Touch screen type plasma spraying system

A plasma and touch screen technology, applied in coating, fusion spraying, metal material coating process, etc., can solve problems such as poor safety performance, safety accidents, easy hydrogen backflow, etc., so that it is not easy to misuse and reduce the probability of damage , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

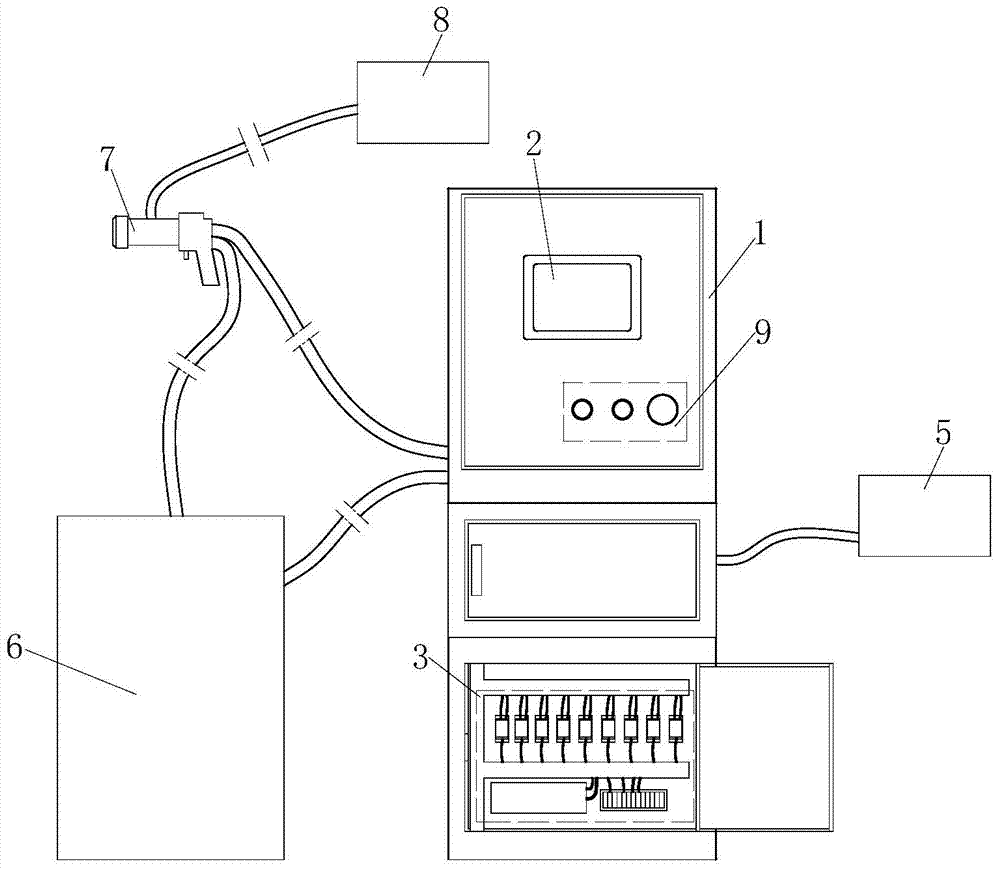

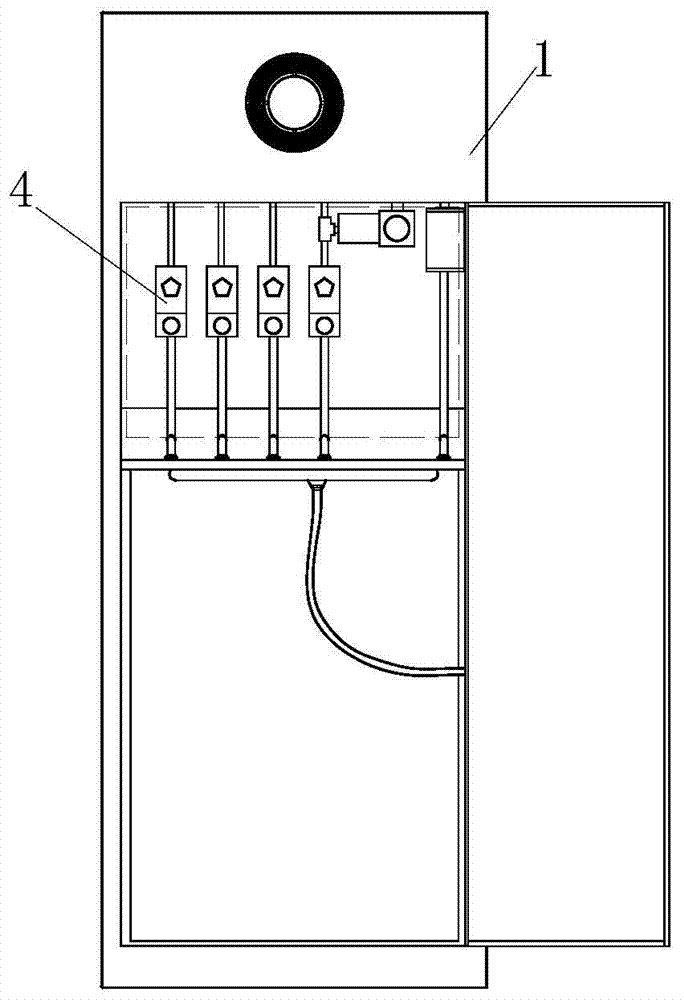

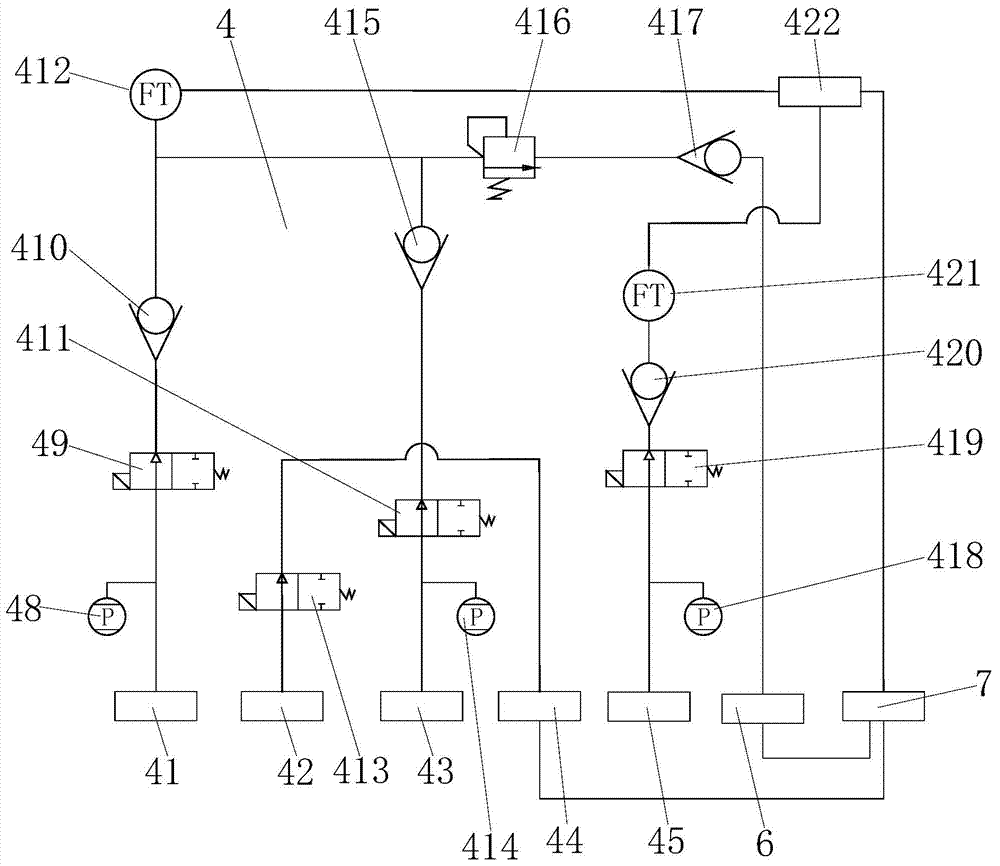

[0039] Such as Figure 1 to Figure 5 As shown, a touch-screen plasma spraying system includes a control cabinet 1, a touch screen 2, a manual control knob 9, a monitoring circuit 3, an actuator 4, a gas tank set 5, a powder feeder 6, a spray gun 7 and a chiller 8 , the monitoring circuit 3 is installed at the lower end of the control cabinet 1, and is connected with the touch screen 2, the manual control knob 9, the actuator 4, the powder feeder 6 and the chiller 8 through wires, and the monitoring circuit 3 includes a power supply circuit 31, a gas circuit Control module 32, air pressure analog quantity acquisition circuit 33, airflow analog quantity acquisition circuit 34 and man-machine interaction interface module 35, described monitoring ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com