Patents

Literature

98 results about "Functionalized polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gel composition for cellular adhesion inhibition

InactiveUS20070031498A1Avoid stickingInhibiting adhesion of cellPowder deliveryBiocideAdhesion processPolyethylene glycol

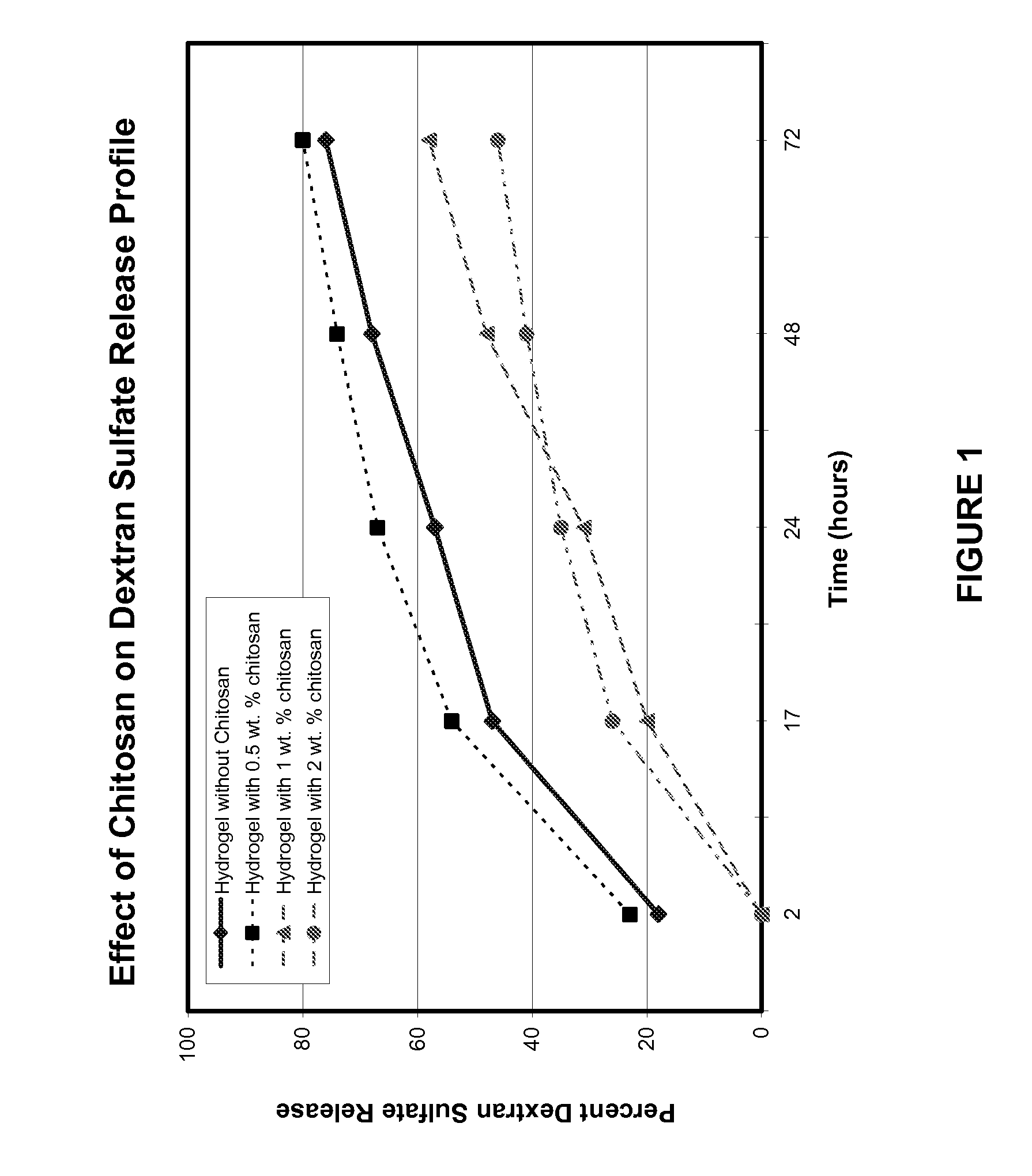

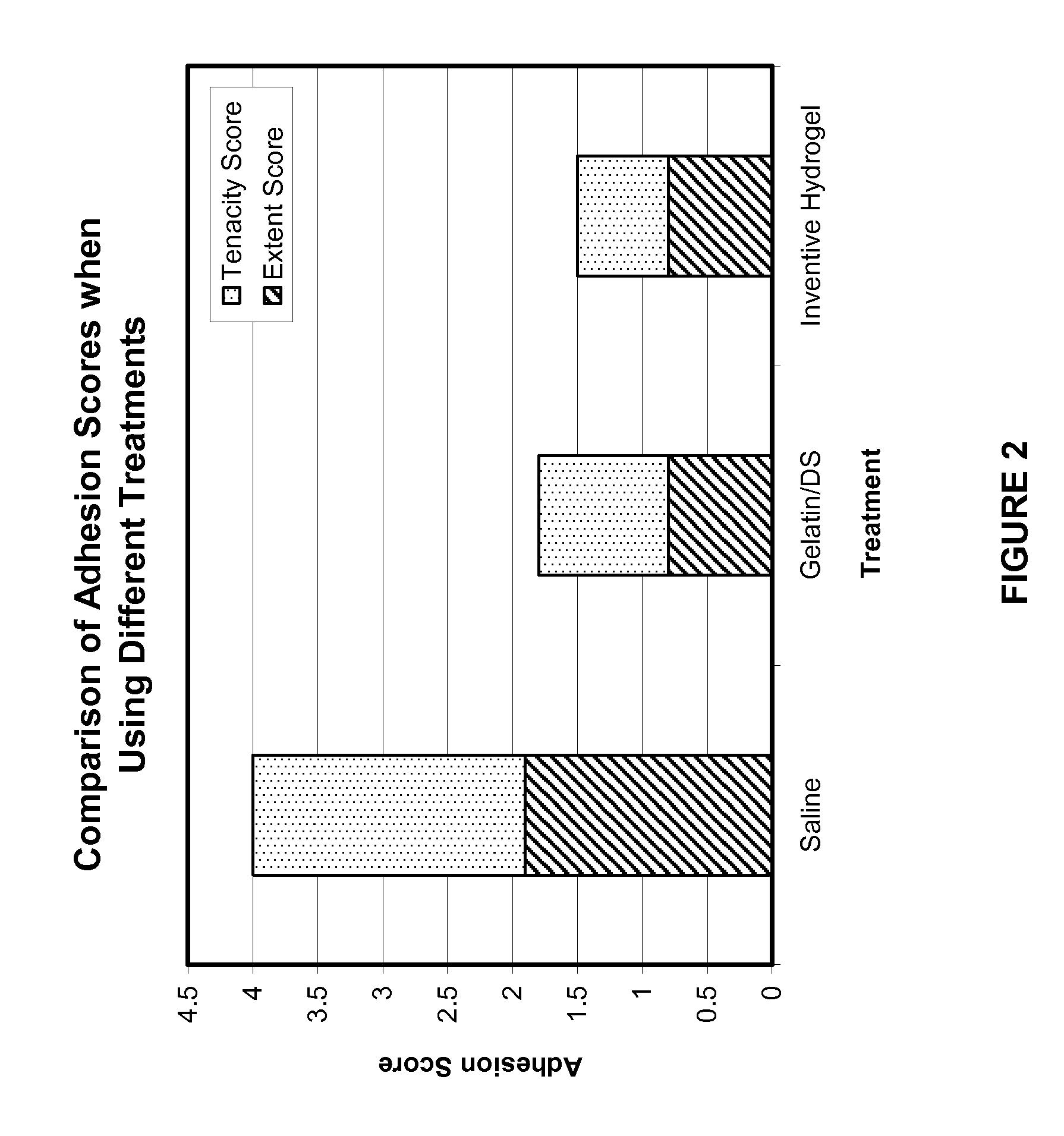

The invention includes compositions for inhibiting cellular adhesion, methods of preparation of such compositions, and methods for preventing cell adhesion at a surgical site comprising application of such compositions. The compositions generally comprise a cellular adhesion inhibitory agent, such as dextran sulfate, and a crosslinked hydrogel matrix, preferentially physically entrapping the adhesion inhibitory agent. The hydrogel matrix can include a first gel component, such as an electrophilically functionalized polyethylene glycol polymer, and at least one additional gel component, preferably nucleophilically functionalized, and preferentially selected from the group consisting of polyethylene glycol polymers, polypeptides, and polysaccharides. The compositions are useful for delivering the cellular adhesion inhibitory agent to a site in need of adhesion inhibition and providing either immediate or metered delivery of the inhibitory agent.

Owner:TRIAD

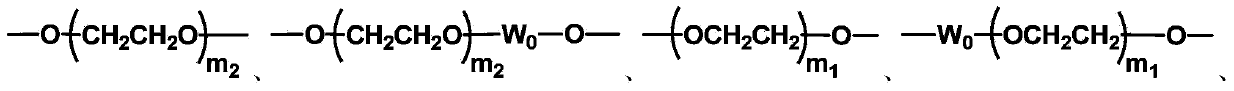

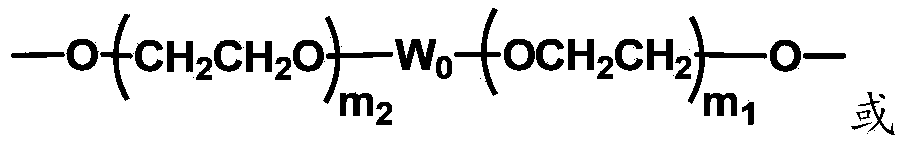

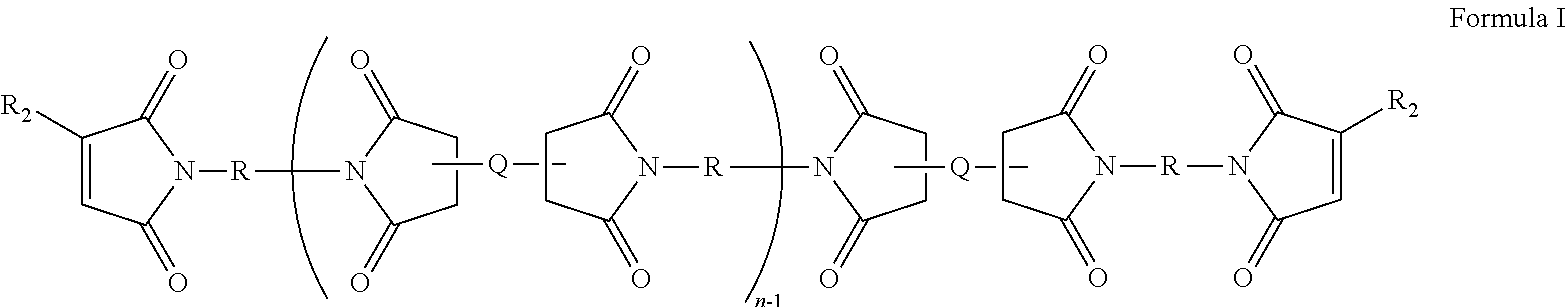

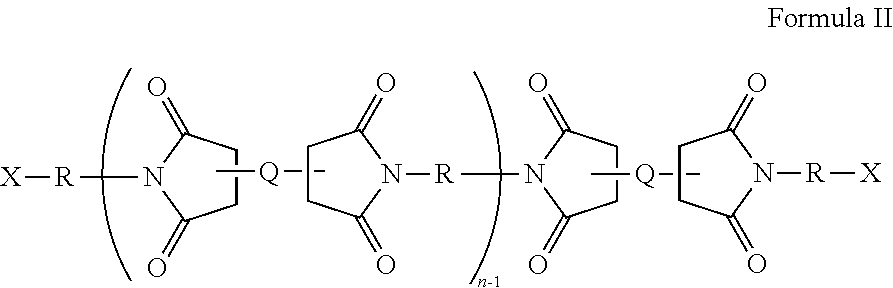

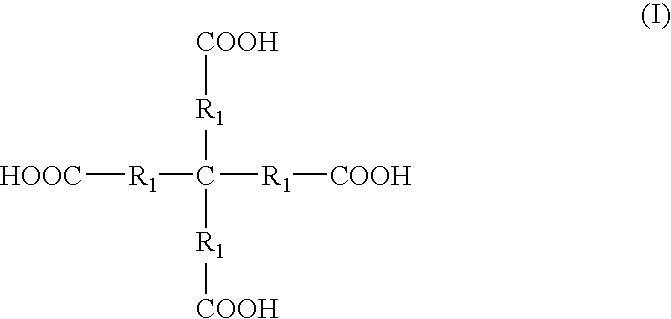

Multifunctional H-type polyethylene glycol derivative and preparation method thereof

ActiveCN104530417AIncrease the number ofImprove modification efficiencyPolymer sciencePolyethylene glycol

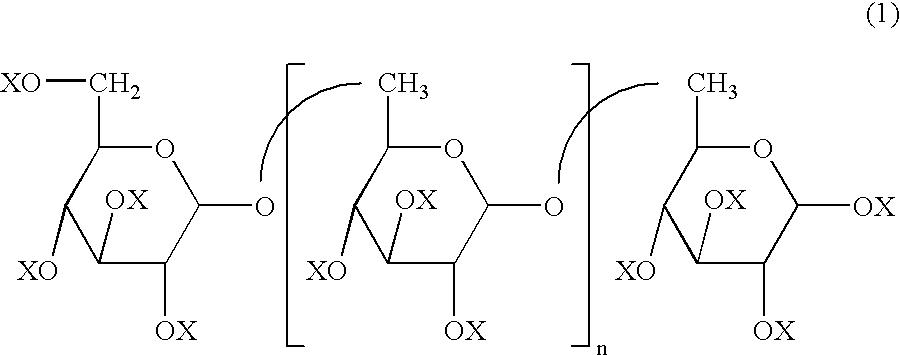

The invention discloses a multifunctional H-type polyethylene glycol derivative and a preparation method thereof. The structure is as shown in formula (1) in the description, wherein a linear main axis LPEG and four PEG branched chains are included, and n1, n2, n3 and n4 are polymerization degrees of the branched chains, respectively; U1 and U2 are trivalent branching groups connecting the main axis LPEG with two PEG branched chains; F1 and F2 contain functional groups or their protected forms R01, and contain or do not contain branching groups G, and correspondingly, the number of R01 is one or more than one; F1 is the same as or different from F2; any linking group in the molecule or linking groups formed with adjacent heteroatom groups are stable or degradable; any PEG chain segment in the molecule independently shows polydispersity or monodispersity. The functionalized polyethylene glycol is diverse in branching structure and branching arm length, is adjustable and easily-controllable in various parameters and performance indexes, and is wide in application.

Owner:XIAMEN SINOPEG BIOTECH

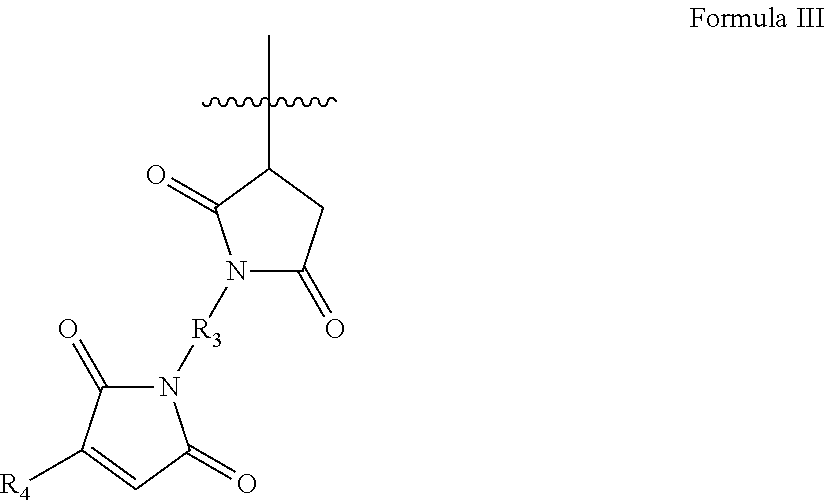

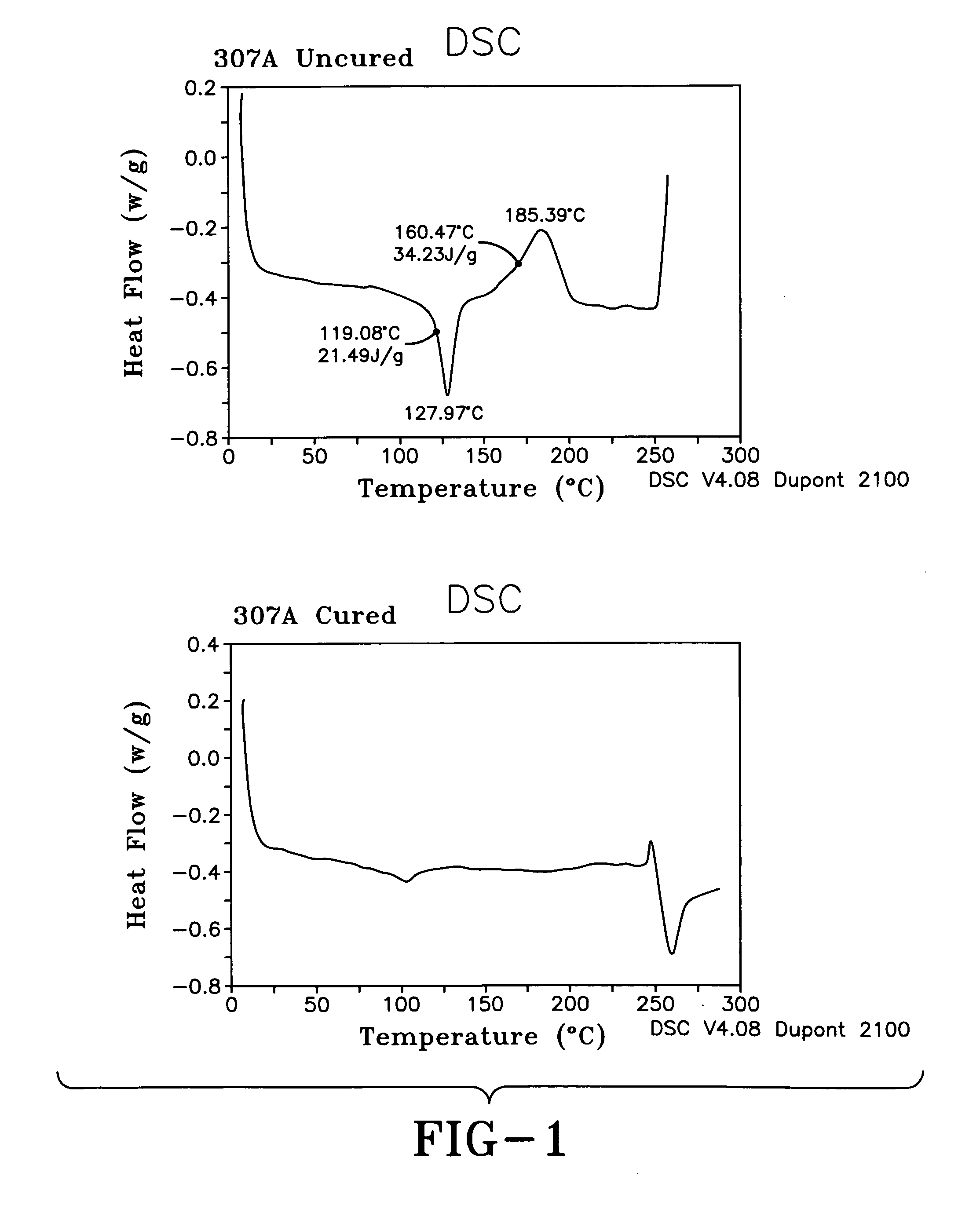

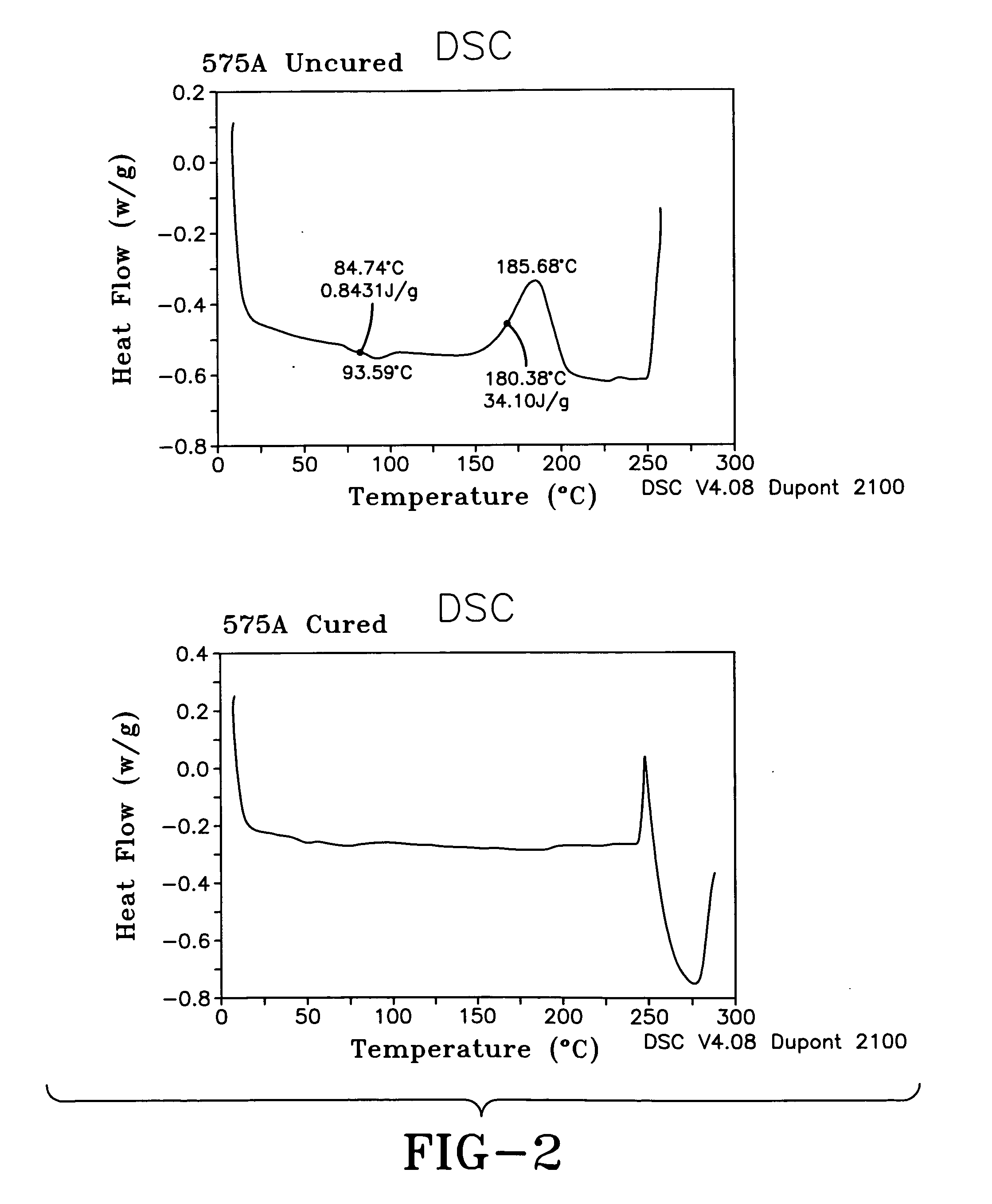

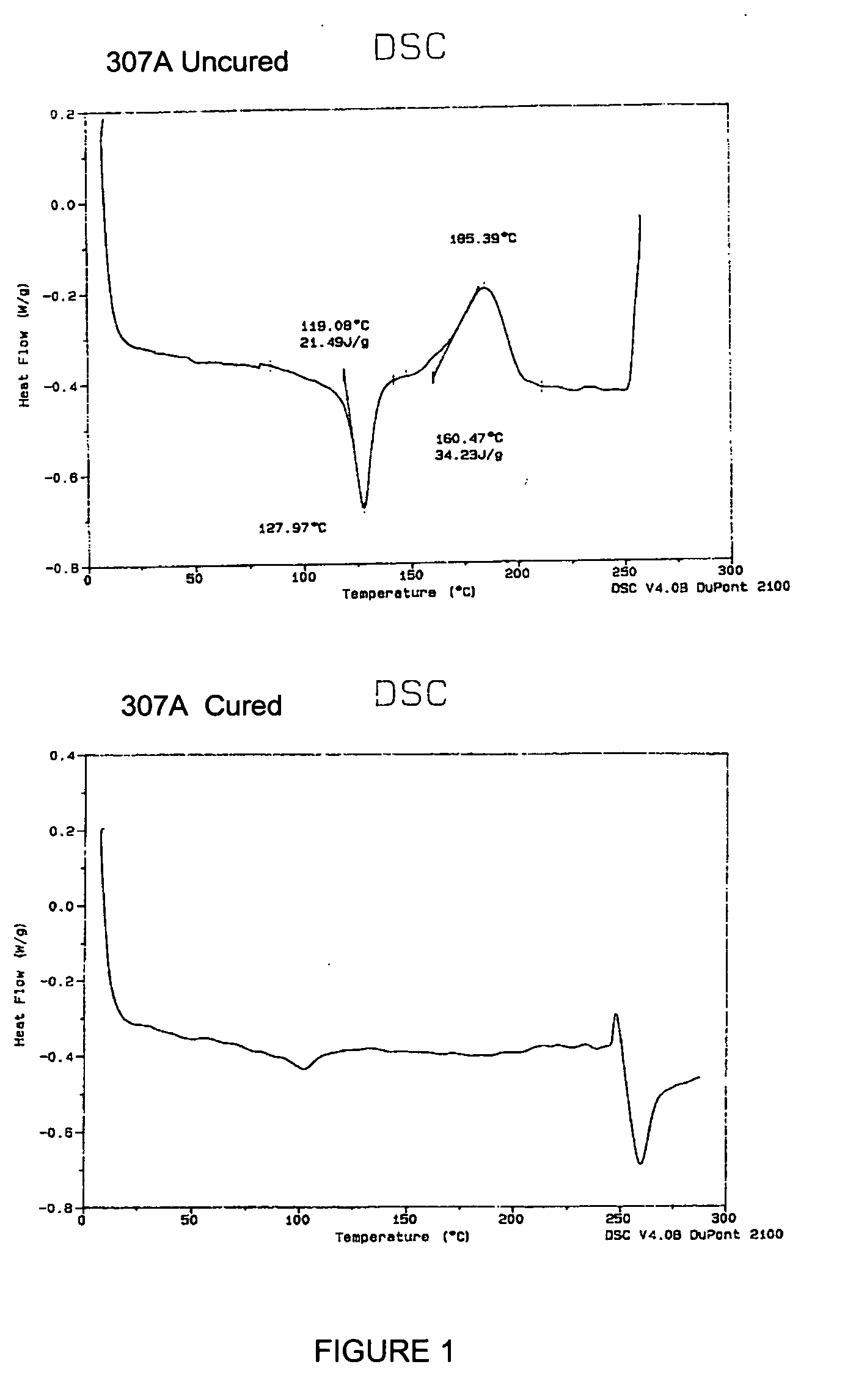

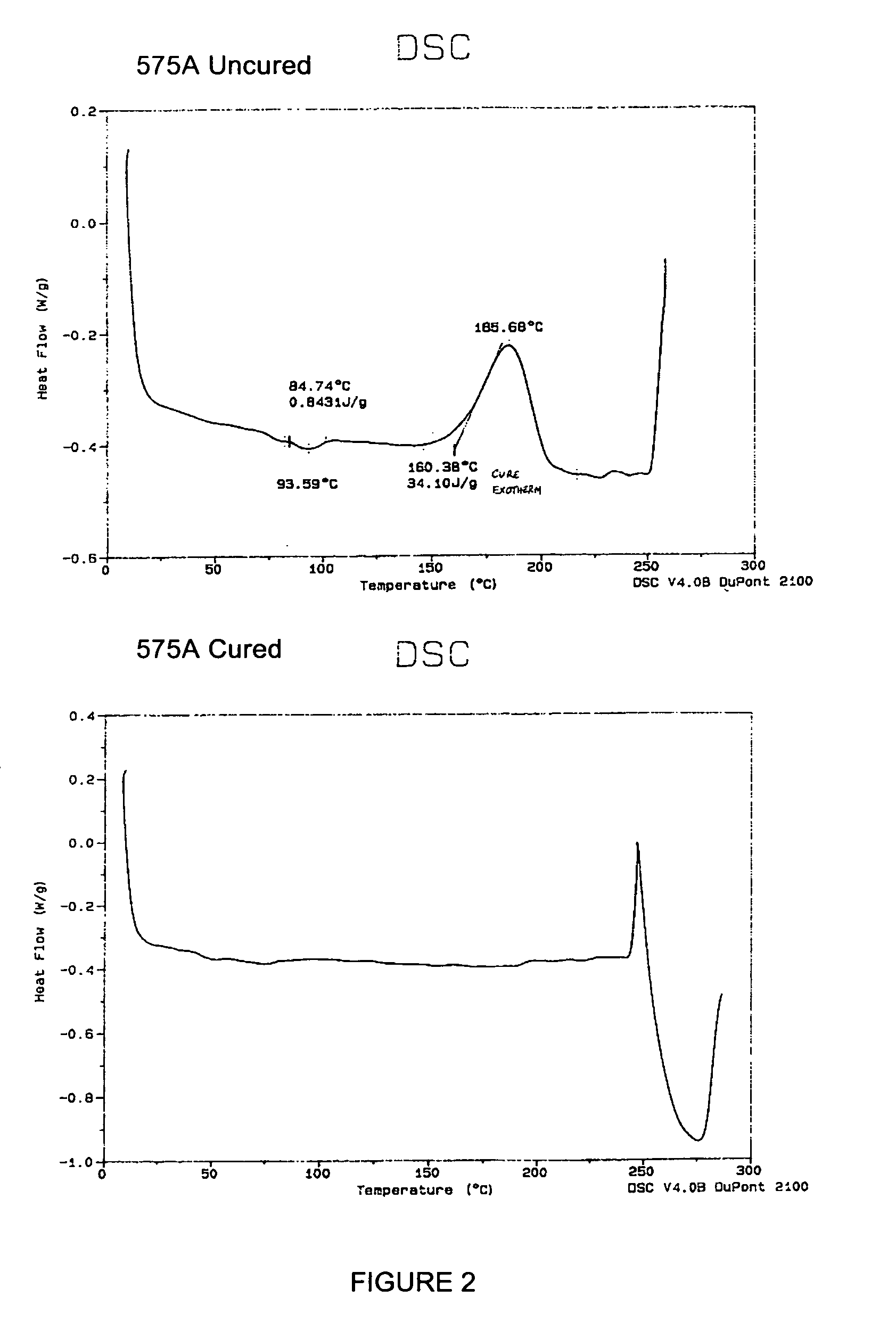

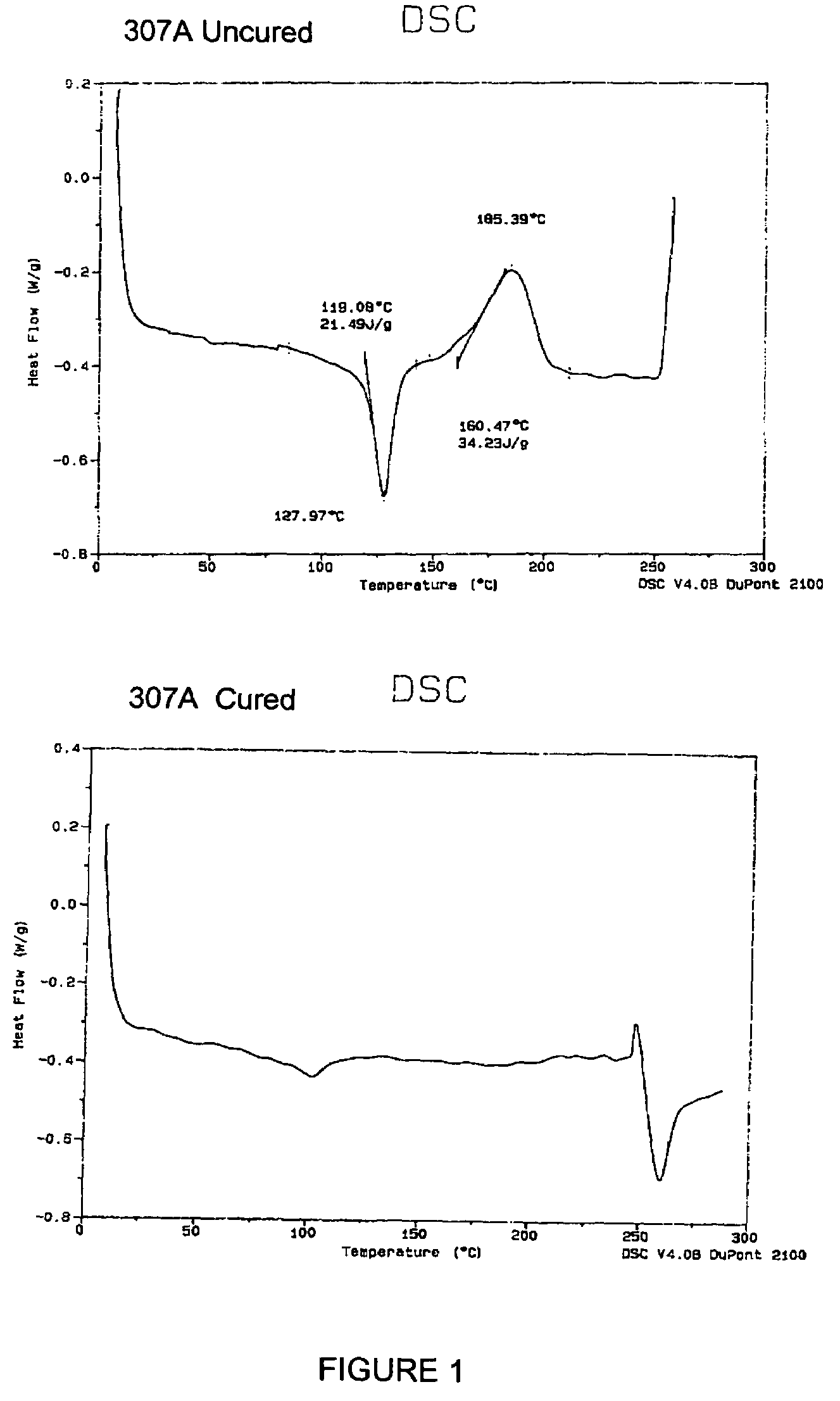

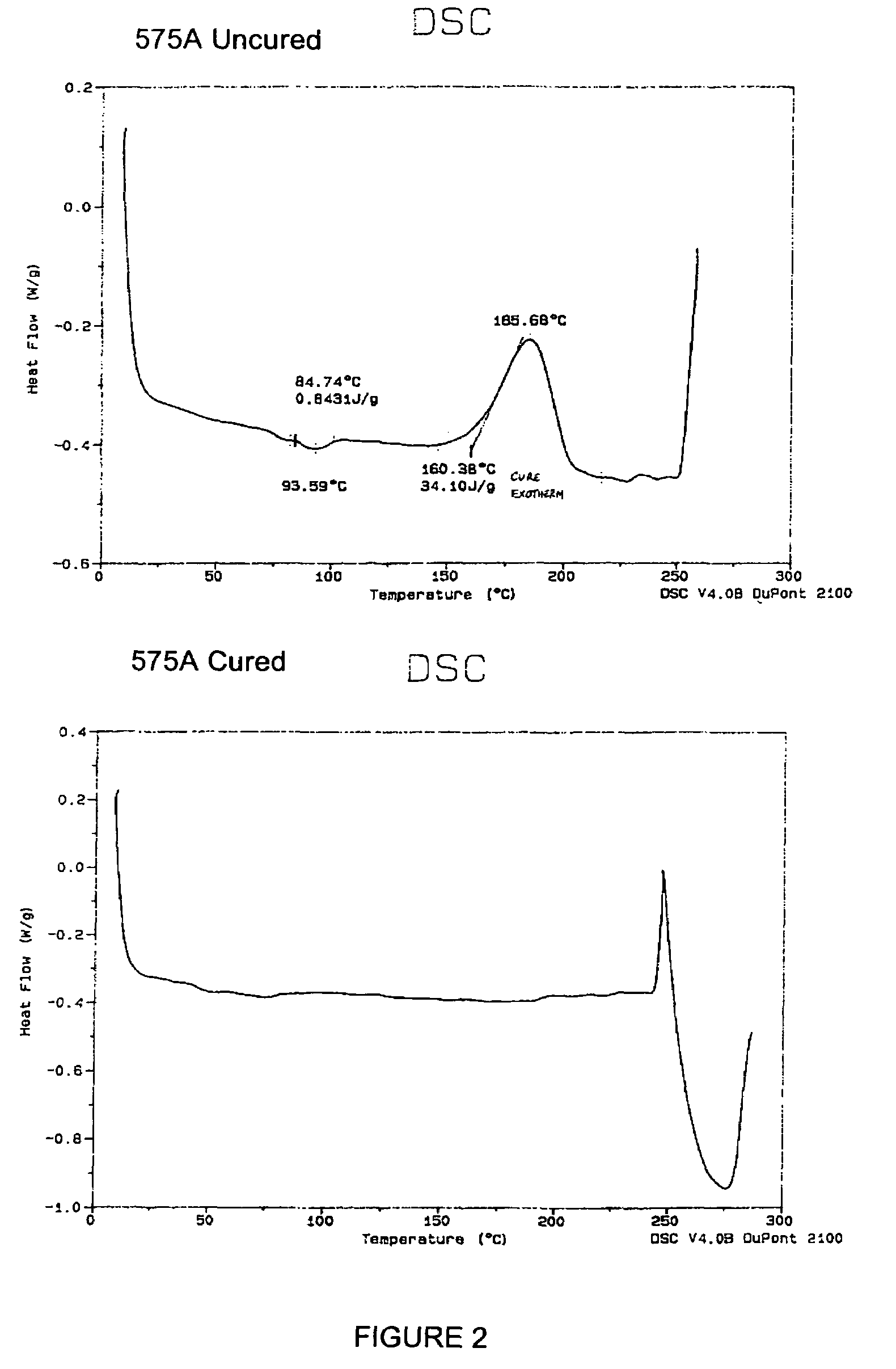

Low dielectric constant, low dielectric dissipation factor coatings, films and adhesives

Curable functionalized imide-linked polyimides compounds have been synthesized that have been found to possess very low dielectric constant and extremely low dissipation factor. These compounds also have a range of high to low modulus, extremely low moisture uptake and are very thermally stable. The combination of these materials in formulation along with functionalized polyethylene, polypropylene, polybutadiens have been found to be ideal for forming films and coatings for the microelectronic applications, multiplayer capacitors and interconnects, and high power cables and wire coatings. The addition of perfluorinated hydrocarbons, and POSS nanoparticles to the formulations have decreased the dielectric constant and dielectric dissipation factor further, and have also improved the flammability of the compositions.

Owner:MIZORI FARHAD G +1

Method for preparing functionalized polyethylene wax

The invention discloses a method for functionalizing polyethylene wax. Petroleum ether is used as a solvent, and functionalized monomers are grafted in a solution. The polyethylene wax can be dissolved and dispersed in the petroleum ether at the temperature of between 90 DEG C and 120 DEG C and is completely separated out when cooled to room temperature; products can be conveniently separated by using difference in solubility; and the solvent can be recycled. Polyethylene wax-grafted-acrylic acid (PEW-g-AA), polyethylene wax-grafted-methacrylic acid (PEW-g-MAA), polyethylene wax-grafted-glycidyl methacrylate (PEW-g-GMA), polyethylene wax-grafted-maleic anhydride (PEW-g-MAH), polyethylene wax-grafted-acrylamide (PEW-g-AM), polyethylene wax-grafted-N-methylol acrylamide (PEW-g-NMAM) and products obtained by neutralization, namely polyethylene wax-grafted-acrylic acid sodium (PEW-g-AAS) and polyethylene wax-grafted-methacrylic acid sodium (PEW-g-AAS), are obtained. The grafting products can be applied to the aspects of polyolefin modification, polyethylene wax emulsion, ink coating and the like. The method has a simple process and can be applied to industrial production.

Owner:张燕妮 +1

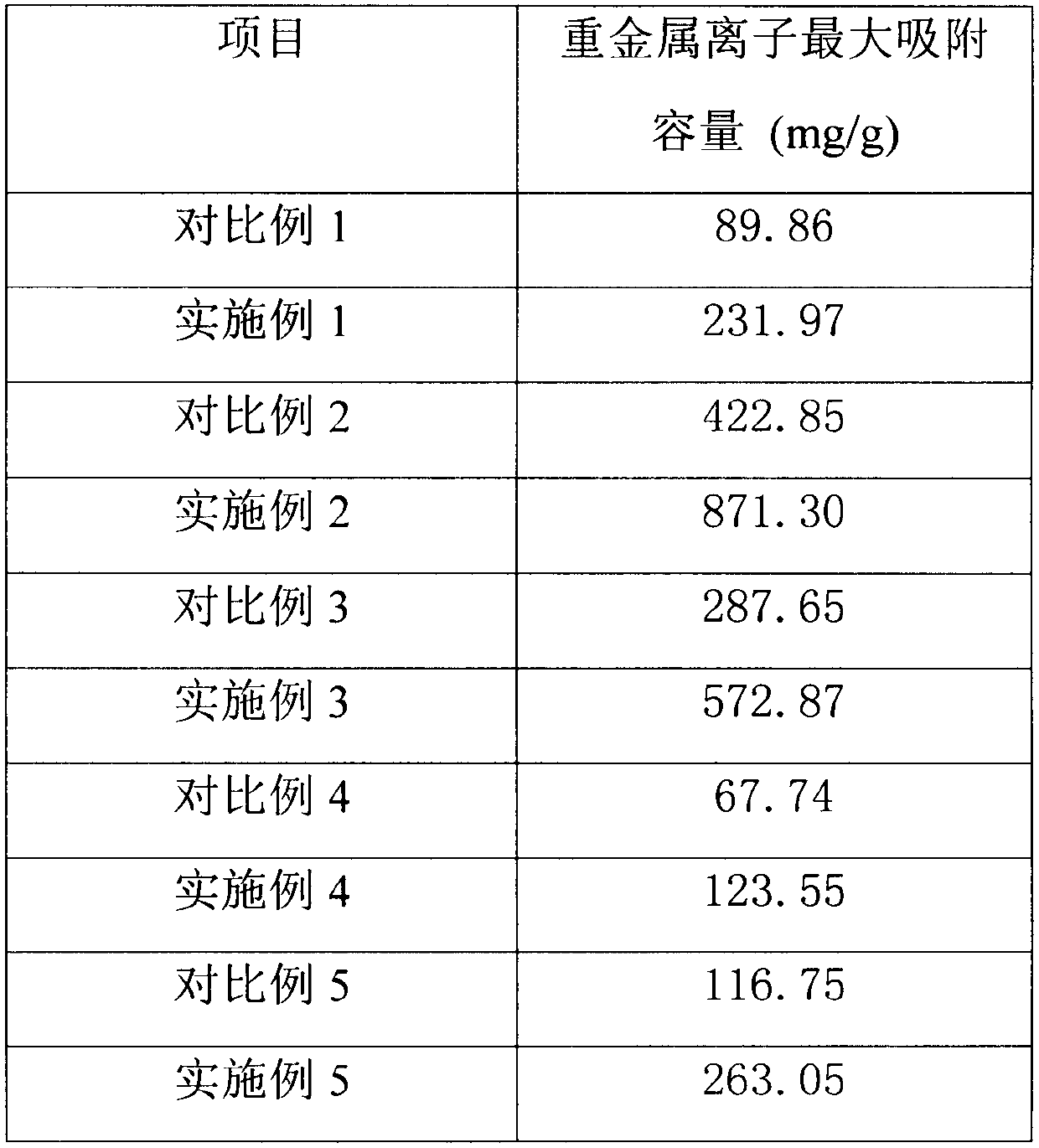

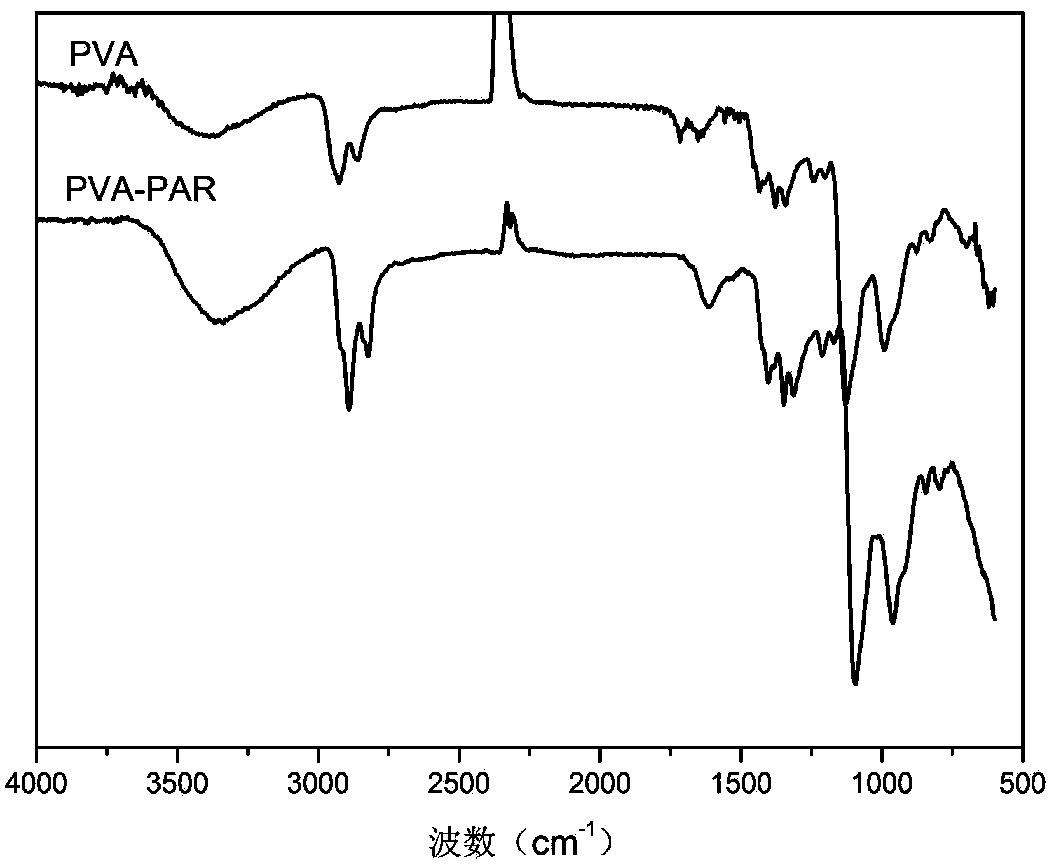

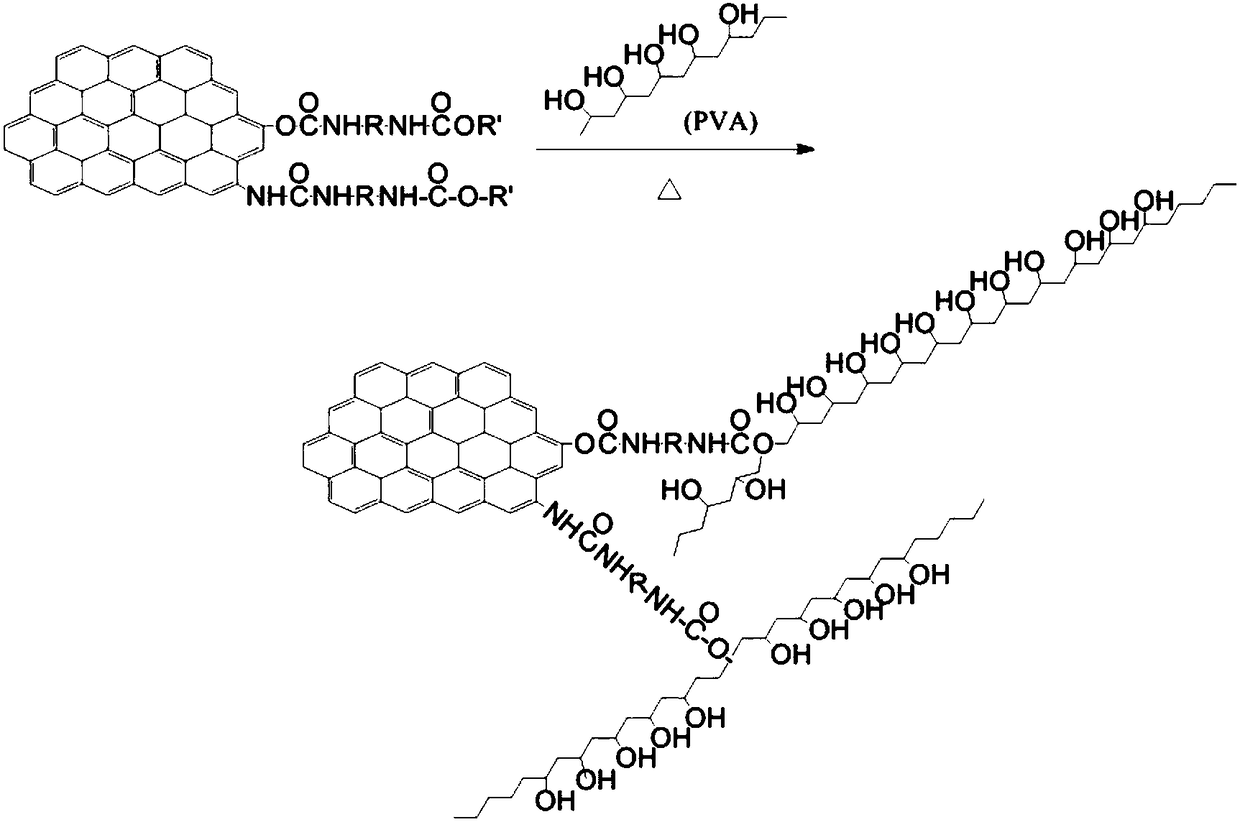

Functionalized polyvinyl alcohol hydrogel and preparation method thereof

ActiveCN103769062ASimple preparation processEasy to operateOther chemical processesWater contaminantsOperabilityPollution

The invention provides novel functionalized polyvinyl alcohol hydrogel capable of adsorbing heavy metal ions and a preparation method of the novel functionalized polyvinyl alcohol hydrogel. The hydrogel comprises functionalized polyvinyl alcohol (PVA), chitosan (CS) and sodium alginate, wherein the weight ratio of the functionalized polyvinyl alcohol to the chitosan ranges from (5:95) to (95:5). The prepared hydrogel has the large adsorption capacity on heavy metal and is high in adsorption speed. The hydrogel is prepared by the following steps: functionalizing the polyvinyl alcohol and completely mixing the functionalized polyvinyl alcohol and the sodium alginate to be dissolved in water; then adding a certain amount of the chitosan and uniformly mixing; and finally, dripping mixed liquid into a calcium chloride-boric acid saturated solution to prepare hydrogel globules. The composite hydrogel provided by the invention is simple in preparation process, strong in operability and stable in performance, can be circularly utilized, has no secondary pollution and is widely applied to the field of heavy metal sewage treatment.

Owner:广州慈康生物科技有限公司

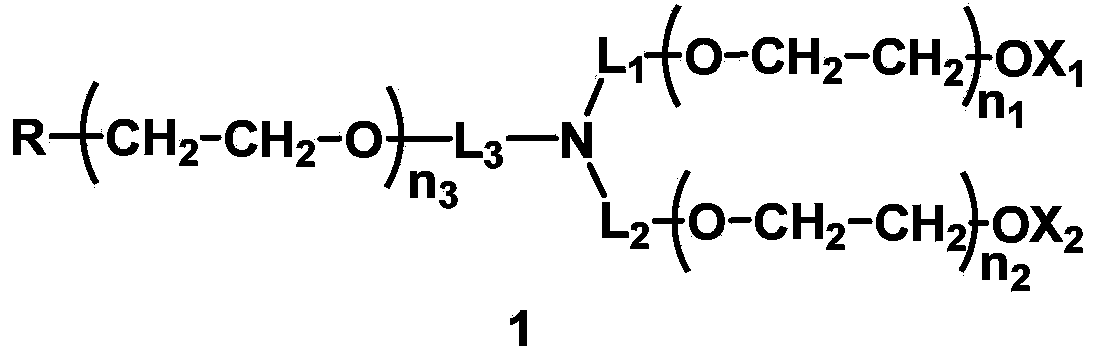

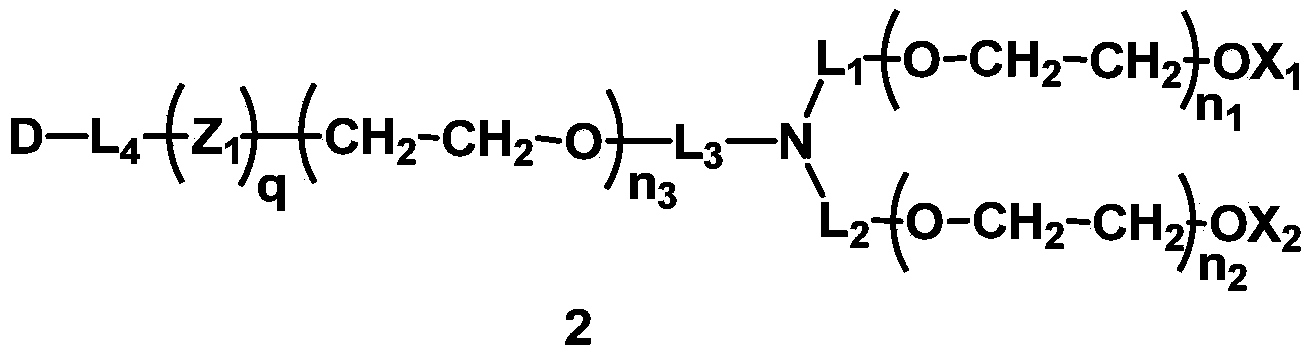

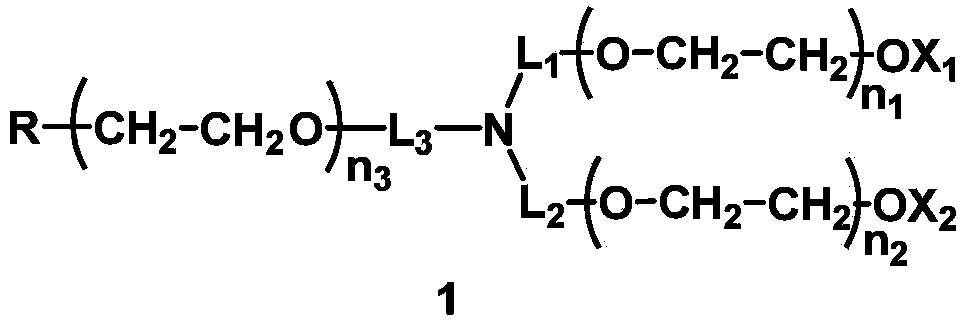

Mono-functionalized polyethylene glycol with nitrogen atom branched center and its preparation method and biologically-relevant matter

ActiveCN104109235ARich varietyShort manufacturing processPharmaceutical non-active ingredientsOxidation-Reduction AgentNitrogen

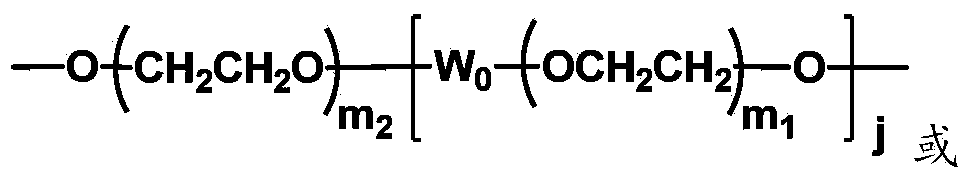

The invention discloses a mono-functionalized polyethylene glycol with a nitrogen atom branched center and its preparation method and biologically-relevant matter. The mono-functionalized polyethylene glycol with a nitrogen atom branched center is shown in the general formula (1). The polyethylene glycol-modified biologically-relevant matter is shown in the general formula (2). X1 and X2 represent alkyl containing 1-20 carbon atoms, n1 and n2 are integers of 2-2000, n3 is an integer of 1-2000, L1, L2 and L3 represent connection groups stably existing under the conditions of light, heat, enzyme, redox, acidic or alkaline condition, R represents a functional group or is in a protected form, D represents a biologically-relevant matter, Z1 represents a connection group, and L4 represents residue formed by a reaction of R and the biologically-relevant matter. The branched polyethylene glycol with the nitrogen atom center can interact with a substrate easily so that the substrate protection based on polyethylene glycol is promoted, the state of the substrate in the human body can be effectively improved and a prospect is wide.

Owner:XIAMEN SINOPEG BIOTECH

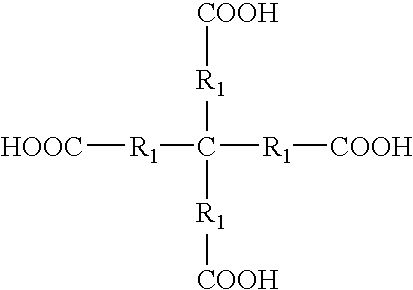

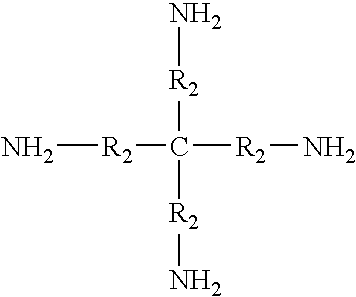

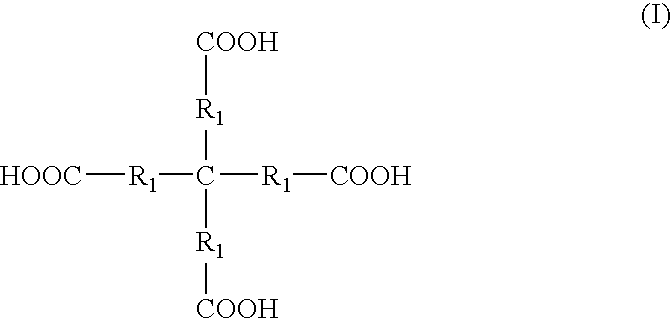

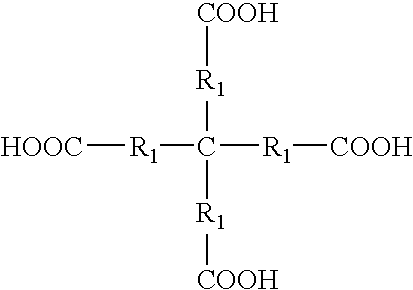

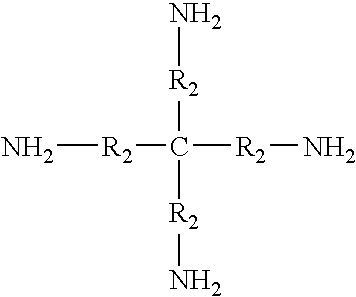

Carbodiimide crosslinking of functionalized polyethylene glycols

ActiveUS20070148128A1Surgical adhesivesSynthetic polymeric active ingredientsAdhesivePolyethylene glycol

A synthetic composition is provided which includes an acid-functional polymer having at least one pendant acid group, an amine-functional polymer having at least one pendant amine group, and a coupling agent. The synthetic composition can be used in human and animal medical applications as an adhesive or sealant.

Owner:TYCO HEALTHCARE GRP LP

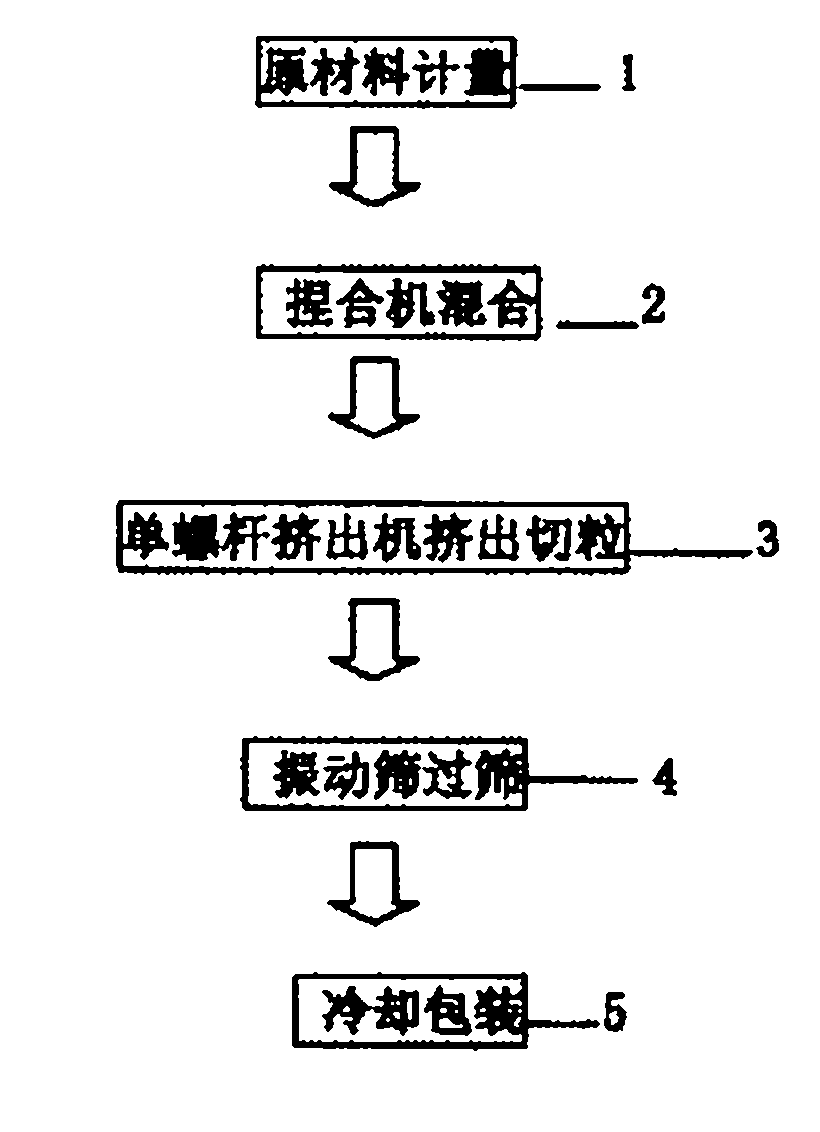

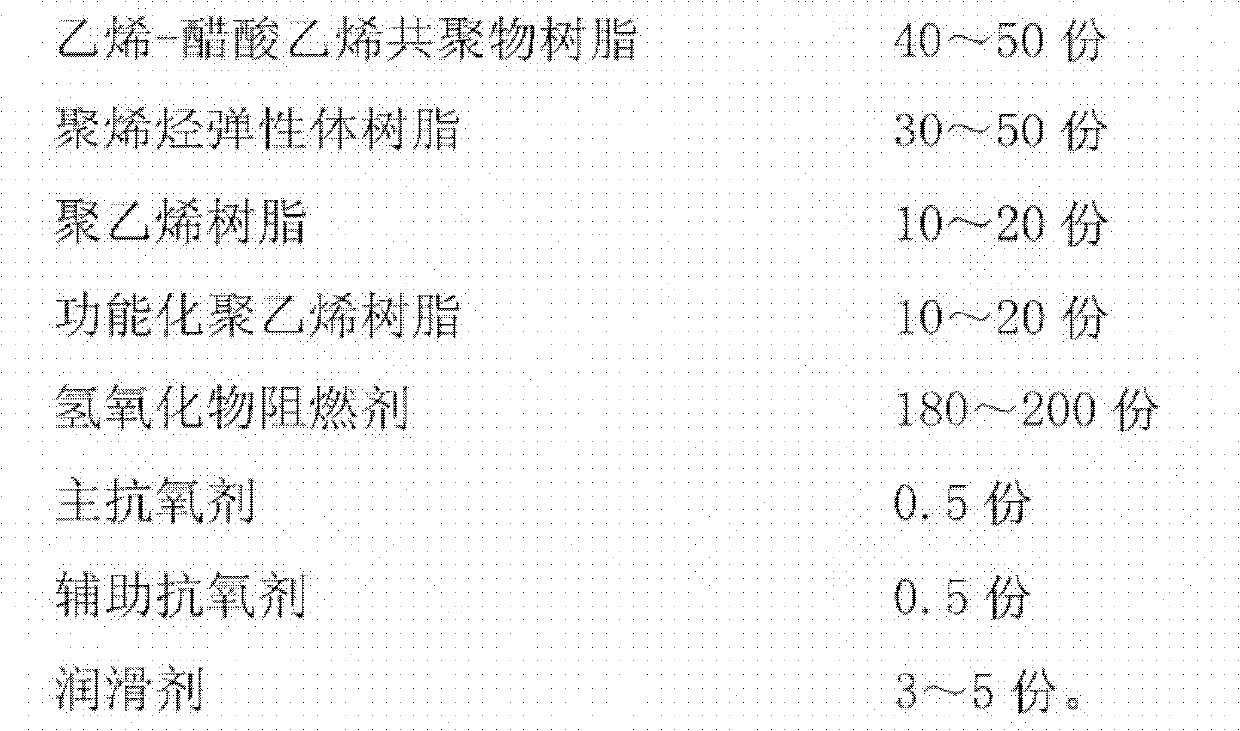

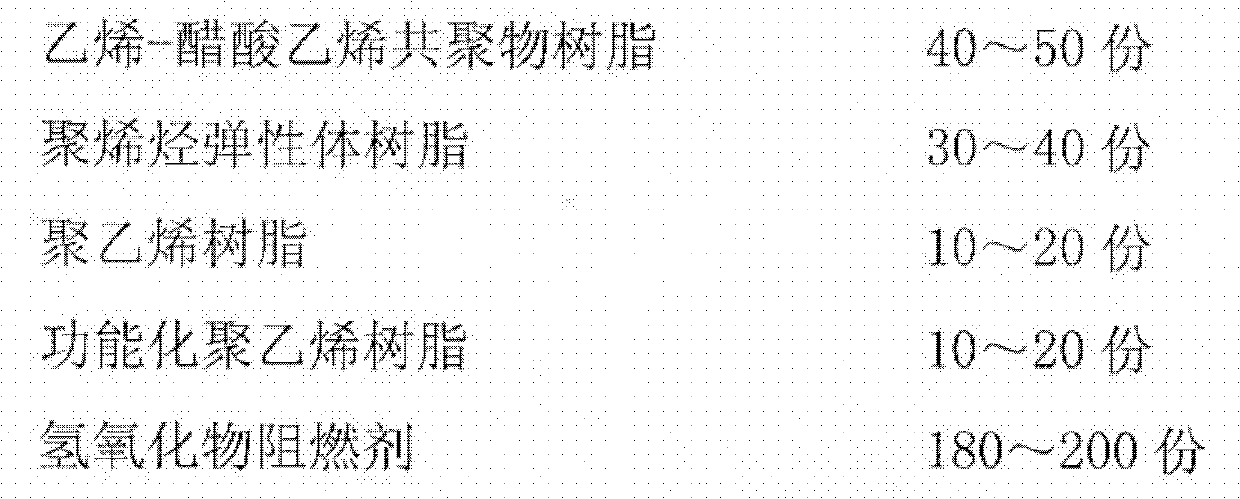

Anti-cracking low-smoke halogen-free flame retardant polyolefin protecting bush material and preparation method thereof

InactiveCN102604199ASolve crackingEasy to usePlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention provides an anti-cracking low-smoke halogen-free flame retardant polyolefin protecting bush material and a preparation method thereof. The protecting bush material is composed of the following components in parts by weight: 40-50 parts of ethylene-vinyl acetate copolymer resin, 30-50 parts of polyolefin elastic body resin, 10-20 parts of polyethylene resin, 10-20 parts of functionalized polyethylene resin, 180-200 parts of hydroxide fire retardant, 0.5 part of primary antioxidant, 0.5 part of auxiliary antioxidant and 3-5 parts of lubricating agent. The preparation method comprises the following steps of: metering raw materials in a raw material formula according to respective weight part and conveying the raw materials into a kneading machine to be uniformly mixed; conveying the mixed materials into a single screw extruder to extrude and particles; then, vibrating by a vibrating sieve; and finally, packaging and cooling to finish the whole preparation process. According to the anti-cracking low-smoke halogen-free flame retardant polyolefin protecting bush material and the preparation method thereof, disclosed by the invention, standard requirements are completely met; ethylene copolymer resin is used the basic raw material, the polyolefin elastic body resin, a compatilizer and the hydroxide fire retardant are added to be commixed to form the anti-cracking low-smoke halogen-free flame retardant polyolefin protecting bush material.

Owner:天津市普立泰高分子科技有限公司

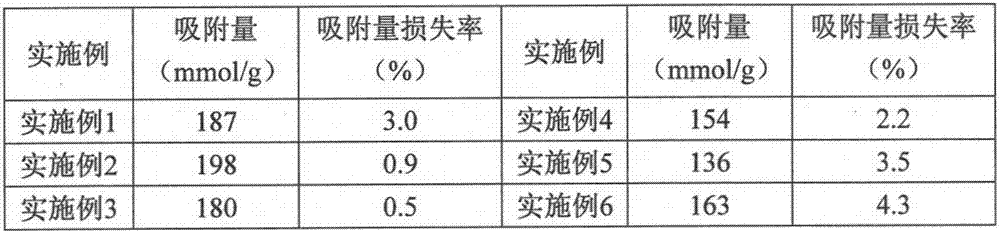

Functionalized polyethylenimine-grafted porous nano-fiber adsorption material and preparation thereof

InactiveCN106975465ALarge specific surface areaHigh porosityGas treatmentOther chemical processesDesorptionUltimate tensile strength

The invention provides a functionalized polyethylenimine-grafted porous nano-fiber adsorption material and preparation thereof. The functionalized polyethylenimine-grafted porous nano-fiber adsorption material is characterized by being prepared from porous polyacrylonitrile nano-fibers; the porous polyacrylonitrile nano-fibers are grafted with functionalized polyethylenimine after being hydrolyzed. After the porous polyacrylonitrile nano-fiber material is subjected to graft modification by using the functionalized polyethylenimine, the carbon dioxide adsorption performance and adsorption and desorption cycling stability of the porous polyacrylonitrile nano-fiber material are greatly improved; therefore, the porous nano-fiber high-efficient adsorption material with certain flexibility and strength can be prepared, and has great utilization potentiality in the field of adsorption.

Owner:DONGHUA UNIV

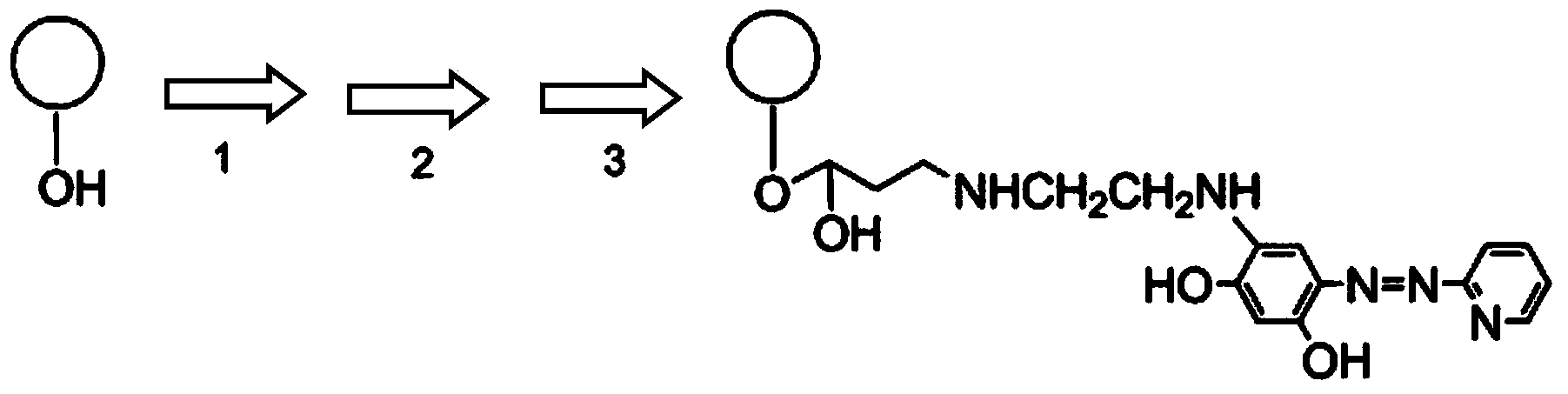

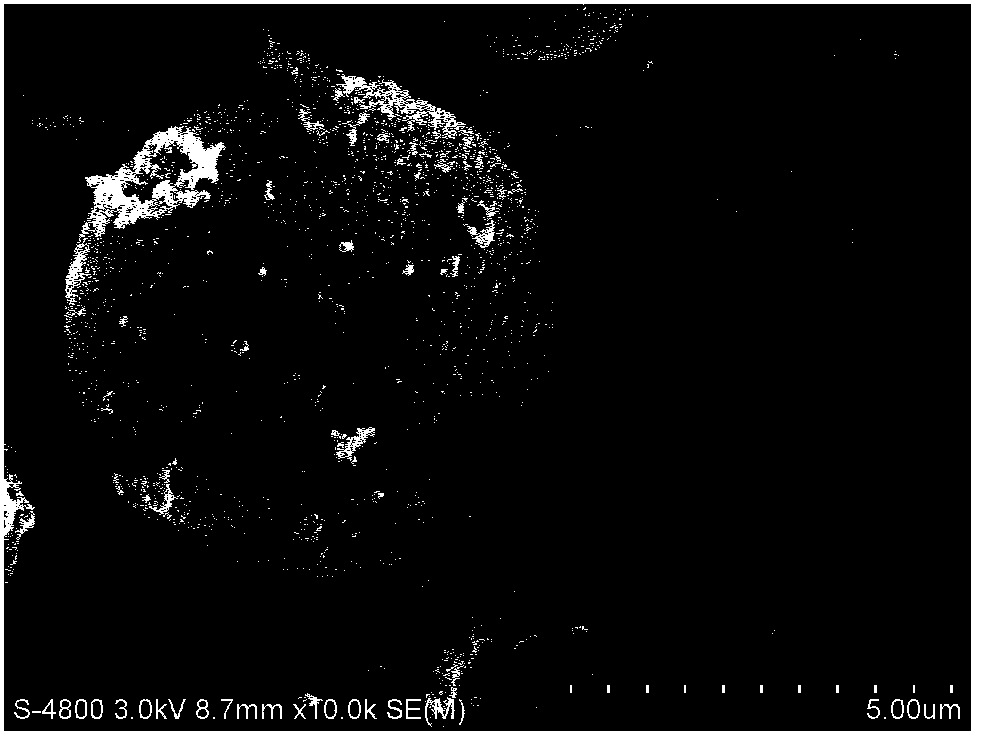

Preparation method and application of functionalized polyvinyl alcohol microspheres

ActiveCN104069782AWith colorWith adsorption functionMicroballoon preparationWater/sewage treatment by sorptionWater bathsEpoxy

The invention discloses a preparation method and application of functionalized polyvinyl alcohol microspheres. The preparation method comprises the following steps: uniformly mixing polyvinyl alcohol microspheres, epoxy chloropropane and a hydrochloric acid solution, carrying out a stirring reaction for 1-5 hours in a water bath, and carrying out centrifuging, water cleaning and drying for later use after the reaction; uniformly mixing the obtained chloridized polyvinyl alcohol microspheres, tetrabutylammonium bromide, ethidene diamine and a sodium hydroxide solution, carrying out the stirring reaction for 4-10 hours in the water bath, and carrying out the centrifuging, ethanol cleaning and the drying for later use after the reaction; and uniformly mixing the obtained aminated polyvinyl alcohol microspheres with 2-(2-pyridine) azo-resorcinol, formaldehyde and distilled water, stirring for 6-18 hours in the presence of nitrogen, and carrying out the centrifuging, the ethanol cleaning and the drying after the reaction, so as to obtain an end product. The functionalized polyvinyl alcohol microspheres provided by the invention can be used for chelating heavy metal and detecting and processing divalent heavy metal ions in wastewater and have the characteristics of simple preparation condition, low cost, short detection response time and high adsorption capacity.

Owner:NANJING HEHAI TECH

Power transmission products having enhanced properties

ActiveUS20100190914A1Improved compositionImprove pillingV-beltsRopes and cables for vehicles/pulleyElastomerHardness

The present invention is directed to the incorporation of functionalized polyethylenes, in amount of about 1% to 95% by weight based upon the weight of the total crosslinkable material, into ethylene alpha olefin elastomers, such as EPDM elastomer compositions, which are crosslinked by peroxides, which results in improved properties, such as hardness and modulus of elongation, and can result in improved higher abrasion resistance, wear resistance, coefficient of friction, tensile strength, and other properties through a broad temperature range, which are beneficial to power transmission products, such as power transmission belts.

Owner:CONTITECH USA INC

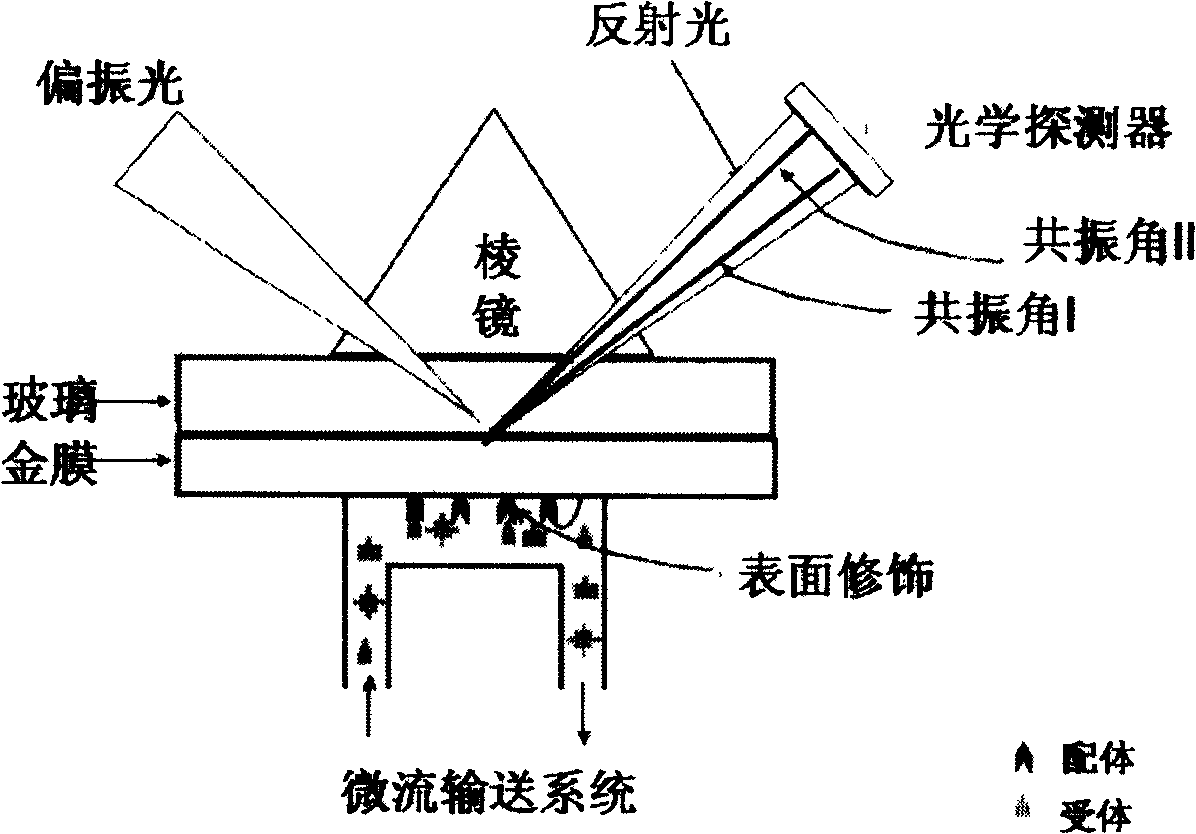

Surface plasma resonance instrument chip based on polyethyleneglycol and method for making same

InactiveCN101261226AMonitor growth in real timeDensity regulationScattering properties measurementsBiological testingPolyethylene glycolBiological signaling

The invention relates to a chip of a surface plasmon resonance instrument which is based on polyethylene glycol and a preparation method. The chip comprises a glass film base and a gold plating film on the glass film base; wherein the gold plating film is provided with an initiator layer which is introduced in the way of self-assembly and a functionalized polyethylene glycol layer which is combined with the initiator layer. The invention uses a quartz crystal microbalance to monitor the growth of the film at the surface of the chip at real time and the chip of the invention effectively solves the problem of non-specific absorption of protein. As the surface ornament of the chip is not limited to traditional carboxylic dextran, the density and types of the functional groups at the chip surface are no longer strictly restricted. Furthermore, the chip of the invention also has good performance in terms of the specificity maintenance and quality control of biological signaling molecule and so on. The preparation method of the chip of the invention has few steps and the low manufacturing cost and is more suitable for industrial production. The chip has more potential of deep development and more superior generality.

Owner:武晓荣

Functionalized polyethylene terephthalate polymers, functionalized derivative polymers of polyethylene terephthalate, methods of making and using same

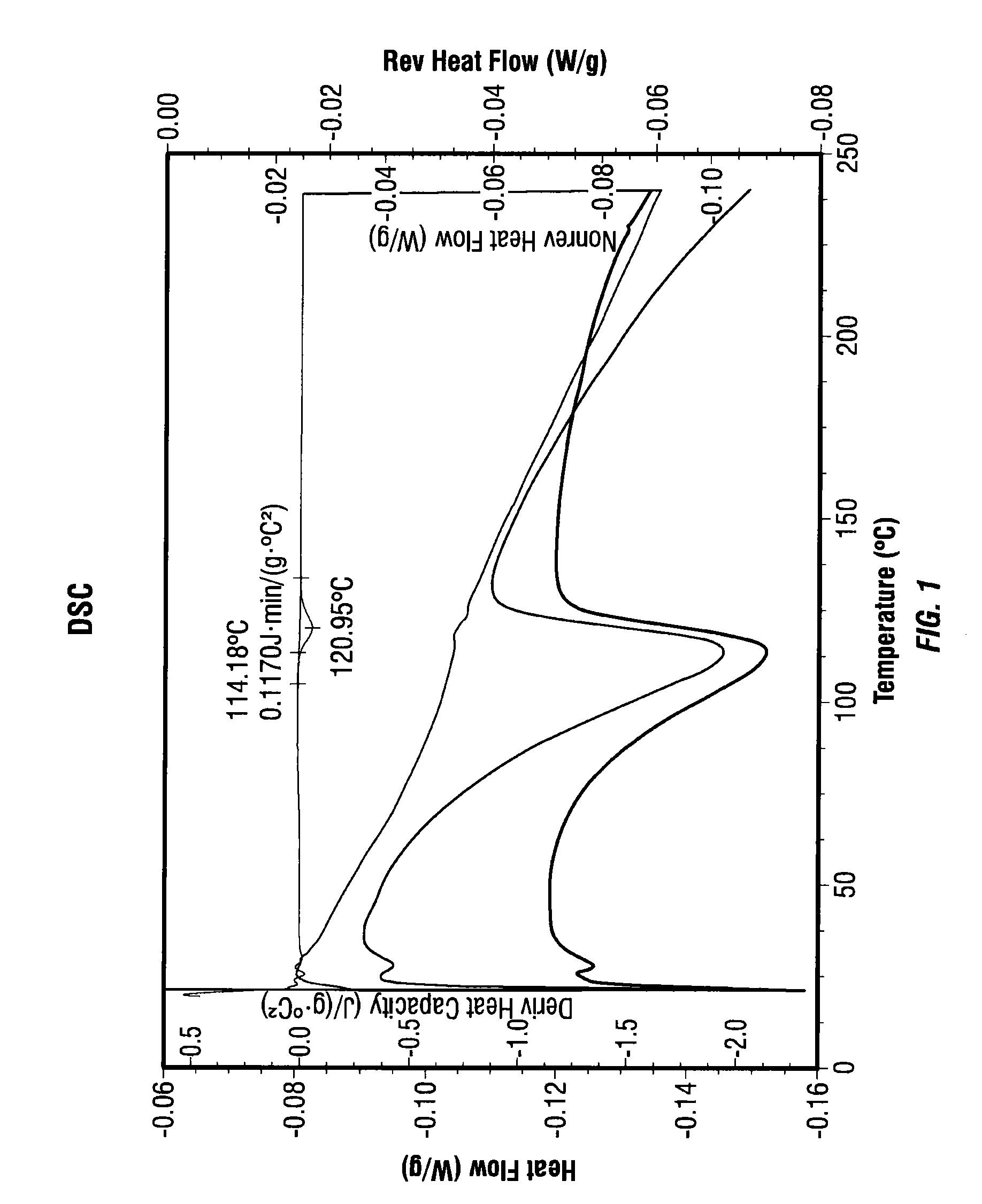

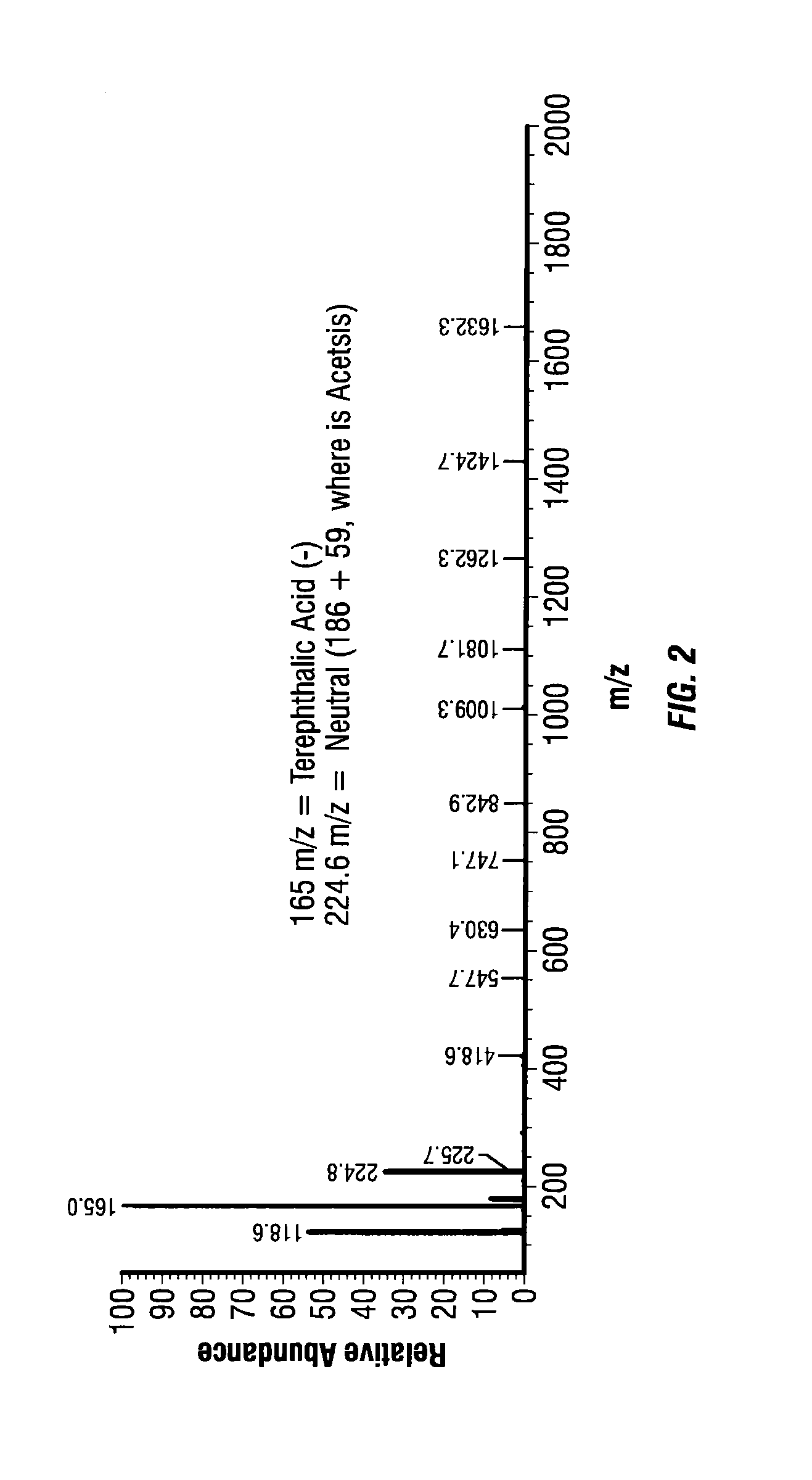

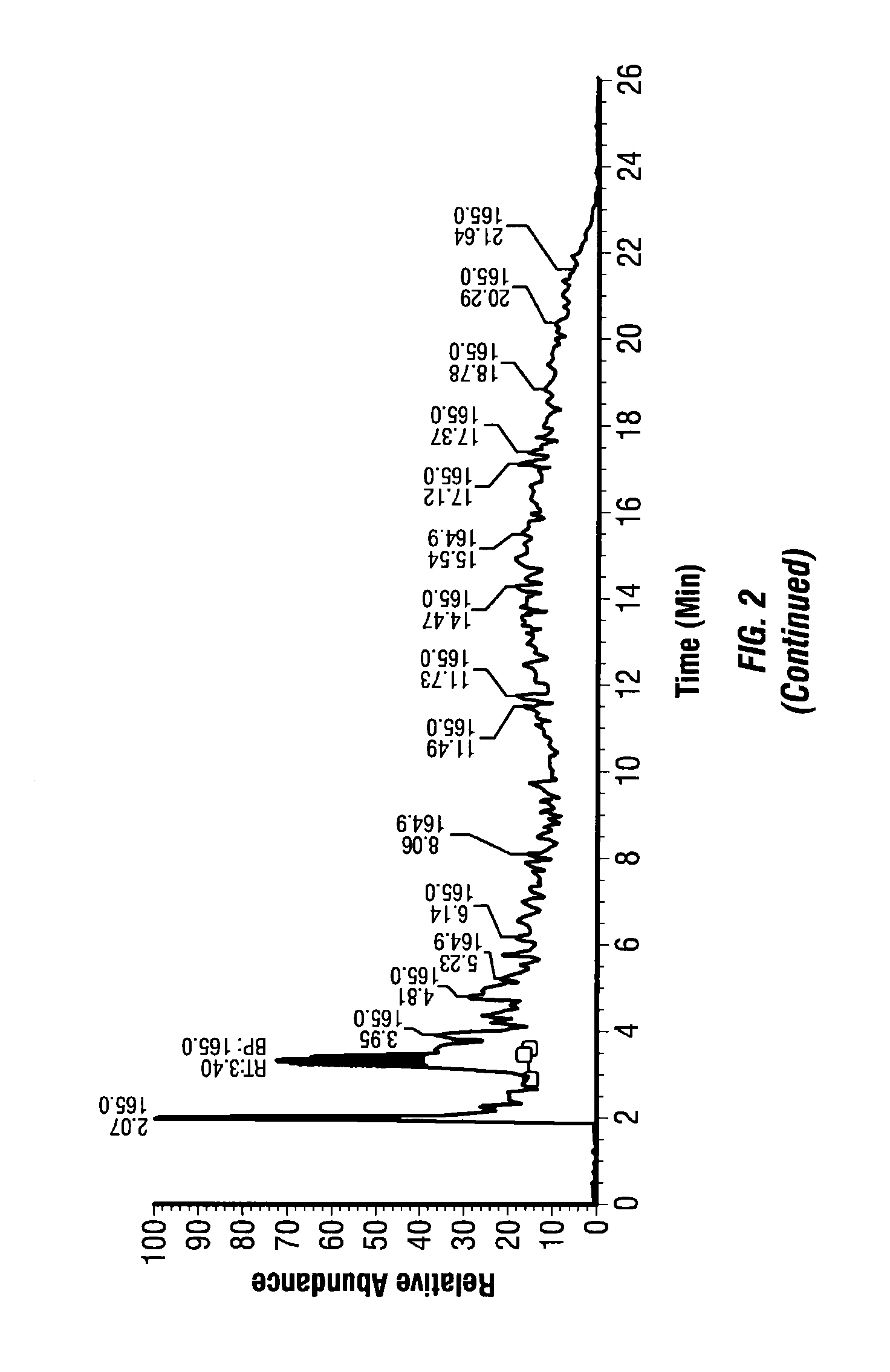

InactiveUS20120190800A1Simple and efficientHigh purity formOrganic chemistryPlastic recyclingPolyethylene terephthalate glycolPolyethylene terephthalate

The presently disclosed and claimed inventive concept(s) relates generally to the functionalized polyethylene terephthalate polymers and functionalized derivatives of PET. More particularly, but not to be construed as limiting, the presently disclosed and claimed inventive concept(s) relate to lower molecular weight functionalized digested PET materials from digesting recycled and methods of making and using same.

Owner:FELICE KRISTOPHER M +3

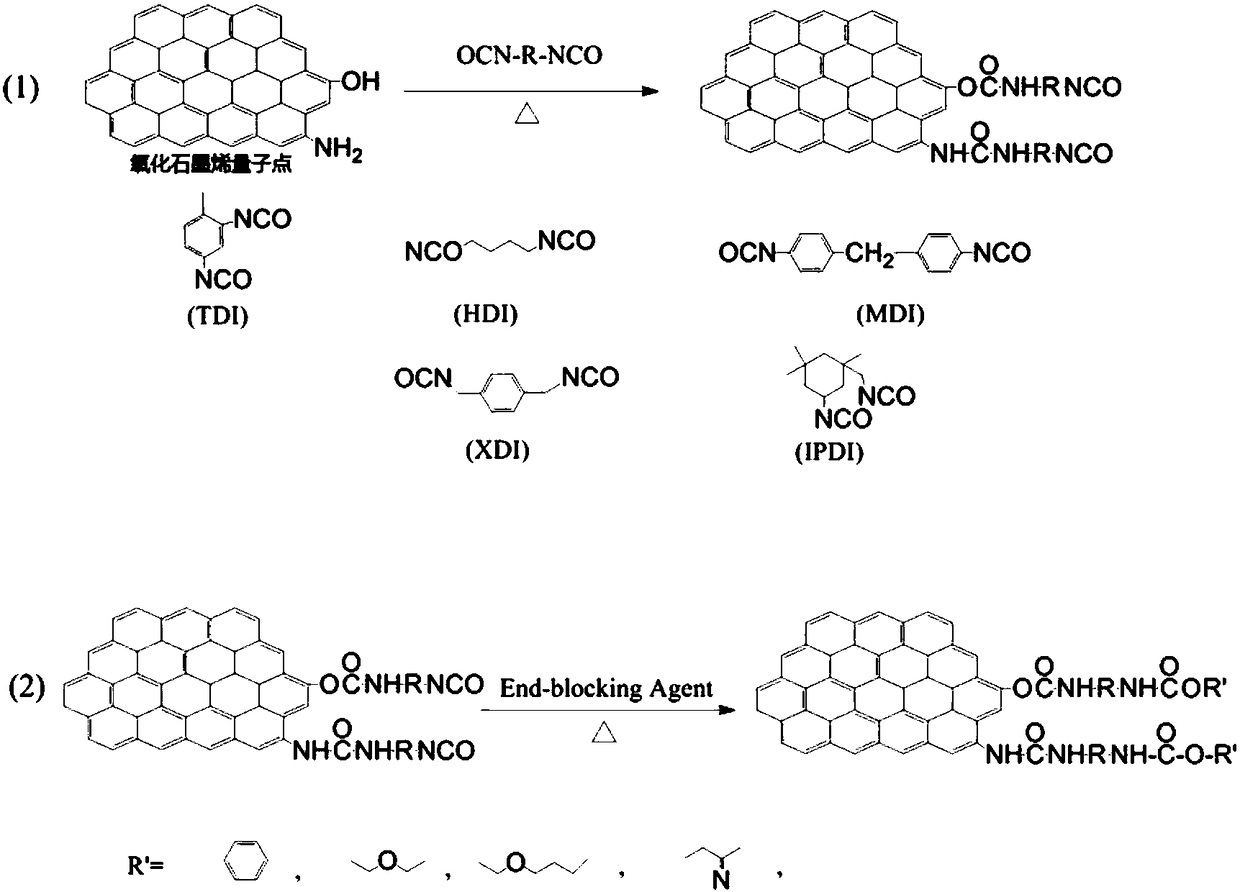

Method for preparing high performance graphene-polyvinyl alcohol composite fiber

InactiveCN108251907AImprove tensile strength at breakHigh strengthMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberProcess equipment

The invention discloses a method for preparing high performance graphene-polyvinyl alcohol composite fiber, the method comprises the following steps: 1) functionalization of blocked isocyanate groupsof graphene quantum dots; 2) preparation of a spinning solution of polyvinyl alcohol-graphene quantum dots (PVA-GQD); 3) wet spinning; 4) post-treatment of nascent fibers; the method is simple, shortin process, low in cost and suitable for large-scale production, and does not require modification of existing polyvinyl alcohol wet spinning process equipment, and the prepared PVA-GQD fiber not onlyhas excellent mechanical properties and easy dispersibility, but also has a metallic luster, and is an ideal concrete reinforcement material, packaging material and clothing fabric.

Owner:重庆中科烯维科技有限公司

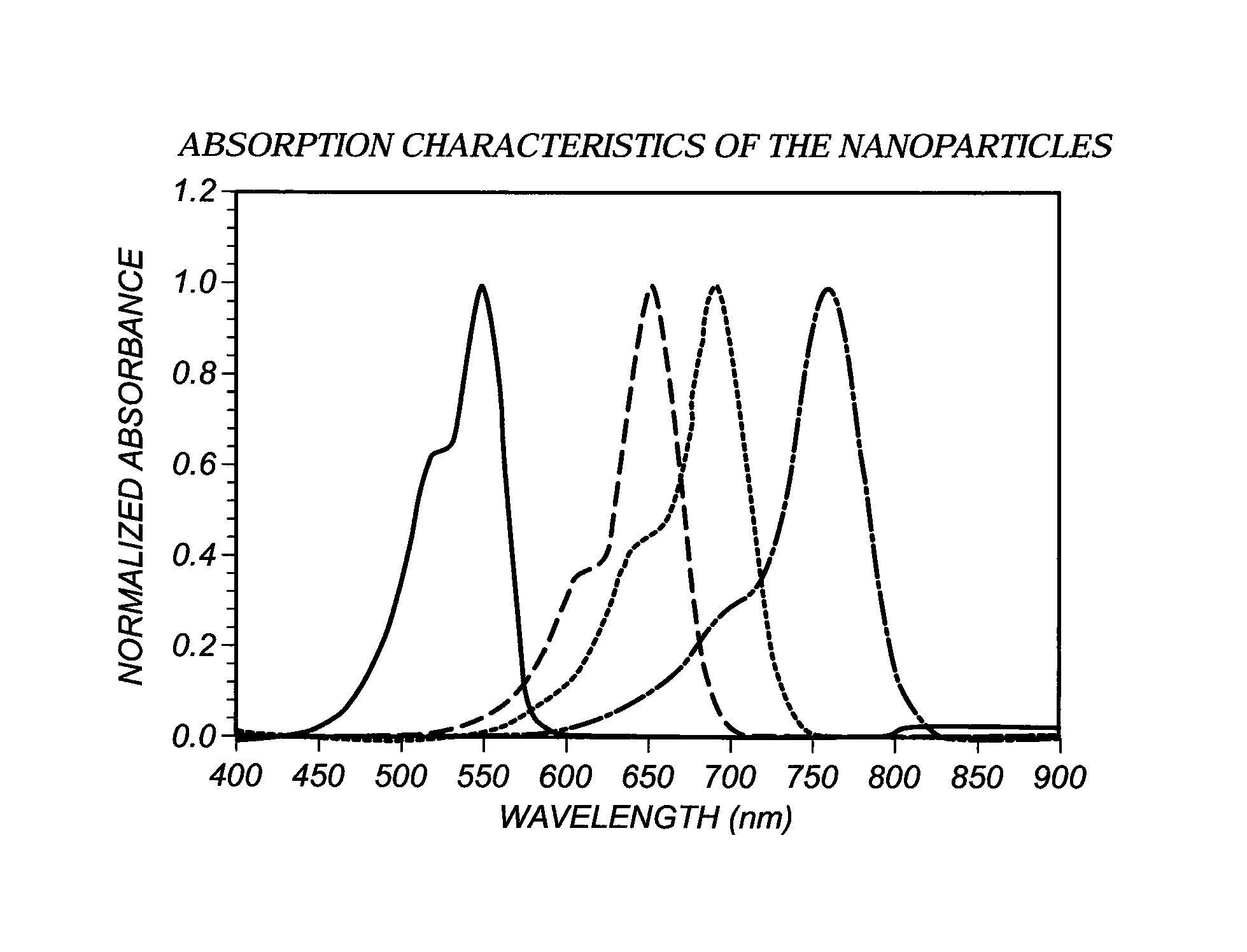

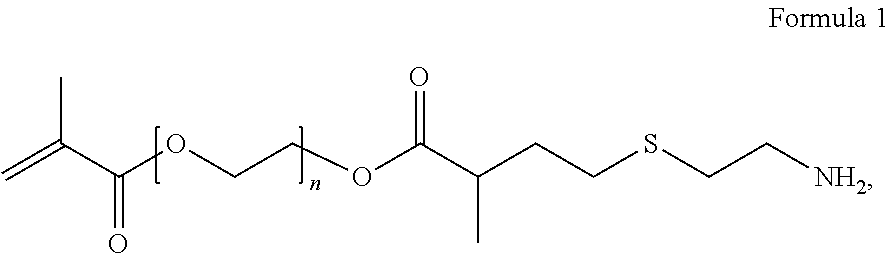

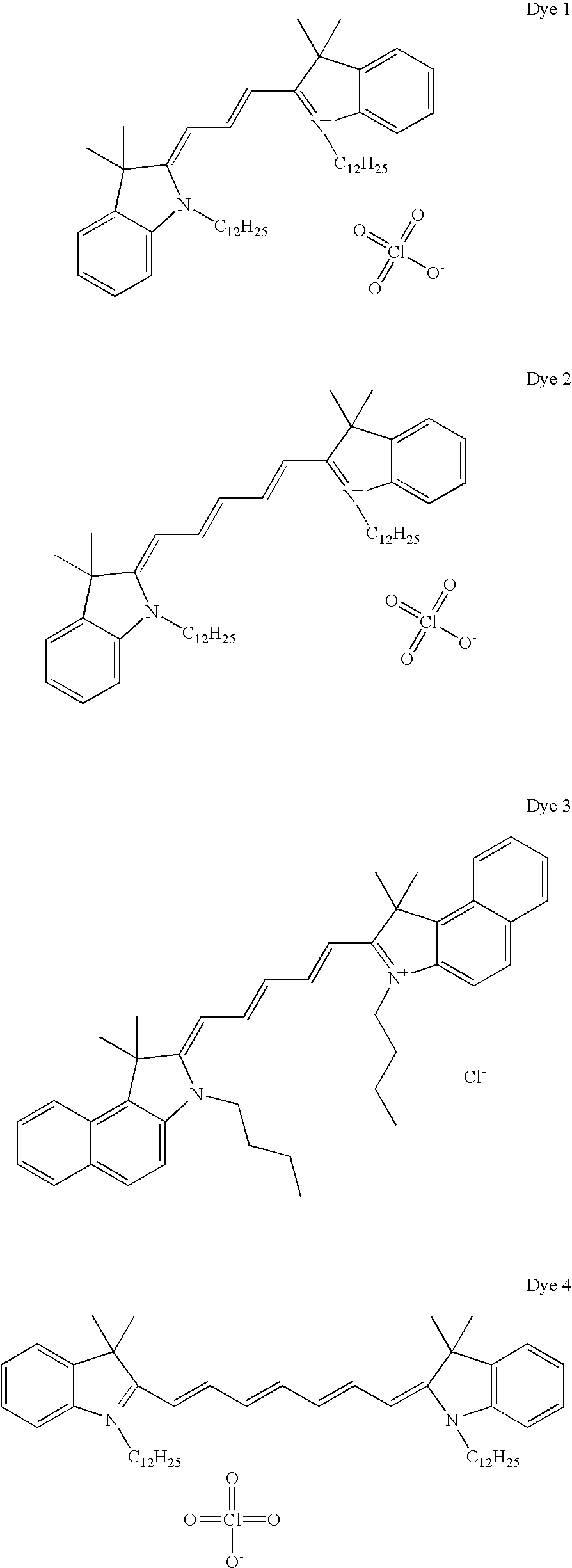

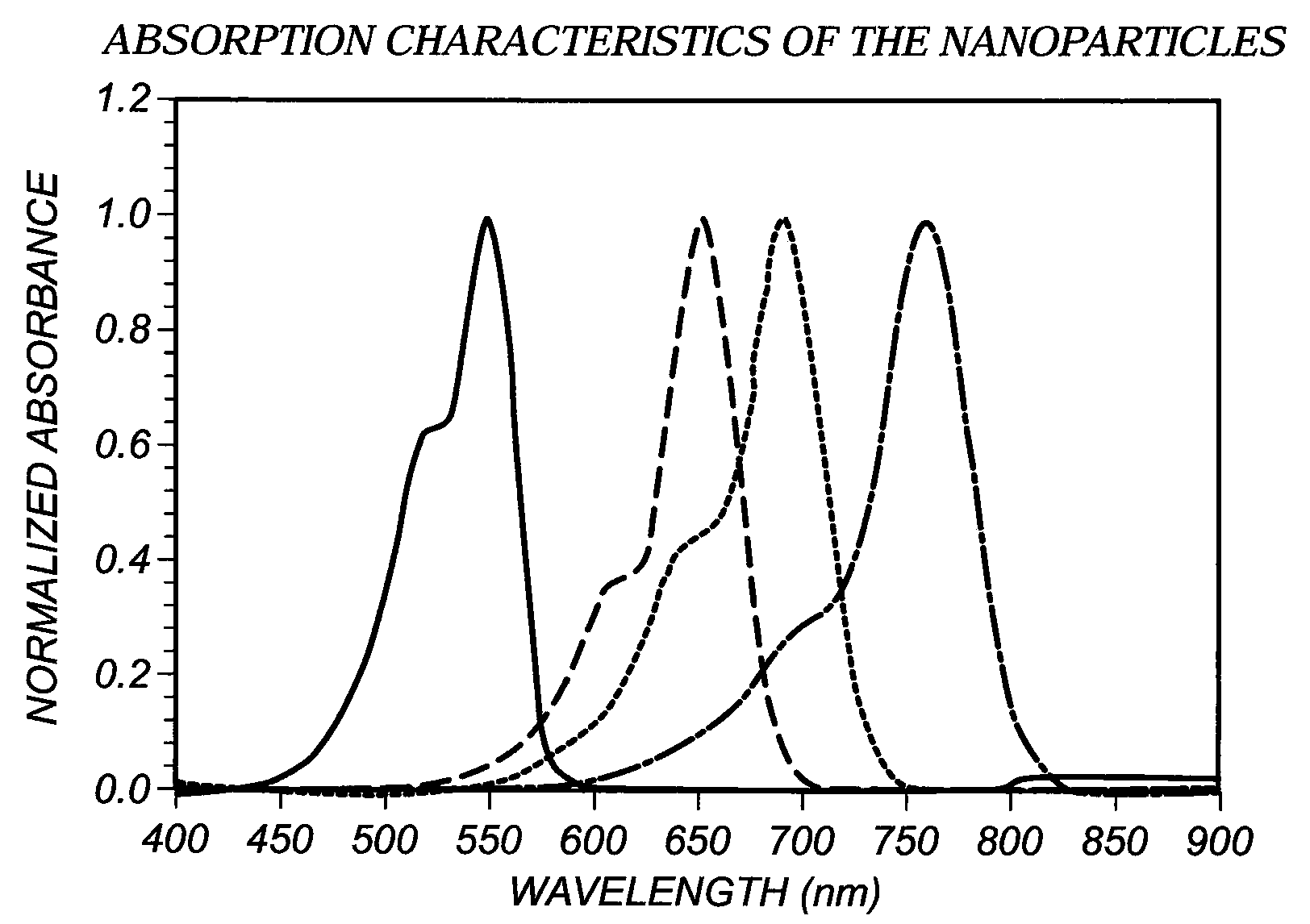

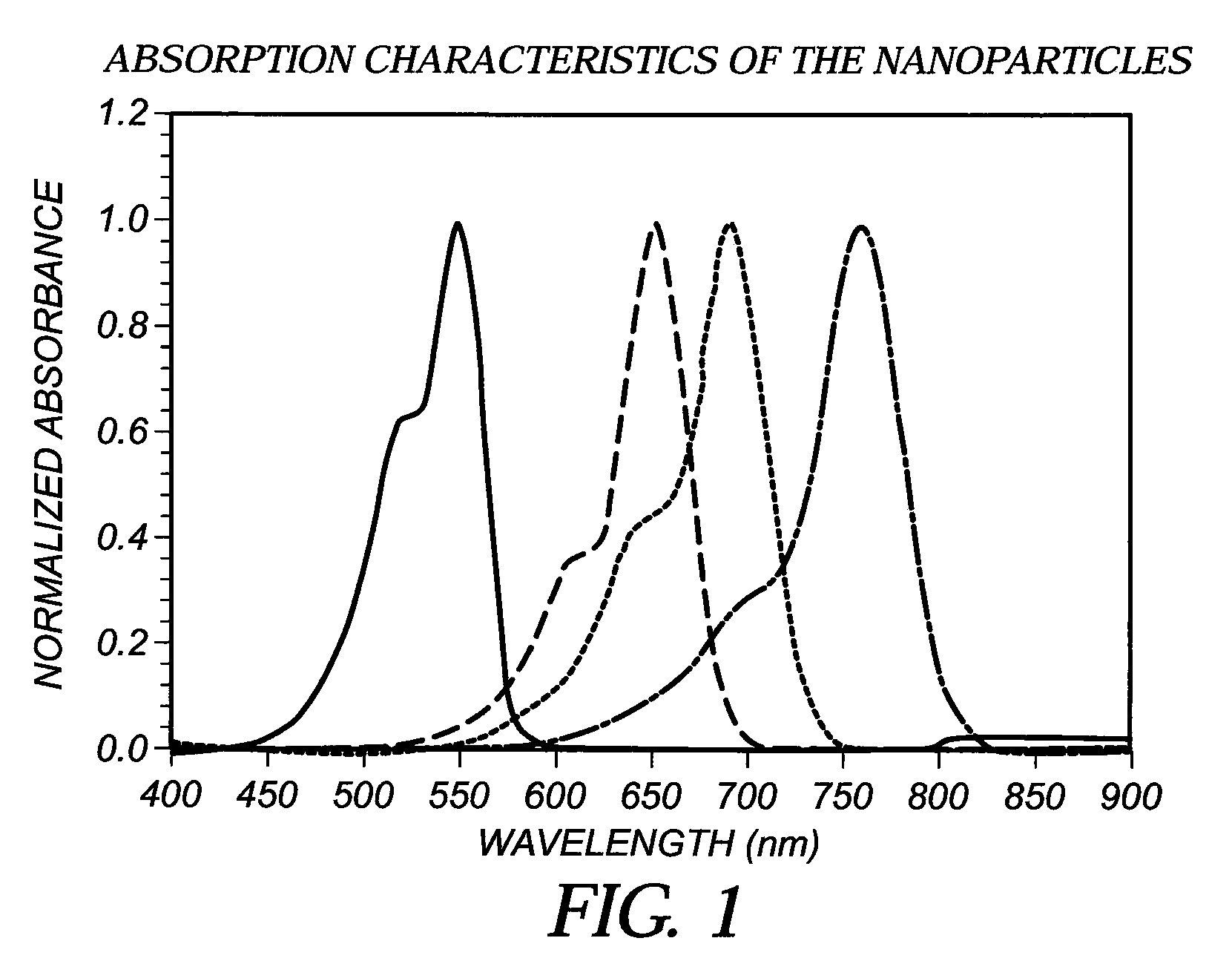

Fluorescence resonance energy transfer detection with nanoparticles for in vitro and in vivo applications

A combination of nanoparticles is disclosed comprised of amine functionalized polyethylene glycol in which one particle with a fluorescent donor dye having one wavelength excitation maximum and at least one additional particle with a second fluorescent dye having a second, higher wavelength excitation maximum, the particles having the same or different biomolecule targeting moieties bound to their external surfaces.

Owner:BRUKER BIOSPIN

Power transmission products having enhanced properties

ActiveUS20060148990A1Improved compositionImprove pillingV-beltsFilm/foil adhesivesElastomerAlpha-olefin

The present invention is directed to the incorporation of functionalized polyethylenes, in amount of about 1% to 95% by weight based upon the weight of the total crosslinkable material, into ethylene alpha olefin elastomers , such as EPDM elastomer compositions, which are crosslinked by peroxides, which results in improved properties, such as hardness and modulus of elongation, and can result in improved higher abrasion resistance, wear resistance, coefficient of friction, tensile strength, and other properties through a broad temperature range, which are beneficial to power transmission products, such as power transmission belts.

Owner:CONTITECH USA INC

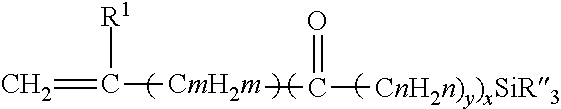

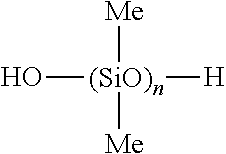

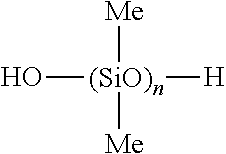

Thermoplastic, semiconductive compositions

ActiveUS9595365B2Non-conductive material with dispersed conductive materialSilanesElectrical resistivity and conductivity

Crosslinkable, semiconductive, peroxide-free thermoplastic compositions having a stable volume resistivity of less than 1000 ohm-cm comprise, based on the weight of the composition:A. 60-90 wt % silane-functionalized polyethylene;B. 0.5-20 wt % organopolysiloxane containing two or more functional end groups;C. 10-20 wt % high conductivity carbon black, e.g., a carbon black having an average particle size of 50 nm or less, a surface area (BET) of 700-1250 m2 / g, and an oil absorption (DBP) of 300-500 ml / 100 g; andD. 0.05-0.2 wt % crosslinking catalyst.

Owner:DOW GLOBAL TECH LLC

Thermoplastic, Semiconductive Compositions

ActiveUS20150200038A1Improve conductivityNon-metal conductorsConductive materialSilanesHigh conductivity

Crosslinkable, semiconductive, peroxide-free thermoplastic compositions having a stable volume resistivity of less than 1000 ohm-cm comprise, based on the weight of the composition:A. 60-90 wt % silane-functionalized polyethylene;B. 0.5-20 wt % organopolysiloxane containing two or more functional end groups;C. 10-20 wt % high conductivity carbon black, e.g., a carbon black having an average particle size of 50 nm or less, a surface area (BET) of 700-1250 m2 / g, and an oil absorption (DBP) of 300-500 ml / 100 g; andD. 0.05-0.2 wt % crosslinking catalyst.

Owner:DOW GLOBAL TECH LLC

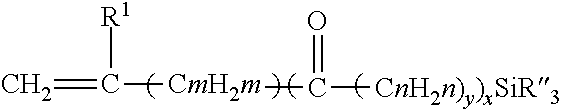

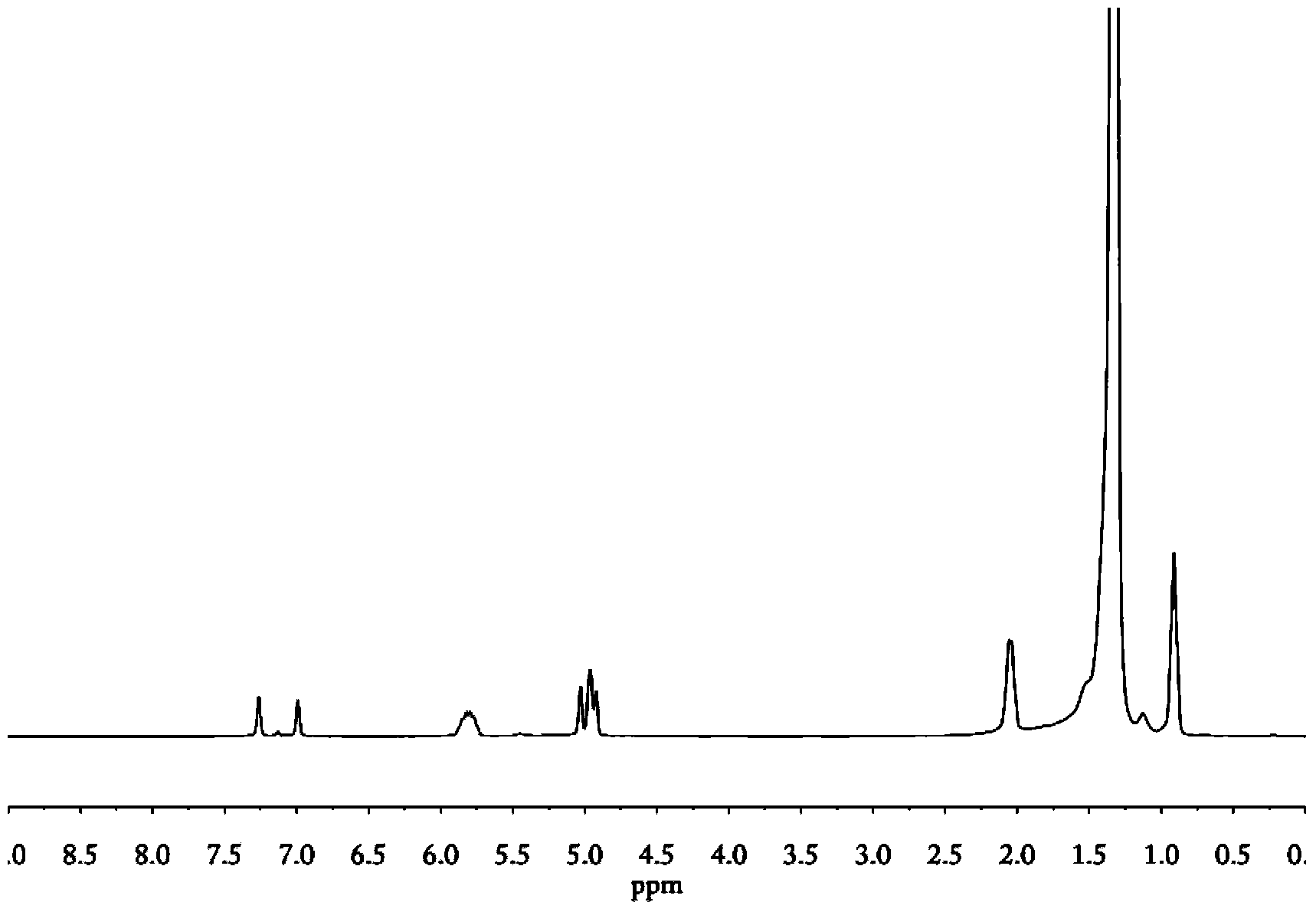

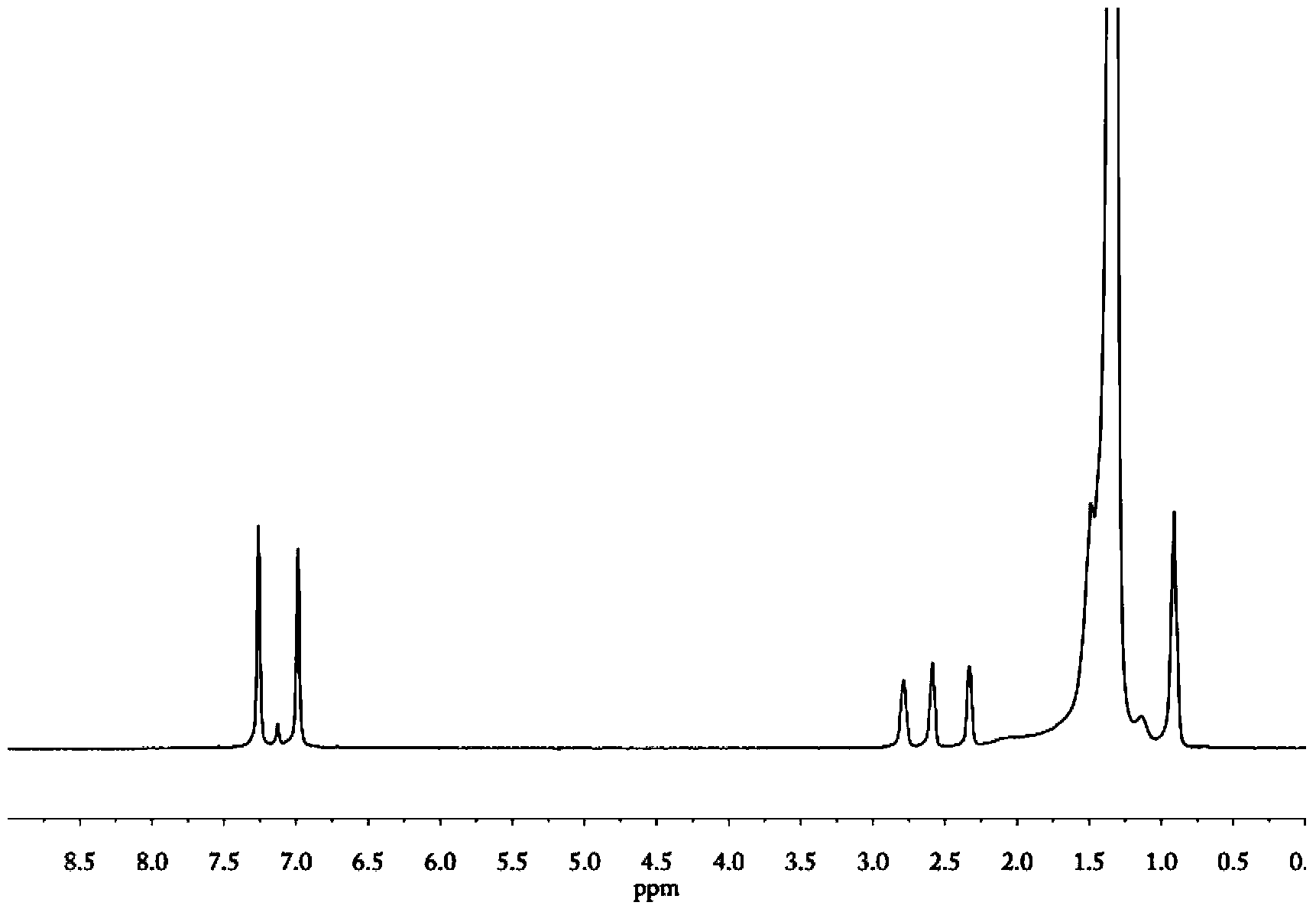

Terminal group-functionalized polyethylene and preparation method thereof

The invention provides terminal group-functionalized polyethylene which is characterized by comprising the following structure as shown in the specification, wherein PE shows a polyethylene chain, and R has a structure shown by a or b; R1 is selected from H, carries or does not carry hetero atoms (such as O, S, P, N, Cl and I) or alkyl of C1-C15 of aryl (such as phenyl). The invention further provides a preparation method of the terminal group-functionalized polyethylene. The terminal group-functionalized polyethylene is abundant in source of active ingredients; the preparation method is simple and convenient and efficient, low in cost, high in product yield, clear in structure, and excellent in performance, and has wide potential application prospects.

Owner:INST OF CHEM CHINESE ACAD OF SCI

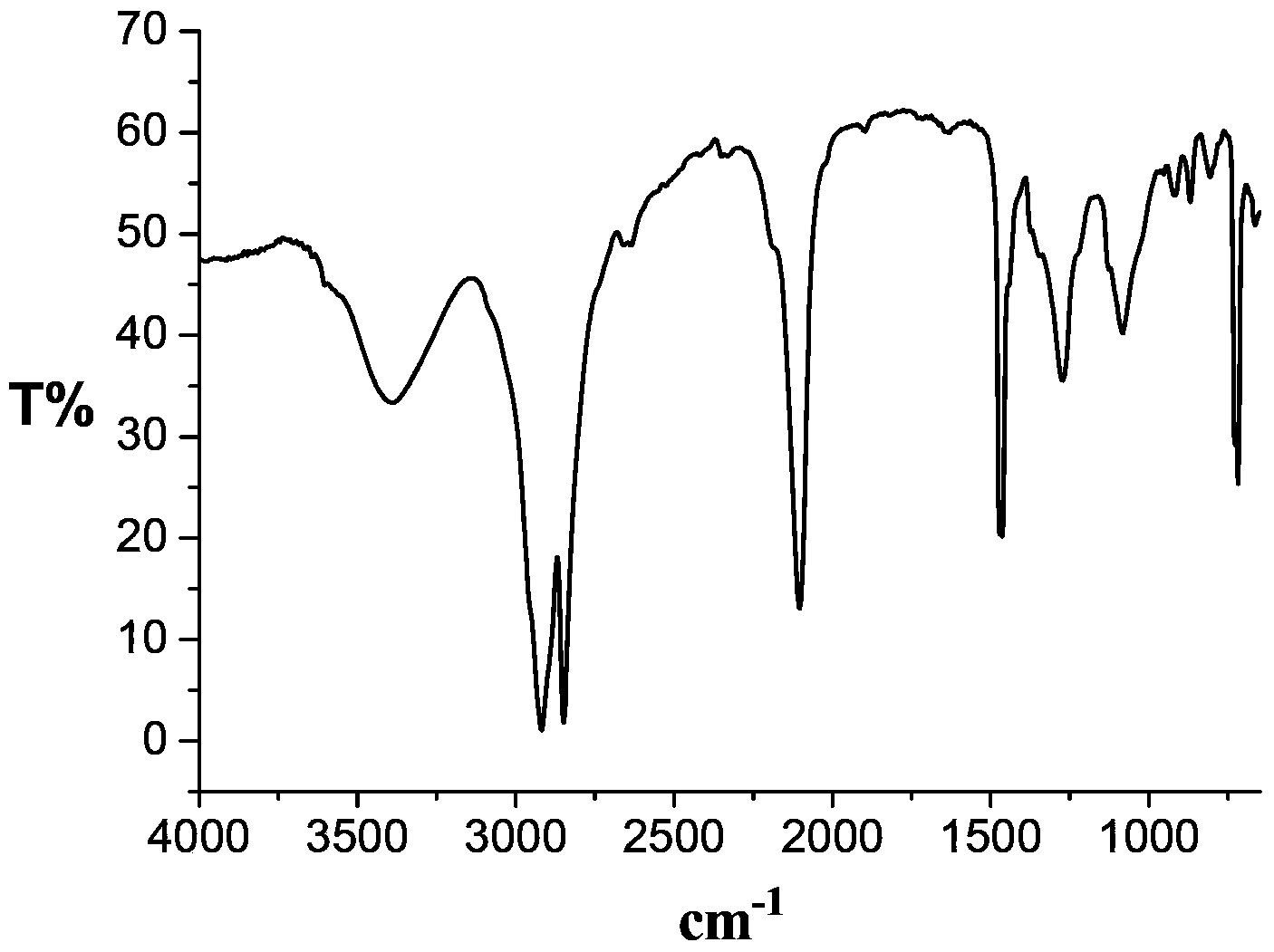

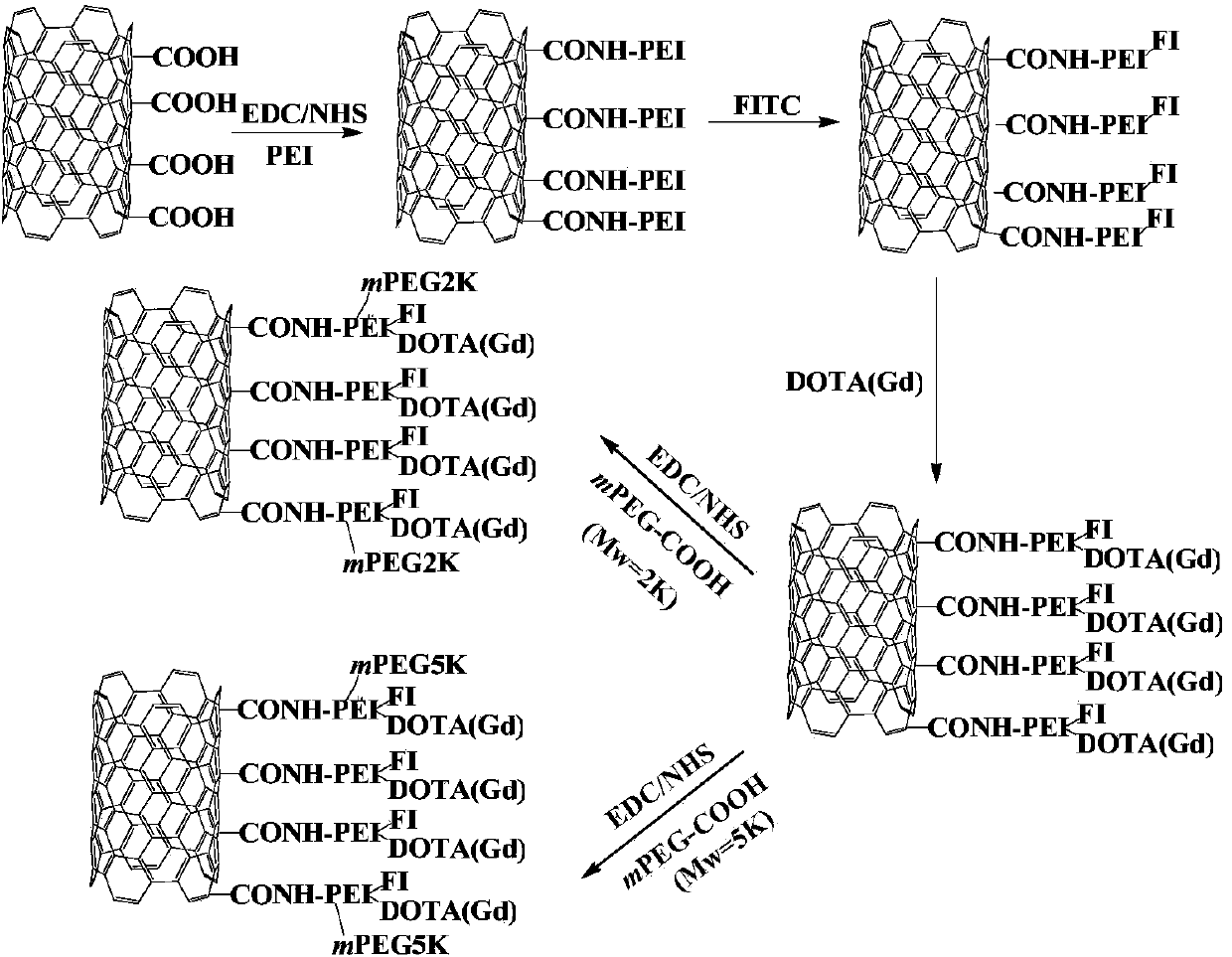

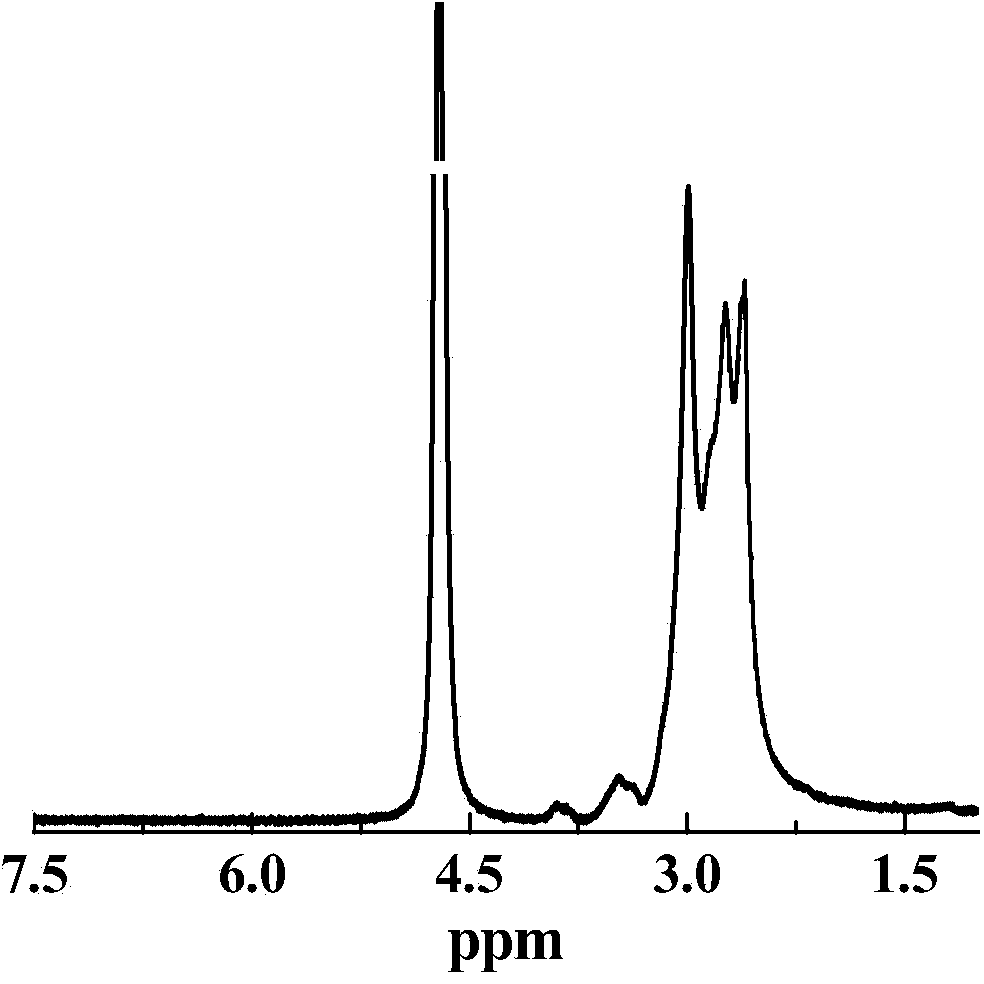

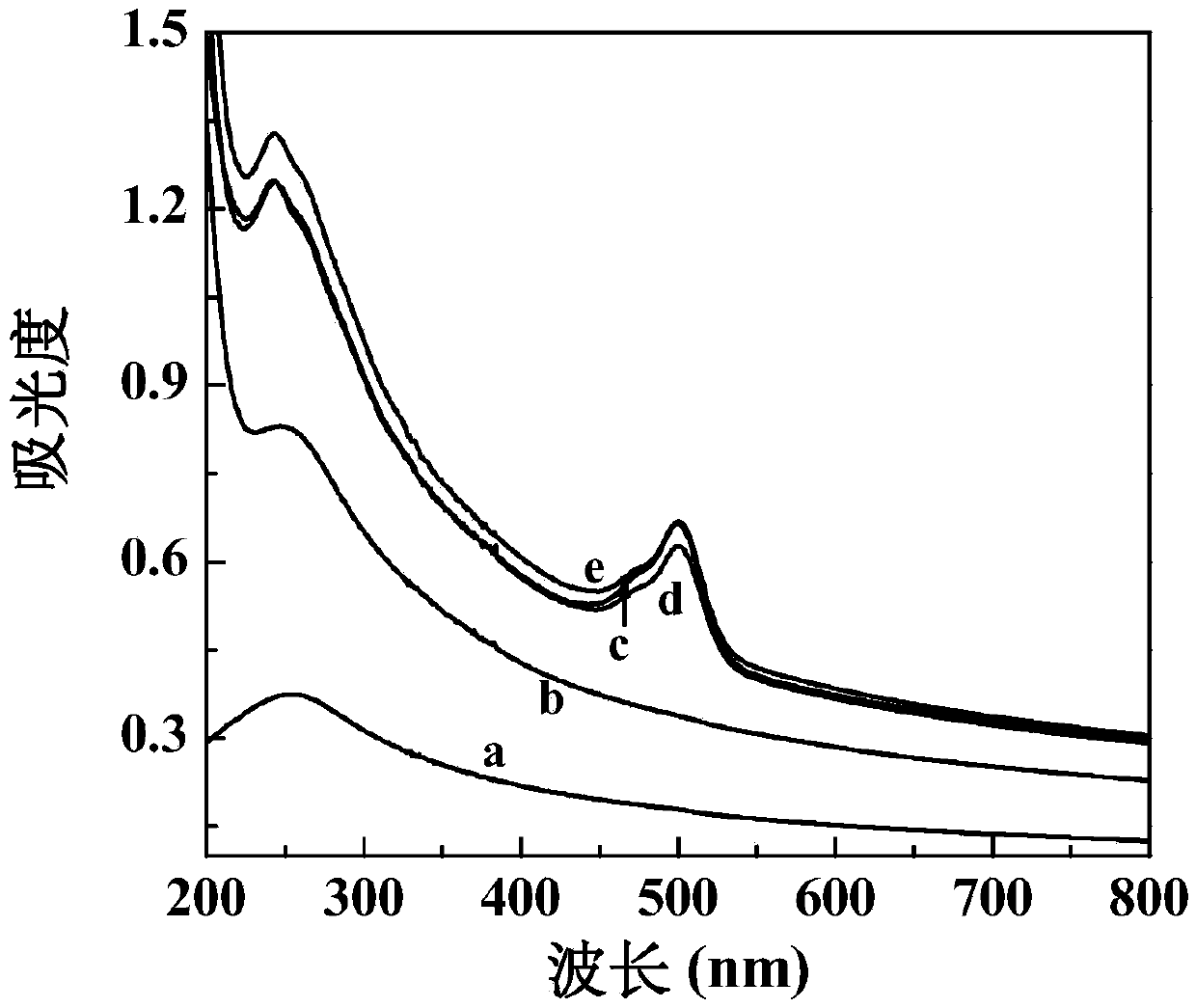

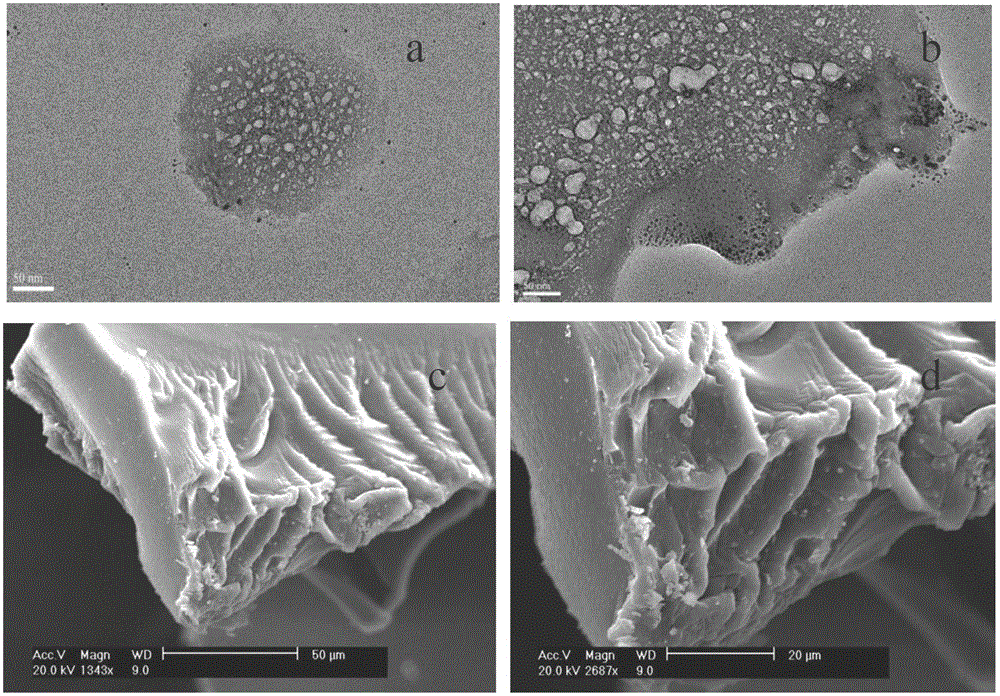

Preparation method of functionalized polyethyleneimine-modified multi-wall carbon nano-tube magnetic resonance imaging contrast agent

The invention relates to a preparation method of a functionalized polyethyleneimine-modified multi-wall carbon nano-tube magnetic resonance imaging contrast agent. The method comprises the steps that: (1) MWCNT / PEI is prepared; (2) a DMSO solution of MWCNT / PEI-FI is prepared, and MWCNT / PEI-FI-DOTA (Gd) is prepared; and (3) MWCNT / PEI-FI-DOTA (Gd)-mPEG2K or MWCNT / PEI-FI-DOTA (Gd)-mPEG5K is finally prepared. The preparation process is simple, and the experiment conditions are normal temperature and normal pressure, such that operation is easy. The adopted preparation process can be used for preparing other functionalized multi-wall carbon nano-tube composite materials. According to the invention, mice in-vivo MR blood vessel and major organ imaging is realized. Also, with the EPR effect of tumor tissues, tumor site MR imaging detection can be realized. Therefore, the method has wide application prospect.

Owner:DONGHUA UNIV +1

Functionalized polyvinyl alcohol adsorbent for managing heavy metal pollution in water and preparation method thereof

ActiveCN103143330ALarge adsorption capacityImprove mechanical propertiesOther chemical processesWater contaminantsAbsorption capacityButyl acetate

The invention discloses a functionalized polyvinyl alcohol adsorbent for managing heavy metal pollution in water. The functionalized polyvinyl alcohol adsorbent is a polymer granule which is prepared from a polyvinyl alcohol-maleic anhydride polymer in modes of swelling and carbonization treatment, wherein the polyvinyl alcohol-maleic anhydride polymer is prepared from polyvinyl alcohol, maleic anhydride and butyl acetate as raw materials. The invention further discloses a preparation method of the functionalized polyvinyl alcohol adsorbent. The absorbing material disclosed by the invention is large in heavy metal absorption capacity, rapid in absorption speed, wide in application range, free of secondary pollution, simple in use method, remarkable in effect, safe and reliable, simple and convenient in preparation process, high in production efficiency and good in product quality, can be recycled and reused and can be produced in large scale.

Owner:广东省地质实验测试中心

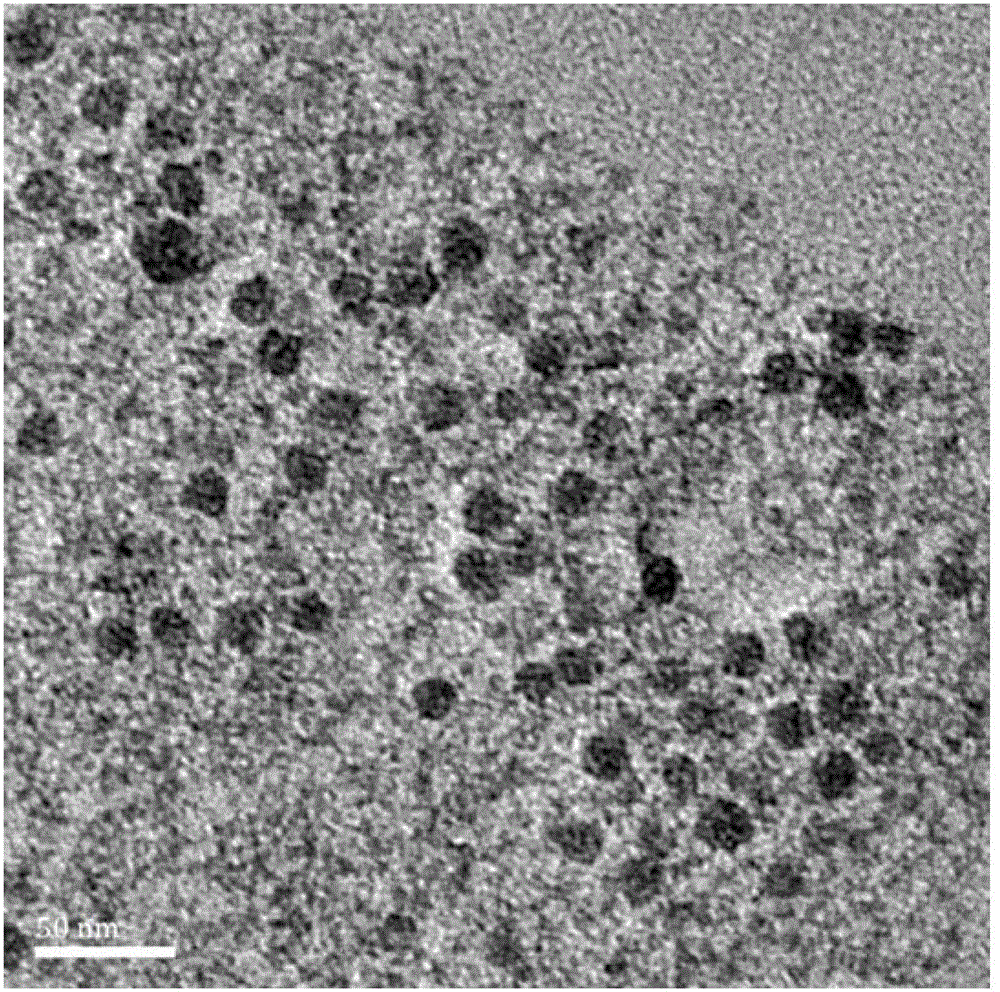

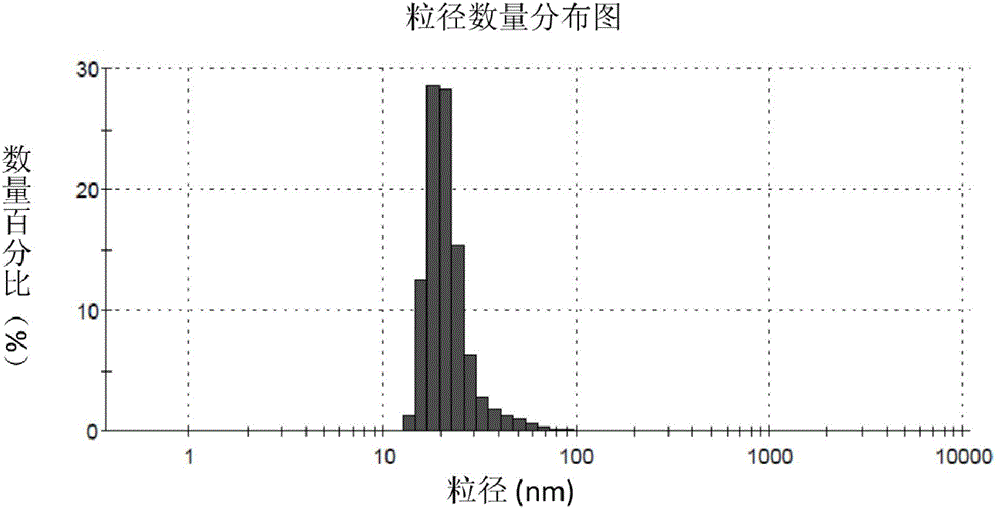

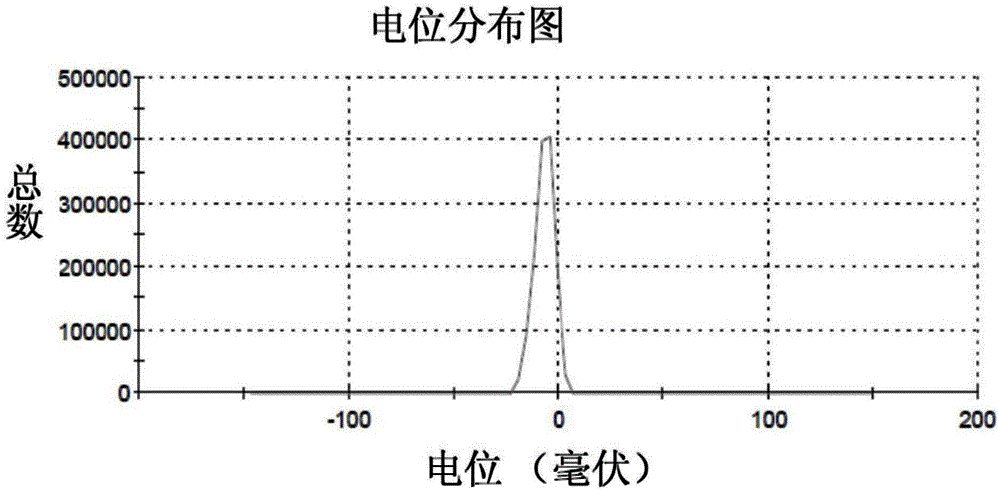

Nano particles modified by alendronic acid functionalized polyethylene glycol and preparation method of nano particles

ActiveCN104147614AExtension of timeLow costGenetic material ingredientsPharmaceutical non-active ingredientsCalcium biphosphateMacromolecular drug

The invention provides nano-particles modified by alendronic acid functionalized polyethylene glycol. The nano particles are calcium phosphate particles or calcium carbonate particles wrapped with target delivery matters; the target delivery matters are selected from DNA, siRNA and protein acromolecular drugs or micro-molecular chemical drugs; alendronic acid functionalized polyethylene glycol covers the surfaces of the nano particles; and the particle size of the nano particles modified by alendronic acid functionalized polyethylene glycol is 20-50 nm. The nano particles modified by alendronic acid functionalized polyethylene glycol are small in particle size; polyalendronic acid-polyethylene glycol can stably cover the surfaces of phosphate-genetic particles, and therefore, the nano particles can be effectively stabilized for a long time; the body circulation time is prolonged; the nano particles disclosed by the invention are low in cost and toxicity, safe and effective. The invention further provides a preparation method of the nano particles modified by the alendronic acid functionalized polyethylene glycol.

Owner:SHENZHEN INST OF ADVANCED TECH

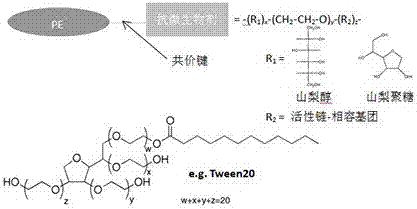

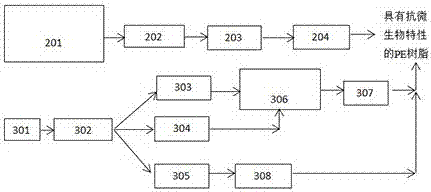

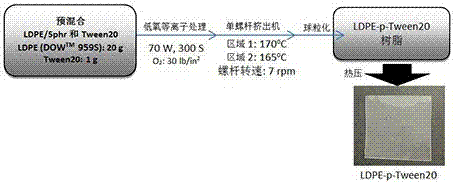

Functionalized polyethylene resin with antibacterial properties and preparation method thereof

ActiveCN107955244AIncrease productionReduce the degree of decompositionBiocideAnimal repellantsActive agentChemistry

The invention relates to a thermoplastic resin and a functionalization method thereof. The thermoplastic resin can be functionalized without the need of an initiator or a bonding agent to promote thereaction, thereby having specific functional properties. In particular, the present invention relates to a method of covalently modifying a thermoplastic resin by using a plasma method before or afterthe step of introducing an active agent having the functional properties into a thermoplastic resin.

Owner:KA SHUL MANUFACTORY CO LTD +2

Fluorescence resonance energy transfer detection with nanoparticles for in vitro and in vivo applications

A combination of nanoparticles is disclosed comprised of amine functionalized polyethylene glycol in which one particle with a fluorescent donor dye having one wavelength excitation maximum and at least one additional particle with a second fluorescent dye having a second, higher wavelength excitation maximum, the particles having the same or different biomolecule targeting moieties bound to their external surfaces.

Owner:BRUKER BIOSPIN

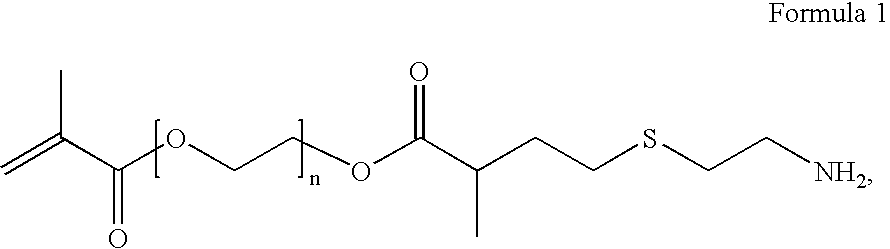

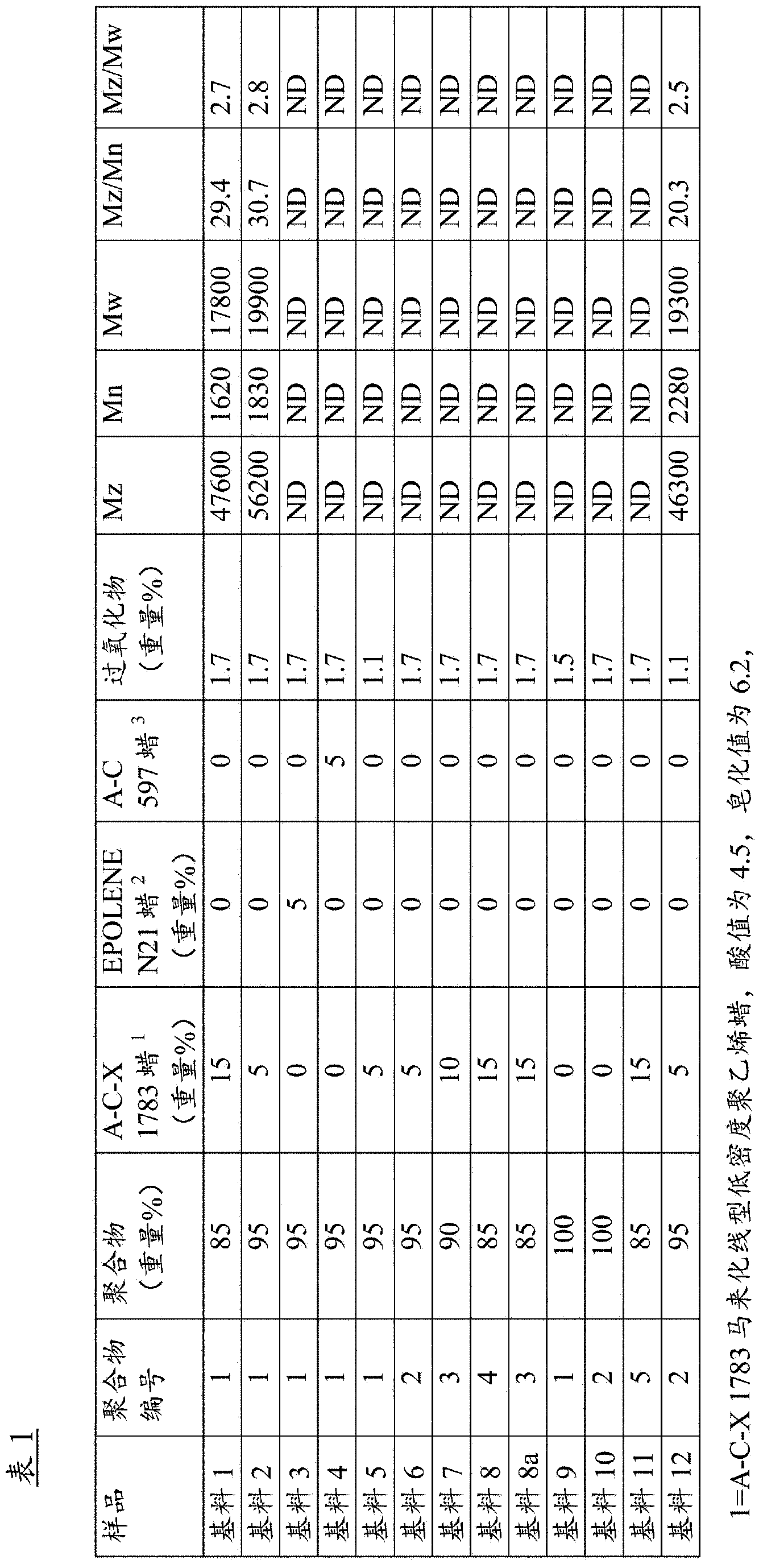

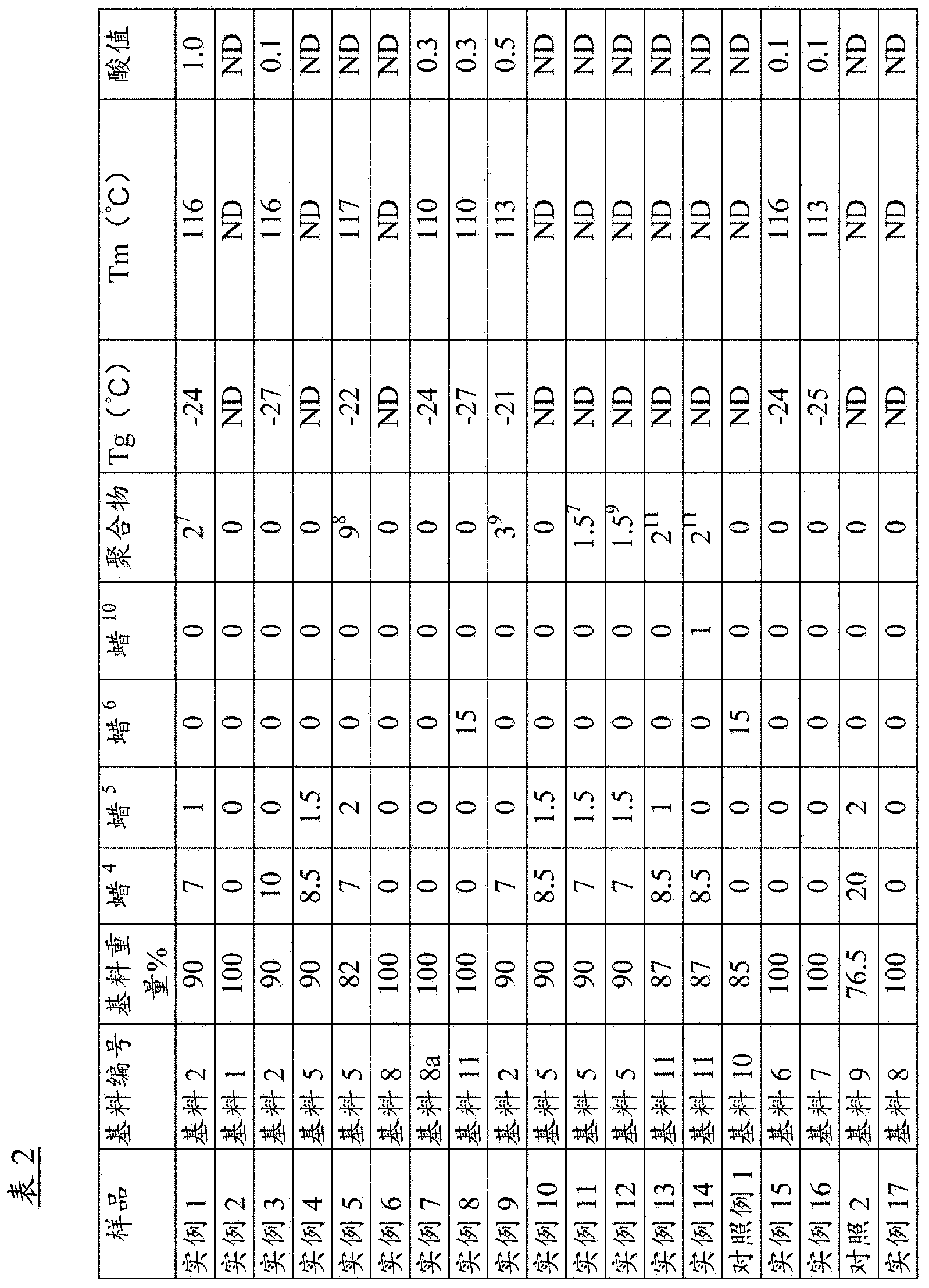

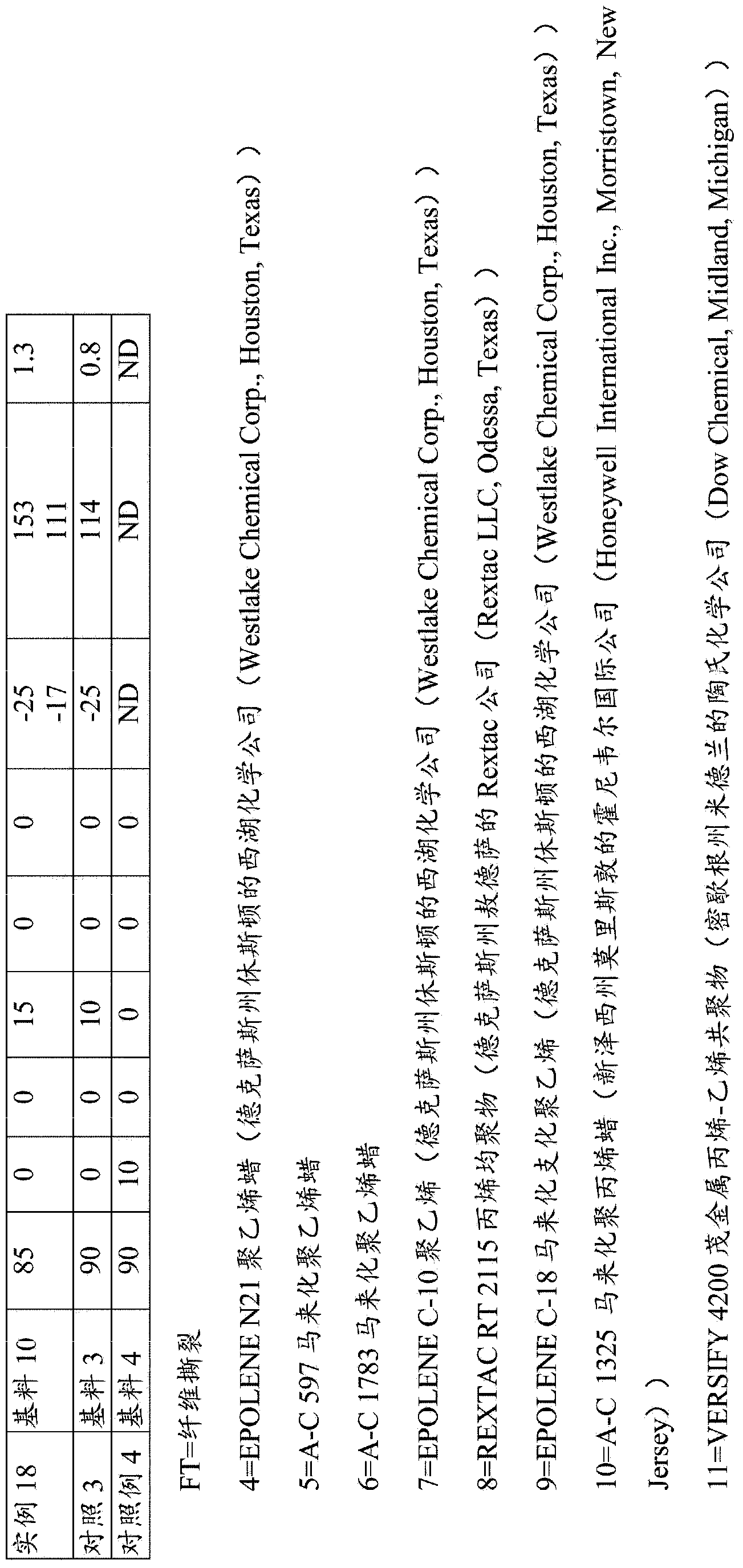

Free radical initiator modified hot melt adhesive composition including functionalized polyethylene and propylene-alpha-olefin polymer

A hot melt adhesive composition that includes a first copolymer that includes the reaction product of a functionalized polyethylene, a propylene-alpha-olefin polymer that includes at least 50 mole % propylene and has a viscosity of no greater than 10,000 centipoise at 190 DEG C, a ratio of z average molecular weight (Mz) to number average molecular weight (Mn) (Mz / Mn) of greater than 20, and a ratio of Mz to weight average molecular weight (Mw) (Mz / Mw) of greater than 3.0, and a free radical initiator.

Owner:HB FULLER CO

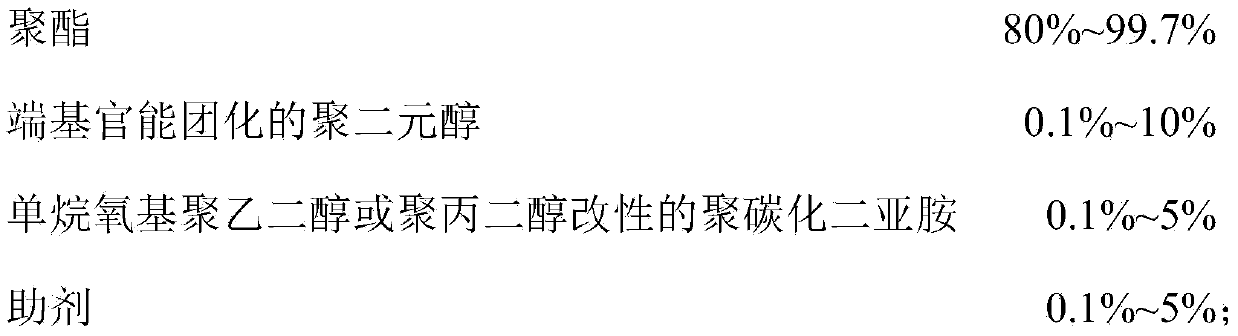

Ageing resistant polyester modified material

ActiveCN103467935AHigh retention of elongation at breakOther properties are idealPolyesterPolymer science

The invention provides an ageing resistant polyester modified material. The ageing resistant polyester modified material is prepared from the following raw materials by mass percentage: 80%-99.7% of polyester, 0.1%-10% of end group functionalized polyethylene glycol, 0.1%-5% of mono alkoxy polyethylene glycol or polypropylene glycol modified poly carbodiimide, and 0.1%-5% of additive. Compared with the prior art, the polyester modified material prepared by the method or the finished product prepared by the polyester modified material has better hydrolysis resistance, before the ageing resistant test of the polyester material, the content of the terminal carboxyl is 0-20eq / t, after ageing resistant treatment, the breaking elongation retention of the polyester is still high, and other properties of the polyester are ideal; no gas harmful to human health is generated in the production process, the viscosity of the melt is not increased so as not to cause difficulty in process, and no low molecular weight material is found to migrate and exude when the product is used.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

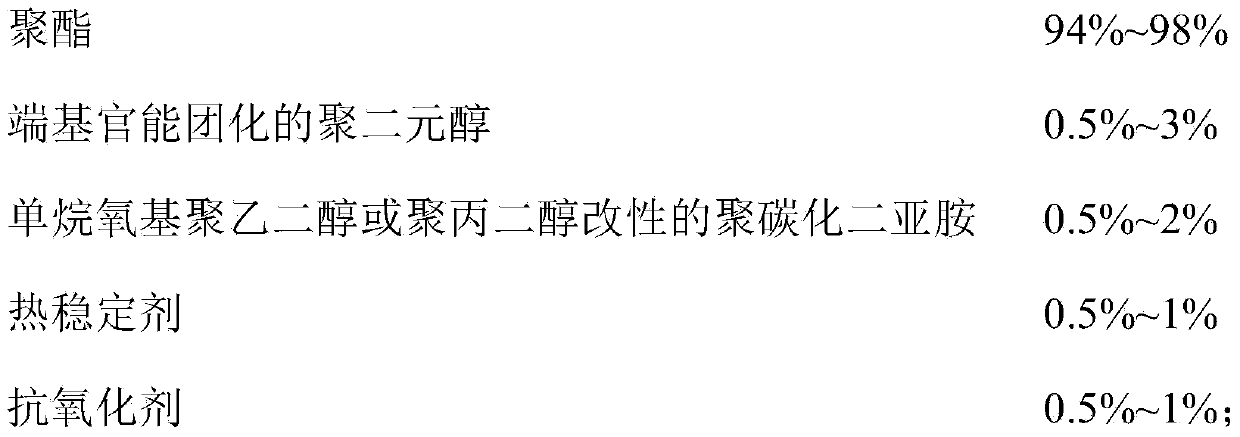

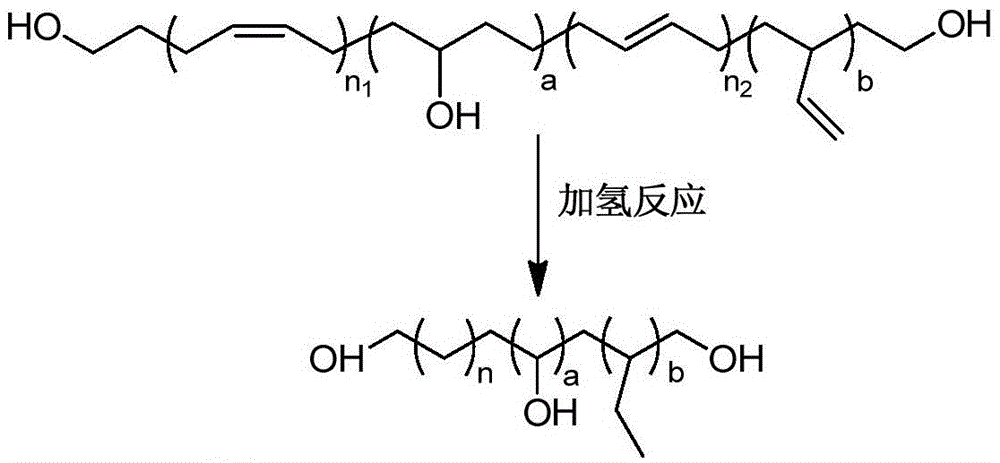

Hydroxy functionalized polyethylene and preparation method thereof

The invention discloses a hydroxy functionalized polyethylene and a preparation method thereof. The hydroxy functionalized polyethylene is characterized by comprising telechelic hydroxy polyethylene and polyhydroxy polyethylene; the polyhydroxy polyethylene is characterized in that hydroxyls are positioned at head and tail ends of a polyethylene molecular chain and in the molecular chain. The method includes: (1) hydrogenating high-cis-1,4-hydroxyl-terminated polybutadiene to prepare telechelic hydroxy functionalized polyethylene; (2) hydrogenating polyhydroxy polybutadiene liquid rubber to prepare polyhydroxy polyethylene. The hydroxy functionalized polyethylene is rich in raw material source and adjustable in position and quantity of hydroxyls, the preparation method is simple, convenient and efficient, and structural clearness, excellent performances and extensive application prospect are realized.

Owner:ZHEJIANG UNIV

Power transmission products having enhanced properties

ActiveUS7655729B2Low viscosityHigh hardnessV-beltsRopes and cables for vehicles/pulleyElastomerHardness

The present invention is directed to the incorporation of functionalized polyethylenes, in amount of about 1% to 95% by weight based upon the weight of the total crosslinkable material, into ethylene alpha olefin elastomers, such as EPDM elastomer compositions, which are crosslinked by peroxides, which results in improved properties, such as hardness and modulus of elongation, and can result in improved higher abrasion resistance, wear resistance, coefficient of friction, tensile strength, and other properties through a broad temperature range, which are beneficial to power transmission products, such as power transmission belts.

Owner:CONTITECH USA INC

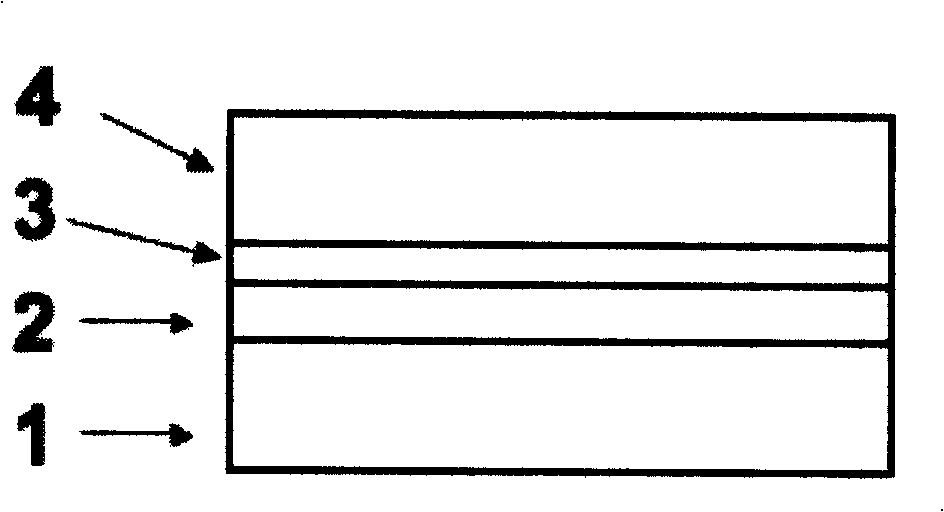

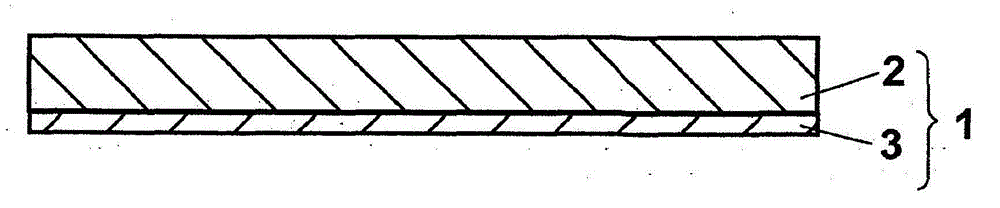

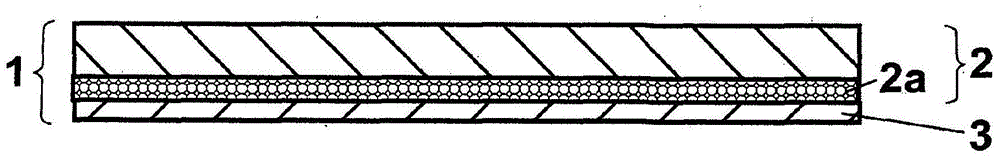

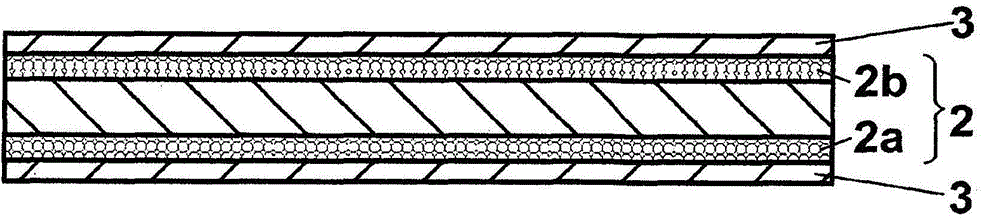

Sealing device with improved adhesion

InactiveCN104379348AReduce usageImprove bindingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesLow-density polyethylenePolyolefin

#CMT# # / CMT# Sealing agent (1) comprises a barrier layer (2) and an adhesive layer (3) comprising: a polymer, which is polyethylene, polypropylene or a copolymer of ethylene and propylene; a polyolefin-based polymer having at least one functional group of carboxylic acids, hydroxy-groups, anhydrides, acetates and glycidyl methacrylates; and azo-dicarbonamide. #CMT# : # / CMT# Independent claims are also included for: (1) sealing a substrate, comprising applying a sealing agent on a substrate, where the adhesive layer faces the substrate, and heating the adhesive layer to a temperature of 80-600[deg] C; and (2) molding of a sealing agent, comprising connecting the molding with adhesive layer, which is previously heated and fixed with the sealing agent. #CMT#USE : # / CMT# The sealing agent is useful for sealing the substrates (claimed). #CMT#ADVANTAGE : # / CMT# The sealing agent: allows rapid sealing of structures; and ensures good adhesion of the sealing agent on the base. #CMT#DESCRIPTION OF DRAWINGS : # / CMT# The figure shows a schematic representation of the sealing agent. 1 : Sealing agent 2 : Barrier layer 3 : Adhesive layer #CMT#POLYMERS : # / CMT# Preferred Components: The polyolefin-based polymer comprises: maleic anhydride functionalized polyethylene, preferably maleic anhydride functionalized low density polyethylene or maleic anhydride functionalized high density polyethylene; maleic anhydride functionalized polypropylene; maleic anhydride functionalized copolymer of ethylene and propylene; maleic anhydride functionalized ethylene-vinyl acetate copolymer; ethylene-vinyl acetate copolymers; glycidyl-methacrylate-functionalized polyethylene; and ethylene-acrylic acid copolymers. The amount of the polyolefin-based polymer is 1-18 wt.%, preferably 8-12 wt.%. The ratio of azodicarbonamide and polyolefin-based polymer is 0.1-1.2, preferably 0.4-0.6. The amount of azodicarbonamide is 3-7 wt.%, preferably 4-6 wt.%, or 0.5-5 wt.%, preferably 1-3 wt.%. The adhesive layer comprises less than 1 wt.%, preferably 0 wt.% epoxy resin, based on the total weight of the adhesive layer. The barrier layer has a foamed part on the side facing towards the adhesive layer. The adhesive layer is tack-free at 23[deg] C. The substrate is made of asphalt. Preferred Method: The method comprises applying a substrate on the barrier layer of the sealing agent. #CMT#EXAMPLE : # / CMT# No suitable example given.

Owner:SIKA TECH AG

Carbodiimide crosslinking of functionalized polyethylene glycols

ActiveUS7910129B2Surgical adhesivesSynthetic polymeric active ingredientsPolymer sciencePolyethylene glycol

A synthetic composition is provided which includes an acid-functional polymer having at least one pendant acid group, an amine-functional polymer having at least one pendant amine group, and a coupling agent. The synthetic composition can be used in human and animal medical applications as an adhesive or sealant.

Owner:COVIDIEN LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com