Energy-saving type chemical adding and stirring device for sludge and sludge treatment system

A sludge dosing and stirring device technology, applied in water/sludge/sewage treatment, sludge treatment, dewatering/drying/concentrated sludge treatment, etc. The treatment method is complicated and does not meet the energy-saving production and other problems, so as to achieve the effect of saving cost and electric energy, sufficient stirring power and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

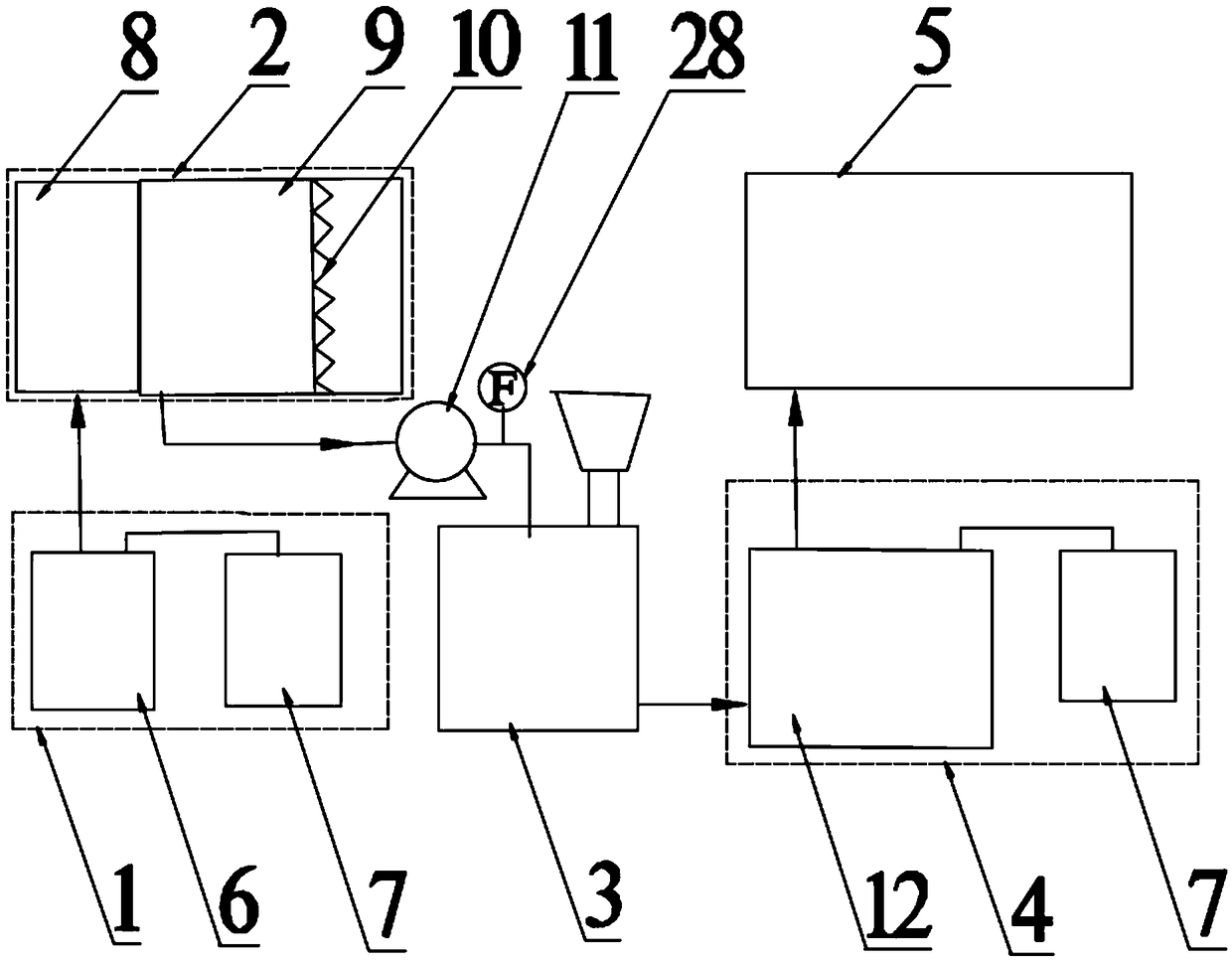

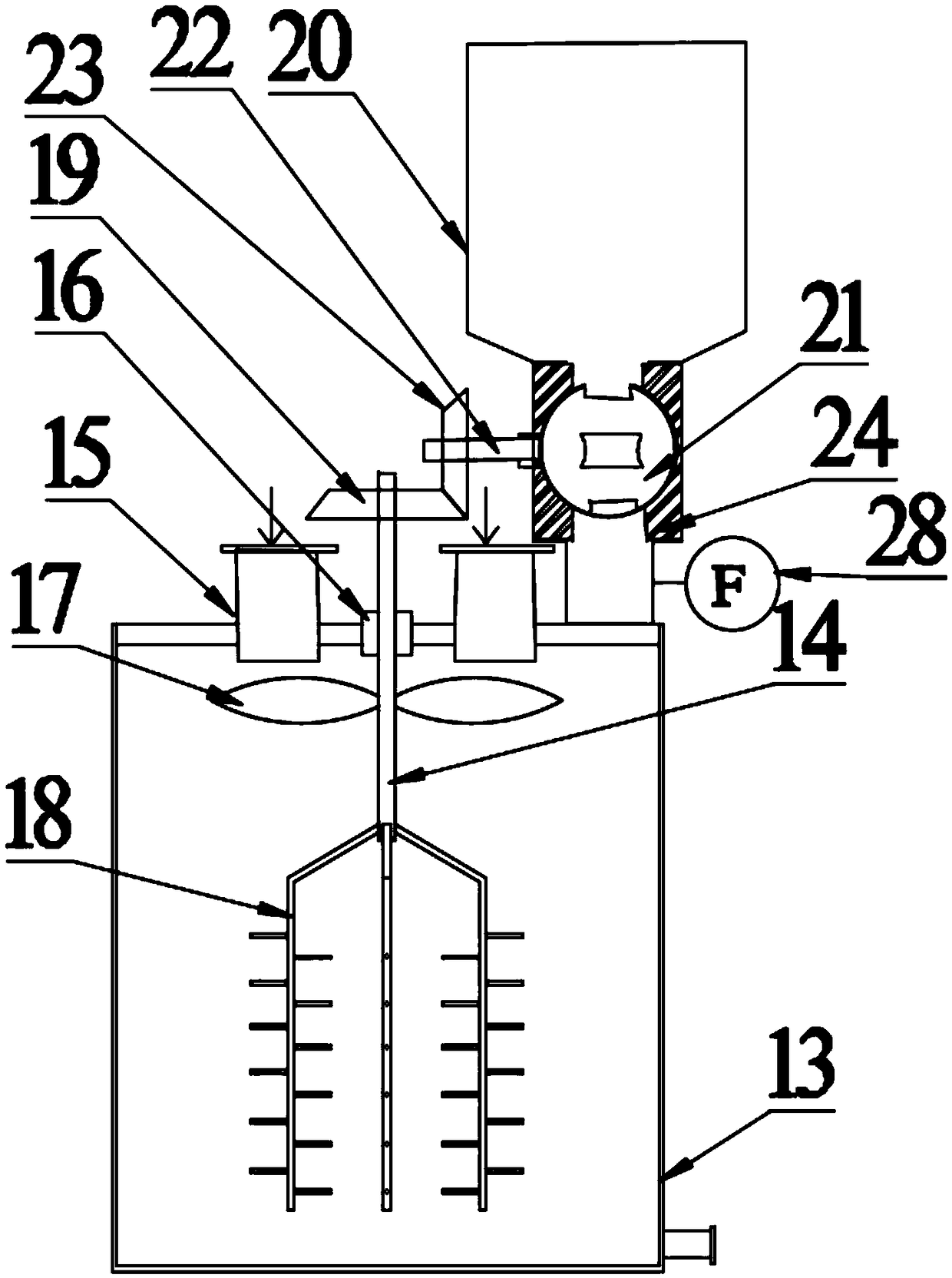

[0032] Such as Figure 1 to 4 As shown, a sludge treatment system includes a sludge preliminary screening device 1, a sludge thickening device 2, an energy-saving sludge dosing and stirring device 3, a sludge storage device 4, and a sludge dewatering device, which are sequentially connected through a sludge pipeline Drying device 5; The sludge preliminary screening device 1 includes a vibrating screen 6 and an air compressor 7 connected to the vibrating screen for removing large strips of impurities in the sludge; the sludge thickening device 2 Including mud cloth tank 8 and thickening tank 9; the mud cloth tank is equipped with a filter to remove fine particles and impurities, and the thickening tank is equipped with an overflow weir 10 to remove the upper layer of clear water in the sludge; the concentrated sludge passes through the high-pressure pump 11 And the sludge conveying pipeline enter the energy-saving sludge dosing and stirring device 3; the sludge outlet of the dos...

Embodiment 2

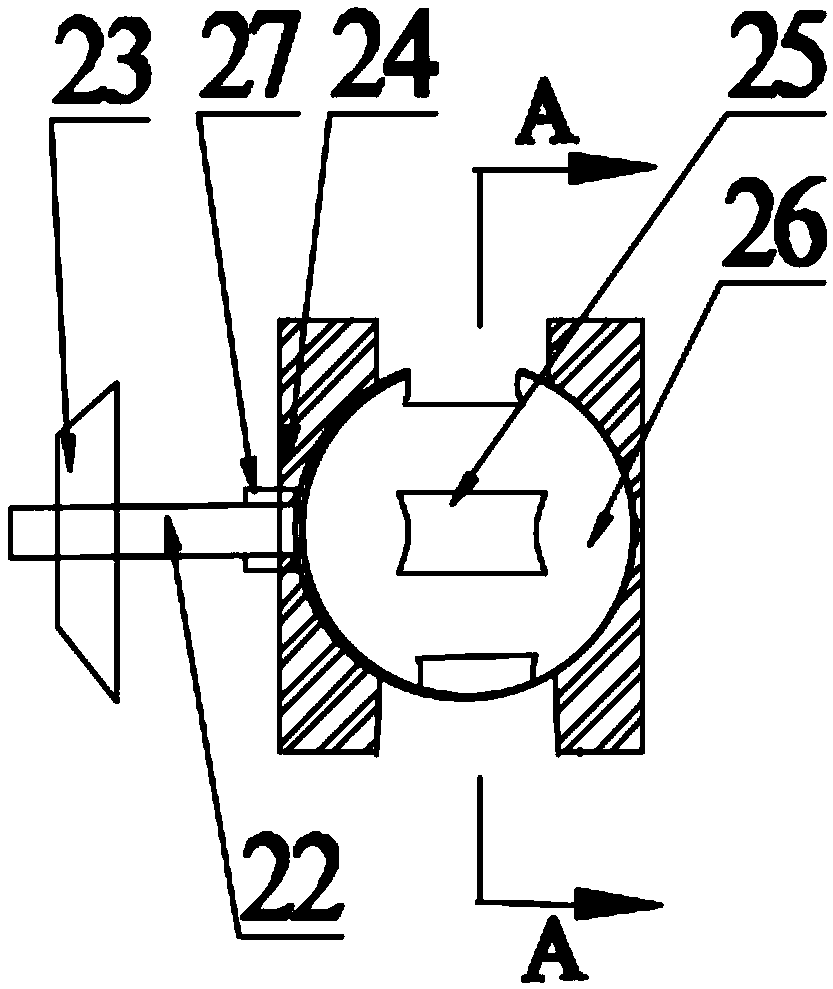

[0038] Such as Figure 5 As shown, with respect to Embodiment 1, two transmission gears are also provided between the rotating shaft and the vertical bevel gear in this embodiment. The first transmission gear 29 is connected to the vertical bevel gear 23 by a connecting rod. The vertical bevel gear 23 and the first transmission gear 29 have the same angular velocity. The second transmission gear 30 is fixed on the shaft 22, and the second transmission gear 30 Driven by the first transmission gear 29 and both have the same linear velocity, the other is the same as the first embodiment.

[0039] The speed change gear provided in this embodiment is used to change the rotation speed of the medicine dosing device, and the rotation speed of the rotating shaft of the medicine dosing switch can be adjusted by using different speed changes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com