Ageing resistant polyester modified material

A polyester modification and anti-aging technology, applied in the field of polyester modified materials, can solve problems such as poor thermal stability, increased yellowness index of products, harmful and irritating odor of human body, etc., and achieve good hydrolysis resistance, elongation at break, etc. High long-term retention rate, ideal effect of other properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

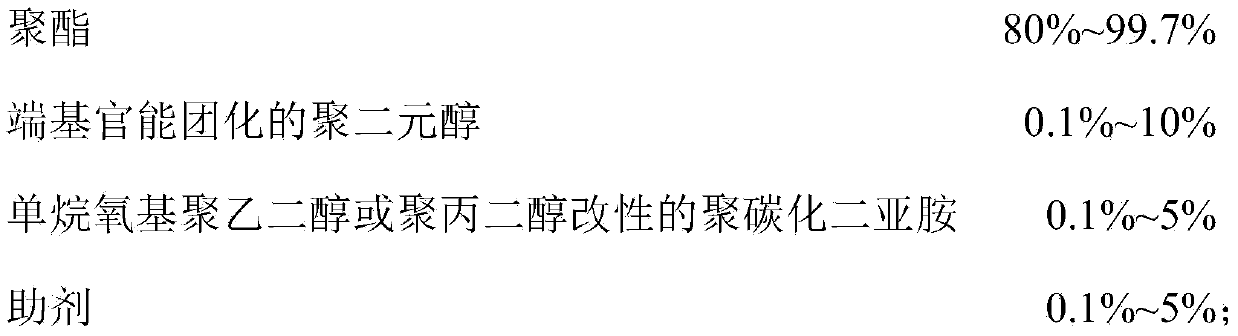

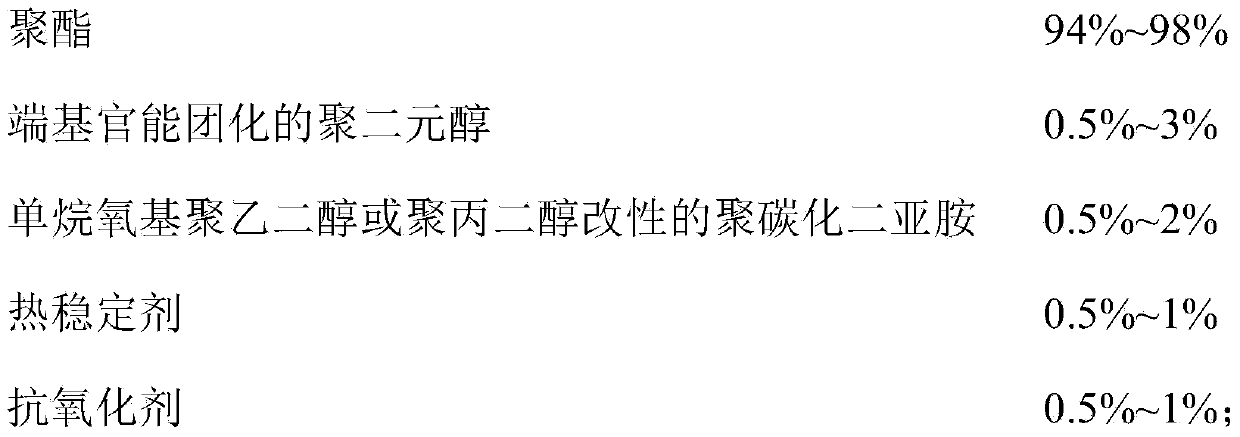

Method used

Image

Examples

Embodiment 1~5

[0036] The components of the modified polyester in this embodiment are as follows: PET resin (after vacuum drying at 150°C), and diaminopolyethylene glycol (H 2 N-PEG-NH 2 , Purchased by Xiamen Sinobanger Biotechnology Co., Ltd.), monomethoxy polyethylene glycol terminated poly4,4'-diphenylmethylcarbodiimide (expressed in MPEG-PMCDI), 0.5% triphosphate Methyl ester and 0.5% antioxidant 1010 were added to the blender and mixed, and then passed through the twin-screw extruder through the above-mentioned preparation process to make a 250μm biaxially oriented film, and tested its terminal carboxyl group concentration, yellowness index and aging resistance (The intrinsic viscosity of the PET resin used in this example is 0.67dl / g, the terminal carboxyl group concentration is 25eq / t, and the molecular weight is 18000-23000). When bisaminopolyethylene glycol is used in a large amount, the melt viscosity is likely to increase more due to the effect of the bifunctional group, which bring...

Embodiment 6~8

[0044] The components of the modified polyester in this embodiment are as follows: PET resin (after being vacuum dried at 150°C), and amino polyethylene glycol monomethyl ether (MPEG-NH 2 , Purchased by Xiamen Sinobanger Biotechnology Co., Ltd.), monomethoxy polyethylene glycol terminated poly4,4'-diphenylmethylcarbodiimide (expressed in MPEG-PMCDI), 0.5% triphosphate Methyl ester and 0.5% antioxidant 1010 (purchased by BASF) were added to the mixer and mixed, and then passed through a twin-screw extruder to make a 250μm biaxially oriented film, and tested its terminal carboxyl group concentration, yellowness index and aging resistance Performance (the intrinsic viscosity of the PET resin used in this example is 0.67dl / g, the terminal carboxyl group concentration is 25eq / t, and the molecular weight is 18000-23000). Using amino polyethylene glycol monomethyl ether (MPEG-NH 2 ) In the case of modifiers, due to the effect of monofunctional groups, the dosage will be increased, and ...

Embodiment 9~12

[0052] The components of the modified polyester in this embodiment are as follows: PET resin (after being vacuum dried at 150°C), and diglycidyl polyethylene glycol (EO-PEG-EO, Xiamen Sinobanger Biotechnology Co., Ltd.) Purchase), monomethoxy polyethylene glycol terminated polyisophorone carbodiimide (expressed in MPEG-PIPDI), 0.5% trimethyl phosphate and 0.5% antioxidant 1010 (purchased from BASF) added After mixing by the blender, a biaxially oriented film of 250μm is made through a twin-screw extruder, and its end carboxyl group concentration, yellowness index and aging resistance are tested (the intrinsic viscosity of the PET resin used in this example is 0.67dl / g, the terminal carboxyl group concentration is 25eq / t, and the molecular weight is 18000-23000). When using diglycidyl polyethylene glycol (EO-PEG-EO) and monomethoxy polyethylene glycol terminated polyisophorone carbodiimide as modifiers, the processing performance and hydrolysis resistance of polyester The perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com