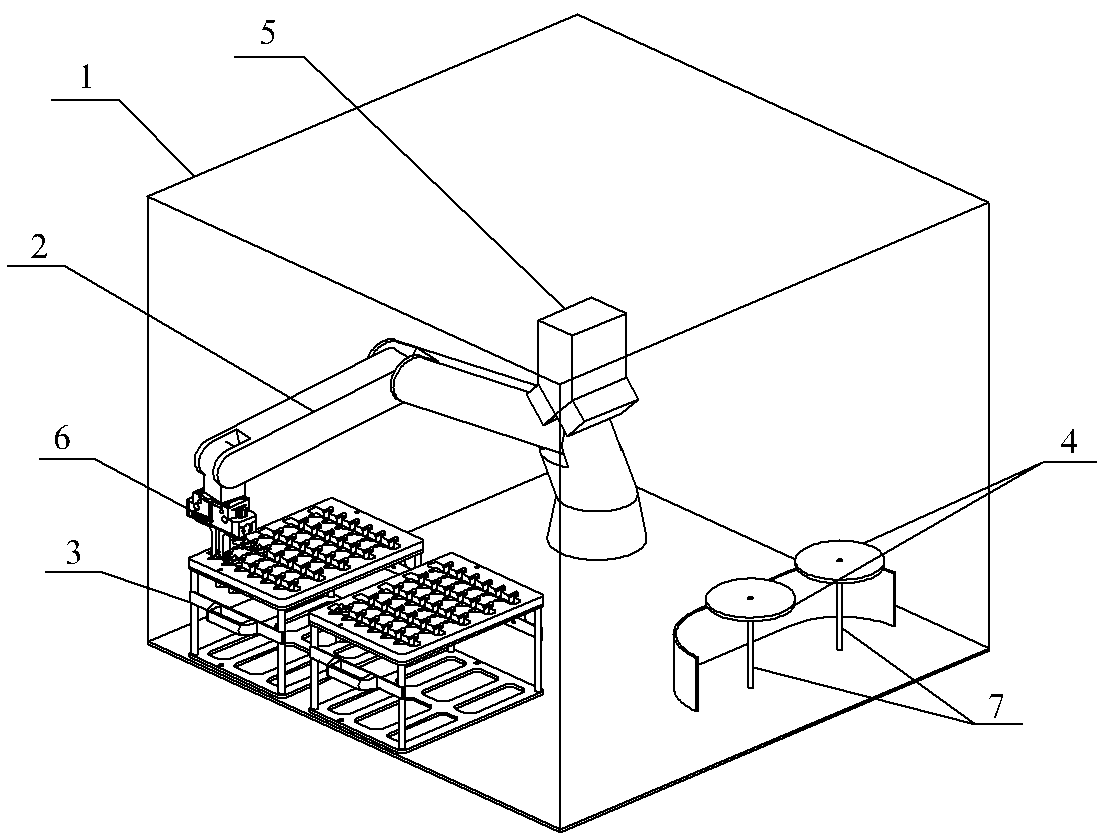

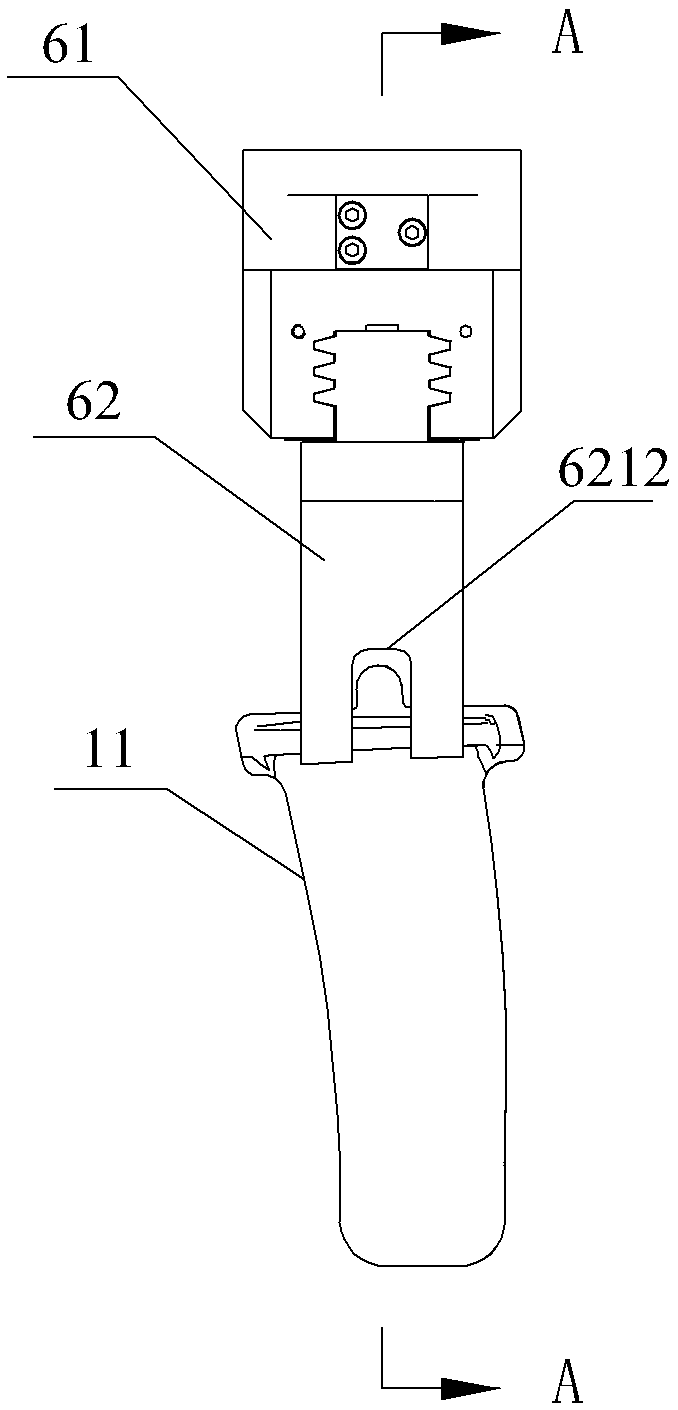

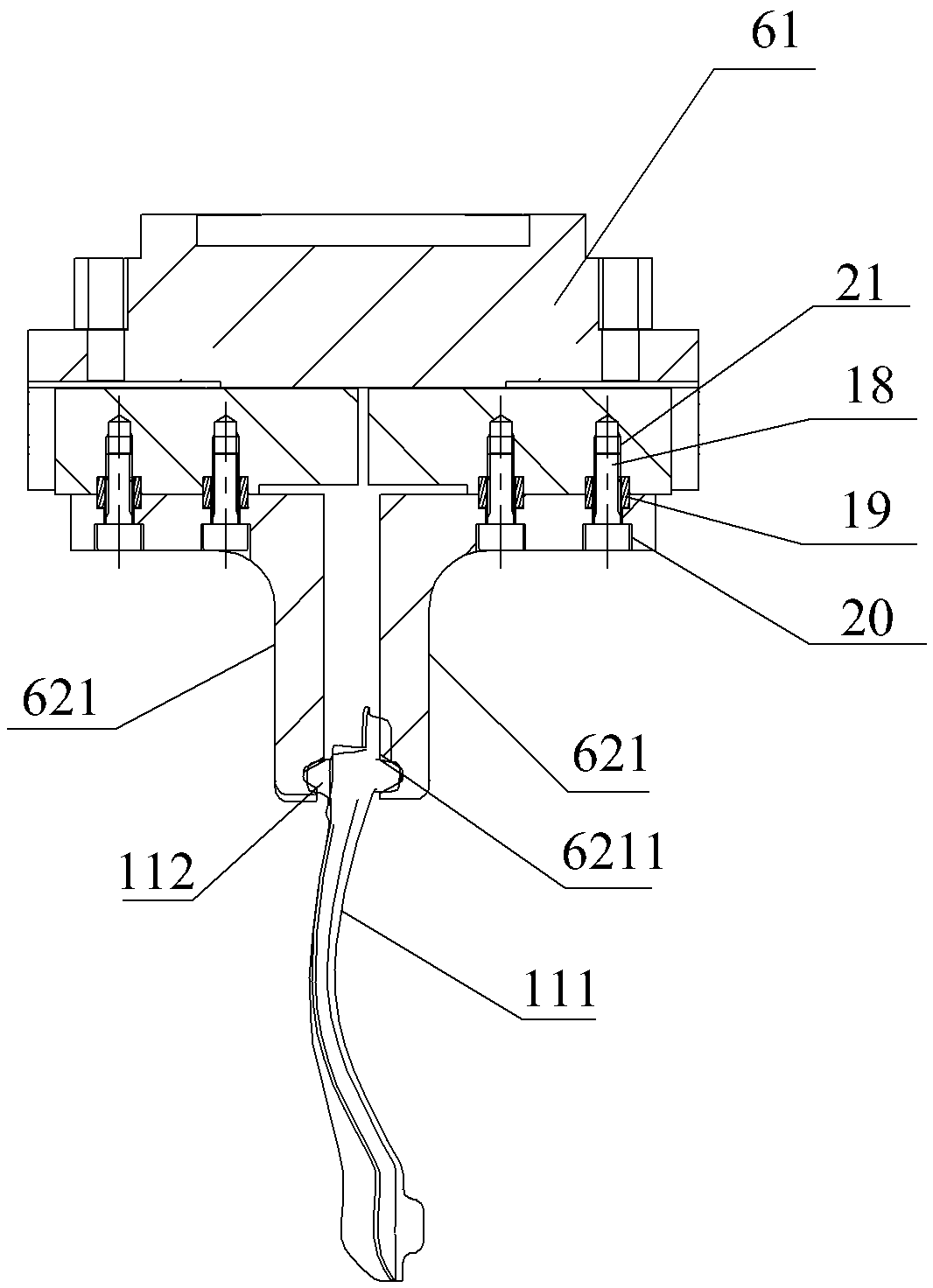

ActiveCN109015241AHigh polishing precisionPolishing precision and controllableGrinding carriagesGrinding feed controlTrailing edgeBatch production

The invention provides an apparatus for polishing an aviation precision forging blade front trailing edge contour. With the apparatus, the problems that in the process of manually polishing a precision forging blade front trailing edge contour in the prior art, the production efficiency is low, the manner is not suitable for batch production, and manual polishing is difficult to control in qualityand stability. The apparatus for polishing the aviation precision forging blade front trailing edge contour comprises a machine case. An industrial robot arm, a material rack and a polishing wheel are installed on the lower part of the interior of the machine case respectively. A laser contour detection device is installed on the upper part of the interior of the machine case. A pair of calipersused for clamping a blade is installed at an actuating end of the industrial robot arm. The polishing wheel is driven by a driving device installed on the machine case to rotate. The laser contour detection device, the calipers and the driving device are connected with a computer of the industrial robot arm in an electronic control manner. The material rack is detachably installed in a drawer on the side of the machine case through a positioning assembly. The material rack comprises a bracket and a material plate. The material plate is detachably installed at the position of an opening in thetop of the bracket through a first positioning assembly. At least two profiling grooves are formed in the material plate.

Owner:无锡航亚科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com