Sealing device with improved adhesion

A technology of utensils and adhesive layers, which is applied in the sealing field of substrates and substrates, and can solve problems such as smoldering and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

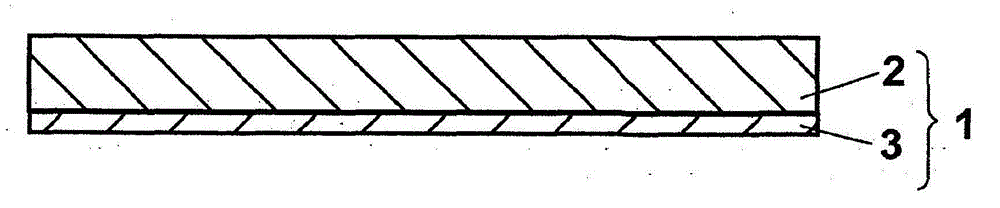

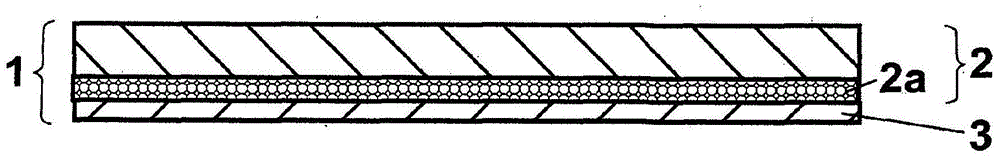

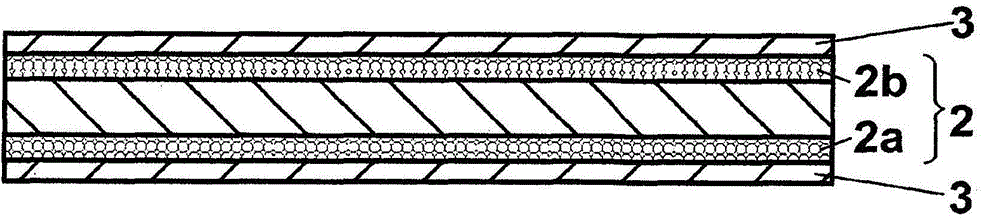

[0011] The invention relates in a first aspect to a sealing device 1 comprising

[0012] a barrier layer 2 comprising a thermoplastic polymer P1,

[0013] and an adhesive layer 3 comprising

[0014] - at least one ethylene-vinyl acetate-copolymer (EVA) P2, and

[0015] - Azodicarbonamide A.

[0016] The barrier layer 2 is preferably bonded directly to the adhesive layer 3 . The term "directly bonded" is understood to mean that no other layers or substances are present between the two materials and that the two materials are directly bonded to each other or adhered in close proximity. At the transition between the two materials, the two materials can be mixed into one another. The adhesive layer 3 can be bonded to the barrier layer 2 over the entire surface or discontinuously (in particular over the entire surface).

[0017] figure 1 The structure of the sealing device 1 is shown, and the sealing device 1 comprises a barrier layer 2 and an adhesive layer 3 , wherein the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com