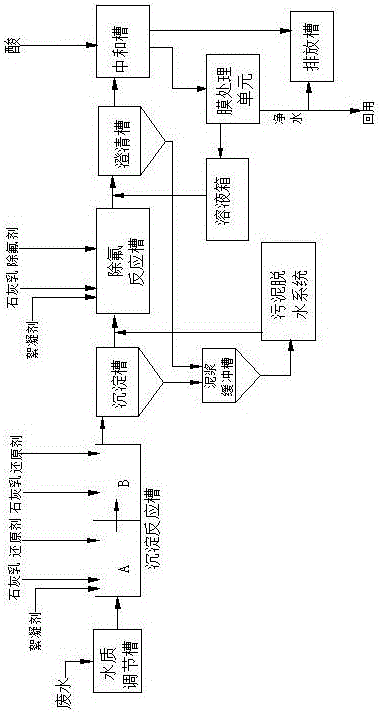

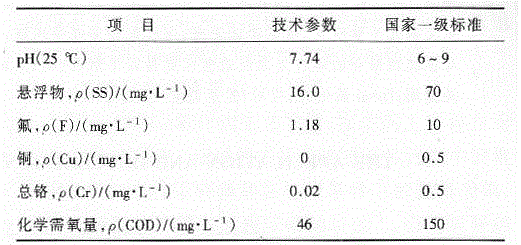

Desulfurization wastewater treatment process

A technology for desulfurization wastewater and treatment process, applied in the field of water treatment, can solve the problems of blockage, reduction, rapid evaporation and crystallization, and achieve the effect of high degree of automation of operation and simple and efficient treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A desulfurization wastewater treatment process includes the following steps:

[0031] 1) The desulfurization wastewater flows into the water quality adjustment tank to buffer, and then is pumped into the precipitation reaction tank by the waste water pump; the water quality adjustment tank is equipped with a level gauge, and the start and stop of the waste water pump and the opening of the flow adjustment valve are controlled according to the level of the water quality adjustment tank , So that the wastewater enters the precipitation reaction tank at a relatively constant flow rate.

[0032] 2) After the desulfurization wastewater flows from the water quality adjustment tank to the precipitation reaction tank, add lime milk to the precipitation reaction tank to precipitate heavy metal ions to form insoluble hydroxides, and then add a reducing agent to reduce the hexavalent chromium to trivalent chromium here . Trivalent chromium combines with hydroxide to form chromium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com