Method for preparing high performance graphene-polyvinyl alcohol composite fiber

A polyvinyl alcohol and composite fiber technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, rayon manufacturing, etc., can solve problems such as not meeting product requirements, reduce neutralization, improve mechanical properties, enhance the effect of the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of high-performance graphene-polyvinyl alcohol composite fiber preparation method is characterized in that, comprises the following steps:

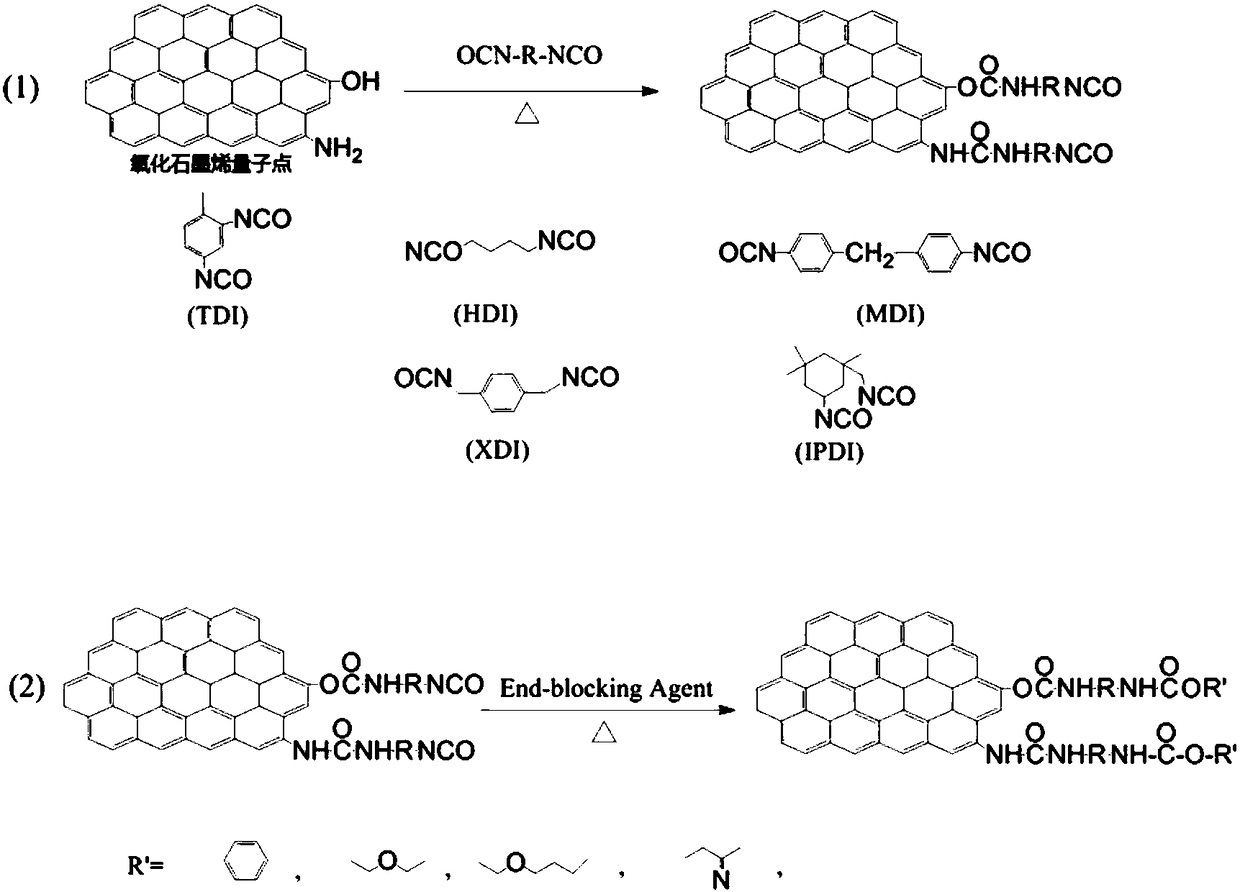

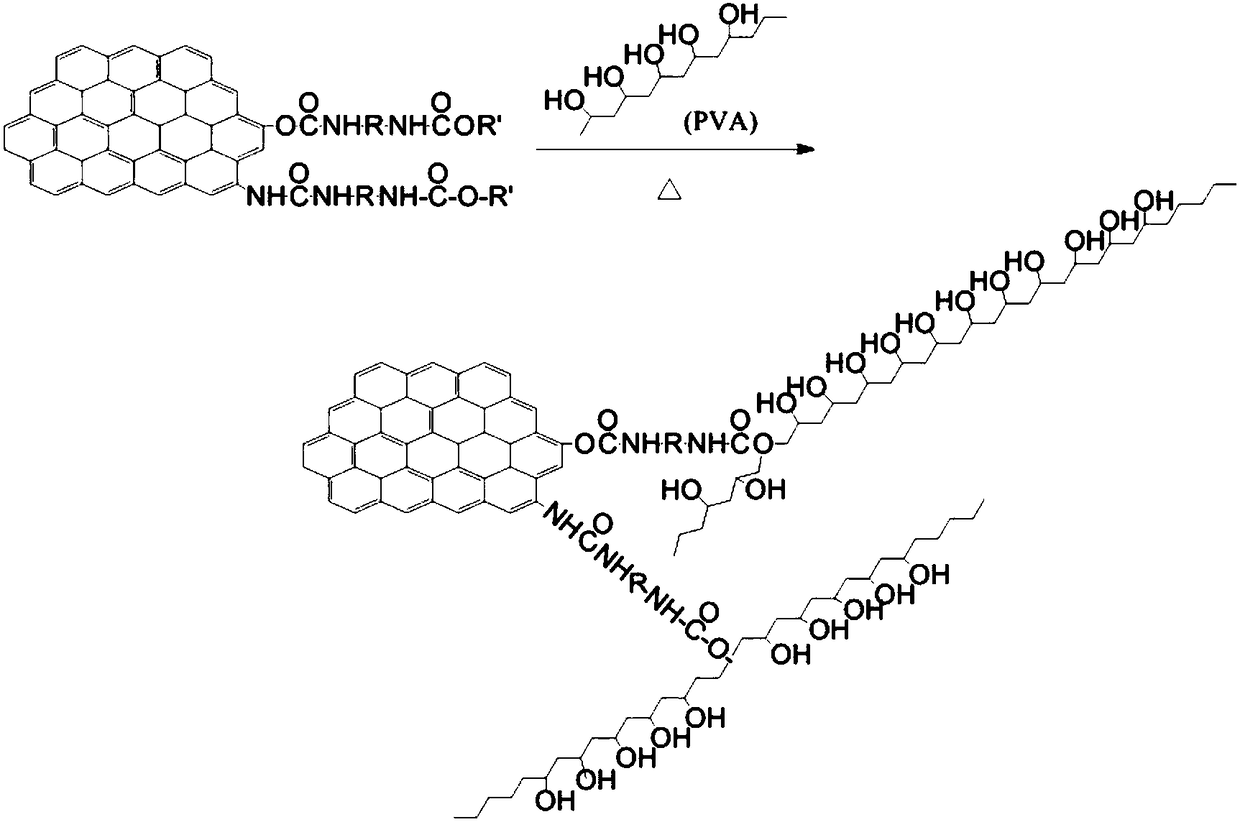

[0049] 1) Capped isocyanate functionalization of graphene oxide quantum dots

[0050] Dissolve 100mg of graphene oxide quantum dots in 100ml of DMF, add 100mg of TDI, ultrasonically disperse for 30min, react at 80°C for 24h and cool to room temperature, centrifuge the product, wash it with ether for 3 times, and place the product in After drying at 60°C for 12 hours, isocyanate-functionalized graphene quantum dots were obtained;

[0051] Weigh 100 mg of isocyanate-functionalized graphene quantum dots and 100 ml of DMF, mix them with ultrasound for 20 minutes, add 100 mg of phenol as a blocking agent, heat the mixed solution to 90 ° C, and react for 5 hours; After washing three times, the solid product was vacuum-dried at 80° C. for 24 hours to obtain graphene quantum dots (GQDs) functionalized with blocked isocyanate groups...

Embodiment 2

[0063] A kind of high-performance graphene-polyvinyl alcohol composite fiber preparation method is characterized in that, comprises the following steps:

[0064] 1) Capped isocyanate functionalization of graphene oxide quantum dots

[0065] Dissolve 200mg of graphene oxide quantum dots in 100ml of DMF, add 150mg of HDI, ultrasonically disperse for 30min, react at 80°C for 24h, then cool to room temperature, centrifuge the product, wash it with ether for 3 times, and place the product in After drying at 60°C for 12 hours, isocyanate-functionalized graphene quantum dots were obtained;

[0066] Weigh 150 mg of isocyanate-functionalized graphene quantum dots and 100 ml of DMF to mix, and ultrasonicate for 20 minutes, add 100 mg of methyl ethyl ketone oxime as a blocking agent, heat the mixed solution to 80 ° C, and react for 3 hours; the mixed solution is centrifuged, and the After washing with ether three times, the solid product was vacuum-dried at 80° C. for 24 hours to obtain...

Embodiment 3

[0078] A kind of high-performance graphene-polyvinyl alcohol composite fiber preparation method is characterized in that, comprises the following steps:

[0079] 1) Capped isocyanate functionalization of graphene oxide quantum dots

[0080] Dissolve 300mg of graphene oxide quantum dots in 500ml of DMF, add 300mg of IPDI, ultrasonically disperse for 30min, react at 80°C for 24h, then cool to room temperature, centrifuge the product, wash it with ether for 3 times, and place the product in After drying at 60°C for 12 hours, isocyanate-functionalized graphene quantum dots were obtained;

[0081] Weigh 200 mg of isocyanate-functionalized graphene quantum dots and 200 ml of DMF, mix them with ultrasound for 20 minutes, add 300 mg of ethylene glycol monoethyl ether as a blocking agent, heat the mixed solution to 90 ° C, and react for 5 hours; After centrifuging, washing with ether three times, the solid product was vacuum-dried at 80° C. for 30 h to obtain graphene quantum dots (GQ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com