Hydroxy functionalized polyethylene and preparation method thereof

A technology of hydroxyl polybutadiene and hydroxyl terminated polybutadiene is applied in the field of hydroxyl functionalized polyethylene and its preparation, and can solve the problems of high application cost, difficult recovery, expensive catalyst and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of described polyhydroxy polybutadiene is:

[0032] 1) butadiene rubber epoxidation reaction prepares epoxidized butadiene rubber;

[0033]Mass concentration is 10g / L-100g / L butadiene rubber and epoxidation reagent epoxidation reaction in reaction medium to prepare epoxidized butadiene rubber;

[0034] The molar ratio of the epoxidation reagent to the butadiene structural unit in the butadiene rubber is 1%-40%; the reaction temperature is between 0°C and 80°C; the reaction time is 30 minutes to 12 between hours;

[0035] 2) Oxidative cracking reaction of epoxidized butadiene rubber to prepare polybutadiene liquid rubber with high cis-1,4 content and epoxidized terminal aldehyde group;

[0036] Epoxidized butadiene rubber is reacted in the reaction medium under the action of oxidative cracking reagent to obtain high cis-1,4 content epoxidized terminal aldehyde polybutadiene liquid rubber;

[0037] The concentration of the epoxidized butadiene ru...

Embodiment 1

[0058] Preparation of high cis-terminated hydroxyl polybutadiene :

[0059] Take 5.00g of nickel-based butadiene rubber (BR9000), dissolve it completely in 100mL of tetrahydrofuran, the rubber concentration is 50g / L, keep the temperature at 30°C, add m-chloroperoxybenzoic acid under vigorous stirring, the amount of m-chloroperoxybenzoic acid is The butadiene structural unit in the nickel-based butadiene rubber (BR9000) is 6%, the reaction time is 6 hours, and the product is precipitated with a large amount of ethanol and vacuum-dried. product by 1 HNMR showed that the epoxy rate was 6%.

[0060] Take 4.00g of the above-mentioned epoxidized butadiene rubber, completely dissolve it in 100mL of tetrahydrofuran, the rubber concentration is 40g / L, keep the temperature at 30°C, add periodic acid under vigorous stirring, the molar ratio of periodic acid to epoxy group is 1 : 1, reacted for 30 minutes. The product can be filtered to obtain polybutadiene liquid rubber with high ci...

Embodiment 2

[0065] The preparation process of high cis-terminated hydroxyl polybutadiene is the same as in Example 1

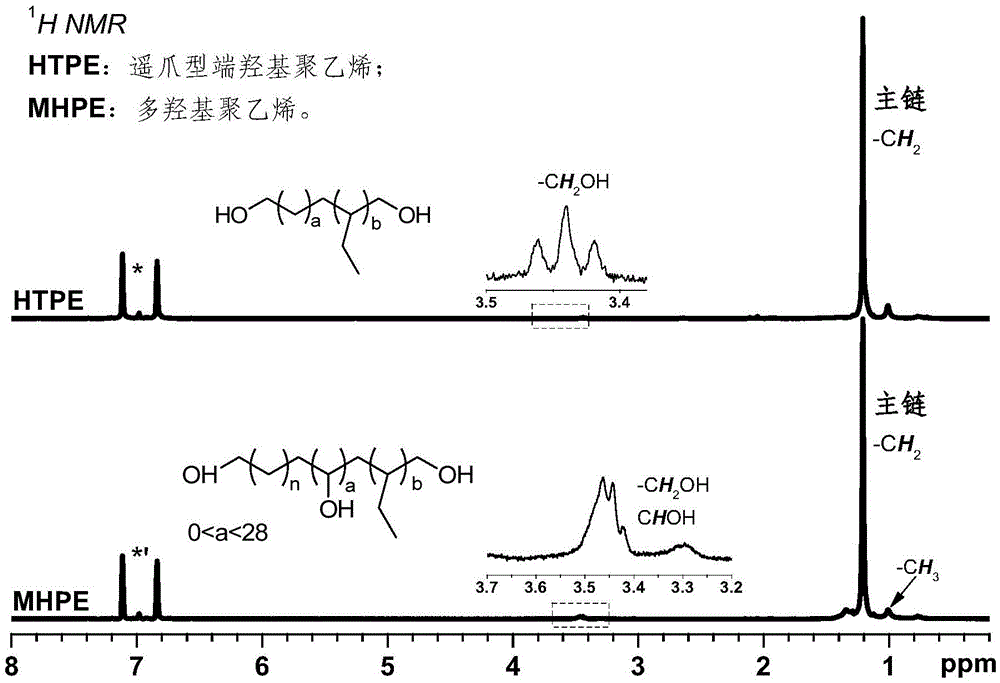

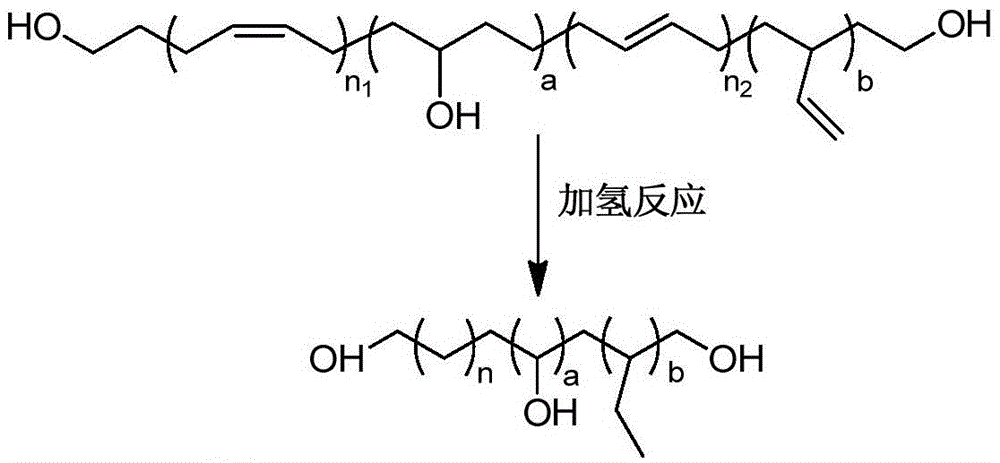

[0066] Take 2.0 g of high cis-hydroxyl-terminated polybutadiene, with a cis-1,4 content of 95%, a hydroxyl functionality of 2.0, a number average molecular weight of 5000 g / mol, and a molecular weight distribution of 1.6. Add 50mL of cyclohexane, transfer the high cis-hydroxyl-terminated polybutadiene solution into the pressure reactor, add nickel naphthenate-triisobutylaluminum, keep the argon atmosphere, heat to 50°C, and pass in hydrogen, Keep the pressure at 0.5 MPa and react for 4 hours. After the reaction is finished, the telechelic hydroxyl-functionalized polyethylene is obtained through cooling, precipitation, separation, purification and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com