Low-temperature-resistant and corrosion-resistant rubber tube and preparation method thereof

A corrosion-resistant and rubber tube technology, applied in the field of low-temperature and corrosion-resistant rubber tubes and its preparation, can solve the problems of rubber tubes that cannot meet the multi-level requirements and single performance, and achieve the effect of good low temperature resistance and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

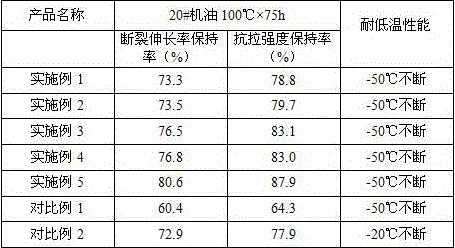

Examples

Embodiment 1

[0016] A low-temperature and corrosion-resistant rubber tube, which is prepared from the following ingredients in parts by weight: 110 parts of ethylene acrylate rubber, 30 parts of quick extruded carbon black, 5 parts of talcum powder, 8 parts of magnesium oxide, 3 parts of hard ester, 1.5 parts of sulfur, 3 parts of N-phenyl-N'-isopropyl-p-phenylenediamine, 1 part of N-cyclohexyl-2-benzothiazole sulfenamide, 2 parts of diphenylguanidine, 5 parts of ethylenediamine 10 parts, tetrahydrophthalate diglycidyl ester epoxy resin 10 parts, vinyl resin 2.5 parts, Hytron acid unsaturated polyester resin 3 parts, acrylate styrene modified water-based alkyd resin 8 parts.

[0017] The preparation method of the above-mentioned low-temperature and corrosion-resistant rubber tube is as follows: (1) ethylene acrylate rubber, quick extruded carbon black, talcum powder, magnesium oxide, hard ester, sulfur, N-phenyl-N'-isopropyl -P-phenylenediamine, N-cyclohexyl-2-benzothiazole sulfenamide, di...

Embodiment 2

[0019] A low-temperature-resistant and corrosion-resistant rubber tube, prepared from the following components by weight: 90 parts of ethylene acrylate rubber, 20 parts of quick extruded carbon black, 15 parts of talcum powder, 3 parts of magnesium oxide, 0.5 parts of hard ester, 0.3 parts of sulfur, 0.5 parts of N-phenyl-N'-isopropyl-p-phenylenediamine, 2 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1 part of diphenylguanidine, 3 parts of ethylenediamine 5 parts, tetrahydrophthalate diglycidyl ester epoxy resin 5 parts, vinyl resin 5 parts, Hytron acid unsaturated polyester resin 8 parts, acrylate styrene modified water-based alkyd resin 8 parts.

[0020] The preparation method of the above-mentioned low-temperature and corrosion-resistant rubber tube is as follows: (1) ethylene acrylate rubber, quick extruded carbon black, talcum powder, magnesium oxide, hard ester, sulfur, N-phenyl-N'-isopropyl -P-phenylenediamine, N-cyclohexyl-2-benzothiazole sulfenamide, diphenylgua...

Embodiment 3

[0022] A low-temperature and corrosion-resistant rubber tube, prepared from the following components by weight: 105 parts of ethylene acrylate rubber, 28 parts of quick extruded carbon black, 12 parts of talcum powder, 4 parts of magnesium oxide, 2 parts of hard ester, 0.5 parts of sulfur, 1 part of N-phenyl-N'-isopropyl-p-phenylenediamine, 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1.8 parts of diphenylguanidine, 3.5 parts of ethylenediamine 7 parts, tetrahydrophthalate diglycidyl ester epoxy resin 7 parts, vinyl resin 4.5 parts, Hytron acid unsaturated polyester resin 7 parts, acrylate styrene modified water-based alkyd resin 5 parts.

[0023] The preparation method of the above-mentioned low-temperature and corrosion-resistant rubber tube is as follows: (1) ethylene acrylate rubber, quick extruded carbon black, talcum powder, magnesium oxide, hard ester, sulfur, N-phenyl-N'-isopropyl -P-phenylenediamine, N-cyclohexyl-2-benzothiazole sulfenamide, diphenylguanidin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com