Method for measuring benzene and benzene series in printing ink

A printing ink and measuring method technology, applied in the field of chemical analysis and detection, to achieve the effect of high degree of automation, good repeatability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

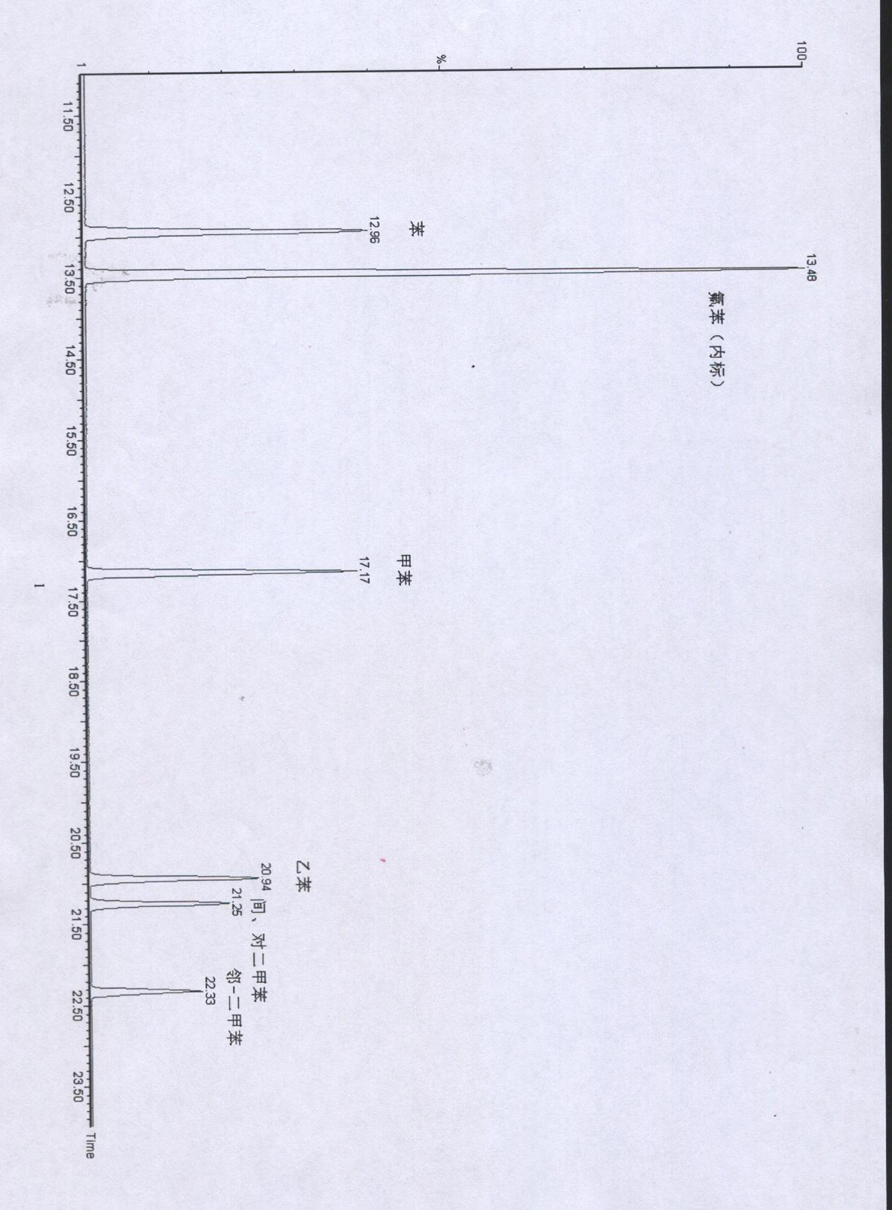

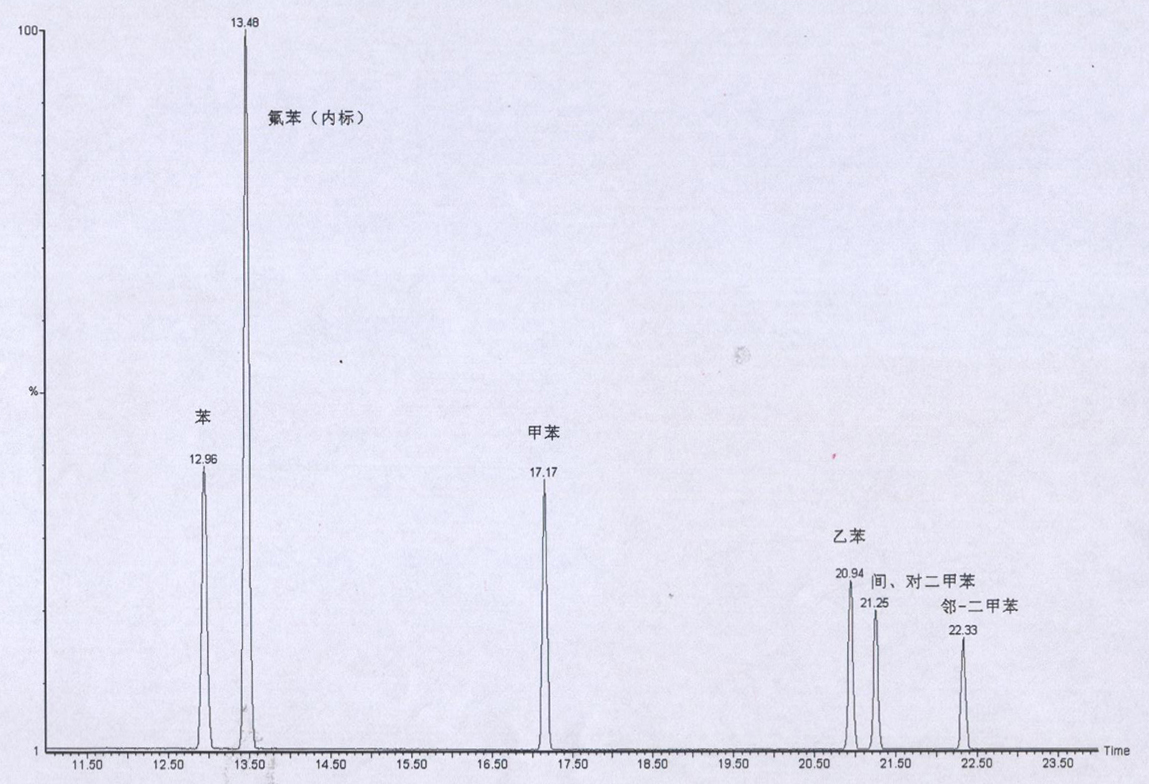

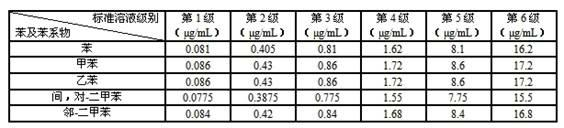

Image

Examples

Embodiment 1

[0048]In the assay method of the present embodiment: select a portion of red ink for gravure printing as sample A, the internal standard solution is a glycerol triacetate solution of fluorobenzene with a mass percent concentration of 0.45 μg / mL, and the headspace of the sample and the standard sample The treatment temperature was 80°C, and the shaking equilibrium time was 30 minutes. The results of the measurement are shown in Table 5.

[0049] Table 5 Detection results of benzene and benzene series in printing ink sample A

[0050]

Embodiment 2

[0052] In the assay method of the present embodiment: a black ink for gravure printing is selected as sample B, and the internal standard solution is a glycerol triacetate solution of fluorobenzene with a mass percent concentration of 0.30 μg / mL. The treatment temperature was 85°C, and the shaking equilibrium time was 40 minutes. The results of the measurement are shown in Table 6.

[0053] Table 6 Detection results of benzene and benzene series in printing ink sample B

[0054]

Embodiment 3

[0056] In the assay method of the present embodiment: a portion of UV black ink is selected as sample C, and the internal standard solution is a glycerol triacetate solution of fluorobenzene with a concentration of 0.45 μg / mL in mass percent, and the headspace treatment temperature of the sample and the standard sample The temperature is 80°C, and the shaking equilibrium time is 30 minutes. The measured results are shown in Table 7.

[0057] Table 7 Detection results of benzene and benzene series in printing ink sample C

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com