Automatic screening and conveying device for connection rod machining

An automatic screening and connecting rod technology, which is applied in metal processing and other directions, can solve problems such as inaccurate placement of connecting rod forgings, temperature drop of connecting rod forgings, and poor quality of processed parts, so as to achieve stable transmission process, reduce labor costs, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

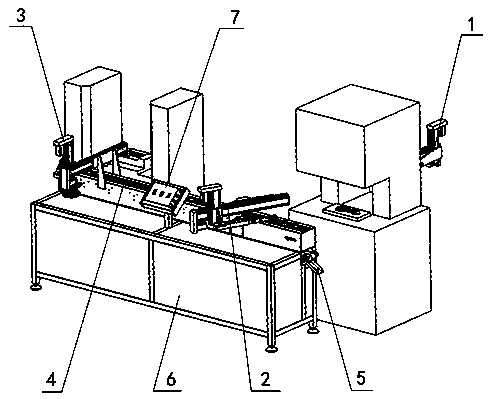

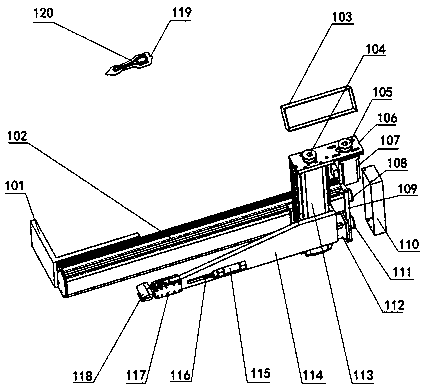

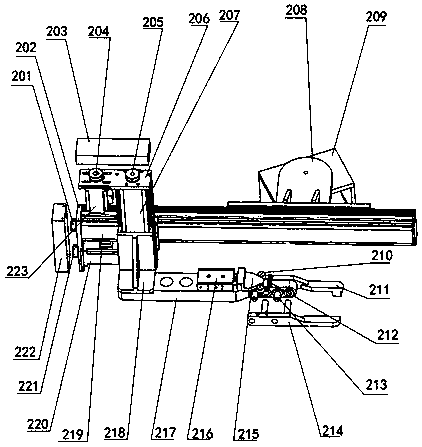

[0025] see Figure 1 to Figure 8 As shown, the equipment for automatic screening and transmission in connecting rod processing of the present invention has reliable operation, high degree of automation, accurate positioning, stable transmission process, improved production efficiency, and reduced labor costs. The present invention divides the automatic screening and transmission of the connecting rod 120 into four parts: the first part is that the manipulator clamps and takes out the connecting rod mold 119 from the trimming press, and the second part is that the manipulator picks up the connecting rod and places it on the transfer unit In the third part, the connecting rod is transferred on the transfer unit and the residue is filtered, and the fourth part is for the manipulator to pick up the connecting rod to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com