Enzyme-metal ion nano compound and preparation method thereof

A nano-composite, metal ion technology, applied in biochemical equipment and methods, enzymes, oxidoreductases, etc., can solve problems such as enzyme inactivation and complex process, and achieve constant enzyme activity, simple operation, and good application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, glucose dehydrogenase-Ca 2+ Preparation of complex

[0036] 1. Prepare PBS buffer solution (pH=7.4) of glucose dehydrogenase with an enzyme concentration of 0.5 mg / mL and 100 mM calcium chloride aqueous solution.

[0037] 2. Take 2 mL of the enzyme solution in step 1 in a glass vial, add 0.02 mL of the calcium chloride solution in step 1, and mix well (in the mixed solution, Ca 2+ The mass ratio of glucose dehydrogenase to glucose dehydrogenase is 0.08:1) and then placed in an incubator at 4°C for 24 hours.

[0038] 3. Add 2wt% sucrose to the mixture obtained in step 2 as a lyoprotectant. The glucose dehydrogenase-calcium ion nanocomposite was obtained by freeze-drying for 12 hours.

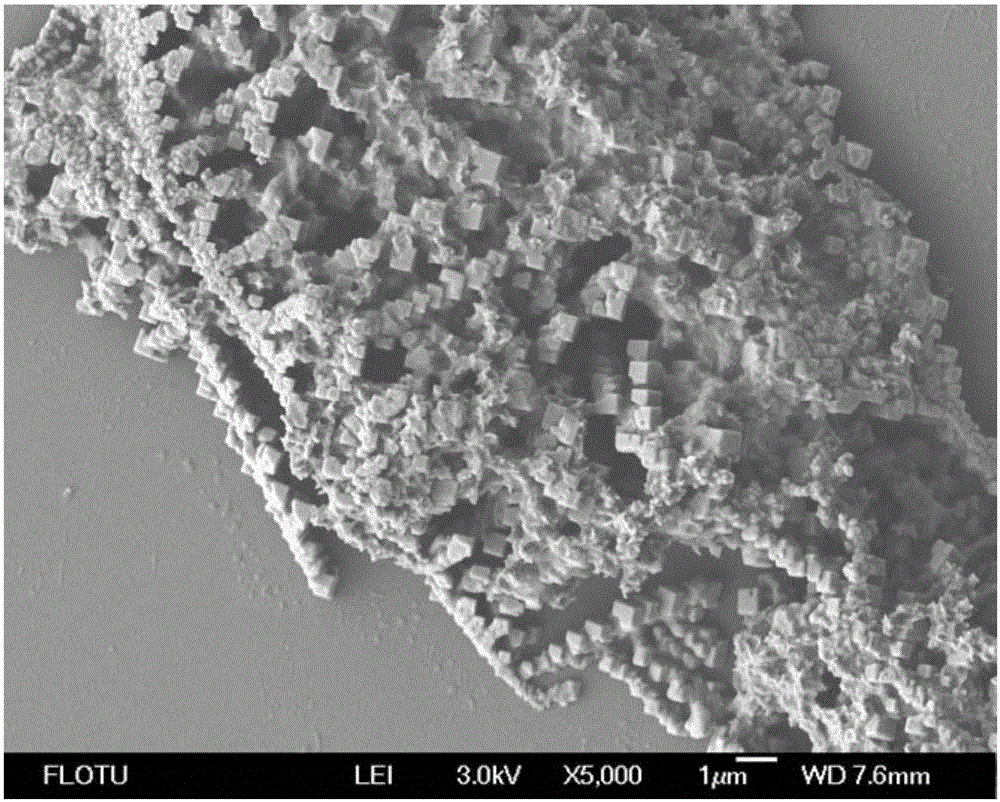

[0039] The scanning electron micrograph of the nanocomposite prepared in this embodiment is as follows figure 1 shown by figure 1 It can be seen that the complex is a polyhedron of about 500 nm.

[0040] The enzyme loading (determined by BCA method to measure the remainin...

Embodiment 2

[0041] Embodiment 2, glucose oxidase-Zn 2+ Preparation of complex

[0042] The calcium chloride solution in the preparation step 1 of embodiment 1 is replaced with zinc chloride solution (50mM) respectively, and glucose dehydrogenase is replaced with glucose oxidase, Zn in the gained mixed solution 2+ The mass ratio to glucose oxidase is 0.065:1, no sucrose is added as a freeze-drying protective agent before freeze-drying, and other operations are the same.

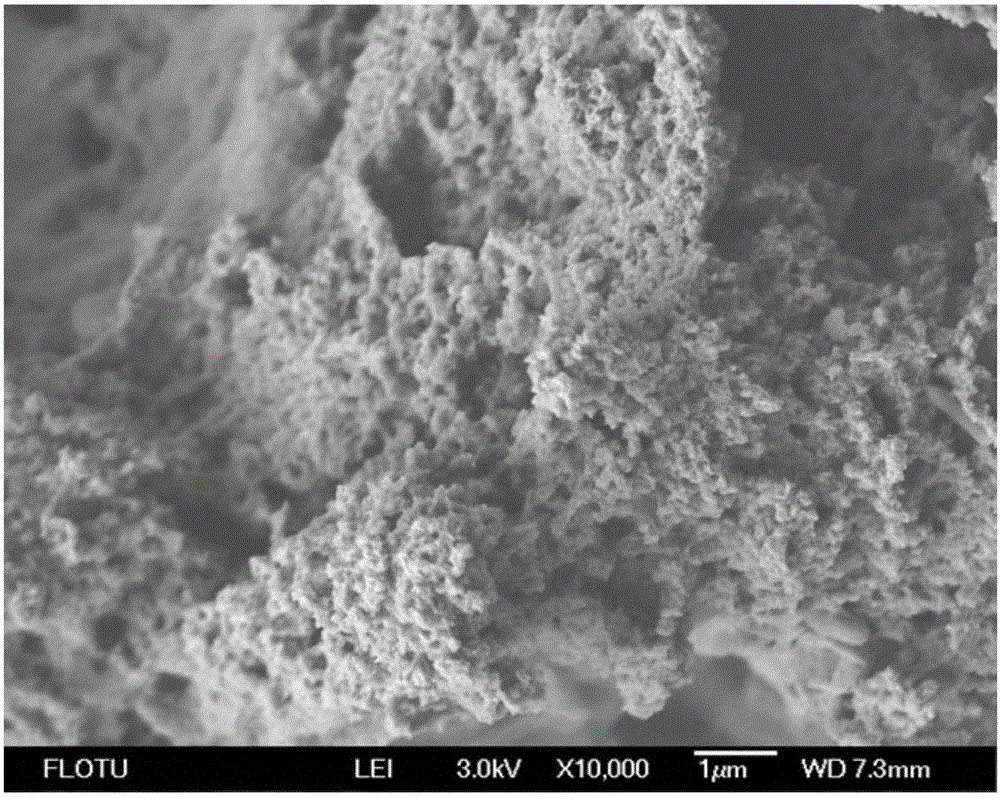

[0043] Glucose Oxidase-Zn 2+ SEM images of nanocomposites / aggregates are shown in figure 2 shown by figure 2 It can be seen that the composite / aggregate presents a porous sheet-like structure.

[0044] Glucose oxidase-Zn prepared by the present embodiment 2+ The enzyme loading in the nanocomposite was 2.1%.

Embodiment 3

[0045] Embodiment 3, glucose dehydrogenase-Cu 2+ Preparation of complex

[0046] The calcium chloride solution in the preparation step 1 of embodiment 1 is replaced with copper sulfate solution (100mM), in the gained mixed solution Cu 2+ The mass ratio to glucose dehydrogenase is 0.128:1, no sucrose is added as a lyoprotectant before lyophilization, and other operations are the same.

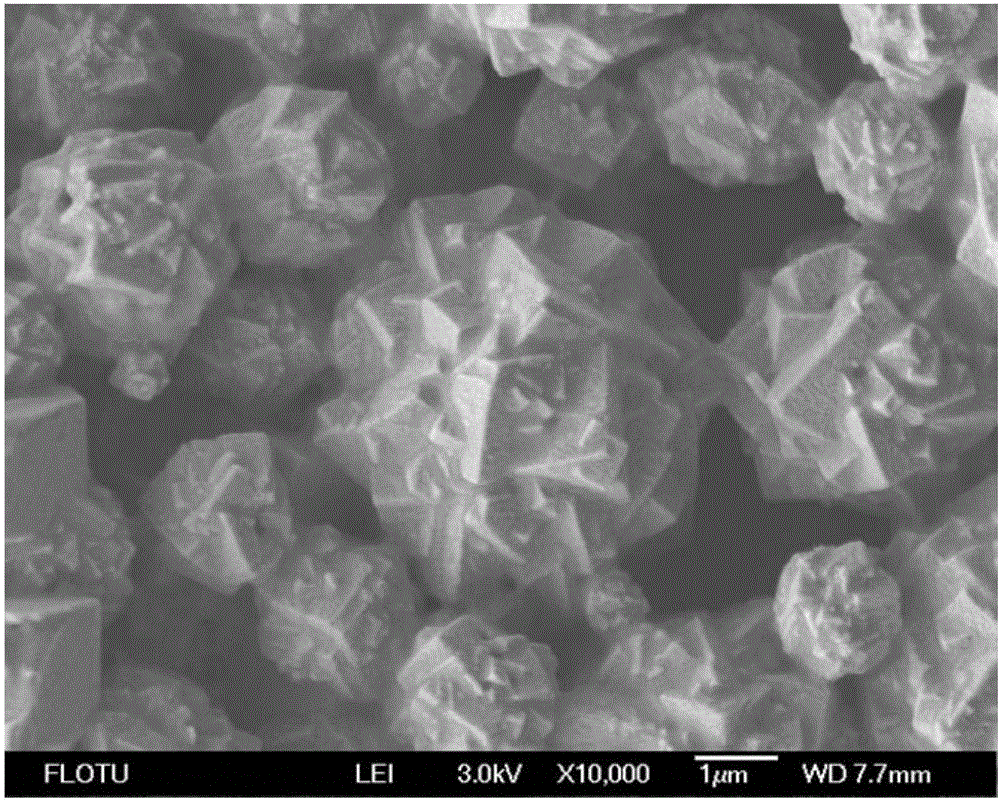

[0047] Glucose dehydrogenase-Cu 2+ The scanning electron microscope image of the nanocomposite is shown in image 3 shown by image 3 It can be seen that the complex is a small ball of about 2um, which is formed by stacking polyhedrons.

[0048] Glucose dehydrogenase-Cu prepared by the present embodiment 2+ The enzyme loading in the nanocomposite was 2.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com