Patents

Literature

46results about How to "With color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

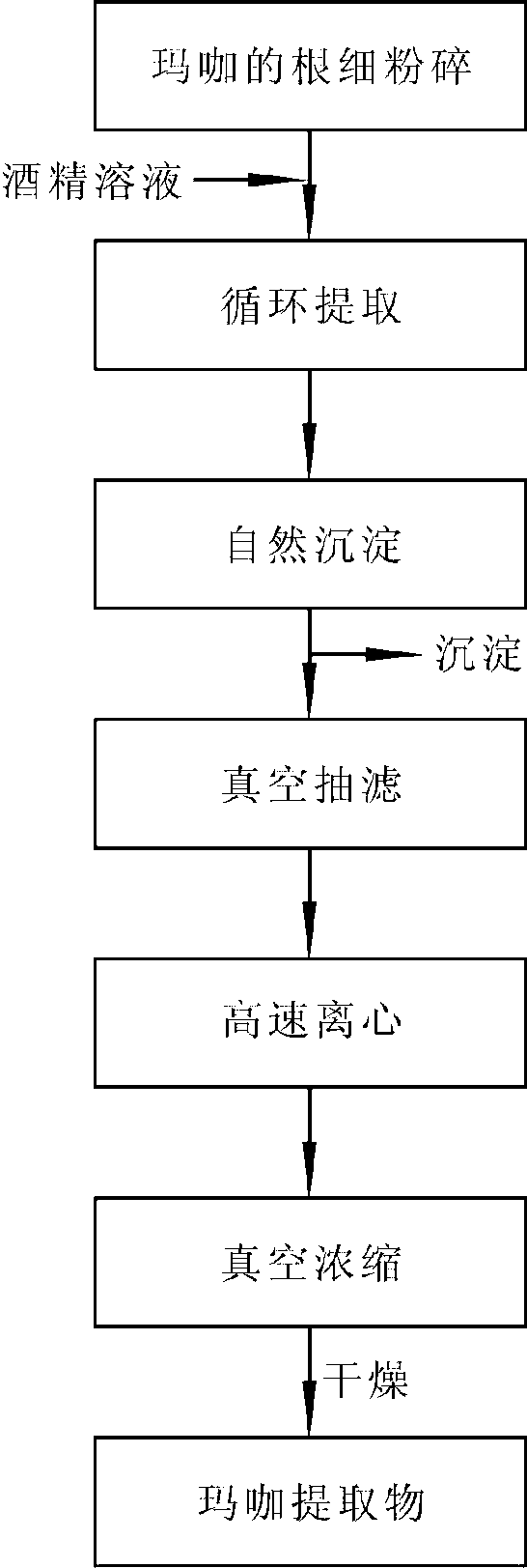

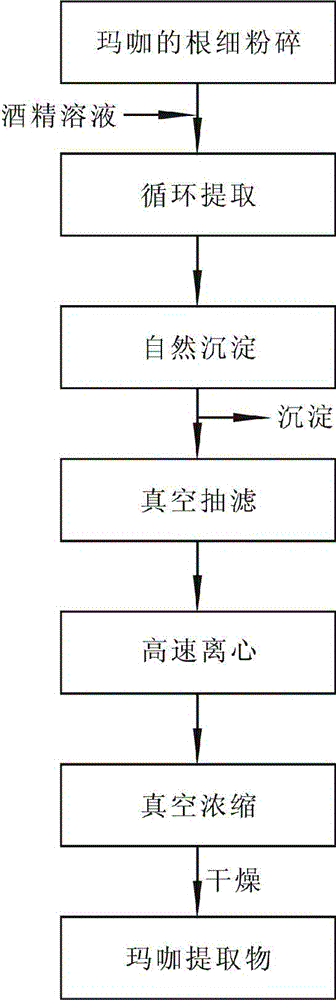

Maca extract and preparation method thereof

The invention discloses a maca extract and a preparation method thereof. The maca extract is prepared by circularly extracting, purifying, concentrating and drying maca serving as a raw material, and comprises 30-40 percent of fatty acid, 18-25 percent of benzyl isothiocyanate and 13-20 percent of macamides and macaenes. The method comprises the following steps of: selecting non-rotten and non-moldy maca which is free from visible external impurities, and finely smashing dried root of maca, wherein the smashing particle size is that the smashed root can pass through a sieve of 60-100 meshes; putting the smashed raw material into an extracting tank, adding 7-9 times of a 50-90 percent alcohol solution, and circularly extracting at the temperature of 45-55 DEG C for 2-5 hours to obtain an extracting solution; putting the extracting solution into a depositing tank for naturally depositing for 6-10 hours, performing suction filtration on a supernatant in vacuum, and centrifuging a filtrate with a high-speed centrifuger at the revolving speed of 10,000-40,000 revolutions per minute; and concentrating a centrifugate in vacuum at the temperature of 40-55 DEG C till the relative density is 1.0-1.3, and drying at the temperature of 40-55 DEG C to obtain a maca extract. The extracting rate of the maca extract is increased greatly, the product purity is increased, and the activity is high.

Owner:CHUXIONG BAICAOLING PHARMA DEV

Instant green tea powder processing method

The invention relates to an instant green tea powder processing method which comprises the following steps of: killing out fresh tea leaves by adopting a vacuum microwave method, carrying out superfine grinding after deep freezing, extracting and superfinely filtering by adopting secondary vacuum ultrasonic wave, and freezing and drying to obtain the instant green tea powder. The killing, extraction and drying steps are completed under a vacuum condition, and the action temperature is low, so that the oxidation of effective ingredients in fresh tea leaves can be effectively avoided; and vacuum ultrasonic extraction after freezing and superfine grinding ensures the full leaching of the effective ingredients. The product produced by the processing method has the advantages of high production efficiency, good product color, fresh taste, good dissolvability, incapability of generating tea cream and the like.

Owner:HEBEI STRONG FOOD

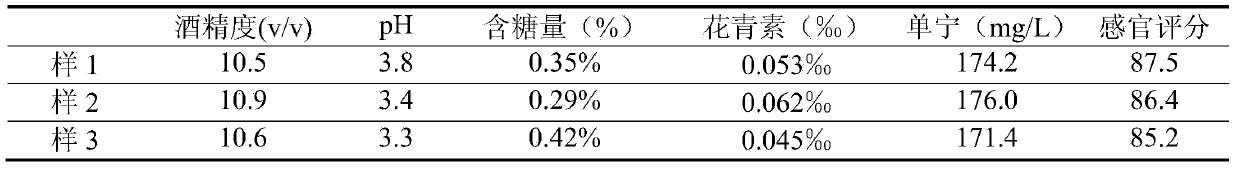

Preparation method of Lycium ruthenicum fruit wine

The invention relates to a preparation method of a Lycium ruthenicum fruit wine, belonging to the technical field of fruit wines and drinks. The preparation method of the Lycium ruthenicum fruit wine sequentially comprises the following steps: (1) raw material selection and treatment; (2) bacteriostasis and degradation treatment; (3) component regulation; (4) primary fermentation; (5) after fermentation; (6) ageing; (7) settling and filtering; and (8) proportioning, sterilizing and packaging. The invention has the advantages that: (1) the Lycium ruthenicum fruit wine is prepared by adopting a modern biological fermentation technology, the preparation method is simple and easy and has strong operability and high popularization, and the product has the characteristics of natural color and luster, flexible taste, intense and deep fruity, low alcoholic strength, stable product property and rich nutrition; and (2) the Lycium ruthenicum fruit wine product has high survival rate of bioactive ingredients and health care function.

Owner:XINJIANG NORMAL UNIVERSITY

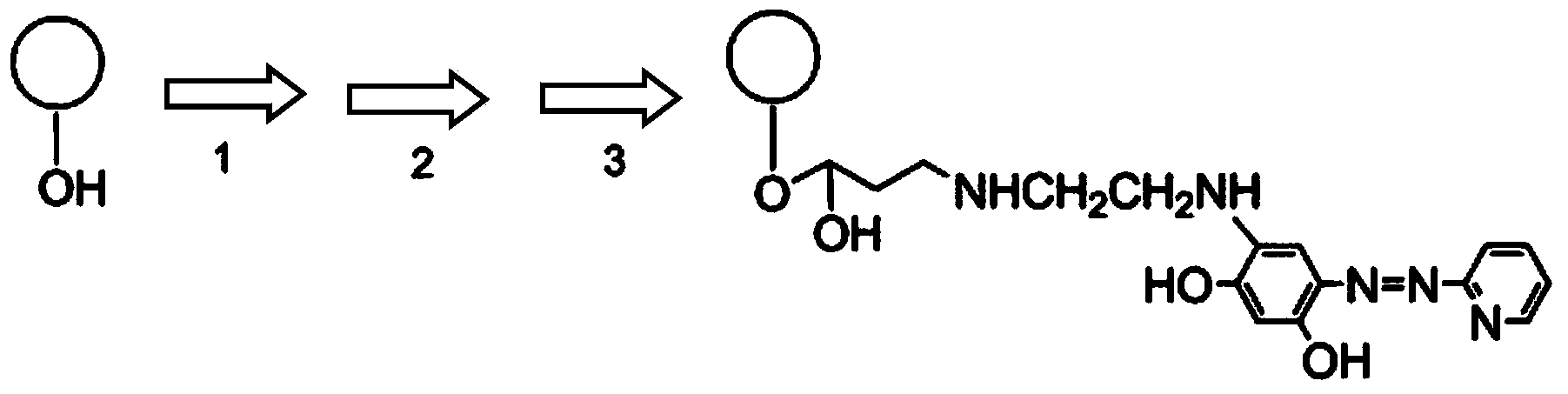

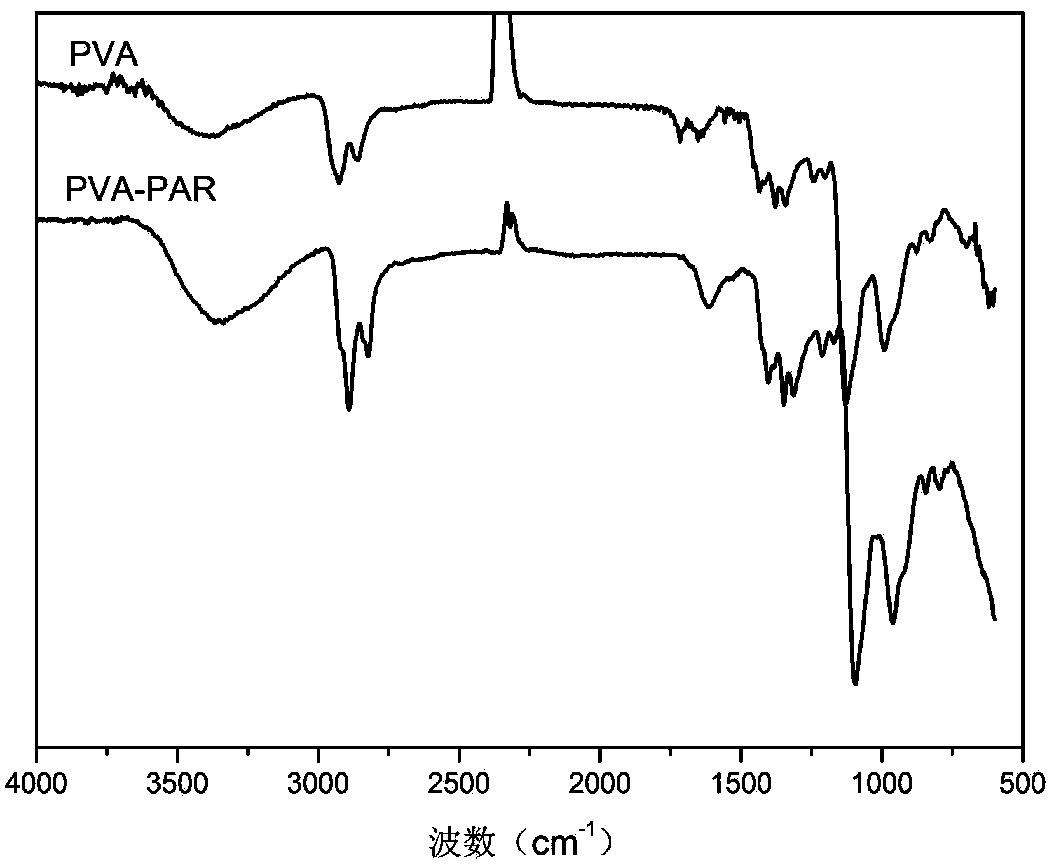

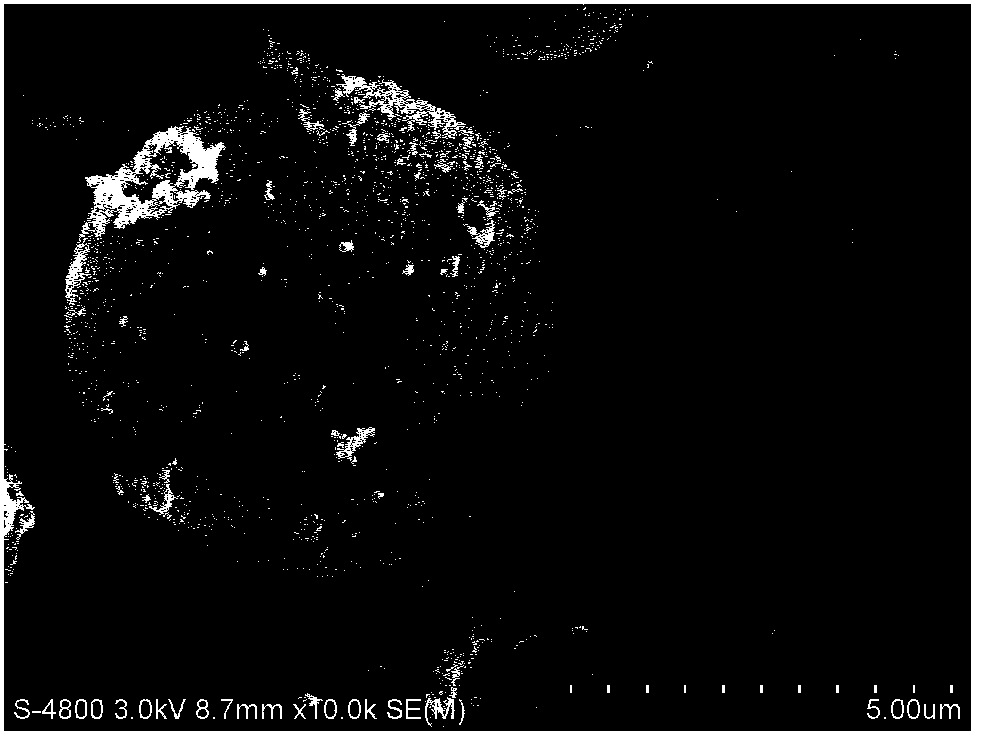

Preparation method and application of functionalized polyvinyl alcohol microspheres

ActiveCN104069782AWith colorWith adsorption functionMicroballoon preparationWater/sewage treatment by sorptionWater bathsEpoxy

The invention discloses a preparation method and application of functionalized polyvinyl alcohol microspheres. The preparation method comprises the following steps: uniformly mixing polyvinyl alcohol microspheres, epoxy chloropropane and a hydrochloric acid solution, carrying out a stirring reaction for 1-5 hours in a water bath, and carrying out centrifuging, water cleaning and drying for later use after the reaction; uniformly mixing the obtained chloridized polyvinyl alcohol microspheres, tetrabutylammonium bromide, ethidene diamine and a sodium hydroxide solution, carrying out the stirring reaction for 4-10 hours in the water bath, and carrying out the centrifuging, ethanol cleaning and the drying for later use after the reaction; and uniformly mixing the obtained aminated polyvinyl alcohol microspheres with 2-(2-pyridine) azo-resorcinol, formaldehyde and distilled water, stirring for 6-18 hours in the presence of nitrogen, and carrying out the centrifuging, the ethanol cleaning and the drying after the reaction, so as to obtain an end product. The functionalized polyvinyl alcohol microspheres provided by the invention can be used for chelating heavy metal and detecting and processing divalent heavy metal ions in wastewater and have the characteristics of simple preparation condition, low cost, short detection response time and high adsorption capacity.

Owner:NANJING HEHAI TECH

Fruit-vegetable juice agar fruit jelly and preparation method thereof

InactiveCN102308899AMaintain nutrientsKeep the flavorConfectionerySweetmeatsOrganic acidTrace element

A fruit-vegetable juice agar fruit jelly comprises the following components in part by weight: 100 parts of fruit-vegetable juice containing 40 to 50 percent by weight of soluble solid, 65 to 85 parts of sweetener, 0.1 to 0.2 parts of citric acid and 2.0 to 3.0 parts of gelatine. The preparation method for the fruit-vegetable juice agar fruit jelly includes the steps of fruit and vegetable juicing, concentration, sugar boiling, blending, cast molding, drying and packaging. The fruit-vegetable juice agar fruit jelly prepared by adopting the method contains carbohydrate, organic acid, vitamins and trace elements, and moreover, the fruit-vegetable juice agar fruit jelly is crystal clear, creamy, tasty, soft and tenacious, and has the peculiar colors and fragrance of fruits and vegetables.

Owner:甘肃省农业科学院农产品贮藏加工研究所

Shrimp food and production method thereof

The invention discloses shrimp food and a production method thereof. In the shrimp food, shrimps used as major materials, vegetables or fungi used as auxiliary materials and seasonings are packaged independently, and the packages are put into an external surface for packaging. The production method of the shrimp food comprises the steps that: the major materials, the auxiliary materials, the seasonings and the like are processed into semi-finished products in a factory according to a cooking method of dishes, so that household cooking is simple and convenient; and the major materials, the auxiliary materials, the seasonings and the like are respectively packaged for long-term storage and market liquidity, so that the packages have the properties of food. The shrimp food has the advantages that: the names of products adopt the names of the dishes; the products have the characteristics of 'color, fragrance, taste, shapes' and the like; the 'complicated and difficult-to-master 'cooking technology and 'multiple and multiplex' auxiliary materials and seasonings are 'simple, standard and convenient' through the industrial processing and production; and the dishes are subjected to the scientific and standard compatibility and sealing packaging, so that the dishes are 'nutrient and safe'.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Konjak-red jujube sugar-free soft sweet and preparation method thereof

A preparation method of konjak-red jujube sugar-free soft sweet comprises the steps of preparing red jujube juice, preparing mixed gel fluid of konjak glucomannan, boiling, condensing and molding, and cutting and drying. The preparation method of the konjak-red jujube sugar-free soft sweet is simple, convenient to obtain materials and low in cost. By using the principle of the generation of hot reversible gel through a synergistic action of konjak glucomannan and carrageenan under an acid condition and fully combining the gel property of konjak glucomannan and the nutritive value of red jujube, the invention overcomes the defects of poor mechanical performance and irregular shaping appearance of common soft sweets, improves thermal property and mechanical property of products and enhancestoughness of products by physically mixing konjak glucomannan and carrageenan. The prepared soft sweet has special color of red jujube and is rich in nutrition, fresh and delicious, and convenient tocarry.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for producing novel environment-friendly wood-plastic floor

The invention discloses a method for producing a novel environment-friendly wood-plastic floor, and belongs to the technical field of production of boards for indoor decoration. Bamboo fibers and polyethylene are used as base materials, and the method comprises the following steps of: adding a plastic filling agent, a reinforcing agent, a flame retardant and a processing aid into the base materials, mixing at a high speed, granulating, performing extrusion molding, cooling and cutting; filling active carbon into middle grooves of a wood-plastic board; sticking the wood-plastic board with a plastic board on the lower layer together at a high temperature; and finally sticking a decorative film to the upper side of the wood-plastic layer. The mass ratio of the bamboo fibers to the polyethylene is 1:1-1:4. The middle grooves of the wood-plastic board are 3 to 5 grooves distributed uniformly in the middle. The method has a simple process; because the bamboo fibers are used as the base materials, the floor has the color, the luster and the toughness of bamboo; because the growth period of the bamboo is short, the materials are convenient to take; and because the active carbon added into the wood-plastic board can absorb harmful gases in the air, the floor has an environment-friendly effect on purification of the air.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Production method of red heart dragon fruit hemp potato bread

ActiveCN104255860ADelicate tasteProtect stomach liningDough treatmentBakery productsFruit juiceFermentation

The invention relates to the food processing field, particularly to a production method of red heart dragon fruit hemp potato bread. The production method comprises producing the red heart dragon fruit juice, producing red heart dragon fruit powder, performing dosing, performing fermentation, performing baking, performing packaging and the like. According to the production method of the red heart dragon fruit hemp potato bread, the taste of the red heart dragon fruit hemp potato bread is delicate, the red heart dragon fruit is produced into the red heart dragon fruit juice and the red heart dragon fruit powder which serve as raw materials to produce the red heart dragon fruit hemp potato bread, the red heart dragon fruit hemp potato bread comprises the bright color and the mellow fragrance of the red heart dragon fruit pulp and nutrients of the red heart dragon fruit, and the health care effect is good.

Owner:上海匠造食品有限公司

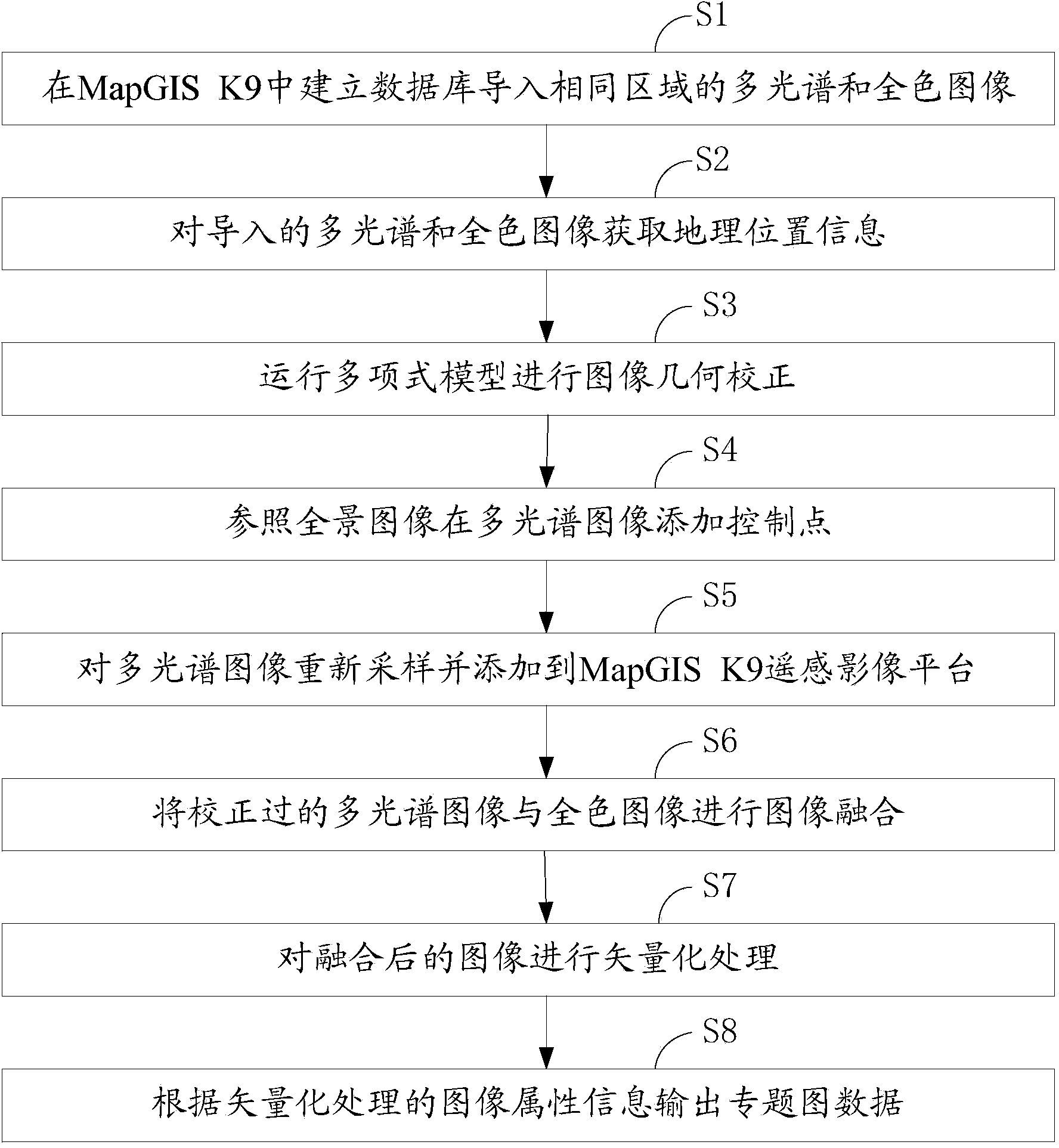

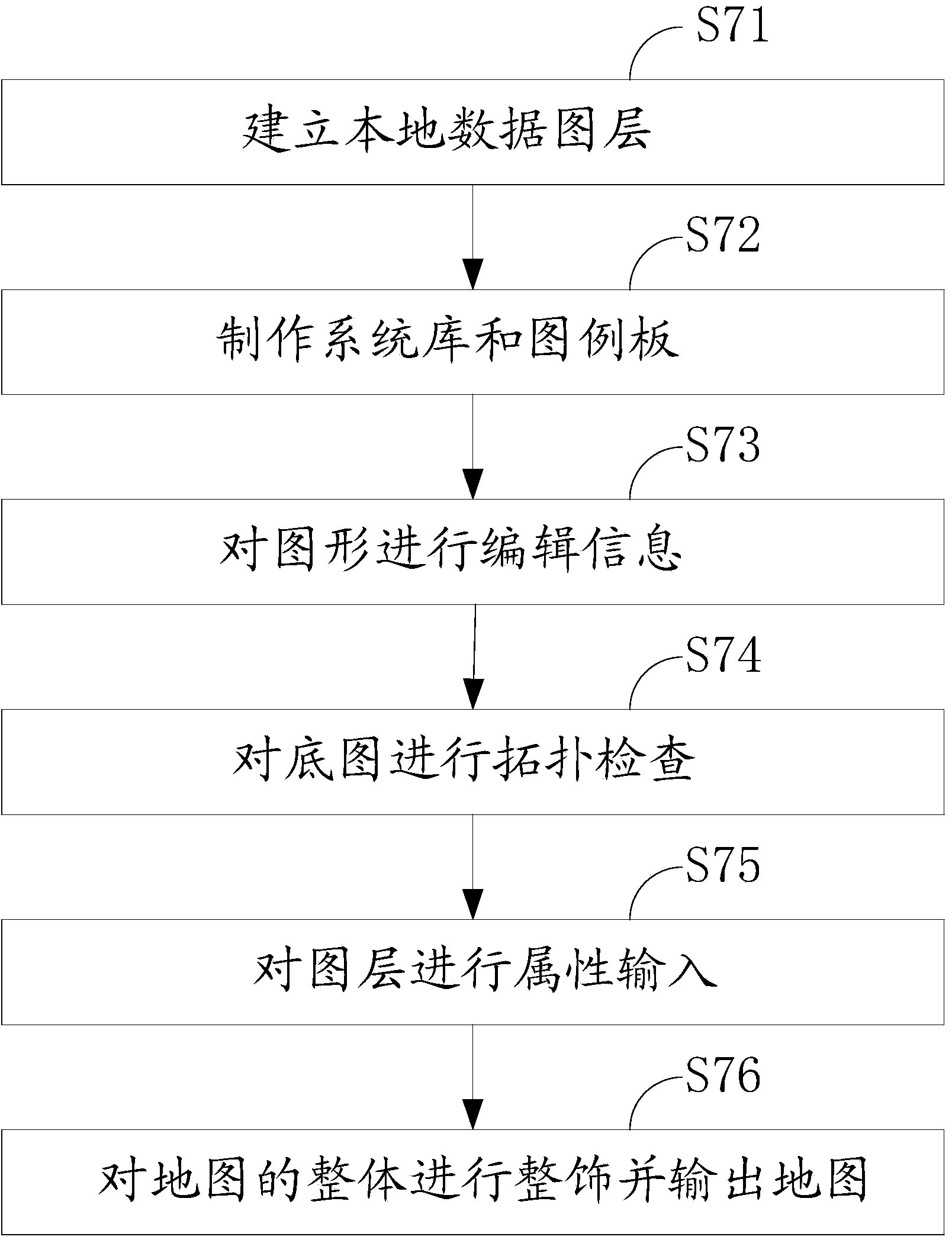

Method and system for manufacturing thematic map by fusing images based on MapGISK9

InactiveCN103955909AWith colorHigh resolutionImage enhancementGeometric image transformationGraphicsGoal recognition

The invention discloses a method and system for manufacturing a thematic map by fusing images based on the MapGISK9. The method for manufacturing the thematic map by fusing the images includes the following steps that firstly, a database is built in the MapGISK9, multispectral images and full-color images in the same area are led in; secondly, the geographical location information of the multispectral images and the full-color images which are led in is obtained; thirdly, the multispectral and images are calibrated with a MapGISK9 remote-sensing image platform; fourthly, the calibrated multispectral images and the full-color images are fused; fifthly, vectorization processing is performed on the fused images. According to the method and system for manufacturing the thematic map by fusing the images based on the MapGISK9, the multispectral images and the full-color images are fused, so that remote-sensing images have colors, the high resolution and projection information, and a series of processing of terrain classification and target identification is fully ensured.

Owner:BEIJING JIAOTONG UNIV

Colored fruit and vegetable fish noodles

InactiveCN101720886AWith colorHas a fishy tasteDough treatmentFood preparationFruits and vegetablesStarch

The invention relates to colored fruit and vegetable fish noodles. The noodles are characterized by comprising the following materials in percent by weight: 30-60% of flour, 20-40% of starch, 10-20% of fish, 5-10% of fruit and vegetable powder, 2-4% of salt, 0.5-1% of alkali and 0.1-0.5% of CMC. Compared with the prior art, the invention has the advantages of colour and lustur of fruit and vegetable, good taste, rich nutrition, and the like.

Owner:周辉

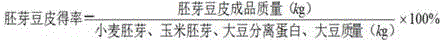

Preparation method of germ bean curd skin

The present invention relates to a preparation method of germ bean curd skin. The preparation method comprises the following steps: (1) a germ mixture consists of wheat germ and corn germ at a ratio of 3 : 1, water is added into the germ mixture, the germ mixture is soaked for 2-4 h, and the soaked germ mixture is ground to obtain germ slurry material; ( 2) soy protein isolate at 35% of the use amount of the germ mixture is weighed, sucrose fatty acid ester at 0.2-0.3% of the weight of the germ slurry material is weighed, the two weighed materials are mixed, the mixture is added into the germ slurry material, and the mixture is subjected to twice homogenization to obtain homogeneous liquid; (3) soy soybeans are soaked in water and the obtain water drained soybeans and water are added into a grinder to conduct grinding to obtain soybean slurry material; and (4) the homogeneous liquid and the soybean slurry material are mixed at a ratio of 1 : 3-4 in a molding groove, the mixed slurry material form a film at 90 DEG C, the film is lifted up and drained, and the drained film is dried at 65 DEG C to obtain the finished products. The prepared germ bean curd skin is high in yield and strong in gluten power. The germ bean curd skin has a special color and luster, and flavor, ensures the nutritional ingredients of the wheat germ, also improves the utilization rate of the germ, and enriches the market of the bean curd skin.

Owner:BENGBU COLLEGE +1

Production process of olive fruit vinegar and olive fruit vinegar

InactiveCN104726311AHigh alcohol contentReduce manufacturing costVinegar preparationBiotechnologySucrose

A production process of an olive fruit vinegar includes the following steps: 1, washing, crushing and juicing the olive fruits, removing the stones and filtering; 2, adding pure rice wine in the olive fruit juice, heating, sterilizing, cooling, adding acetic acid bacteria, and conducting ventilation acetic fermentation to obtain an olive pulp raw vinegar; 3, evenly stirring olive pulp raw vinegar, licorice, longan, Momordica grosvenori, mint, roughhaired holly root, oil orange, glucose or sucrose and water to obtain an olive fruit vinegar blending stock solution; and 4, filtering the olive fruit vinegar blending stock solution, conducting hot filling and sterilizing. The process reduces the production cost by a third, and simplifies the process flow, does not require repeated fermentation, saves the processing time, and is easy for production and realization of energy saving and environmental protection; and the produce olive fruit vinegar does not contain residue, has the color, smell and taste of normal fruit vinegar, does not have bad smell and odor or visible external impurities and is in an even state.

Owner:赵建维

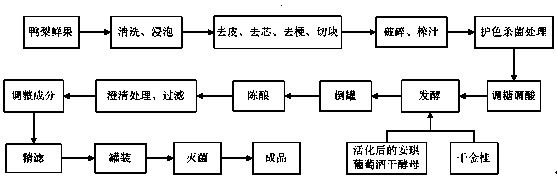

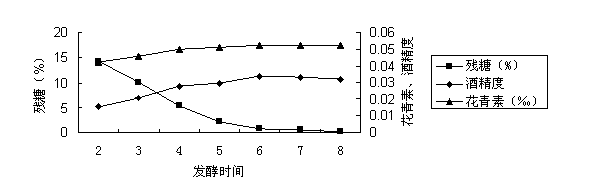

Process for producing osmanthus fragrans Chinese pear fruit wine

The invention discloses a process for producing osmanthus fragrans Chinese pear fruit wine, which belongs to the field of agriculture product machining. The wine is made by fermenting Chinese pear and osmanthus fragrans as main materials, the sour and sweet fruit taste of the Chinese pear, the sweet fragrance of the osmanthus fragrans, and the healthcare effects of the two materials are retained. The invention mainly focuses on research on novel fruit wine which is made by mixing and fermenting the Chinese pear and the osmanthus fragrans. The process comprises the following steps: juicing fresh Chinese pear as a raw material, wherein the ratio of juice to water is 1:(0.5-1.5), adding 3-5g of dried golden osmanthus fragrans into each liter of the fermentation liquid, subsequently inoculating activated grape wine high-activity yeast to brew the osmanthus fragrans Chinese pear fruit wine, wherein the fermentation condition is that the fermentation period is 6-8 days, the main fermentation temperature is 18-22 DEG C, the initial adjusted sugar degree is 20-22%, the initial pH value is 4.0-4.5, and the yeast inoculation amount is 6-10%, and the alcoholic strength of a fruit wine finished product brewed under such conditions is about 10-11% (v / v), and the wine is pure and gentle in taste, transparent and clear in color, thick and long-lasting in fragrance, thick in fruit fragrance and soft and tender in wine fragrance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

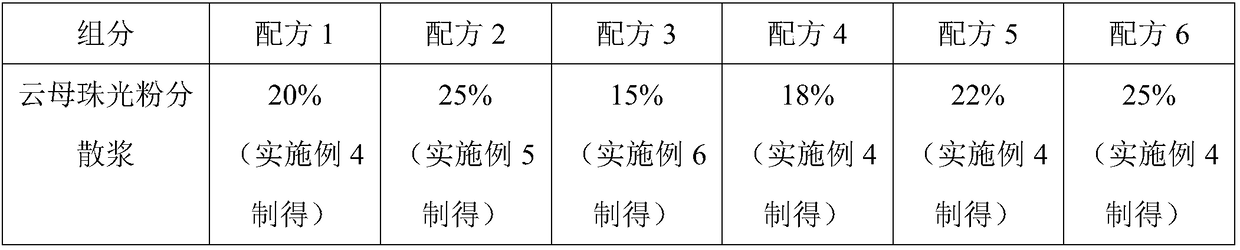

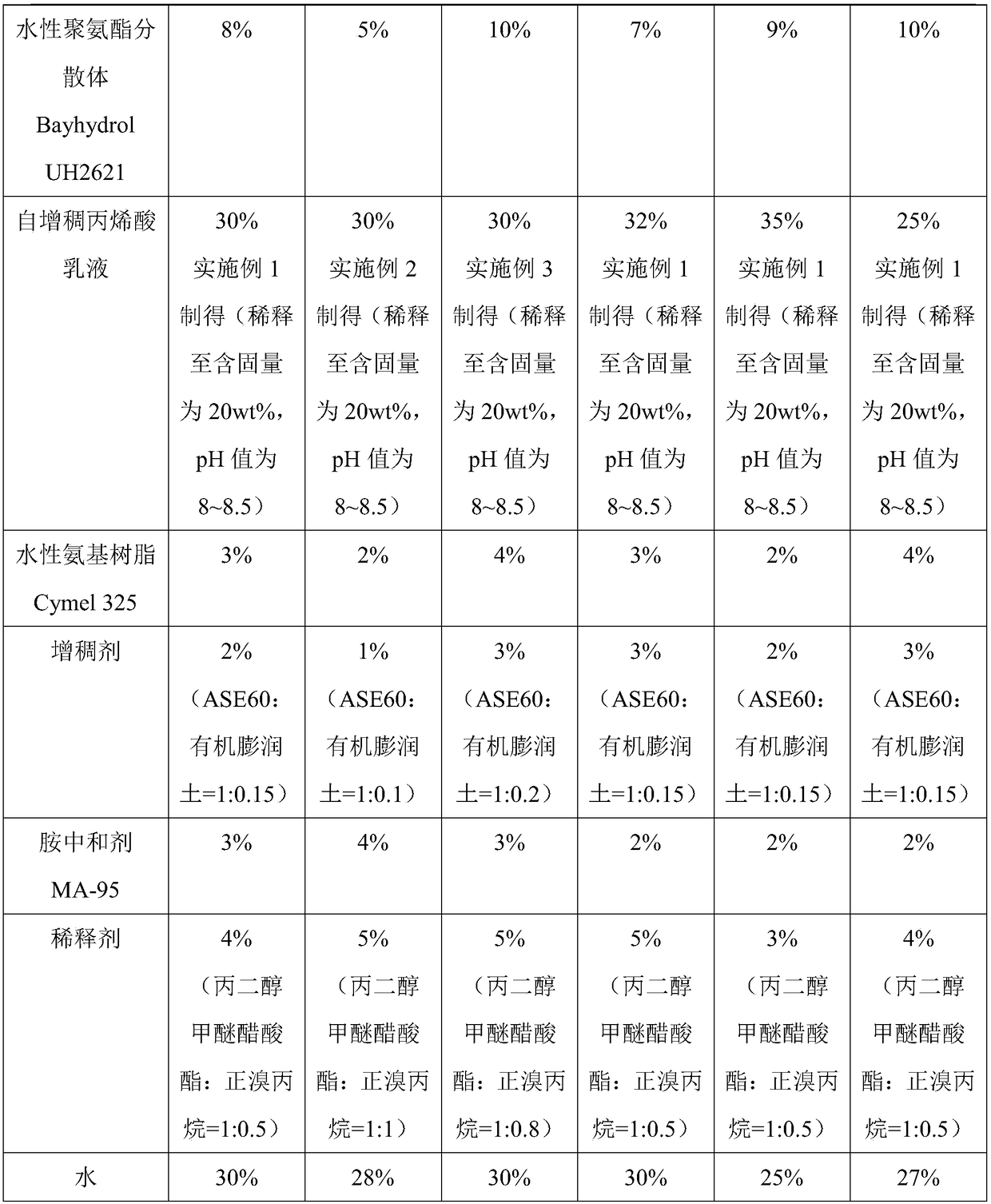

Waterborne interference type pearly flashing paint for automobile and preparation method of waterborne interference type pearly flashing paint

ActiveCN109401506AMatching scienceFast dryingAnti-corrosive paintsPolyurethane dispersionWeather resistance

The invention discloses a waterborne interference type pearly flashing paint for an automobile and a preparation method of the waterborne interference type pearly flashing paint. The waterborne interference type pearly flashing paint is prepared from the following components: mica pearl powder dispersion paste, waterborne polyurethane dispersoid, self-thickening acrylic emulsion, waterborne amidogen resin, a thickening agent, an amine neutralizer, a diluent and water. The waterborne interference type pearly flashing paint has scientific matching, the components are adjusted mutually, the drying speed is high, the construction performance is good, the requirements of 2C1B coating process on coating are met, costs are greatly saved, energy consumption is reduced, and the water-soluble interference type pearly flashing paint has the advantages of energy conservation and emission reduction. A paint film formed by the pearly flashing paint has gorgeous and gentle gloss, has pearly colors, is full of sense of beauty, does not have phenomena such as color difference, floating, seediness, dulling or poor pearl effect, has excellent water resistance and corrosion resistance performance andgood weather resistance performance, and meets the decorative requirements of limousines.

Owner:辰新恒达科技有限公司

Processing method of artificial leather

InactiveCN106393857ASoft surfaceIncrease elasticityLamination ancillary operationsLaminationAdhesiveEngineering

The invention discloses a processing method of artificial leather. The method comprises the following steps: (1) subjecting animal skin to fur removing, deoiling and degreasing neutralizing treatment, airing and cutting the animal skin to obtain a semi-finished leather piece; (2) cutting elastic fabric into the shape of the semi-finished leather piece, wherein the size of the elastic fabric is set to ensure that the size of the elastic fabric at the pre-stretching state is kept consistent with the size of the semi-finished leather piece; (3) adhering non-woven fabric with one side of the elastic fabric together, trimming the non-woven fabric until the shape and the size of the non-woven fabric are same with the shape and the size of the elastic fabric; (4) uniformly applying adhesive on the meat surface of the semi-finished leather piece, aligning the surface of the semi-finished leather piece with the other side of the elastic fabric, bonding them; spreading and airing them, and releasing the pre-stretching state of the elastic fabric to obtain the leather semi-finished product; (5) performing printing and dyeing by printing and dyeing paper and removing the printing and dyeing paper; (6) processing the leather by using a leather processing treatment agent to obtain a leather finished product. The leather material produced by the method is soft in surface and good in elasticity, the leather is not easy to deform and has the same color, luster and service life with the real leather.

Owner:浙江奥王服饰有限公司

Novel environment-protection stereo brocade modified coating

This invention discloses one kind of new environmental three-dimensional brocade modified dope, it contains water, dispersant, wetting agent, bead burnishing powder, defoamer, alcohol ester - 12, anticorrosion disinfectant, thickening agent, pH conditioner, parent metal, 2% hydroxide ethylol cellulose solution and 801 modified rubber, the weight share of each related ingredient respectively is: Water is 15-18, dispersing agent is 0.2, wetting agent is 0.1, bead burnishing powder is 9-10, defoamer is 0.4, the alcohol ester - 12 is 0.8-2, anticorrosion disinfectant is 0.1-0.2, thickening agent is 0.1-1, pH conditioner is 0.2, parent metal is 38-45, 2% hydroxide ethylol cellulose solution is 5-10 and 801 modified rubber is 15-25. This dope can spray the needed design, which has an effect of the wallpaper and the mural, and make the luster bright, which has the three-dimensional brocade effect.

Owner:沈双平

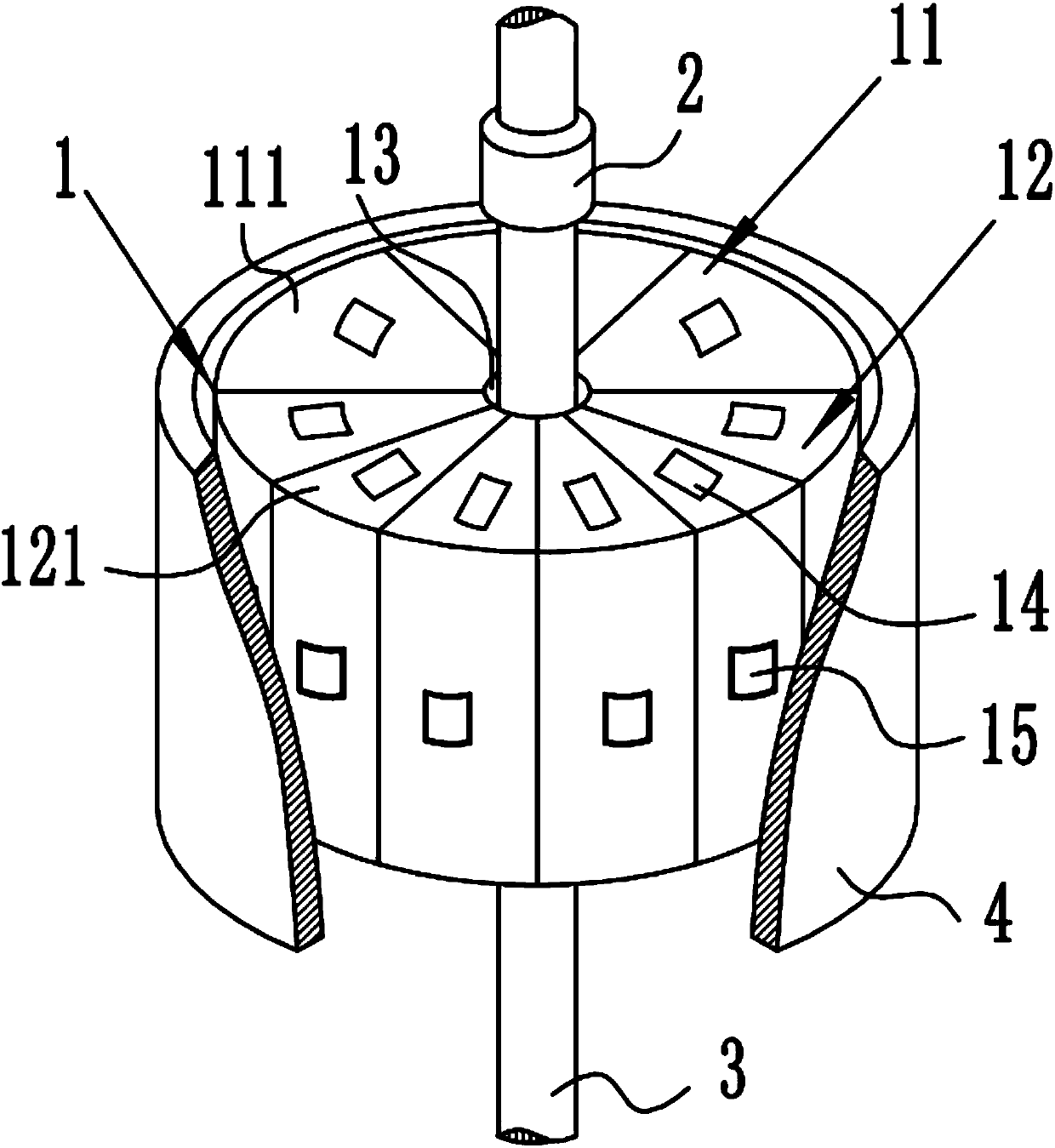

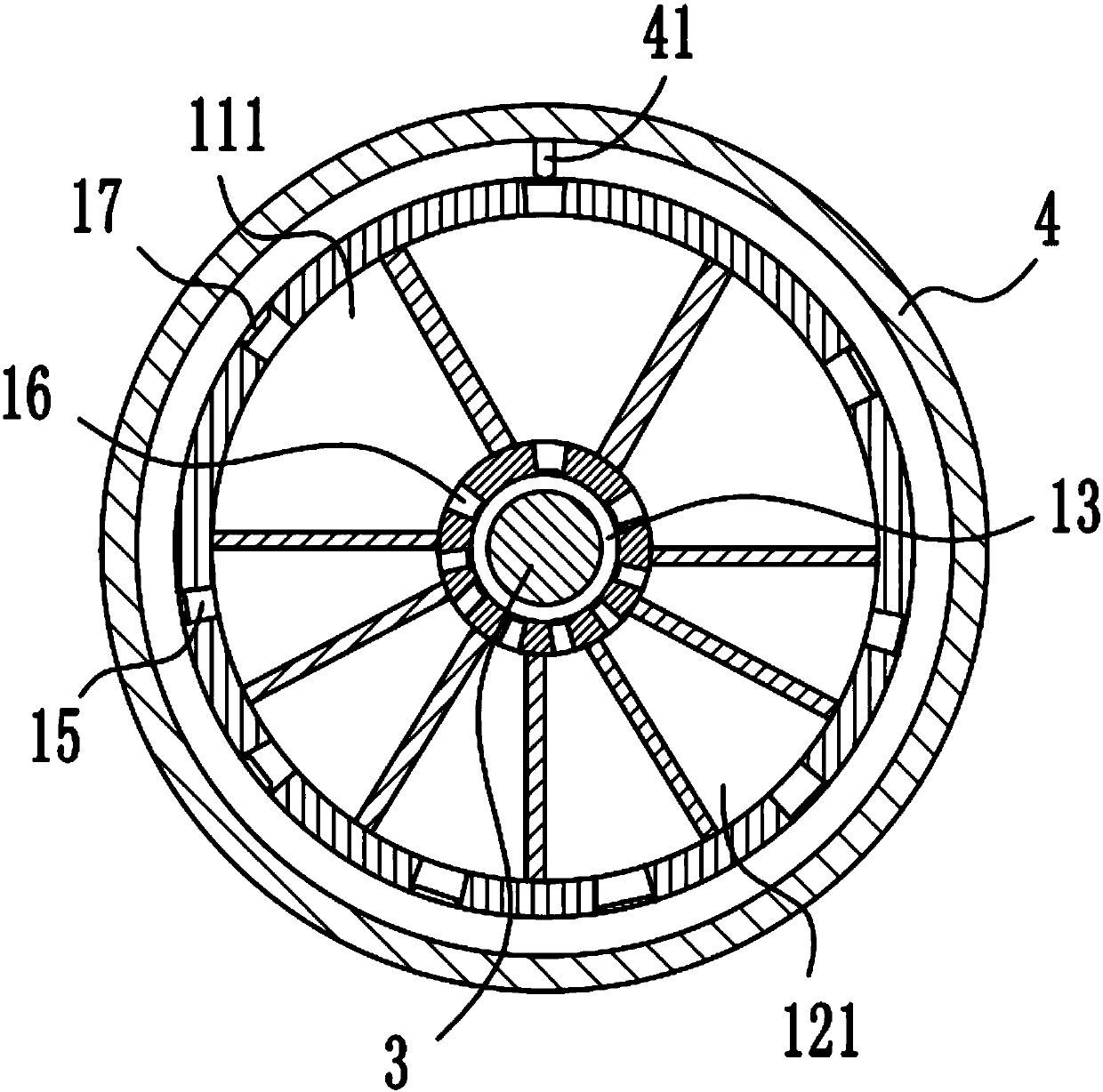

Automatic coloring 3D printing ink box

ActiveCN107839214AGuaranteed continuityEasy to useManufacturing enclosuresManufacturing material handlingEngineeringColor matching

The invention relates to the field of printing equipment, in particular to an automatic coloring 3D printing ink box. The automatic coloring 3D printing ink box comprises an ink box body. A through wire hole is formed in the ink box body in the axial direction. A primary color area and a color matching area are arranged on the ink box body. Three primary color boxes used for containing dyeing powder are arranged in the primary color area. Multiple color matching boxes used for containing dyeing powder are arranged in the color matching area. Coloring holes communicating with the wire hole areformed in the sides, facing the wire hole, of the primary color boxes and the color matching boxes. Multiple air inlet holes communicating with the primary color boxes and the color matching boxes areformed in the outer side wall of the ink box body. A driving cylinder rotating around the ink box body is arranged on the ink box body in the circumferential direction. A nozzle capable of charging air into the air inlet holes is arranged on the inner side of the driving cylinder. The nozzle rotates around the ink box body along with the driving cylinder. One-way valves which can be ejected openby the nozzle and can automatically reset are hinged to the positions of the air inlet holes. By means of the automatic coloring 3D printing ink box, the phenomenon that printing work is interrupted for increasing or replacing linear consumables with corresponding colors is not needed, use is convenient, and meanwhile continuity of the printing work is ensured.

Owner:贵州云侠科技有限公司

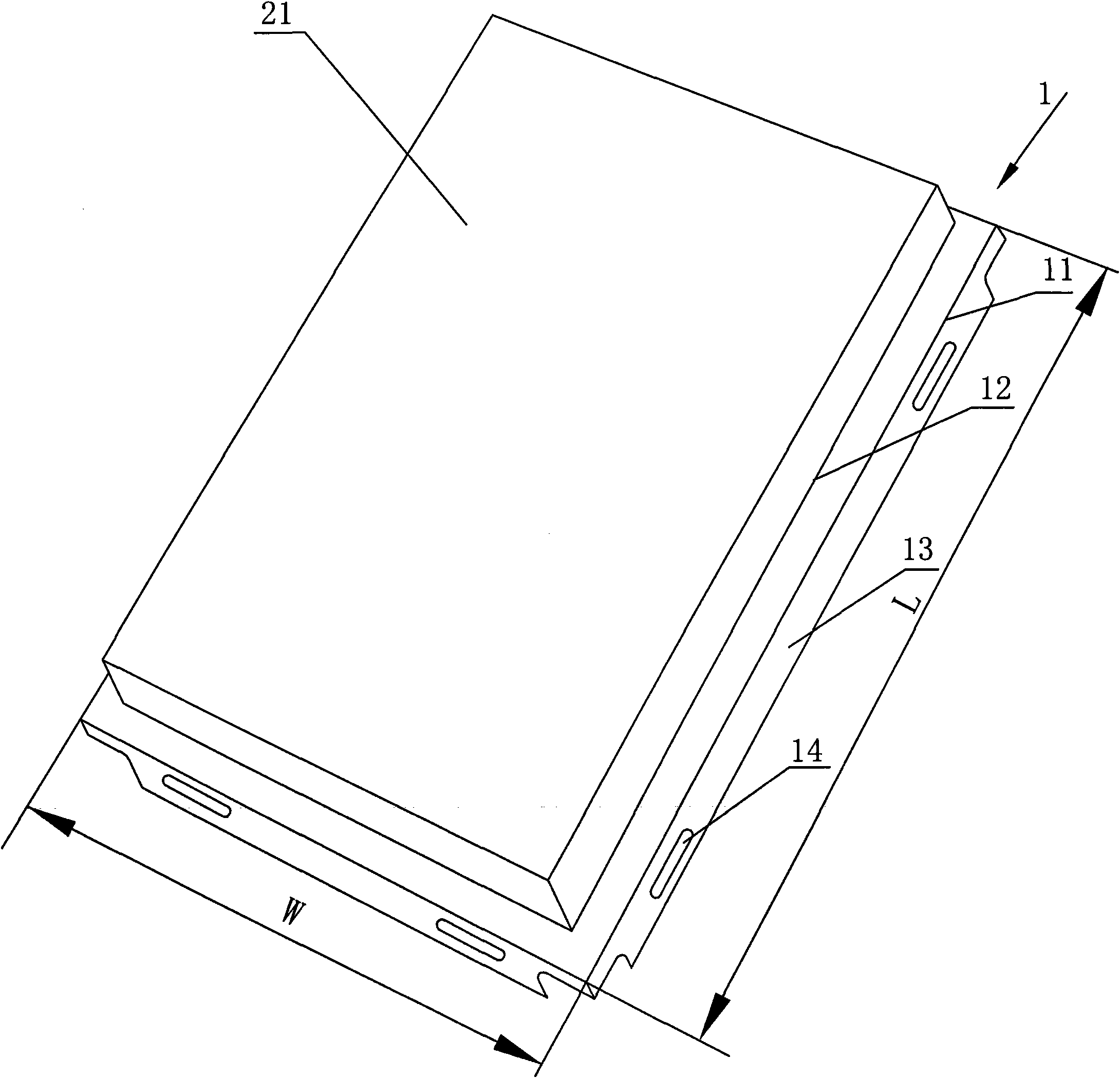

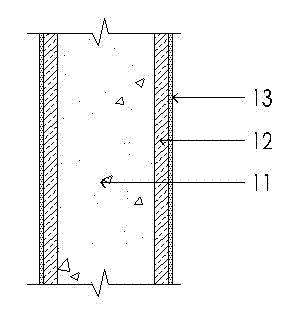

Aluminum alloy ceiling buckle plate in specific specification

InactiveCN102102432AImprove visual effectsOverall perception coordinationCovering/liningsKeelEngineering

The invention relates to an aluminum ceiling buckle plate in specific specification, which has the peripheral width or length in the following ranges: 16.1 to 23cm, 37.5 to 42.5cm; 59 to 62cm; 66.1 to 69.8cm; 80.5 to 81.5cm and 88 to 176cm. The ceiling buckle plate is a combined ceiling buckle plate which is used together with a shaping keel, and comprises a buckle plate frame and a groove-shaped buckle plate body fixedly which is connected with the buckle plate frame and has the same or different color, the combination manner of the ceiling buckle plate can be outer concave combination type, parallel combination type or inner concave combination type; the ceiling buckle plate can also be an aluminum alloy composite buckle plate, which comprises a hollow buckle plate and filler arranged inside the hollow buckle plate; owing to the peripheral width or length in particular ranges, the ceiling buckle plate is not only flexible and fast in installation and disassembly, but also has more standard product design and high installation precision. In particular, the ceiling buckle plate accords with the principal of aesthetic design and has extremely outstanding integral visual effect.

Owner:上海方智达家居用品销售有限公司

A kind of maca extract and preparation method thereof

The invention discloses a maca extract and a preparation method thereof. The maca extract is prepared by circularly extracting, purifying, concentrating and drying maca serving as a raw material, and comprises 30-40 percent of fatty acid, 18-25 percent of benzyl isothiocyanate and 13-20 percent of macamides and macaenes. The method comprises the following steps of: selecting non-rotten and non-moldy maca which is free from visible external impurities, and finely smashing dried root of maca, wherein the smashing particle size is that the smashed root can pass through a sieve of 60-100 meshes; putting the smashed raw material into an extracting tank, adding 7-9 times of a 50-90 percent alcohol solution, and circularly extracting at the temperature of 45-55 DEG C for 2-5 hours to obtain an extracting solution; putting the extracting solution into a depositing tank for naturally depositing for 6-10 hours, performing suction filtration on a supernatant in vacuum, and centrifuging a filtrate with a high-speed centrifuger at the revolving speed of 10,000-40,000 revolutions per minute; and concentrating a centrifugate in vacuum at the temperature of 40-55 DEG C till the relative density is 1.0-1.3, and drying at the temperature of 40-55 DEG C to obtain a maca extract. The extracting rate of the maca extract is increased greatly, the product purity is increased, and the activity is high.

Owner:CHUXIONG BAICAOLING PHARMA DEV

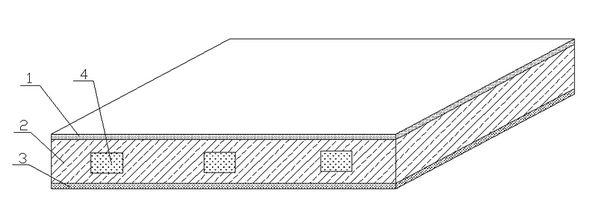

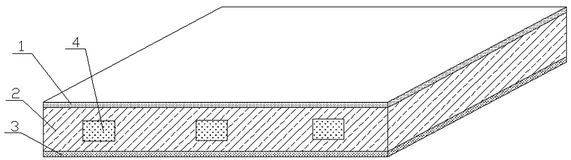

Novel decorative plate

InactiveCN102852304AWith colorPattern changeableCovering/liningsSpecial ornamental structuresGraphical designGraphic design

The invention discloses a novel decorative plate which comprises a first decorative colored paper layer which is covered by second decorative colored paper layers which are covered by surface transparent layers. Preferably, the decorative plate comprises the first decorative colored paper layer, two side faces of the first decorative colored paper layer are covered by the second decorative colored paper layers respectively, each of the second decorative colored paper layers is covered by the surface transparent layer, and set patterns formed by curving are distributed on the surface of the novel decorative plate. The novel decorative plate has the advantages of simple structure, fire proofing, environmental protection, difficulty in deformation and the like, and is convenient and quick to construct, convenient to maintain, and supportive of industrial and integrated production mounting, so that manpower cost is lowered, construction circle is shortened, and quality is improved. In addition, different artistic effects can be generated according to different graphic designs and manufacturing processes, so that the novel decorative plate has higher design flexibility and can better meet requirements on humanization.

Owner:SUZHOU KELIDA BUILDING & DECORATION CO LTD

Soy sauce and production method thereof

The invention discloses soy sauce and a production method thereof. The soy sauce is brewed through the procedures of raw material treatment, cooking, starter propagation, fermentation, filtration, sterilization and filling. The production method of the soy sauce comprises the following steps: adding pod peppers when the fermentation is carried out for 100 days, continuing performing fermentation,enabling the pod peppers to permeate into soy sauce mash, and performing squeezing and filtering to fuse the spicy taste of the pod peppers with the soy sauce in the soy sauce mash so as to obtain thesoy sauce with a spicy taste. The obtained soy sauce not only has an original sauce flavor, a delicious taste and a color of the soy sauce, but also has peppery taste loved by the masses of people.

Owner:江西鱼鹰食品股份有限公司

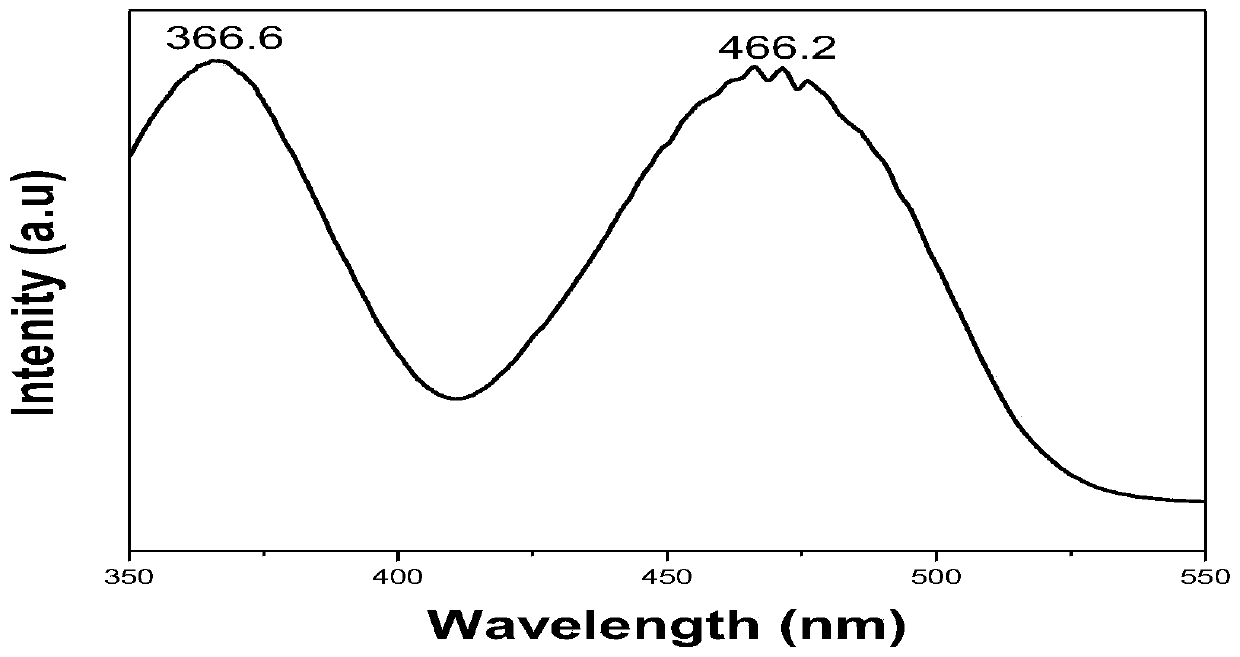

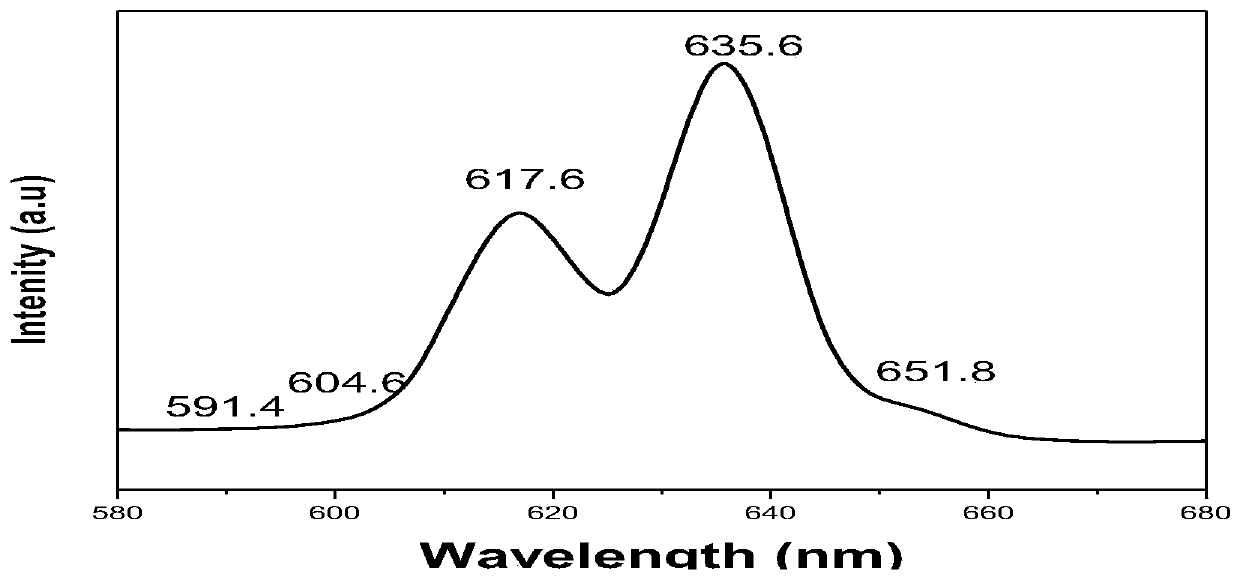

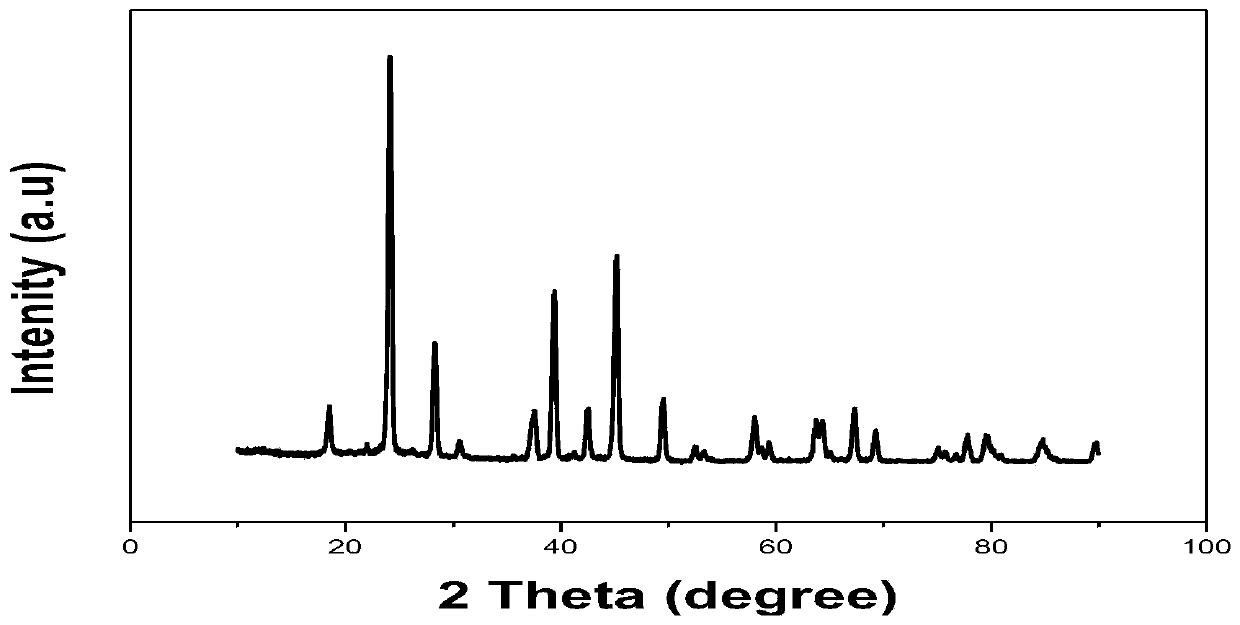

Red fluorescent powder and preparation method thereof

InactiveCN110172346AWith narrowband emissionWith colorEnergy efficient lightingLuminescent compositionsLuminous intensityFluorescence

The invention relates to red fluorescent powder with water-proof performance. A general formula of the red fluorescent powder is Me2xBa1-xTi1-yF6:yMn4+; Me is Li, Na, K, Rb and Cs ions; x is greater than 0 and less than 1; and y is greater than 0 and less than 0.5. The red fluorescent powder is particularly prepared by the following steps: sequentially and slowly dropwise adding a Ba salt solutionand a Me salt into an H2TiF6 aqueous solution for reaction at normal temperature and pressure to prepare MexBa1-xTiF6, uniformly mixing and adding MexBa1-xTiF6 and KMnO4 into an HF aqueous solution for reaction to form a target product, namely Me2xBa1-xTi1-yF6:yMn4+. The fluorescent powder prepared by the method has the prominent advantages of narrowband emission, high lighting effect, high development and the like, is uniform in particle size, and has very good water resistance; the luminous intensity of the fluorescent powder in water can be greater than the original luminous intensity by above 70% and is good in stability; the fluorescent powder solves the problem of high possibility of wetting and hydrolysis of the traditional red fluorescent powder; the problems of performance degradation of the fluorescent powder due to a coating or an organic envelope are avoided; and the fluorescent powder can be widely applied to the technical field of high development and warm color temperature white light LED (light-emitting diode) package, fluorescent tube coating and the like and to illumination in some humid environments.

Owner:CHONGQING UNIV OF ARTS & SCI

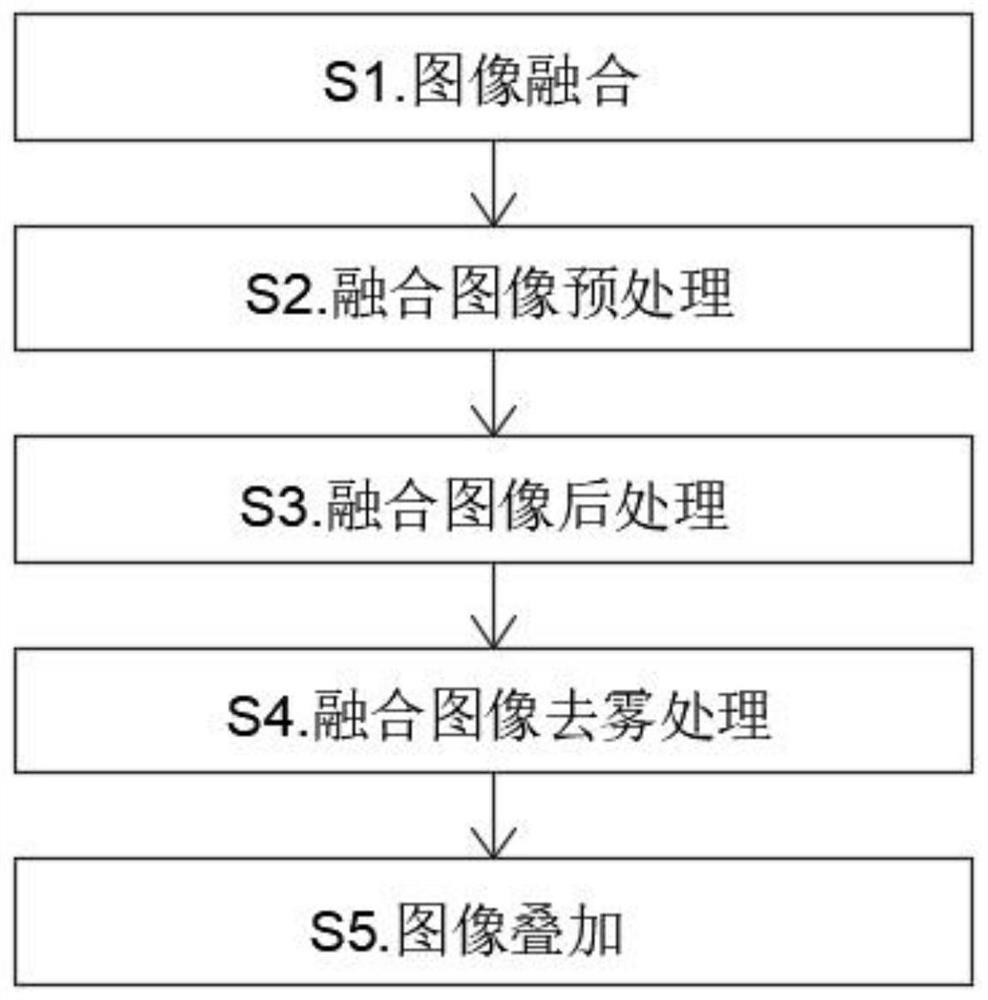

Multispectral satellite remote sensing image fusion method

PendingCN113888421AIncrease spatial geometric resolutionWith colorImage enhancementImage analysisColor imageRemote sensing image fusion

The invention discloses a multispectral satellite remote sensing image fusion method. The method comprises the following steps: S1, fusing an image; S2, preprocessing the fused image, cutting the fused image through radiation correction and ortho-rectification, and selecting a required image area; S3, post-processing the fused image, and reducing noise interference of the image and filtering spurs through geometric constraint and morphological processing; S4, defogging the fused image, establishing a foggy day image degradation model by using the visible light image and the millimeter wave image, and defogging the fused image by using the foggy day image degradation model to obtain a defogged image; and S5, carrying out image superposition. The satellite remote sensing images are fused based on the compressive sensing theory, the spatial geometric resolution of the multispectral images can be improved by using the multispectral images and the panchromatic images with the same spatial resolution, and in addition, by fusing the high-spatial-resolution panchromatic grayscale images and the low-spatial-resolution multispectral color images, image resolution can be improved, and the fused image has colors.

Owner:北京和德宇航技术有限公司

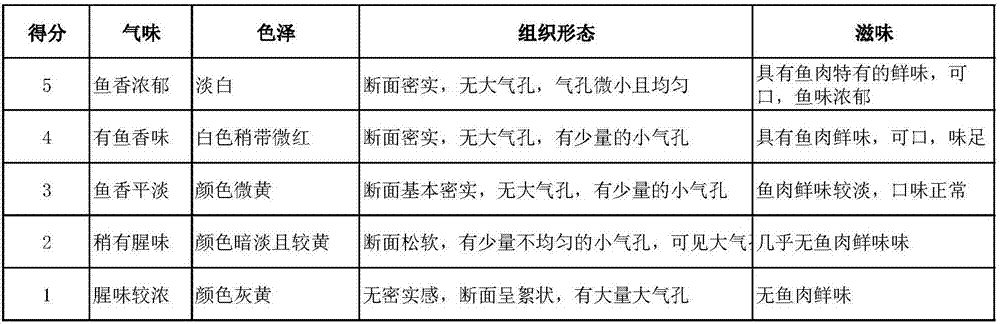

Spotted maigre meat ball and processing technology thereof

The invention discloses a Spotted maigre meat ball. The Spotted maigre meat ball is produced from, by mass, 0.1-0.3% of carnosol, 1-3% of sucrose ester, 0.1-0.3% of chitin, 3-5% of glucomannan, 0.5-1% of betaine, 3-5% of peach gum powder, 1-3% of rice embryo oil, 1.5-2% of edible salt, 0.5-1% of a ginger juice, 1-3% of cooking wine, 0.5-1% of white sugar, 1-2% of soy proteins, 3-5% of egg white, 0.2-0.5% of transglutaminase, 5-10% of potato starch, 20-25% of water, and the balance of Spotted maigre meat. The Spotted maigre meat ball has the characteristics of good frost resistance, good color, good sensory quality, good texture properties and good flavor. The invention also discloses a processing technology of the Spotted maigre meat ball. The technology has the advantages of simple steps, high operability, suitableness for industrialized production, provision of an effective way for the rich resource of Spotted maigre in China, and facilitation of the increase of the economic values of the Spotted maigre.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Stainless-steel-colored aluminum alloy and preparation method thereof

The invention relates to the technical field of aluminum alloys, in particular to a stainless-steel-colored aluminum alloy and a preparation method thereof. The stainless-steel-colored aluminum alloyis prepared from the following components in percentage by weight: 0.38-0.41% of silicon, less than 0.15% of iron, less than 0.1% of copper, less than 0.1% of manganese, 0.48-0.51% of magnesium, lessthan 0.1% of chrome, less than 0.1% of zinc, less than 0.1% of titanium and the balance of aluminum and impurities, wherein the single impurity is less than 0.05%, and the total amount of the impurities is less than 0.15%. The stainless-steel-colored aluminum alloy has the color and gloss of an existing stainless steel profile, has a mirror effect of stainless steel, has the smaller density and lower cost than those of the stainless steel profile, and can replace the existing stainless steel profile to be applied to building decoration.

Owner:东莞市润华铝业有限公司

XO sauce and preparation method thereof

The invention provides XO sauce and a preparation method thereof. The XO sauce comprises the following components in part by weight: 40 to 45 parts of fried fresh needle mushroom, fresh pleurotus eryngii and fresh chilli, 40 to 50 parts of water, 2 to 2.5 parts of salt, 1.5 to 2.0 parts of sugar, 1.5 to 2.5 parts of peanut flour, 7 to 9 parts of chilli oil and 0 to 3 parts of mushroom powder. Theinvention provides the XO sauce and the preparation method thereof; the prepared XO sauce has the mouthfeel, the color and the texture of the conventional XO sauce, and is applied to vegetarians; theneedle mushroom, pleurotus eryngii and chilli raw materials are cheap; and production cost is lower than that of the conventional XO sauce.

Owner:ZHENGZHOU SYNEAR FOOD

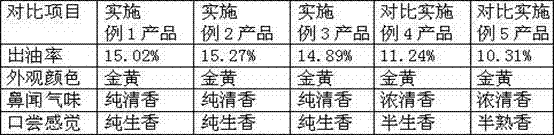

Cold pressing method of abelmoschus esculentus oil

A cold pressing method of abelmoschus esculentus oil belongs to the technical field of agricultural product processing and comprises thirteen steps of cleaning, impurity removal, grading, washing, sterilization, drying, spreading for cooling, rotation, pulverization, squeezing, filtering, loading and examination and sterilization. The cold pressing method has the beneficial effect that a microwave sterilization method is adopted to achieve a sterilization effect in a low-temperature environment; spreading for cooling is carried out before cold pressing, so that the natural flavor and color of abelmoschus esculentus oil is ensued; high-speed rotation is carried out to make molecules in abelmoschus esculentus seeds in a pre-separation state; the molecules are broken immediately after rotation to make the fat component in a pre-separation state; and then cold pressing is carried out to increase the oil yield. It is shown in the examination that the oil yield of cold pressing is increased from about 10% in the prior art to about 15%. The natural flavor and color of abelmoschus esculentus oil are guaranteed, and the quality of the oil product is improved.

Owner:重庆有益农业开发有限公司

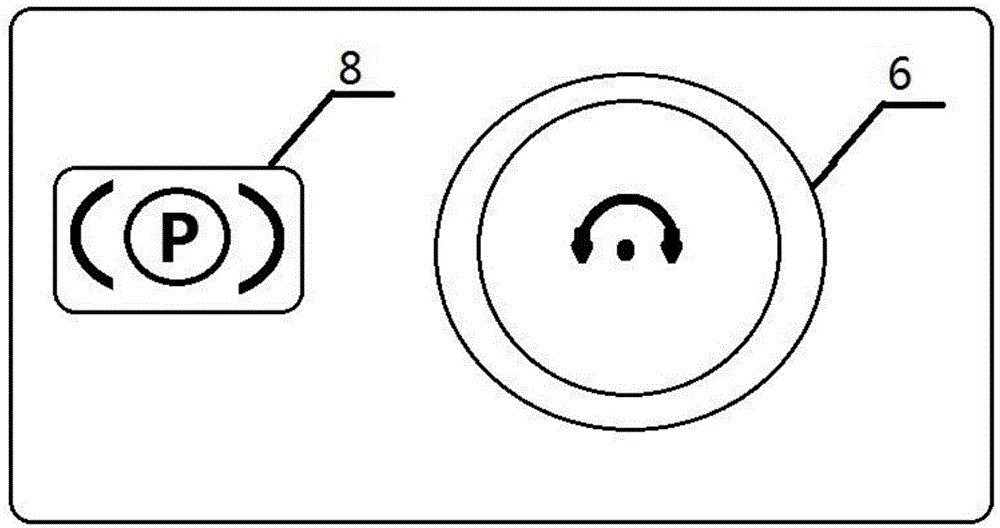

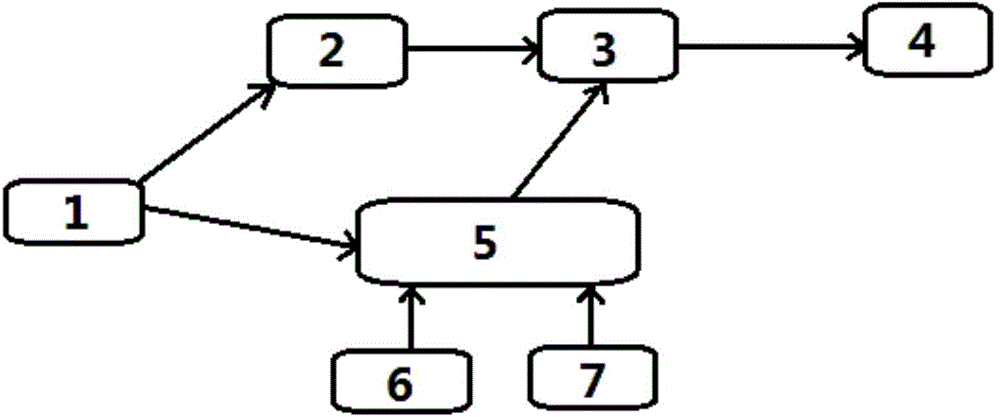

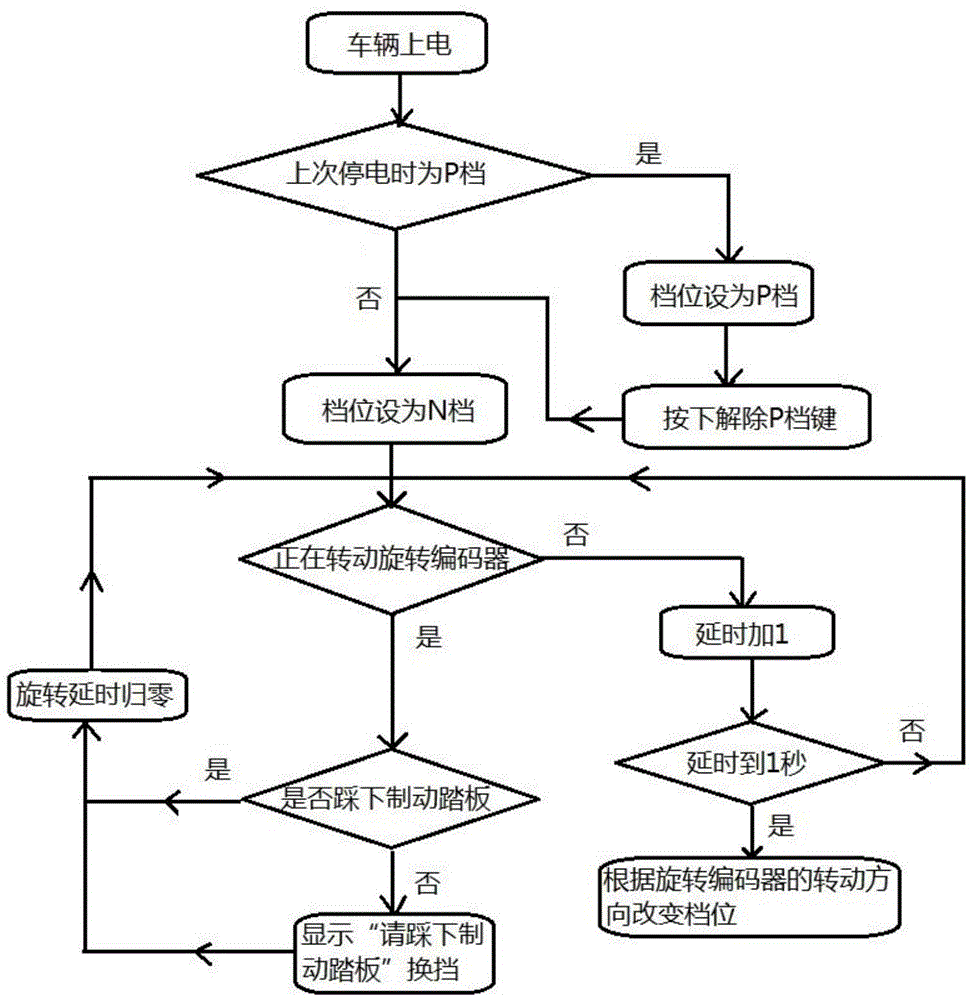

Gear switch and display device of three-wheeled electric automobile and control method of gear switch and display device

InactiveCN104442560AAvoid insecurityImprove reliabilityGearing controlSignalling/lighting devicesKey pressingCar manufacturing

The invention discloses a gear switch and display device of a three-wheeled electric automobile and a control method of the gear switch and display device, and belongs to the field of electric automobile manufacturing. The gear switch and display device comprises an automobile power supply module, a DC-AC boosting module, a display module drive circuit, a main control board and a brake pedal, wherein the automobile power supply module is connected with the DC-AC boosting module and the main control board, and the DC-AC boosting module and the main control board are connected with the display module drive circuit. The gear switch and display device further comprises a gear display module, a rotary encoder and a parking key, wherein the gear display module is arranged on an automobile instrument panel, the rotary encoder and the parking key are arranged in a center control part, the rotary encoder and the parking key are connected with the main control board through wire harnesses, and the gear display module is connected with the display module drive circuit through a wire harness. The gear switch and display device has the advantages of being simple in gear shift, safe and reliable to operate and clear in display.

Owner:MAANSHAN YIDAI ELECTRIC VEHICLE TECH

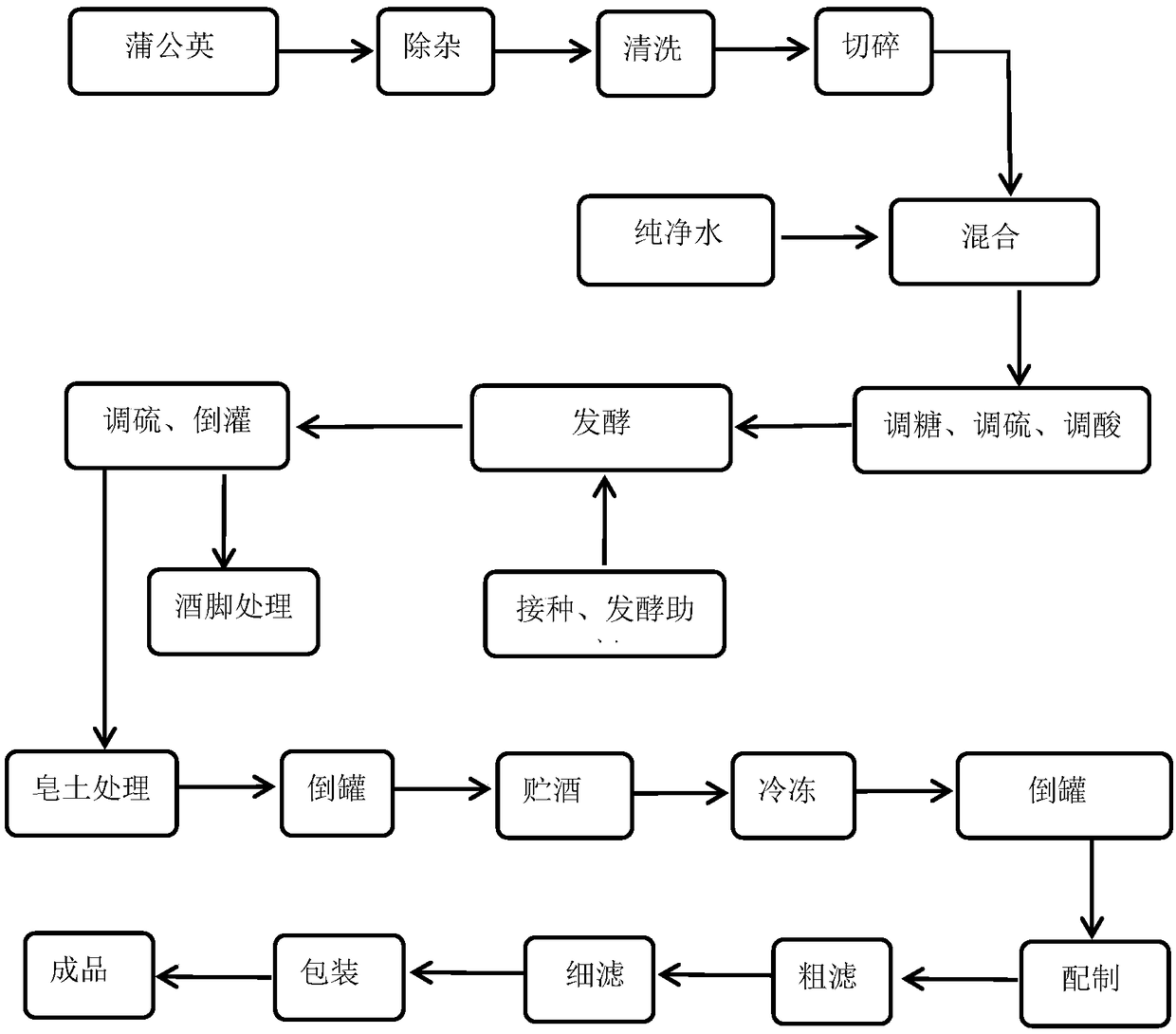

Preparation method of dandelion fermented wine

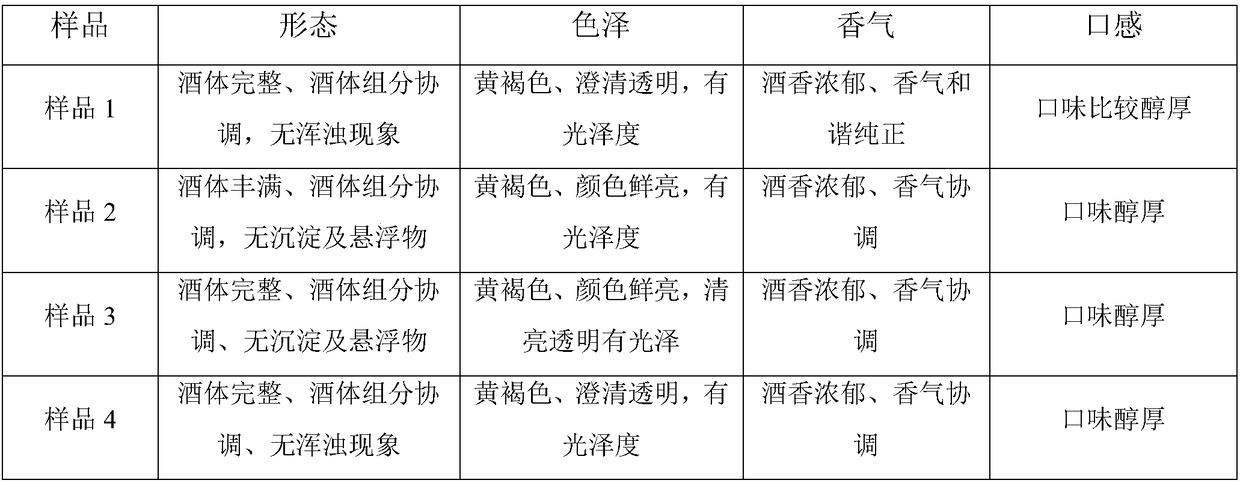

InactiveCN109294790AWith colorRich bouquetMicroorganism based processesAlcoholic beverage preparationFiltrationSulfur

The invention belongs to the technical field of wine processing, and more specifically relates to a preparation method of a dandelion fermented wine. The preparation method comprises following steps:raw material processing, mixing, sugar adjusting, sulfur adjusting, acid adjusting, inoculation and fermentation, bentonite processing, refrigeration processing, and press filtration. The preparationmethod is simple; the dandelion fermented wine is thick in wine fragrance; the wine body is complete; wine components are coordinative; no precipitate or suspension substance is generated; and the medical efficiency of dandelion is achieved.

Owner:青海珠峰冬虫夏草工程技术研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com