Compression roller mechanism suitable for curved surface laying of composite material

A pressure roller mechanism and composite material technology, which is applied in the field of pressure roller mechanism, can solve the problems of difficulty in guaranteeing laying quality, restricting the shape of parts, and low efficiency of manual laying, so as to improve laying efficiency, meet different needs, and ensure laying put quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

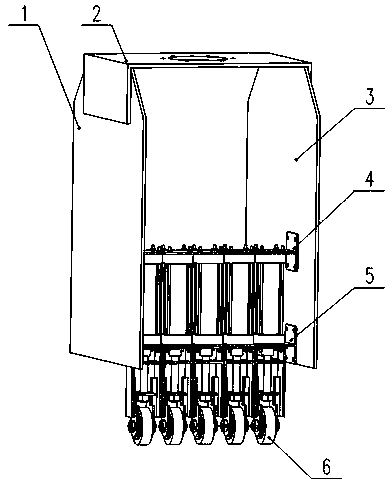

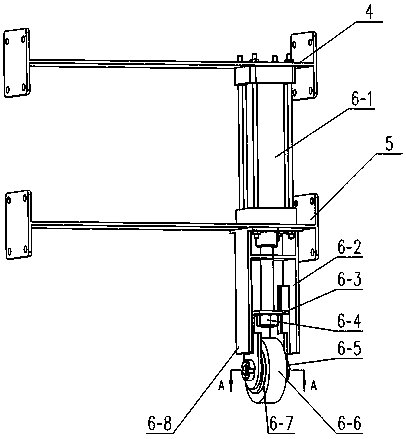

[0017] The pressure roller mechanism of the composite material automatic laying device suitable for curved surfaces of the present invention includes five independent pneumatic pressure roller mechanisms 6 and 6-3 on the cylinder base, 6-4 on the bottom of the pneumatic cylinder base and 6-4 on the bottom of the pneumatic cylinder base. Fixing is realized by bolt connection, and the left and right ends of 6-3 on the base of the pneumatic cylinder and 6-4 on the base of the pneumatic cylinder are respectively connected with the left frame 1 and the right frame 2 by bolts.

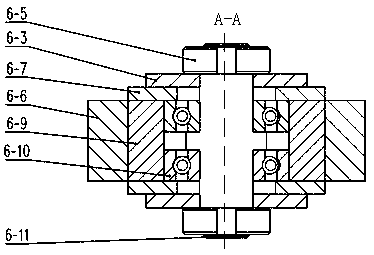

[0018] In the independent pressure roller mechanism, the bottom of the pressure roller base 6-3 is connected with the cylinder rod through nuts, and the left and right sides are respectively assembled with the guide rail left 6-8 and the guide rail right 6-9 through grooves, and the guide rail left 6-9 -8 and the bottom of the guide rail right 6-9 are fixed with the lower 5 of the cylinder base by bolts. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com