Preparation method and application of functionalized polyvinyl alcohol microspheres

A technology of polyvinyl alcohol microspheres and functionalization, which is applied in the direction of microsphere preparation, microcapsule preparation, adsorption water/sewage treatment, etc., can solve the problems of high cost experimental conditions, easy loss of heavy metal samples, etc., and achieve low cost and easy preparation Mild Conditions, Visible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of functionalized polyvinyl alcohol microspheres, comprising the following steps:

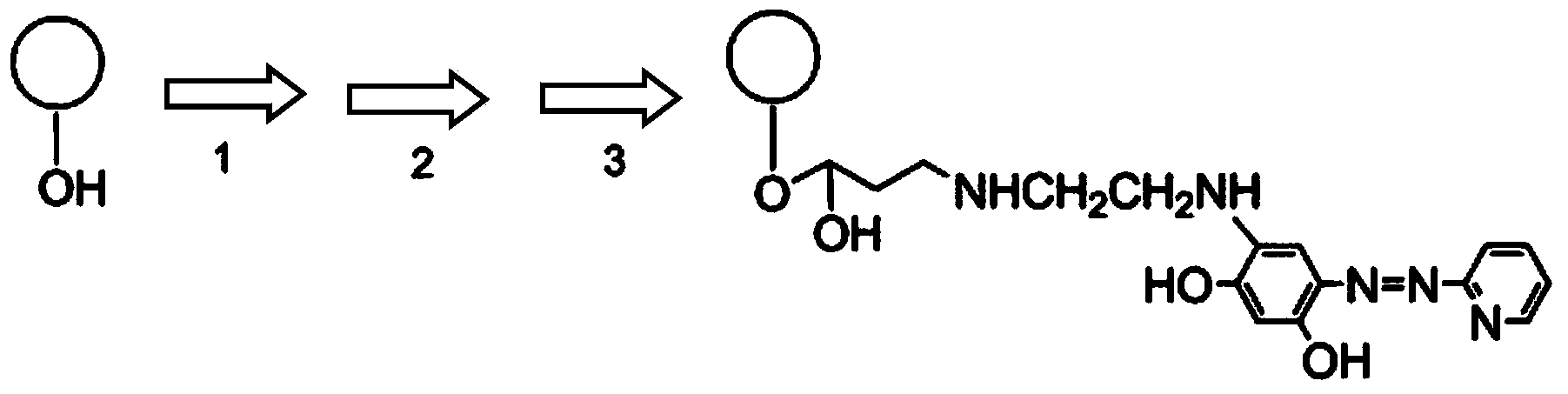

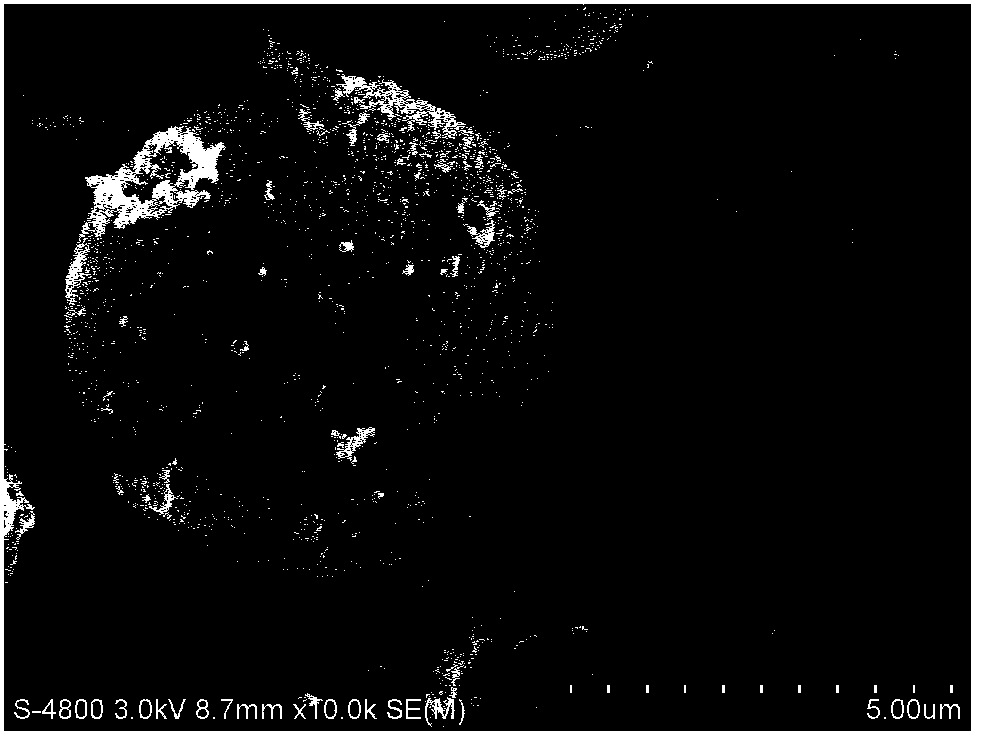

[0046] Preparation of polyvinyl alcohol microspheres by inverse suspension cross-linking method: first dissolve 4g of polyvinyl alcohol (PVA) (1799) in 40mL of water, stir mechanically in a boiling water bath for 1h, remove from the boiling water bath and cool to 60°C, add 80mL of liquid paraffin and 1g Span 80, stirred for 2h and then added 2mL1mol L -1 hydrochloric acid solution and 4mL glutaraldehyde solution at a rotating speed of 500rpm (the radius of the stirring paddle is 2cm), after stirring for 30min, centrifuge at a rotating speed of 4000rpm (the radius of the centrifuge is 13.5cm) for 3min, separate the microspheres, and wash them with petroleum ether for 3 times, and then vacuum-dried to obtain a white powdery solid, that is, polyvinyl alcohol microspheres, with a particle size of 1-50 μm. The reaction principle is as figure 1 shown.

[0047] Take 1g o...

Embodiment 2

[0052] A preparation method of functionalized polyvinyl alcohol microspheres, comprising the following steps:

[0053] Dissolve 4g of polyvinyl alcohol (PVA) (1799) in 40mL of water, stir mechanically in a boiling water bath for 1h, remove from the boiling water bath and cool to 60°C, add 80mL of liquid paraffin and 1g of Span 80, stir for 2h, then add 2mL of 1mol·L -1 hydrochloric acid solution and 4mL glutaraldehyde solution at a rotating speed of 500rpm (the radius of the stirring paddle is 2cm), after stirring for 30min, centrifuge at a rotating speed of 4000rpm (the radius of the centrifuge is 13.5cm) for 3min, separate the microspheres, and wash them with petroleum ether for 3 times, and then vacuum-dried to obtain a white powdery solid, that is, polyvinyl alcohol microspheres, with a particle size of 1-50 μm.

[0054] Take 1g of the above-prepared polyvinyl alcohol microspheres and 4mL epichlorohydrin, add it to 50mL hydrochloric acid with a pH of 2, heat it in a water ...

Embodiment 3

[0059] A preparation method of functionalized polyvinyl alcohol microspheres, comprising the following steps:

[0060] Dissolve 4g of polyvinyl alcohol (PVA) (1799) in 40mL of water, stir mechanically in a boiling water bath for 1h, remove from the boiling water bath and cool to 60°C, add 80mL of liquid paraffin and 1g of Span 80, stir for 2h, then add 2mL of 1mol·L -1 hydrochloric acid solution and 4mL glutaraldehyde solution at a rotating speed of 500rpm (the radius of the stirring paddle is 2cm), after stirring for 30min, centrifuge at a rotating speed of 4000rpm (the radius of the centrifuge is 13.5cm) for 3min, separate the microspheres, and wash them with petroleum ether for 3 times, and then vacuum-dried to obtain a white powdery solid, that is, polyvinyl alcohol microspheres, with a particle size of 1-50 μm.

[0061] Take 1g of the above-prepared polyvinyl alcohol microspheres and 10mL of epichlorohydrin, add it to 100mL of hydrochloric acid with a pH of 5, heat it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com