Blanking assembly of rack assembling control system

A control system and blanking technology, which is applied in the direction of manufacturing tools, metal processing, manipulators, etc., can solve the problems of lack of production efficiency, achieve the effect of improving the degree of automation and production efficiency, and realizing automatic clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

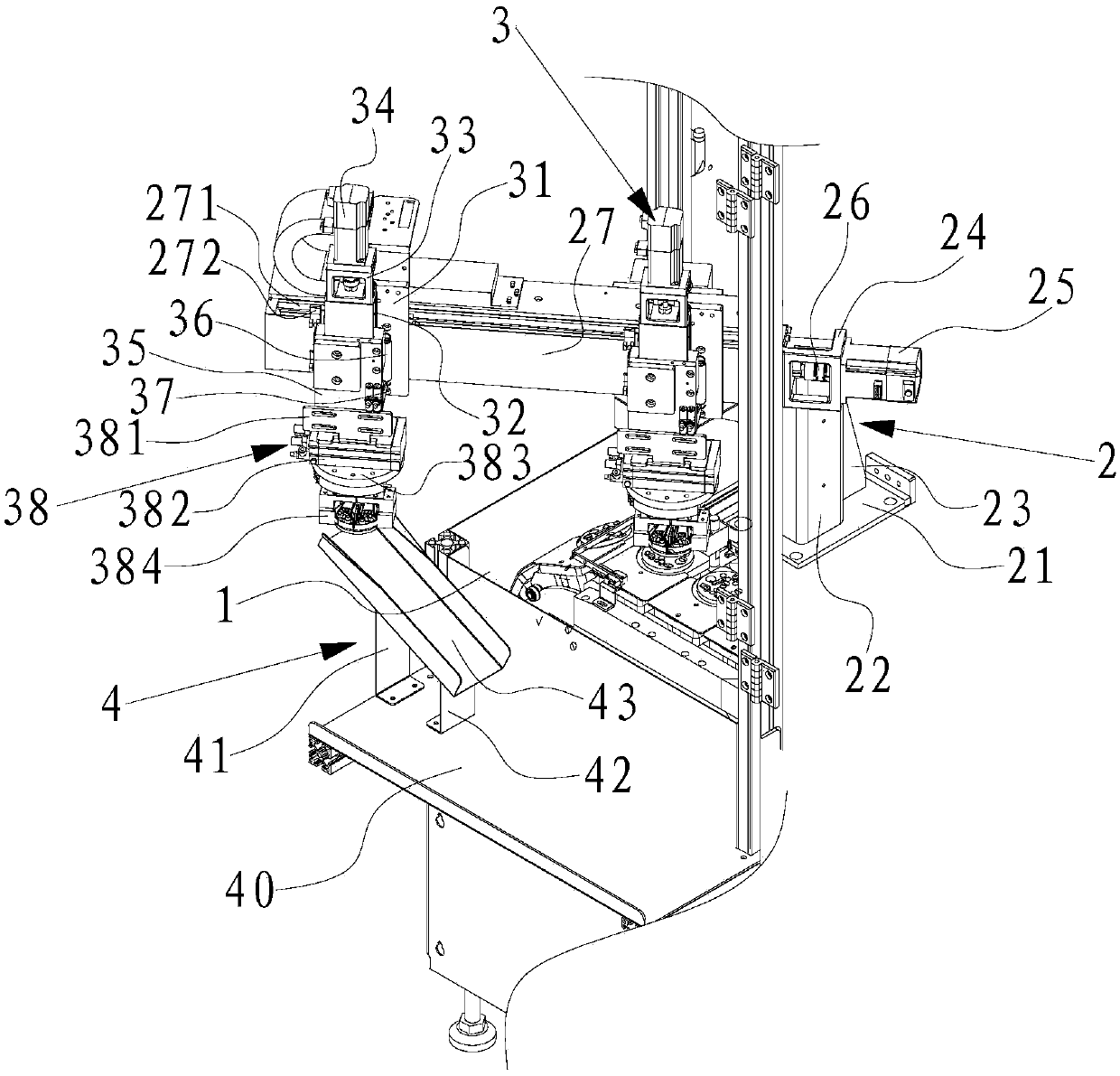

[0016] Such as figure 1 The blanking assembly of the rack assembly control system shown mainly includes a support table 1, a translation mechanism 2, and a clamping mechanism 3, etc.

[0017] Wherein, the translation mechanism 2 includes a fixed base plate 21 installed on the upper surface of the support platform 1, a support column 22 erected on the upper surface of the fixed base plate 21 (that is, one end of the support column 22 is fixed on the upper surface of the fixed base plate 21), and a support column fixed on the support column. The first fixed mount 24 on the top of 22 (fixed mode adopts conventional bolts etc., the same below), the first motor 25 installed on the first fixed mount 24 side, installed on the first fixed mount 24 other side and provided with walking The horizontal guide column 27 of the groove 271, the first lead scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com