Closed type printing and dyeing waste water processing system

A printing and dyeing wastewater and treatment system technology, which is applied in textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of insufficient understanding of the nature of printing and dyeing wastewater, improper operation technology and management technology, and unstable operation and other problems, to achieve the effect of low investment and operation cost, high efficiency and reliability, and short hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

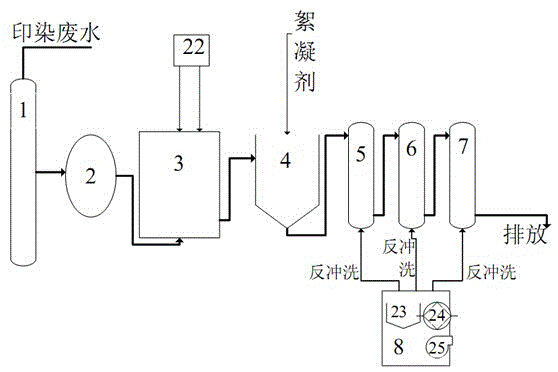

[0017] A closed printing and dyeing wastewater treatment system, which includes a filter 1, a reservoir 2, a regulating tank 3, a reaction tank 4, a quartz sand filter tank 5, an activated carbon filter tank 6, a suspended filler filter tank 7, and a backwash room 8. External automatic dosing machine 22, blower 25, backwash pump 24, clean water tank 23. The printing and dyeing wastewater is discharged into the inlet of filter 1 through a pipe connection, the outlet of filter 1 is connected to the inlet of reservoir 2 through a pipe, and the outlet of reservoir 2 is connected to the inlet of regulating tank 3 through a pipe. The water outlet of 3 is connected to the water inlet of the reaction tank through a pipe, the water outlet of the reaction tank 4 is connected to the water inlet of the quartz sand filter tank 5 through a pipe, and the water outlet of the quartz sand filter tank 5 is connected to the water inlet of the activated carbon filter tank 6 through a pipe. The wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com