Automatic storage conveying system for steel wire calendered large roller shutter fabrics

A technology for conveying systems and roller blinds, which is applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of scattered material management, space occupation, and difficulty in the close connection between production management and production links, etc., to improve production Efficiency and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

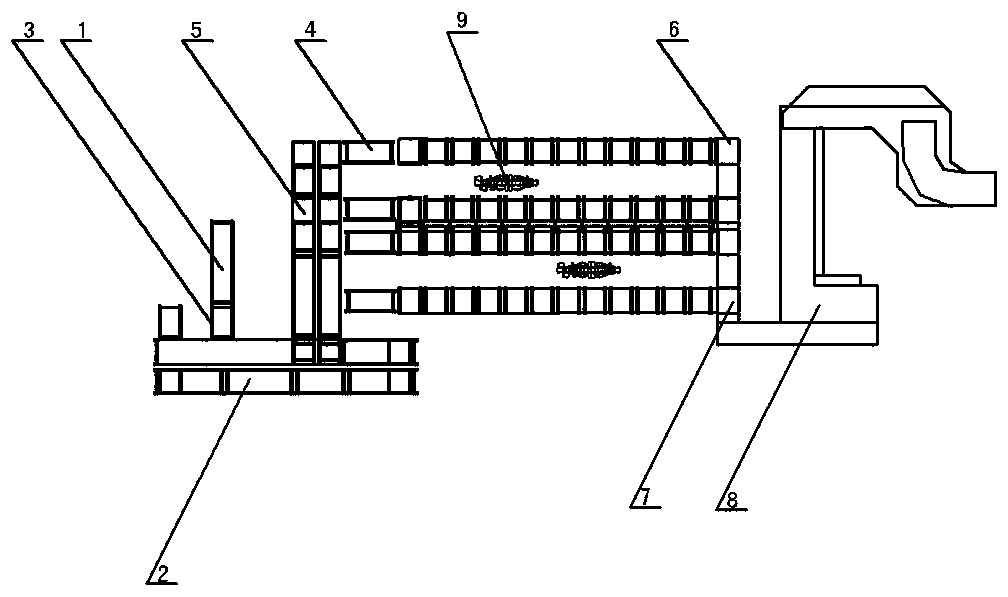

[0017] The automatic storage and conveying system for large roll curtain fabrics by steel wire calendering according to the present invention includes output storage area, vertical storage area and consumption storage area which are arranged in sequence;

[0018] The output storage area includes a truss 1, a hoisting device and a chain machine conveyor belt 2. One end of the chain machine conveyor belt 2 is provided with a storage platform 3, and the other end is connected with the vertical storage area. The truss 1 is collapsed on the storage platform 3 Above, the truss 1 is provided with a lifting device slidingly connected with it;

[0019] Described vertical storehouse comprises several storehouse racks 4 that are arranged parallel to each other, and described each storehouse rack 4 is all respectively provided with a warehouse-in end and a warehouse-out end, and the warehouse-in ends of several storehouse racks 4 are all on the same side of the vertical storehouse. On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com