Patents

Literature

120 results about "Industrial enzymes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial enzymes are enzymes that are commercially used in a variety of industries such as pharmaceuticals, chemical production, biofuels, food & beverage, and consumer products. Due to advancements in recent years, biocatalysis through isolated enzymes is considered more economical than use of whole cells. Enzymes may be used as a unit operation within a process to generate a desired product, or may be the product of interest. Industrial biological catalysis through enzymes has experienced rapid growth in recent years due to their ability to operate at mild conditions, and exceptional chiral and positional specificity, things that traditional chemical processes lack. Isolated enzymes are typically used in hydrolytic and isomerization reactions. Whole cells are typically used when a reaction requires a co-factor. Although co-factors may be generated in vitro, it is typically more cost-effective to use metabolically active cells.

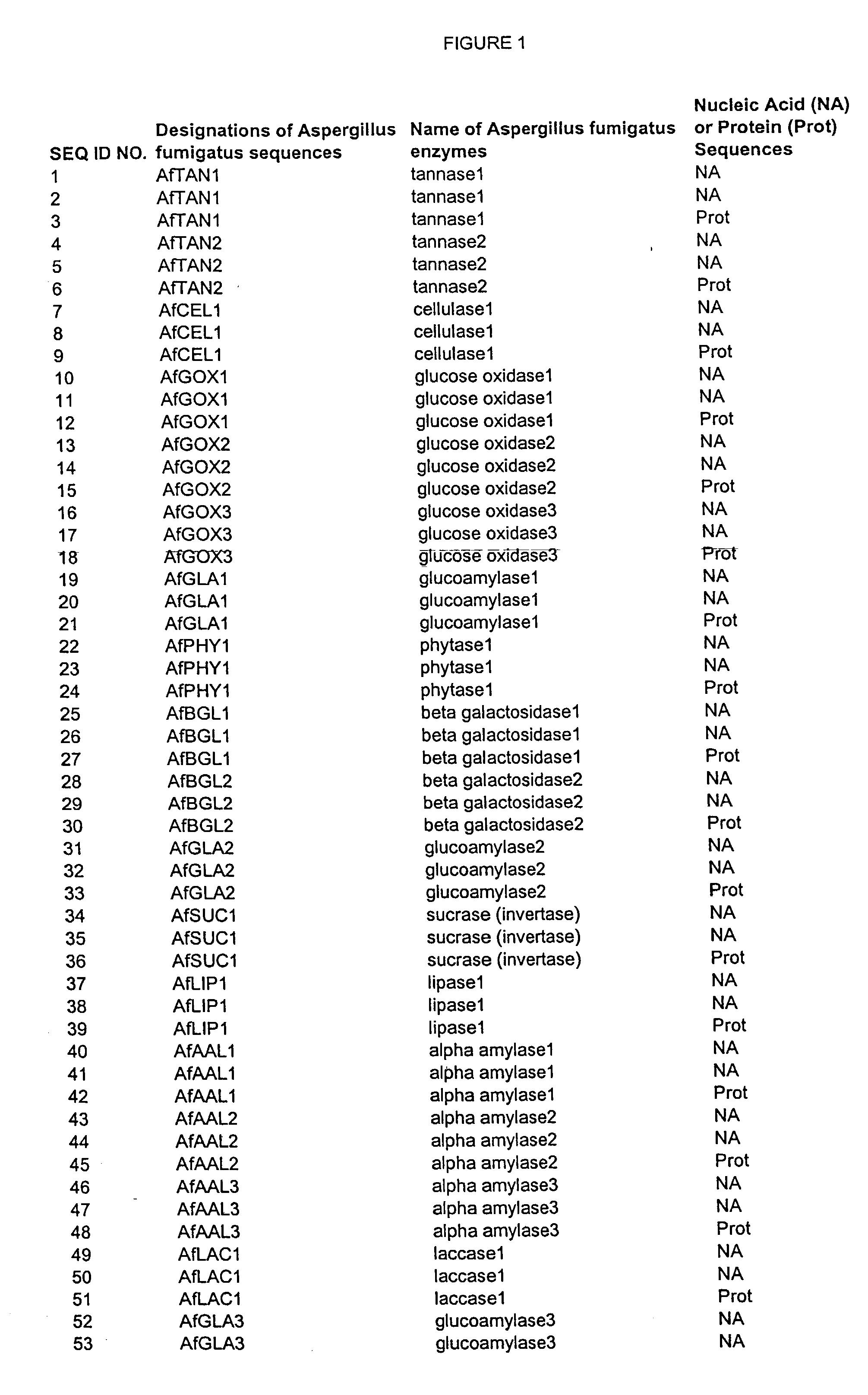

Nucleic acids of aspergillus fumigatus encoding industrial enzymes and methods of use

The present invention provides nucleotide sequences of Aspegillus fumigatus that encode proteins which exhibit enzyme activities. Vectors, expression constructs, and host cells comprising the nucleotide sequences of the enzyme genes are also provided. The invention further provides methods for producing the enzymes, and methods for modifying the enzymes in order to improve their desirable characteristics. The activities displayed by the enzymes of the invention include those of a tannase, cellulase, glucose oxidase, glucoamylase, phytase, beta-galactosidases, invertase, lipase, alpha-amylase, laccase, polygalacturonase or xylanase. The enzymes of the invention can be used in a variety of industrial processes. Enzymatically active compositions in various forms as well as antibodies to the enzymes and fragments thereof, are also provided.

Owner:MERCK & CO INC

Enhancement of industrial enzymes

InactiveUS6274178B1Improve usabilityImproved animal fodderAnimal feeding stuffAccessory food factorsIndustrial enzymesMicrowave irradiation

A method for enhancing or increasing the metabolisable dietary content of a plant-based animal feed, the method comprising reacting the feed with an enzyme capable of releasing a metabolisable dietary component from the feed under the influence of microwave irradiation such that the metabolisable dietary content of the feed is enhanced or increased.

Owner:CELLENCOR INC

Nicotinamide ribokinase mutant and application thereof

ActiveCN110373398AMild reaction conditionsStable energy cycle systemTransferasesFermentationSingle mutationNicotinamide mononucleotide

Owner:JIANGSU CHENGXIN PHARMA

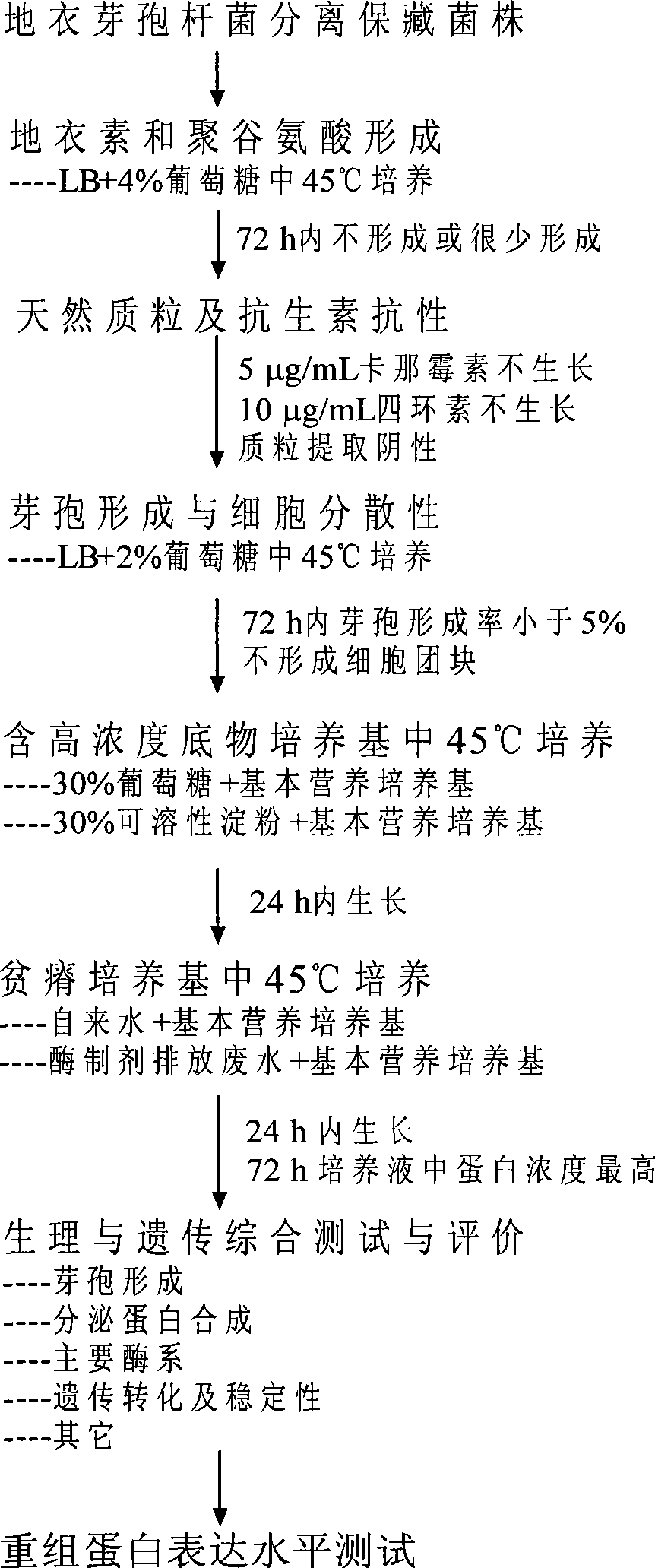

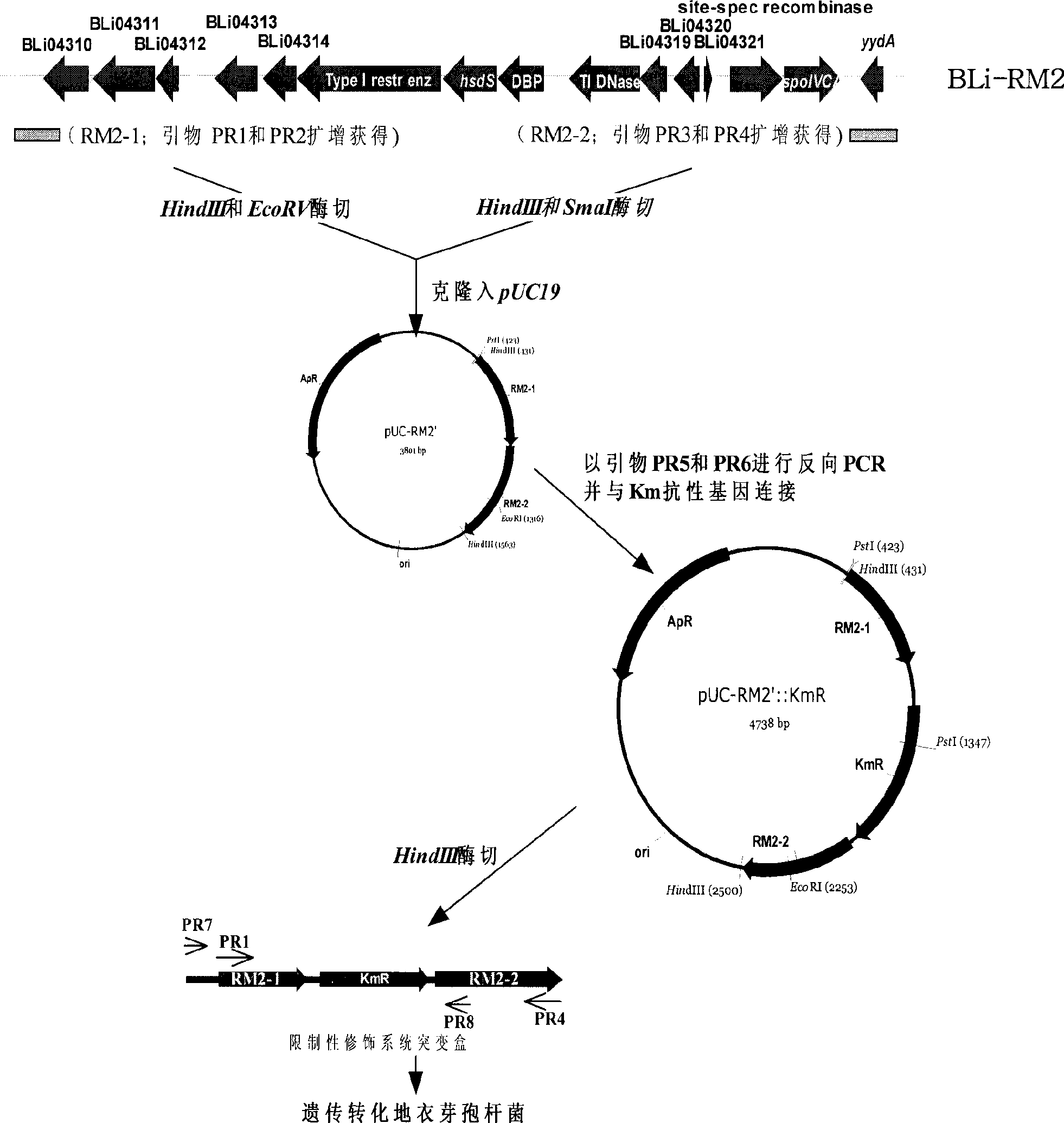

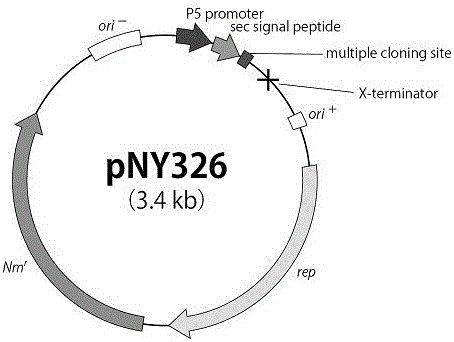

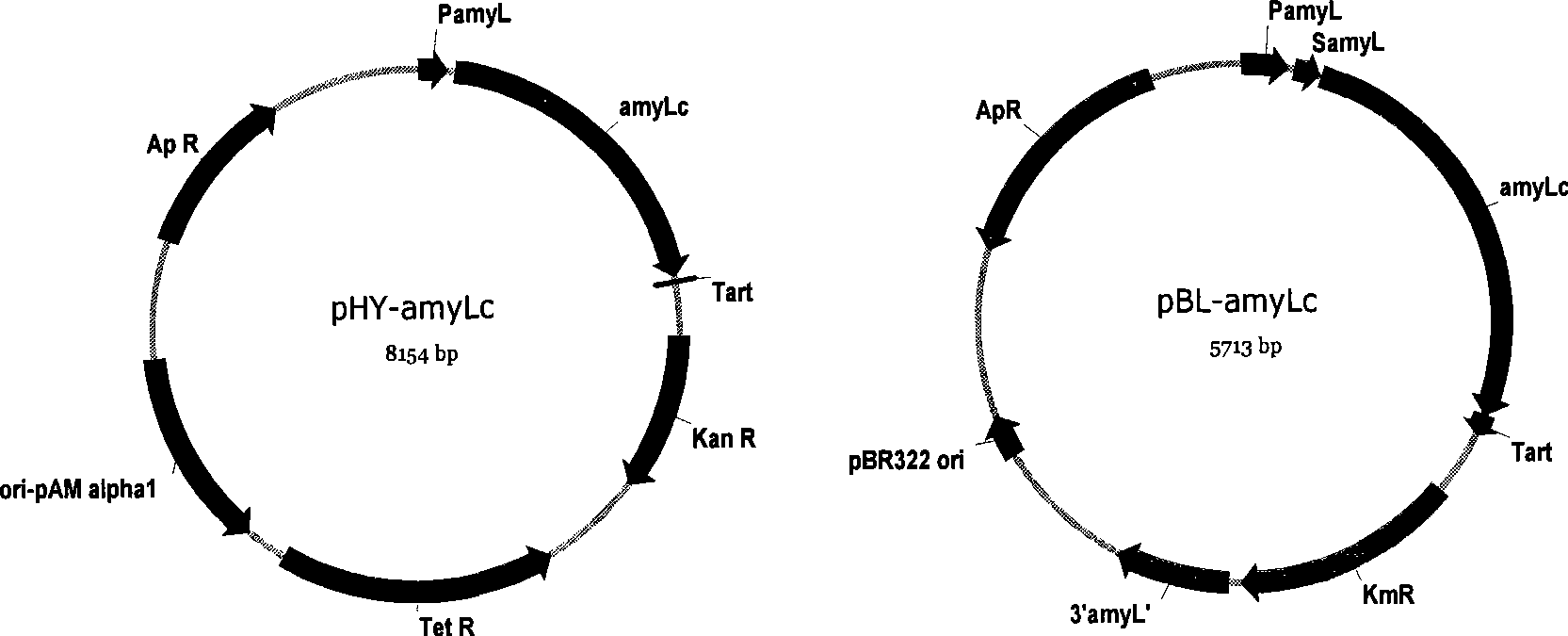

Host cell and method for efficient expression and secretion thereof in recombinant protein

ActiveCN101418276AHighly secreted expressionLower Fermentation Manufacturing CostsBacteriaHydrolasesBacillus licheniformisBacillus megaterium

The invention relates to a host cell and a method for the host cell applied in efficient secretion expression of a recombinant protein, which belongs to the filed of microbiological engineering and fermentation engineering. The invention provides a bacillus licheniformis host cell CBB3008 which is preserved in the China Center for Type Culture Collection with the preserving number of CCTCC NO: M 208236. The invention transforms an expression plasmid of an industrial enzyme which is obtained by a gene cloning technology into the host cell to synthesize an industrial enzyme preparation in the host cell efficiently, and then secretes the synthesized enzyme protein into a culture medium efficiently through a protein secretion system of the host cell, thus the invention can guide efficient secretion production of the industrial enzyme preparation. Therefore, the invention is helpful to reduce the fermentative production cost of the industrial enzyme preparation, simplify the fermentative production process and reduce the environmental pressure of the fermentation industry. A method for host cell screening and genetic improvement of the invention can also be used for other types of host cells, in particular for the breeding of the host cells of bacillus subtilis, bacillus megaterium, bacillus pumilus, bacillus starch solution and the like.

Owner:福建福大百特生物科技有限公司

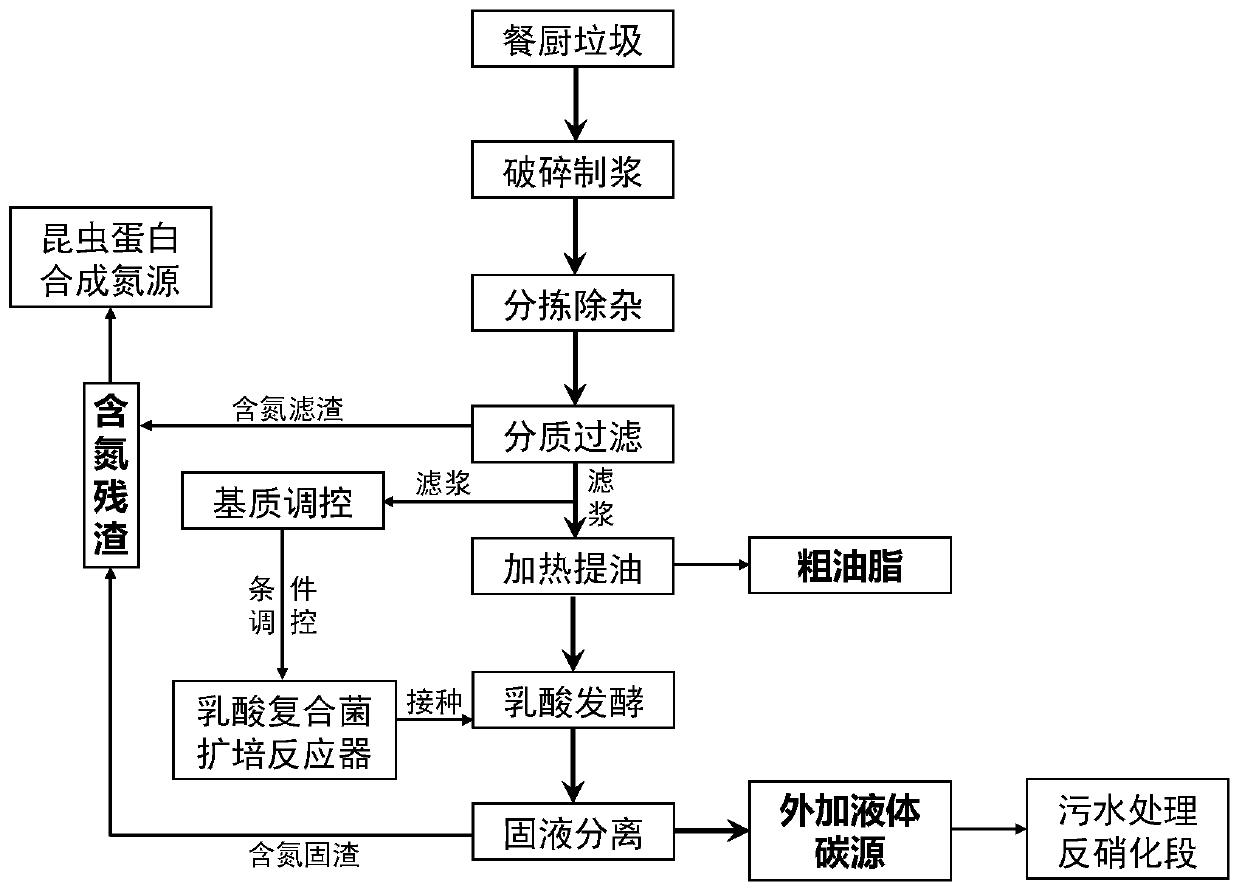

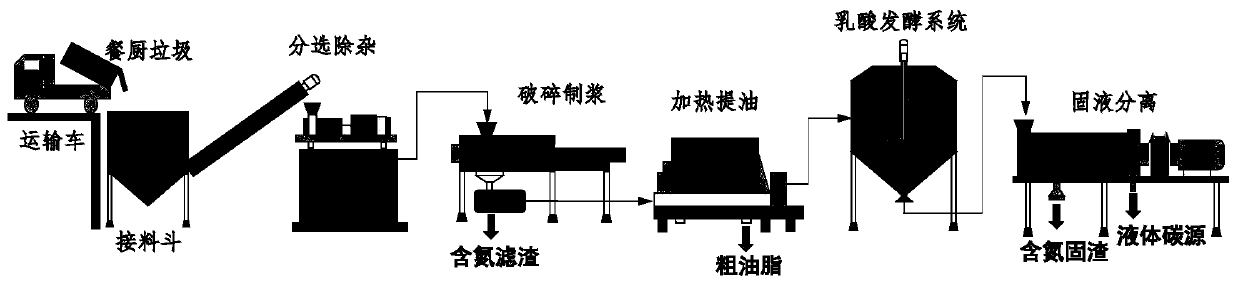

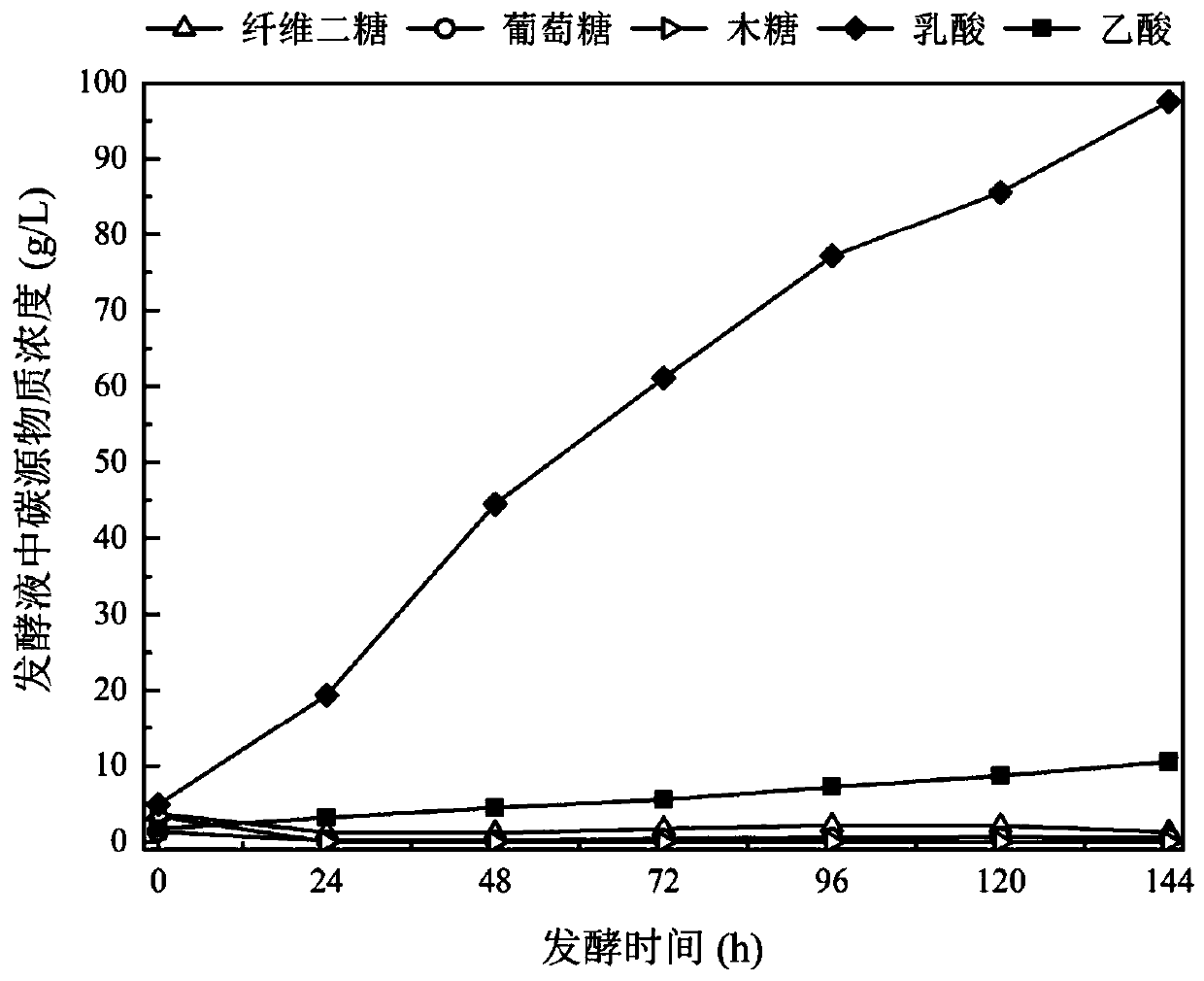

Method for producing wastewater denitrification carbon source through lactic acid fermentation of kitchen waste

ActiveCN111333179ASolve the problem of low COD/TNEfficient resource utilizationWater treatment compoundsTreatment with anaerobic digestion processesNutritionWaste oil

The invention discloses a method for producing a wastewater denitrification carbon source through lactic acid fermentation of kitchen waste, and belongs to the technical field of solid waste resourceful treatment. The method comprises the steps of adopting kitchen waste as a raw material; sorting and impurity removal, controlling the solid-to-liquid ratio, grinding, pulping, and carrying out quality-based and phase-splitting treatment; after the waste oil is heated and recycled, the residual garbage slurry is injected into an anaerobic fermentation tank for batch lactic acid fermentation, after fermentation is finished, solid-liquid separation is carried out, lactic acid-containing supernatant can be directly used as a liquid carbon source in the sewage denitrification stage, a good biological denitrification effect is achieved, nitrogen-containing residues can be collected and recycled, and full recycling is achieved. According to the invention, kitchen waste is directly used for efficient open lactic acid fermentation; according to the method, the indigenous microbial flora in the kitchen waste is fully utilized to hydrolyze the substrate and efficiently and directionally convertthe substrate into lactic acid, exogenous nutrition and industrial enzyme preparations do not need to be added, the process is simple, the production cost is low, a cheap carbon source is provided for a denitrification section of a sewage treatment plant while resource utilization of the kitchen waste is realized, and the biological denitrification efficiency is improved.

Owner:UNIV OF SCI & TECH BEIJING

Bacillus tequilensis and application thereof

The invention discloses bacillus tequilensis CGX5-1 which is preserved with the number CGMCC No.5935 in China General Microbiological Culture Collection Center on March 26, 2012. The bacillus tequilensis has high capability of producing beta-1, 3-1, 4-glucanase, and the bacillus tequilensis and good genes thereof are applied to the field of production of industrial enzyme preparations and have good prospects in reduction of cost for producing the beta-1, 3-1, 4-glucanase and improvement on enzyme preparation quality.

Owner:JIANGNAN UNIV

Prepn and use of enzyme prepn for use in hemp degluing industrial process

InactiveCN1374398ANo pollution in the processImprove working conditionsBacteriaBacteriological rettingBreaking strengthMicroorganism

The present invention relates to the field of microbial engineering technology. The enzyme preparation is prepared through the process including slant culture and storing, shaking culture, seeding tank culture and fermenting tank production of high enzyme activity bacteria strain. Bacillus subtilis of No.13 strain and preservation number CCTCC No.M200038 is selected. The hemp degumming process includes the fermentation of enzyme liquid filtering residue, diluting bacteria liquid to 3-6 times, regulating the pH value of fermented enzyme liquid in degluing tank to 7.5-9.0, hemp material pre-treatment, degumming with degumming liquid for 2-10 hr. The process of the present invention has no environmental pollution, and can produce hemp top with length, fineness and breaking strength superior to those of chemical process.

Owner:山东省纤维检验局 +2

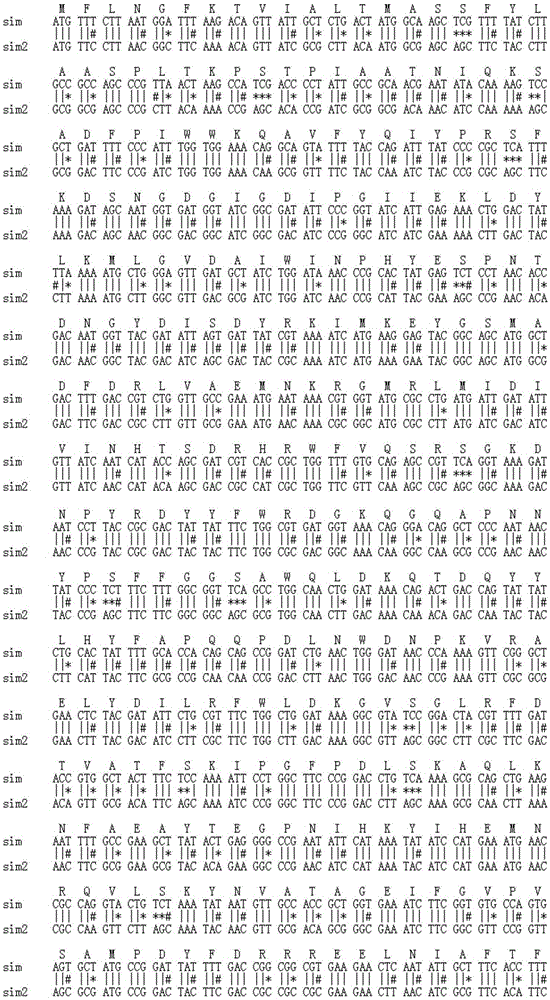

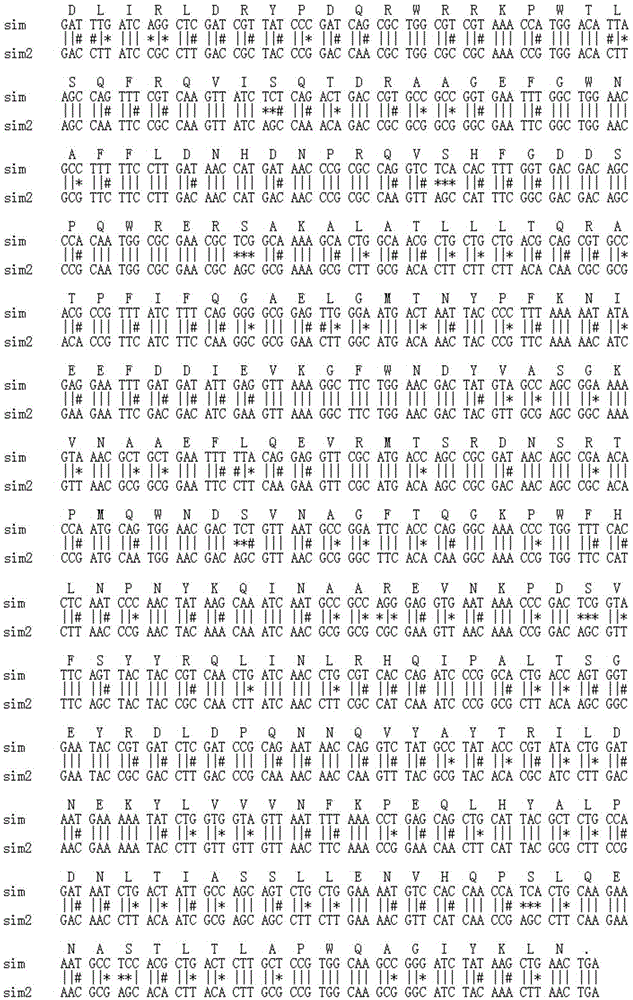

Efficient preparation method and gene engineering bacteria of sucrose isomerase

ActiveCN105255925AHigh expressionHighly secreted expressionBacteriaMicroorganism based processesBacillus licheniformisCell culture media

The invention discloses gene engineering bacteria with a high yield of sucrose isomerase, and a method for efficiently producing the sucrose isomerase, and belongs to the technical field of gene engineering and fermentation engineering. According to the method, codon and signal peptide optimization is adopted to ensure that the expression quantity of a sucrose isomerase gene in bacillus licheniformis is improved by more than or equal to 3 times compared with the original expression quantity. Finally, a growth medium and a fermentation process suitable for synthesis and secretion of an enzyme, and recovery and preparation of a product are established, so that the content of isomaltulose in the product reaches 100%. Therefore, a firm foundation is laid for the application of the sucrose isomerase in food and other industries, and a technical support is provided for efficient preparation of other industrial enzyme preparations.

Owner:森大(天津)生物科技有限公司

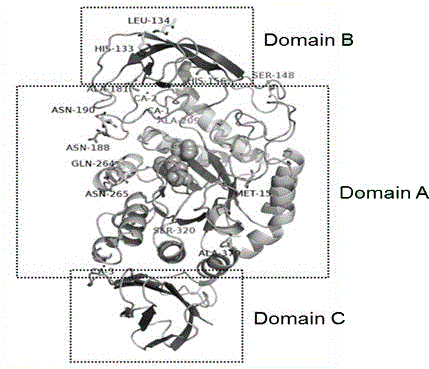

Acid and high temperature resistant alpha-amylase and genes and engineering bacteria of alpha-amylase and preparation method

ActiveCN106086048AHigh expressionEfficient degradationBacteriaMicroorganism based processesAcid-fastChemical industry

The invention discloses genes and engineering bacteria of acid and high temperature resistant alpha-amylase and a preparation method of the genes and engineering bacteria. Compared with a mutant reported by literature, under the condition that the pH ranges from 4.2 to 4.6, and the temperature is 95 DEG C, the thermostability of the acid and high temperature resistant alpha-amylase is enhanced, the expression quantity is 50 times that of existing acid and high temperature resistant alpha-amylase, the alpha-amylase is applied to the fields of chemical industry, food, medicine and the like, starch can be efficiently degraded under the conditions of strong acidity and high temperature, the process can be simplified, environmental pollution is reduced, and a wide application prospect is achieved. Meanwhile, according to genes and engineering bacteria of the acid and high temperature resistant alpha-amylase and the preparation method of the genes and engineering bacteria, rational design of applied combined construction prediction has important guiding significance in improving thermostability of an industrial enzyme.

Owner:JILIN UNIV

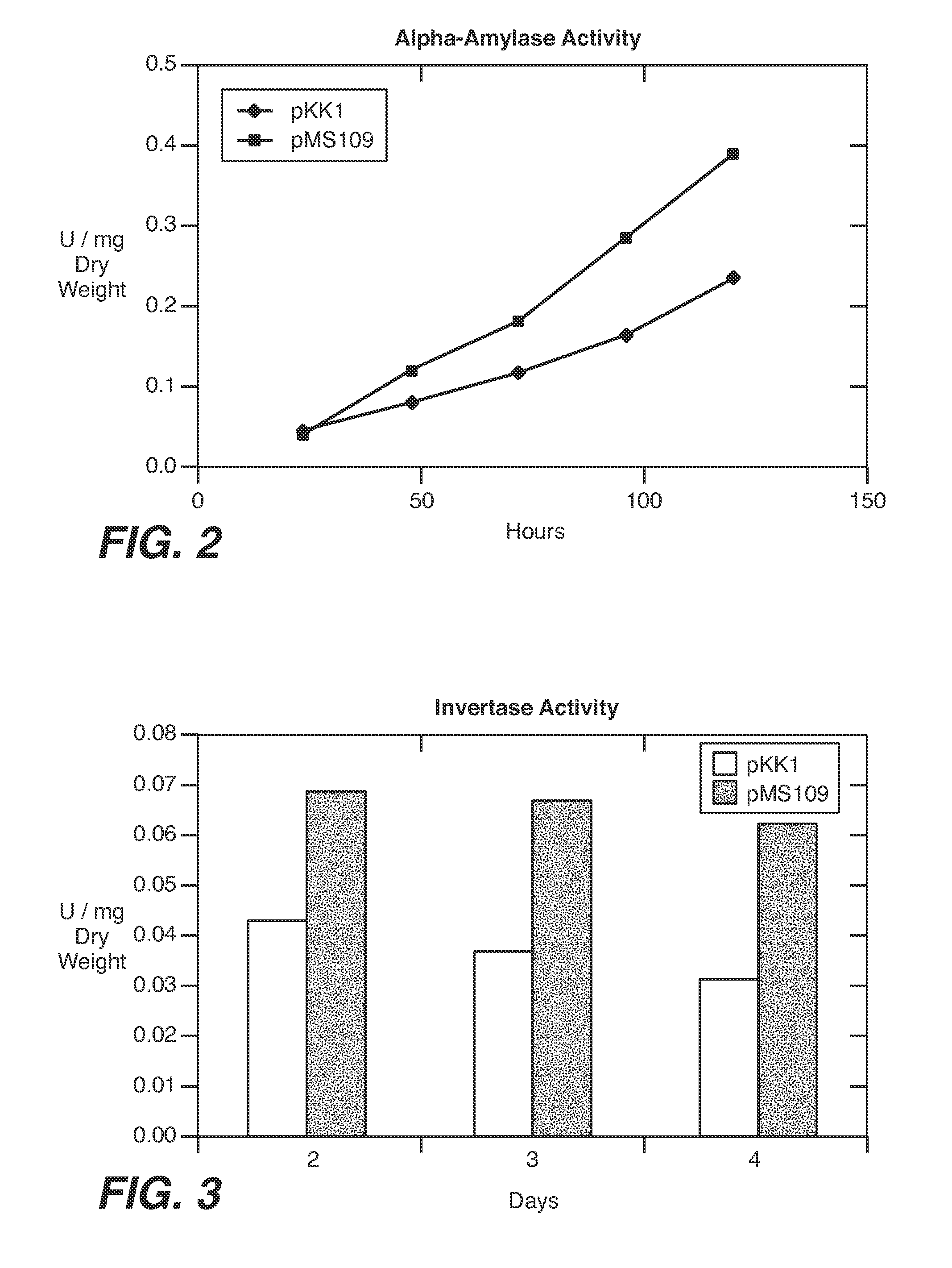

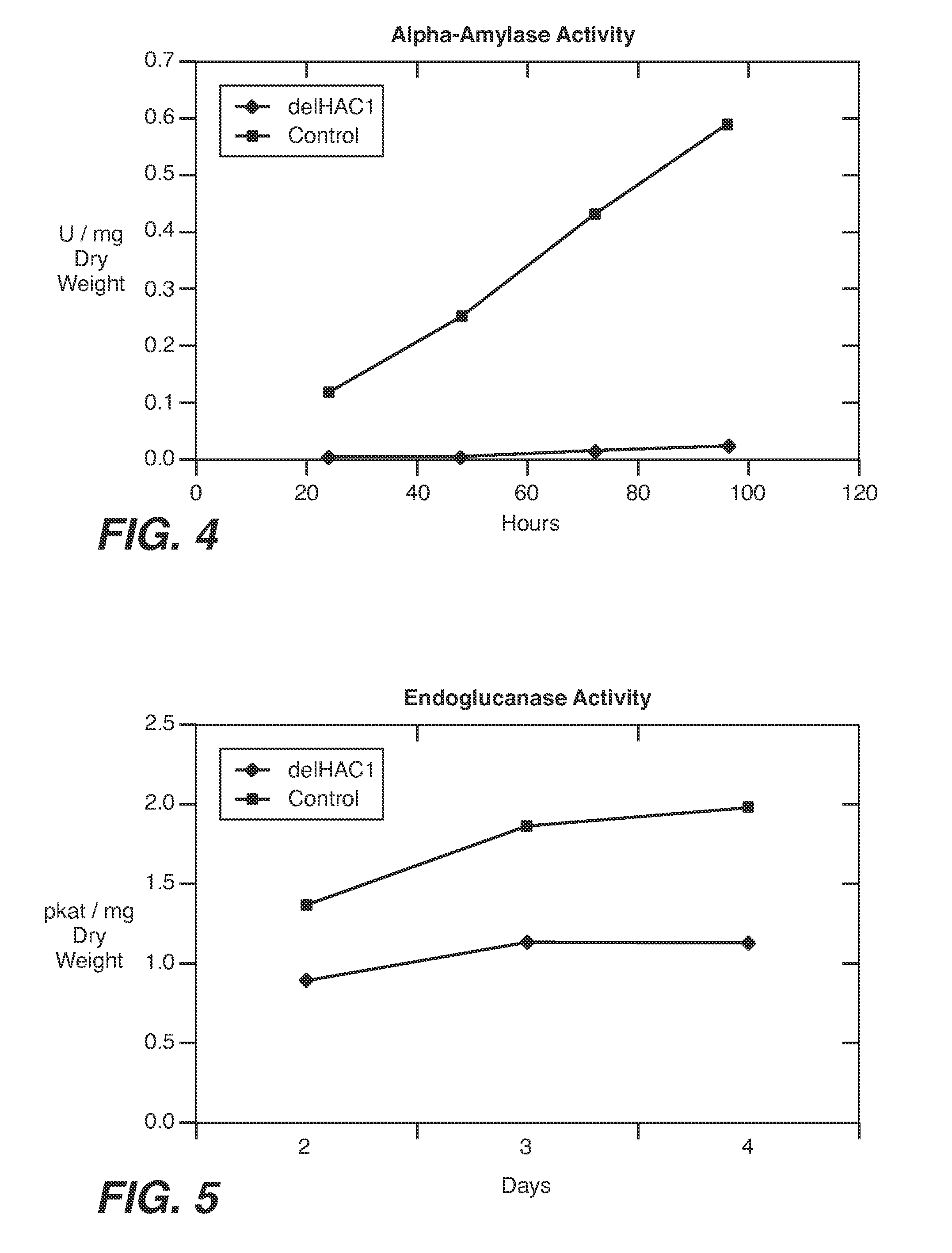

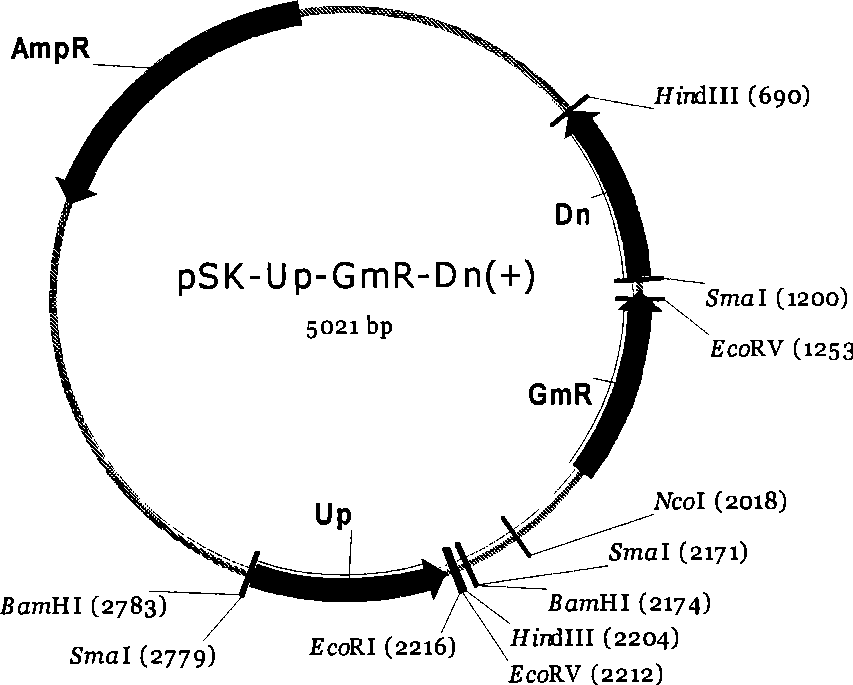

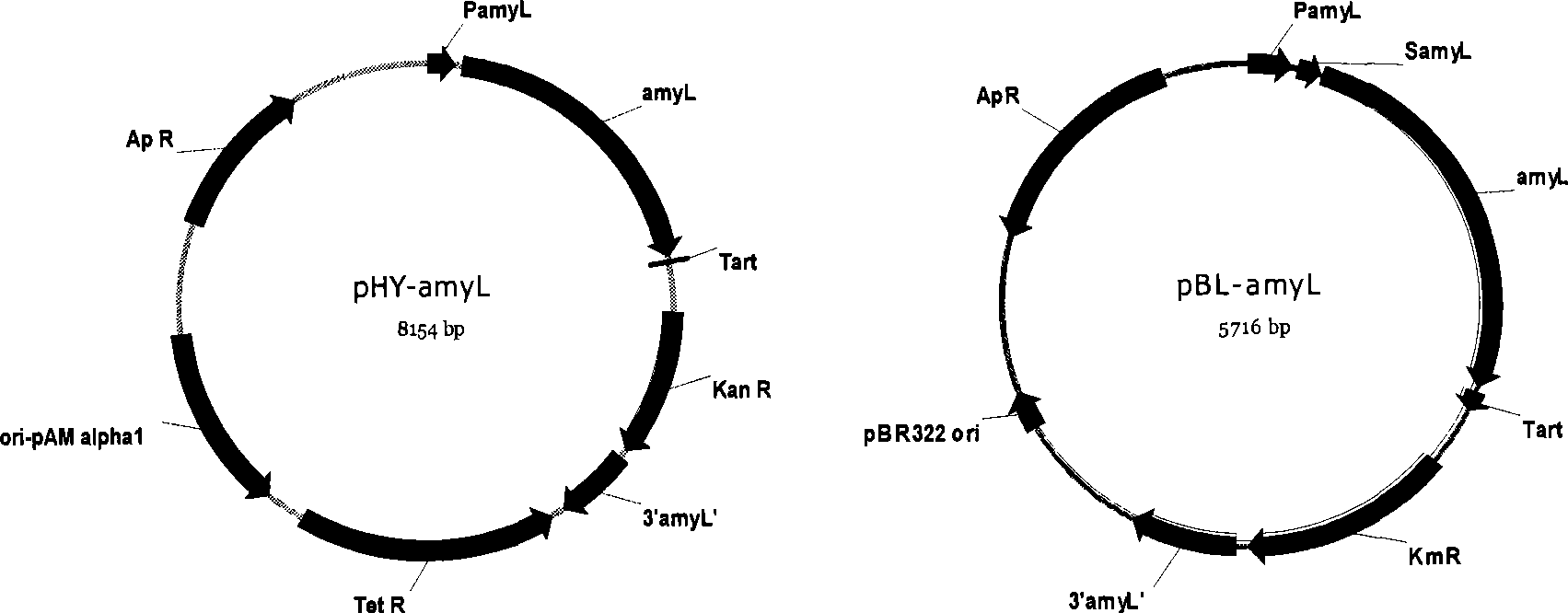

Increased production of secreted proteins by recombinant eukaryotic cells

Owner:DANISCO US INC

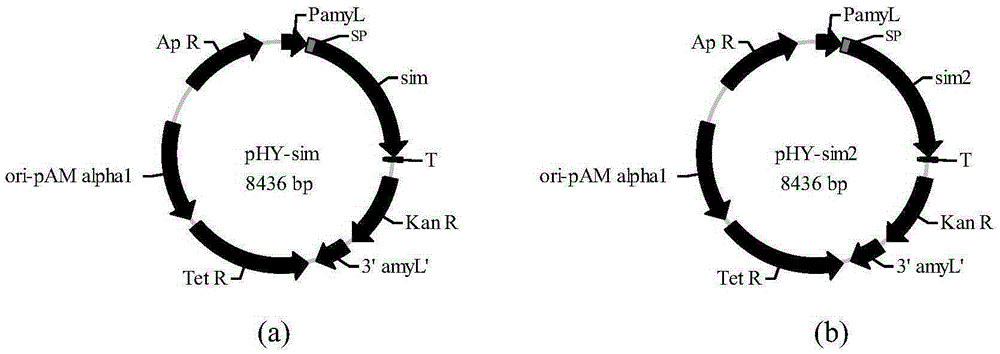

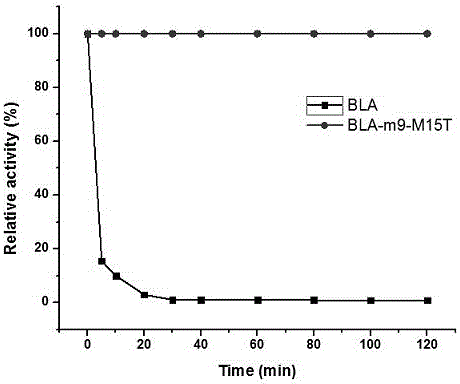

High efficiency preparation method of high temperature alpha-amylase and mutant thereof

ActiveCN101457230AImprove translationEfficient secretionBacteriaMicroorganism based processesBacillus licheniformisAmylosucrase activity

A high temperature alpha-amylase and a high efficiency preparation method of the mutant thereof belongs to the fermentation engineering field. The invention provides a method for high efficiently secreting expressing a high temperature alpha-amylase and mutant thereof with alpha-amylase activity through a bacillus, especially a bacillus licheniformis mutant strain as a host cell. The synthesis and secretion level of the high temperature alpha-amylase or mutant thereof of the recombinant strain of the invention reaches 18-25mg / mL during fed-batch fermentation and is 3-4.5 times of the original strain high temperature alpha-amylase synthesis level. The high temperature alpha-amylase of the invention is useful for reducing the fermentation manufacture cost of the industrial enzyme, simplifying the fermentation manufacture process and reducing fermentation industrial environment pressure.

Owner:福建福大百特生物科技有限公司

Prepn and use of enzyme prepn for use in hemp degluing industrial process

InactiveCN1188513CNo pollution in the processImprove working conditionsBacteriaBacteriological rettingMicroorganismPulp and paper industry

The present invention relates to the field of microbial engineering technology. The enzyme preparation is prepared through the process including slant culture and storing, shaking culture, seeding tank culture and fermenting tank production of high enzyme activity bacteria strain. Bacillus subtilis of No.13 strain and preservation number CCTCC No.M200038 is selected. The hemp degumming process includes the fermentation of enzyme liquid filtering residue, diluting bacteria liquid to 3-6 times, regulating the pH value of fermented enzyme liquid in degluing tank to 7.5-9.0, hemp material pre-treatment, degumming with degumming liquid for 2-10 hr. The process of the present invention has no environmental pollution, and can produce hemp top with length, fineness and breaking strength superior to those of chemical process.

Owner:山东省纤维检验局 +2

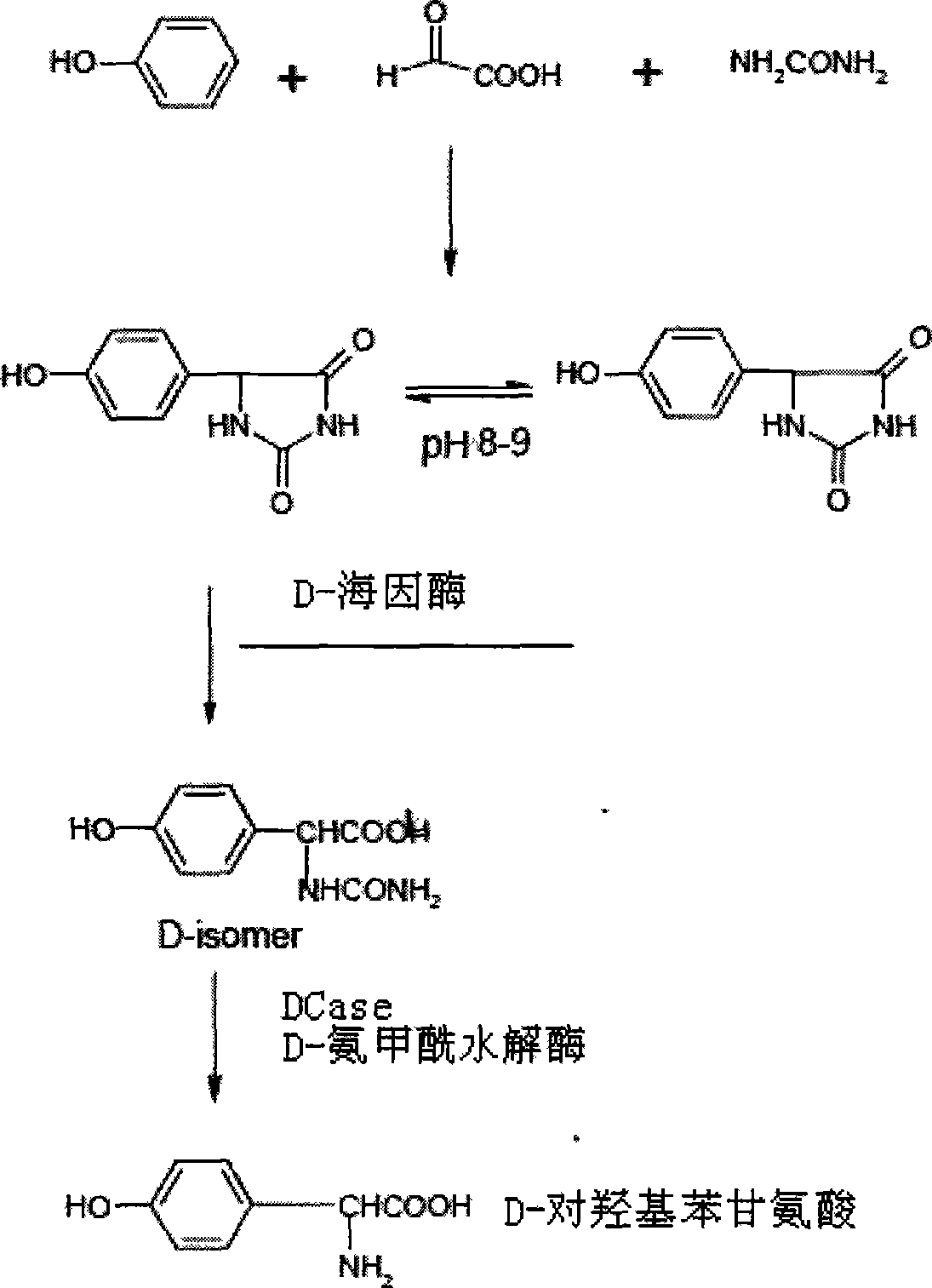

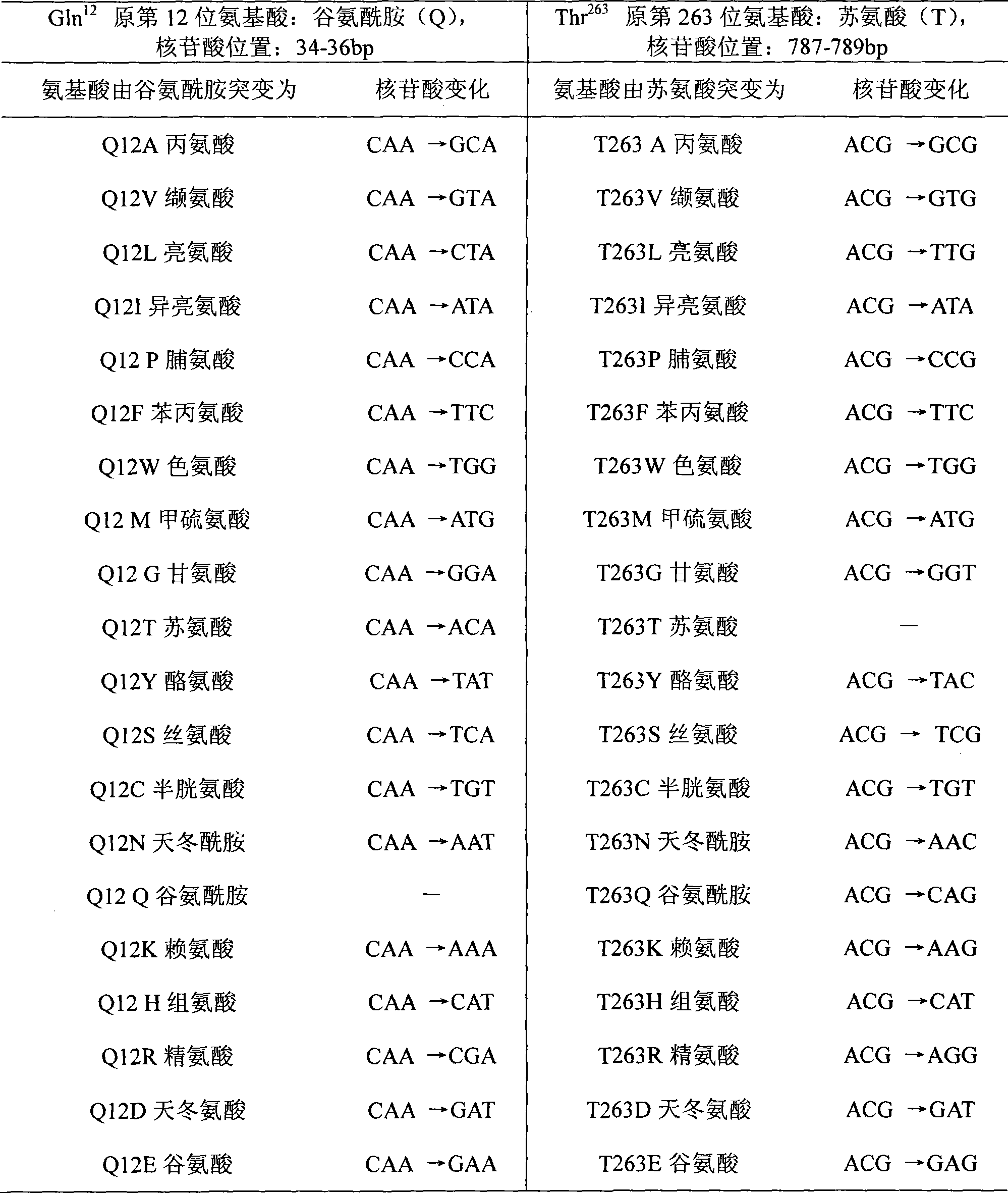

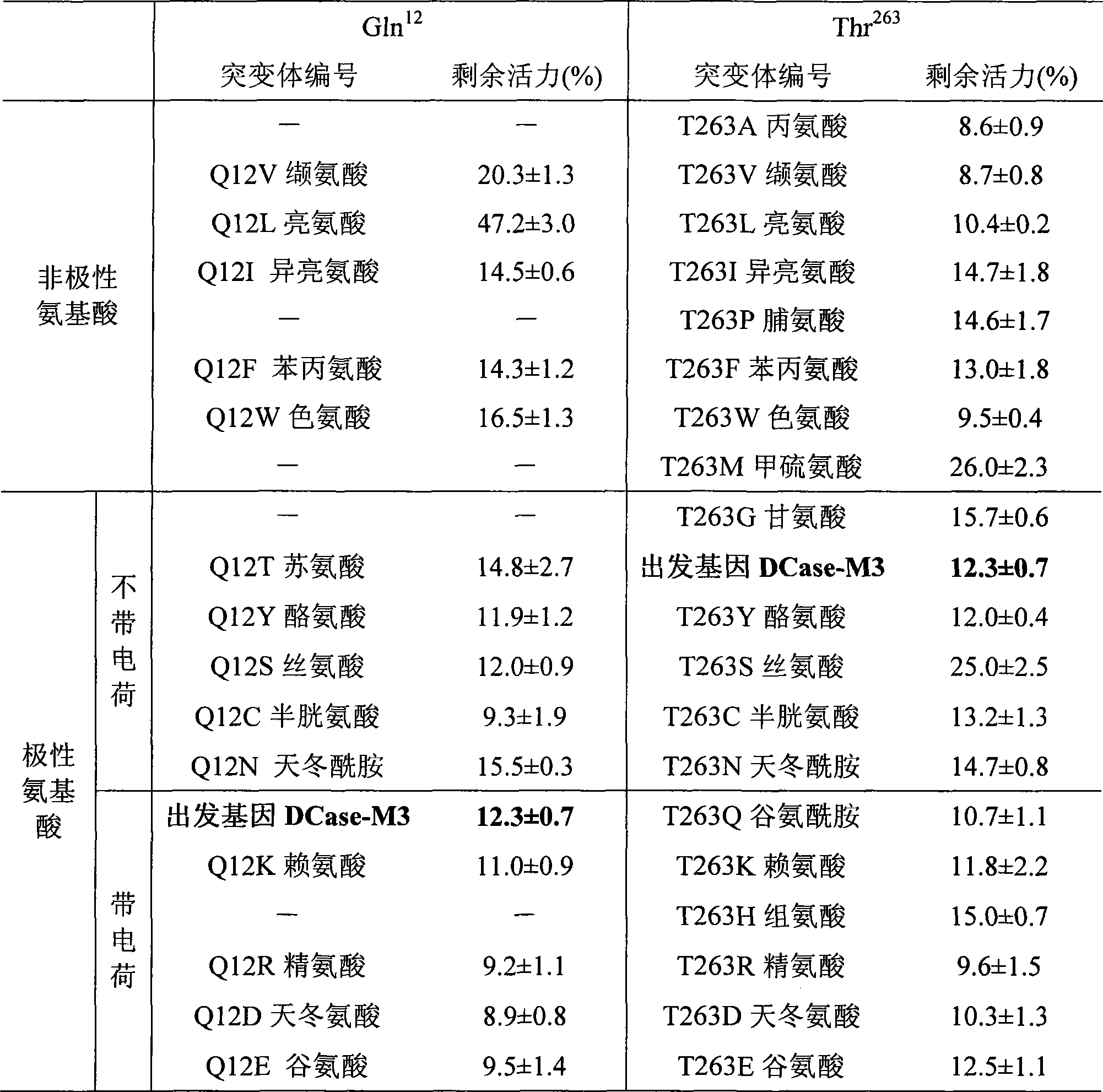

Mutant of D-carbamyl hydrolysis enzyme and application thereof

The invention discloses a mutant of D-carbamyl hydrolysis enzyme and application thereof in producing D-p-hydroxyphenylglycine. The method comprises the following steps that: a mutant is obtained by the directed evolution technology and mutates into nonpolar amino acid in 12-glutamine of the D-carbamyl hydrolysis enzyme; another mutant mutates into methionine in 263-threonine of the D-carbamyl hydrolysis enzyme; a third mutant mutates into serine in 263-threonine of the D-carbamyl hydrolysis enzyme; a fourth mutant mutates into the threonine in 12-glutamine of the D-carbamyl hydrolysis enzyme; and the 263-threonine mutates into the serine. The mutant enzyme shows higher thermal stability and enzyme activity in the production of the D-p-hydroxyphenylglycine, and indicates that using the directed evolution technology to reconstruct industrial enzyme is a quite effective method.

Owner:洛阳华荣生物技术有限公司

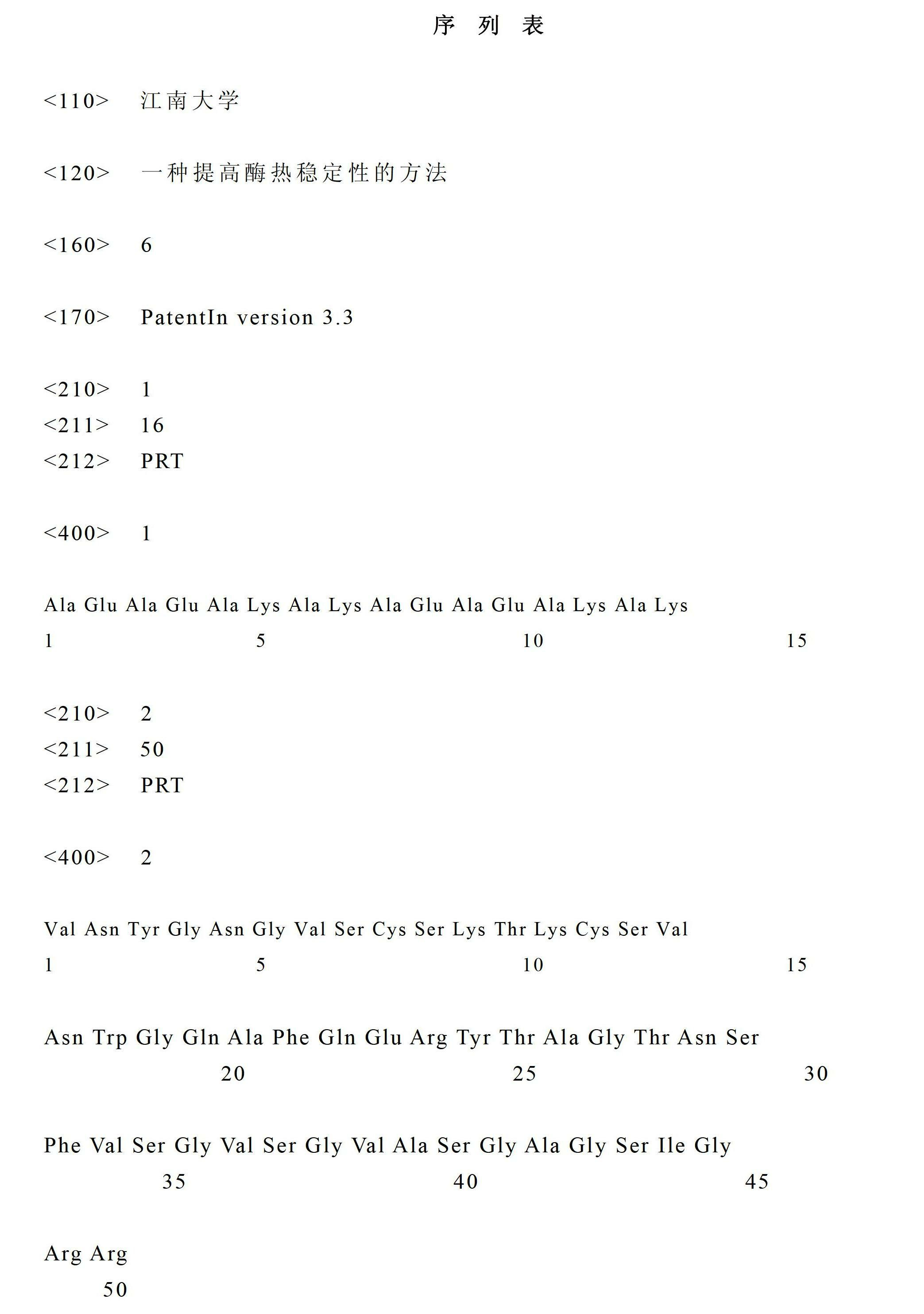

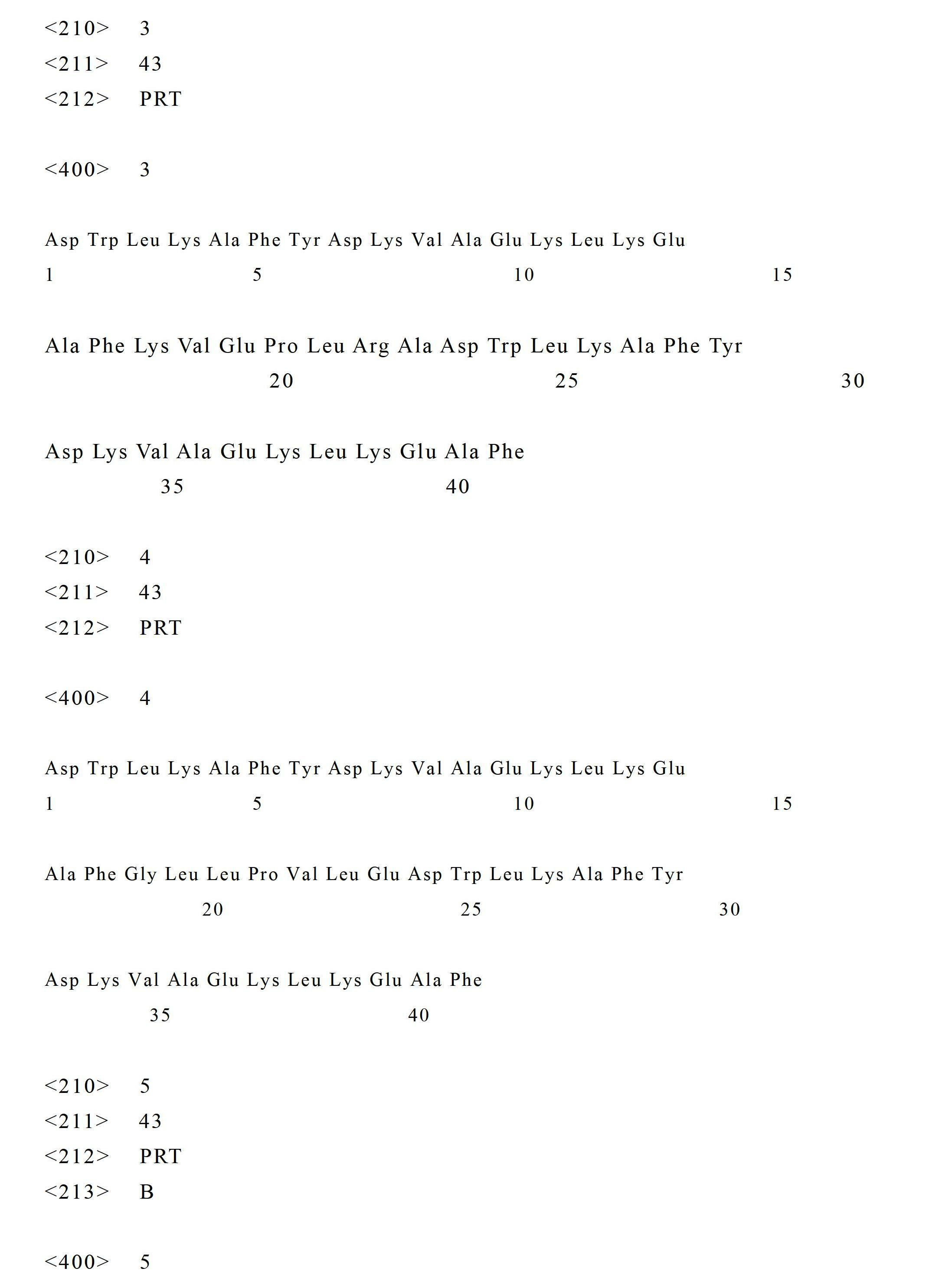

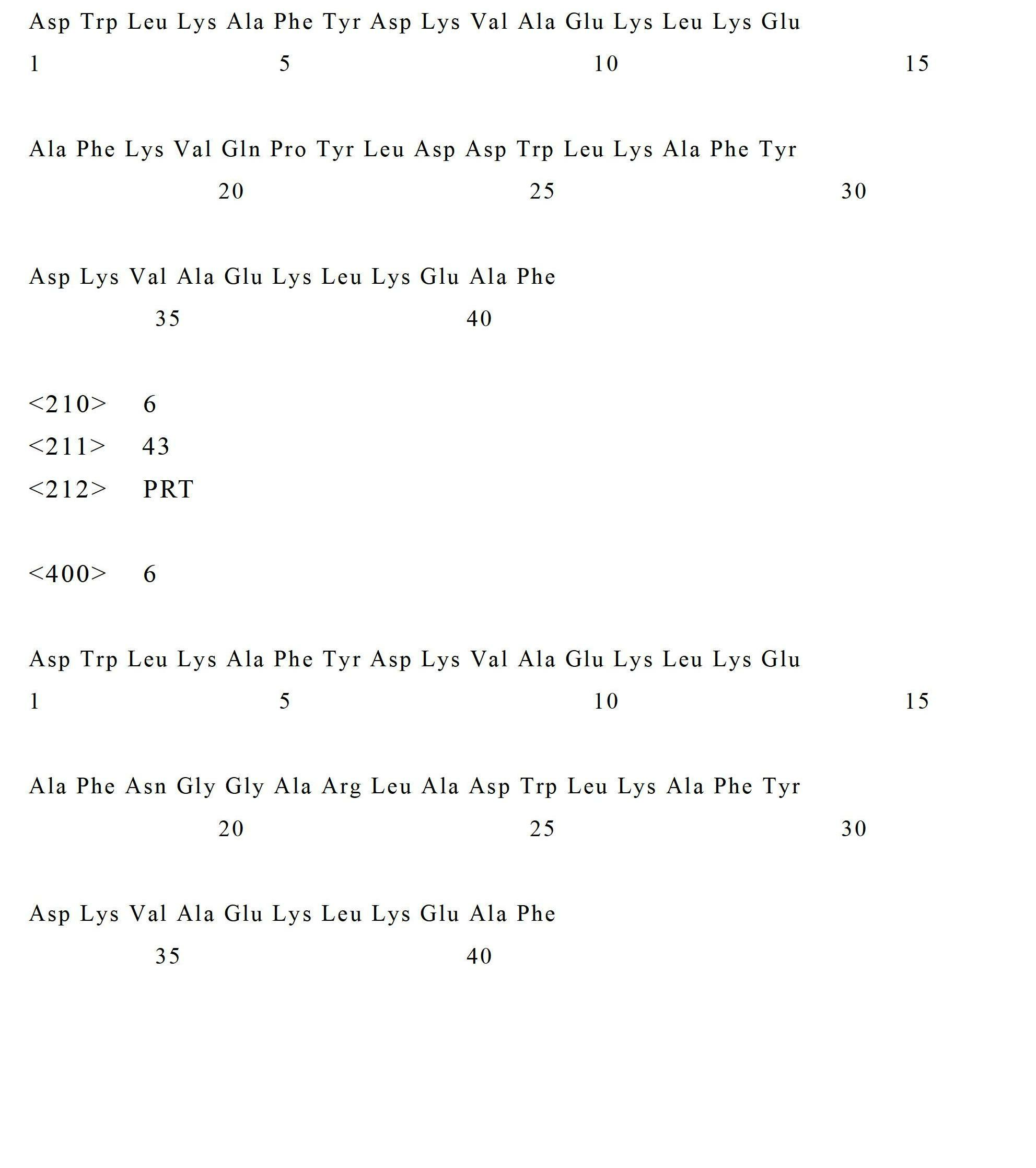

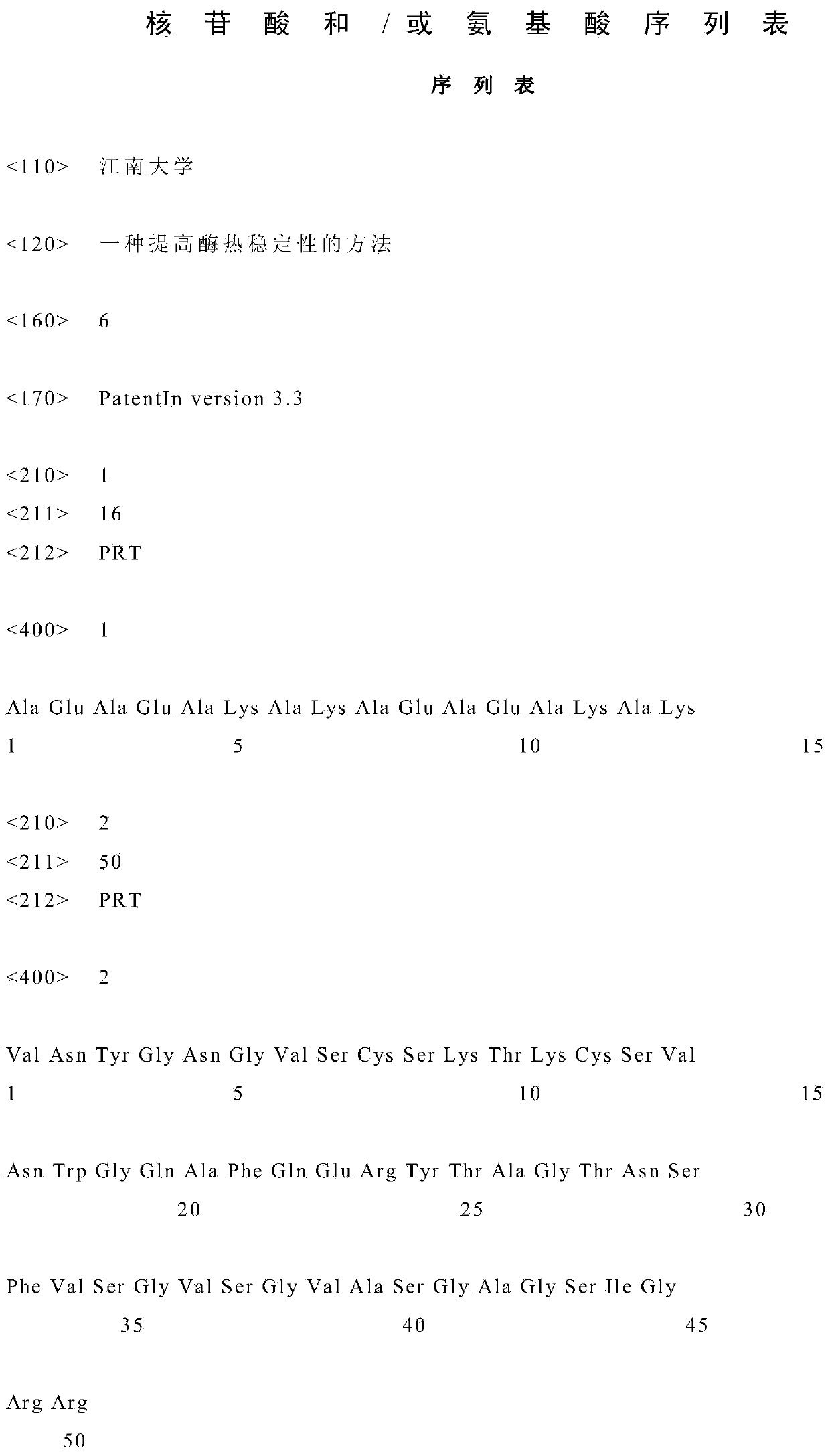

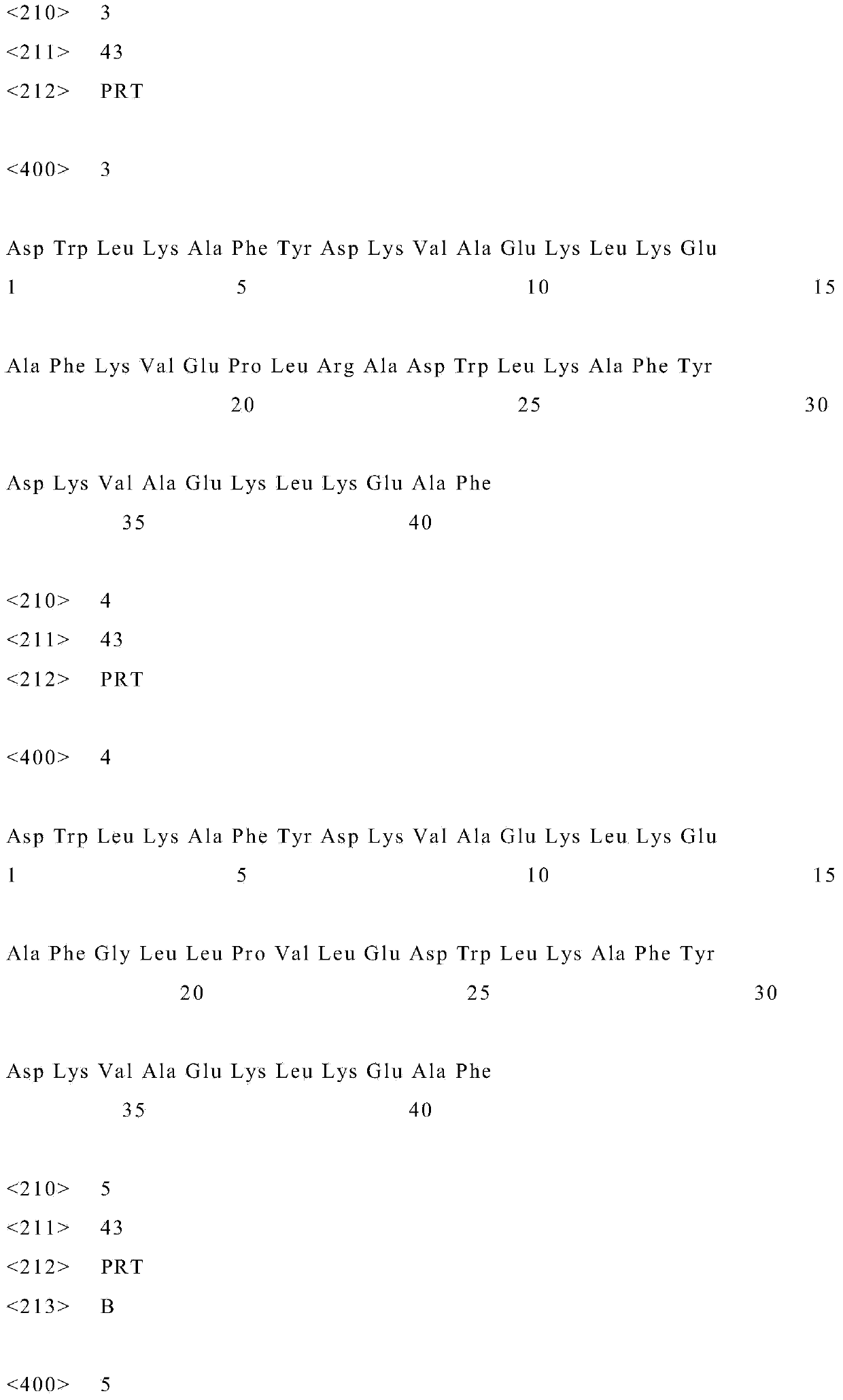

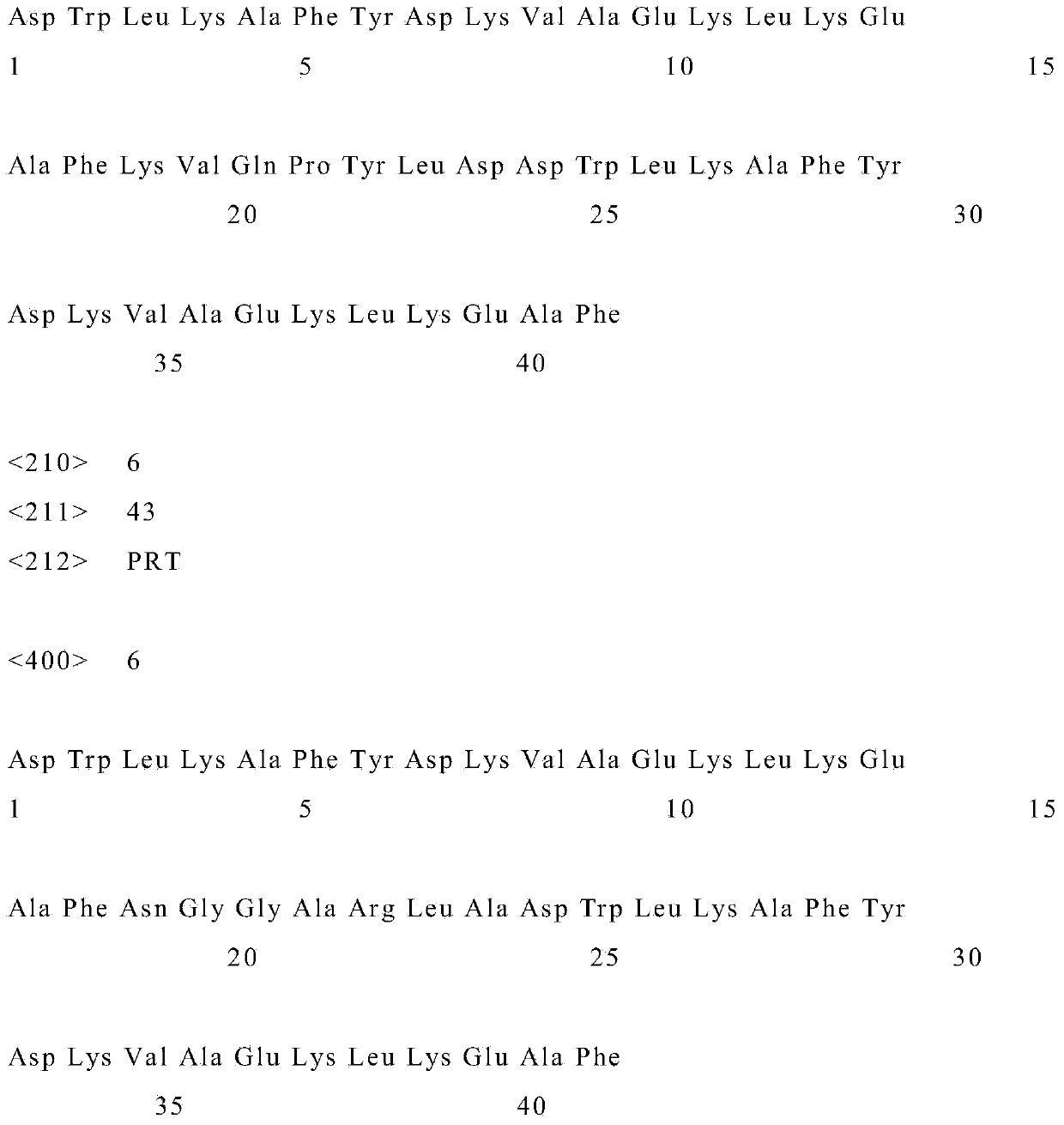

Method for improving thermal stability of enzyme

ActiveCN102660570AImprove thermal stabilityImprove methodTransferasesMicroorganism based processesSmall peptideThermal stability

The invention discloses a method for improving the thermal stability of enzyme. The method is used for obtaining the recombinant enzyme with the improved thermal stability through fusion expression of parents small peptide and the recombinant enzyme, wherein the sequence of the optimized parents small peptide is DWLKAFYDKVAEKLKEAFKVQPYLDDWLKAFYDKVAEKLKEAF. The method has the advantages of being remarkable in effect, simple in process and convenient to promote. The method serves as a new method and idea for quickly improving the thermal stability of the industrial enzyme.

Owner:JIANGNAN UNIV

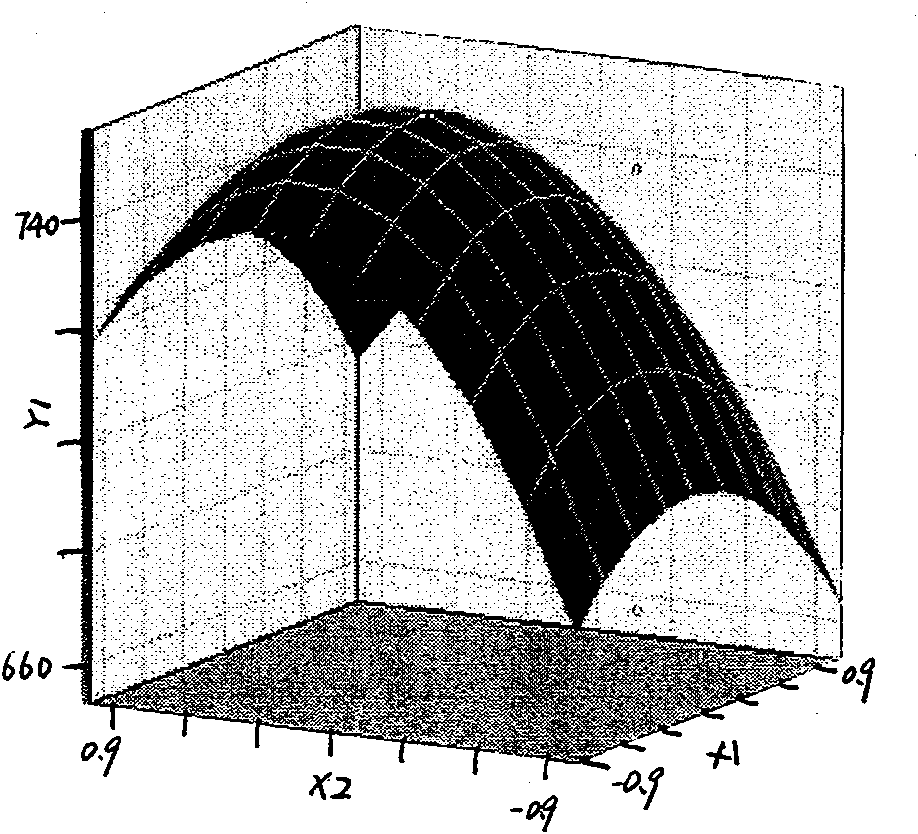

Optimization method of culture conditions of alkaline pectinase gene engineering bacteria

InactiveCN101781641AHigh activityGood fermentation conditionsMicroorganism based processesEnzymesPectinaseMicrobiology

The invention relates to an optimization method of culture conditions of alkaline pectinase gene engineering bacteria, comprising the following steps: (1) adopting a single-factor experiment to optimize the fermentation medium formation of the alkaline pectinase gene engineering bacteria to obtain a preliminarily optimized fermentation medium; (2) optimizing a target strain medium with a response surface methodology to obtain the target strain medium; and (3) optimizing the fermentation culture conditions to the target strain by a post-optimizing medium to obtain the optimization culture conditions. The invention gropes a set of optimal fermentation culture conditions to ensure that enzymatic activity produced by engineering bacteria fermentation reaches 758.7825U / ml which is improved by 50 times compared with the activity of alkaline pectinase produced by original wide strains and is improved by 3 times compared with the enzymatic activity of alkaline pectinase produced by LB fermentation medium fermentation gene engineering bacteria, so that the invention has an important meaning for improving the market competitiveness of industrial enzyme.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

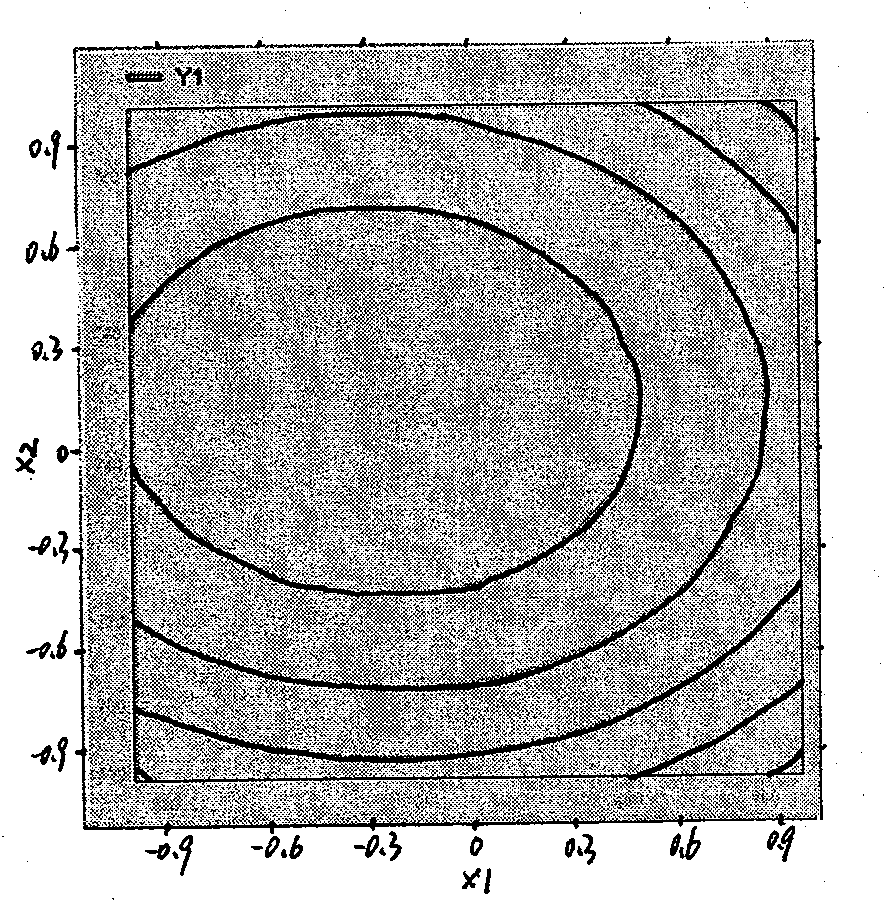

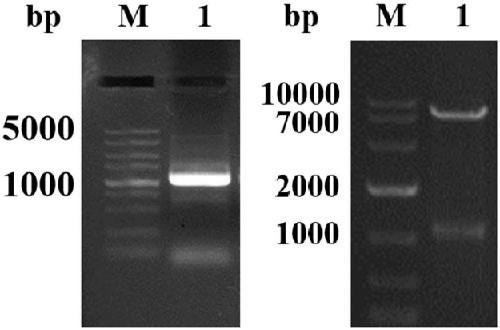

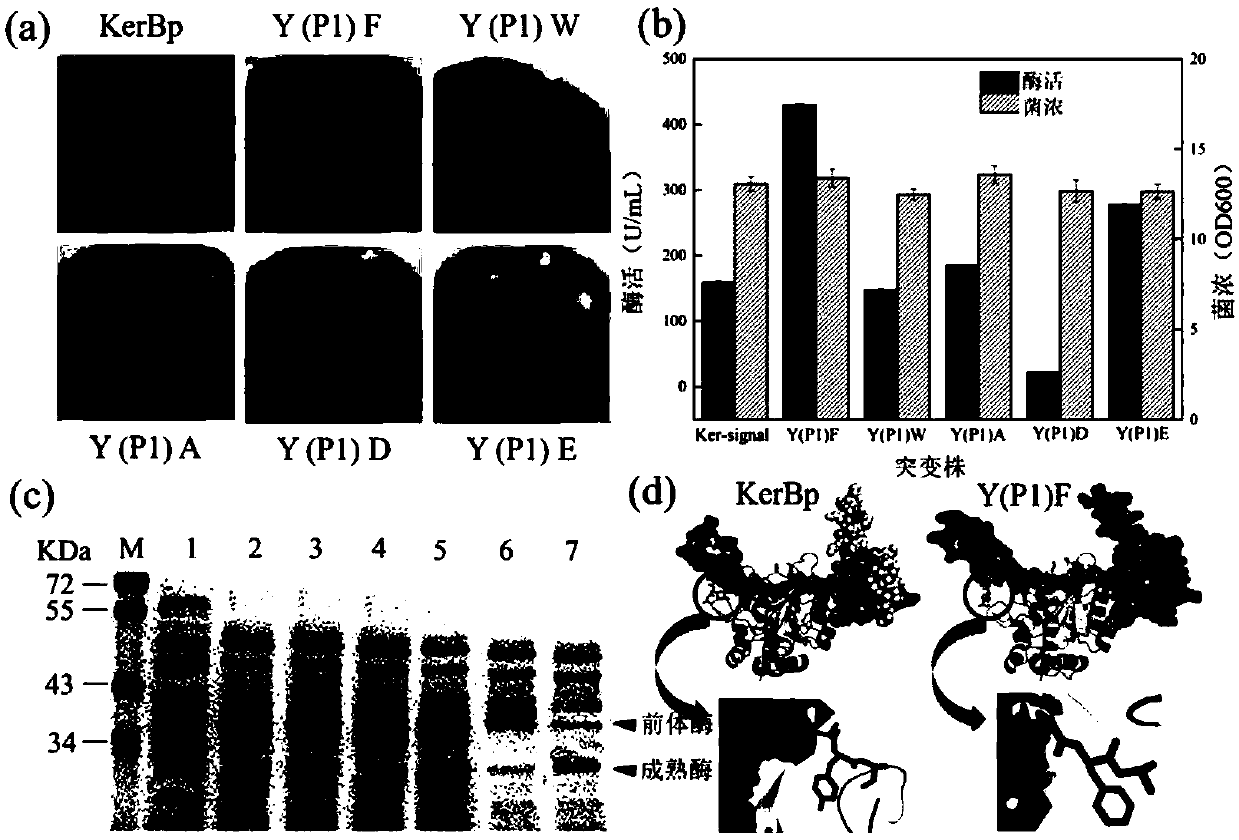

Keratinase mutant with improved catalytic performance and application

InactiveCN109593746AImprove thermal stabilitySuitable for industrial mass productionBacteriaHydrolasesMulti siteWater baths

The invention discloses a keratinase mutant with improved catalytic performance and an application, belongs to the technical field of genetic engineering and provides recombinant keratinase constructed on the basis of leading peptide engineering and multi-site saturated mutation and a leading peptide engineering method. A recombination strain M7 shows high keratinase catalytic potential, enzyme activity is remarkably improved from 179 U / mL to 1114 U / mL, the optimal reaction temperature is 40 DEG C, the optimal reaction pH is 10.0, over 80% enzyme activity is retained after water bath processing is performed for 90 min at 40 DEG C, heat stability is better, and the keratinase mutant is suitable for industrial large-scale production. Besides, the method for modifying protease with the leading peptide engineering can be a universal way for modifying industrial enzyme with the self-shearing characteristic.

Owner:JIANGNAN UNIV

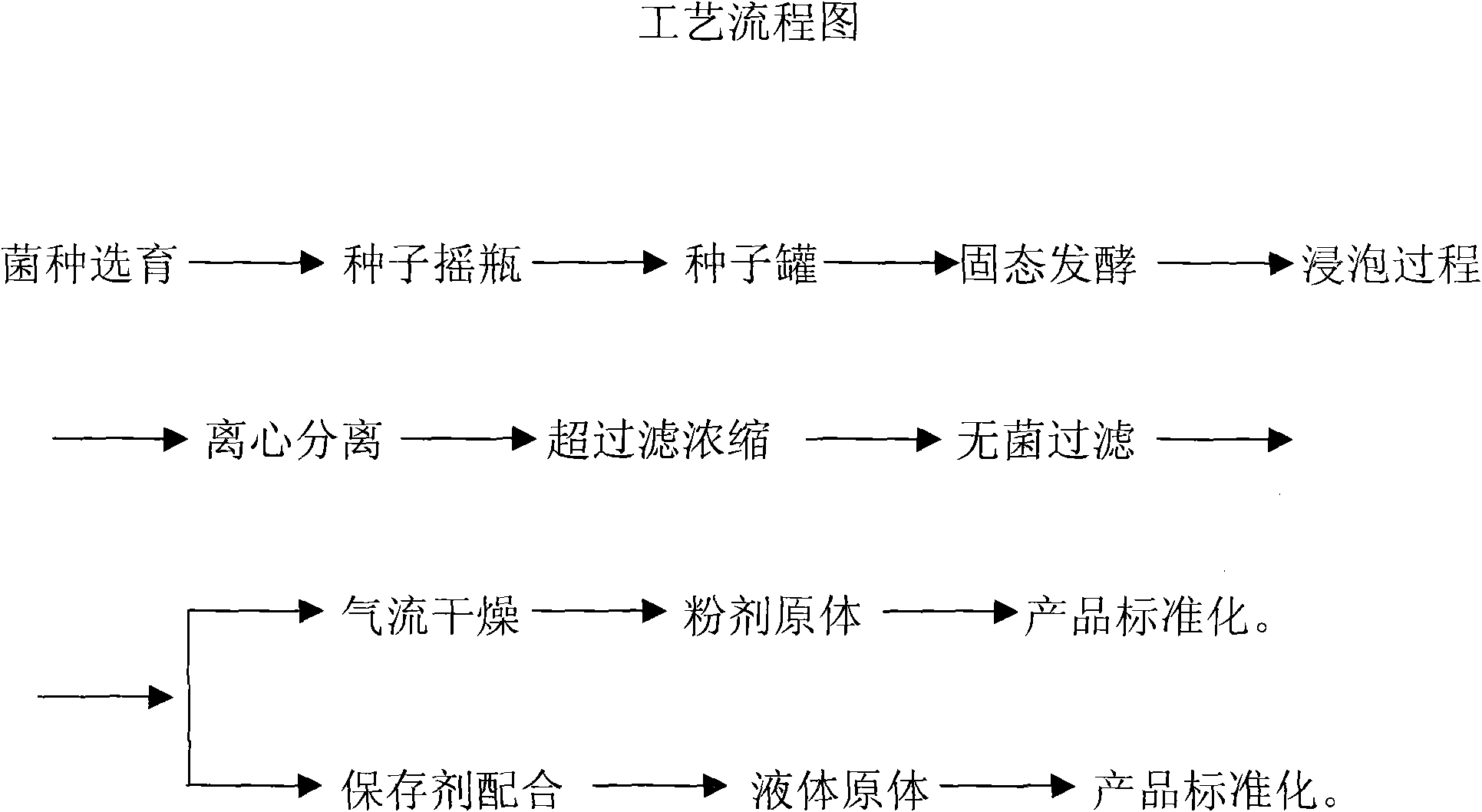

Technology for preparing lactose enzyme

InactiveCN101570745APromote reproductionHigh fermentation activityMicroorganism based processesEnzymesMicroorganismLactase

The invention provides a method for preparing lactose enzyme which is a novel high-efficient preparation. In the method, bacteria are processed by NTG with a certain concentration to produce high yield bacteria, solid fermentation is carried out under the condition which is suitable for the growth of microorganisms of the high yield bacteria, and industrial enzyme with high purity quotient and ideal yield coefficient is obtained by extracting and separating under a totally enclosed condition. The method has the advantages of soft preparing condition and little generation of three wastes.

Owner:JIAMI SHANGHAI BIOLOGICAL ENG

Method for preparing ginseng anti-cancer active component by immobilized enzyme

The immobilized enzyme process for preparing effective anticancer ginseng component includes the steps of immobilizing industrial enzyme preparation, converting immobilized enzyme and collecting converted product; and features that the glycosyl radical in diol type ginsenoside molecule is fixed point excised by the immobilized enzyme to form the target compound C-K. The process is superior to available process, which has environmental pollution, drastic reaction, serious damage on aglycone, low product yield and other demerits. The process of the present invention is simple, low in cost and high in efficiency, and may be applied in preparing great amount of C-K for preparing antitumor medicine.

Owner:LIAONING UNIV OF TRADITIONAL CHINESE MEDICINE

Method for preparing clove oil microcapsules employing cyclodextrin mother solution

ActiveCN101648126AReduce pollutionSimple processEssential-oils/perfumesMicroballoon preparationActivated carbonAdditive ingredient

The invention relates to a method for preparing clove oil microcapsules employing cyclodextrin mother solution, belonging to the technical field of the preparation of clove oil microcapsules. The method comprises the following steps: using the waste cyclodextrin mother solution in the industrial enzyme conversion preparation method of beta-cyclodextrin as raw material, treating with activated carbon, selecting proper inclusion process and adopting effective ingredients such as beta-cyclodextrin and the like in the mother solution to pack clove oil which is volatile flavoring fragrancy industrial material and preparing clove oil microcapsules. Compared with the clove oil microcapsules prepared from the finished beta-cyclodextrin, the product of the invention has the similar shape and properties. The cost of the method of the invention is much lower that that of the traditional method so as to realize the effective reuse of waste and the method also reduces the pollution to the environment.

Owner:JIANGNAN UNIV

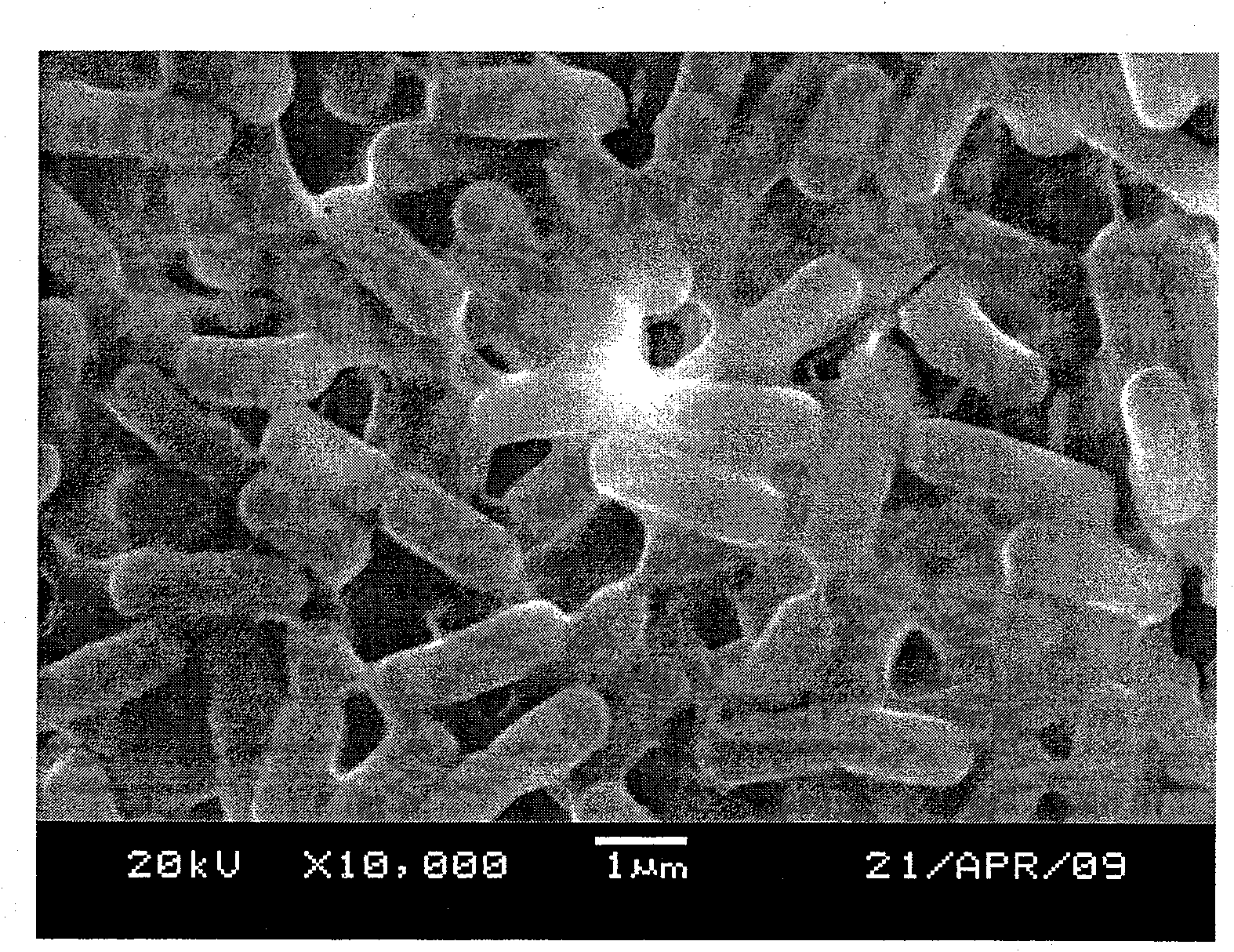

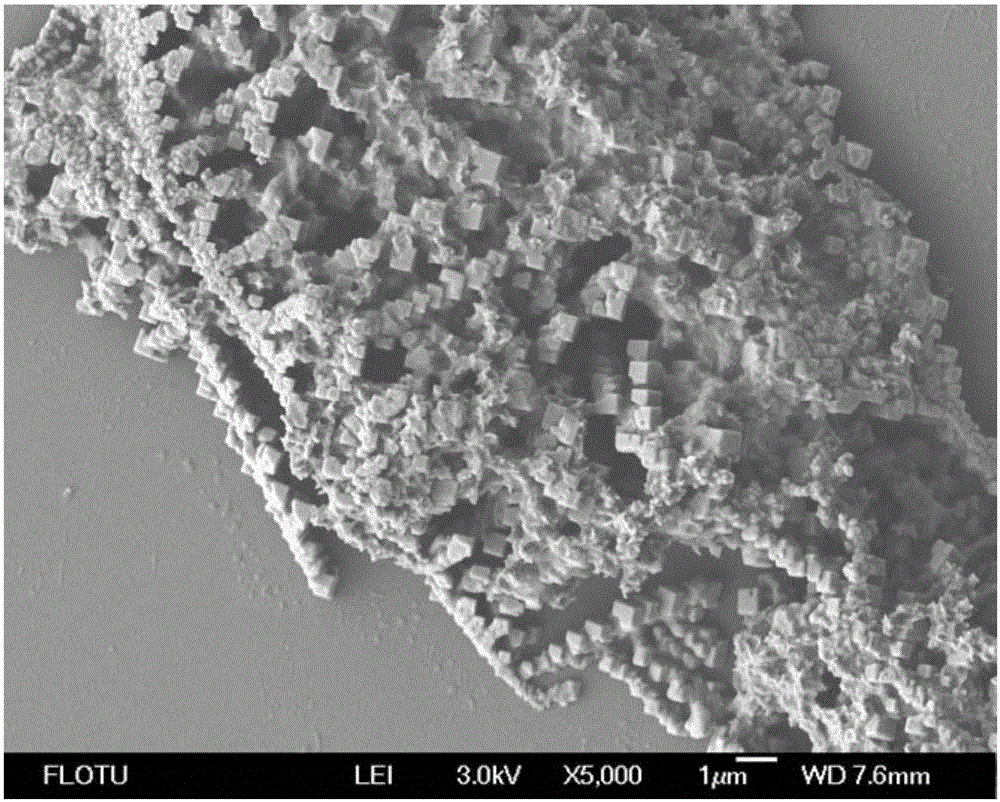

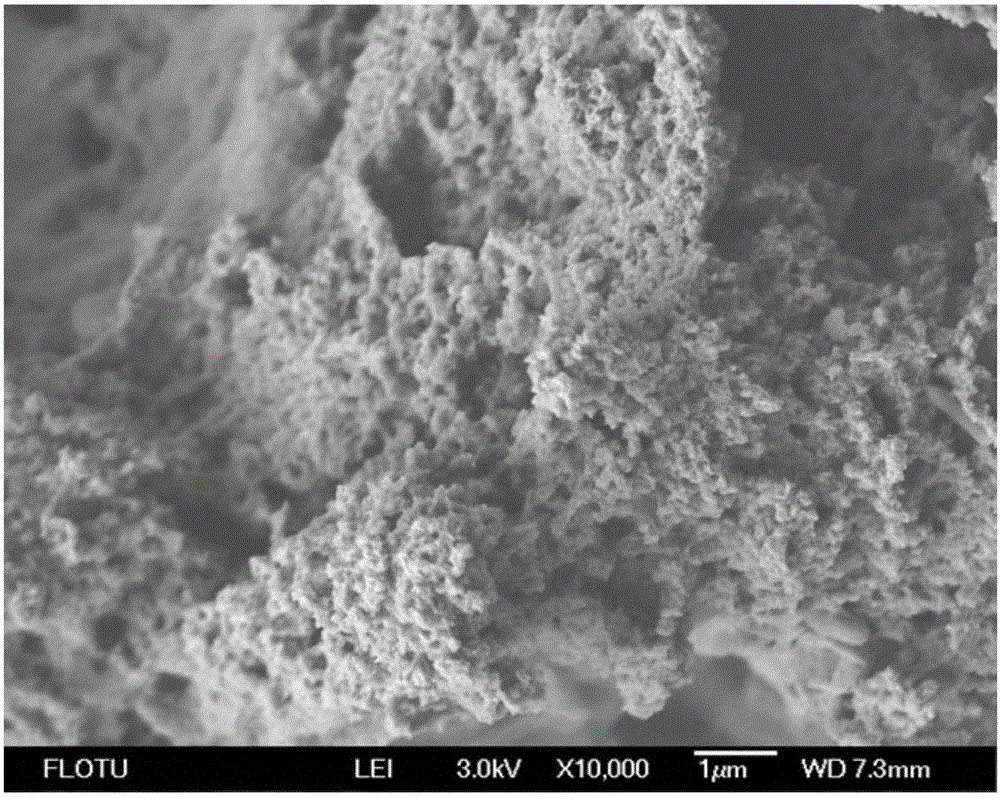

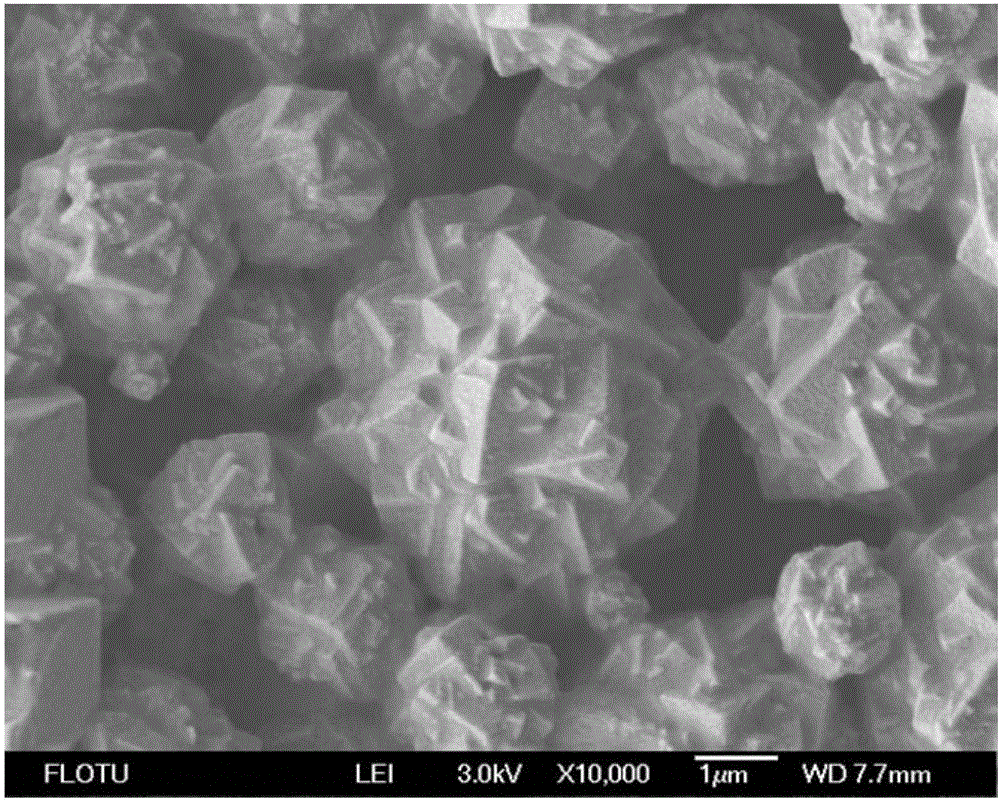

Enzyme-metal ion nano compound and preparation method thereof

InactiveCN105754985AImprove stabilityEasy to operateOxidoreductasesOn/in inorganic carrierIndustrial enzymesNickel ions

The invention discloses an enzyme-metal ion nano compound and a preparation method thereof.The preparation method includes following steps: drying a water solution of metal ions and enzyme to obtain the enzyme-metal ion nano compound, wherein the metal ions are one of calcium ions, magnesium ions, iron ions, ferrous ions, copper ions, barium ions, manganous ions, bivalent nickel ions and zinc ions.An enzyme immobilization method has the advantages of simple operation and low cost.By controlling concentration of the metal ions and the enzyme in the solution, the enzyme-metal ion nano compound prepared by the method is not generated in a precipitate form while a nano compound of 500-1200 nm soluble in the water solution is formed, stability of the enzyme in the nano compound is improved remarkably, and enzyme activity is basically maintained unchanged and even is improved.Due to above characteristics, the enzyme-metal ion nano compound is different from conventional nano carrier immobilized enzyme, and has good application prospect in the field of industrial enzyme catalysis, biosensors and biomedicine.

Owner:TSINGHUA UNIV

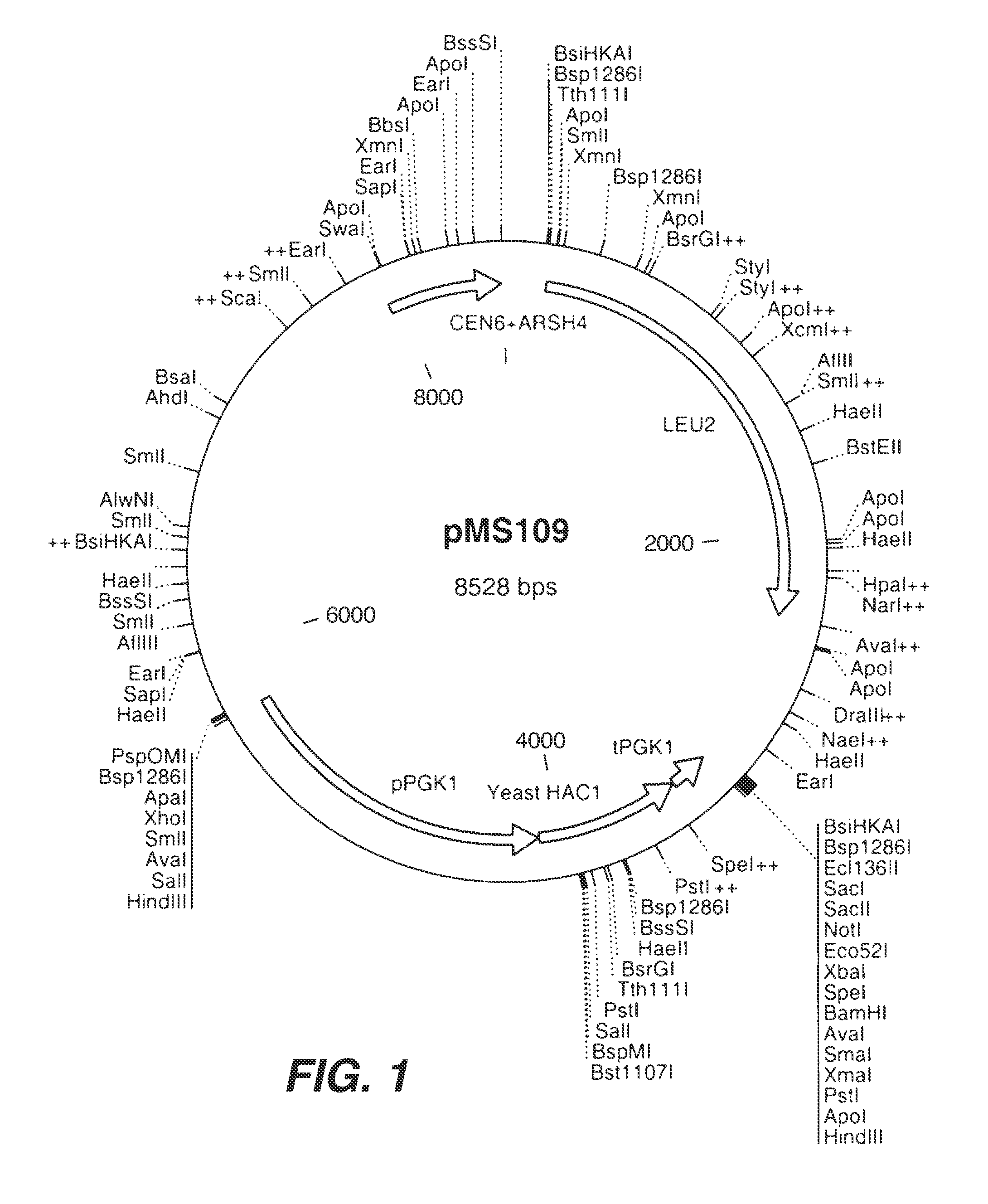

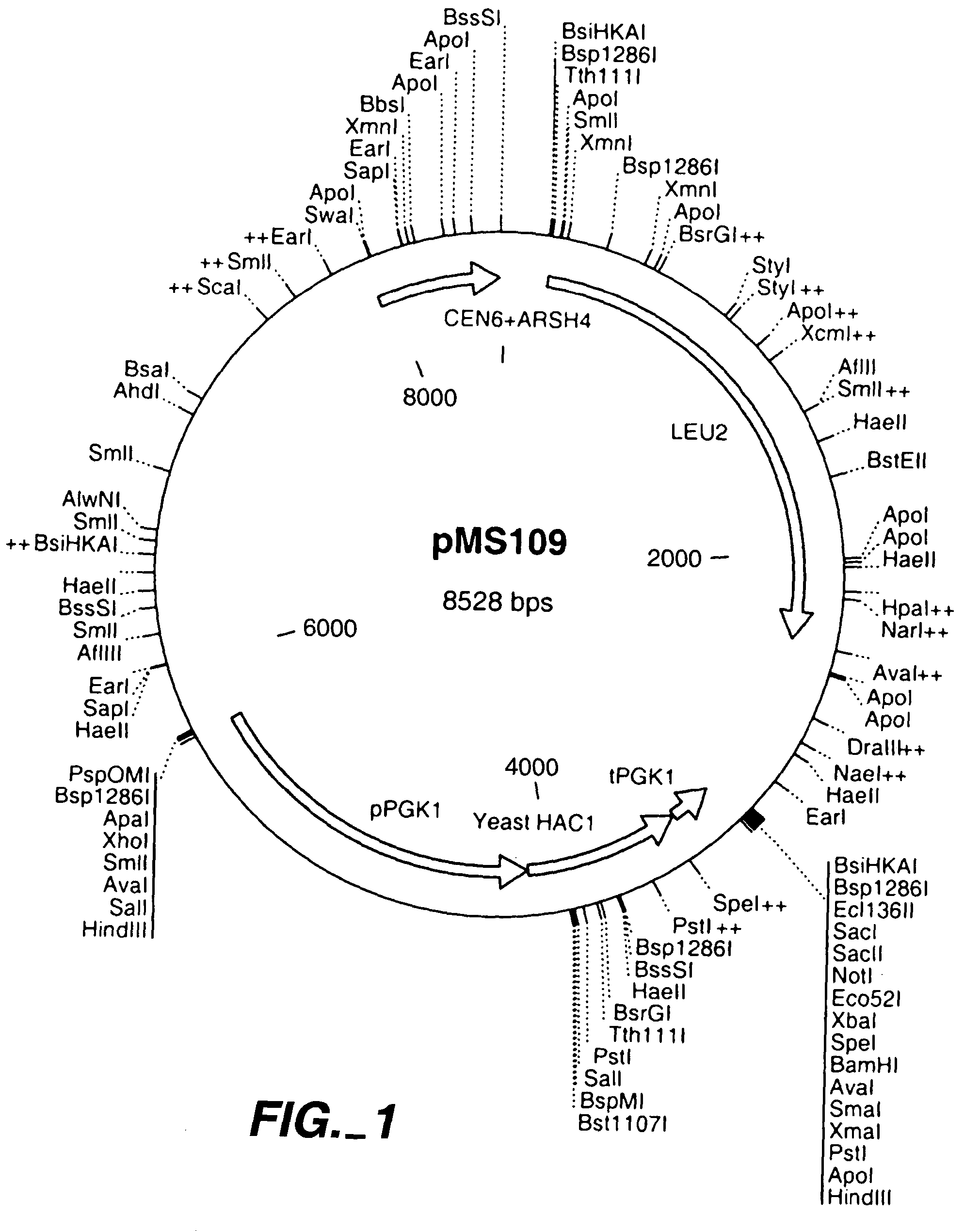

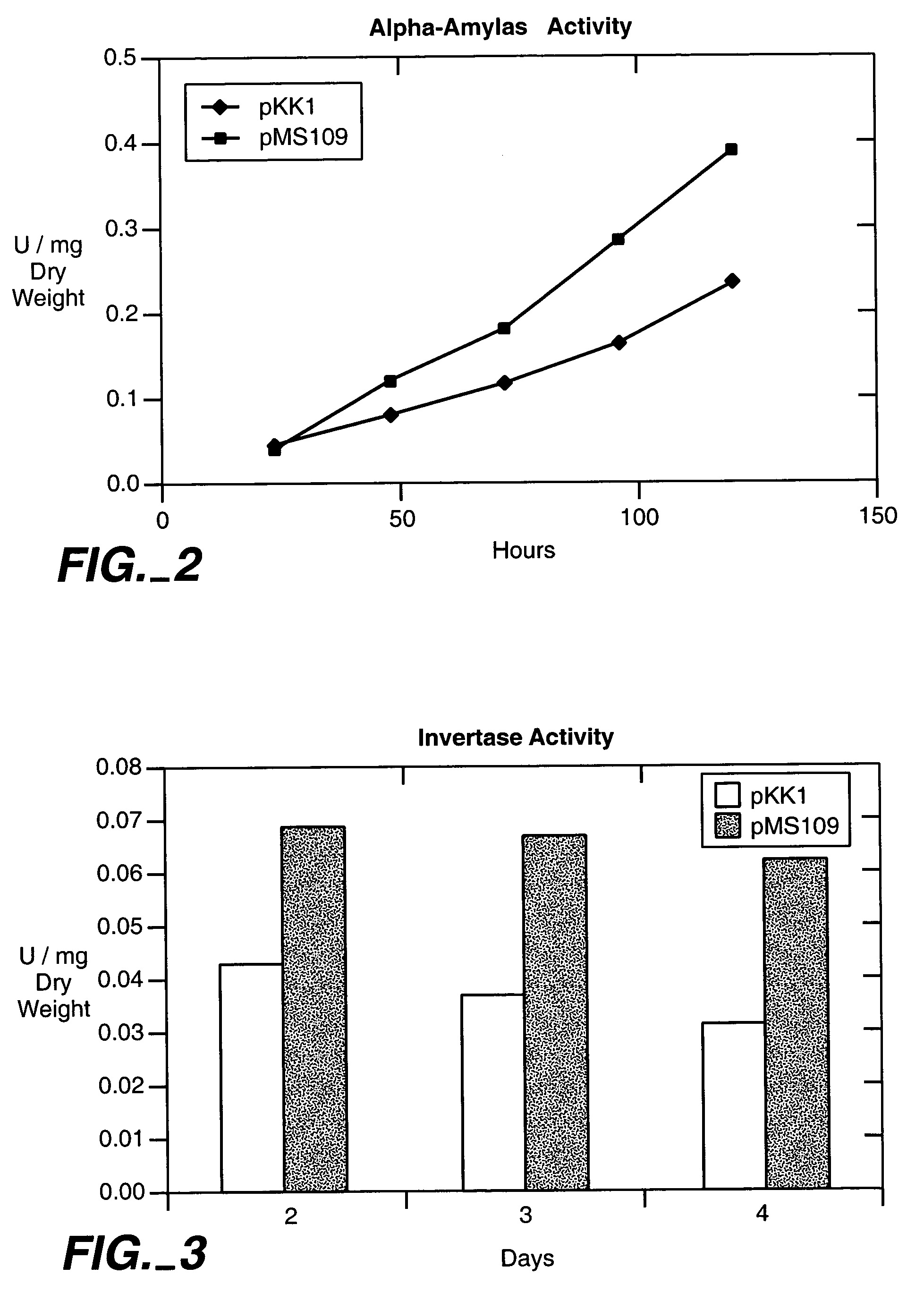

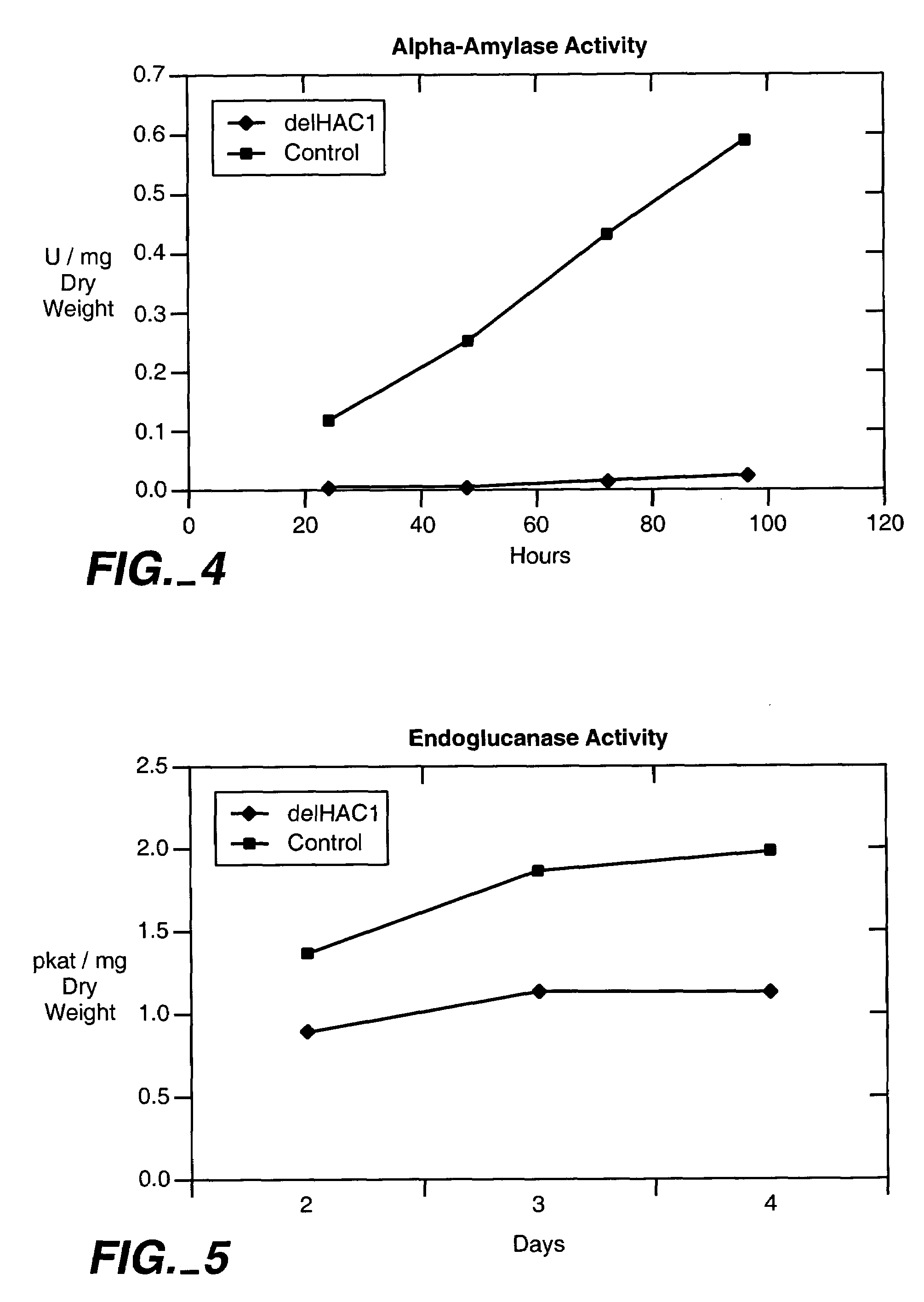

Increased production of secreted proteins by recombinant eukaryotic cells

Described herein are methods for increasing the amount of protein secreted by a cell. In one case, a cell is provided which contains a heterologous nucleic acid encoding a protein having unfolded protein response modulating activity and a heterologous nucleic acid encoding a protein of interest to be secreted. In one case, the protein having unfolded protein response modulating activity is selected from the proteins selected from the group consisting of HAC1, PTC2 and IRE1. The protein of interest can be any secreted protein such as a therapeutic or an industrial enzyme. For example the protein can be selected from the group consisting of lipase, cellulase, endo-glucosidase H, protease, carbohydrase, reductase, oxidase, isomerase, transferase, kinase, phosphatase, alpha-amylase, glucoamylase, lignocellulose hemicellulase, pectinase and ligninase.

Owner:DANISCO US INC

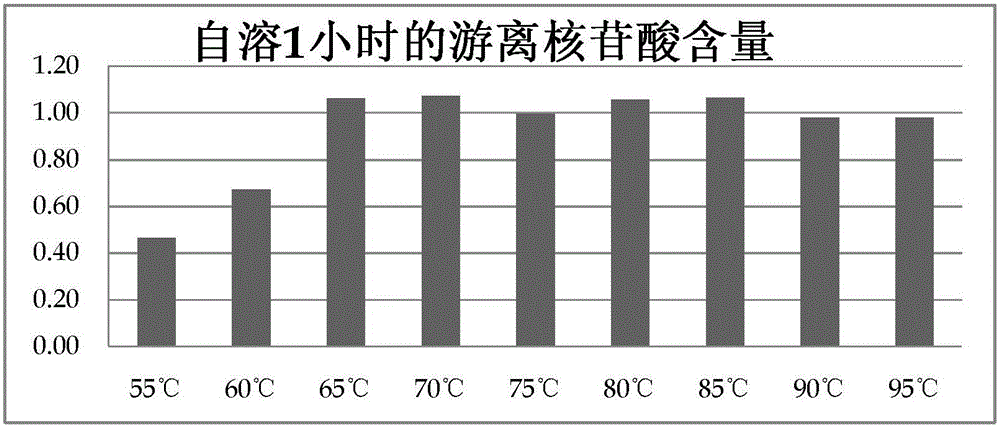

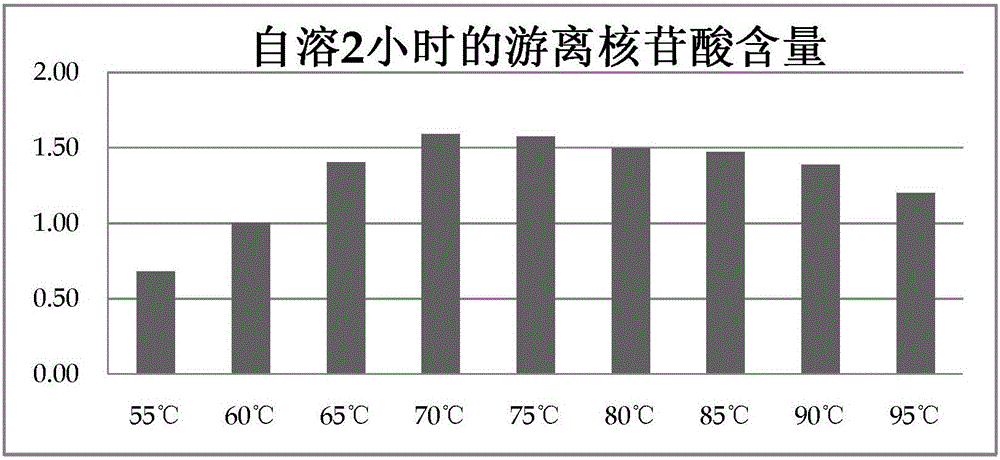

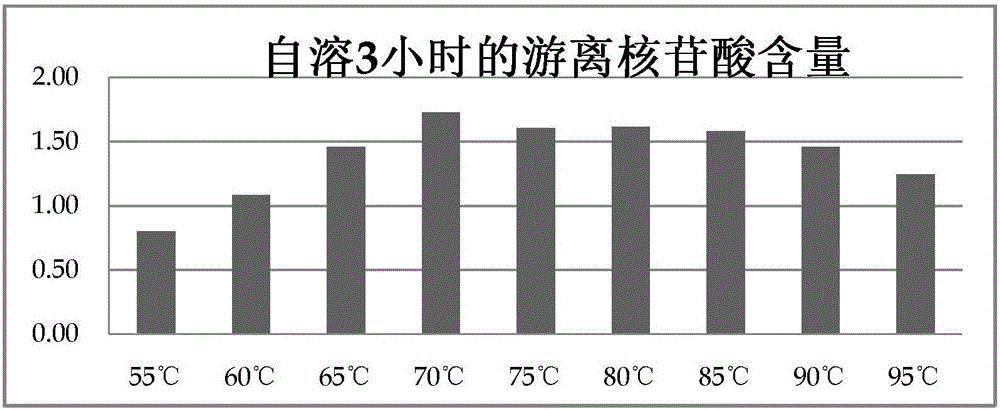

Autolysis process method for producing high-activity material yeast autolysate and yeast product prepared by same

PendingCN106190847ASolve the defect of low autolysis efficiencyImprove liquidityYeast food ingredientsMicroorganism lysisSingle-cell proteinHigh activity

The invention discloses an autolysis process method for producing high-activity material yeast autolysate. Specific single-cell protein not treated through sterilization and keeping original endogenous enzyme activity and yeast are mixed and autolyzed according to the dry biomass of 2-8 to 8-2, then dried and sterilized, autolysis is performed at a low temperature period and a high temperature period, in the low temperature period, the temperature ranges is kept at 45 to 60 DEG C for 20 to 60 minutes, and in the high temperature period, the temperature is kept at 75 to 95 DEG C for 30 to 120 minutes. According to the autolysis process method provided by the invention, the specific single-cell protein containing rich endogenous enzyme is innovatively taken as an exogenous enzyme directly applied to yeast autolysis, the activity of the exogenous enzyme is higher than that of industrial enzyme, and since the autolysis temperature is raised, the problem of pollution caused by over low temperature can be solved, and product quality is improved.

Owner:ICELL SUSTAINABLE SHANGHAI NUTRITION CO LTD

Method for preparing special peanut cake powder for fermentation

The invention relates to a method for preparing special peanut cake powder for fermentation. The method comprises the following steps of: taking non-mildew peanut cake, crushing, passing a 40-mesh mesh sieve, and taking sieved materials to obtain the peanut cake powder; mixing the peanut cake powder and an industrial enzyme preparation, conveying into a double-screw extruding and bulking machine after mixing uniformly, extruding and bulking; drying extruded and bulked materials, and enabling the water content of the materials to be less than 8-12%; and crushing the dried materials by a micro-powder machine while controlling the temperature to be below 80 DEG C in the crushing process to obtain the special peanut cake powder for fermentation. The method has the advantages that not only is the problem for the need of a nitrogen-source culture medium with comprehensive nutrition in industrial fermentation solved and is the need for normal metabolic and synthetic products of microorganisms in the industrial fermentation process met, but also the special culture medium for fermentation can also provide proper precursor substances, coenzymes or cofactors and the like for forming the metabolic products, so that the yield of metabolites is increased.

Owner:HENAN ZHENXIN BIOTECH CO LTD

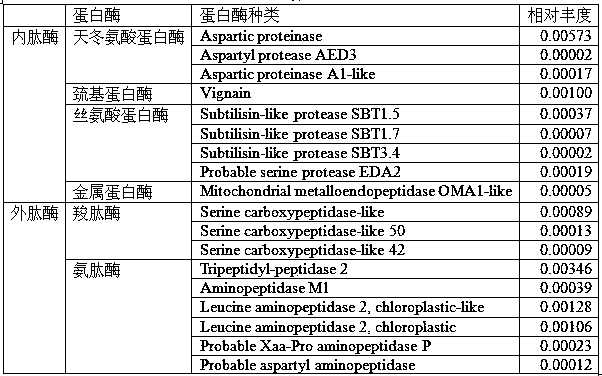

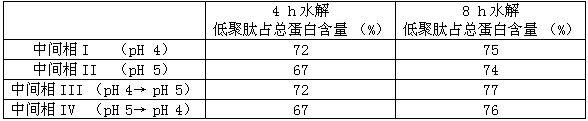

Method for preparing oligopeptide refreshing beverage by using endogenous endopeptidase and exopeptidase to hydrolyze sesame protein

ActiveCN110810687AIncrease economic value addedLow costFood processingProtein composition from vegetable seedsBiotechnologyOrganic solvent

The invention discloses a method for preparing an oligopeptide refreshing beverage by using endogenous endopeptidase and exopeptidase to hydrolyze sesame protein, and belongs to the technical field ofplant protein processing. The method comprises the following steps: sesame seeds are soaked at low temperature and peeled, pulping is performed, filtration is performed to obtain water extracts of peeled sesame seeds, centrifugation is performed on the water extracts to obtain a light phase, an intermediate phase and a heavy phase, protein in the intermediate phase is hydrolyzed by using the sesame endogenous endopeptidase and exopeptidase, centrifugation is performed to remove oil in the intermediate phase, the obtained supernatant and other materials are mixed, sterilization is performed, and packaging is performed to obtain the sesame oligopeptide refreshing beverage. The sesame oligopeptide refreshing beverage prepared by the method has the fragrant smell of the sesame seeds, and notonly is easier to digest and absorb, but also contains some physiologically active peptides; and the method provided by the invention does not use any industrial enzyme preparations or organic solvents, and the preparation process is environmentally friendly.

Owner:JIANGNAN UNIV

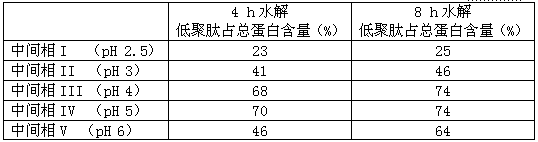

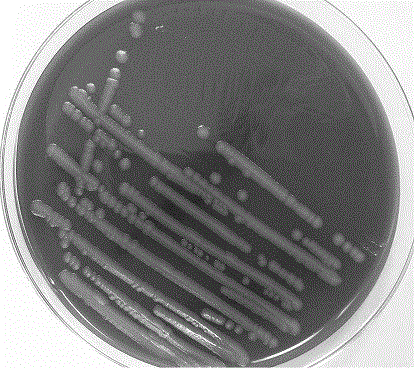

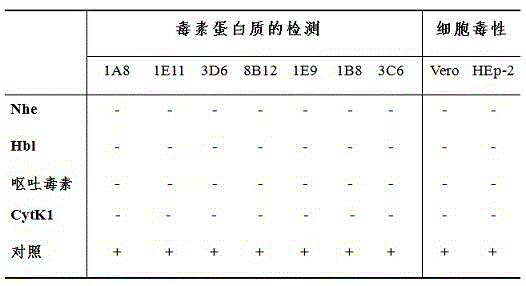

Avirulent Bacillus cereus strain pBC-1 and application thereof

The invention discloses an avirulent Bacillus cereus strain pBC-1, which is preserved in China General Microbiological Culture Collection Center (CGMCC, in Institute of Microbiology, Chinese Academy of Sciences, No. 3, Courtyard No.1, Beicheng West Road, Zhaoyang District, Beijing City, China, 100101), with an accession number of CGMCC No. 9535. Identification results show that the sequence of the strain pBC-1 is Bacillus cereus. Results of analysis at the levels of genes, protein and cells, the strain pBC-1 provided by the invention does not generate any toxin selected from a group consisting of cereulide, hemolysin BL (Hbl), non-hemolytic enterotoxin (Nhe) and cytotoxin K (CytK). The strain has wide application potential and can be applied to medicine and health care, feed additives or biological veterinary drugs as a probiotic candidate bacterial strain and used for removing pollutants in water bodies and preparing and purifying industrial enzymes.

Owner:朱奎

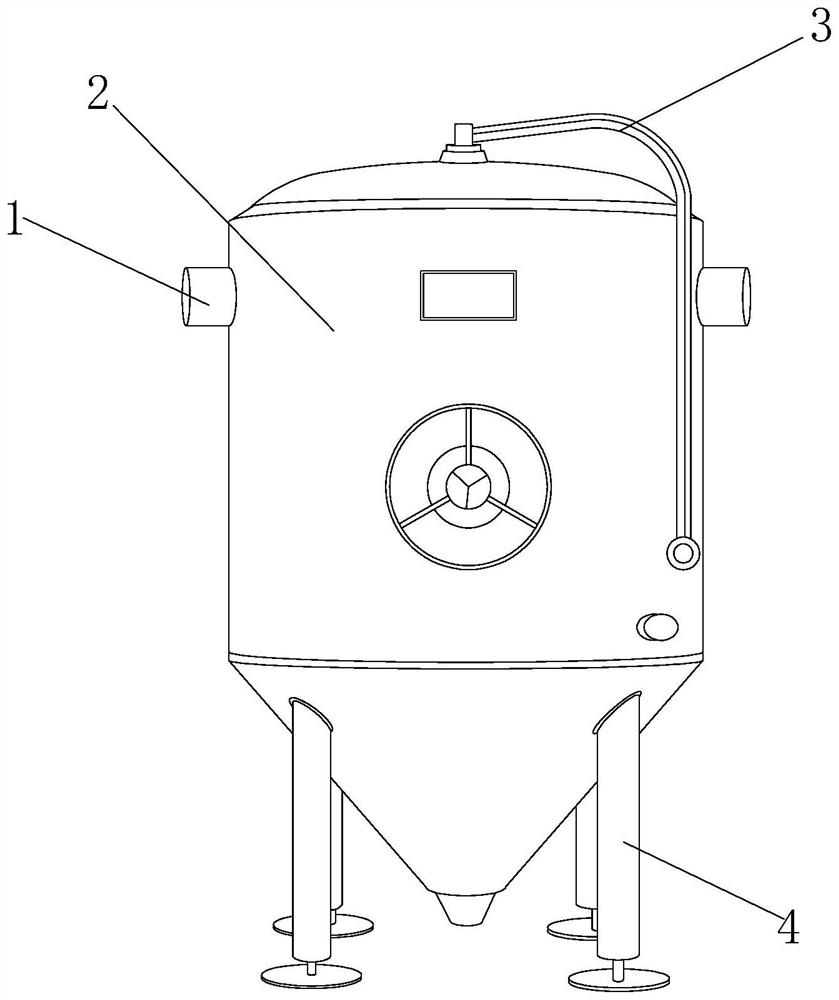

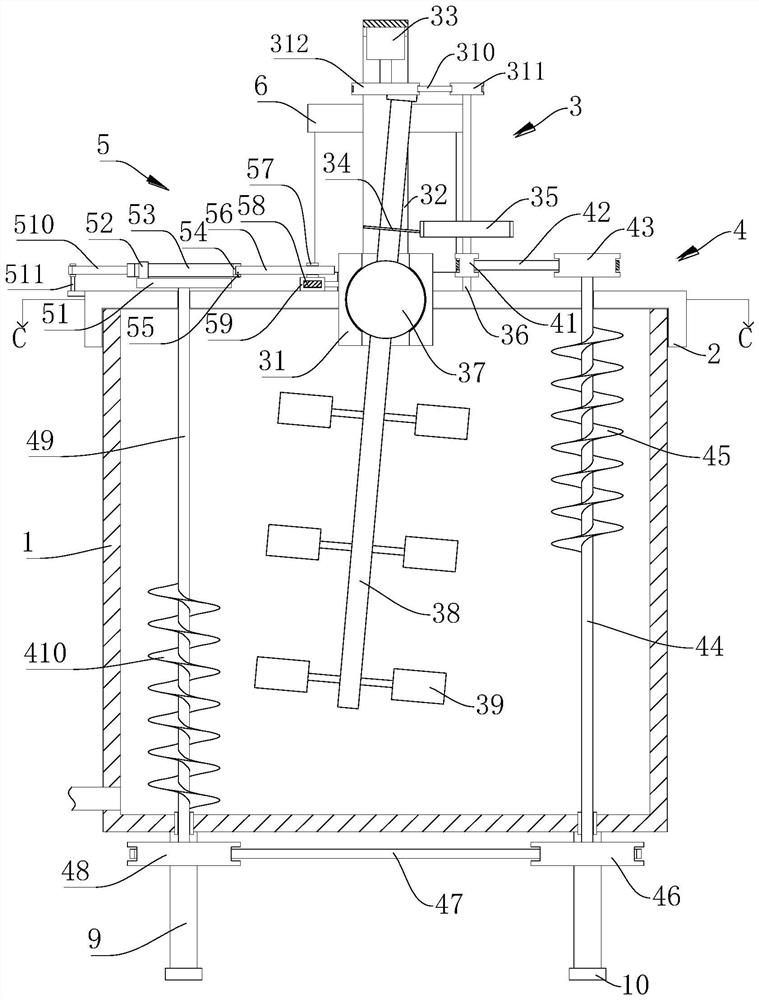

Solution blending device for industrial enzyme preparation

InactiveCN113351059AAvoid mixingAvoid enteringRotary stirring mixersMixer accessoriesEngineeringMechanical engineering

The invention discloses a solution blending device for industrial enzyme preparation. The device structurally comprises a connecting pipe, a stirring tank, a transmission pipe and supports, the connecting pipe is horizontally connected to the left and right sides of the upper end of the stirring tank, the transmission pipe is located at the front end of the stirring tank, and the supports are fixedly embedded and connected to four corners of the lower end of the stirring tank; the stirring tank is composed of a stirring tank, spraying devices, a rotating shaft and transverse rods, the spraying devices are fixedly connected to the left end and the right end of the inner side of the stirring tank in an embedded mode, the rotating shaft is located between the spraying devices, and the transverse rods are movably clamped to the left side and the right side of the rotating shaft. When new raw materials are mixed and sprayed, an overturning mechanism is extruded to swing outwards to a vertical state, while swinging, a sliding block can drive a magnetic block to slide along with the inclined gradient under the limitation of a sliding rod, when the magnetic block slides, a removing block can be dragged to move towards a collecting device from the upper end of the overturning mechanism, and a pushing plate makes contact with the surface of the overturning mechanism in the moving process to remove mixed liquid adhering to the surface, and the mixed liquid is avoided from mixing with new raw materials.

Owner:陈珍珍

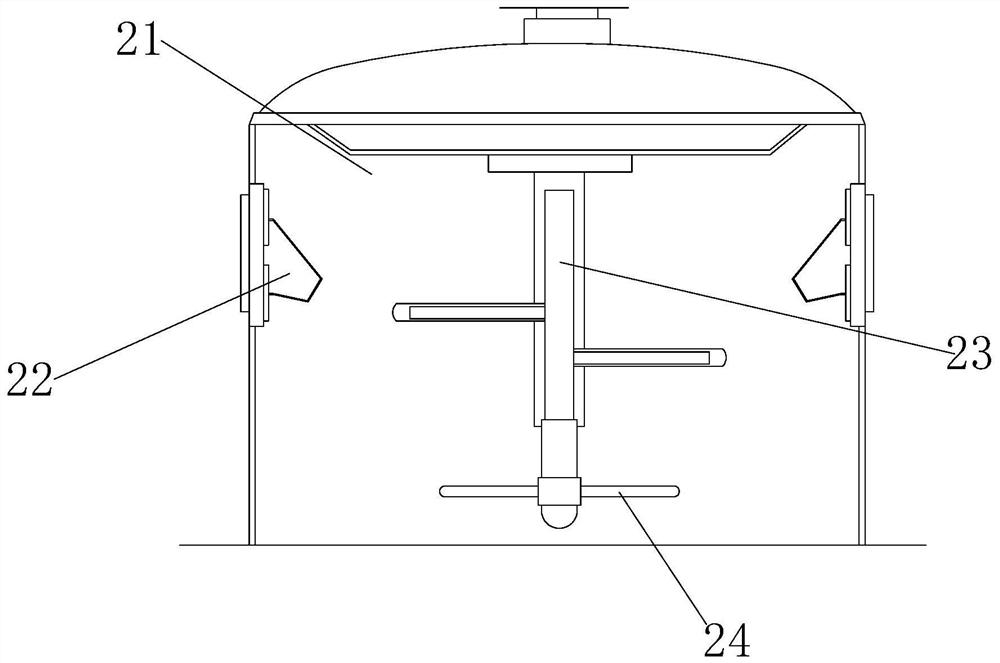

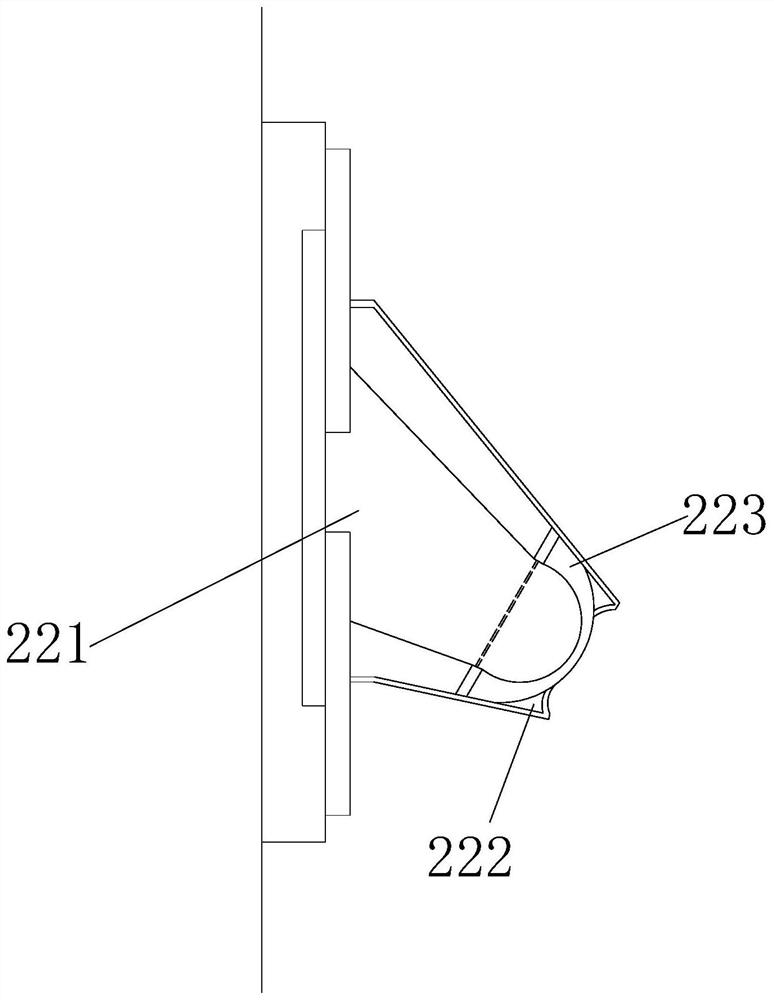

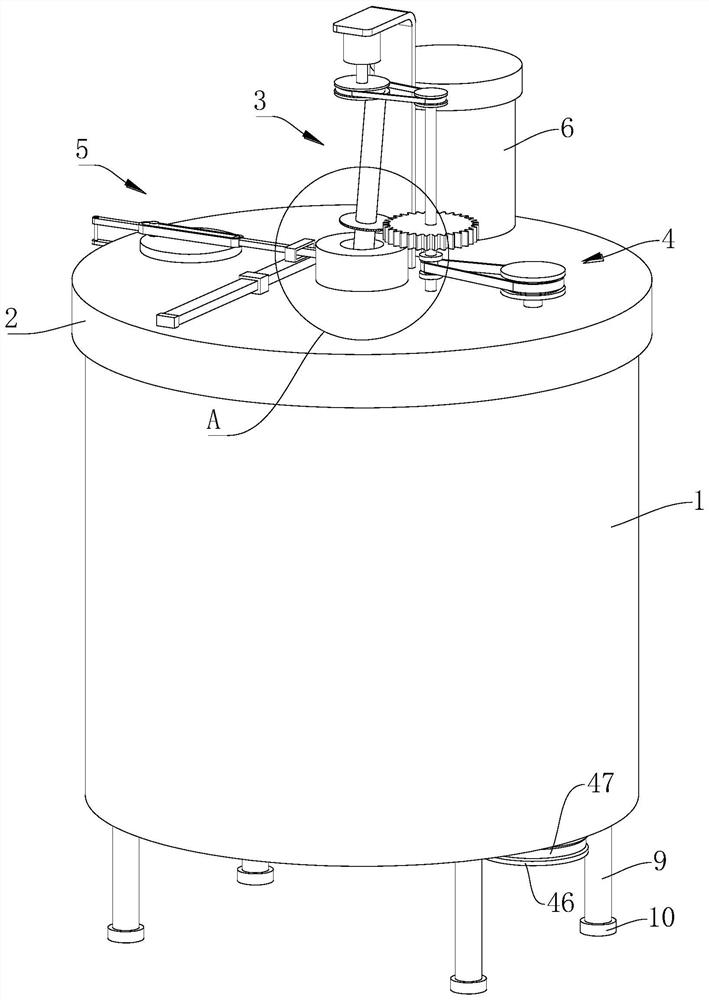

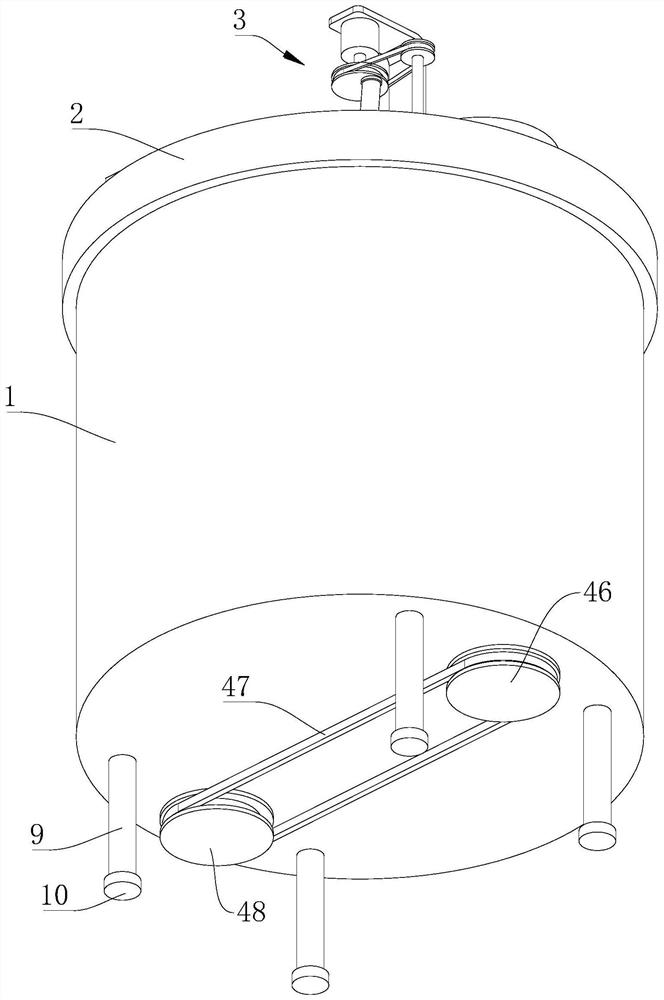

Mixing device for preparing industrial enzyme preparation

PendingCN112246122APrevent spinningImprove the mixing effectBioreactor/fermenter combinationsBiological substance pretreatmentsDrive shaftElectric machinery

The invention relates to the technical field of preparation of an industrial enzyme preparation, and particularly relates to a mixing device for preparing an industrial enzyme preparation. The mixingdevice comprises a mixing box, wherein supporting legs are fixedly mounted on the lower end face of the mixing box, a box cover is in threaded connection with the upper end of the mixing box, a main stirring piece is fixedly mounted on the upper end face of the box cover, a containing box is fixedly installed on one side of the upper end face of the box cover, the main stirring piece comprises a limiting sleeve, an installation plate, a motor, a first gear, a second gear, a connecting shaft, a sleeving ball, a driving shaft, stirring blades, a third belt, a linkage disc and a driving plate, the limiting sleeve is fixedly installed in the middle of the box cover, and the installation plate is fixedly installed on the upper end face of the box cover. The mixing device is good in mixing effect and worthy of popularization.

Owner:普玉蓉

Enzymatic thermal stability improving method

ActiveCN103740659AImprove thermal stabilityImprove methodHydrolasesTransferasesThermal stabilityRecombinase

The invention discloses an enzymatic thermal stability improving method. Fusion expression of an amphiphilic short peptide and recombinase is carried out to obtain thermal stability-improved recombinase. The optimal sequence of the amphiphilic short peptide is DWLKAFYDKVAEKLKEAFKVQPYLDDWLKAFYDKVAEKLKEAF. The method has the advantages of substantial effect, simple process and convenient popularization, and provides a new method and idea for the rapid improvement of the thermal stability of industrial enzymes.

Owner:JIANGNAN UNIV

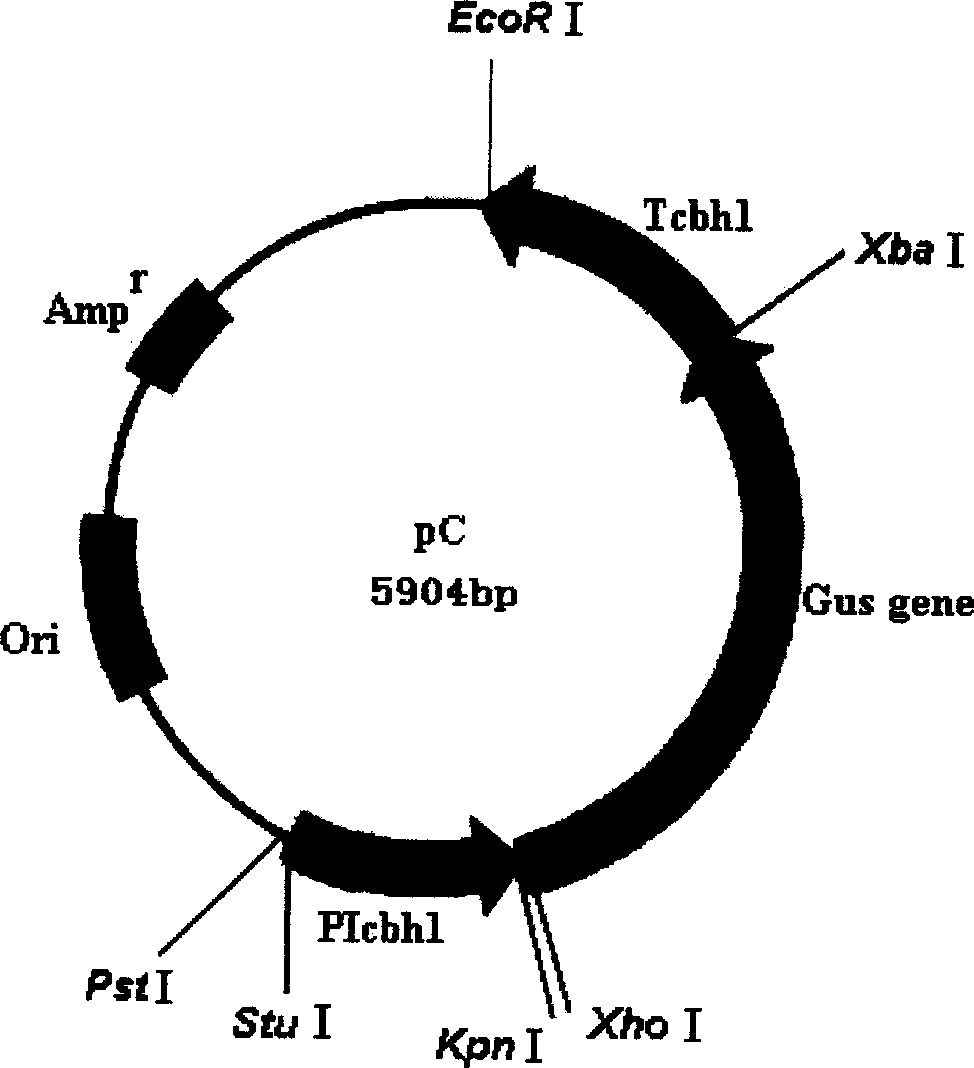

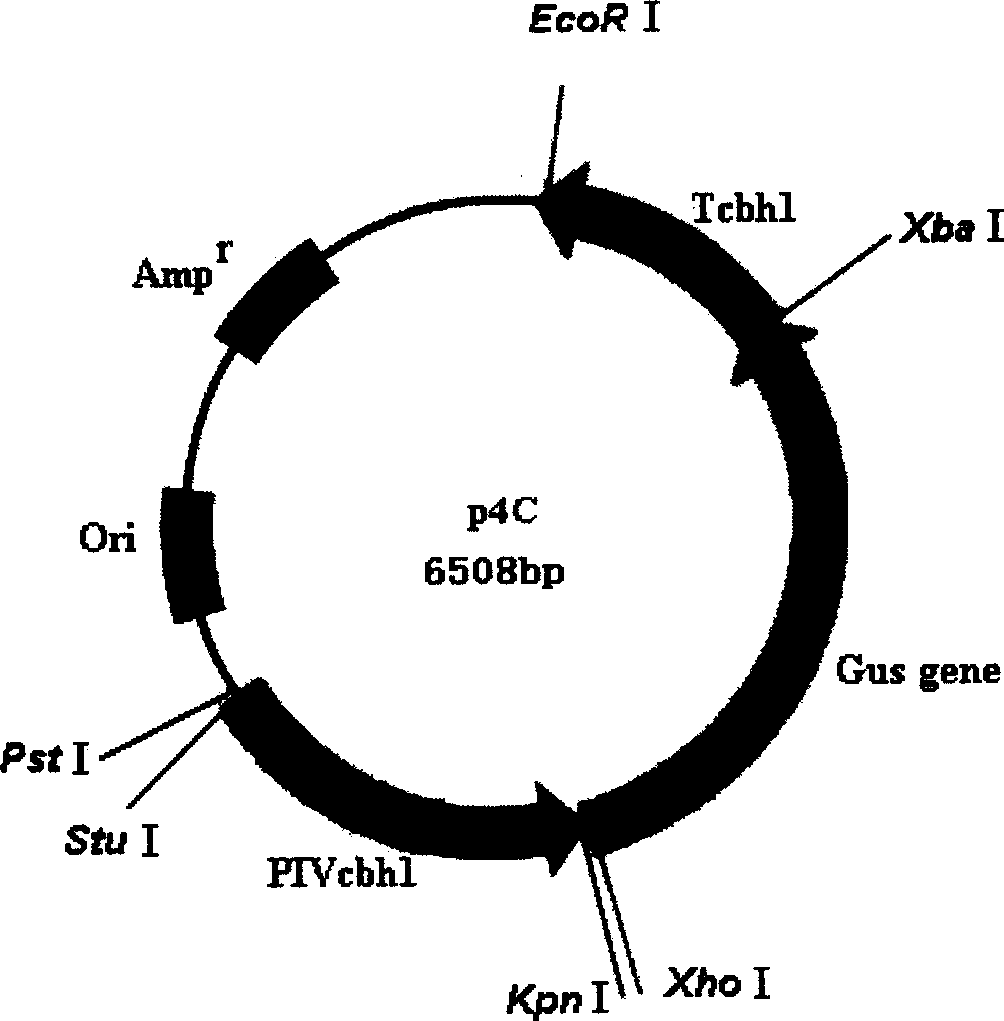

Promoter used for producing industrial enzyme with high prodn. rate

The invention discloses a promoter to produce industry enzyme in Trichoderma reesei. The invention recombines dextrose stop point on PCR lack Trichoderma reesei exterior contact dextrose fiber disaccharide hydrolase I gene promoter, and takes alteration to the function area by taking multi copy strategy to gain a series of high promoting activity promoter.

Owner:SHANDONG UNIV

Method for producing mullein glucoside monomeric compound

The invention relates to a method for producing mullein glucoside monomeric compound, which comprises the following steps: carrying out high-temperature enzyme deactivation and cell rupture on fleshystem fresh cistanche deserticola or cistanche deserticola decoction pieces; taking beta-glucosidase industrial enzyme preparation as biological catalyst; carrying out biocatalysis reaction by a solidstate fermentation reactor; rupturing glucose residue ligand terminal by echinacoside zymolyte in catalyzed hydrolysis substrate (belt-1,6-glycosidic bond); directionally translating into high-activity mullein glucoside monomeric compound; and then carrying out systematic process treatment, such as serosity extraction, separation and purification, concentration and drying and the like to obtain the mullein glucoside monomeric compound. By adjusting separation and purification process conditions, the purity percentage content of the meal or drying material of the obtained mullein glucoside monomeric compound can reach 35.8%-89.5%. The mullein glucoside monomeric compound has the characteristics of micromolecule and low polarity, can show good absorptivity and special pharmacology activity in drug absorption.

Owner:SUN YAT SEN UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com