Automatic machining production line for parts of silicone oil clutch of large vehicle

A technology for silicone oil clutches and parts, applied in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as increasing costs, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

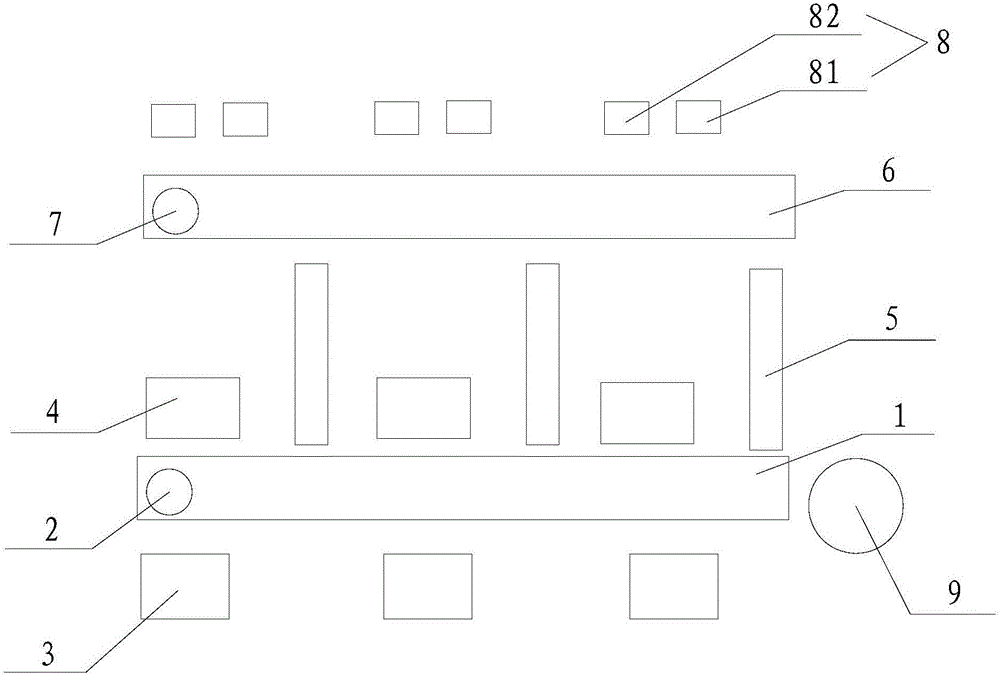

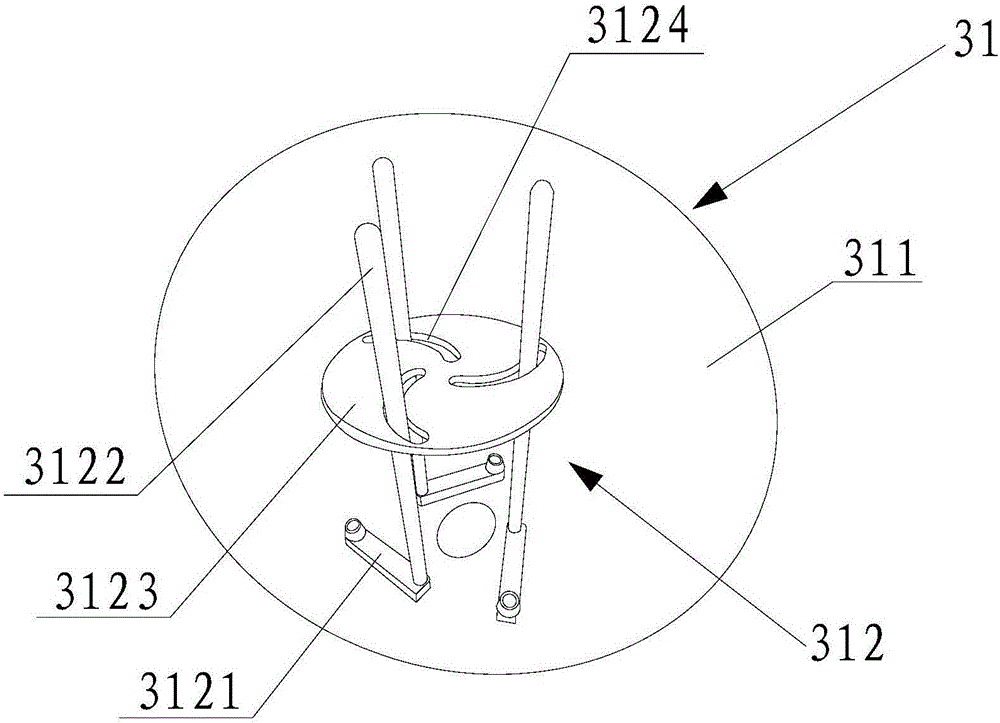

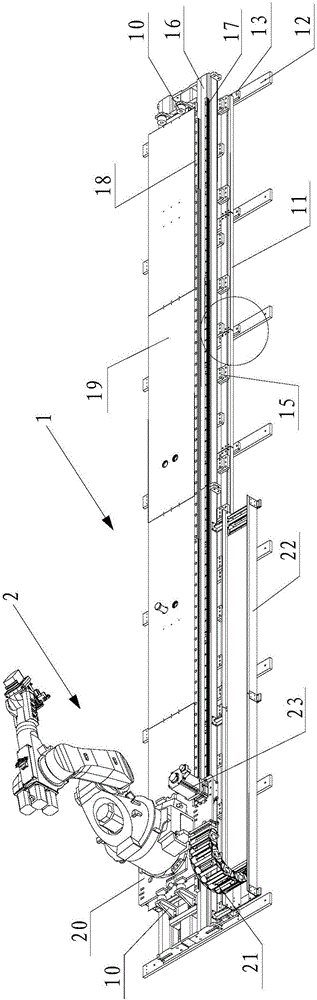

[0019] Such as Figure 1 to Figure 5 The large-scale vehicle silicon oil clutch parts automatic processing production line shown mainly includes the first traveling track assembly 1, the reclaiming robot 2, the storage mechanism 3, the machining center 4 and the transmission mechanism 5, etc.

[0020] Wherein, there are multiple storage mechanisms 3 (three in the present embodiment, respectively corresponding to three parts of the silicone oil clutch), and they are arranged on one side of the first walking track assembly 1; a plurality of storage mechanisms 3 are in the same position as The first walking track assembly 1 is on a parallel straight line. The machining center 4 is arranged on the other side of the first traveling track assembly 1 , and it corresponds to the storage mechanism 3 one by one. The quantity of transmission mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com