Patents

Literature

144results about How to "High degree of operation automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

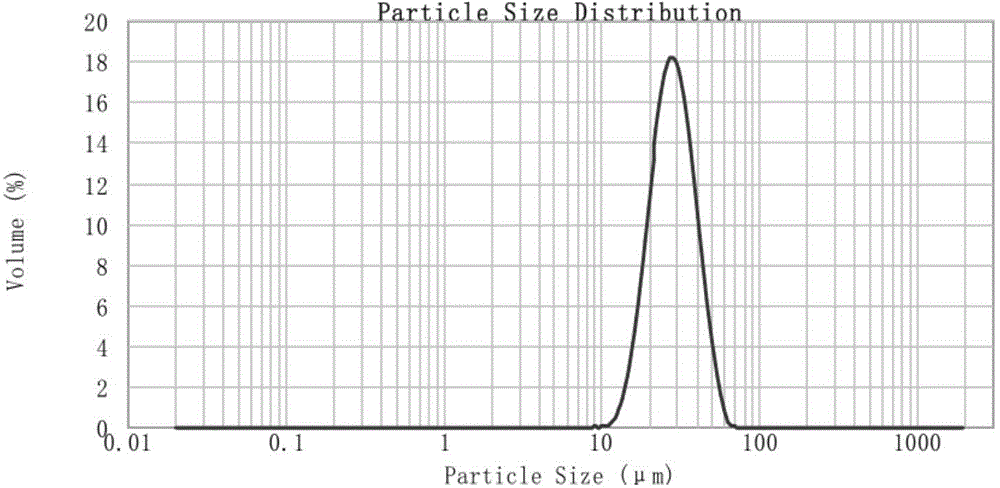

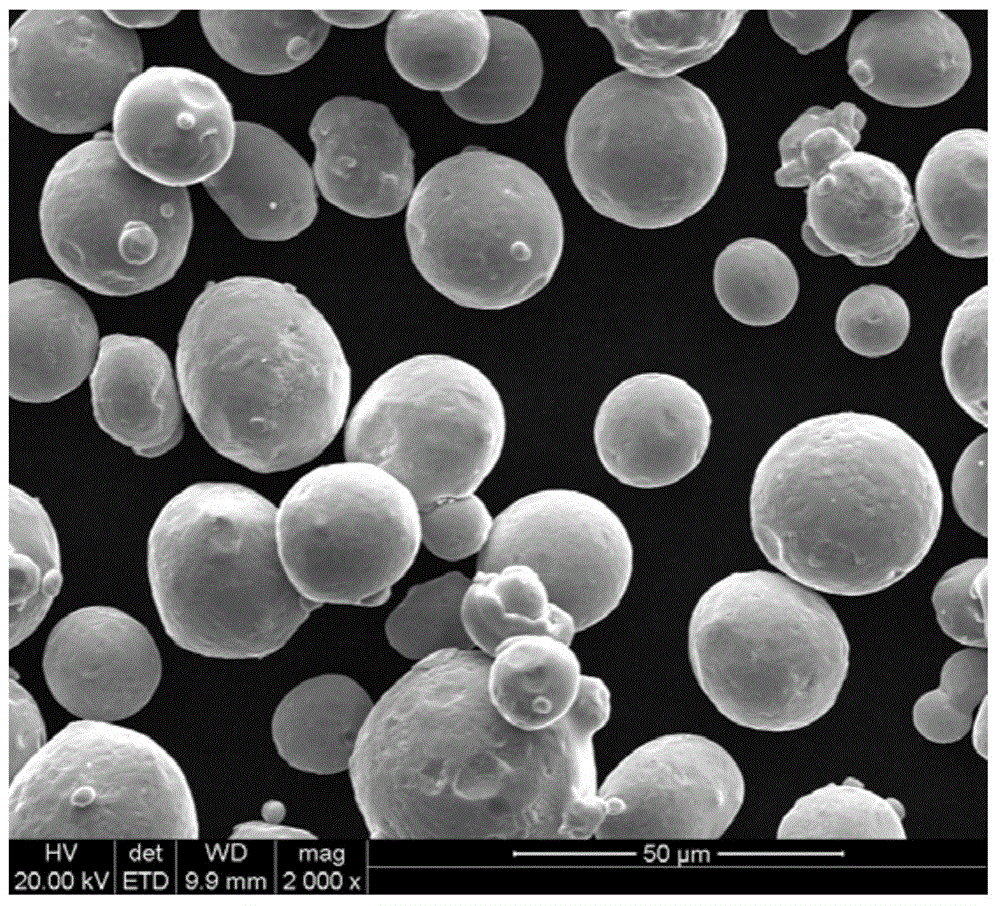

Preparation method of Incone1625 nickel base alloy powder for selective laser melting technology

ActiveCN104923797AAppropriate ratioImprove purityAdditive manufacturing apparatusSelective laser meltingManufacturing technology

The invention relates to a preparation method of Incone1625 nickel base alloy powder for a selective laser melting technology. The method combines a vacuum electrode induction smelting technology with an ultrasonic tight coupling atomization technology, applies methods of ultrasonic vibration separation and airflow classification, and matches powder with different particle sizes to prepare the Incone1625 nickel base alloy powder suitable for the selective laser melting technology. Compared with the prior art, the Incone1625 nickel base alloy powder, prepared by the method, has such performance characteristics as high sphericility, uniform particle size distribution, low oxygen content and low impurity content, satisfies the performance requirements of the selective laser melting technology on powder materials, and promotes the development of a metal material increase manufacturing technology.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD +1

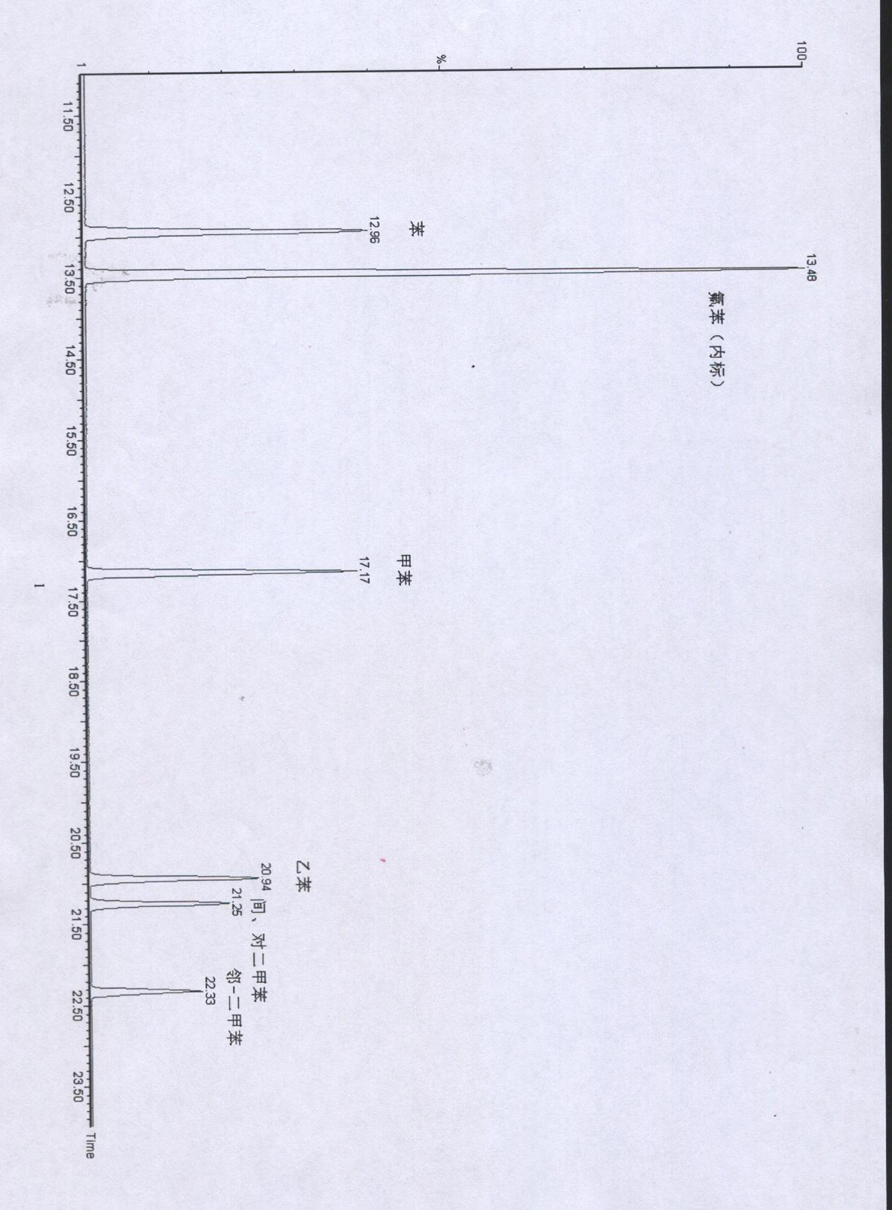

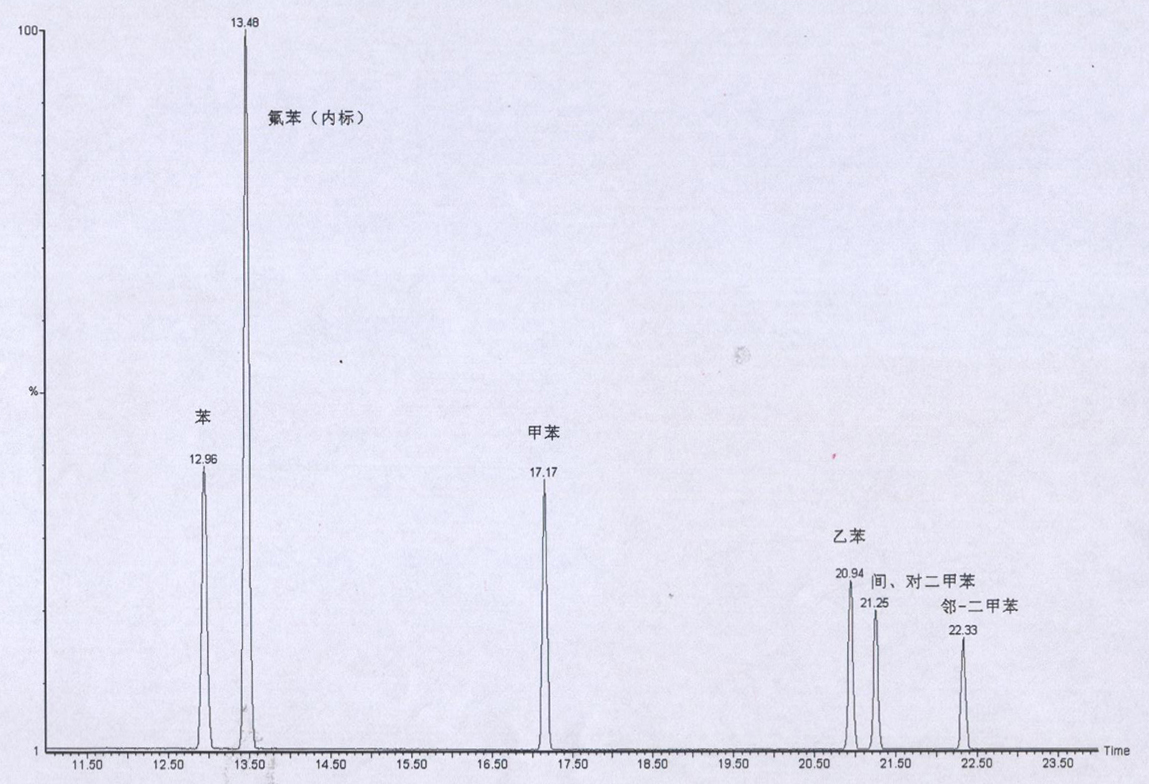

Method for measuring benzene and benzene series in printing ink

ActiveCN101876652AReduce distractionsChemically stableComponent separationInternal standardPhysical chemistry

The invention discloses a method for measuring benzene and benzene series in printing ink. In the method, fluorobenzene is used as an internal standard substance, and the benzene and benzene series content of the printing ink is measured by headspace gas chromatography-mass spectrometry. The measuring method has the advantages of simple sample pretreatment, high automation degree of the whole operation, high measurement sensitivity and repeatability, capability of realizing measurement continuity, and suitability for simultaneous, quick and accurate detection of the benzene and benzene series content of batch printing ink. The invention provides a method and scientific evidences for analyzing and controlling the benzene and benzene series content of the printing ink.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

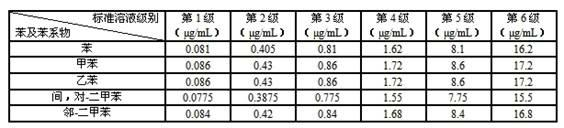

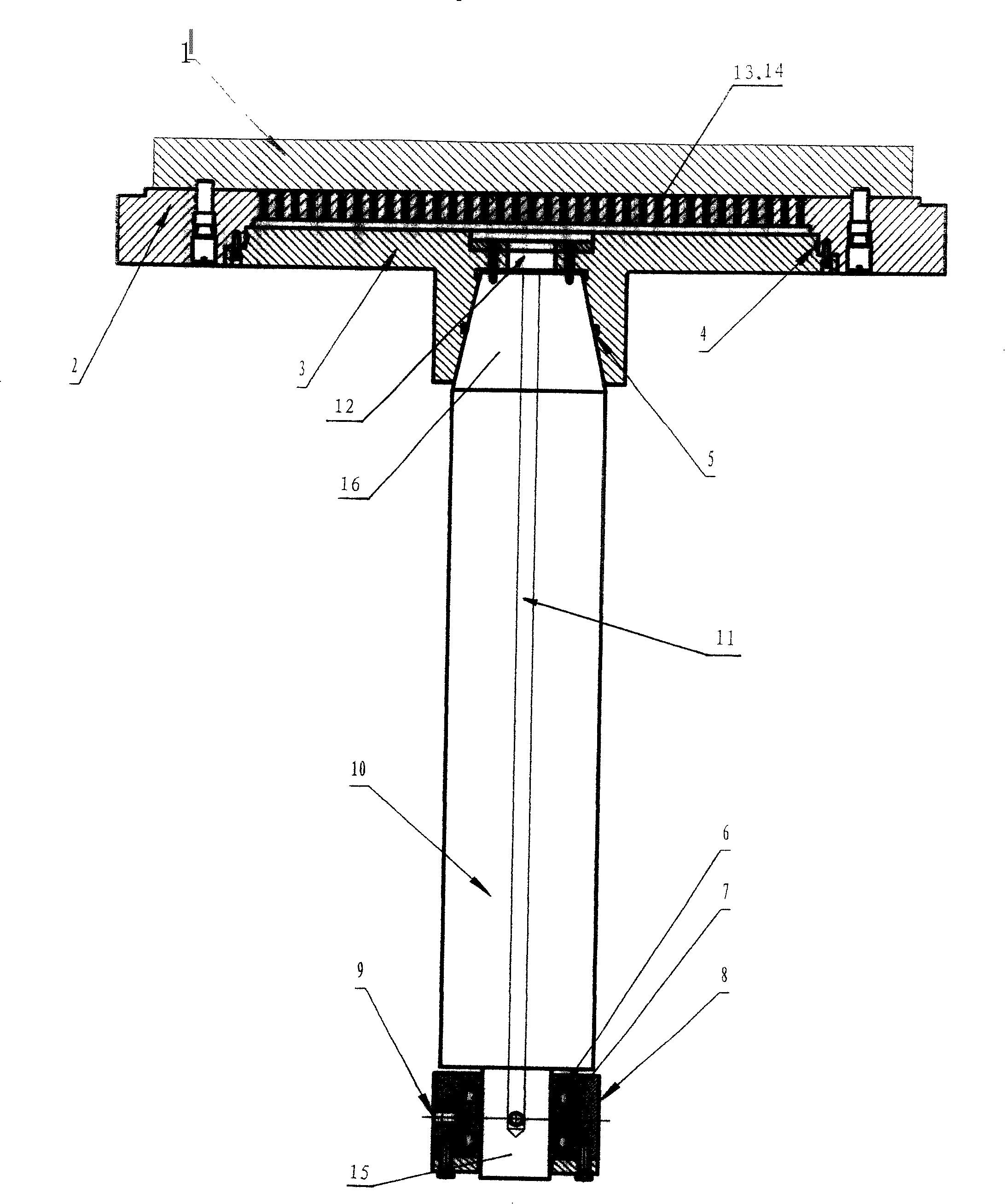

Ring-shaped lead rail of vertical type lathe

InactiveCN101204779AChange suctionGuarantee processing qualityEngine sealsPositioning apparatusEngineeringMachine tool

The invention provides a vacuum chuck used for a precision lathe relating to the field of latch frocks. A traditional lathe clamp traditionally adopts a machinery chuck which can generate deformation easily on chuck work-pieces and thin wall work-pieces of precision machining and affect the machining quality. The invention adopts a vacuum system to absorb the machining work-piece, thus avoiding the defects. The tail part of a main shaft of the lathe with a vacuum pipeline is connected with an external vacuum system and the end part of the main shaft of the lathe is provided with the vacuum chuck. The surface of the vacuum chuck is provided with a plurality of air suction openings. The machining work-piece is arranged on the vacuum chuck and is absorbed on the vacuum chuck tightly with the enlarging of the vacuum degree. The work-piece clamping mode ensures the machining quality and improves the automation degree. The invention also has the beneficial effects of simple structure and convenient operation.

Owner:TIANSHUI SPARK MACHINE TOOL

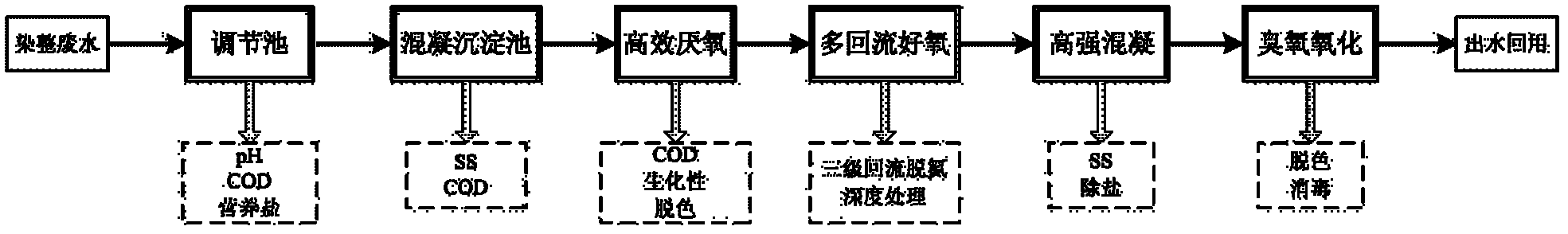

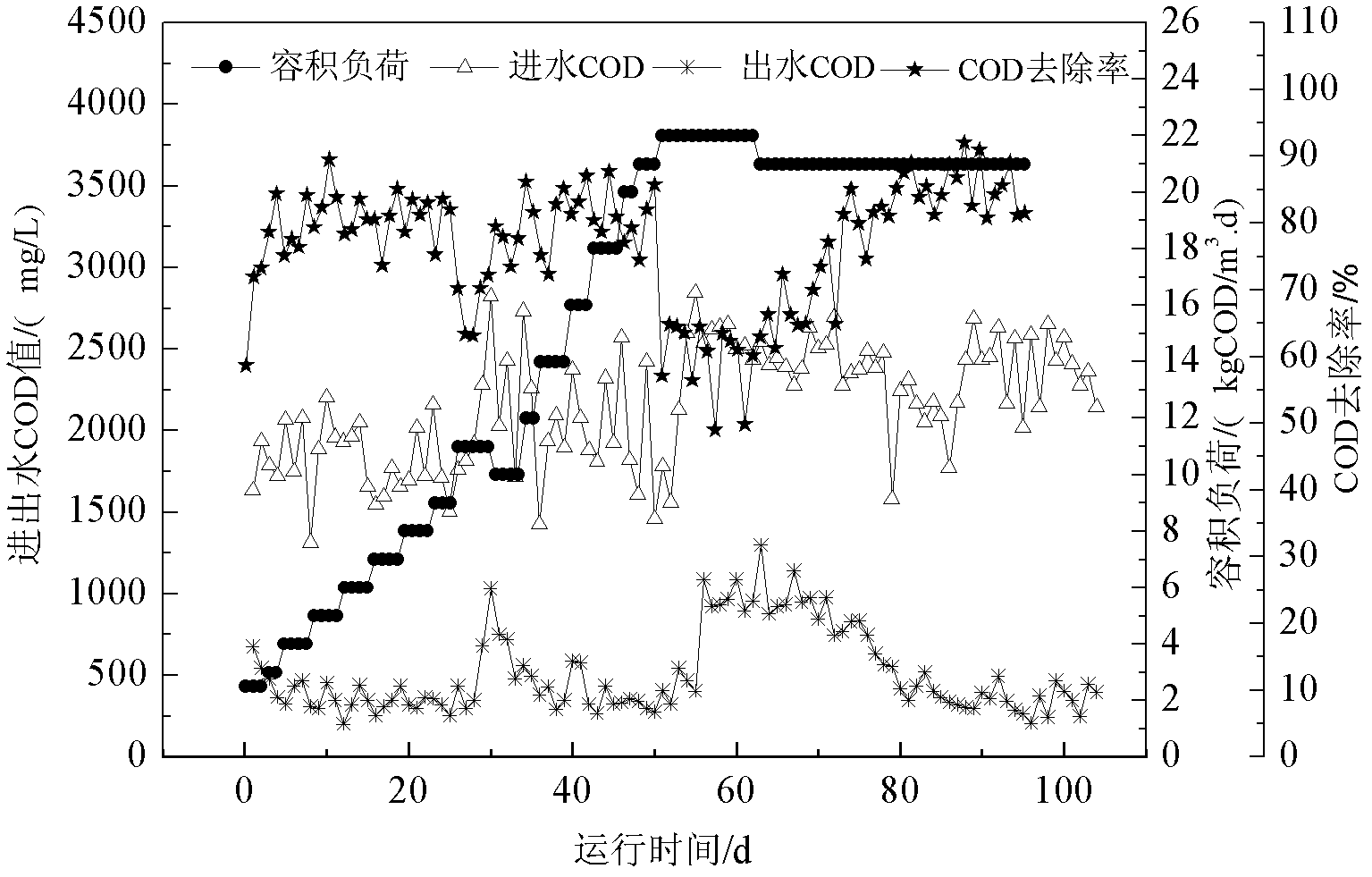

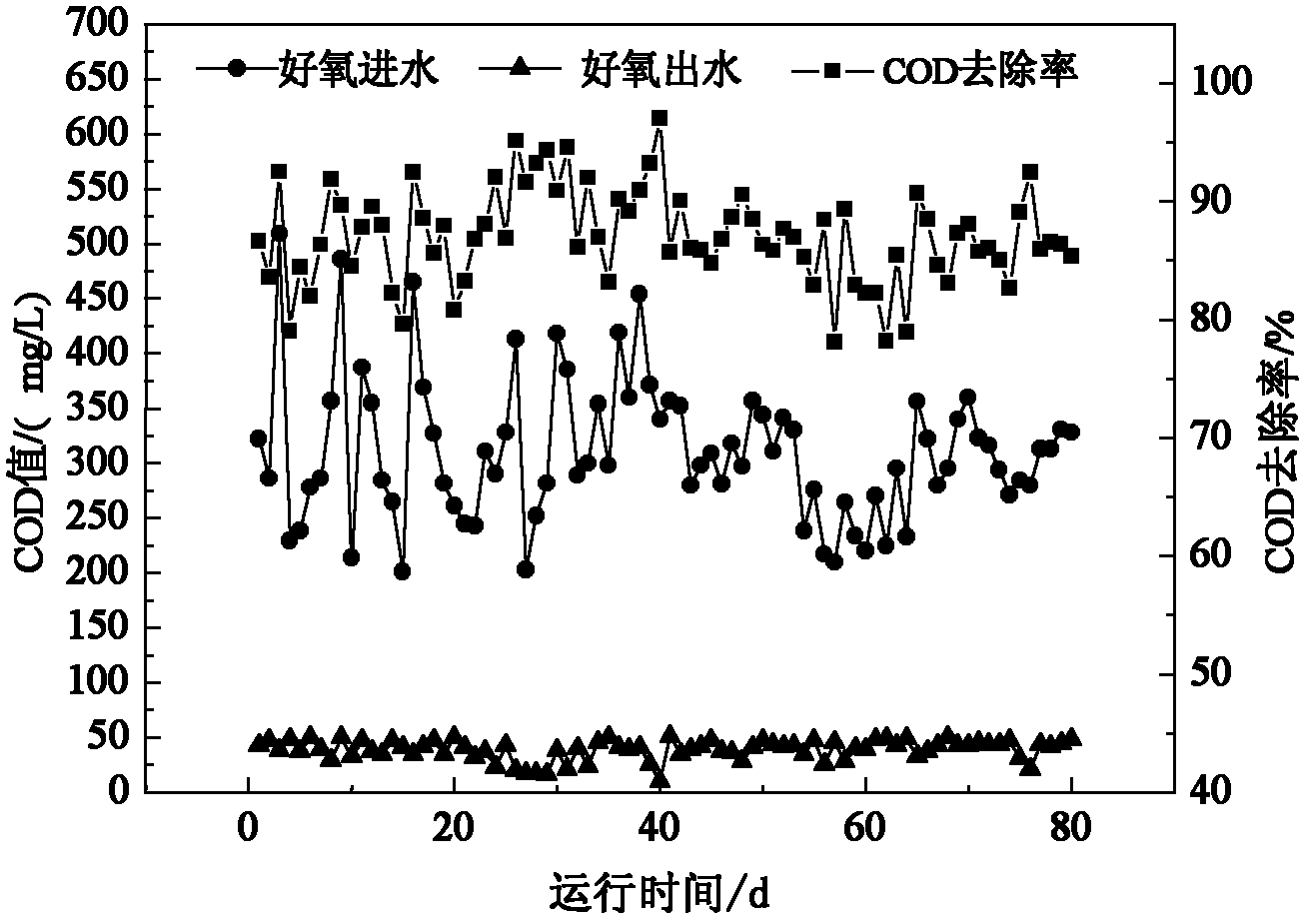

Method for recycling textile dyeing and finishing wastewater

ActiveCN102190412AGood effect of energy saving and emission reductionTargetedTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAerobic treatment systemWater quality

The invention discloses a method for recycling textile dyeing and finishing wastewater, which comprises the following steps of: regulating the pH of the textile dyeing and finishing wastewater in a regulating tank to be 7.0 by using acidic solution, performing coagulative precipitation in a coagulative precipitation tank by using an inorganic flocculating agent, and performing anaerobic treatmentin a high-efficiency anaerobic reactor; performing anaerobic / anoxic and aerobic circulation treatment in a multi-stage circulation aerobic treatment system, wherein the multi-stage circulation aerobic treatment system consists of anaerobic / anoxic reaction tanks A and aerobic reaction tanks O in an A-O-A-O-A-O-A staggered series connection mode; performing coagulative precipitation in a high-efficiency air floatation coagulative precipitation tank; and performing ozone oxidation and disinfection in an ozone oxidation tank to obtain recycled water. Compared with the conventional physical-chemical method, the technology has the advantages that: operating cost is obviously reduced, and over 30 percent of economic benefit is achieved. The quality of the treated water is high, and 70 percent ofrecycling rate can be achieved.

Owner:JIANGSU SHANGDA WATER AFFAIR

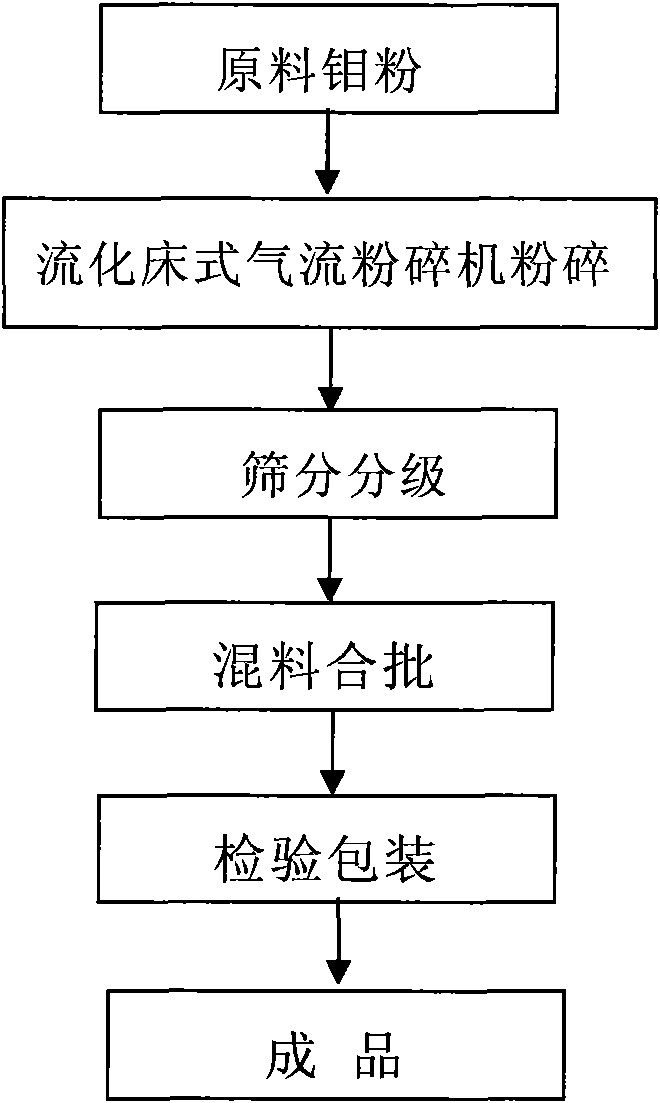

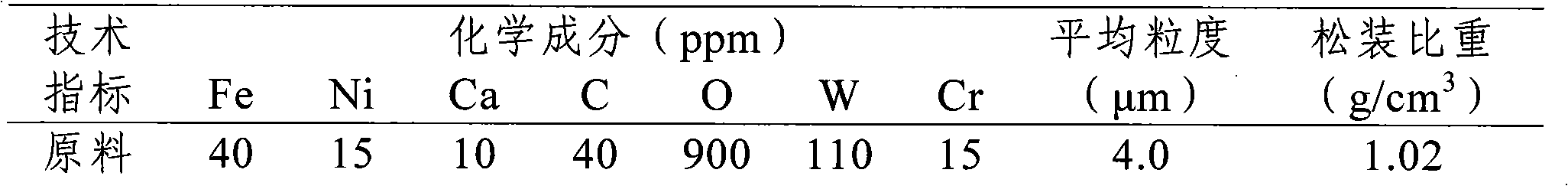

Method for preparing high bulk density molybdenum powder

The invention discloses a method for preparing high bulk density molybdenum powder, which comprises the following steps: processing common molybdenum powder by purified and dried nitrogen in a fluidized bed jet mill; performing on-line sieve classification on the processed molybdenum powder; and mixing the classified molybdenum powder into batches, and inspecting and packaging into finished product molybdenum powder. The method has simple process, high operating automation degree, low production cost, good product consistency and easy realization of industrialization; the method improves the bulk density of the molybdenum powder by processing the common molybdenum powder in the fluidized bed jet mill, improves the agglomeration of molybdenum powder particles, reduces 'arch bridge' effect generated when the molybdenum powder is filled in a die, and contributes to the press forming of the molybdenum powder; and the molybdenum powder prepared by the method has wide applicable range, is widely applied in the industries such as electronics and environment-friendly automobiles, and in particular has great potential in the aspect of molybdenum copper cooling plates of the environment-friendly automobiles.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Method for producing high-degree of polymerization polyvinyl chloride resin by using suspension method

The invention discloses a method for producing high-degree of polymerization polyvinyl chloride resin by using a suspension method, which comprises the following steps of: step 1, charging by adopting a constant-temperate water feeding technology, a whole-process airtight feeding technology and a DCS (Distributed Control System) automatic control technology; step 2, producing the high-degree of polymerization polyvinyl chloride resin by adopting a low-temperature method; and step 3, obtaining the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000. With the adoption of the method for producing the high-degree of polymerization polyvinyl chloride resin by using the suspension method, the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000 can be produced in a 70 m<3> polymerization kettle system, has the advantages of low energy consumption, large batch production and stable quality and can be produced in the whole year.

Owner:HANGZHOU ELECTROCHEM GROUP

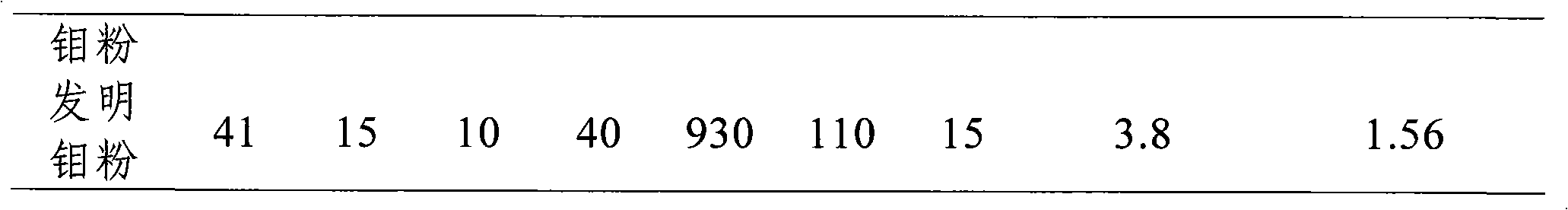

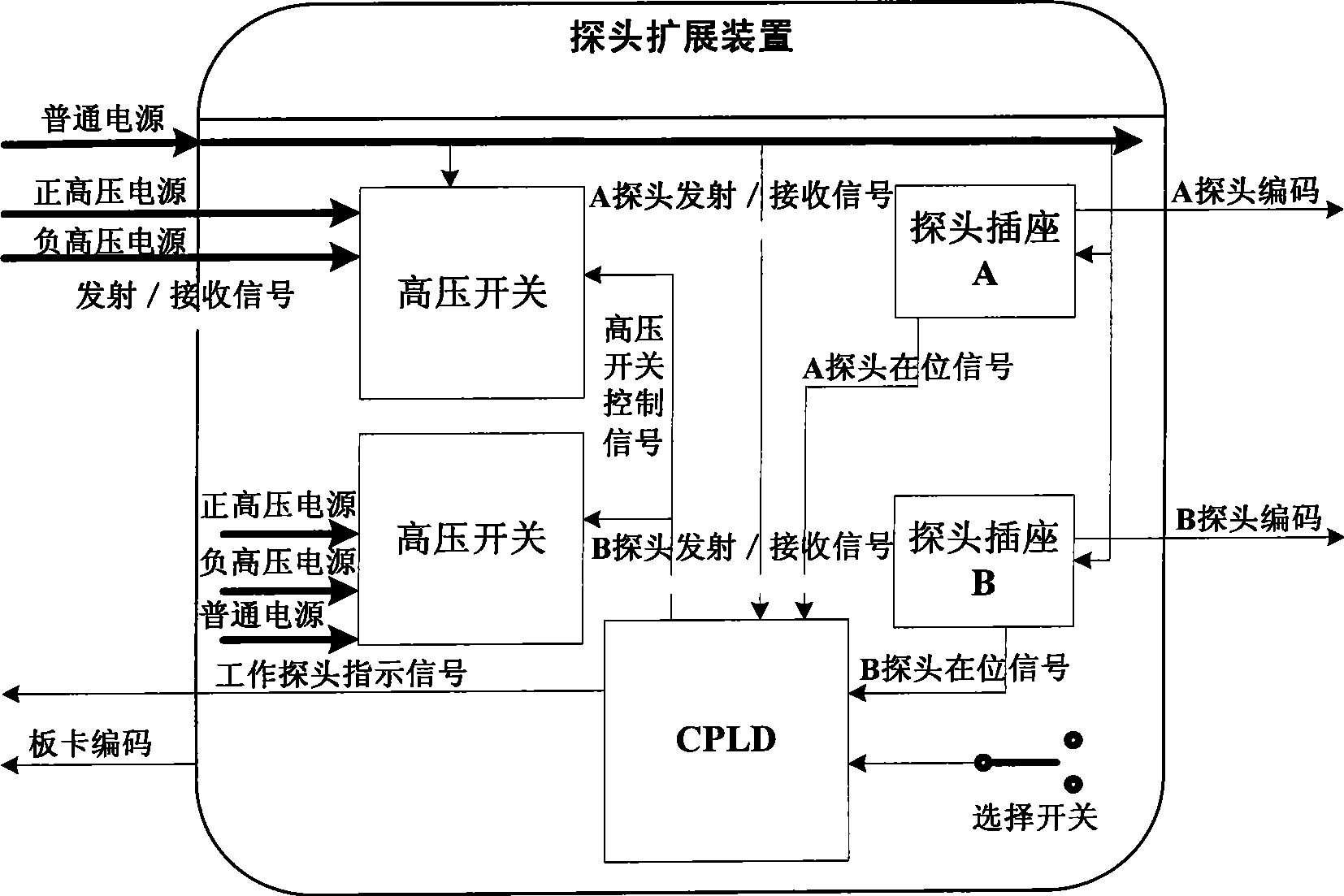

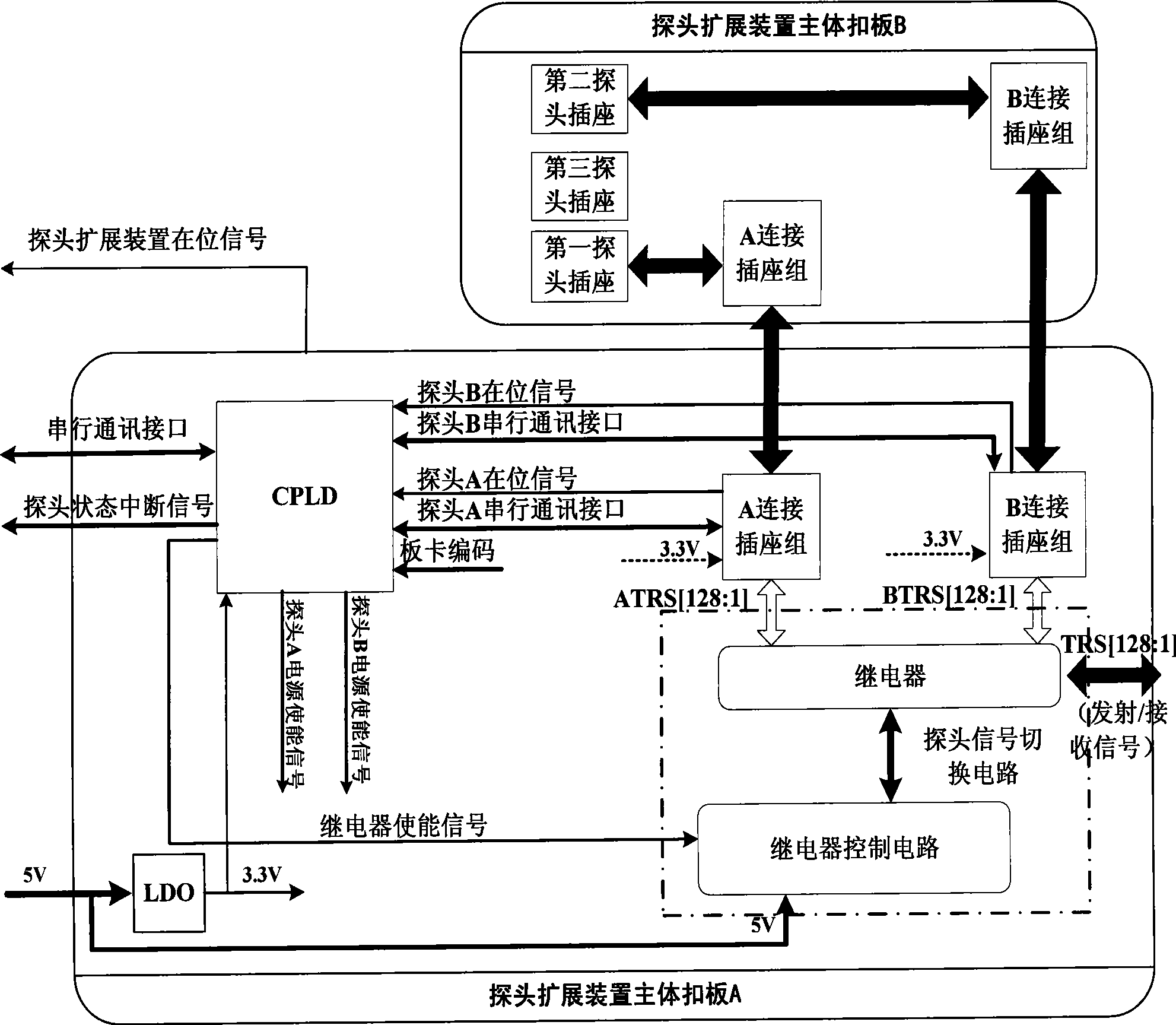

Electric device probe expansion device and expansion-probe control method of main frame

ActiveCN101455575AEasy to controlReliable controlUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsCommunication interfaceElectricity

The present invention discloses a probe expanding device of electronic equipment and a method for controlling expanding probe by the host machine, wherein the device comprises a body and a probe expanding device plug. The body is provided with a controller, a probe signal commutation circuit, a first probe socket, a second probe socket and a probe expanding device plug. A host machine determines whether the reading of expanding probe is finished and enquires the on-position state of probe through a controller of probe expanding device. The probe which is to be executed with information reading transmits a power supply enable signal through a controller for supplying power to the corresponding probe. The communication interface of corresponding probe is gated for reading probe information. When the host machine confirms that the probe information reading is finished, a probe de-electrifying command is transmitted to the controller by the host machine. The controller controls the power supply enable signal. The corresponding probe is de-electrified and the operation is finished. An interface communication connection is realized between the probe expanding device and the host machine device according to the invention. An inner controller analyzes command of host machine system and realizes the functions of probe identifying, working probe switching, etc. The control to various functions is conveniently and reliably executed. The automatization degree of operation is high.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

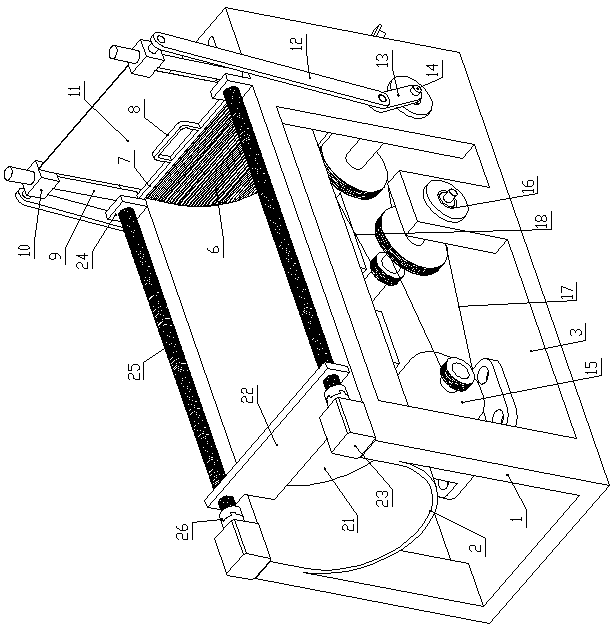

Vegetable foods slicing and slitting device and slicing and slitting method

PendingCN109732691APrinciples of ScienceCompact structureMetal working apparatusSlice thicknessEngineering

The invention discloses a vegetable foods slicing and slitting device. The vegetable foods slicing and slitting device comprises a frame which is in a cuboid shape, a material guide groove used for containing vegetable raw material is formed in the inner upper part of the frame, the material guide groove is thorough from front to rear, the top of the material guide groove is open, the inner spaceof the cross section of the material guide groove is of a U-shaped structure, the front side of the top of the frame is provided with a lifting type slicing mechanism which is positioned right above the front port of the material guide groove, a power driving mechanism is arranged in the frame, the power driving mechanism is connected with the lifting type slicing mechanism, the top of the frame is provided with a slicing thickness adjusting mechanism arranged in the front side of the lifting type slicing mechanism, a slitting tool is arranged on the rear side of the lifting type slicing mechanism and on the inner wall of the material guide groove, and a linear stepping driving mechanism used for driving the vegetable raw material to move forwards along the material guide groove is arranged at the top of the frame. During operation, workers only need to put the raw material into the device, labor intensity is greatly reduced, two functions of slicing and slitting are achieved at the same time, the slicing or slitting operation efficiency is high, the slicing thickness is consistent, and the thickness of slicing or slitting can be conveniently adjusted.

Owner:HUANGHE S & T COLLEGE

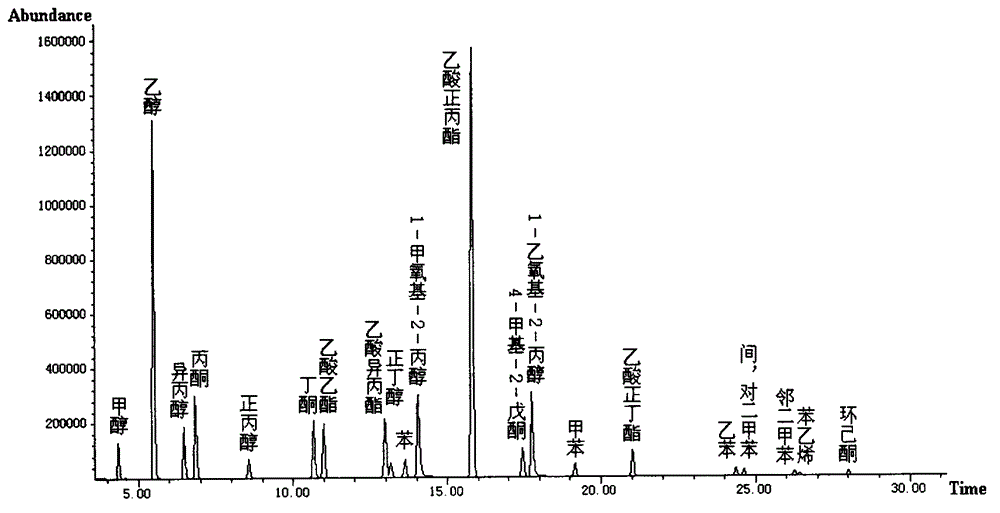

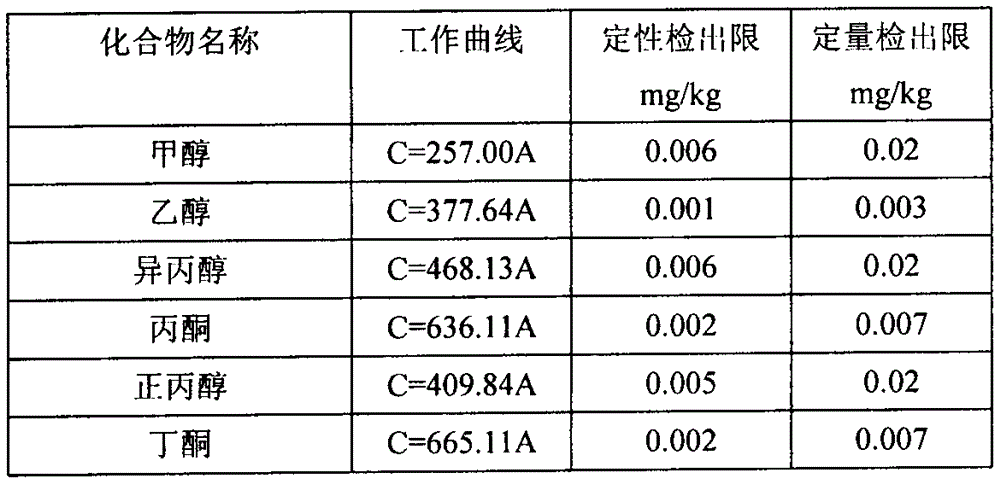

Method for detecting volatile organic compounds in cigarette tipping paper printing ink

InactiveCN104597166AEasy to handleAchieving Simultaneous DetectionComponent separationCyclohexanoneN-Propyl alcohol

The invention relates to a method for detecting the contents of 22 kinds of volatile organic compounds in cigarette tipping paper printing ink, including benzene, toluene, ethylbenzene, ortho / meta / para-xylene, phenethylene, methanol, ethanol, isopropyl alcohol, n-propyl alcohol, n-butanol, acetone, 4-methyl-2-pentanone, butanone, cyclohexanone, ethyl acetate, n-propyl acetate, n-butyl acetate, isopropyl acetate, 1-methoxy-2-propyl alcohol and 1-ethoxy-2-propyl alcohol. Detection is performed by headspace gas chromatography by taking glyceryl triacetate as a matrix rectifier. According to the method provided by the invention, a sample pretreatment process is simple, the automation degree of the whole operation is high, the simultaneous detection of various volatile organic compounds can be realized, and the detection sensitivity, the recovery rate and the result precision are high.

Owner:GUANGXI ZHENLONG IND

Automatic X-ray metal detection and rubber cutting machine

ActiveCN105058498AEfficient removalReduce operational burdenMetal working apparatusRubber materialProgrammable logic controller

The invention belongs to the field of metal residue detection in the rubber industry, and particularly relates to an automatic X-ray metal detection and rubber cutting machine. The machine comprises a material transport and conveying belt, an X-ray detector, a cutter structure and a PLC (Programmable Logic Controller) control component, wherein the material transport and conveying belt is used for conveying a to-be-detected rubber material to advance at the predetermined speed along the predetermined direction; the X-ray detector is used for performing on-line detection on the rubber material passing through an induction end of the X-ray detector; the cutter structure is arranged at a belt surface at the rear of an induction area of the X-ray detector in the conveying direction of a conveying belt part; and the PLC control component is used for receiving a metal induction signal transmitted by the X-ray detector, performing coordinate point positioning in a plane coordinates system based on transverse movement positioning of the cutter structure and longitudinal movement positioning of the conveying belt part, and driving a power mechanism to drive a cutter part to make lifting movement to cut the rubber material under the cutter part. The machine can realize the effect of rapid-pace and high-efficiency metal detection and rubber cutting operation, and can also guarantee the accuracy and reliability of the rubber cutting operation.

Owner:安徽精致机电科技有限公司

Method for recovering alkali and organic substance from pomace and waste liquid

InactiveCN1450227ADischarge volume reductionReduce total pollutionRegeneration of alkali lyeLiquid wasteAdditional values

The method for covering alkali and organic substance from pulp waste liquor includes the following steps: under the condition of that temp. is 20-60 deg.c and pressure is 1.5-3.0 MPa the pulp waste liquor is passed through the fixed membrane separation system to make separation to obtain the trapped liquor in which the concentration of organic substance is 90g / l and transmitted liquor containing sodium hydroxide, said transmitted liquor containing sodium hydroxide can be recovered, and can be used in pulp production, and the described trapped liquor containing organic substance can be evaporated and concentrated, and can be used for preparing products with high additional value after it is treated by means of modification process.

Owner:凯能高科技工程(上海)有限公司

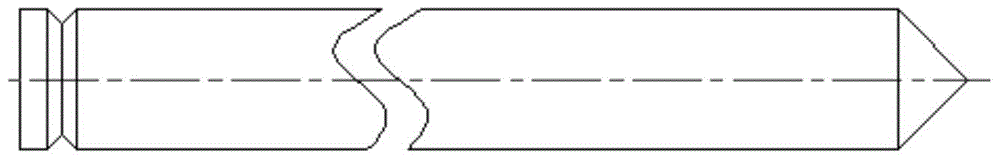

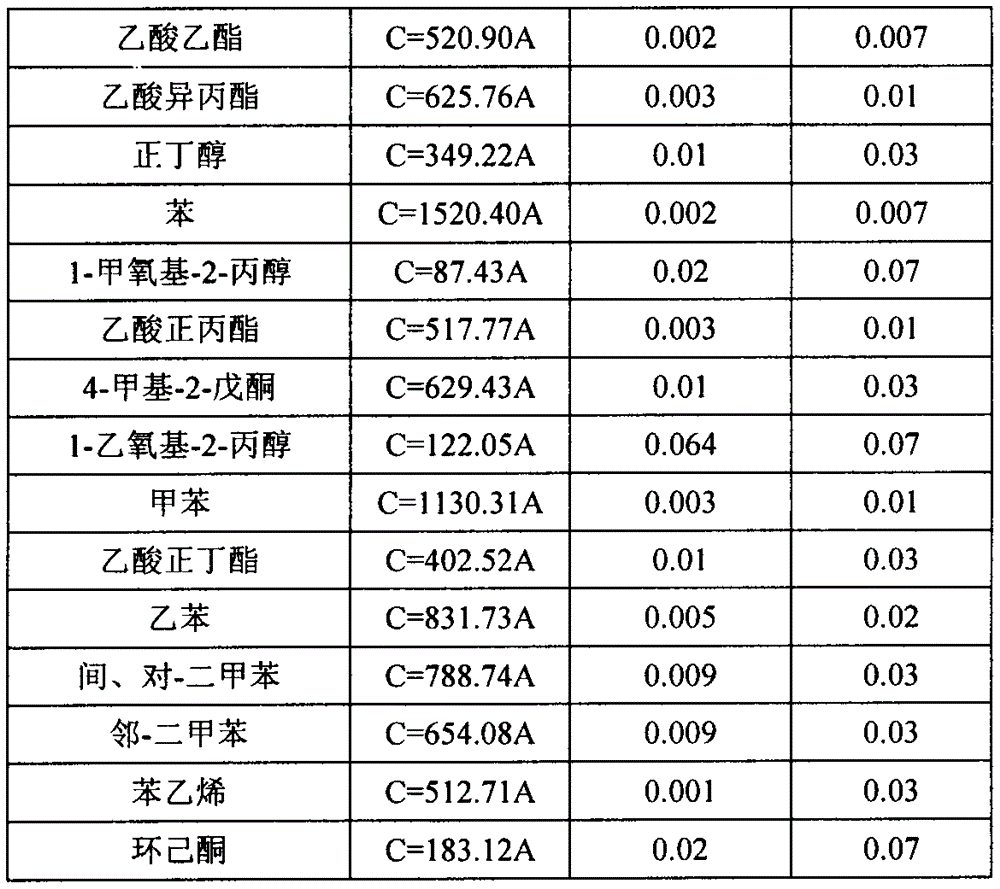

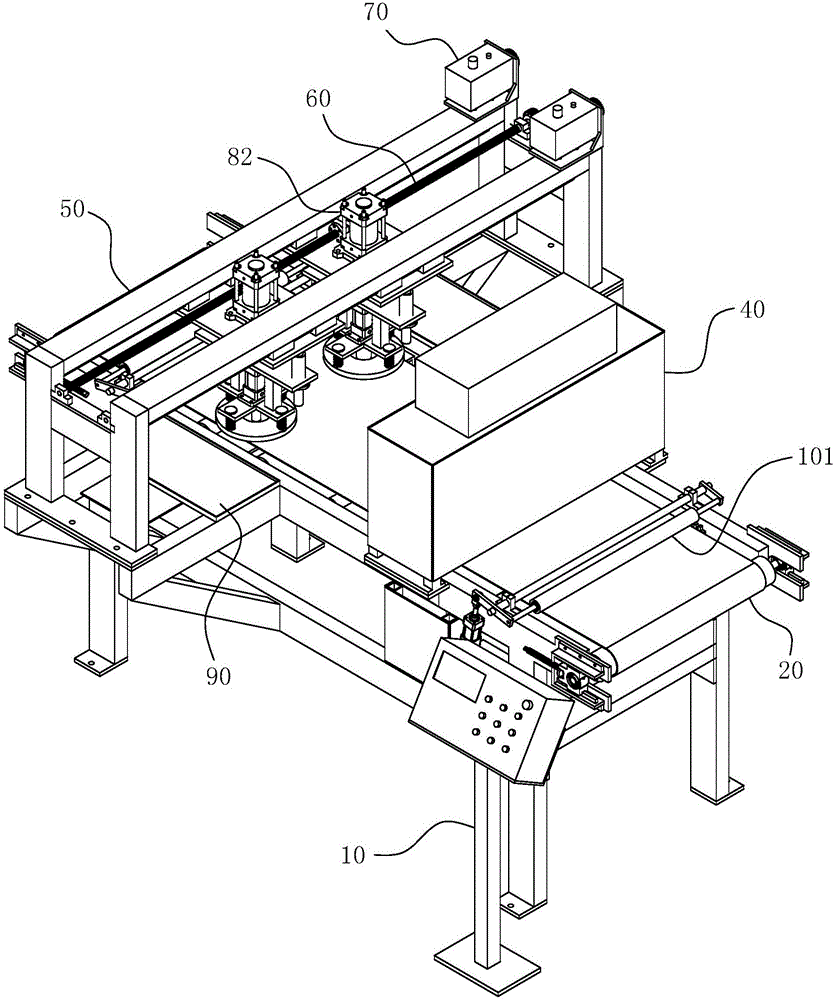

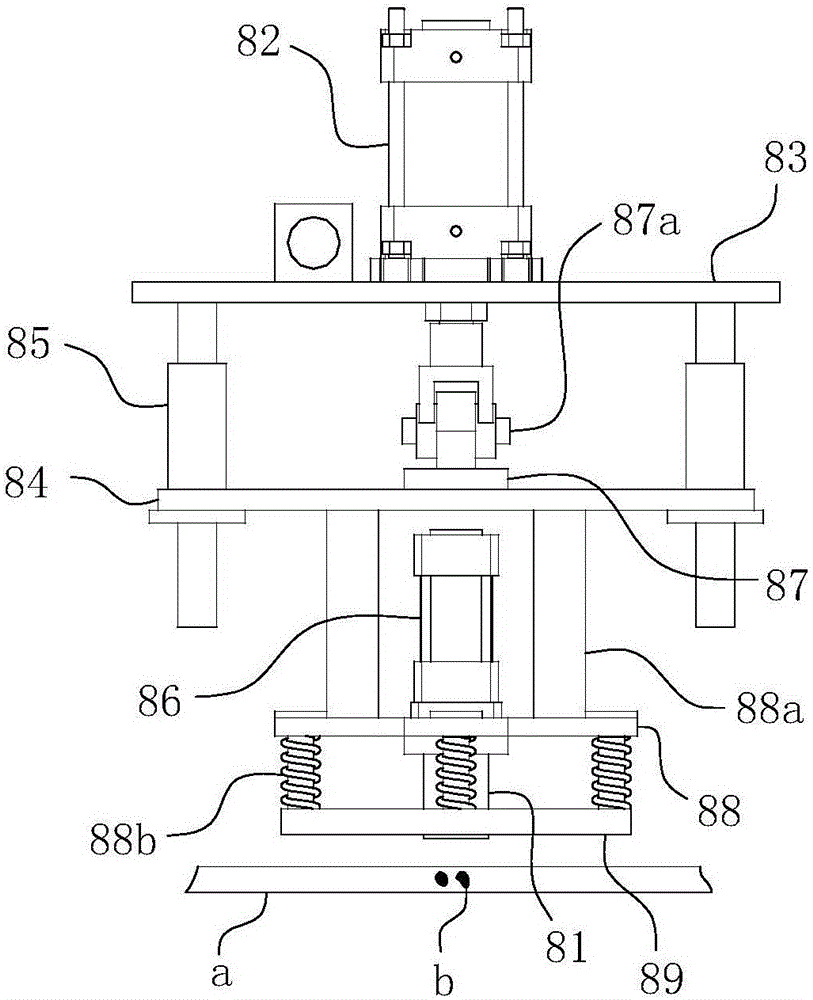

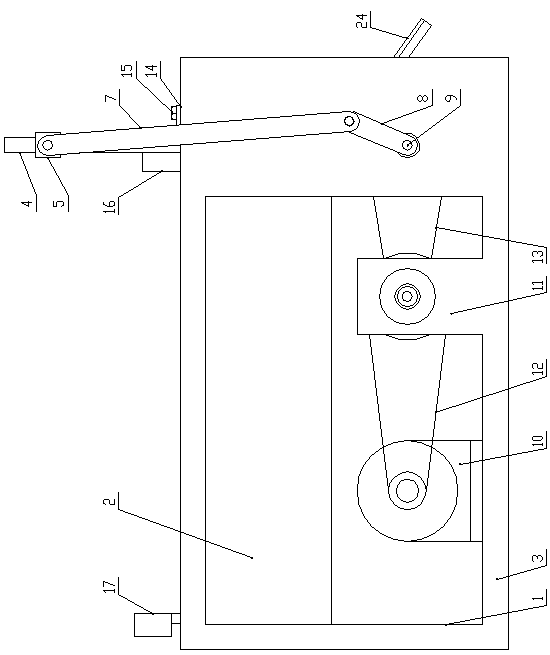

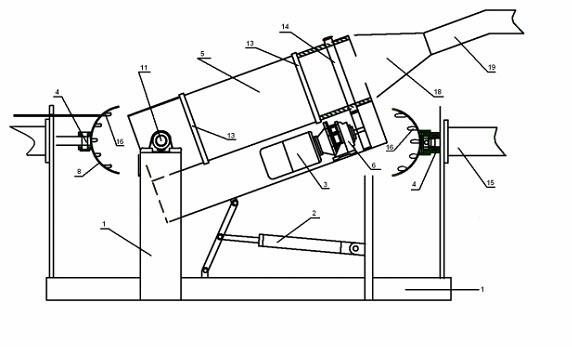

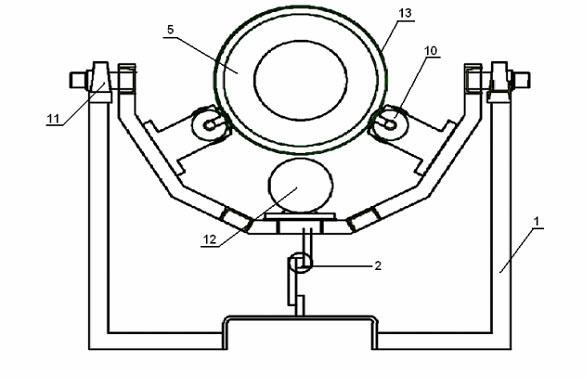

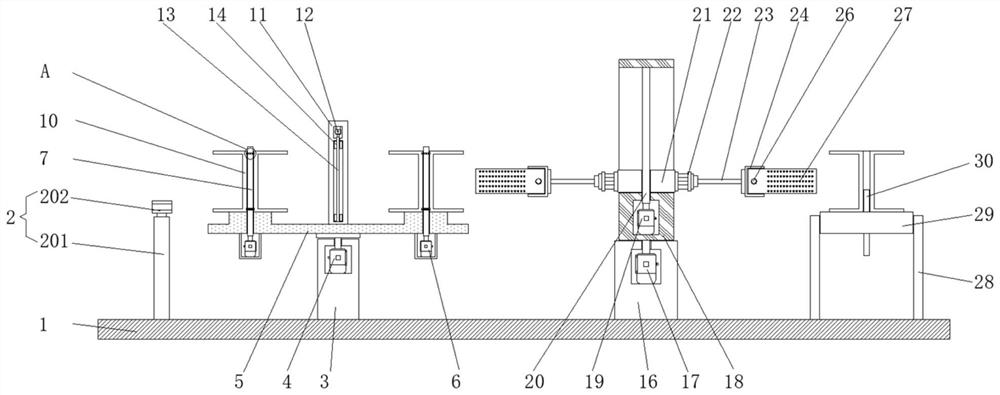

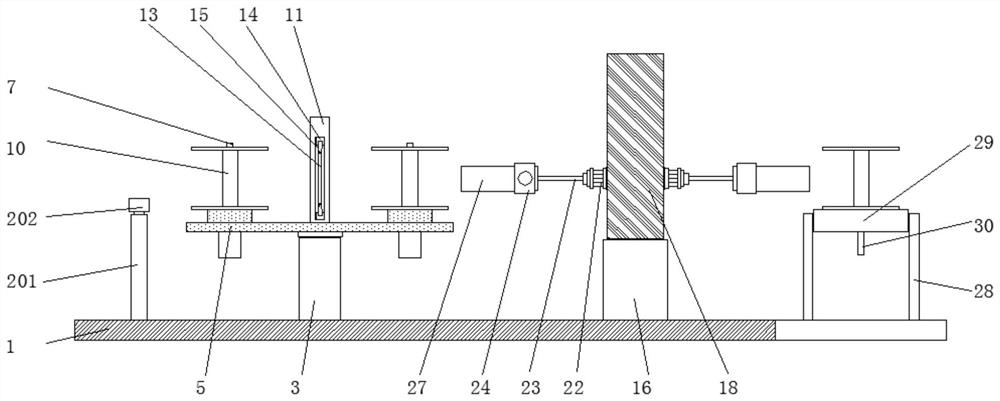

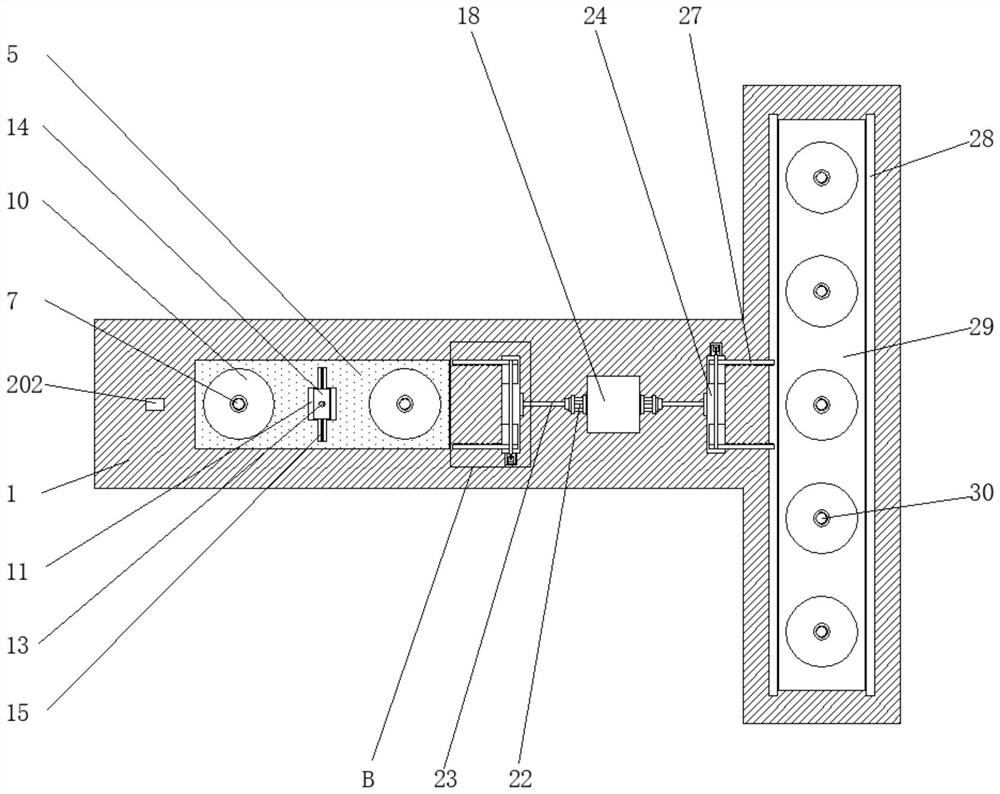

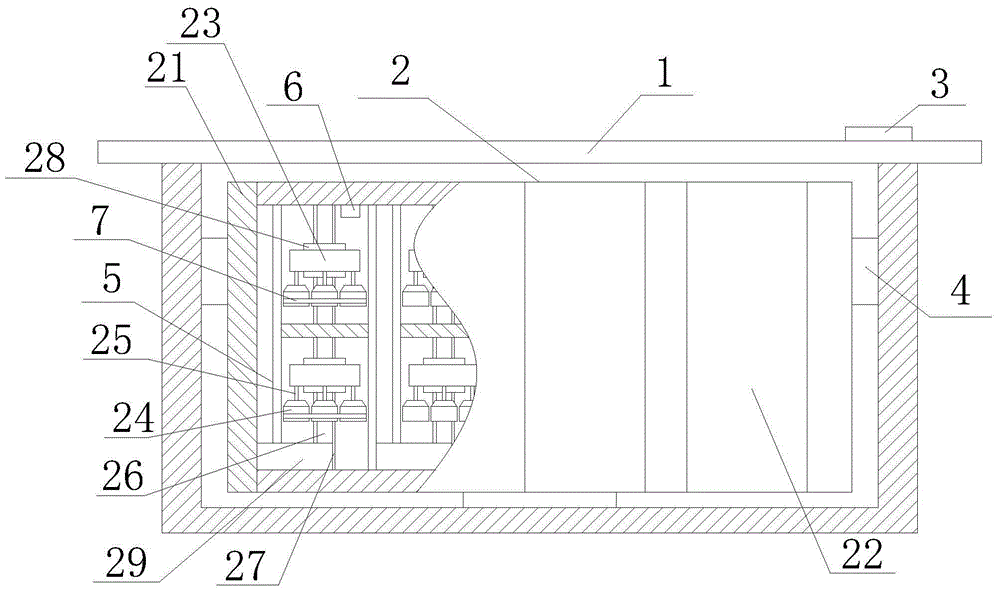

Coal slime forming machine

ActiveCN104927956AReasonable structural designHigh degree of operation automationDrying gas arrangementsSolid fuelsEngineeringFeeding tube

The invention discloses a coal slime forming machine and relates to the technical field of coal treatment technology. The forming machine comprises a power mechanism, a feeding and forming mechanism and a conveying and drying mechanism. The power mechanism comprises a lifting rod moving vertically; the feeding and forming mechanism comprises a feeding tube, and a forming pressure applying die and a forming pressure bearing die which match with each other vertically and mutually; the forming pressure applying die is connected to the bottom of the lifting rod; the conveying and drying mechanism is located at the bottom of the forming pressure bearing die, the conveying belt of the conveying and drying mechanism is provided with a puncture device and a drying device sequentially in the conveying direction of the conveying belt, and the tail of the conveying and drying mechanism is provided with a material collection device. The forming machine is reasonable in structure, the machining efficiency is high, and the automation level is high.

Owner:JIANGSU ZHONGWEI HEAVY IND MACHINERY

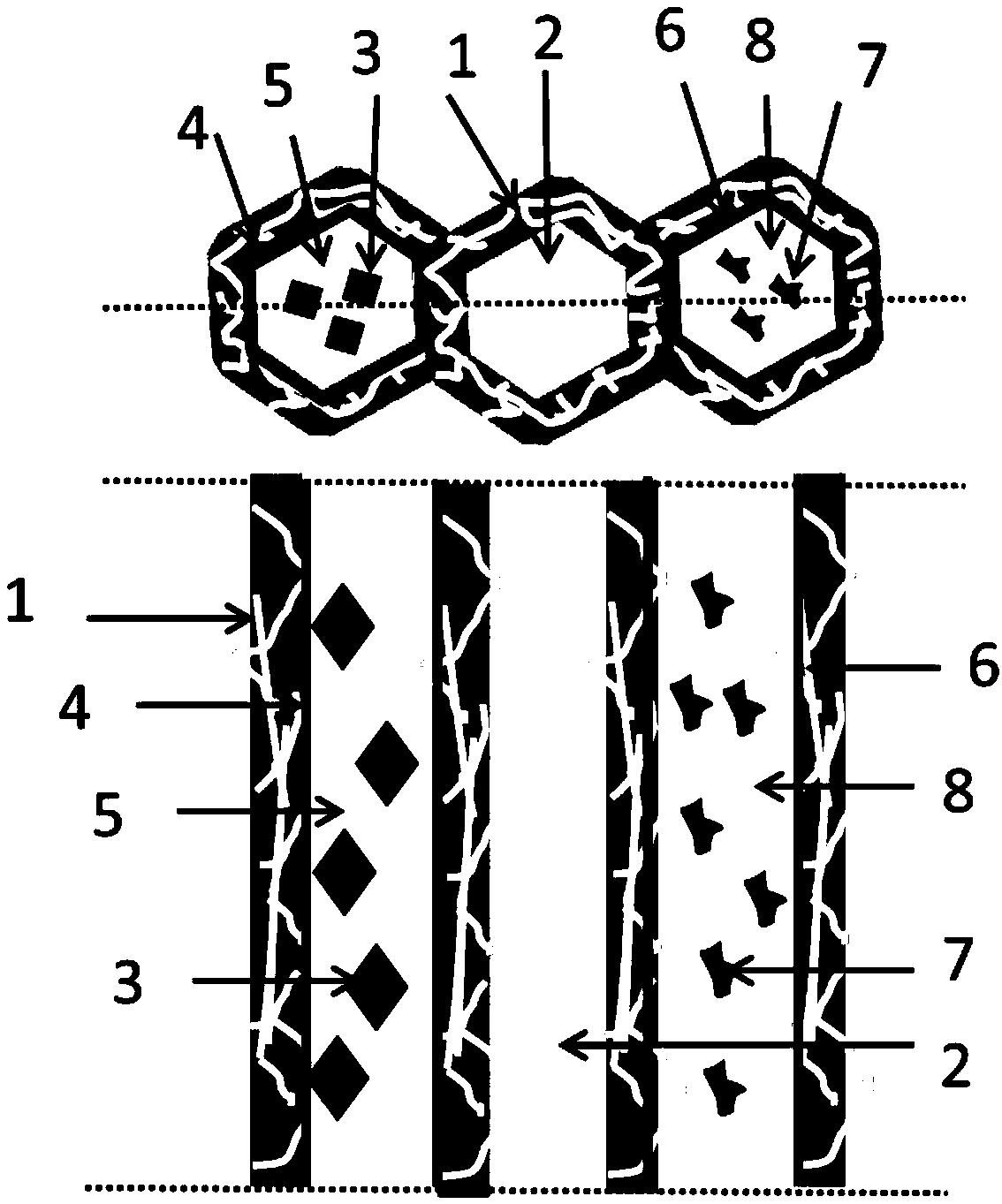

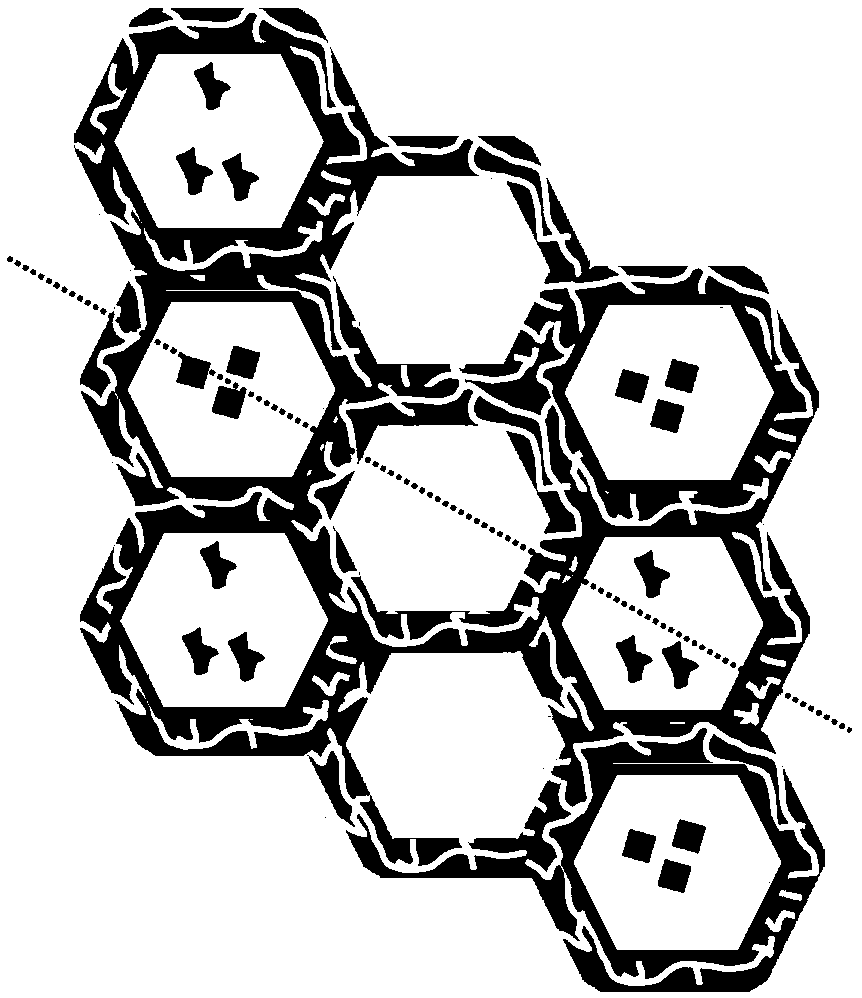

Lithium extracting unit adopting flowing electrode, extending device and continuous operating method

The invention belongs to the field of lithium ion collection and in particular relates to a lithium extracting unit adopting a flowing electrode, an extending device and a continuous operating method.The lithium extracting unit comprises an electric adsorption module and an electric desorption module corresponding to the electric adsorption module. The electric adsorption module comprises three adsorption module flowing channels constructed by a porous material. The invention can be used for finish a continuous operation f electric adsorption-electric desorption and a lithium enriching solution rich in lithium ions, therein an adsorbent is used circularly. The invention solves the problems that the lithium extracting efficiency by an intermittent lithium extracting operation and a continuous lithium extracting operation by adopting a fixed electrode is low and the electrode or a fluid is tedious to switch. Meanwhile, by adopting standard dimension modules, output is amplified and amplification effect is avoided by extending the quantity of the modules.

Owner:TIANJIN UNIV OF SCI & TECH

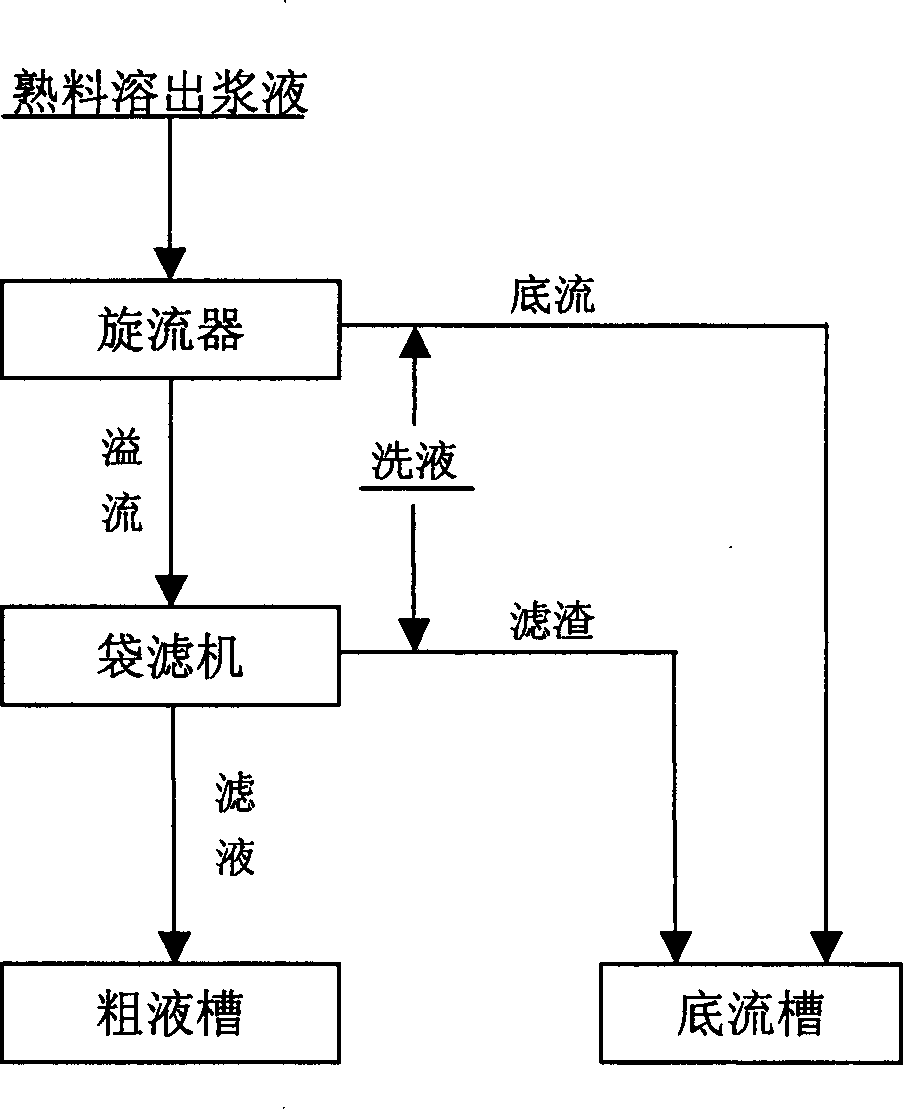

Sintering process of separating red mud for alumina production

The red mud separating process includes cyclonic grading the chamotte lixiviating slurry from the chamotte lixiviating step in a swirler while controlling the feeding pressure in 0.245-0.255 MPa, exhausting the slurry with coarse grains and high solid content via the bottom exhaust port to bottom groove, filtering the slurry with fine grains and low solid content in a bag filter to separate red mud from solution, flushing the filter slag to bottom groove, and returning the filtrate to the coarse liquid groove. The present invention has reasonable separation process, short and stable red mud separating period, high alumina and sodium oxide lixiviating rate and other advantages.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

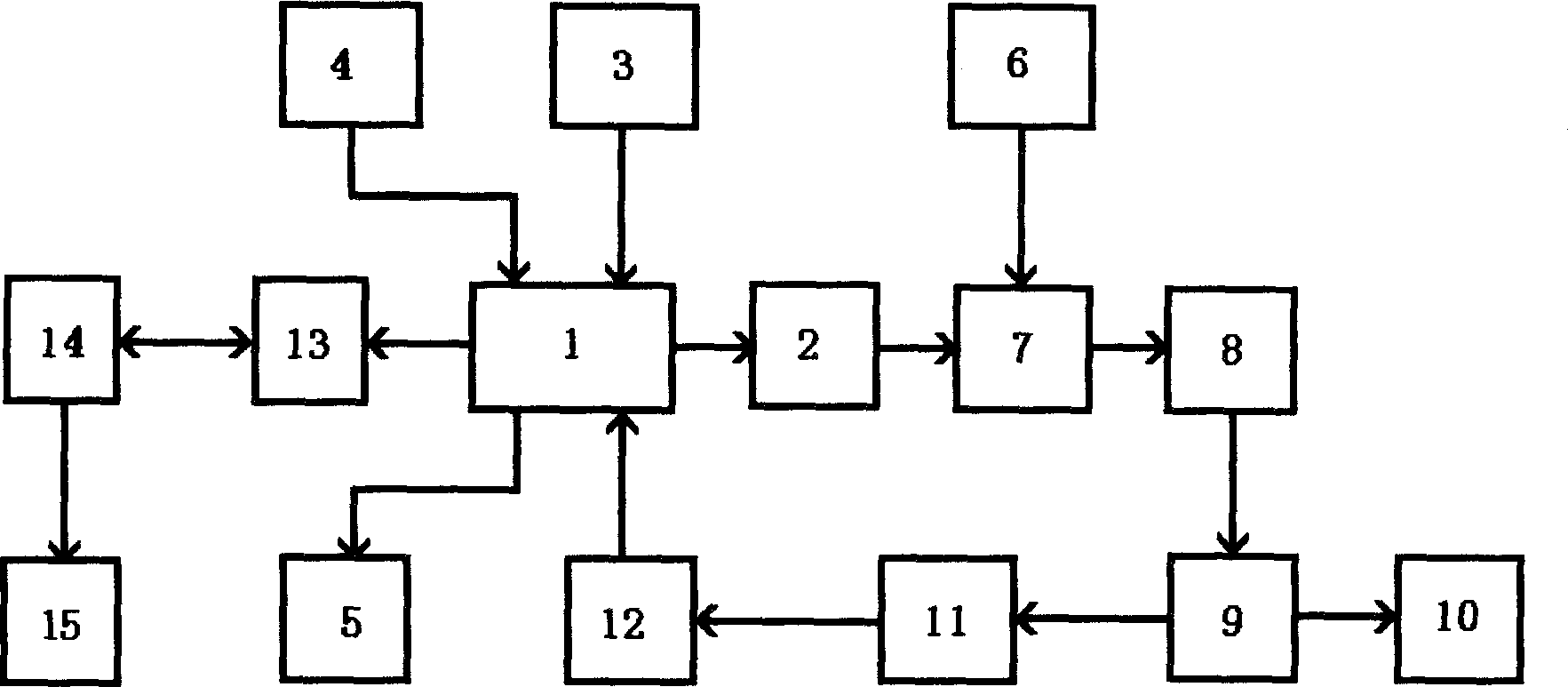

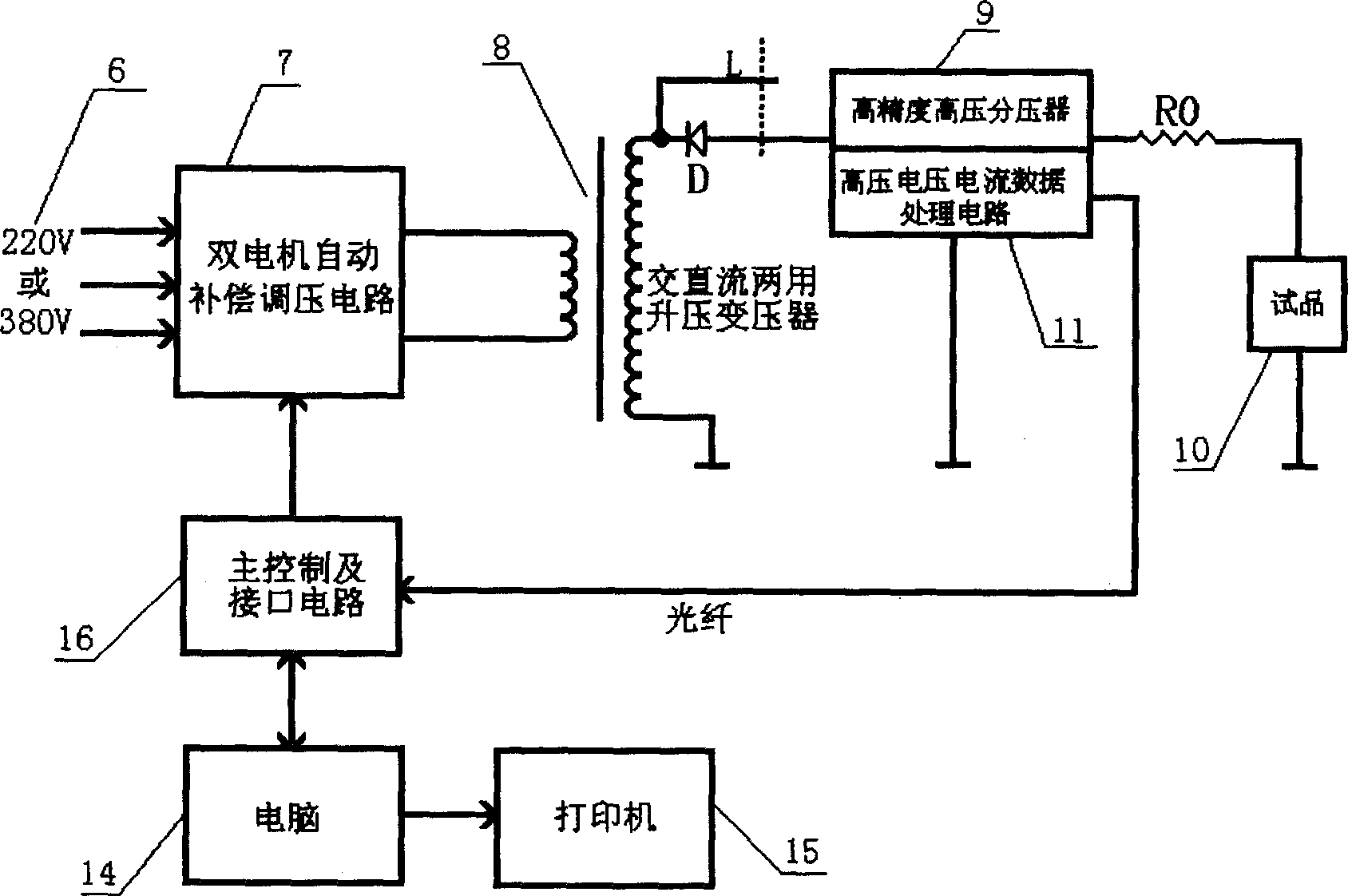

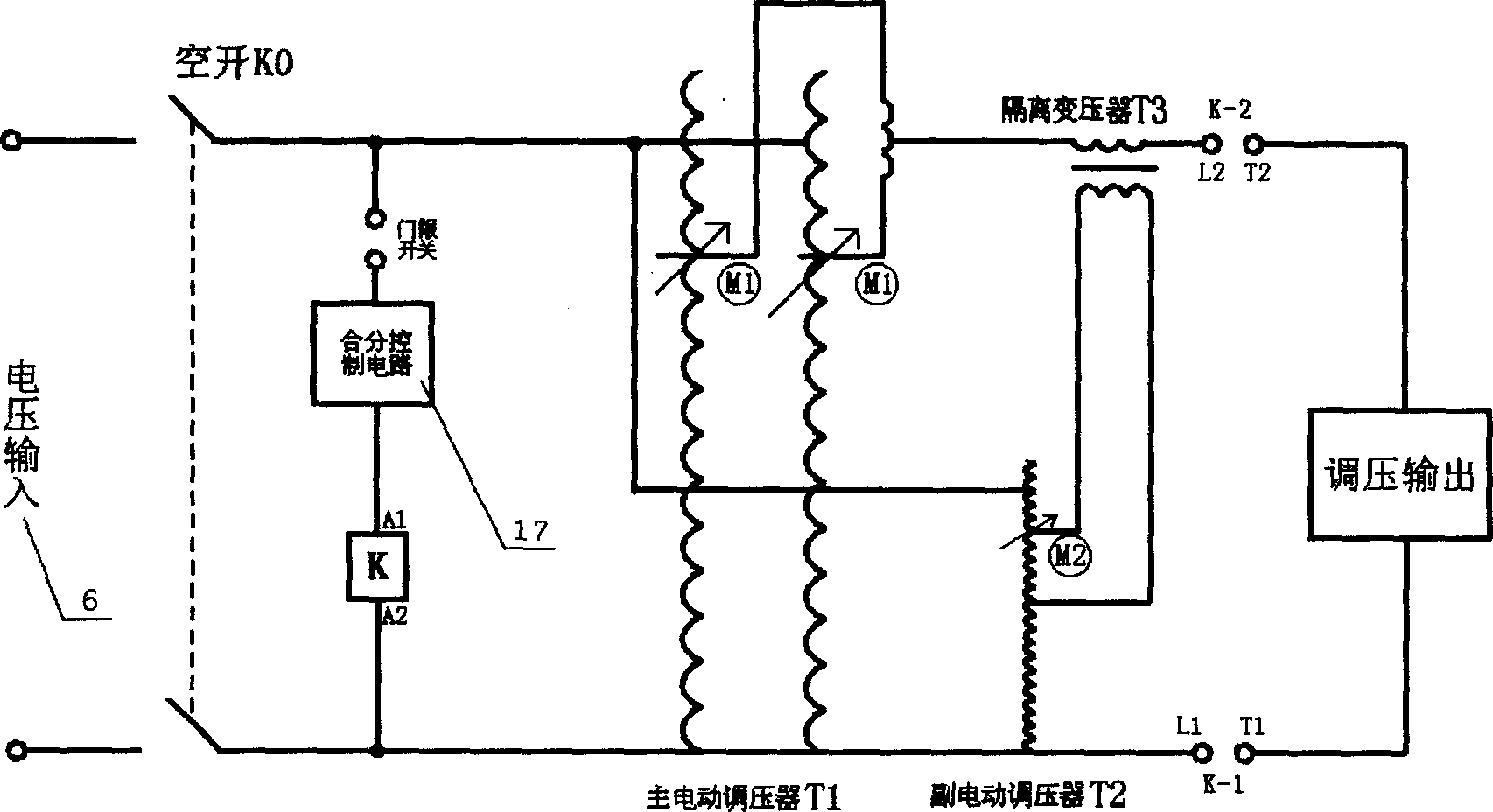

Intelligent AC-DC withstand voltage test apparatus

InactiveCN1488951ASimple structureHigh degree of operation automationTesting circuitsDynamo-electric machine testingTransformerEngineering

Main control circuit is connected to a serial interface circuit linked to a computer, which is connected to a printer. The main control circuit is also connected to a key-press circuit, display circuit, power supply for supplying the signal and control circuit and the motor control circuit. The motor control circuit is connected to dual electrical motor auto compensation voltage regulating circuit, which is connected to a supply circuit of main power source and AC / DC booster transformer linked to a voltage divider, which is connected to articles to be tested. A data processing circuit through optical fiber is connected to the data receive circuit connected to the main control circuit. The device can fulfill following testing: AC withstand voltage, large capacity DC withstand voltage, solid insulating material, line frequency electrical strength test and breakdown test. The invented device possesses features of good safety and high efficiency.

Owner:XIAN FRIEND ELECTRONICS T&S

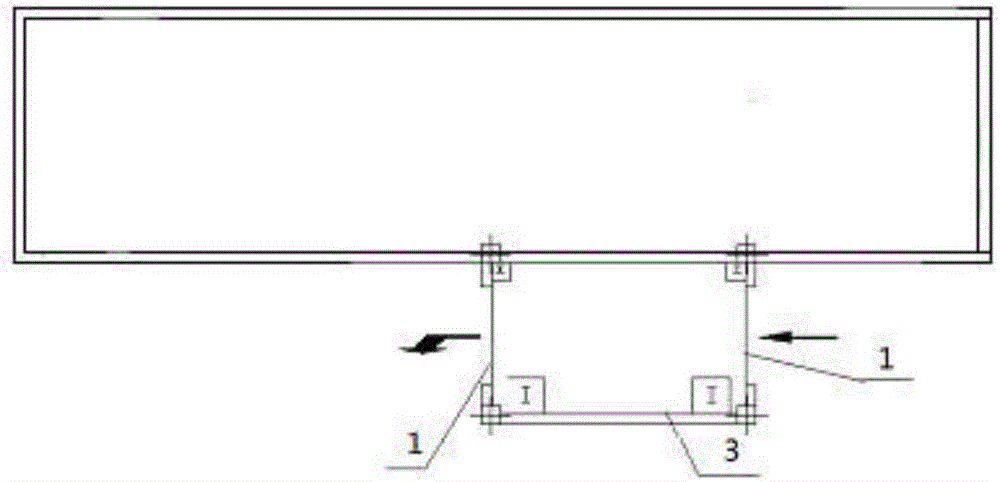

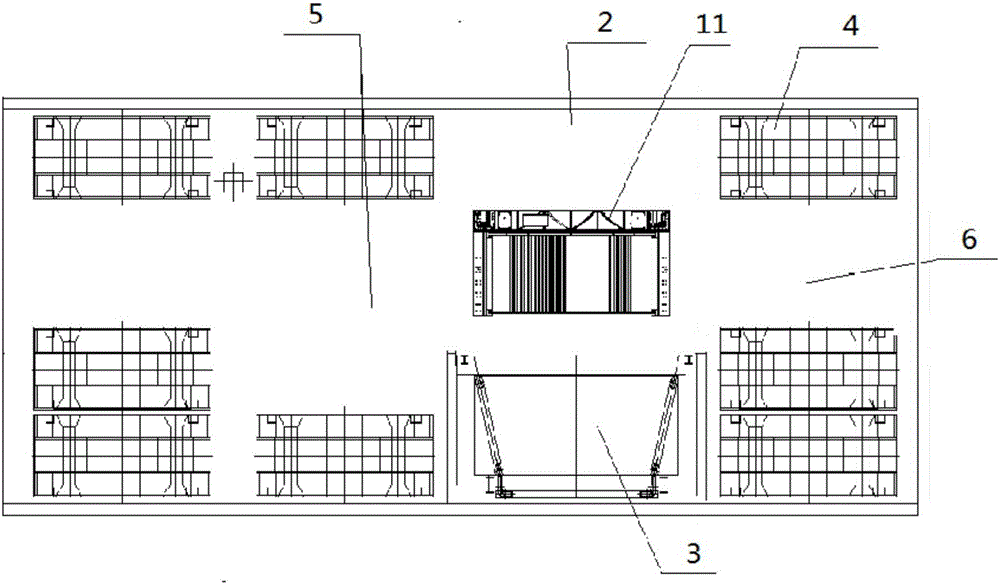

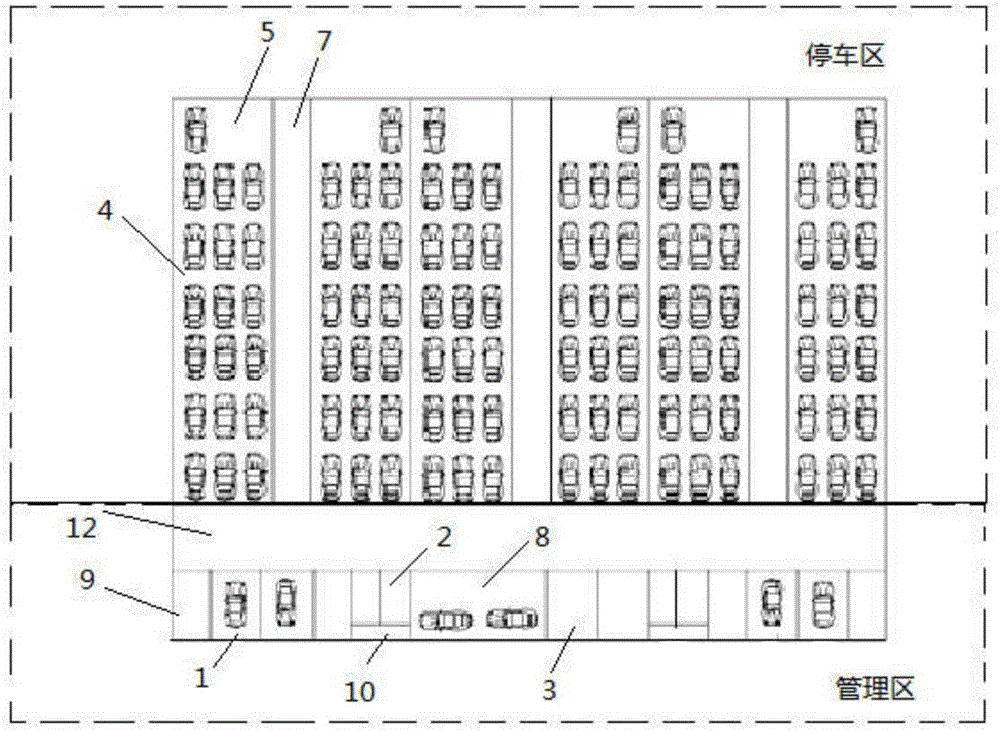

Automatic parking equipment

The embodiment of the invention provides automatic parking equipment. The automatic parking equipment at least comprises one layer. Each layer of the parking equipment comprises a management area and a parking area. Each management area includes an elevator and an AGV charging station. The management area in the first layer is also provided with a passageway. Each parking area comprises an AGV and a plurality of parking units, wherein each parking unit comprises a parking unit, a vehicle transferring area and an AGV operating area. The AGVs are used for carrying and transferring vehicles. The vehicle transferring areas are used for temporary storage of the vehicles when the vehicles are picked up. The AGV operating areas are channels for the AGVs to carry the vehicles. According to the automatic parking equipment provided by the invention, the AGVs are used as vehicle carrying carriers, and design, installation and debugging of original parking equipment are simplified by applying the AGVs; scheduling is flexible, and transferring is convenient; and a large vehicle transferring space does not need to be arranged, layout of the parking equipment is made reasonable, and the space utilization rate is high.

Owner:北京泊宝机器人科技有限公司

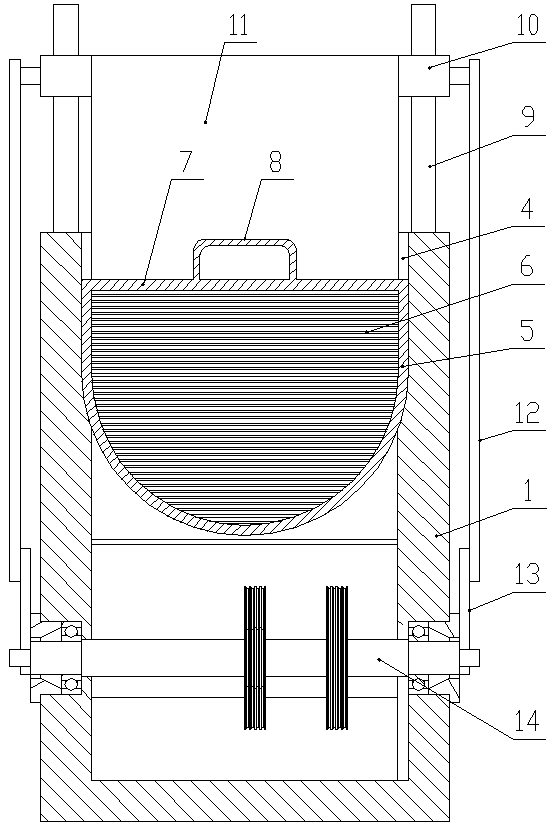

Slicing device of fruit and vegetable foods and slicing method of slicing device

PendingCN109760115ASimple structureNo power consumptionMetal working apparatusSlice thicknessAgricultural engineering

The invention relates to a slicing device of fruit and vegetable foods. The slicing device of the fruit and vegetable foods comprises a frame, the frame is of a cuboid shape, a material guiding grooveused for placing fruit and vegetable raw materials is internally formed in the upper part of the frame, the front part and the rear part of the material guiding groove communicate with each other, the top of the material guiding groove is opened, a lifting type cutter mechanism located over the front end opening of the material guiding groove is arranged on the front side of the top of the frame,a base plate is internally arranged on the bottom of the frame, the base plate is provided with a power driving mechanism, the power driving mechanism is connected with the lifting type cutter mechanism through a power transmission mechanism, a slice-thickness adjusting mechanism arranged on the front side of the lifting type cutter mechanism is arranged on the top of the frame, and a magnetic adsorption mechanism used for driving the fruit and vegetable raw materials to move forwards along the material guiding groove and arranged on the rear side of the lifting type cutter mechanism is arranged on the top of the frame. According to the slicing device of the fruit and vegetable foods and a slicing method of the slicing device, design is novel, the structure is simple, manual work is onlyneeded to put in the fruit and vegetable raw materials, the labor intensity is greatly lowered, the slicing efficiency is high, the thicknesses of slices are coincident, and the thicknesses of the slices are conveniently adjusted.

Owner:HUANGHE S & T COLLEGE

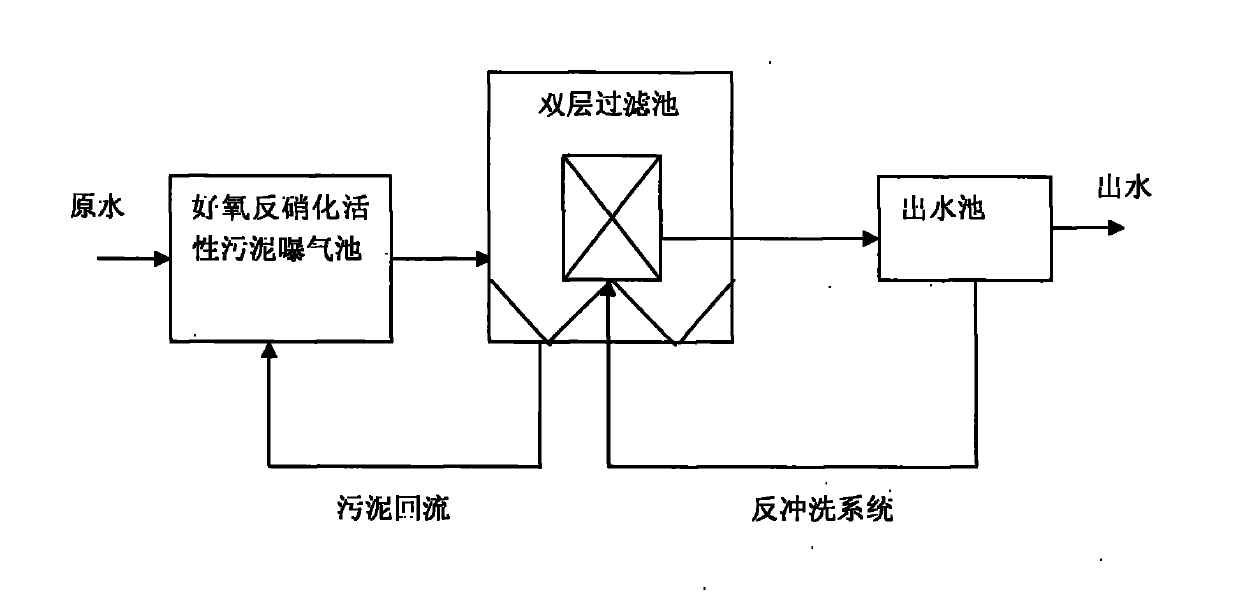

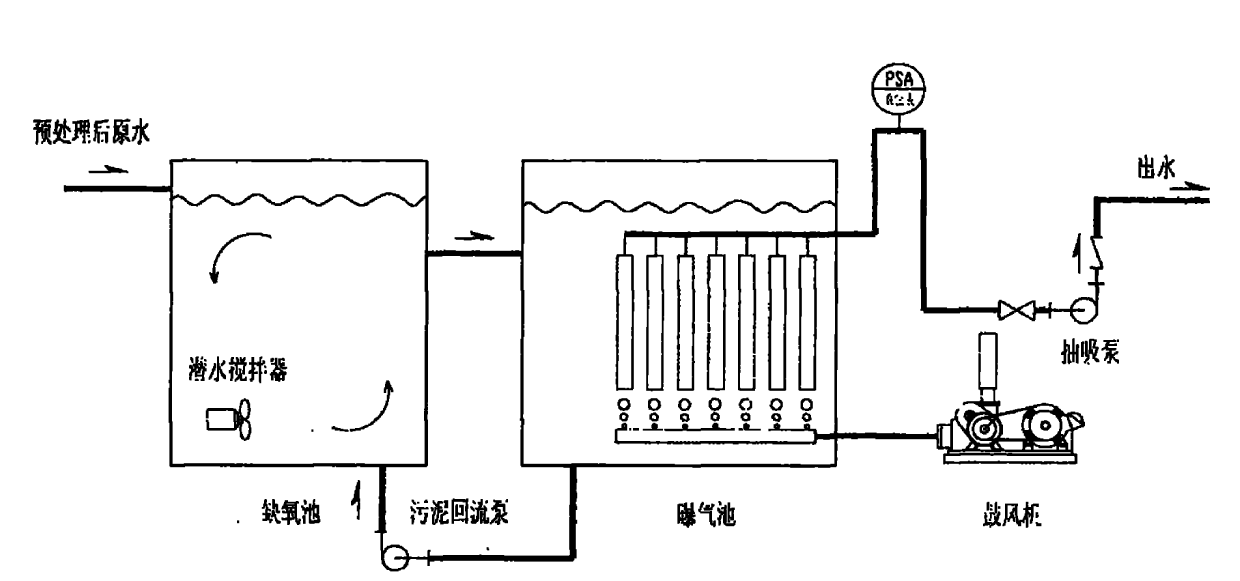

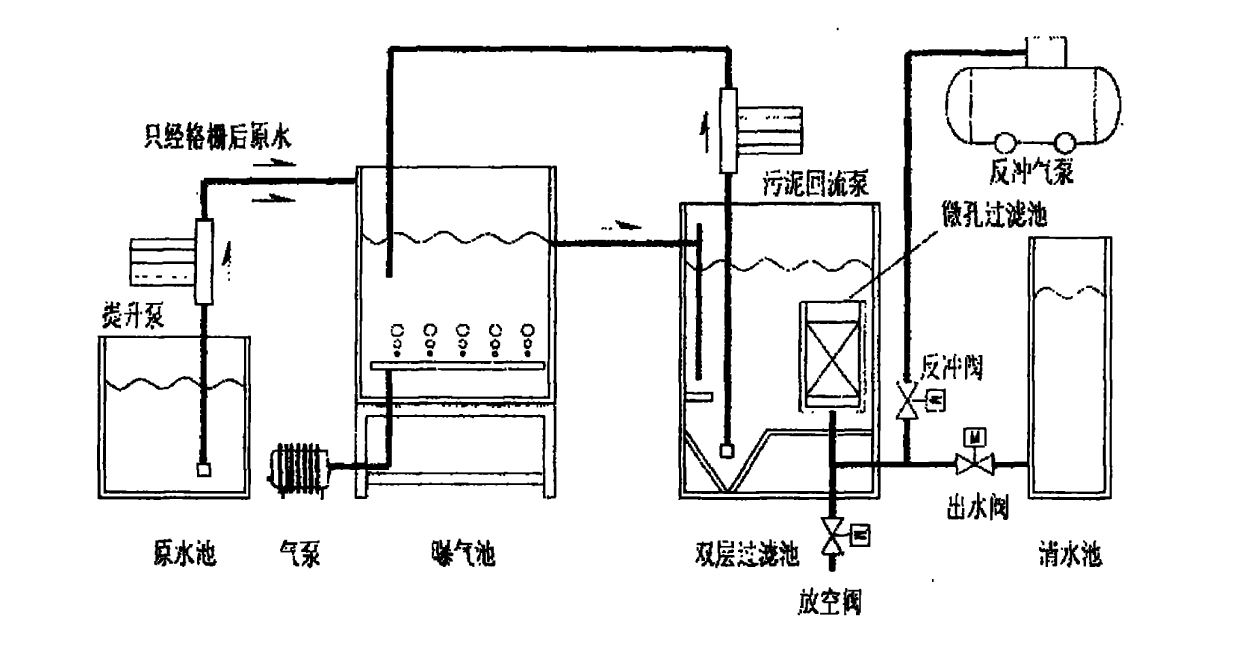

Method for treating municipal sewage by adopting millipore FBR (Filter Bio-reactor)

ActiveCN102070279AMeet the requirements of emission standardsLess investmentMultistage water/sewage treatmentEmission standardMunicipal sewage

The invention discloses a method for treating municipal sewage by adopting a millipore FBR (Filter Bio-reactor), belonging to the technical field of resources and environments. The municipal sewage can be treated by adopting a mode of combining aerobic denitrification with a dual-layer millipore filter tank in the method, thus pollutants, such as NH3-N, TN (Total N), COD, SS, TP (Total Phosphorus) and the like, in the municipal sewage can be greatly effectively reduced, the treated discharge water can reach the national earth surface IV class water standard, wherein CODCr is not more than 30mg / l, NH3-N is not more than 1.5mg / l, the total N (lake, reservoir, in the terms of N) is not more than 1.5mg / l, the total phosphorus (in the terms of P) is not more than 0.3mg / l, and the potassium permanganate index is not more than 10. The discharge water can be directly discharged in an earth surface riverway so as to reduce the environment pollution and meet the requirement on the increasingly improved municipal sewage emission standard. The invention can be applied to building municipal sewage treatment plants and modifying and reconstructing the traditional sewage treatment plants.

Owner:JIANGSU XIANTONG ENVIRONMENT TECH

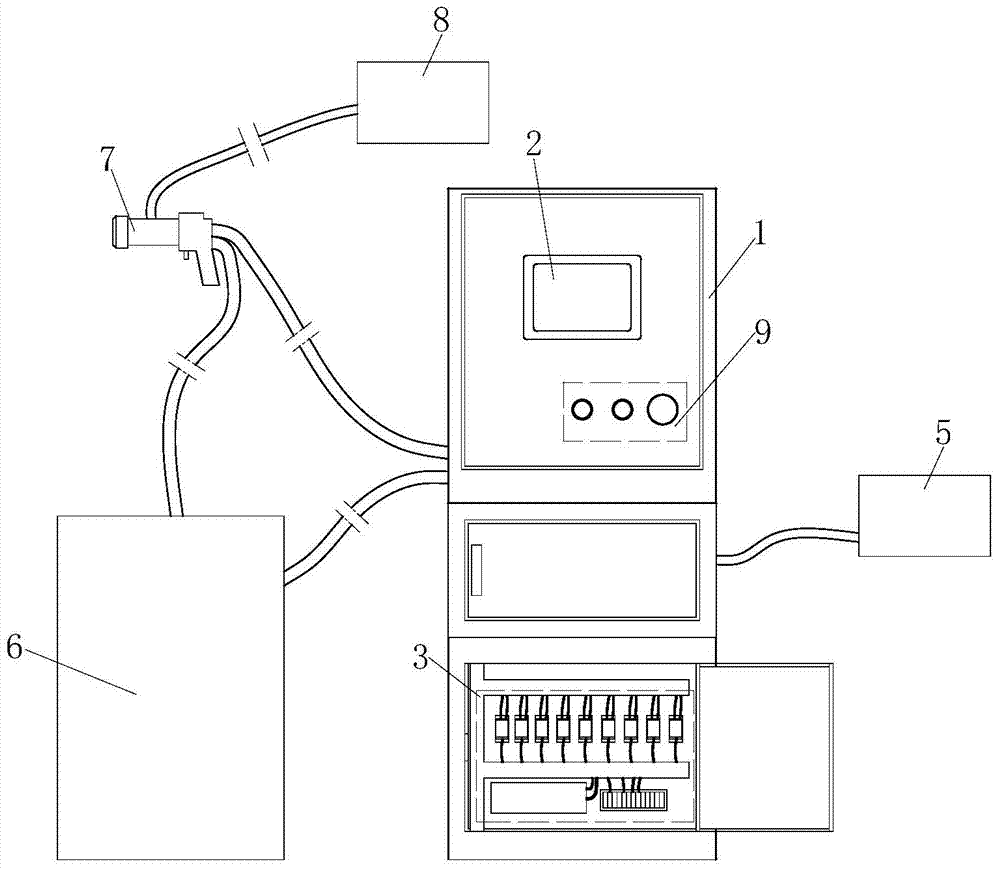

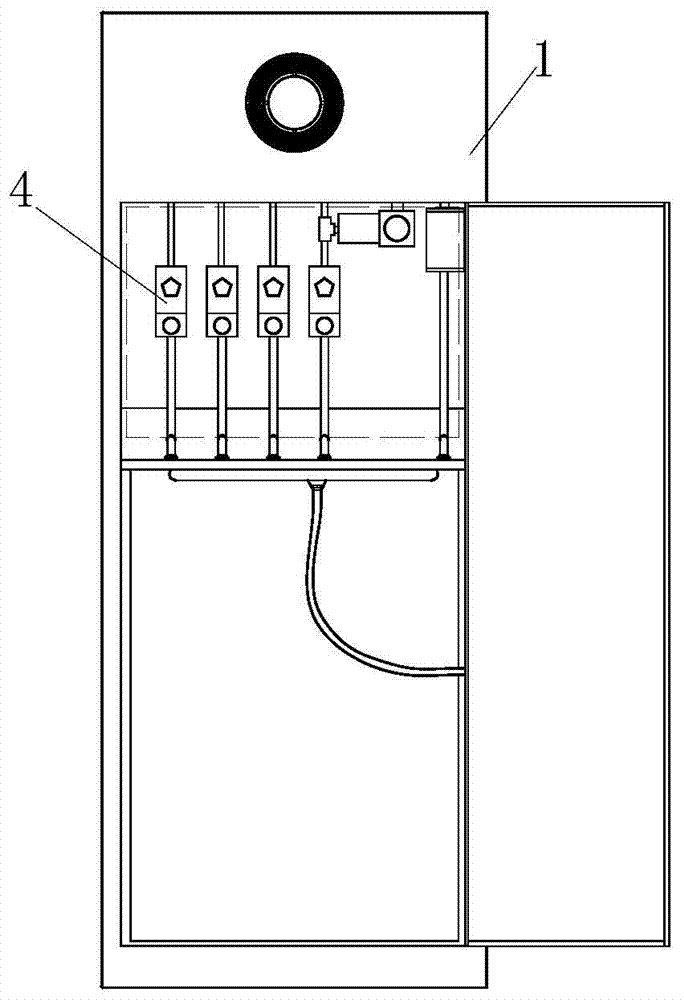

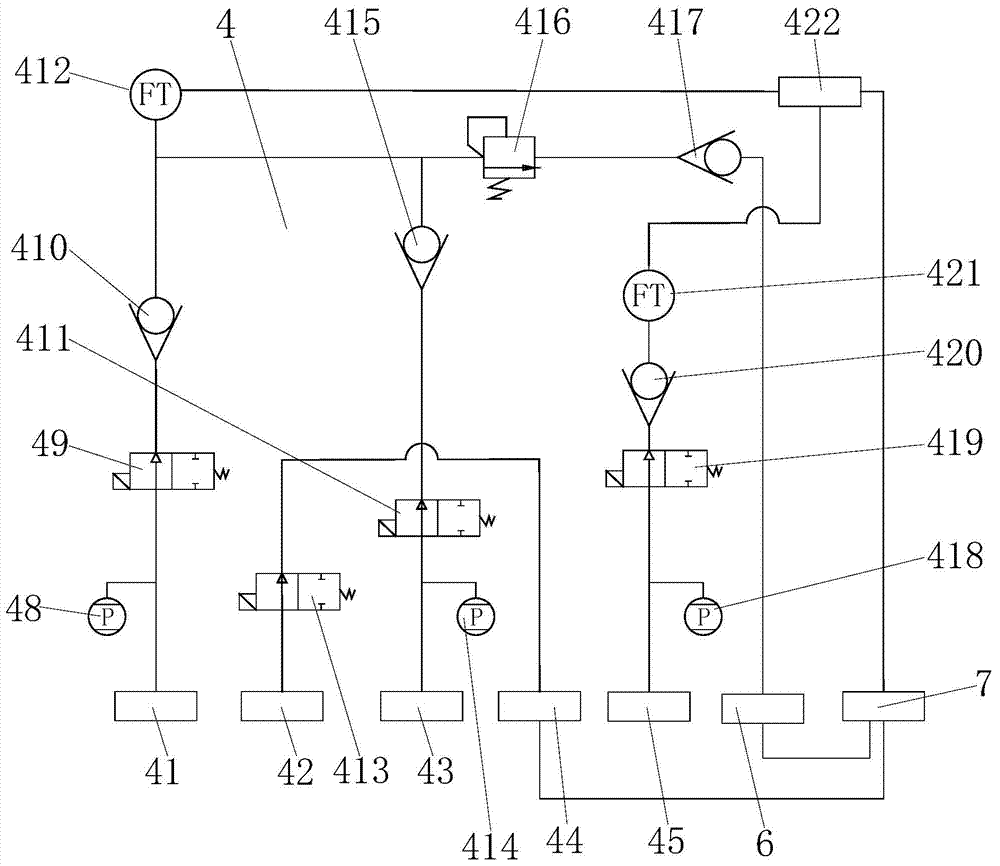

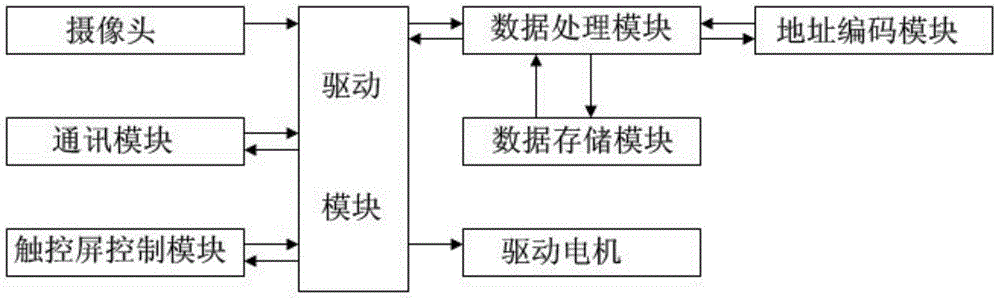

Touch screen type plasma spraying system

The invention relates to a touch screen type plasma spraying system. The touch screen type plasma spraying system comprises a control cabinet, a touch screen, a manual control knob, a monitoring circuit, a performing device, a gas tank set, a powder feeder, a spraying gun and a water cooler, wherein the monitoring circuit is arranged at the lower end of the control cabinet; the touch screen is arranged at the upper end of the control cabinet; the manual control knob is arranged at the upper end of the control cabinet; the performing device is arranged inside the control cabinet and connected to the spraying gun by virtue of a pipeline; the gas tank set is connected to the control cabinet by virtue of a pipeline; the powder feeder is connected to the control cabinet by virtue of a pipeline and connected to the spraying gun by virtue of a pipeline; the spraying gun and the control cabinet are connected by virtue of a pipeline; and the water cooler and the spraying gun are connected by virtue of a pipeline. The touch screen type plasma spraying system has the advantages of high operation automation degree, high control sensitivity, and the like, can be used for realizing spraying workpieces quickly, ensuring the system stability and security by virtue of automatic control, avoiding a safety accident caused by gas reflow and guaranteeing the body security of operation staff.

Owner:WUHU DINGHAN REMFR TECH

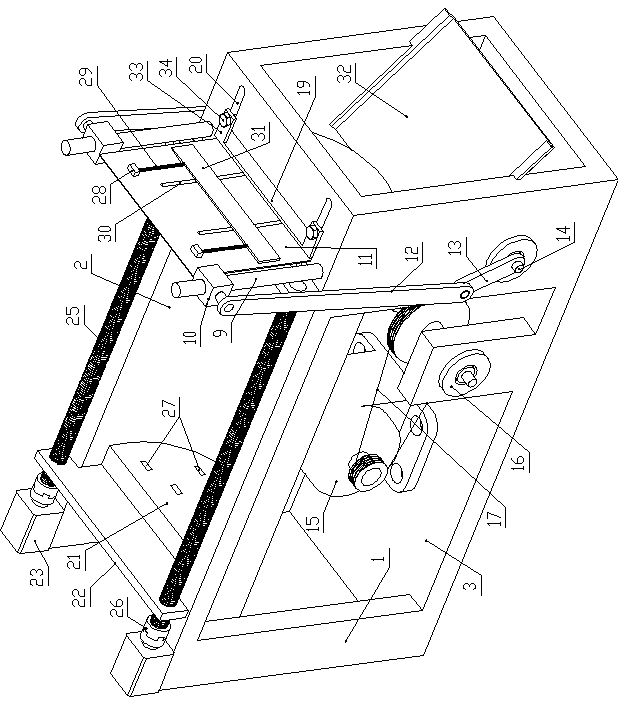

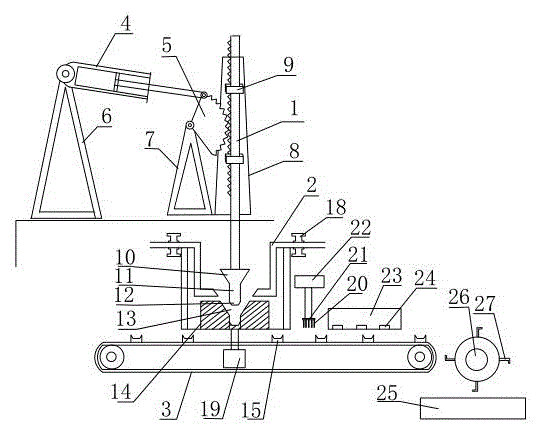

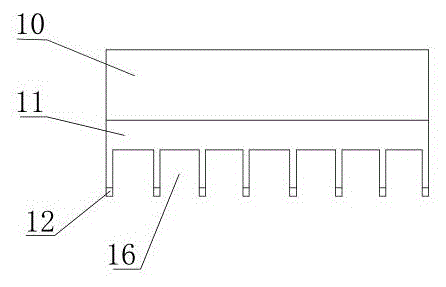

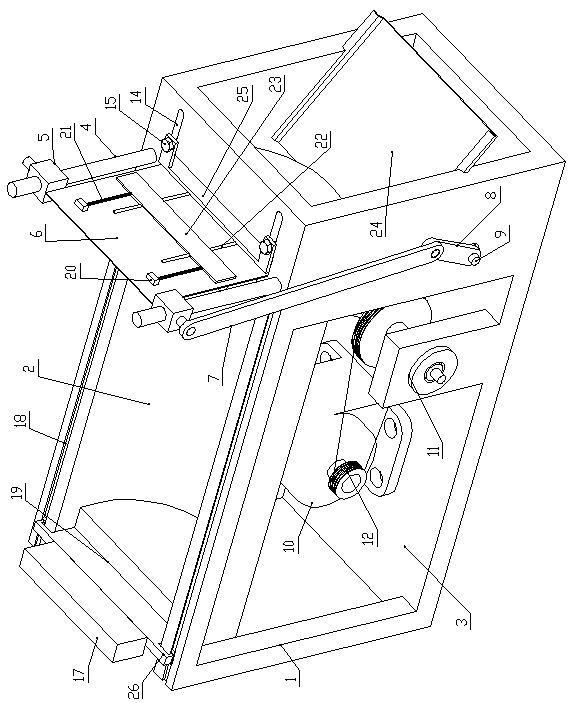

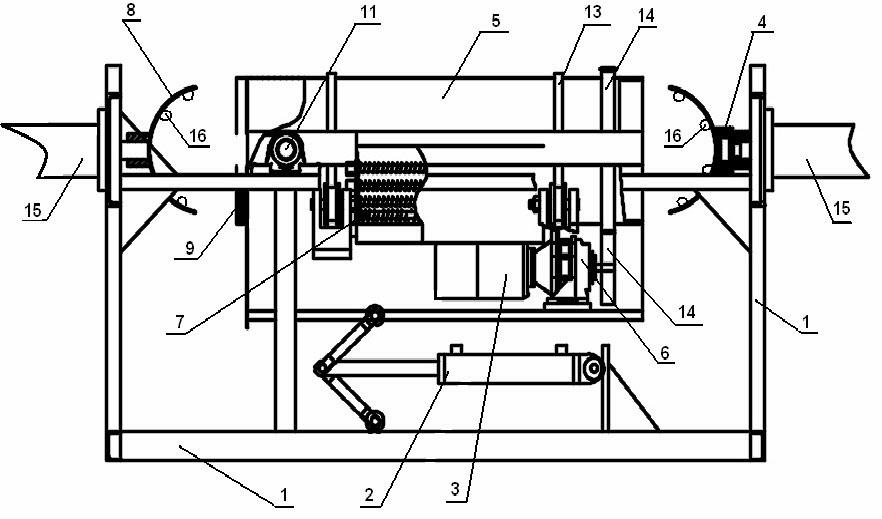

Technology and device for full automatic cloth-free wrapping-twisting of oolong tea

InactiveCN102687772AReduce manufacturing costImprove qualityPre-extraction tea treatmentProcess engineeringIndustrial engineering

The invention relates to a technology and a device for full automatic cloth-free wrapping-twisting of oolong tea. The technology for full automatic cloth-free wrapping-twisting of oolong tea comprises the following steps of 1, automatic tea-feeding, 2, primary twisting, ball-breaking and sifting, 3, heating and primary drying, and 4, secondary kneading and shaping wrapping. The technology cooperates with the device. The device comprises a foundation support, a lifting device, a motor and transmission mechanism, a hydraulic device, a roller device, a guide wheel device, a temperature-control heating device, a wrapping-twisting head device, an automatic door device, and an automatic tea feeding / discharging device. Through the technology and the device, tea green leaves especially such as oolong tea green leaves can be twisted for shaping repeatedly and automatically. The technology and the device realize cloth-free wrapping-twisting, greatly improve wrapping-twisting efficiency, reduce labor intensity and a labor cost and realize continuous and automatic processing of oolong tea.

Owner:漳州弘烨机械制造有限公司

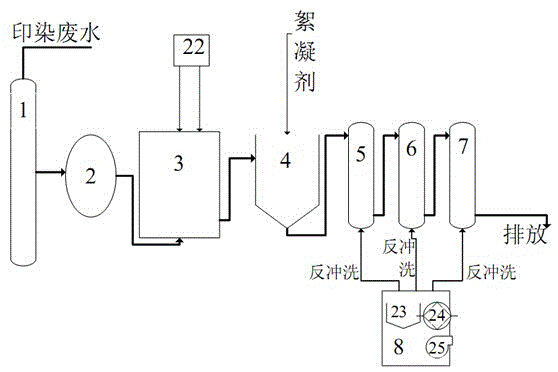

Closed type printing and dyeing waste water processing system

InactiveCN104478139AGuaranteed uptimeSmall footprintWater/sewage treatmentMultistage water/sewage treatmentAutomatic controlTurbidity

The invention discloses a closed type printing and dyeing waste water processing system. The closed type printing and dyeing waste water processing system comprises a filter, a water storage pond, a regulating pond, a reaction pond, a quartz sand filter tank, an activated carbon filter tank, a suspended filler filter tank, a back flush room, an external automatic reagent adding machine, an air blower, a back flush pump and a clear water pond. The quartz sand filter tank, the activated carbon filter tank and the suspended filler filter tank are detachable filter tanks, and manual filler replacing and cleaning can be carried out. A programmable logic controller is adopted in the whole system to carry out operation, and automatic control of the on-off state of a water pump is achieved. The removal rate of suspended matter can reach 94.9 percent, the chroma removing rate can reach 92.1 percent, and the turbidity removing rate can reach 98.3 percent.

Owner:黄相贵

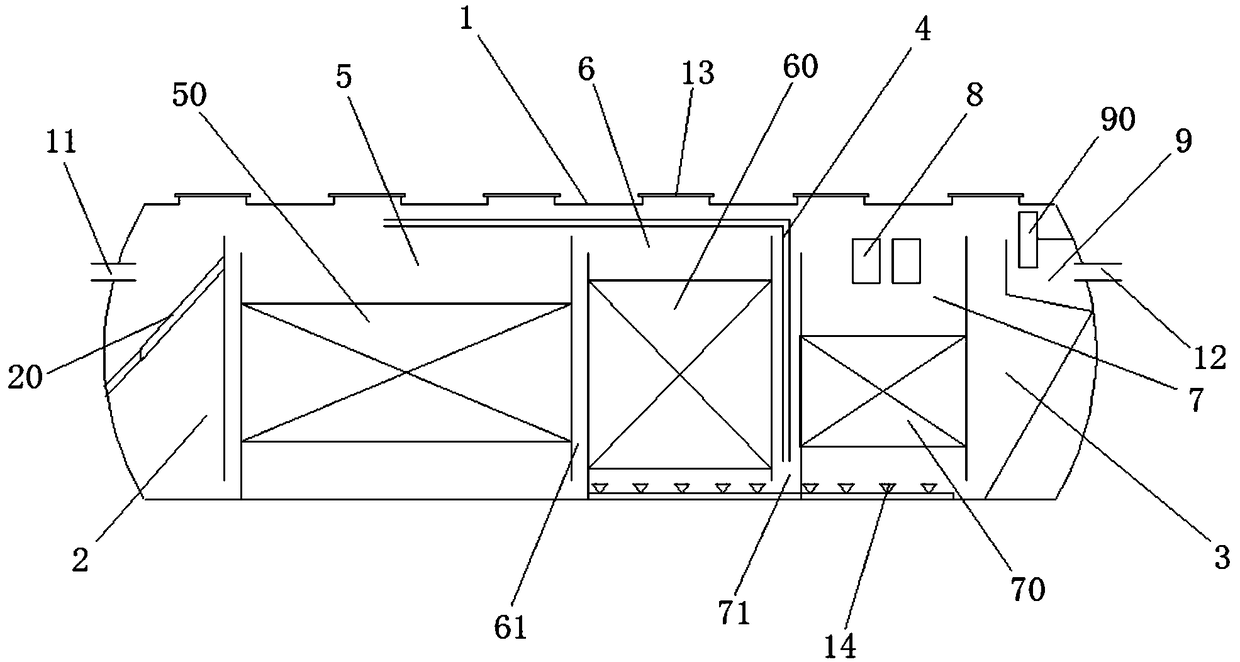

Sewage treatment device

PendingCN109205957AHigh degree of operation automationSimple structureWater/sewage treatment by irradiationSpecific water treatment objectivesTerrainEutrophication

The invention discloses a sewage treatment device, which comprises a tank body, an anaerobic groove, an aerobic groove and a backflow pipe, wherein the anaerobic groove is formed between a water inletand a water outlet of the tank body; the backflow pipe is communicated with the bottom of the anaerobic groove and the top of the anaerobic groove. The device is designed by aiming at the rural sewage and the small-scale urban sewage; the anti-shock loading capability of the tank body structure is high; the structure is simple; the installation cost is low; the building period is short; the operation automation degree is high; the dismounting and regulation can be performed at any time according to requirements in different terrains; the use is flexible and convenient; the phosphorus-containing total concentration of the treated outlet water is lower than 0.2mg / L; the water body eutrophication influence is avoided.

Owner:深圳市水务规划设计院股份有限公司

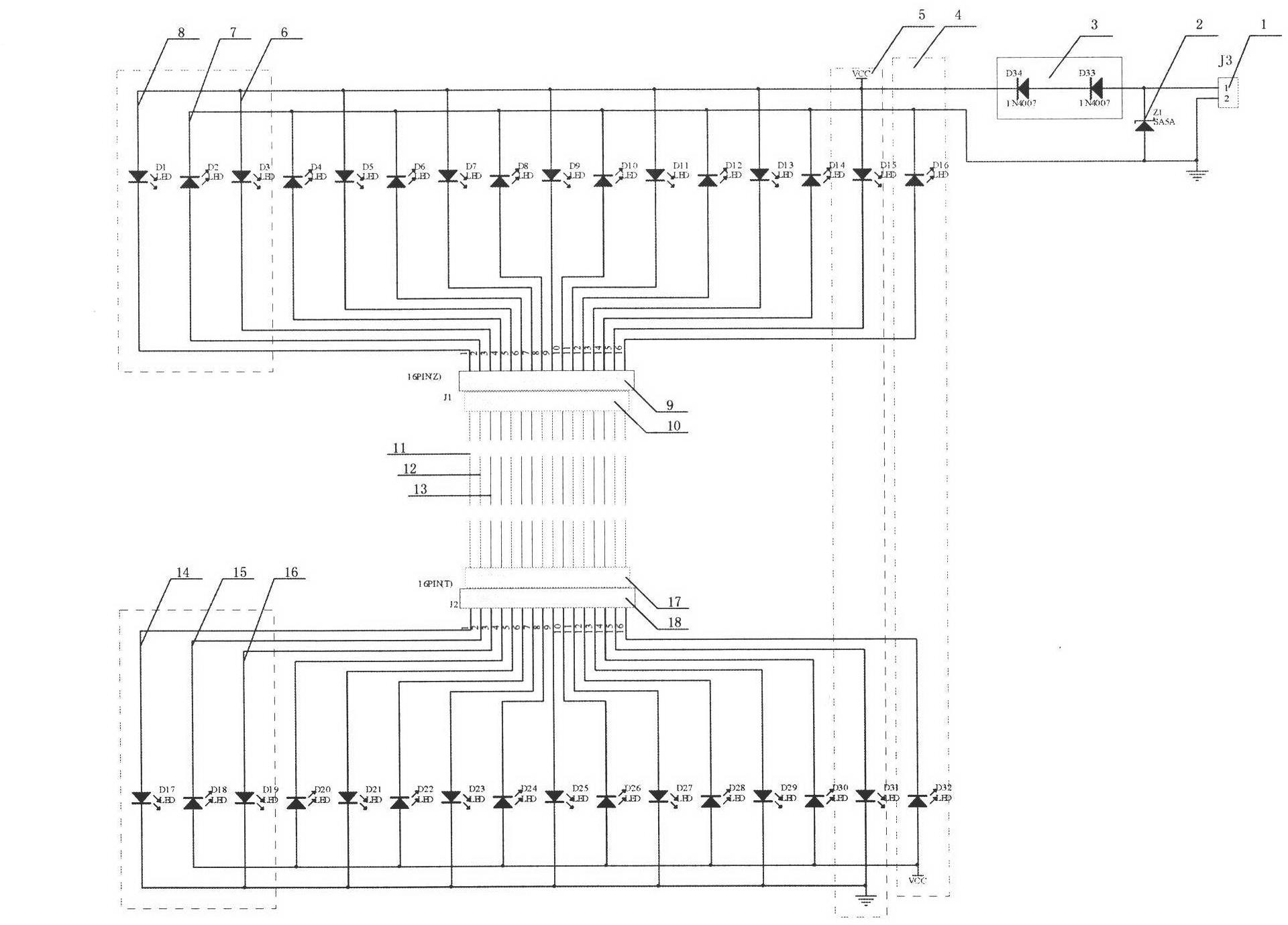

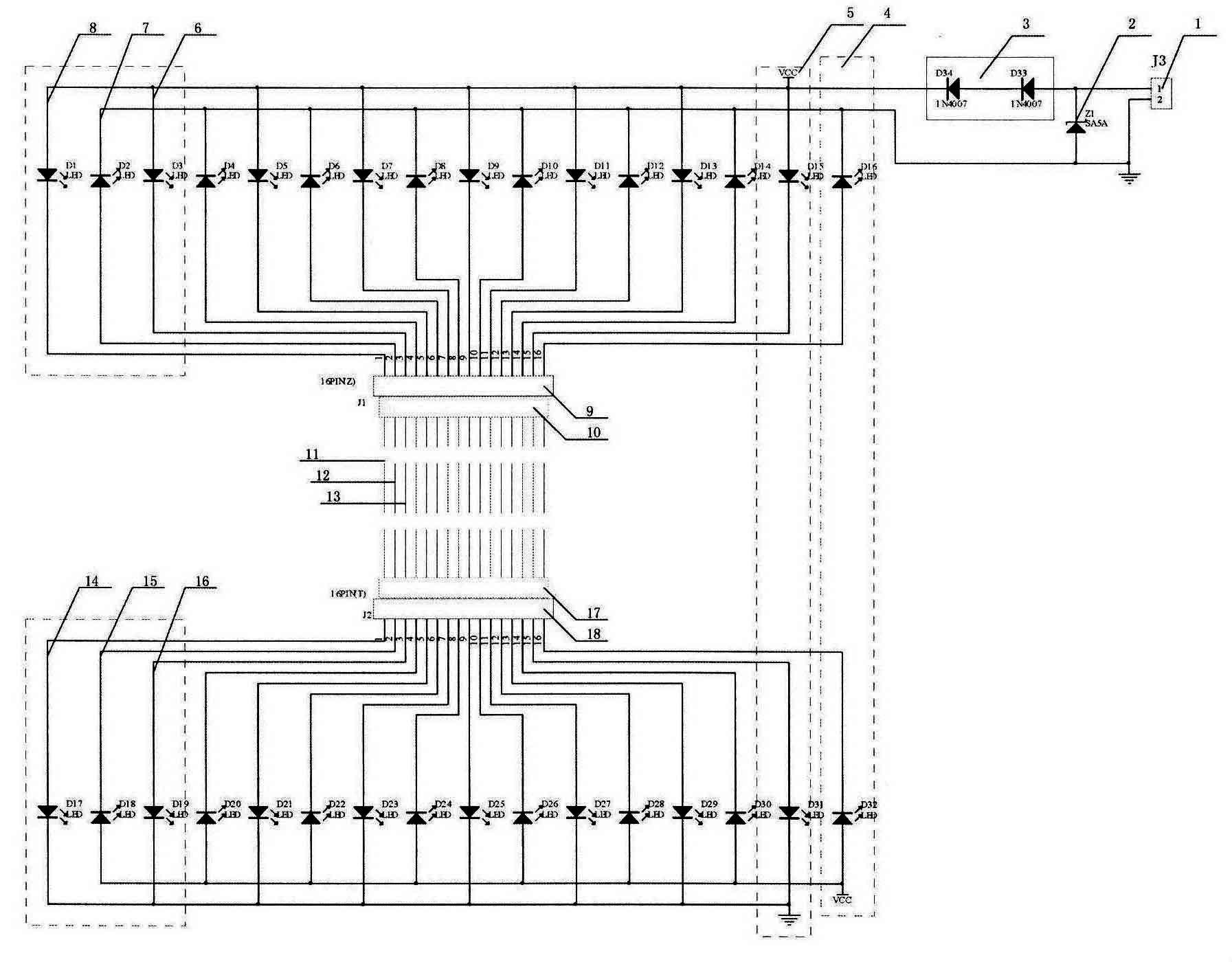

Rapid and reliable flat cable assembly detection device

ActiveCN102323510AHigh degree of operation automationQuality improvementElectrical testingEngineeringLight-emitting diode

The invention relates to a rapid and reliable flat cable assembly detection device which is used for detecting positive and negative design of light emitting diodes through adjacent flat cables and solving the problem of short circuit detection. A complementary design is adopted in short circuit detection circuits at two ends of a flat cable, i.e., the anode of the light emitting diode at one end is connected with a dual-row socket, and the cathode of the light emitting diode at the other end is connected with a dual-row socket. By means of the structures of the short circuit detection circuits, the open circuit detection of a light emitting diode stack is realized, the detection is rapid and convenient as well as accurate and reliable to ensure that the degree of automation in operation of the detection device is greatly improved; and a flat cable assembly checked by using the detection device has greatly improved quality and reliability and working efficiency increased by tens to hundreds of times.

Owner:CHINA NORTH IND GRP NO 70 RES INST

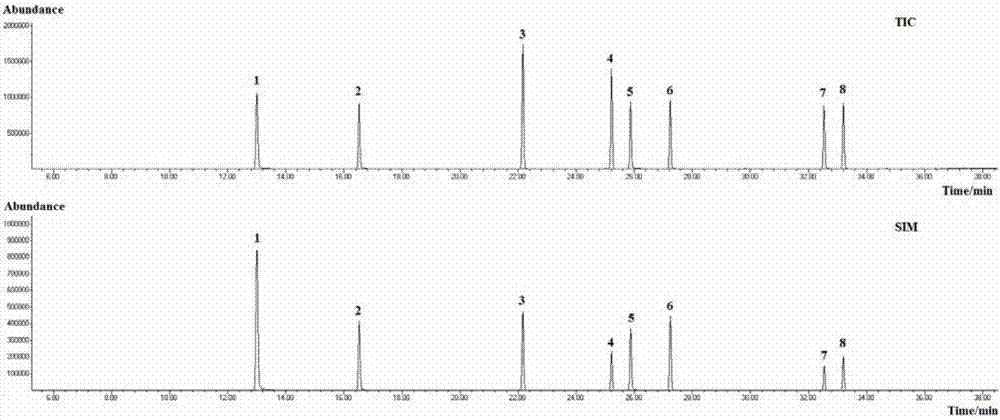

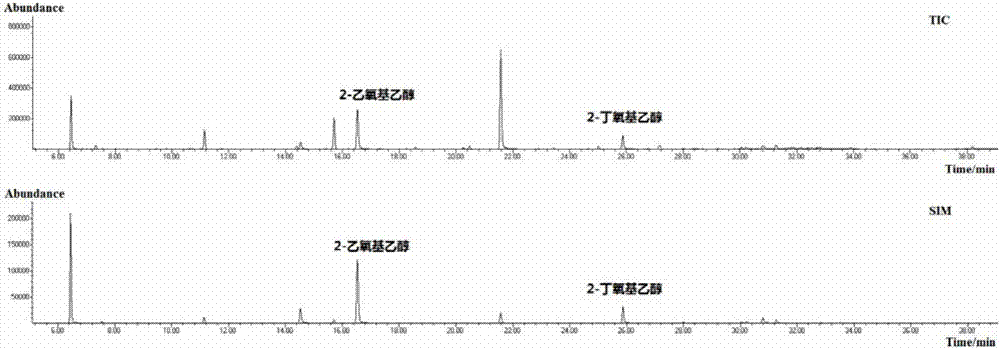

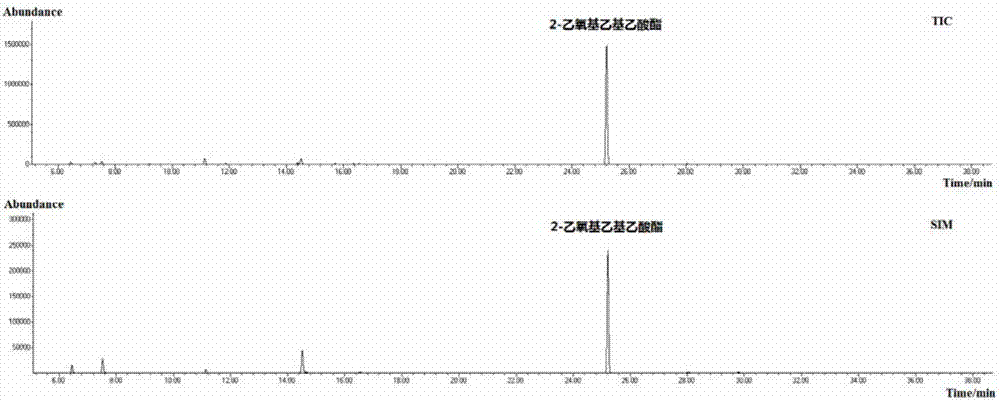

Method for measuring glycol ether substance in package paper for cigarette

ActiveCN106872620AEasy to handleHigh degree of operation automationComponent separationMass spectrum analysisAmount of substance

The invention provides a method for measuring a glycol ether substance in package paper for a cigarette. The method specifically comprises the following steps of 1), preparation of a test sample; 2), preparation of a standard sample; 3), sample detection: subjecting the test sample and the standard sample to head space-gas chromatographic / mass spectrometric measurement respectively, so as to obtain total ion current chromatograms and selected ion chromatograms of the test sample and the standard sample; 4), qualitative analysis: by using retention time and a fragment ion peak of the glycol ether substance in the total ion current chromatogram of the standard sample as references, determining the glycol ether substance existing in the test sample; 5), quantitative analysis: establishing a standard working curve through the content of glycol ether in the standard sample and the selected ion monitoring chromatogram of the standard sample, and carrying out quantification by an external standard method, so as to obtain the content of the glycol ether substance in the test sample. The method for measuring the glycol ether substance in the package paper for the cigarette, which is provided by the invention, is high in sensitivity and good in repetitiveness and recovery rate; an effective technical means is provided for the qualitative and quantitative analysis of the glycol ether substance in the package paper for the cigarette.

Owner:SHANGHAI TOBACCO GRP CO LTD

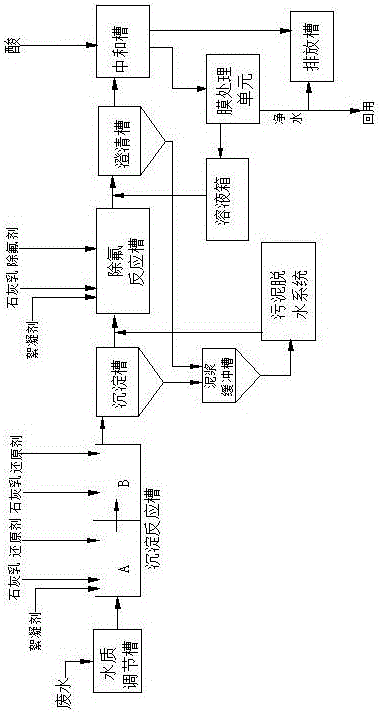

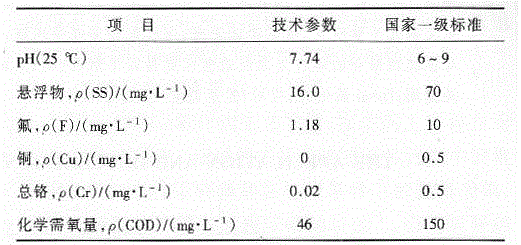

Desulfurization wastewater treatment process

InactiveCN105858960AEfficient removalEasy to handleWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWastewaterWater quality

The invention provides a desulfurization wastewater treatment process, comprising the following steps: 1) water quality adjustment tank; 2) precipitation reaction tank; 3) sedimentation tank; 4) defluorination reaction tank; 5) clarification tank; 6) neutralization tank; 7) Membrane treatment unit; 8) Discharge tank. The invention effectively removes reducing substances (COD), hexavalent chromium, fluorine ions and the like in waste water. Taking the desulfurization wastewater treatment of a power plant as an example, through the comprehensive application of neutralization and reduction processes, the effluent indicators in actual operation are lower than 100mg / L COD, hexavalent chromium is lower than 0.5 mg / L, and fluoride ion is lower than 10 mg / L. The processing process is simple and efficient, and the operation is highly automated. The desulfurization wastewater treatment capacity has reached and exceeded the design capacity.

Owner:NANJING HAIYI ENVIRONMENTAL PROTECTION ENG

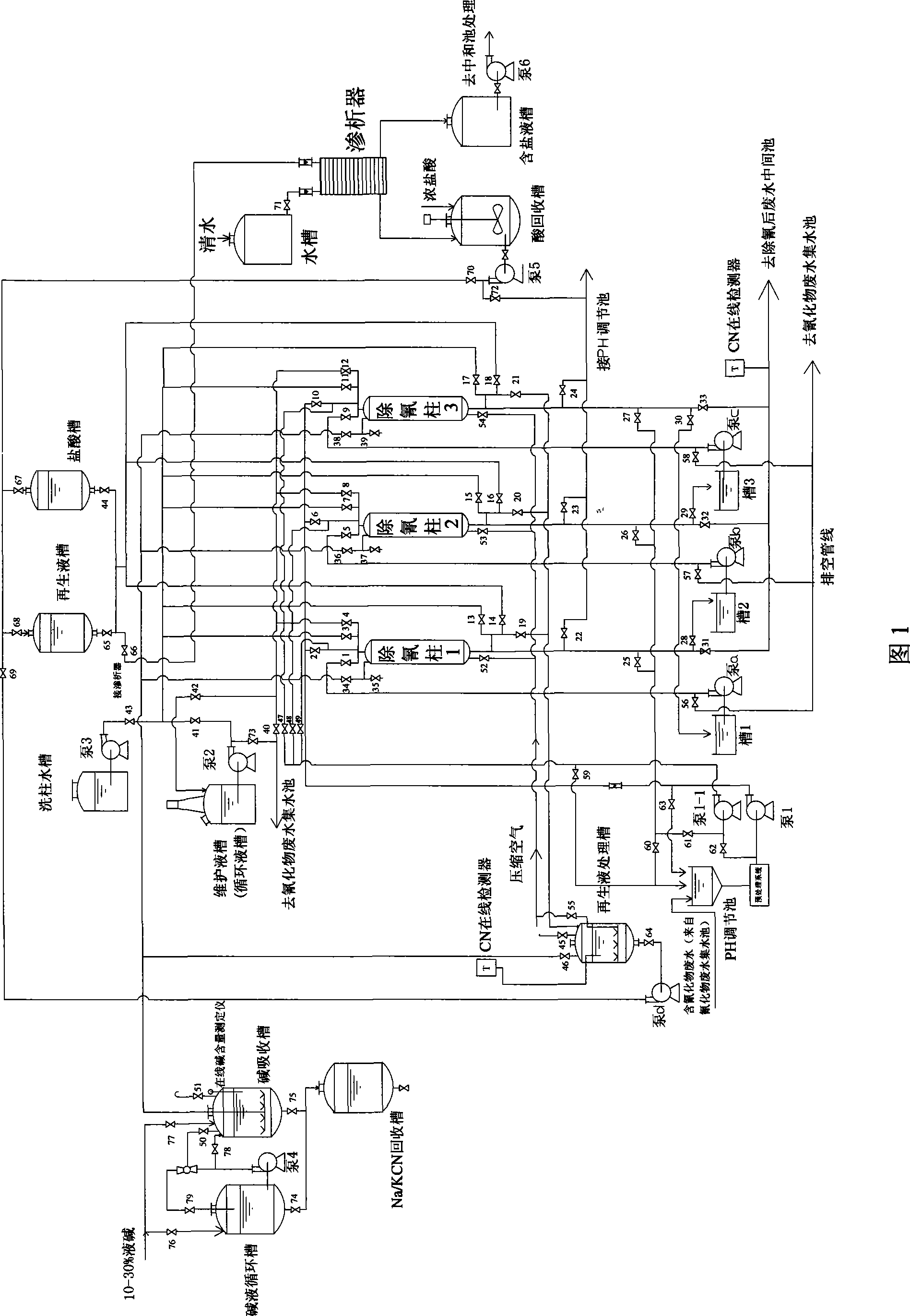

Ion exchange treatment process for cyanide containing wastewater

InactiveCN101367569AHigh degree of operation automationGood waste water treatment effectIon-exchange column/bed processesWater/sewage treatment by ion-exchangeIonIon exchange

The invention discloses an ion exchange method treatment technology of the waste water which comprises cyanide. The ion exchange method treatment technology combines the waste water pH value adjustment, absorption, regeneration and maintenance with the recovery of CN<-> ion and hydrochloric acid, realizes ion exchange automatic processing of the CN<-> ion in the waste water which comprises cyanide, has the advantages of high operation automaticity, being safe and reliable, good waste water treatment effect, being capable of recycling the cyanide, low operation cost, effective maintenance to ion exchange resin, long-term and stable working performance and so on. Compared with the chemical method to treat the waste water which comprises cyanide, the ion exchange method treatment technology has the advantages that the ion exchange method treatment technology does not need to add chemical agent in the waste water, has low salt rate in the waste water after being treated, is favor of the recycling of the waste water, and can recycle the cyanide.

Owner:SURFACE & INTERFACE CHEM ENG TECH RES CENT NANJING UNIV

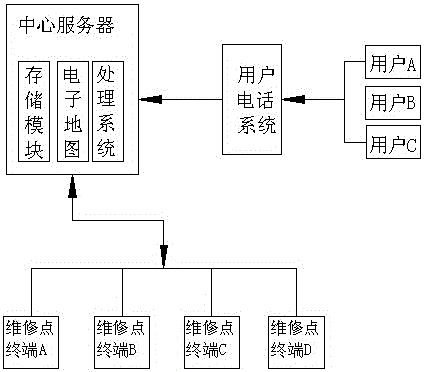

Star network topological structure and distribution network rush repair method based on star network topological structure

InactiveCN105072187AEfficient use ofImprove repair efficiencyTransmissionStructure of Management InformationComputer module

The invention discloses a star network topological structure and a distribution network rush repair method based on the star network topological structure. The star network topological structure comprises maintenance point terminals, a central server and a user telephone system, wherein the user telephone system and each maintenance point terminal are connected with the central server via a network, thereby forming the star topological structure network; the user telephone system can upload acquired repair-waiting information to each maintenance point terminal in the central server, and transmit maintenance point working condition information in to a storage module in real time via the network respectively for storage; and the central server can process repair information and perform allocation after comparison of the stored maintenance point working condition information with displayed position information. After adoption of the structure and the method, repair resources are utilized reasonably; the rush repair efficiency is increased; the rush repair cost is lowered; and the rush repair resources are utilized fully and effectively. The star network topological structure is simple in structure, high in operation automation degree and reasonable and scientific in allocation, and the maintenance cost and social resources are saved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ZHENJIANG POWER SUPPLY CO +1

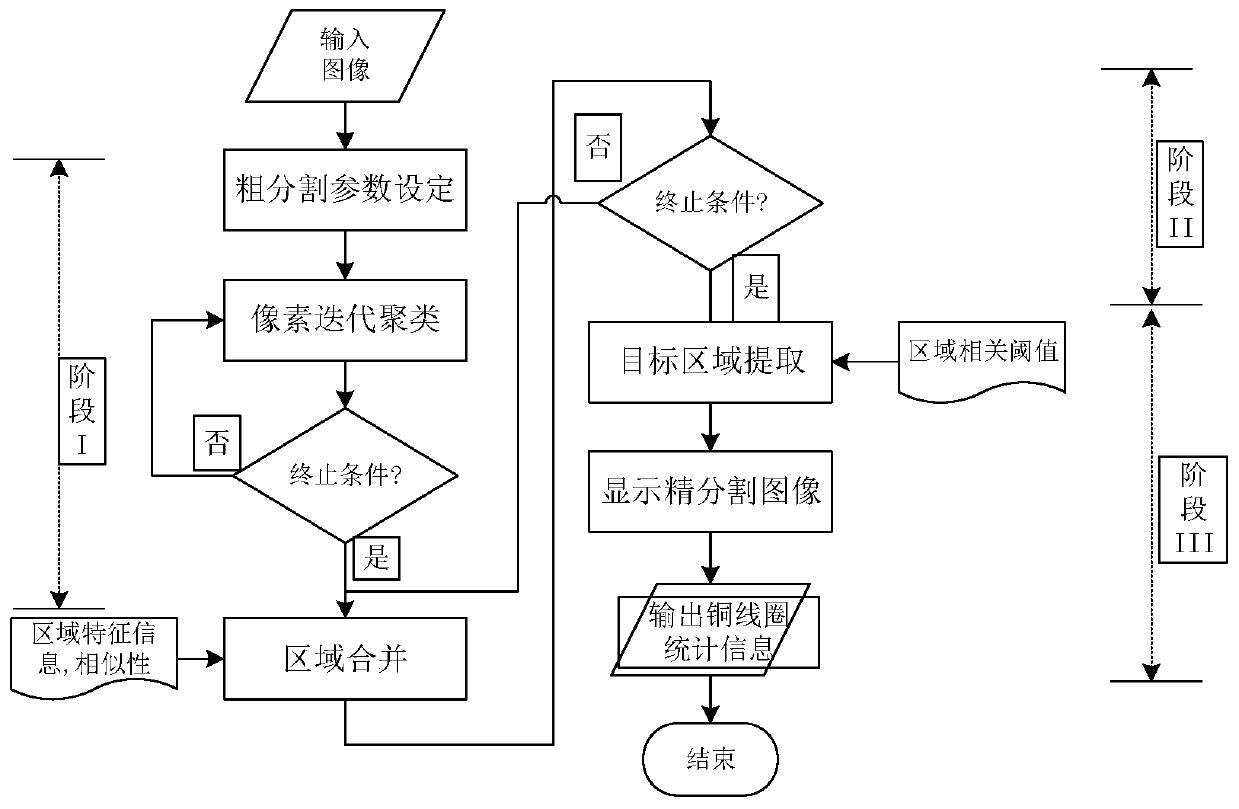

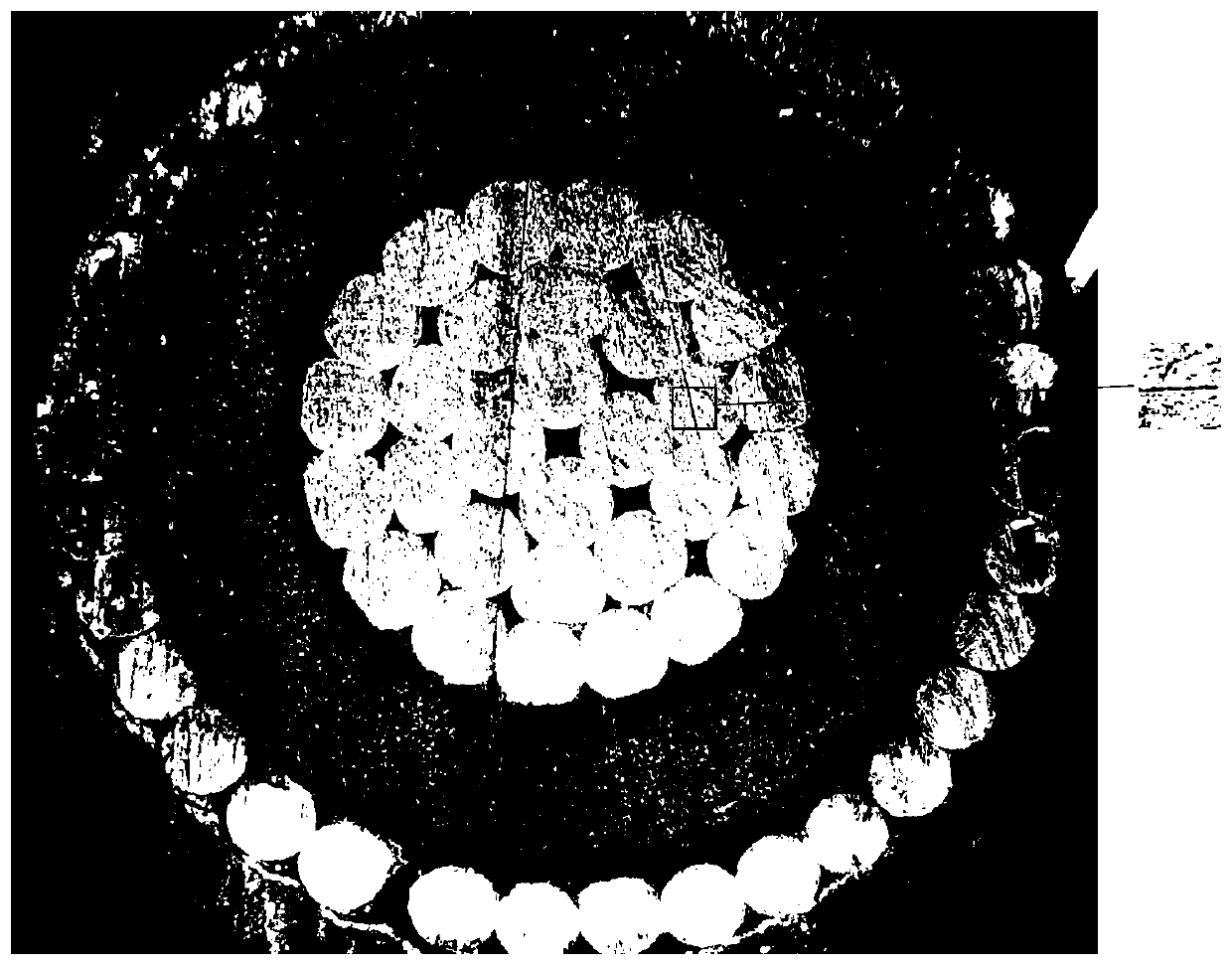

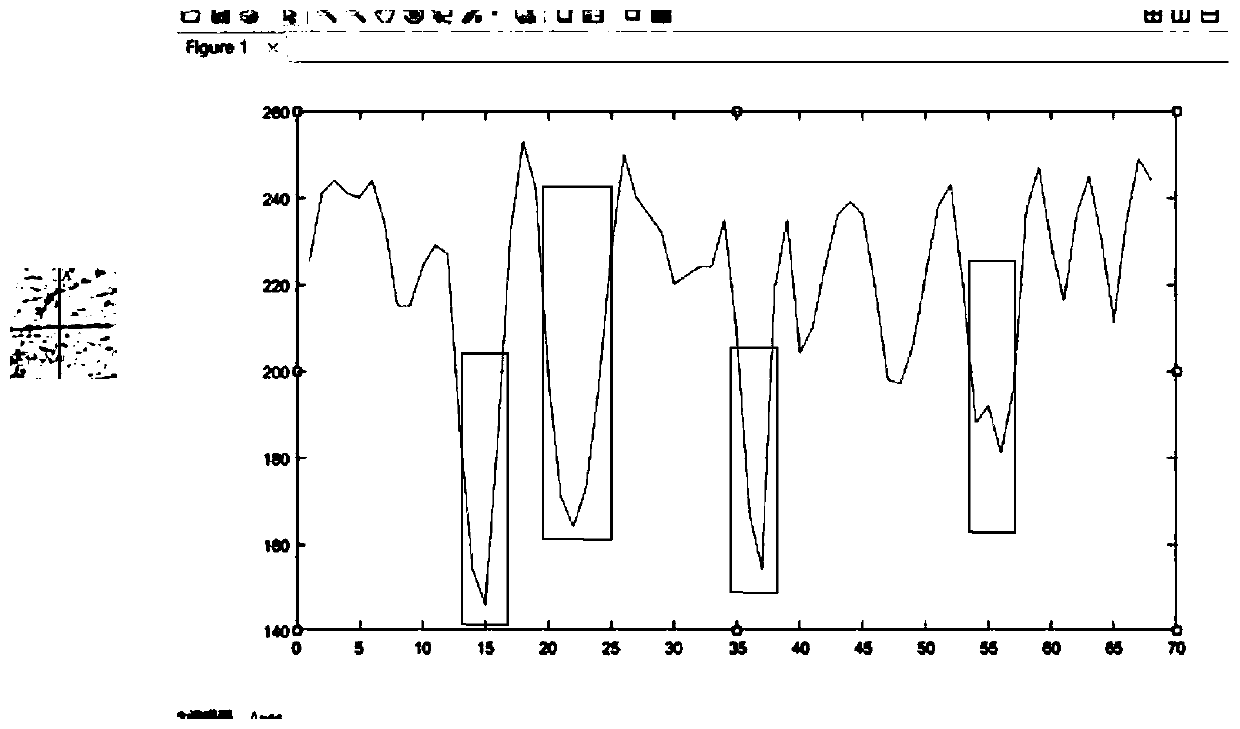

Cable conductor sectional area measuring method and system based on imaging method

ActiveCN110827311AAccurate measurementHigh degree of operation automationImage analysisCharacter and pattern recognitionThresholdingComputer science

The invention belongs to the technical field of cable detection, and discloses a cable conductor sectional area measurement method and system based on an imaging method, and the method comprises the steps: carrying out the initial segmentation of a local region of a detected cable end face image through self-iteration clustering; carrying out homogeneous region merging by using the feature information of each region after segmentation to obtain an accurate segmentation result; extracting a target area based on the area correlation threshold, obtaining a fine segmentation image of the cable conductor, and obtaining the number of pixels occupied by the cable conductor based on the fine segmentation image; obtaining a measured value of the sectional area of the measured cable conductor according to the number of pixels and the number of pixels corresponding to the unit area of the cable conductor, wherein the pixel number corresponding to the unit area is obtained by using a standard workpiece with a known size as a measurement target to accurately measure the pixel number. The measurement method has the advantages of no damage, no contact, high detection speed and high automation degree, realizes accurate measurement of the effective sectional area of the end surface of the cable, and can be applied to conductor sectional area measurement of various types of cables.

Owner:中铁十一局集团电务工程有限公司 +2

Winding device for textile thread processing

InactiveCN112537699AEasy winding handlingContinuous and efficient winding operationFilament handlingEngineeringStructural engineering

The invention discloses a winding device for textile thread processing. The winding device comprises a thread guiding mechanism, a locking mechanism, a rotating frame and a conveying belt device, a second sliding block is slidably connected into the rotating frame, a clamping plate is slidably connected into the second sliding rail, and the conveying belt device is rotatably connected between supporting plates. According to the winding device for textile thread processing, the front half part of the conveying belt device is used for conveying empty winding reels, and the rear half part of theconveying belt device is used for conveying the winding reels wound with threads; hook-and-loop fasteners are fixed to the surfaces of the outer sides of the winding reels, and after one ends of the textile threads manually penetrate through a thread guide barrel to adhere to one winding reel on the left side of the upper end face of a rotating table, the winding reel rotates so that the textile threads can be conveniently wound; after one reel of textile threads is wound, the rotating table horizontally rotates by 180 degrees, so that the textile threads adhere to the other winding reel; andafter the textile threads are cut off through shear knives, winding operation can be continued to be conducted by the other winding reel, and therefore the whole winding operation is continuous and efficient.

Owner:徐州银宇纺织有限公司

Novel fully-automatic and intelligent article storage cabinet

Owner:SUZHOU HEMEI ELECTRIC APPLIANCE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com