Solution blending device for industrial enzyme preparation

An industrial and solution technology, applied in the field of solution preparation devices for industrial enzyme preparation, can solve problems such as affecting the purity of the solution, stickiness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

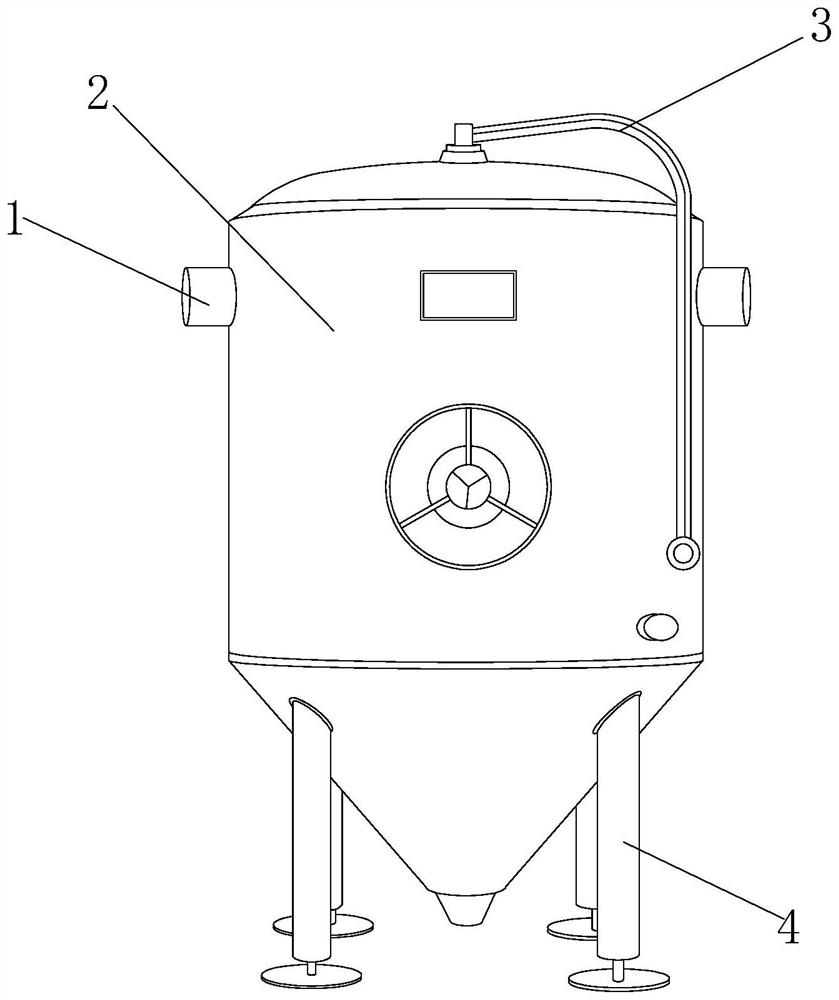

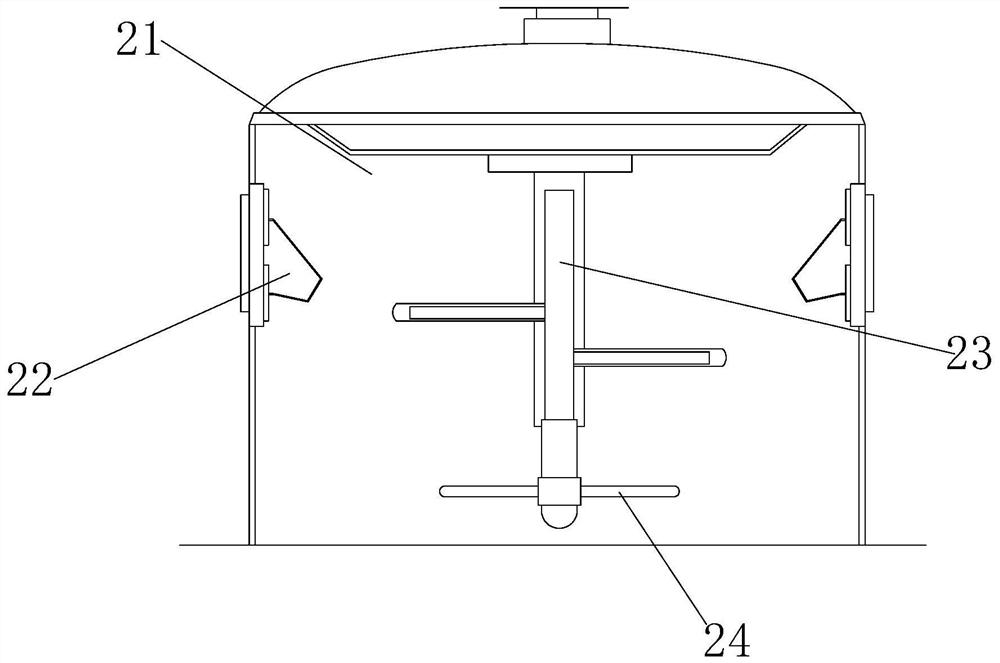

[0029] as attached figure 1 to attach Figure 6 Shown:

[0030] The invention provides a solution preparation device for industrial enzyme preparation, the structure of which includes a connecting pipe 1, a stirring tank 2, a transmission pipe 3, and a support 4. The connecting pipe 1 is horizontally connected to the left and right sides of the upper end of the stirring tank 2, and the transmission The pipe 3 is located at the front end of the mixing tank 2, and the bracket 4 is embedded and connected to the four corners of the lower end of the mixing tank 2; It is fixedly connected to the left and right ends of the inner side of the stirring tank 21 , the rotating shaft 23 is located between the spraying devices 22 , and the cross bar 24 is movably engaged with the left and right sides of the rotating shaft 23 .

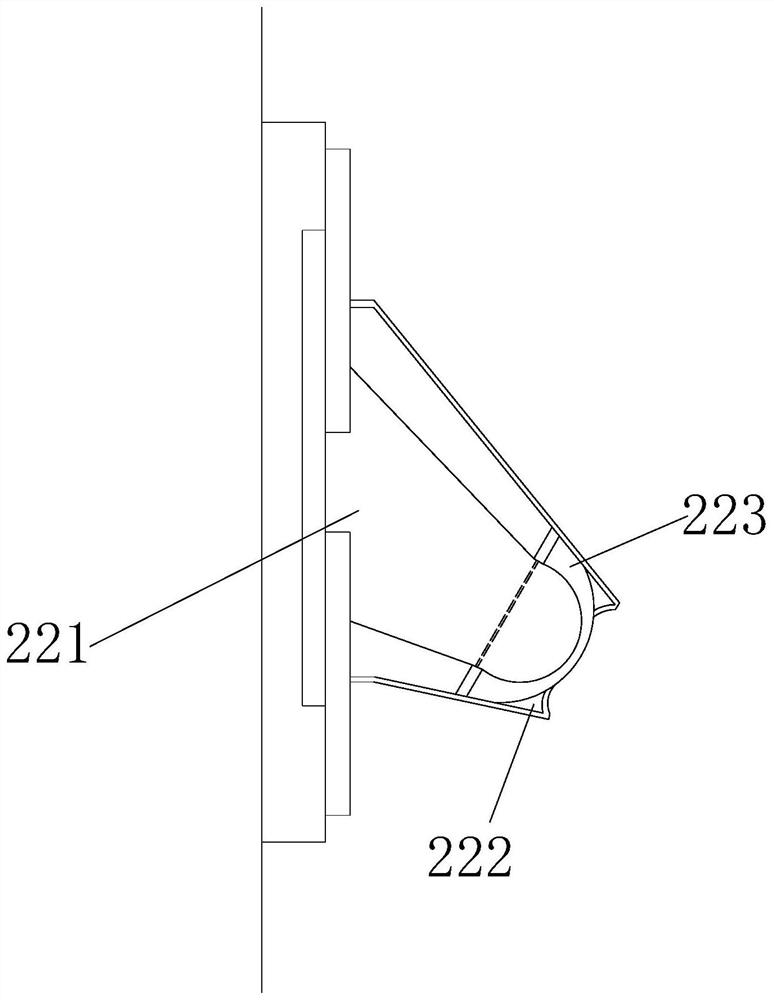

[0031] Wherein, the spraying device 22 is composed of a spraying slot 221, an extension frame 222, and a blocking device 223. The spraying slot 221 is located ins...

Embodiment 2

[0038] as attached Figure 7 to attach Figure 9 As shown: the barrier device 223 is composed of a top block 231, a collection device 232, a flow tank 233, and a turning mechanism 234. The collection device 232 is riveted to the upper end of the top block 231. Between the collection devices 232, the flipping mechanism 234 is located at the lower end of the flow tank 233. There are two flipping mechanisms 234, which are installed in the lower end of the flow tank 233 in an arc shape, and are made of rubber, so as to facilitate the spraying of the spray hole. out of position to avoid adhering the mixed liquid and mixing with new raw materials.

[0039] Wherein, the collection device 232 is composed of a collection piece 321, a hollow net 322, and a hollow groove 323. The collection piece 321 is located at the lower end of the hollow groove 323, and the hollow net 322 is embedded and connected to the upper end of the collection piece 321. The collection piece The outer contour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com