Automatic coloring 3D printing ink box

A 3D printing and ink cartridge technology, which is applied in the direction of 3D object support structure, accessories for processing main materials, additive manufacturing, etc., can solve the problems of delay in printing process, heavy workload, and troublesome process of replacing linear consumables, etc., to improve continuity , to avoid the effect of color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail through specific embodiments below.

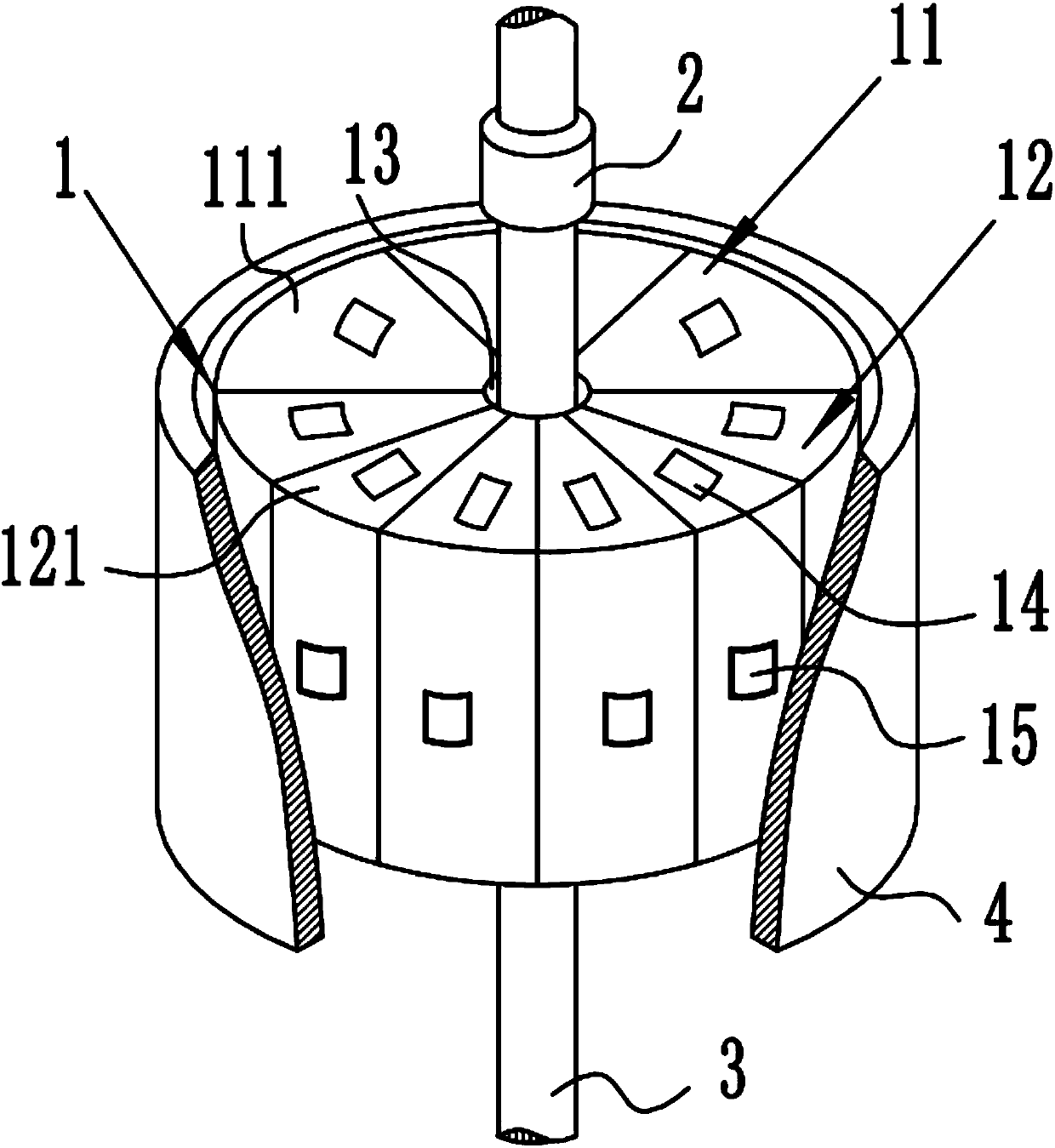

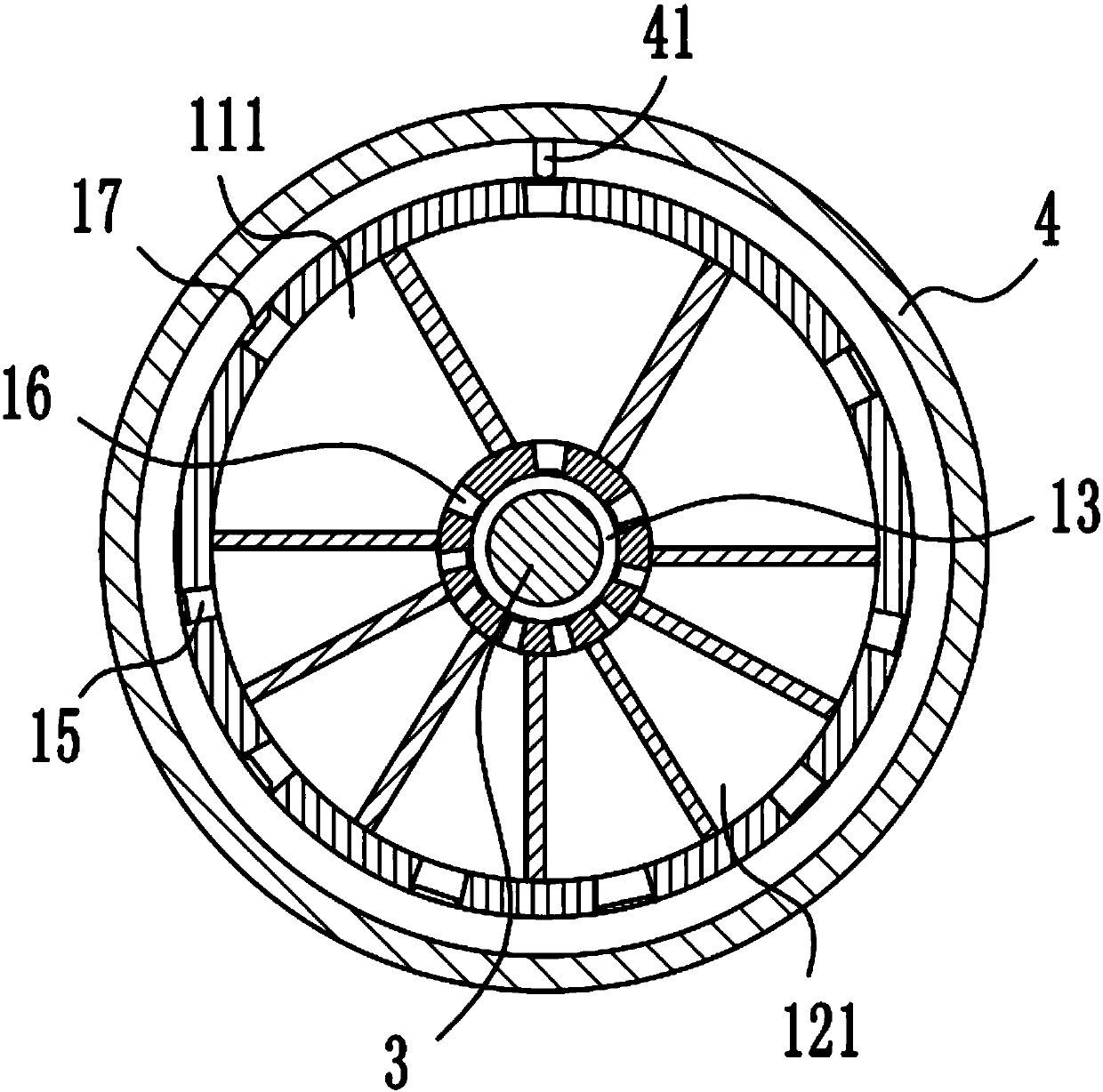

[0027] The reference signs in the accompanying drawings of the description include: ink cartridge body 1, friction sleeve 2, linear consumables 3, drive cylinder 4, primary color area 11, primary color box 111, toning area 12, toning box 121, wire hole 13, adding Cover 14, air inlet hole 15, colored hole 16, one-way door 17, nozzle 41.

[0028] Self-coloring 3D printing cartridges such as figure 1 and figure 2 As shown, the ink cartridge body 1 is included, the ink cartridge body 1 is cylindrical, and a wire hole 13 is provided along the axial direction of the ink cartridge body 1. There is a friction sleeve 2 for the wire to pass through and to rub against the wire. The inner wall of the wire hole 13 is slidingly fitted with a plurality of inserts corresponding to the coloring hole 16 and can be drawn out. The insert is arc-shaped, and the lower end of the insert is A to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com