Solid-liquid separation method for Pichia pastoris fermentation broth

A Pichia pastoris, solid-liquid separation technology, applied in the field of separation and purification of Pichia pastoris expression recombinant protein fermentation liquid, can solve the problems of difficult removal of bacteria, high cost of solid-liquid separation, suitable for industrial production, and reduce the purification process Effect of pressure and easy solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (comparative example)

[0034] Using our own strains and fermentation technology to produce recombinant human serum albumin in a 100L fermenter, the OD600 of the fermentation broth was measured to be 421, and the target protein content in the supernatant was detected after centrifugation. 1 9.5g / L, after dilution, detect C2 is 3.5g / L, and the calculated bacterial cell concentration p is 41.7%.

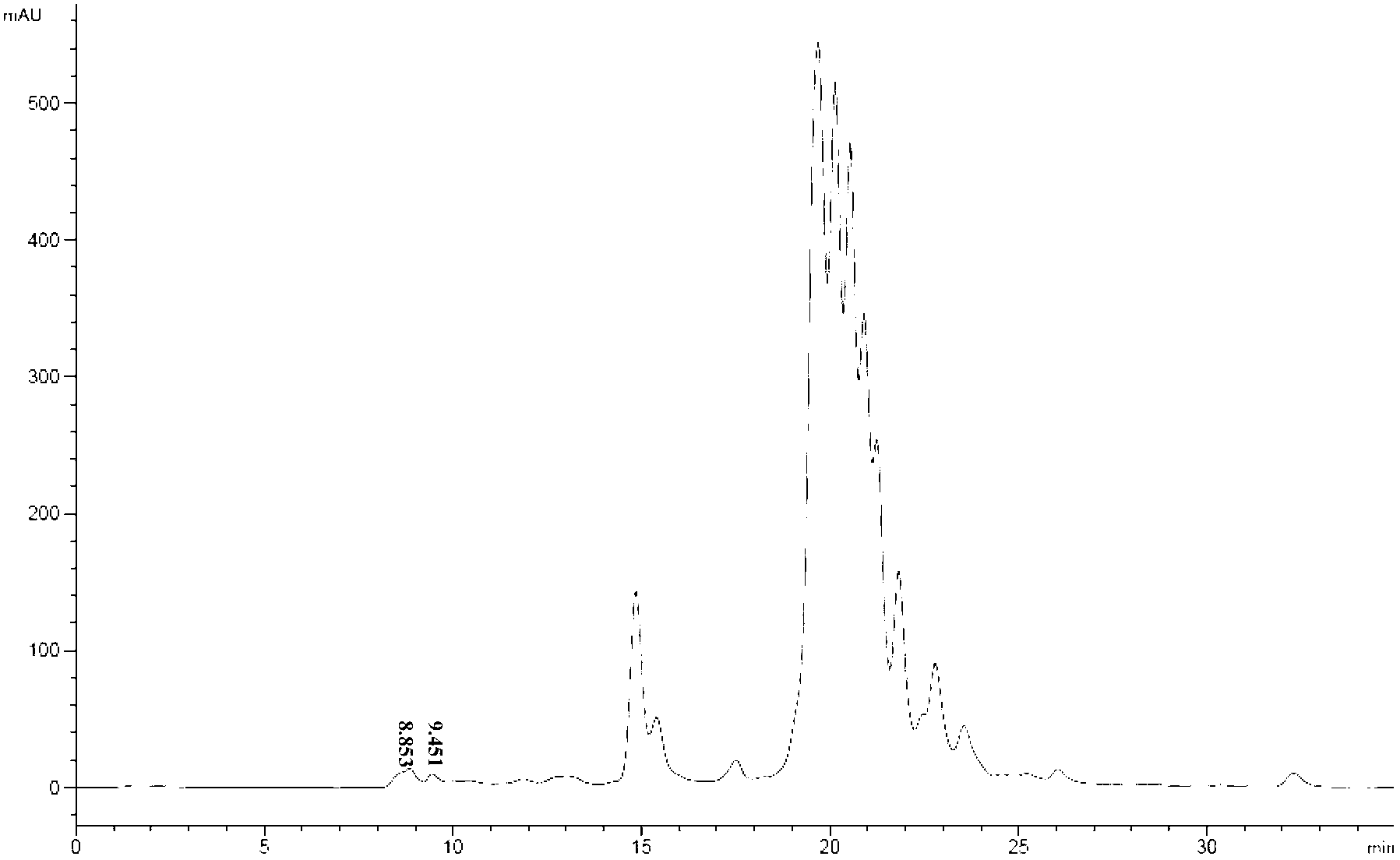

[0035] After the fermentation, take 400ml of recombinant human albumin fermentation liquid (calculated total protein is 2.2g), put it in a centrifuge cup, centrifuge at 10000rpm in a Beckman centrifuge at 4°C for 5min, obtain 210ml of supernatant, and detect the supernatant Protein content is 8.1g / L (protein total amount is 1.70g) in the liquid, and macromolecule impurity content is 7.5% (attached figure 1 RT=8.853 and 9.451 two impurity peaks), the OD600 of the fermentation broth after centrifugation was 22.3, the calculated bacterium removal rate was 94.7%, and t...

Embodiment 2

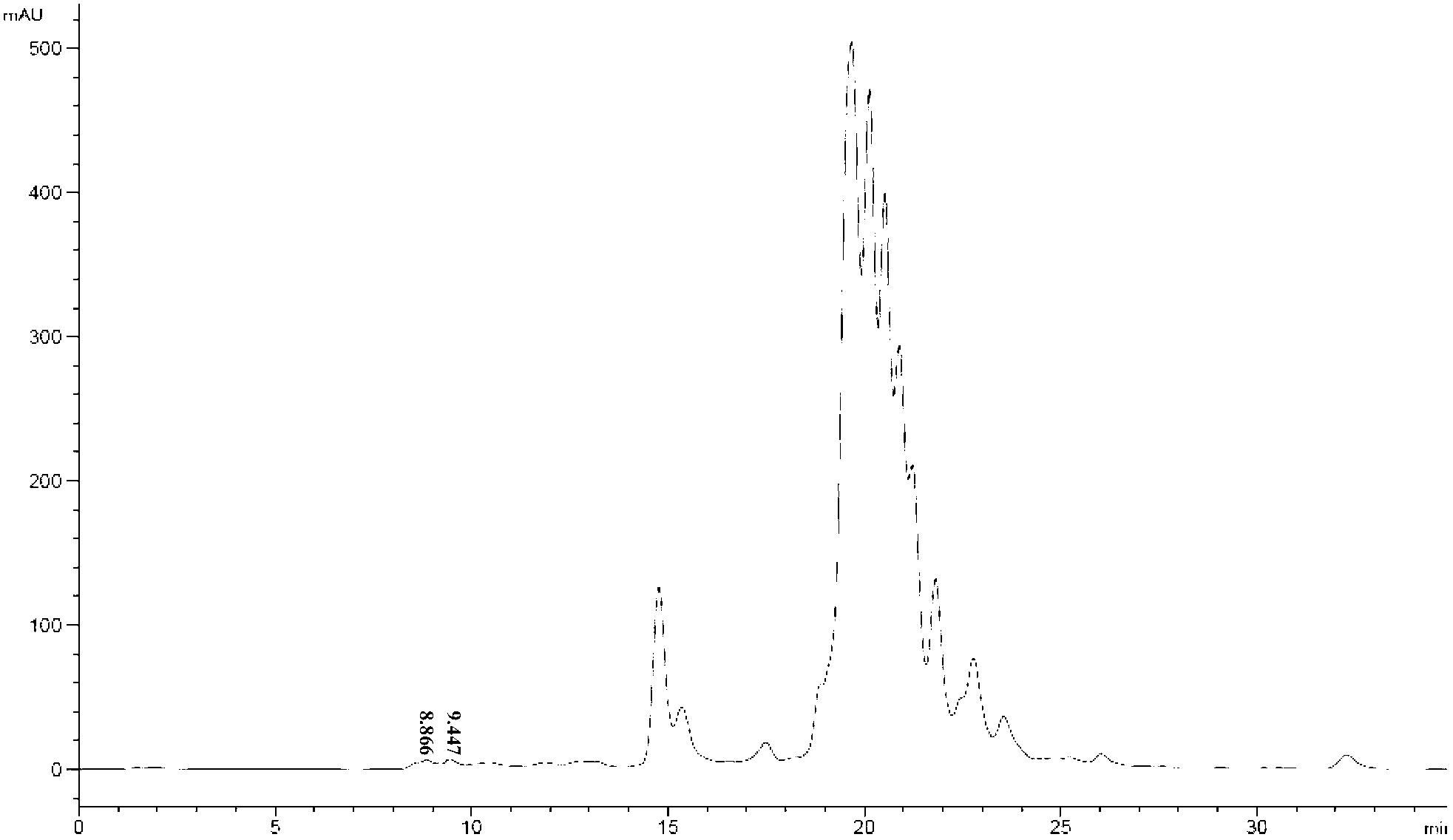

[0037] 0.176g chitosan is dissolved in the acetic acid solution of 39.6ml 1%, then adds 0.4ml dehydrated alcohol, stirs, then joins in the 400ml recombinant human albumin fermented liquid described in embodiment 1, controls operating temperature Stir at 15°C for 30 minutes, add sodium bicarbonate, adjust the pH to 9.5, and stir to flocculate chitosan.

[0038] The above mixed solution was placed in a centrifuge cup, centrifuged at 10000rpm in a Beckman centrifuge at 4°C for 5min to obtain 250ml of supernatant, and the protein content in the supernatant was detected to be 7.06g / L (the total amount of protein was 1.765g). The high molecular impurity content was 3.0%, the OD600 of the fermented liquid after centrifugation was 2.8, the calculated cell removal rate was 99.3%, and the protein recovery rate was 80.2%.

Embodiment 3

[0040] 0.44g chitosan was dissolved in 40ml 1% acetic acid solution, then added in the 400ml recombinant human albumin fermentation broth described in Example 1, controlled operating temperature 15°C, stirred for 30min, added sodium carbonate, adjusted pH To 8.5, stir to flocculate the chitosan.

[0041] The above mixed solution was placed in a centrifuge cup, centrifuged at 10000rpm in a Beckman centrifuge at 4°C for 5min to obtain 250ml of supernatant, and the protein content in the supernatant was detected to be 7.2g / L (the total amount of protein was 1.8g). The high molecular impurity content was 3.3%, the OD600 of the fermented liquid after centrifugation was 1.1, the calculated cell removal rate was 99.7%, and the protein recovery rate was 81.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com