Mulching film machine for garden road construction

A technology of road construction and mulching machine, which is applied to roads, roads, road repair and other directions, can solve problems such as time-consuming and labor-intensive, and achieve the effect of improving maintenance effect, improving laying efficiency, and improving spreading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

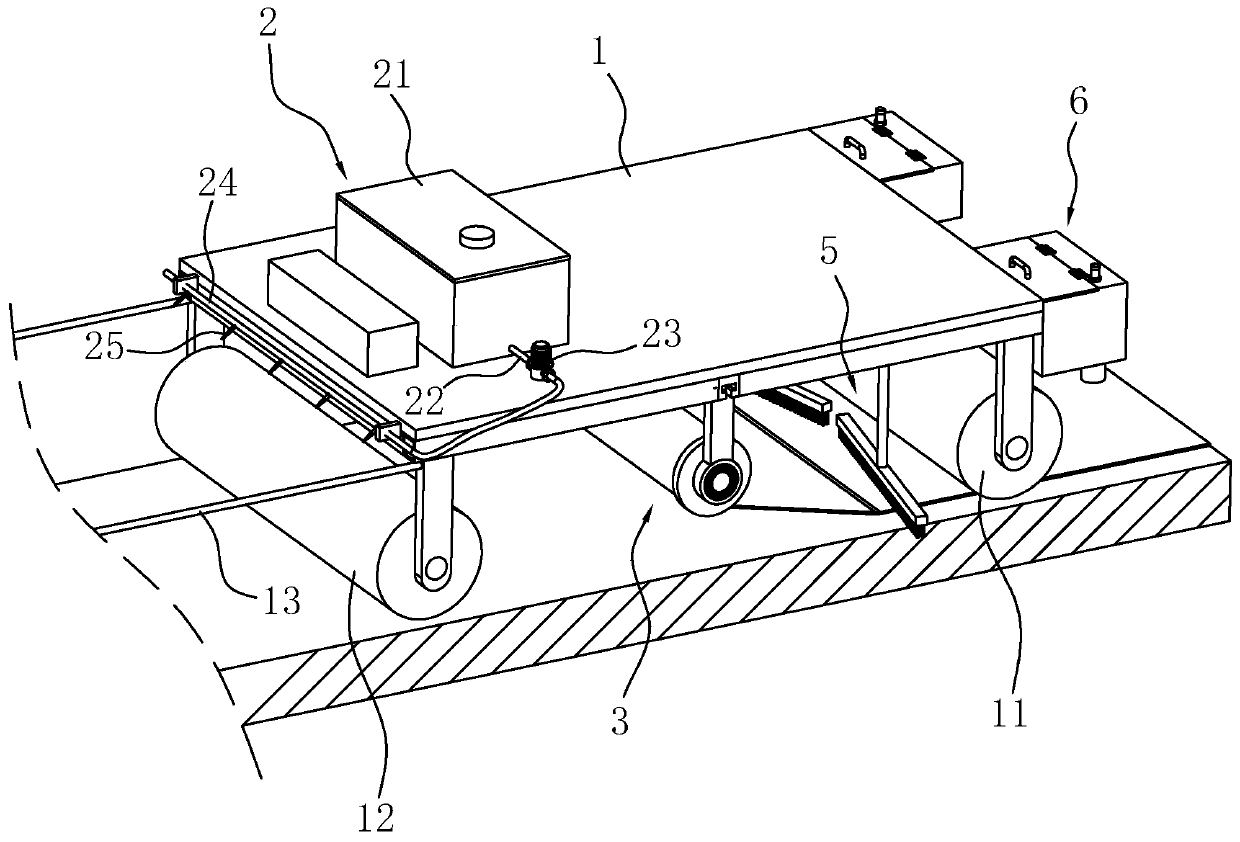

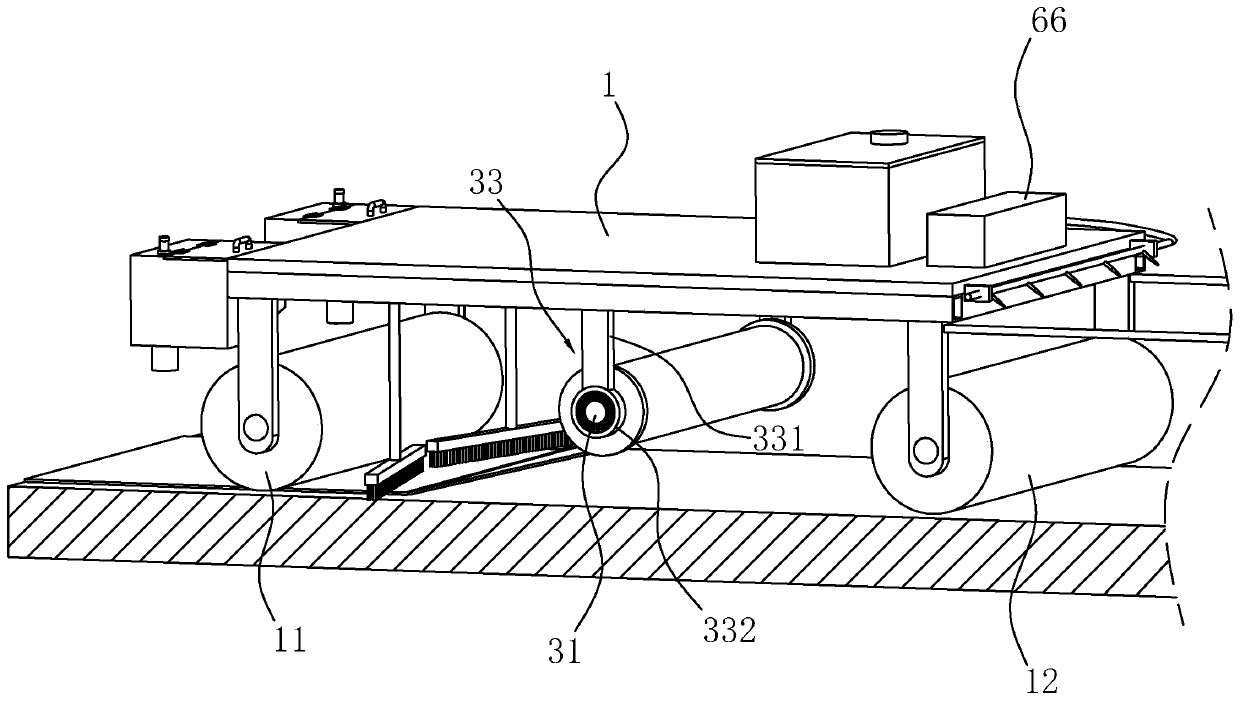

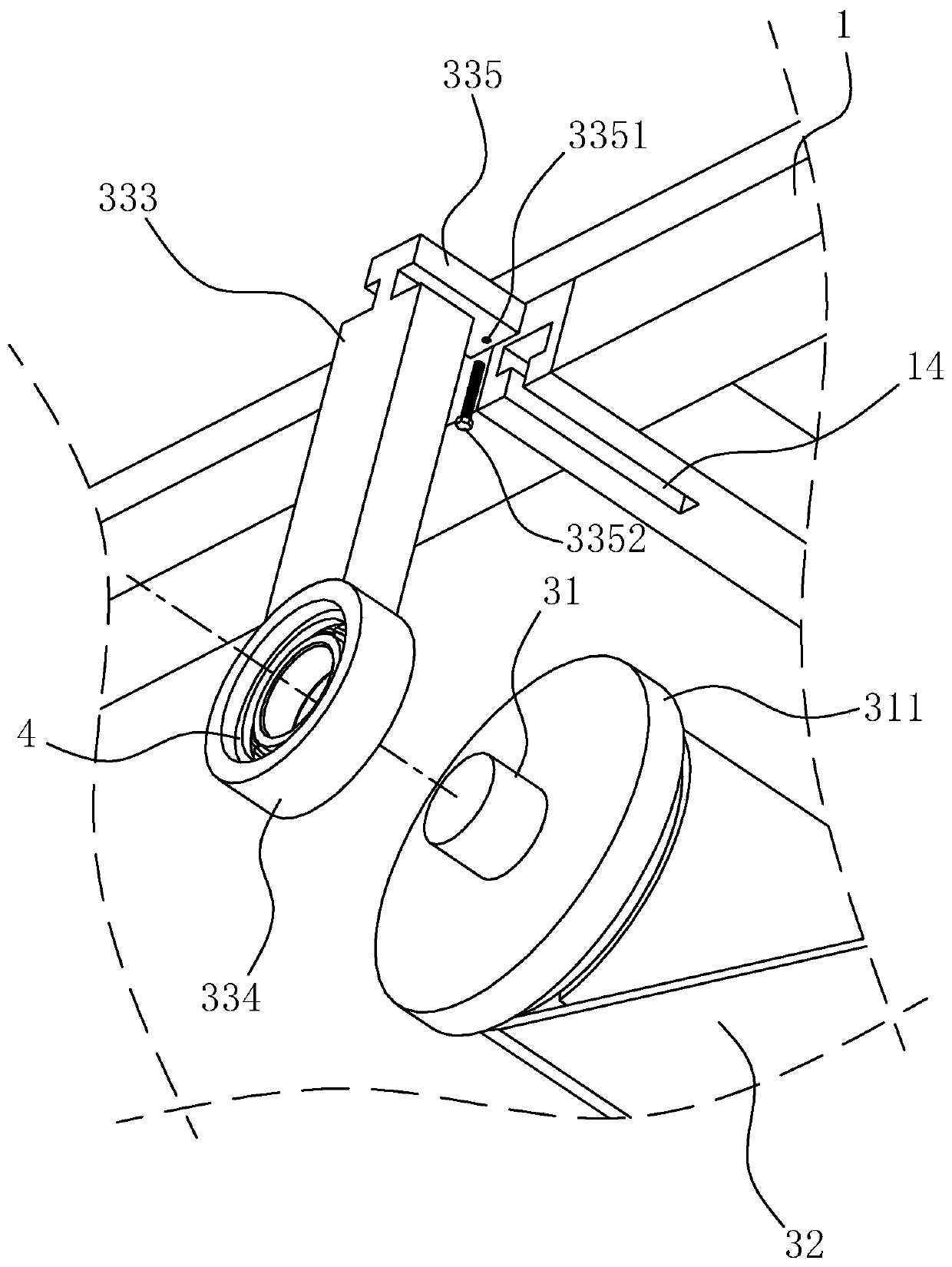

[0035] A mulching machine for garden road construction, such as figure 1 As shown, it includes a horizontally arranged frame body 1; a first traveling roller 11 and a second traveling roller 12 horizontally arranged below the frame body 1; a water spray device 2 arranged on the frame body 1 for wetting the concrete floor; And the mulch laying device 3 for laying the mulch 32 is arranged under the frame body 1 . The first traveling roller 11 and the second traveling roller 12 have the same size, the first traveling roller 11 and the second traveling roller 12 are set at the same width as the frame body 1, and the first traveling roller 11 and the second traveling roller 12 are arranged on the side of the frame body 1 The two sides of the head and the tail are parallel to each other, and the first traveling roller 11 and the second traveling roller 12 are rotatably connected with the frame body 1 . Two stay cords 13 are affixed to the edge of the second walking roller 12 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com