Sintering process of separating red mud for alumina production

A separation method and sintering method, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of low dissolution rate, large secondary reaction loss, long contact time, etc. The effect of a short separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

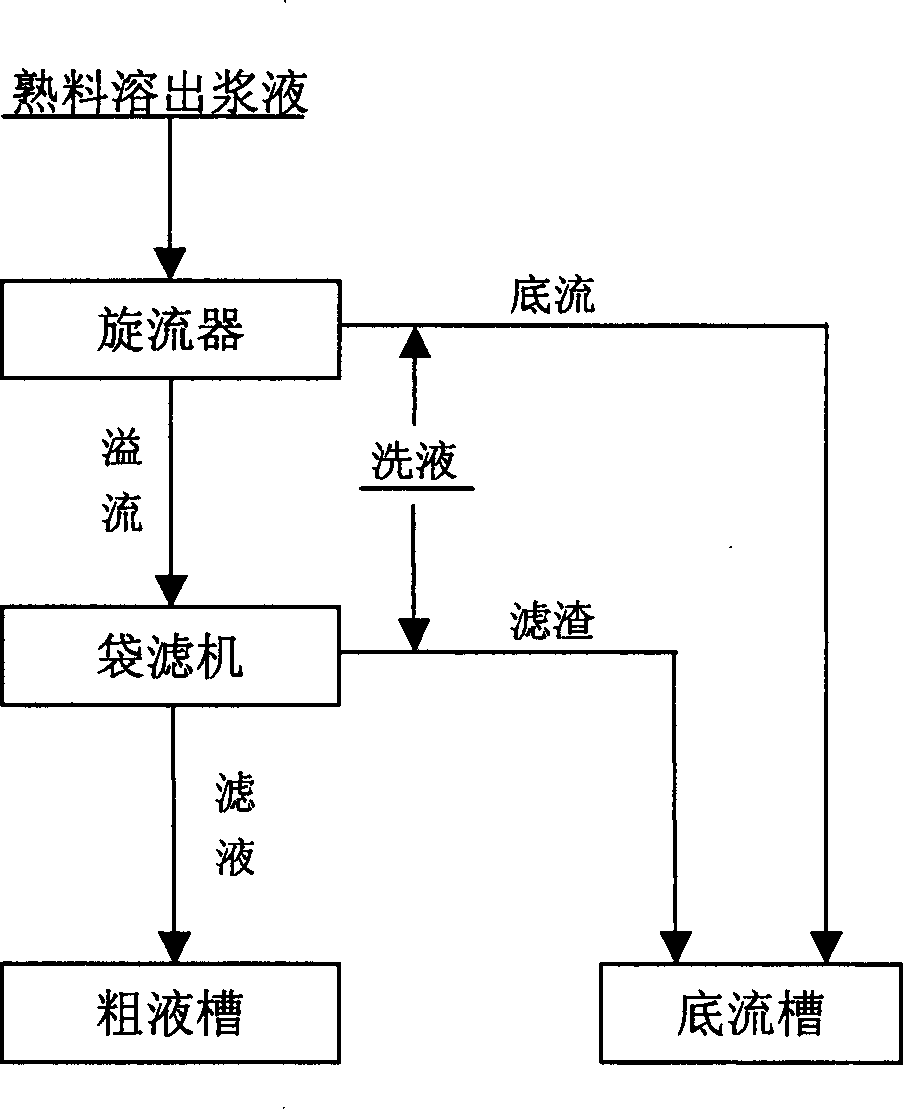

[0008] Embodiment of the present invention: the clinker dissolution slurry from the clinker dissolution process is sent to the cyclone for cyclone classification, and the feed pressure of the cyclone is controlled between 0.245 and 0.255Mpa to make the coarse particle high solid slurry Excluded from the bottom flow port of the cyclone, washed into the bottom flow tank with washing liquid; the fine particle low solid slurry enters the bag filter, and the red mud is separated from the solution through the filter cloth (polypropylene cloth), and the separated filter residue is washed into the bottom flow tank with washing liquid The bottom flow tank, the filtrate enters the crude liquid tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com