Cold pressing method of abelmoschus esculentus oil

A technology of okra and okra seeds, which is applied in the field of agricultural product processing, can solve problems such as low oil yield and waste of nutrients, and achieve the effects of increasing oil yield, improving product quality, and ensuring natural flavor and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

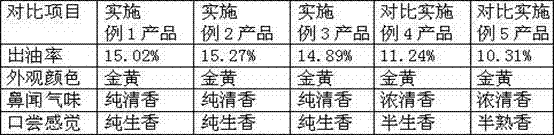

Examples

Embodiment 1

[0028] (1) Cleaning: Select okra seeds with full grains, no impurities and no damage.

[0029] ⑵Impurity removal: Remove the impurities in the okra seeds with the impurity remover.

[0030] (3) Grading: Use a color sorter to further remove impurities in the okra seeds and carry out grading. Our company divides okra seeds into special grade, excellent grade and qualified grade according to the plumpness of okra seeds. Generally, special grade accounts for 20% of the total weight, excellent grade accounts for 60% of the total weight, and qualified grade accounts for 20% of the total weight.

[0031] (4) Cleaning: the okra seeds after grading are cleaned; in this embodiment, 500kg of high-grade okra seeds are cleaned.

[0032] (5) Sterilization: Sterilize the washed okra seeds with a microwave sterilizer; the control frequency is 600MHz, the temperature is 60°C, and the sterilization time is 9 minutes.

[0033] (6) Drying: Then put the okra seeds into the aseptic workshop and d...

Embodiment 2

[0042] (1) Cleaning: Select okra seeds with full grains, no impurities and no damage.

[0043] ⑵Impurity removal: Remove the impurities in the okra seeds with the impurity remover.

[0044] (3) Grading: Use a color sorter to further remove impurities in the okra seeds and carry out grading. Our company divides okra seeds into special grade, excellent grade and qualified grade according to the plumpness of okra seeds. Generally, special grade accounts for 20% of the total weight, excellent grade accounts for 60% of the total weight, and qualified grade accounts for 20% of the total weight.

[0045] (4) Cleaning: the okra seeds after grading are cleaned; in this embodiment, 500kg of high-grade okra seeds are cleaned.

[0046] (5) Sterilization: Sterilize the washed okra seeds with a microwave sterilizer; the control frequency is 900MHz, the temperature is 65°C, and the sterilization time is 8 minutes.

[0047] (6) Drying: Then put the okra seeds into the aseptic workshop and d...

Embodiment 3

[0056](1) Cleaning: Select okra seeds with full grains, no impurities and no damage.

[0057] ⑵Impurity removal: Remove the impurities in the okra seeds with the impurity remover.

[0058] (3) Grading: Use a color sorter to further remove impurities in the okra seeds and carry out grading. Our company divides the okra seeds into special grade, excellent grade and qualified grade according to the fullness of the okra seeds. Generally, the special grade accounts for 20% of the total weight, the excellent grade accounts for 60% of the total weight, and the qualified grade accounts for 20% of the total weight.

[0059] (4) Cleaning: the okra seeds after grading are cleaned; in this embodiment, 500kg of high-grade okra seeds are cleaned.

[0060] (5) Sterilization: Sterilize the washed okra seeds with a microwave sterilizer; the control frequency is 1200MHz, the temperature is 70°C, and the sterilization time is 7 minutes.

[0061] (6) Drying: Then put the okra seeds into the ase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com