Acid and high temperature resistant alpha-amylase and genes and engineering bacteria of alpha-amylase and preparation method

A technology of amylase and acid resistance, which is applied in the field of bioengineering to achieve the effects of enhanced thermal stability, broad application prospects and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Construction of Acid and High Temperature α-Amylase Gene

[0037] 1. Construction of BLA mutants

[0038] According to the BLA mutation sites reported in the literature, corresponding site-directed mutagenesis primers (Table 1) were designed. Using BLA as the starting sequence, five BLA mutants were constructed by whole-plasmid PCR, and these five mutants were expressed in the same expression vector. Express in the same host cell to obtain five mutant acid-resistant and high-temperature α-amylases;

[0039] 2. Determination and analysis of enzymatic properties of BLA mutants

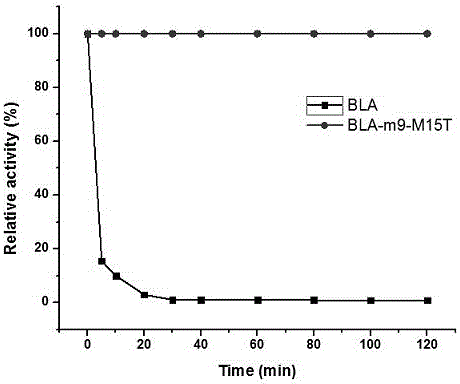

[0040] According to the analysis of enzymatic properties, it is found that BLA-m9 and BLA-m6 have the best thermal stability at pH 4.5, and BLA-m9 has higher specific activity in the range of pH 4.0-5.0 and good acid resistance;

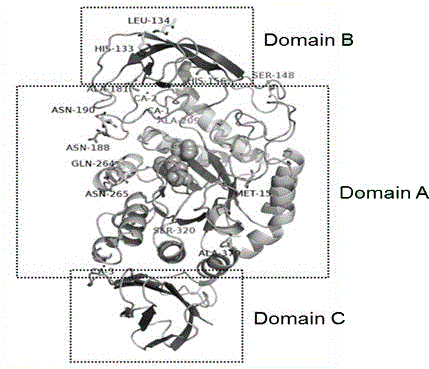

[0041] 3. Structural analysis of BLA mutants

[0042] The homology modeling of five mutants of BLA was carried out by SWISS-MODEL, and the models of BLA-4480, BLA-m6,...

Embodiment 2

[0049] Preparation of acid-resistant and high-temperature α-amylase engineered bacteria

[0050] 1. Construction of recombinant expression plasmids

[0051] Digest the target fragment on the mutant plasmid with Pst I and Hind III, enzyme digestion reaction system: 10 μL plasmid + 1 μL Pst I + 1 μL Hind III + 10 μL buffer + 15 μL ddH 2 O, reaction conditions: 37°C, 3h; purify and recover the digested fragment with a gel recovery kit;

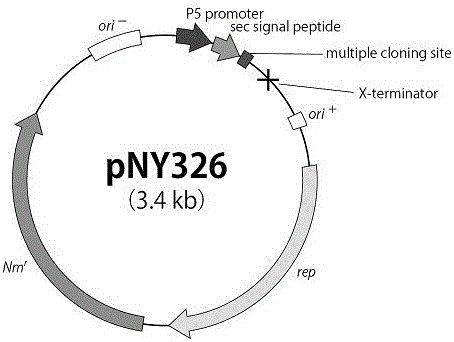

[0052] The pNY326 vector plasmid ( figure 1 ) with Pst I and Hind III for double enzyme digestion and dephosphorylation treatment, enzyme digestion reaction system: 10 μL plasmid + 1 μL Pst I + 1 μL Hind III + 10 μL buffer + 15 μL ddH 2 O, reaction conditions: 37°C, 3h; pNY digested fragments were phosphorylated with alkaline phosphatase (CIAP), reaction system: 20 μL double digestion reaction solution + 2 μL CIAP + 3 μL buffer + 5 μL ddH 2 O, reaction conditions: 37°C, 3h; the phosphorylated pNY fragments were purified and recovered with a ge...

Embodiment 3

[0059] Preparation of acid-resistant and high-temperature α-amylase

[0060] Express and purify acid-resistant high-temperature α-amylase according to the following method: inoculate the acid-resistant high-temperature α-amylase recombinant strain in 20mL MTNm medium, 37°C, 180rpm constant temperature shaking culture for about 12h, until OD600 is 1.0 to obtain seed liquid; The seed solution was inoculated in a 5L fermenter containing 2L of TMNm medium with a 2% inoculum amount, cultured at a constant temperature of 30°C, with a rotation speed of 200rpm for 72 hours, and an air flow of 10vvm; the pH value was monitored in real time during the fermentation process, and acid and alkali were automatically replenished to maintain the culture The pH value of the liquid is about 6.86; after 72 hours of cultivation, the supernatant is centrifuged to obtain the crude enzyme liquid; the crude enzyme liquid is purified to obtain electrophoretic pure acid-resistant high-temperature α-amyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com