Kerbstone paving truck with concrete laying function

A curbstone and concrete technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of time-consuming, laborious, and bruised curbstones, and achieve the effects of convenient construction, convenient positioning, and improved laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

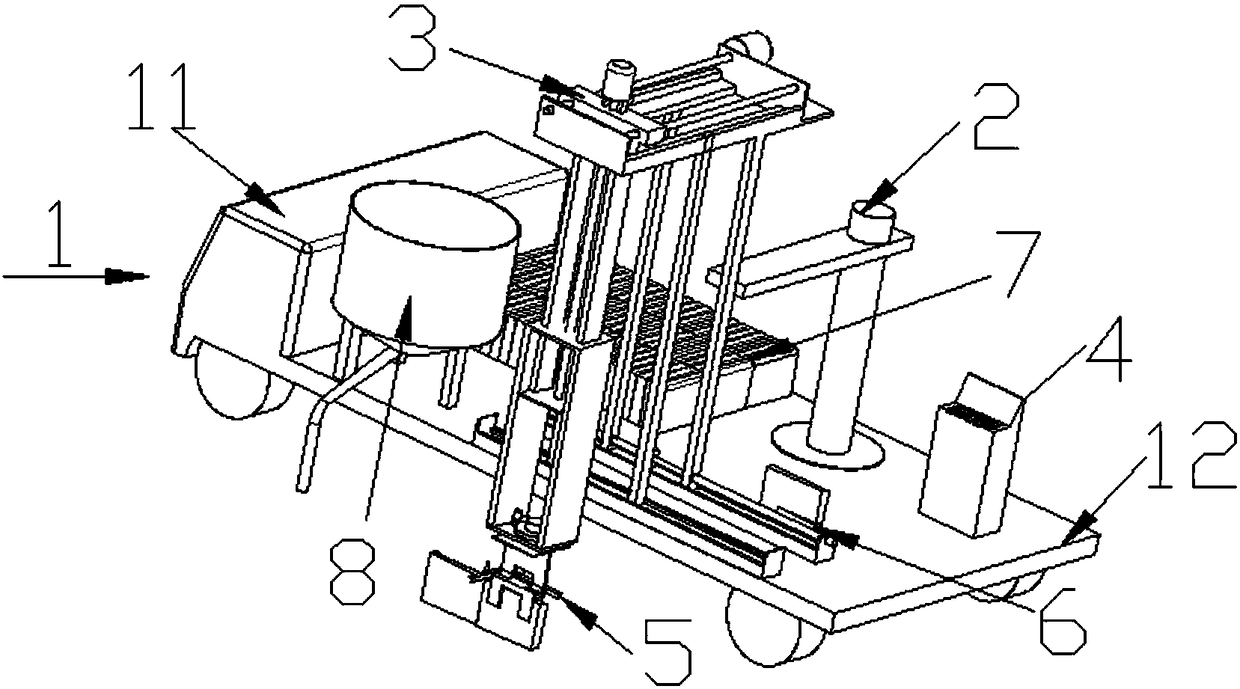

[0042] Such as Figure 1 to Figure 7 As shown, a curb laying vehicle with concrete laying function, including automobile assembly 1, cantilever crane 2, laying device 3, control device 4, alignment frame 5, origin resting plate 6, curb stone 7, mixer 8;

[0043] The automobile assembly 1 includes a cab 11 and a car bucket 12;

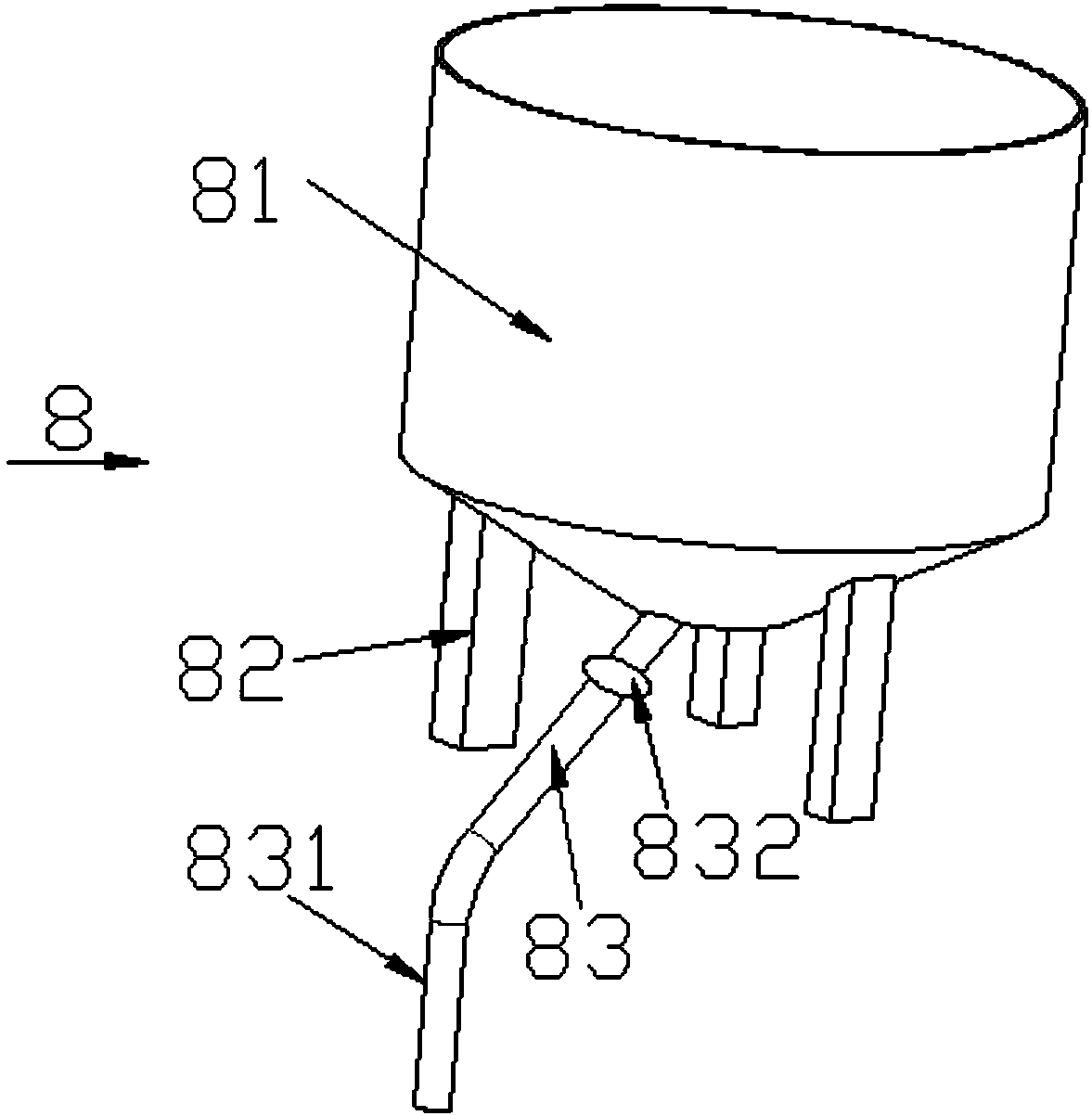

[0044] The mixer 8 includes a mixing bucket 81, a support foot 82 is provided below the mixing bucket, and the support foot 82 is fixed on the vehicle bucket 12, and the mixer 8 is arranged in front of the laying device 3;

[0045] The mixing barrel 81 is provided with a discharge pipe 83; the end of the discharge pipe 83 is provided with a hose portion 831, and the discharge pipe 83 is provided with a discharge switch 832;

[0046] The cantilever crane 2 is arranged on the vehicle body 12; the vehicle body 12 is also provided with an origin resting plate 6, a control device 4, and a laying device 3;

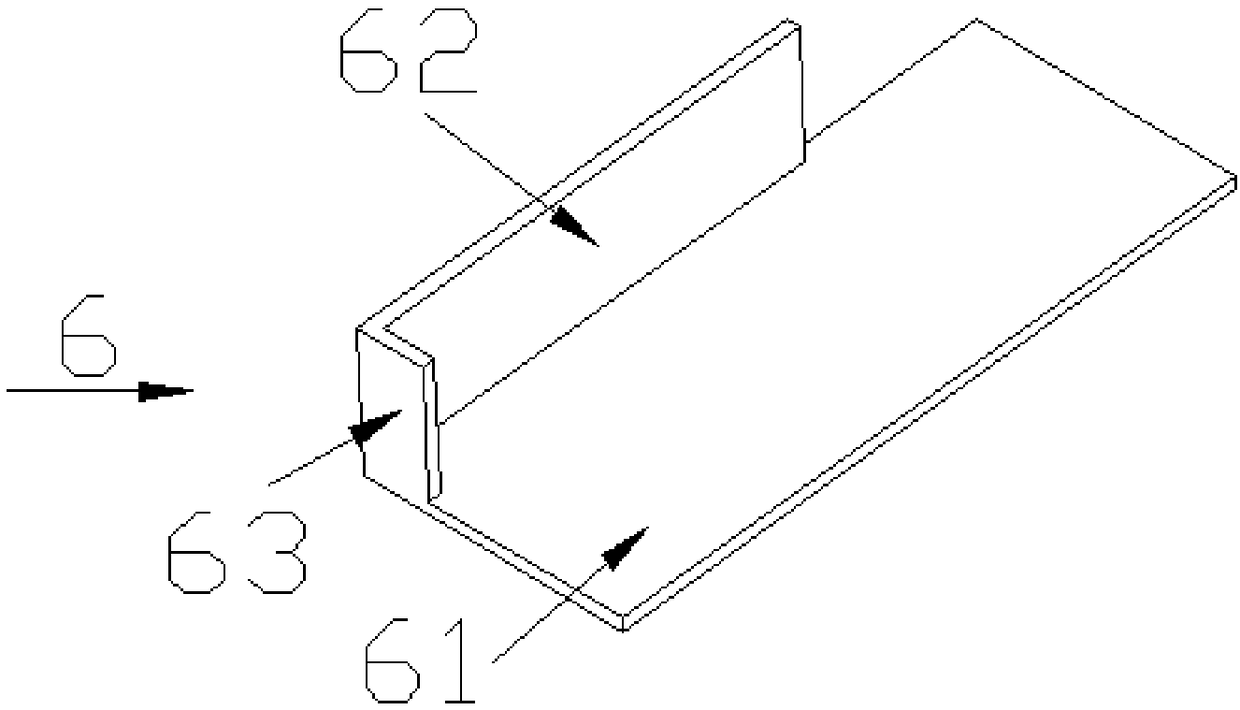

[0047] The origin resting plate 6 includes a res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com