Tunnel waterproof plate laying trolley

A tunnel waterproof board and laying trolley technology, which is applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems that the waterproof board cannot play a waterproof role, the waterproof board is separated from the inner wall of the tunnel, and the repair difficulty coefficient is high, so as to ensure the laying The effect of improving quality, improving laying efficiency and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

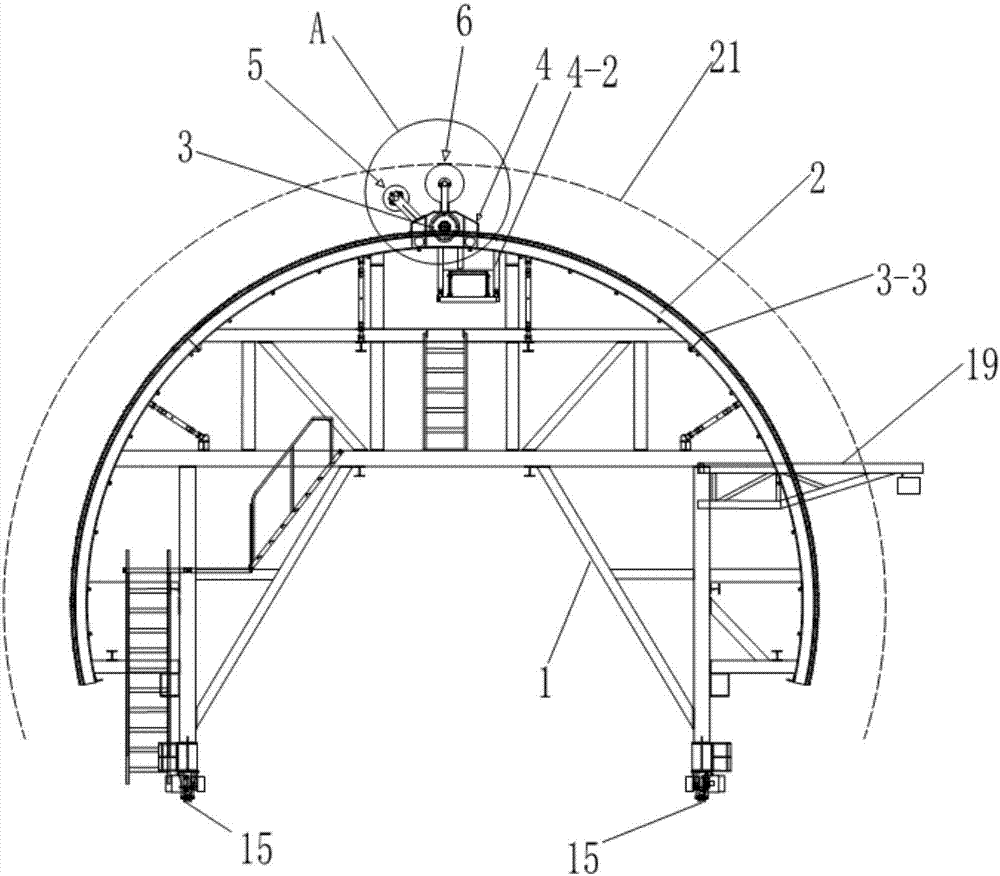

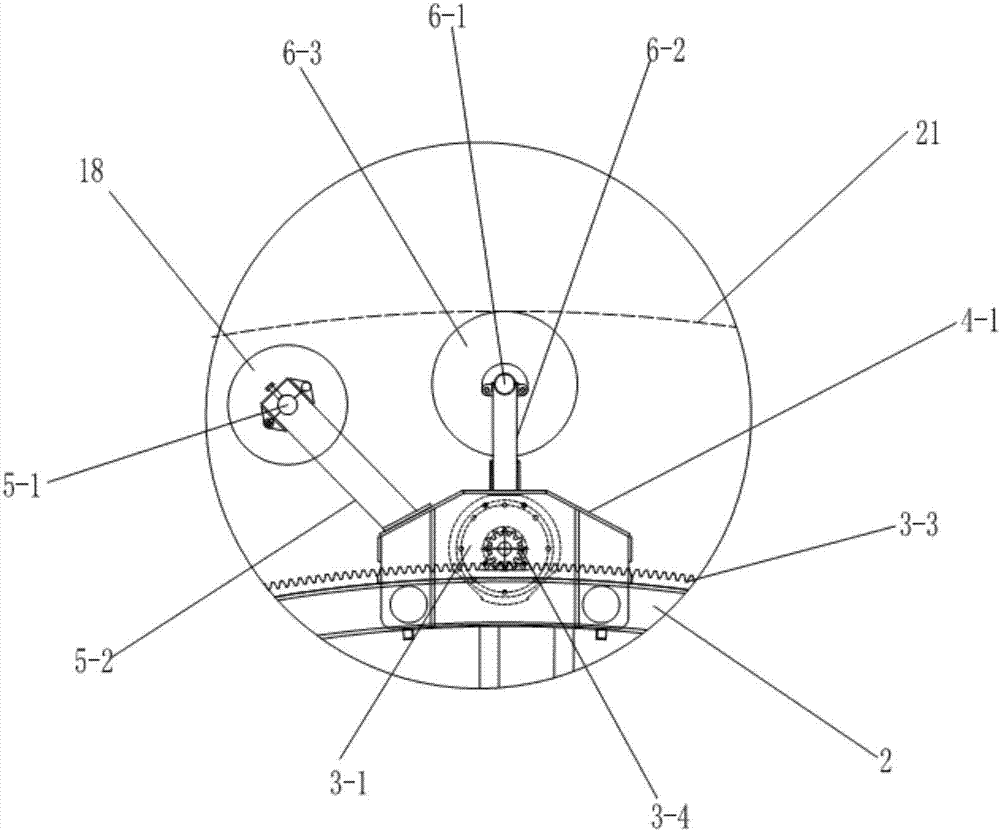

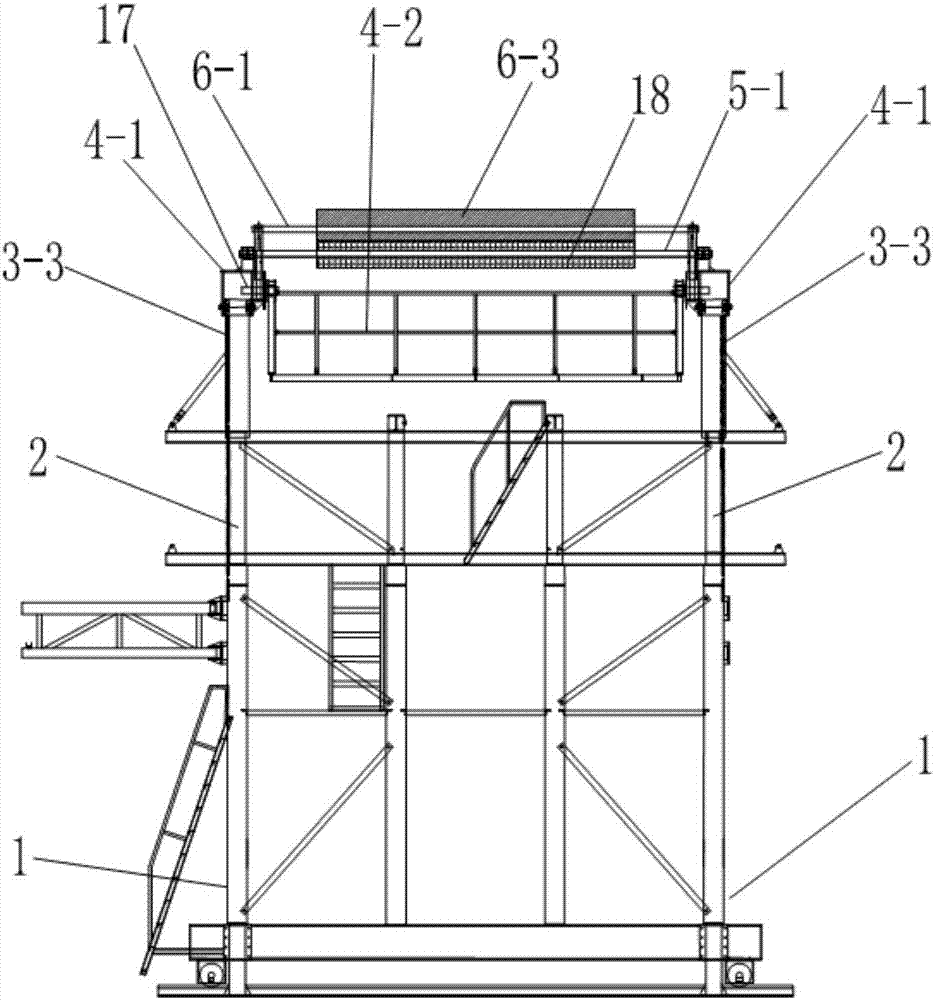

[0076] like figure 1 The shown trolley for laying waterproof boards for tunnels includes multiple trolley portal frames 1 arranged side by side. The trolley portal frames 1 are provided with arch rings 2 that match the inner wall 21 of the tunnel. There is a climbing mechanism 4 that moves along the circumferential direction of the arch ring 2. The climbing mechanism 4 is installed on the arch ring 2 through the transmission assembly 3. The climbing mechanism 4 is provided with a waterproof board 18 for laying the inner wall 21 of the tunnel. The laying assembly 5 and the smoothing assembly 6 for smoothing the waterproof board 18 laid on the inner wall 21 of the tunnel.

[0077] like figure 1 , figure 2 and image 3 As shown, in the present embodiment, the climbing mechanism 4 includes two crawling boxes 4-1 respectively connected by transmission to two adjacent arch rings 2 and a crawling box installed between the two crawling boxes 4-1. Dolly 4-2, crawling dolly 4-2 rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com