On-line identification and measurement automation system of vehicle wheel

A measurement automation and automatic identification system technology, applied in wheel testing, measuring devices, instruments, etc., can solve the problems of relying on manual inspection, high labor intensity, and increased labor, so as to ensure traceability, save quality costs, and save money. artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

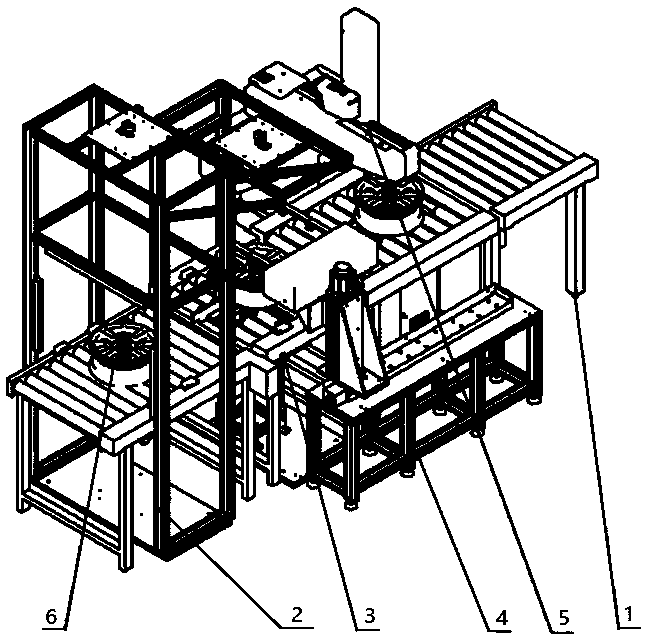

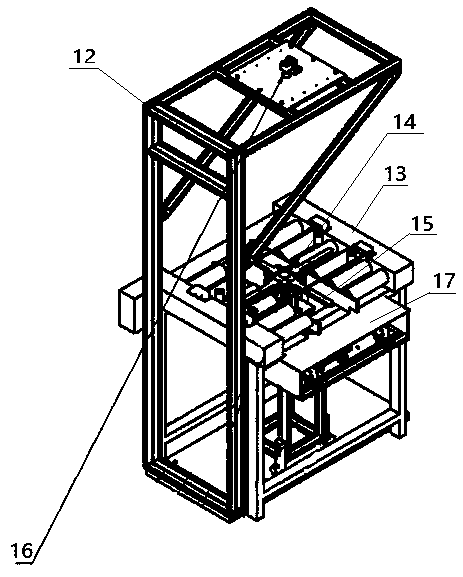

[0028] An automatic system for online recognition and measurement of wheels, including a first automatic transmission material line (not shown), an automatic wheel identification system 2, an automatic adjustment mechanism for wheel pose and posture 3, a handling mechanism 4, an online detection device 5, a second automatic transmission material Line 1, the first automatic material transmission line, the automatic wheel identification system 2, the automatic wheel position adjustment mechanism 3, the online detection equipment 5, and the second automatic material transmission line 1 are set in sequence.

[0029] The first automatic material transmission line is used for transporting the wheels to the automatic wheel identification system 2 . The automatic wheel identification system 2 is used to determine the unique identity of the wheel according to the color, diameter and height of the spoke surface of the wheel, transmit the unique identity information of the wheel to the on...

Embodiment 2

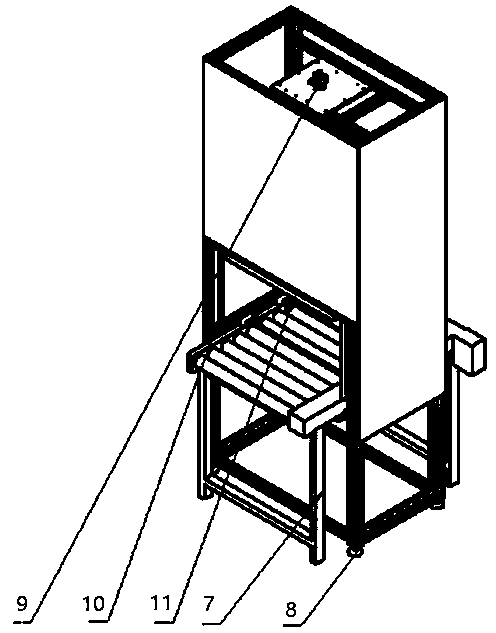

[0038] The difference between embodiment 2 and embodiment 1 lies in: the way of obtaining the unique identity of the wheel is different, and the structure of the corresponding automatic wheel identification system 2 is different. The specific automatic wheel identification system 2 identifies the unique identity of the wheel according to the two-dimensional code information on the wheel, and the automatic wheel identification system 2 includes a third automatic transmission material line 7, a code scanning identification frame, a code scanner, and a code scanning identification frame The top is fixed with a code scanner, the third automatic transmission material line 7 passes through the first image recognition frame 8, and the wheel detection sensor is arranged on the third automatic transmission material line 7 to detect that the wheel is in place, and the code scanner can scan the position on the wheel. The QR code obtains the unique identity information of the wheel. The r...

Embodiment 3

[0040]The difference between embodiment 3 and embodiment 1 lies in: the way of obtaining the unique identity of the wheel is different, and the structure of the corresponding automatic wheel identification system 2 is different. An automatic wheel identification and measurement system, which determines the unique identity of the wheel according to the two-dimensional code information on the wheel, the color of the spoke surface, the diameter and the height of the wheel. The structure of the corresponding automatic wheel identification system 2 includes a code scanner and a first Camera recognition module 9. Specifically, the automatic wheel recognition system 2 includes a third automatic material transmission line 7, a first image recognition frame 8, a first camera recognition module 9, a code scanner, a wheel width recognition sensor 10, a wheel diameter recognition sensor 11, a first The top of an image recognition frame 8 is fixed with a first camera recognition module 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com