Kerb laying vehicle

A technology of curbs and car bodies, which is applied in the field of road construction, can solve the problems of curb bruises, time-consuming and labor-intensive problems, and achieve the effects of facilitating construction, reducing labor intensity, and reducing intermediate transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

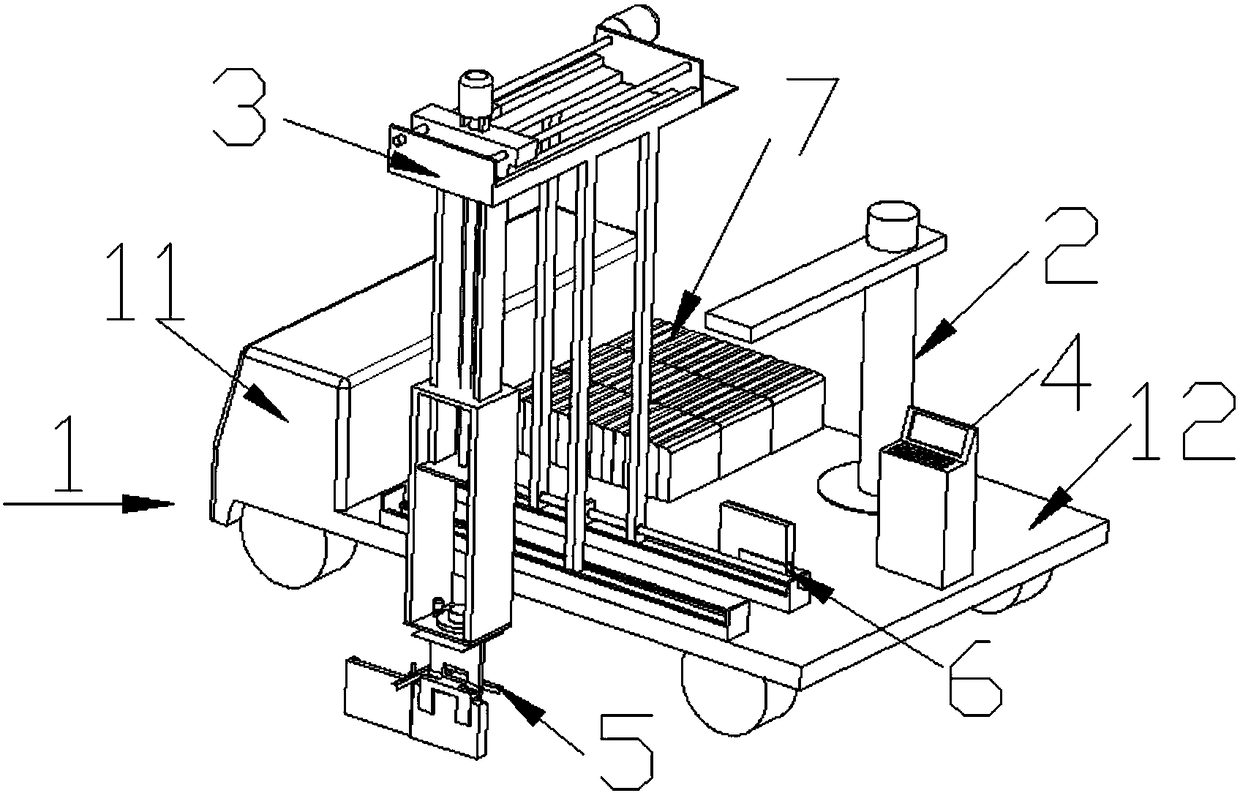

[0039] like Figure 1 to Figure 6 As shown, a curb laying vehicle includes a car assembly 1, a cantilever crane 2, a laying device 3, a control device 4, an alignment frame 5, an origin resting plate 6, and a curb 7;

[0040] The automobile assembly 1 includes a cab 11 and a car bucket 12;

[0041] The cantilever crane 2 is arranged on the vehicle body 12;

[0042] The car bucket 12 is also provided with an origin resting plate 6, a control device 4, and a laying device 3;

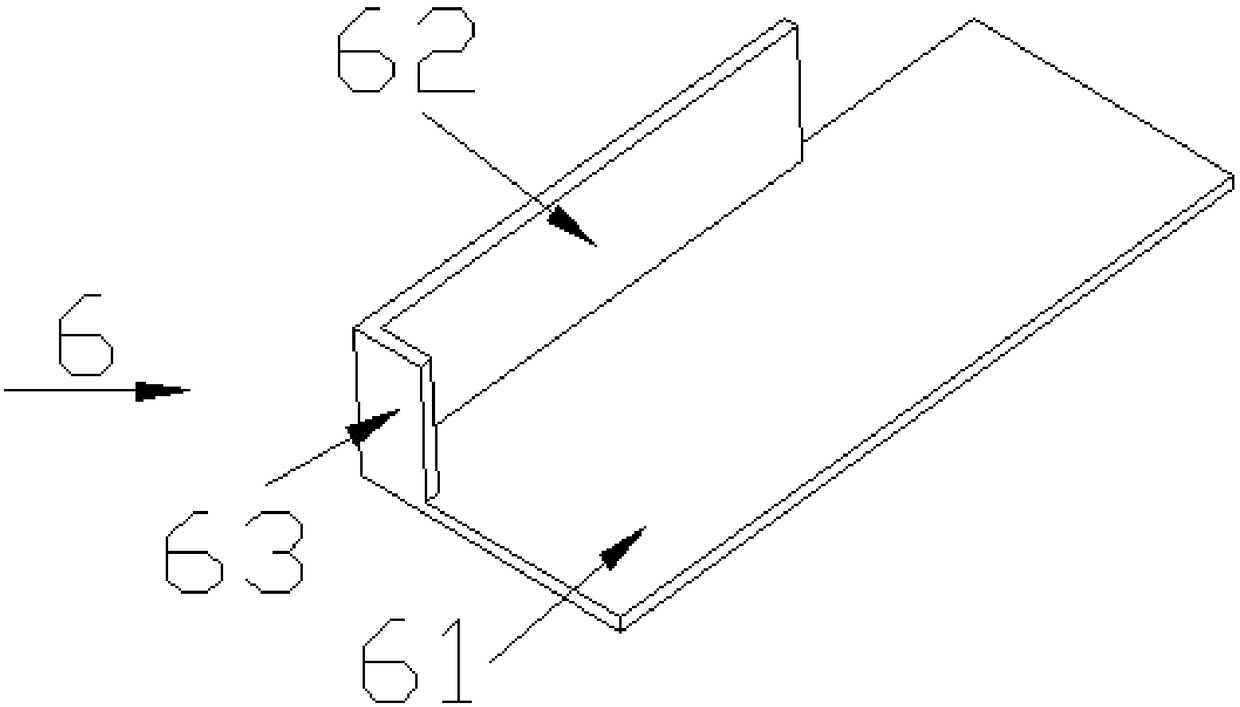

[0043] The origin resting plate 6 includes a resting bottom plate 61, on which a horizontal backrest board 62 and a longitudinal backrest board 63 are vertically arranged;

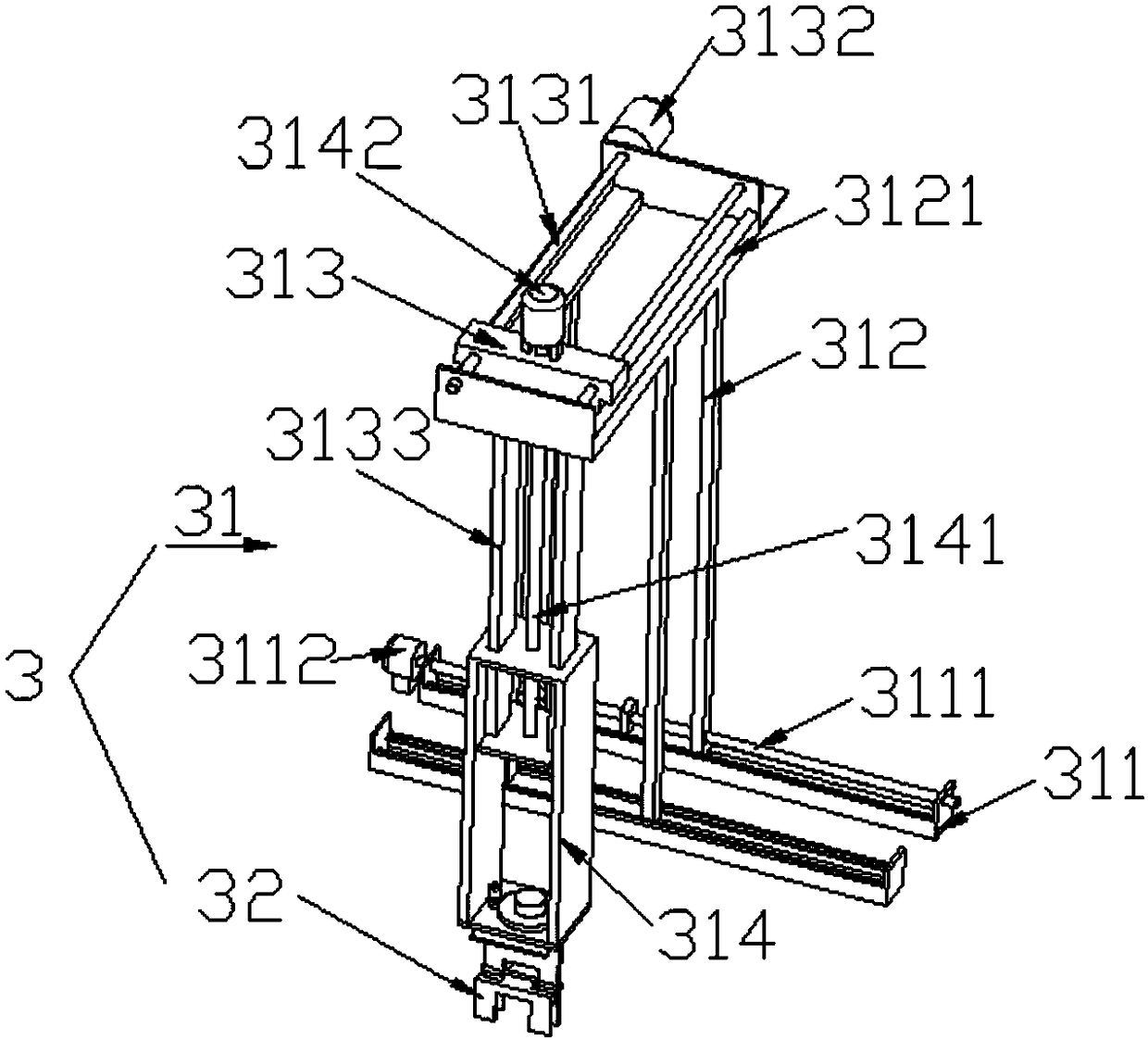

[0044] The laying device 3 includes a linkage mechanism 31 and a clamping device 32;

[0045] The clamping device 32 includes a first clamping plate 321, a second clamping plate 322, and a direction adjusting device 325;

[0046] The first clamping plate 321 is arranged vertically, the second clamping plate 322 is in a “Z” shape, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com