Automatic ceramic wine bottle sorting and conveying device

A technology of ceramic wine bottles and conveying devices, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve problems such as prone to errors, reduced work efficiency, and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

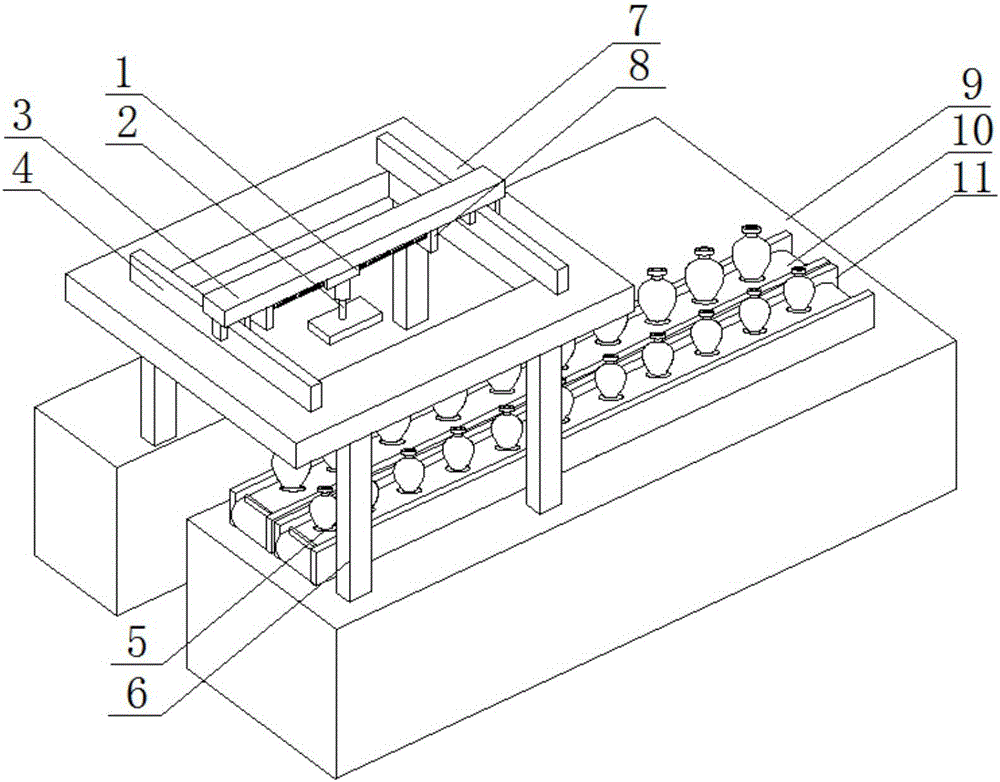

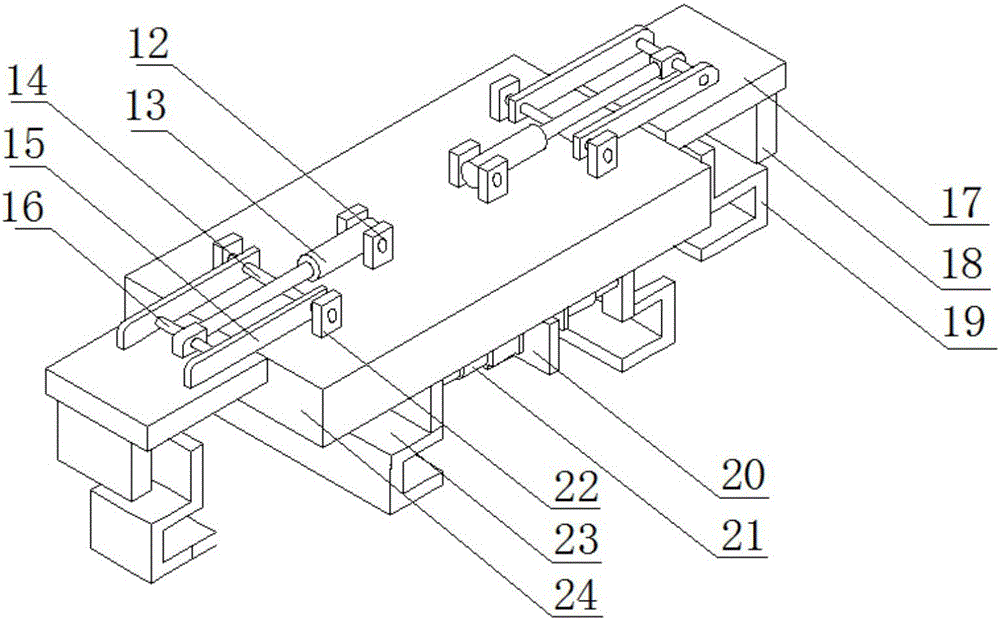

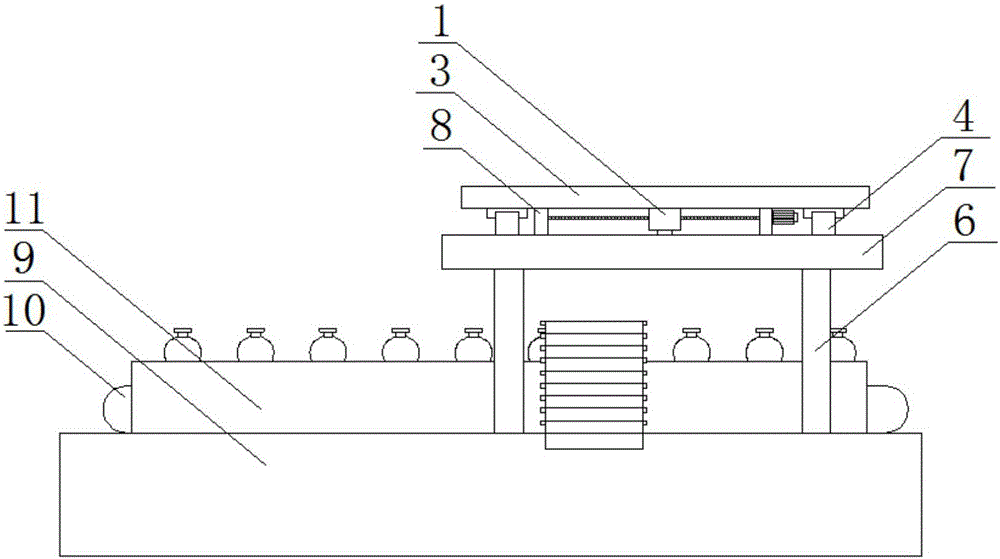

[0016] refer to Figure 1-3 , an automatic sorting and conveying device for ceramic wine bottles, including an operation table 9, on which operations are performed, and a gap is provided on one side of the operation table 9, and when sorting and conveying, the staff pushes the trolley into the gap Inside, the upper end of the operating table 9 is provided with two parallel transmission mechanisms 10, and both sides of the two transmission mechanisms 10 are provided with baffles 11, and the two transmission mechanisms 10 are used to transmit different types of ceramic wine bottles. The upper end of 9 is provided with four support columns 6, and the upper end of suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com