Technology and device for full automatic cloth-free wrapping-twisting of oolong tea

A fully automatic, oolong tea technology, applied in the direction of tea processing before extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

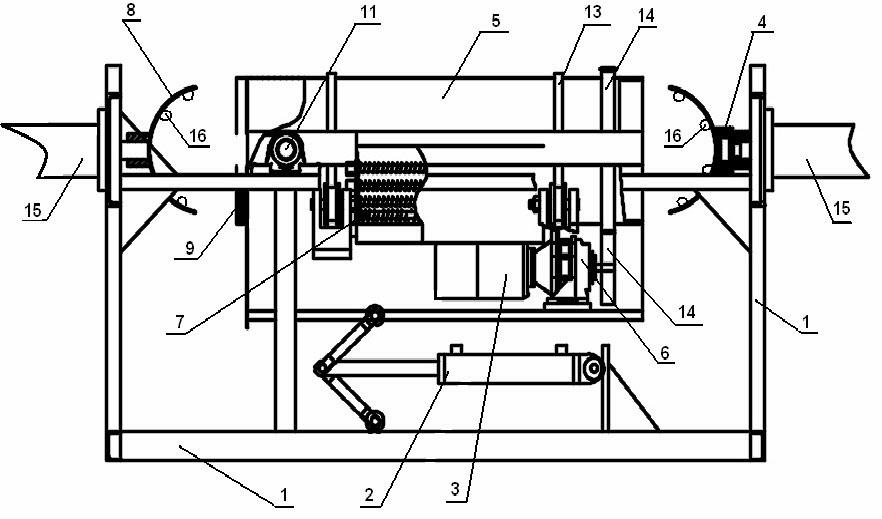

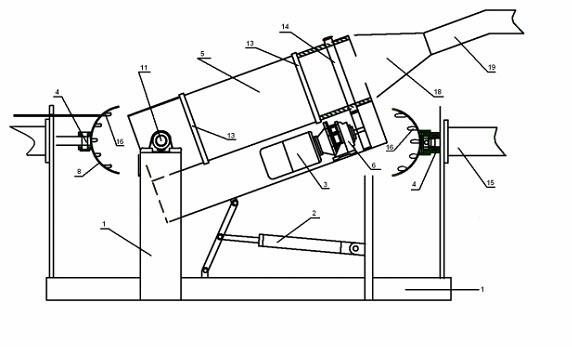

[0033] refer to Figure 1 to Figure 5 , a fully automatic oolong tea wrapping and kneading equipment without cloth, the equipment consists of a base 1, a lifting device 2, a motor and a transmission mechanism 3, a hydraulic device 4, a roller device, a guide wheel device 6, a temperature control heating device 7, and a kneading head Device, automatic door device 9 forms.

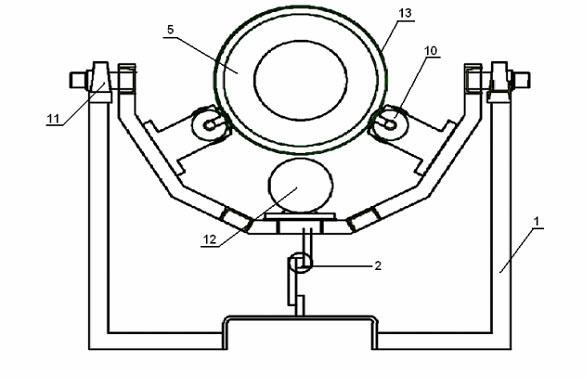

[0034] The roller device includes a roller 5 and two pairs of roller support wheels 10. The roller is the main place for kneading and is installed on the support 1 assembly. One end of the roller 5 shaft is fixed on the support to rotate the shaft 11; the support 1 assembly can The rotation of the radial horizontal center line of the cylinder 5 can also change the axial inclination angle of the cylinder. When feeding tea green leaves, the support 1 assembly can move 0-20° inclination around the radial horizontal center line of the drum 5, so that the upper port of the drum 5 is upwardly fed into the leaves;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com