System for storing and fetching multiple drill rods

A multi-drill pipe and drill pipe technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of low work efficiency, easy deviation of the center of gravity, unsafe construction process, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0044] The following is an example of a multi-drill pipe storage and pick-and-place system applied to a rock drill.

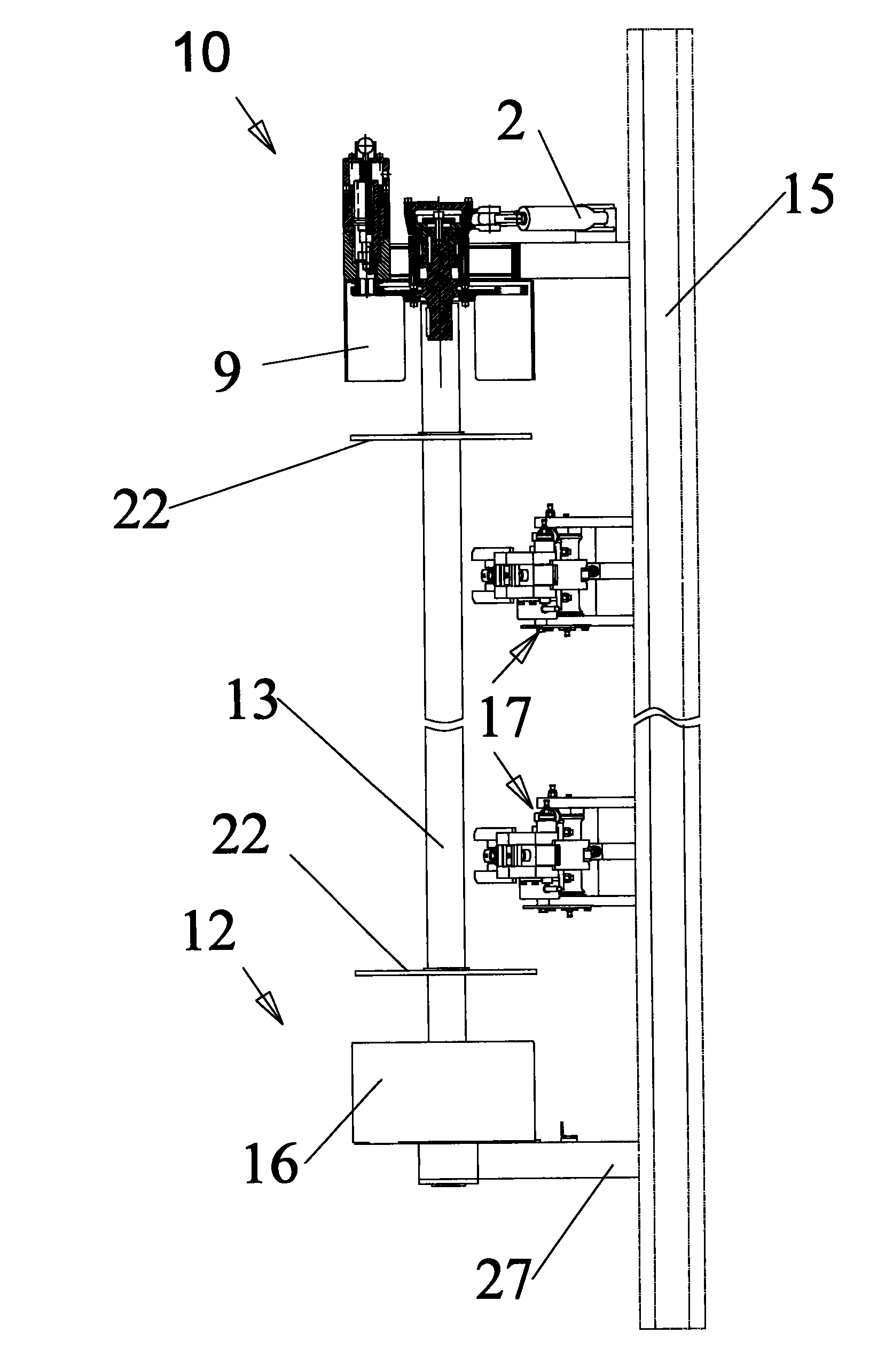

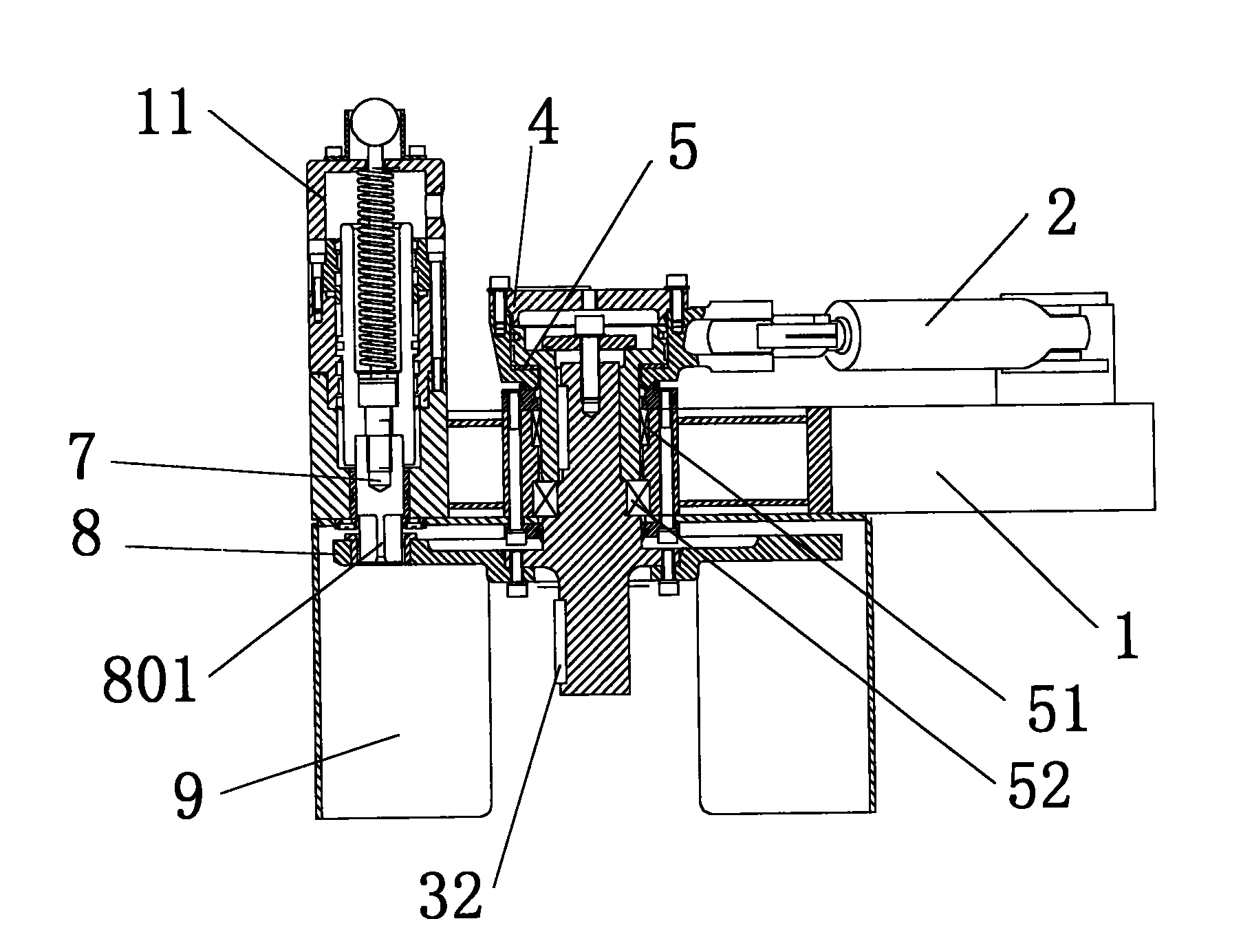

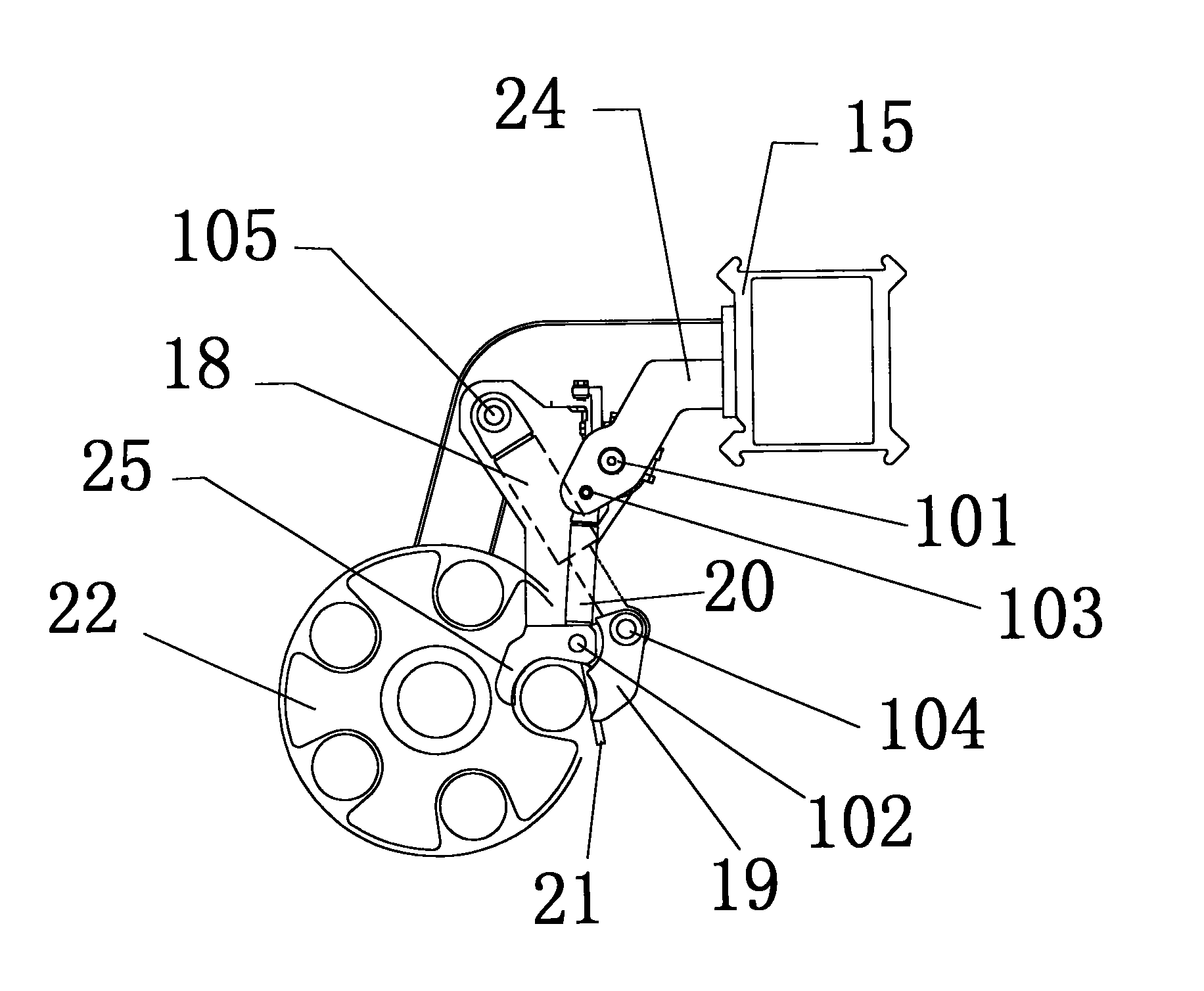

[0045] like Figure 1-Figure 4 As shown, the multi-drill rod storage and pick-and-place system of the embodiment of the present invention includes a drill rod storehouse for storing drill pipes, two manipulators 17 for clamping drill pipes and for installing the drill pipe storehouse and manipulator 17 The propulsion beam 15; as figure 1 , figure 2 As shown, the drill rod magazine includes a main shaft 13, an upper support 10 and a lower support 12, wherein:

[0046]Main shaft 13 is parallel to advancing beam 15, and the top and bottom of main shaft 13 are respectively provided with a faceplate 22, and faceplate 22 is all perpendicular to main shaft 13, and the periphery of each faceplate 22 is evenly provided with a plurality of grooves, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com