Patents

Literature

51results about How to "Avoid color differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

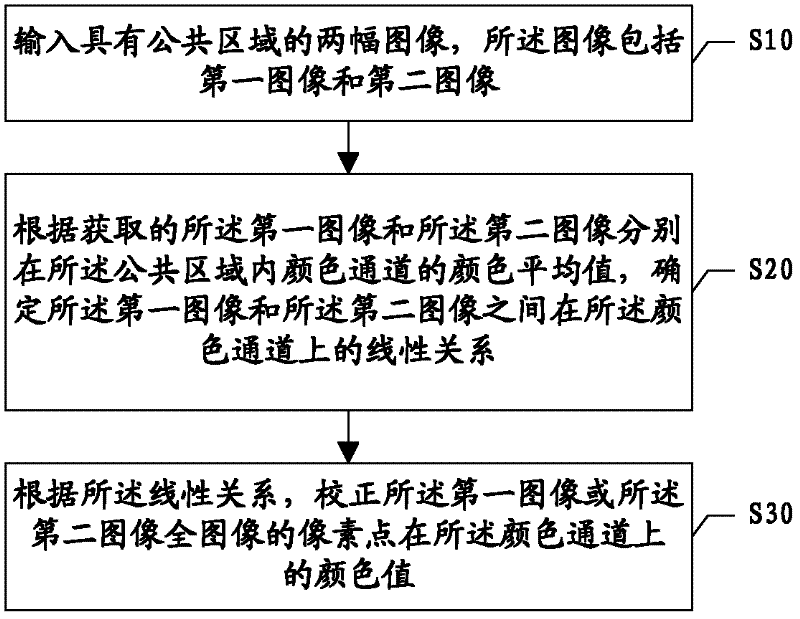

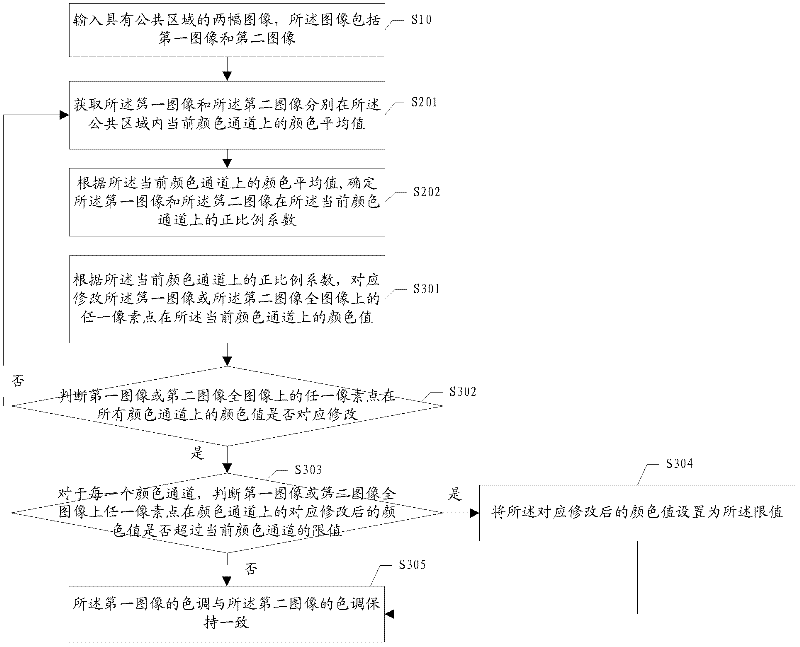

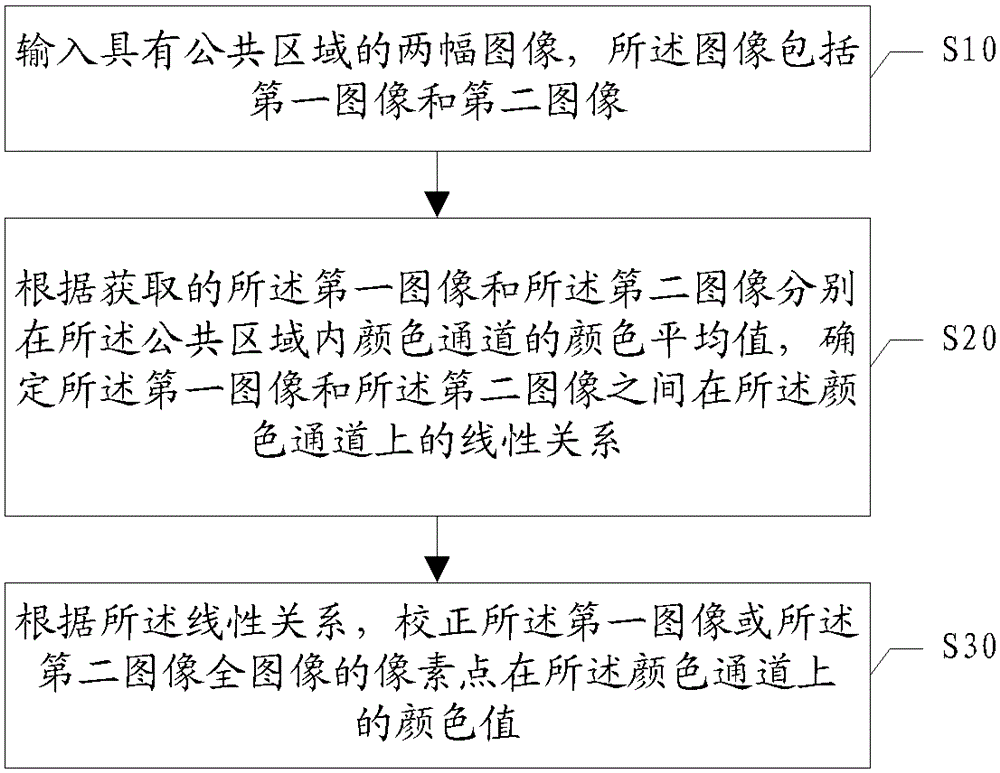

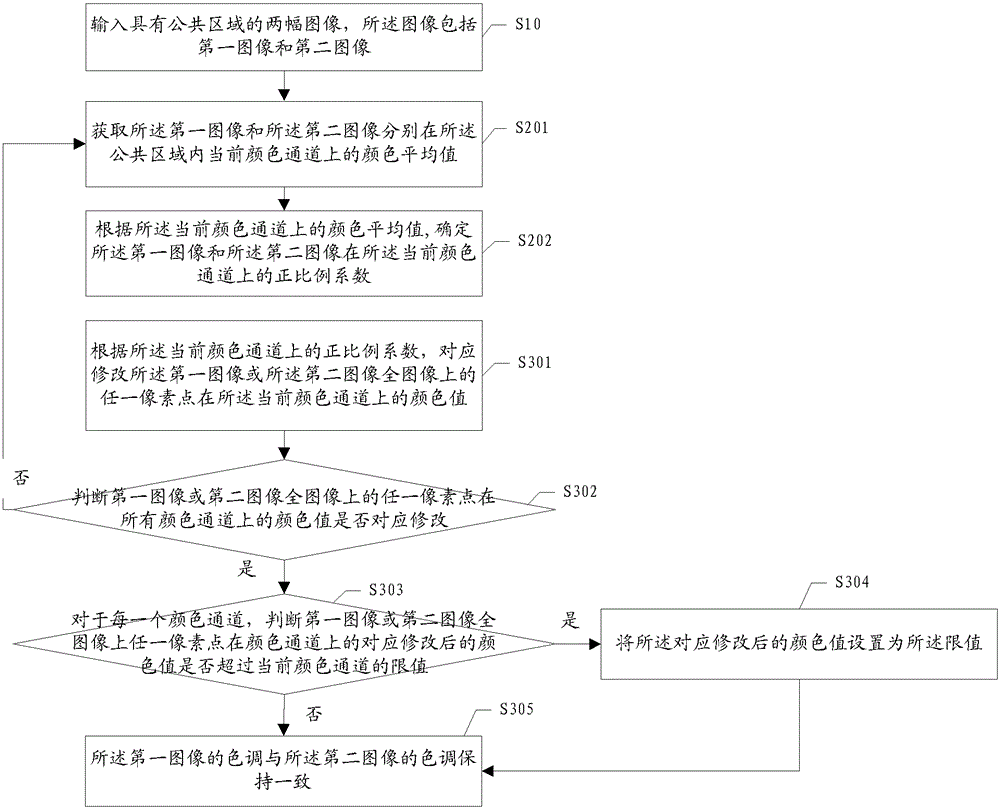

Method and device for correcting color between images

ActiveCN102542548AAvoid color differencesSolve lighting problemsImage enhancementColor correctionLinear relationship

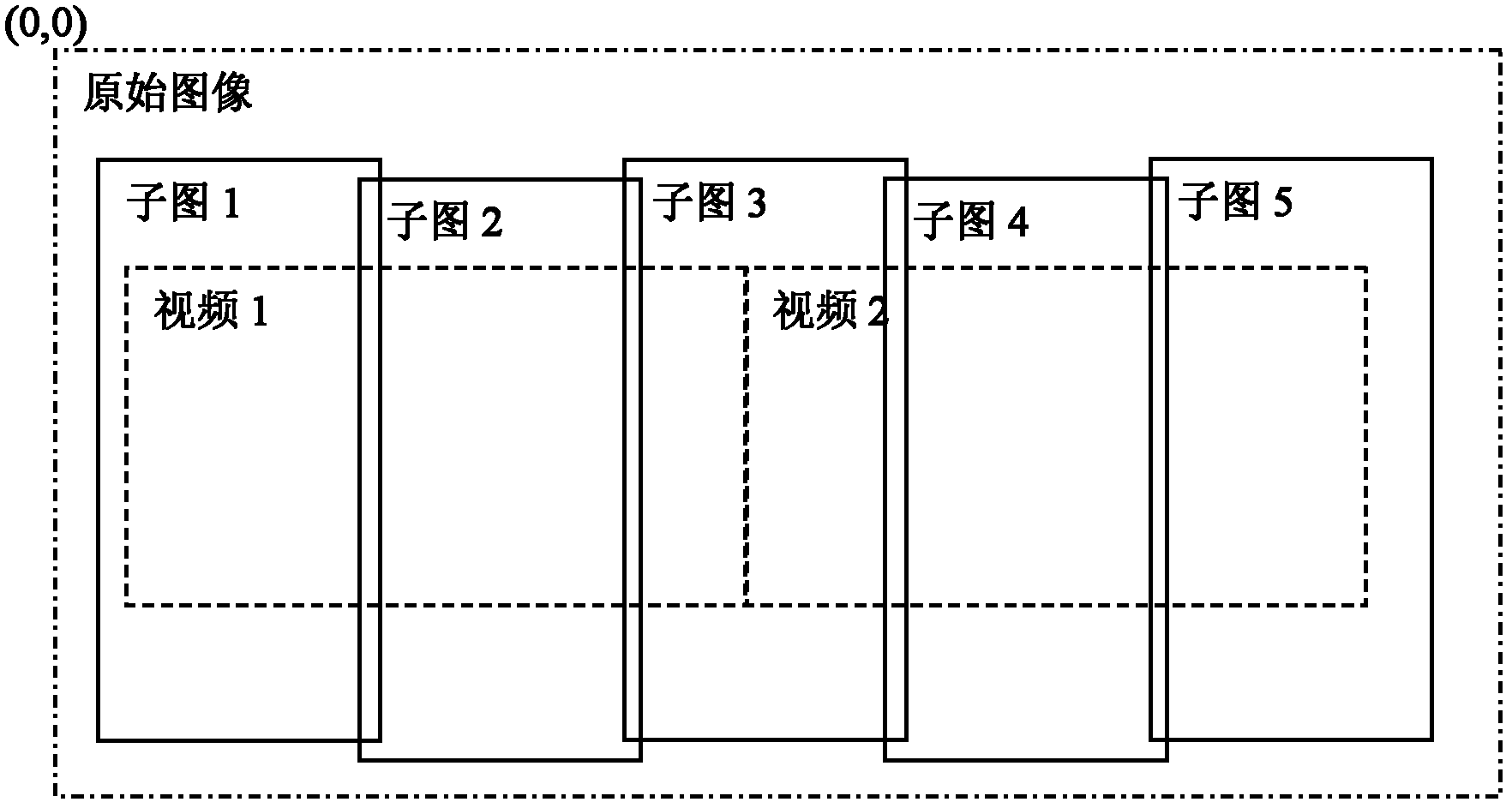

The invention discloses a method for correcting color between images. The method comprises the steps of inputting two images including a first image and a second image having a common public area; determining the linear relationship on a color channel between the first image and the second image by respectively acquiring the color average value of the color channel in the common area of the first image and the second image; and correcting the color value of pixels on the full image of the first image or the second image according to the linear relationship. The invention also discloses a device for correcting color between images. The method and the device provided by the invention can solve the consistency problem of illumination and color tone in panoramic image generation, image registration and image fusion, and can be specifically used in picture processing software of PC (personal computer) terminal, mobile phone and tablet PC, with the advantages of stable correction effect and wide application.

Owner:WONDERSHARE TECH CO LTD

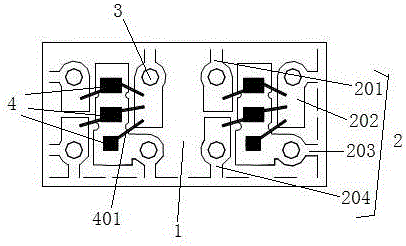

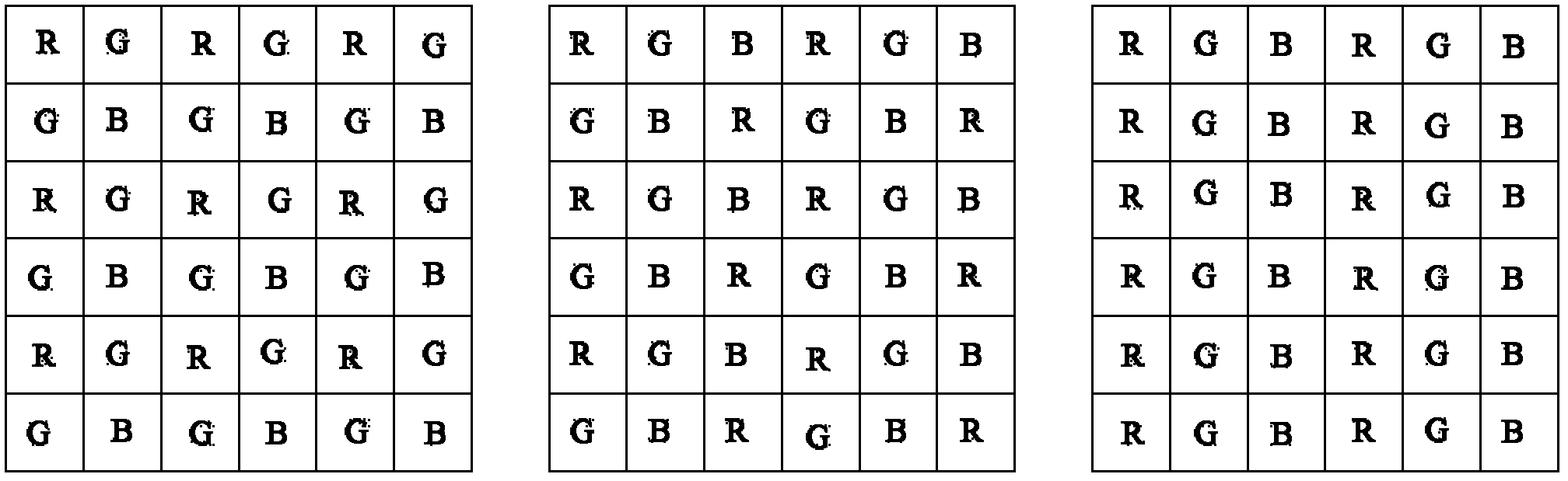

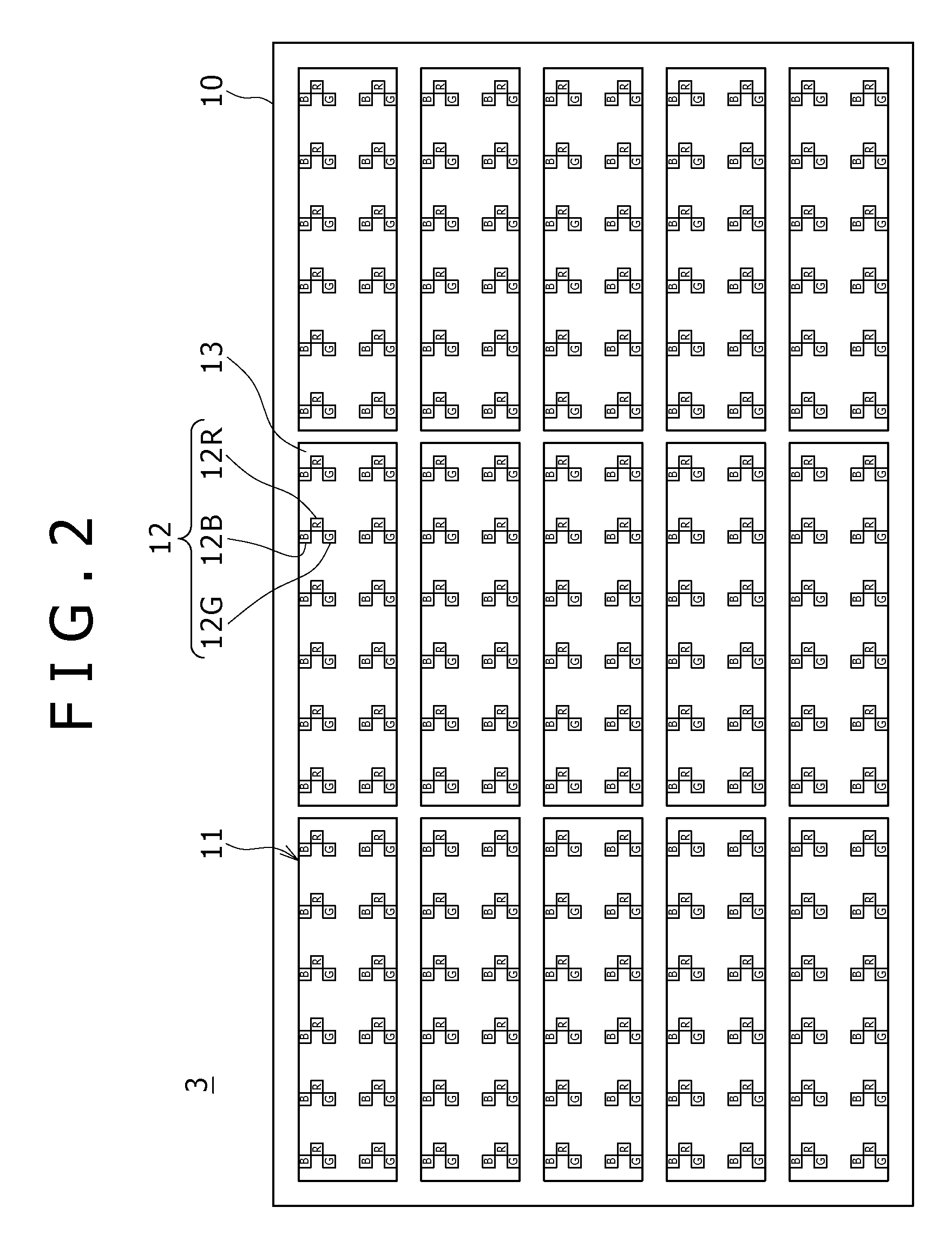

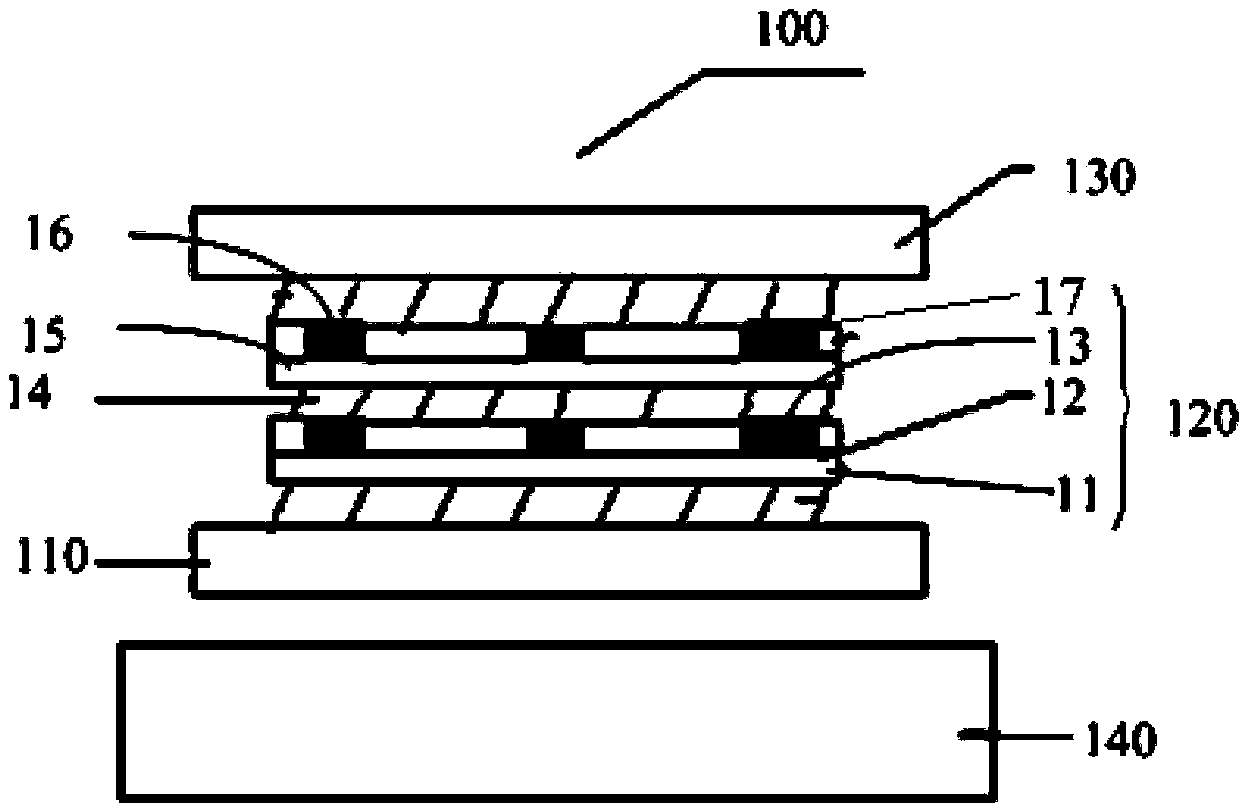

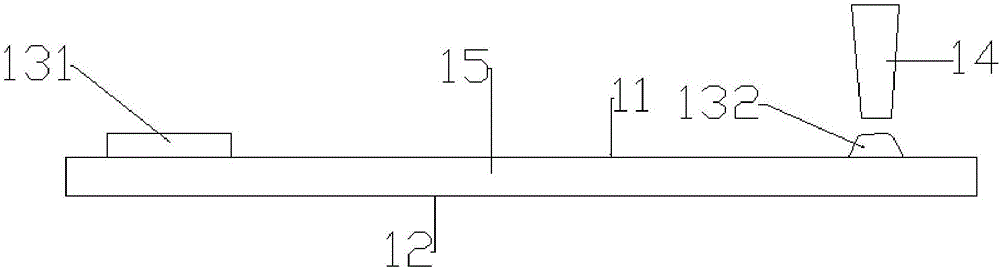

Encapsulation module for surface mounted RGB-LED (Red, Green, Blue-Light Emitting Diode) and manufacturing method thereof

ActiveCN106847801AIncrease productivityImprove the ability to resist external mechanical strengthSolid-state devicesIdentification meansSurface mountingEngineering

The invention provides an encapsulation module for a surface mounted RGB-LED (Red, Green, Blue-Light Emitting Diode) and a manufacturing method thereof. The encapsulation module comprises a substrate and light emitting units, wherein the light emitting units are arranged on the substrate; the light emitting units are provided with protective layers; the quantity of the light emitting units is at least two; each light emitting unit comprises four mutually independent upper bonding pads and one group of RGB LED chips; the RGB LED chips are arranged on any one upper bonding pad, and are connected with the other three upper bonding pads through keys and lines; the upper bonding pads are provided with metallic holes which pass through the substrate and are conductively communicated up and down; the positions, corresponding to the metallic holes, of the reverse surface of the substrate are provided with lower bonding pads; the lower bonding pads are mutually independent. By using the encapsulation module, multiple light emitting units are integrated in one encapsulation module; the production efficiency of an LED in subsequent application and production is greatly improved; the production cost is greatly decreased.

Owner:SHANDONG JIERUNHONG OPTOELECTRONICS CO LTD

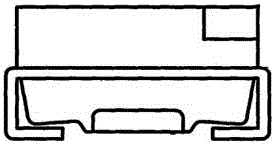

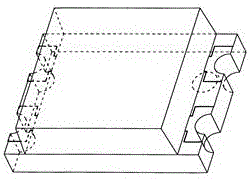

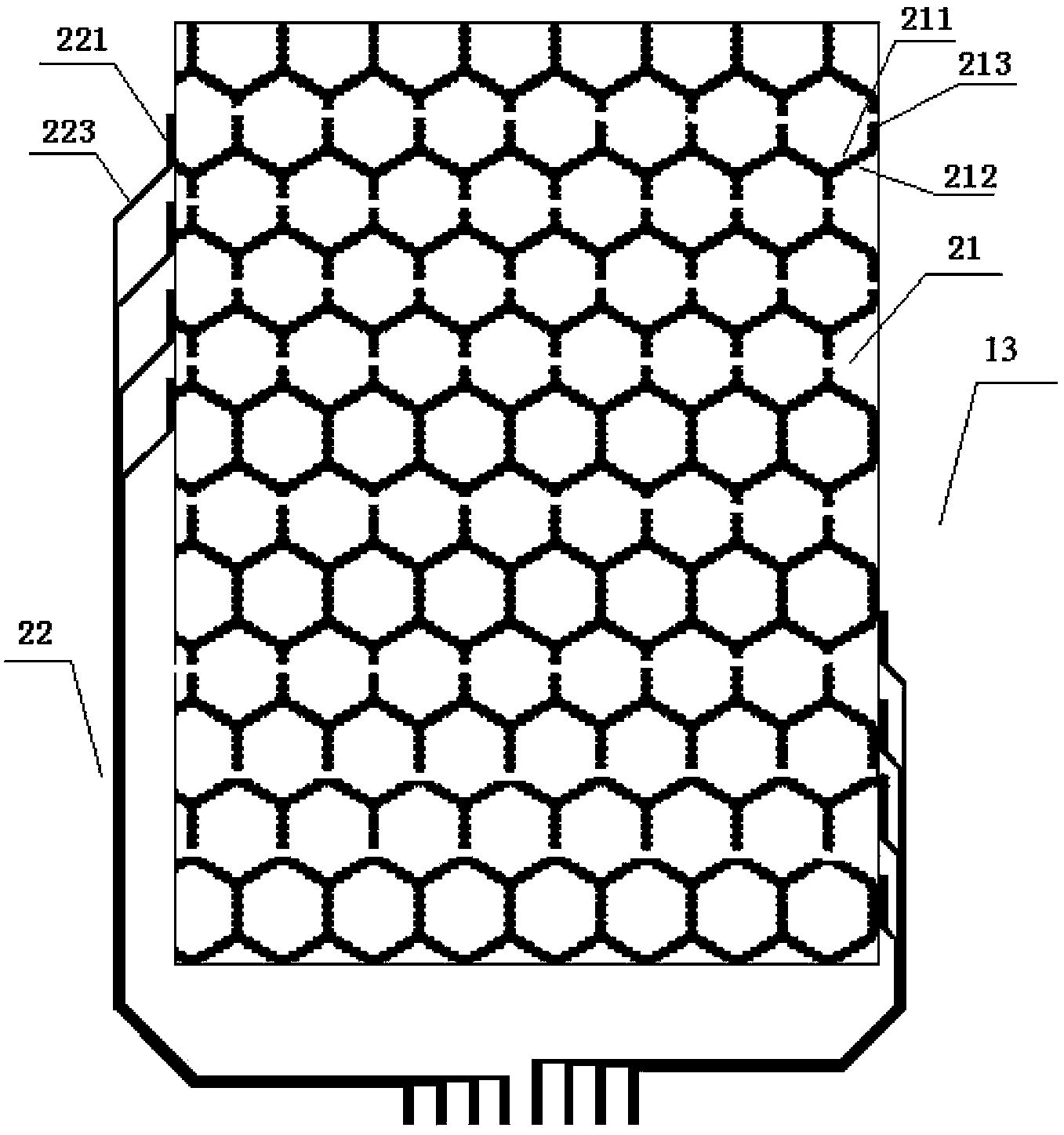

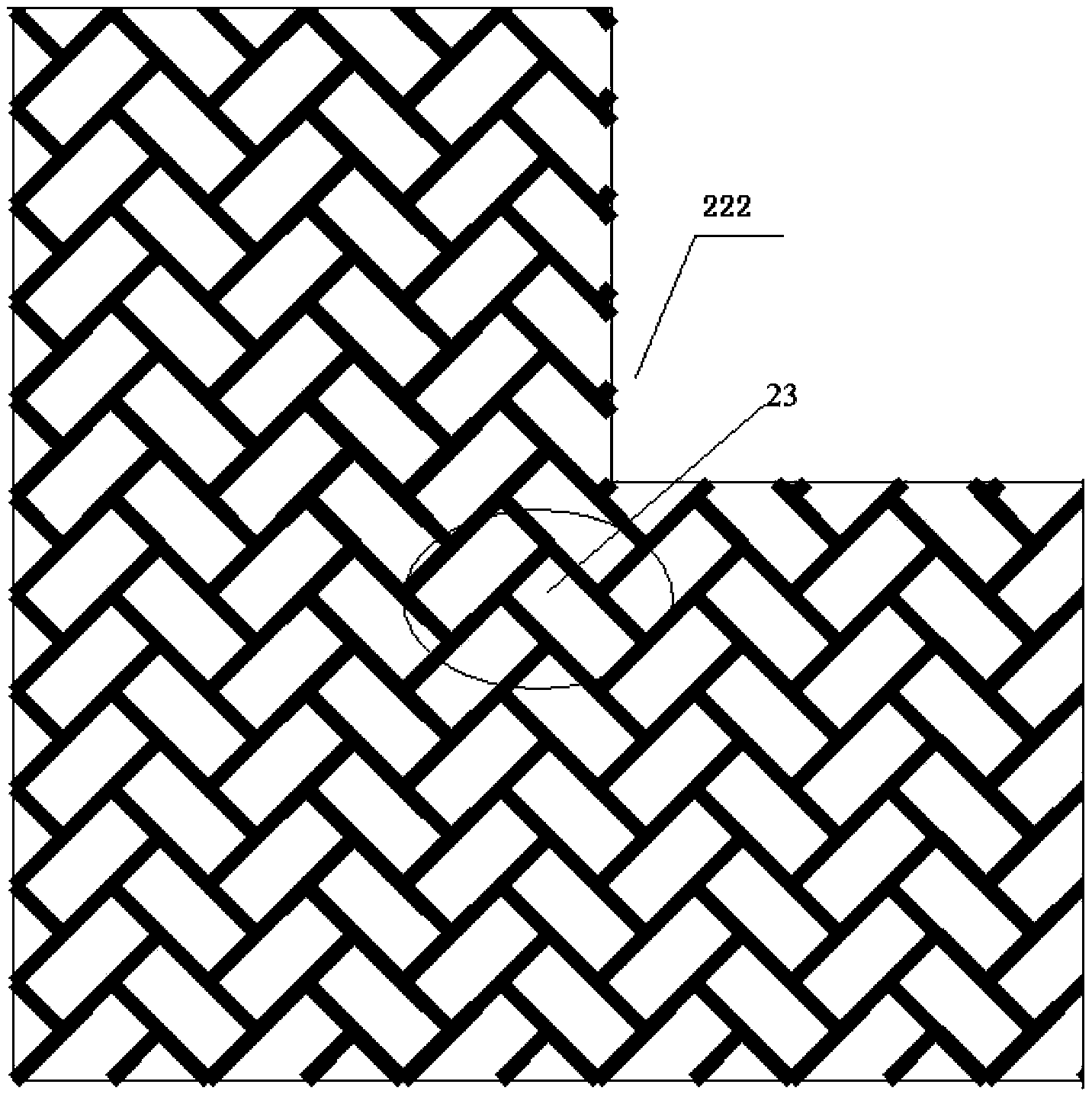

QFN surface-mounted RGB-LED encapsulation module and manufacturing method thereof

PendingCN106847800AQuick exportHigh resolutionSolid-state devicesIdentification meansSurface mountingEngineering

The invention provides a QFN surface-mounted RGB-LED encapsulation module and a manufacturing method thereof. The RGB-LED encapsulation module comprises an encapsulation bracket and light-emitting units arranged on the encapsulation bracket, wherein the number of the light-emitting units is at least two; the encapsulation bracket comprises a metal baseplate and an insulating frame; a bracket electrode for fixing crystal and bonding a wire is arranged at a region, where each light-emitting unit is located, by the metal baseplate; each light-emitting unit comprises an RGB-LED chip fixed on the metal baseplate and a bond and a wire for connecting the RGB-LED chip and a bracket electrode; a protective layer is arranged on each light-emitting unit; the bracket electrode is connected with an external circuit through a bonding pad arranged on the back of the metal baseplate. The encapsulation module is in direct contact with a PCB through the metal baseplate, so that chip heat can be quickly led out; a bowl-cup structure is formed on the front, so that a light-emitting surface is unique; the multiple light-emitting units are integrated on the one encapsulation module, so that the production efficiency is further improved.

Owner:SHANDONG JIERUNHONG OPTOELECTRONICS CO LTD

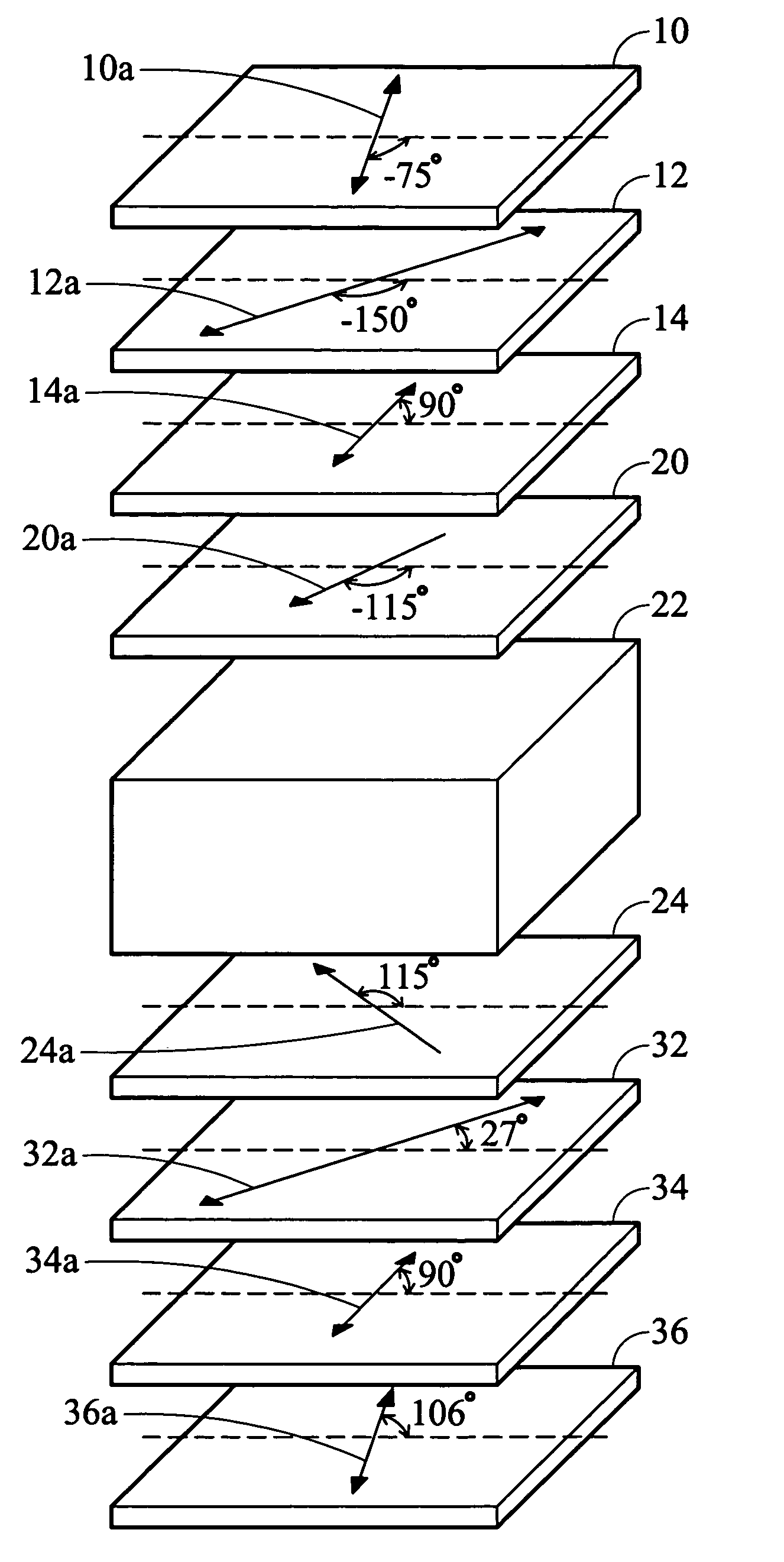

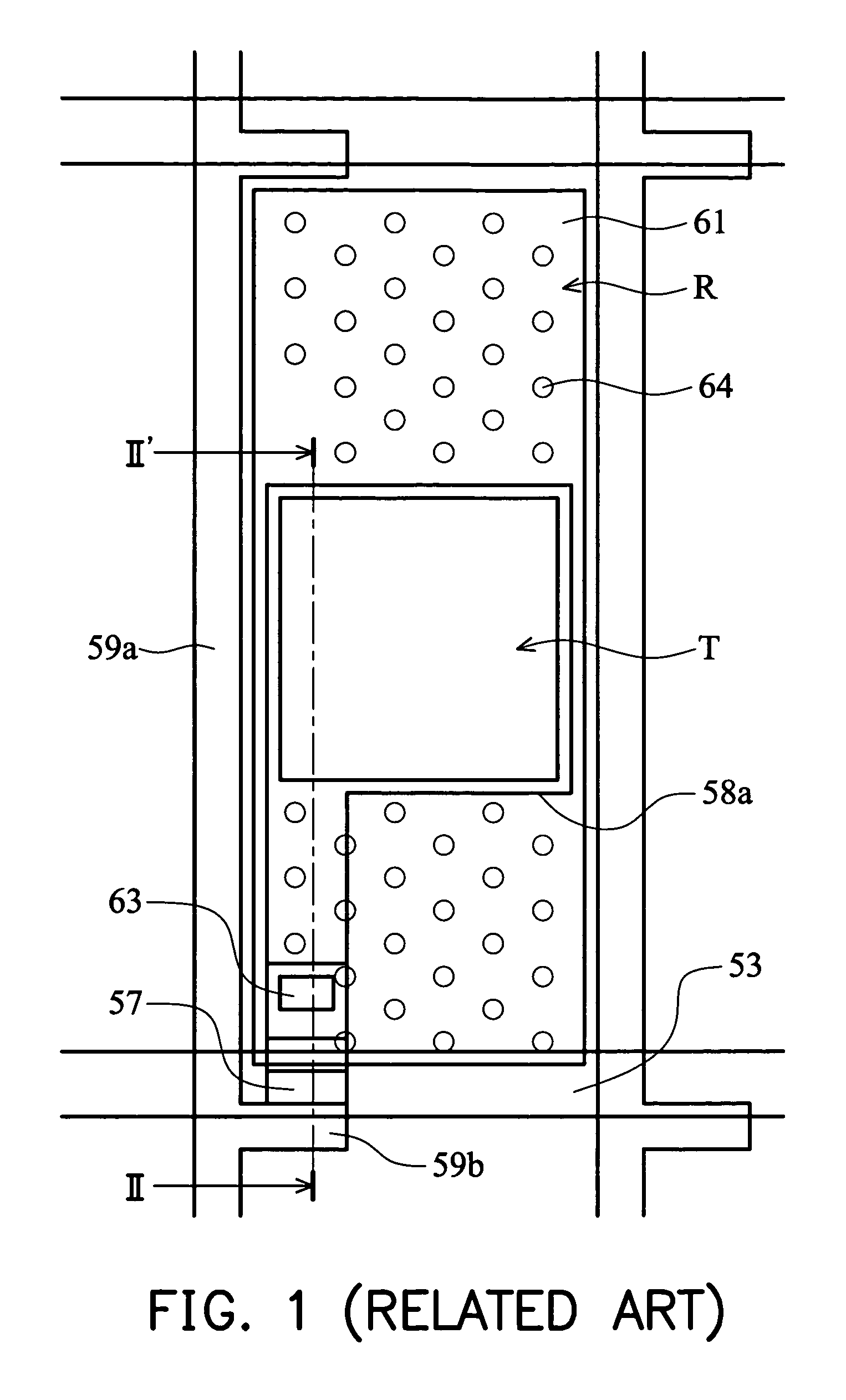

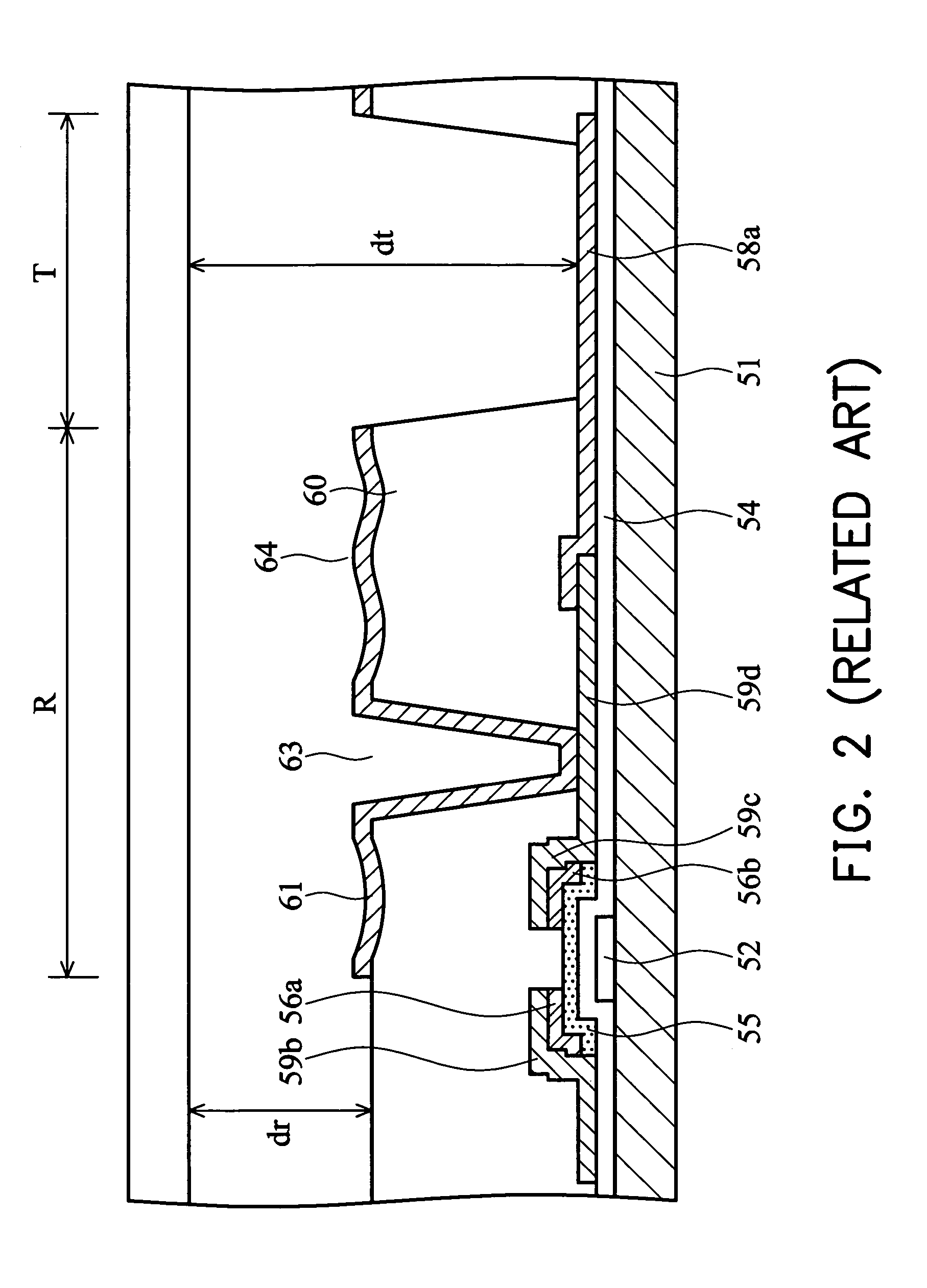

Transflective liquid crystal display device having particular angles between optical axes

ActiveUS6999144B2Avoid color differencesLiquid crystal compositionsNon-linear opticsOptical axisColor difference

A transflective liquid crystal device capable of balancing a color difference between a reflective region and a transmissive region. The arrangement conditions of optical elements in the transflective LCD are as follows. The twist angle of the liquid crystal is about 40°˜80°. The angles βup, βdown, θup and θdown are about −20°˜−60°, −20°˜20°, 60°˜110°, −30°˜20° respectively. The angle between the retardation axes of the upper λ / 2 plate and the upper λ / 4 plate is about 30°˜100°, and the angle between the retardation axes of the lower λ / 2 plate and the lower λ / 4 plate is about 30°˜80°.

Owner:AU OPTRONICS CORP

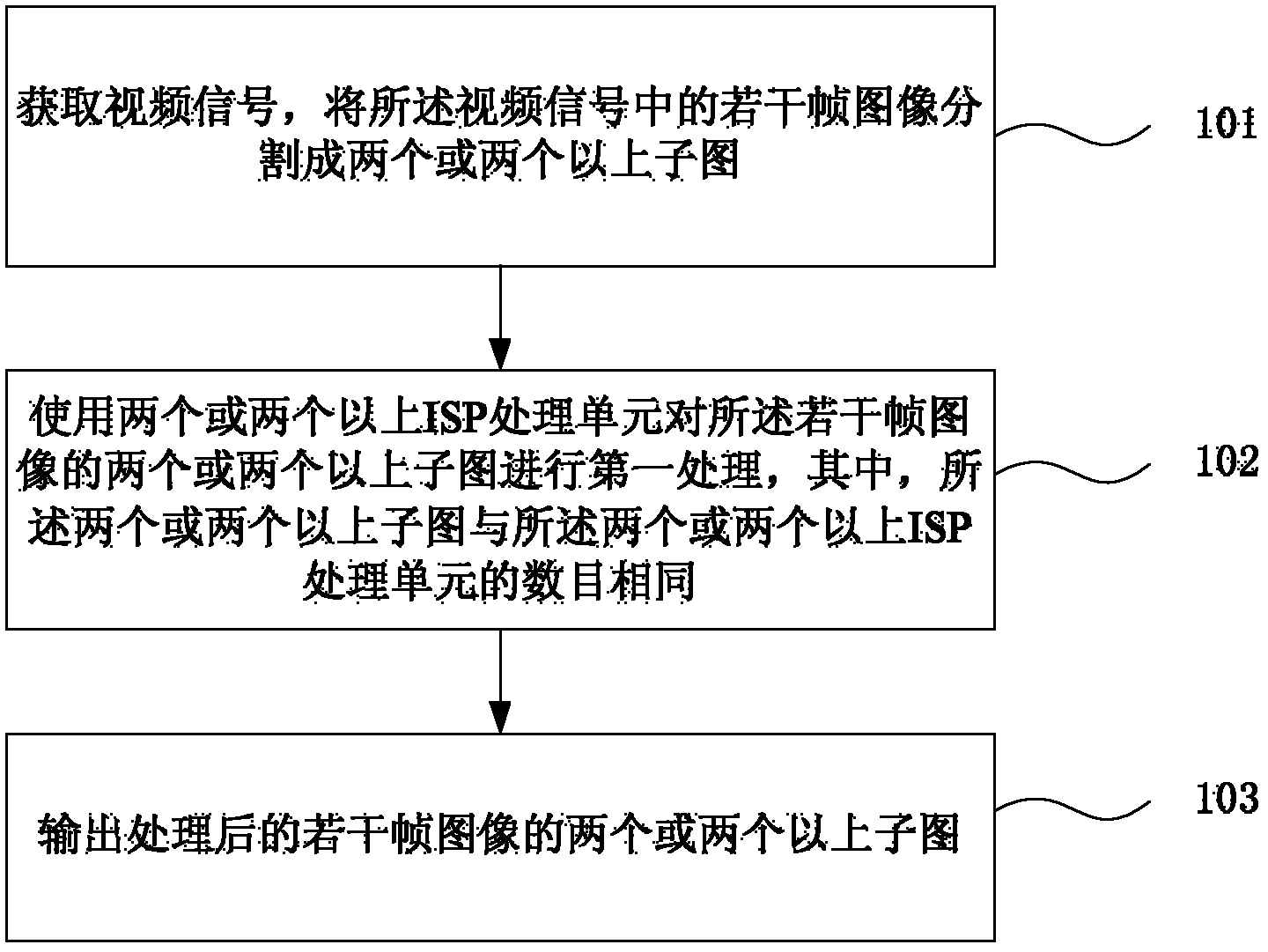

Video signal processing method and photographic equipment

ActiveCN102665031AAvoid unclearAvoid missingTelevision system detailsColor signal processing circuitsImage resolutionImage segmentation

The invention discloses a video signal processing method and photographic equipment, and belongs to the field of video cameras. The method comprises the following steps of: acquiring a video signal, and dividing a plurality of frames of images in the video signal into two or more than two sub-images; primarily processing the two or more than two sub-images of the plurality of frames of images by using two or more than two image sensor processor (ISP) processing units; and outputting the processed two or more than two sub-images of the plurality of frames of images. The photographic equipment comprises a lens, a sensor, an image divider, a controller and the two or more than two ISP processing units. Image division is used, and the two or more than two ISP processing units are used for performing path division processing on the divided sub-images, so that the resolution of the output images can be improved, image blurring at splicing parts can be avoided, an ultrahigh-definition video camera can be implemented, and the shortcomings of gap overlapping or deficiency, color differences, asynchrony and the like caused by the use of a plurality of video cameras for image splicing in the conventional ultrahigh-definition video camera system are overcome.

Owner:HUAWEI TECH CO LTD

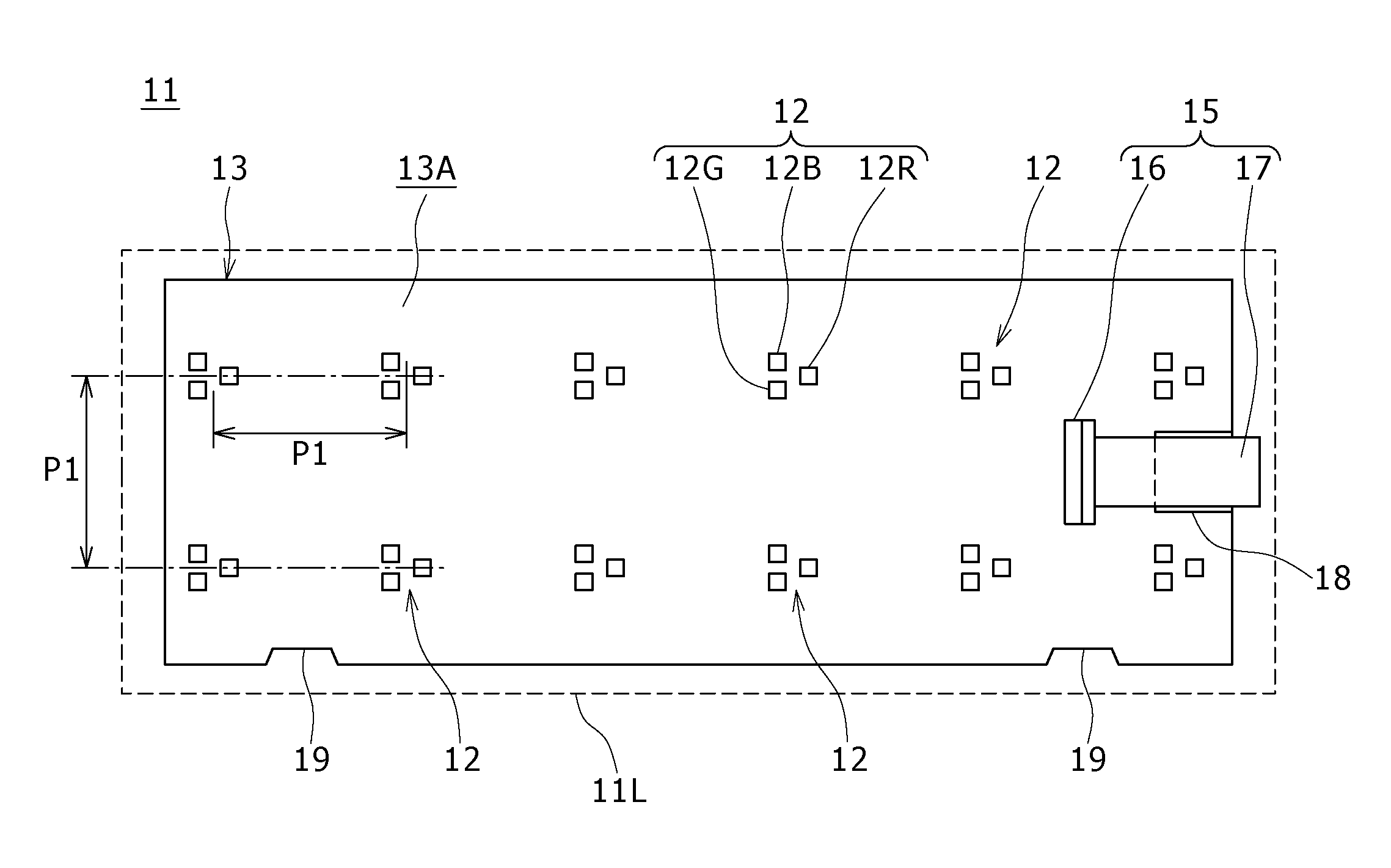

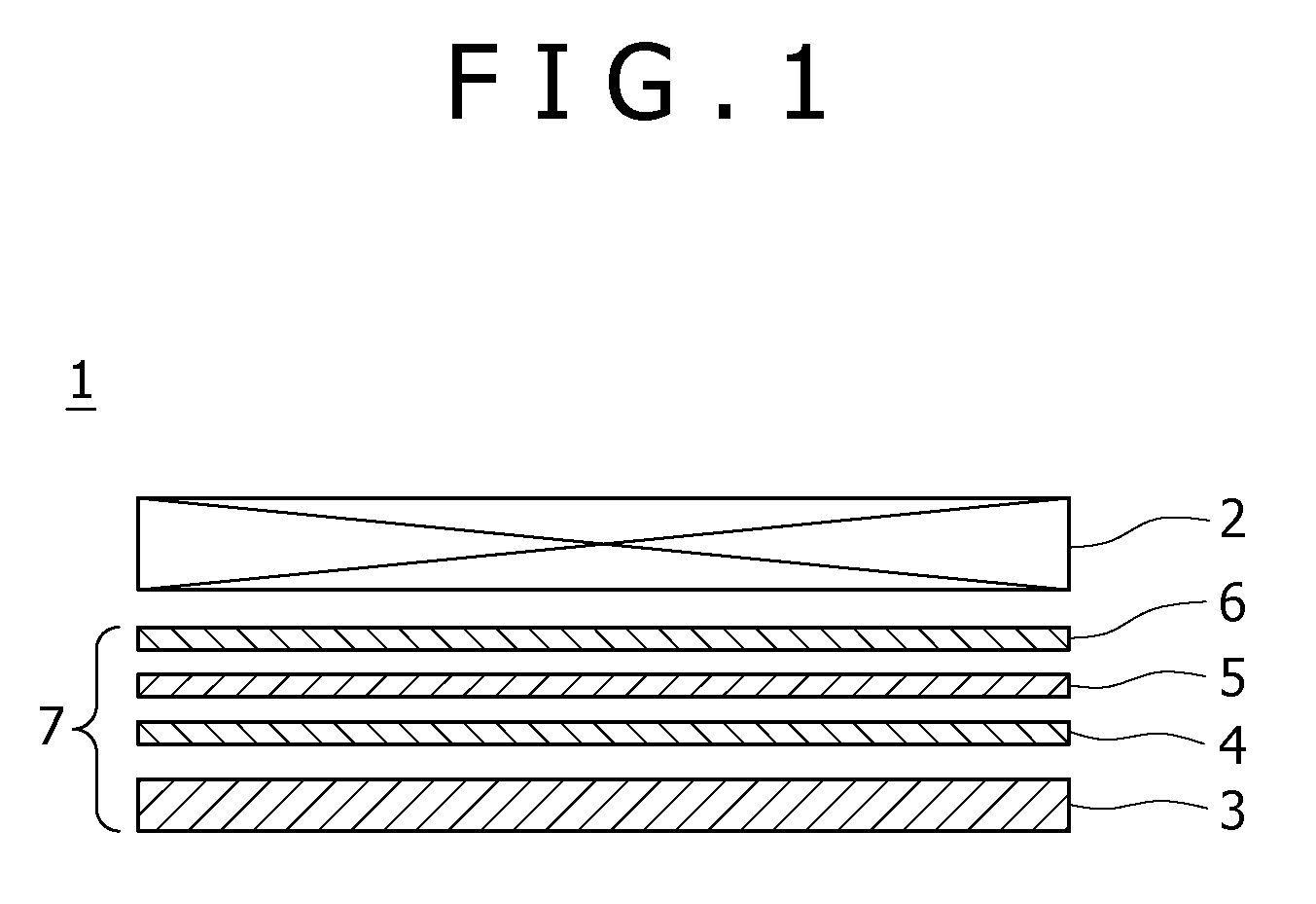

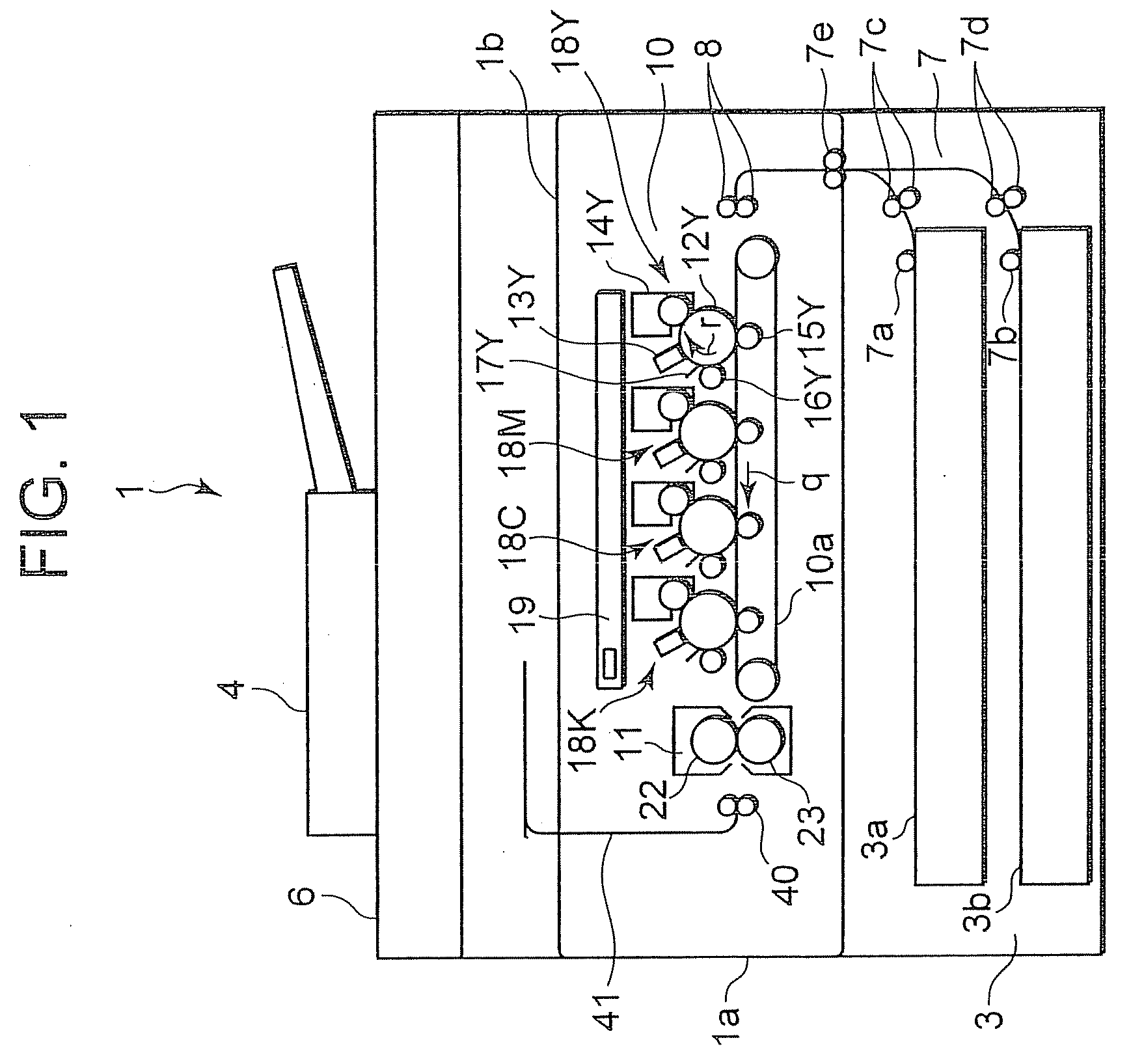

Light source module, light source apparatus and liquid crystal display

InactiveUS7878680B2Improve propertiesUniform brightnessLighting support devicesLighting heating/cooling arrangementsLiquid-crystal displayDevice form

A light source module includes a light emitting diode and a wiring board. The light emitting diode (LED) chip group includes LED chips for red, green and blue colors. A plurality of the LED chip groups are mounted on the wiring board. A surface on one side of the wiring board is a device forming surface including the plurality of the LED chip groups, an external connecting terminal for leading out electrodes, and a wiring pattern for electrical connection between the LED chip groups and the external connecting terminal. A surface on the other side of the wiring board is a heat radiating surface which is thermally connected to the device forming surface and operative to radiate heat generated at the device forming surface to the exterior.

Owner:SONY CORP

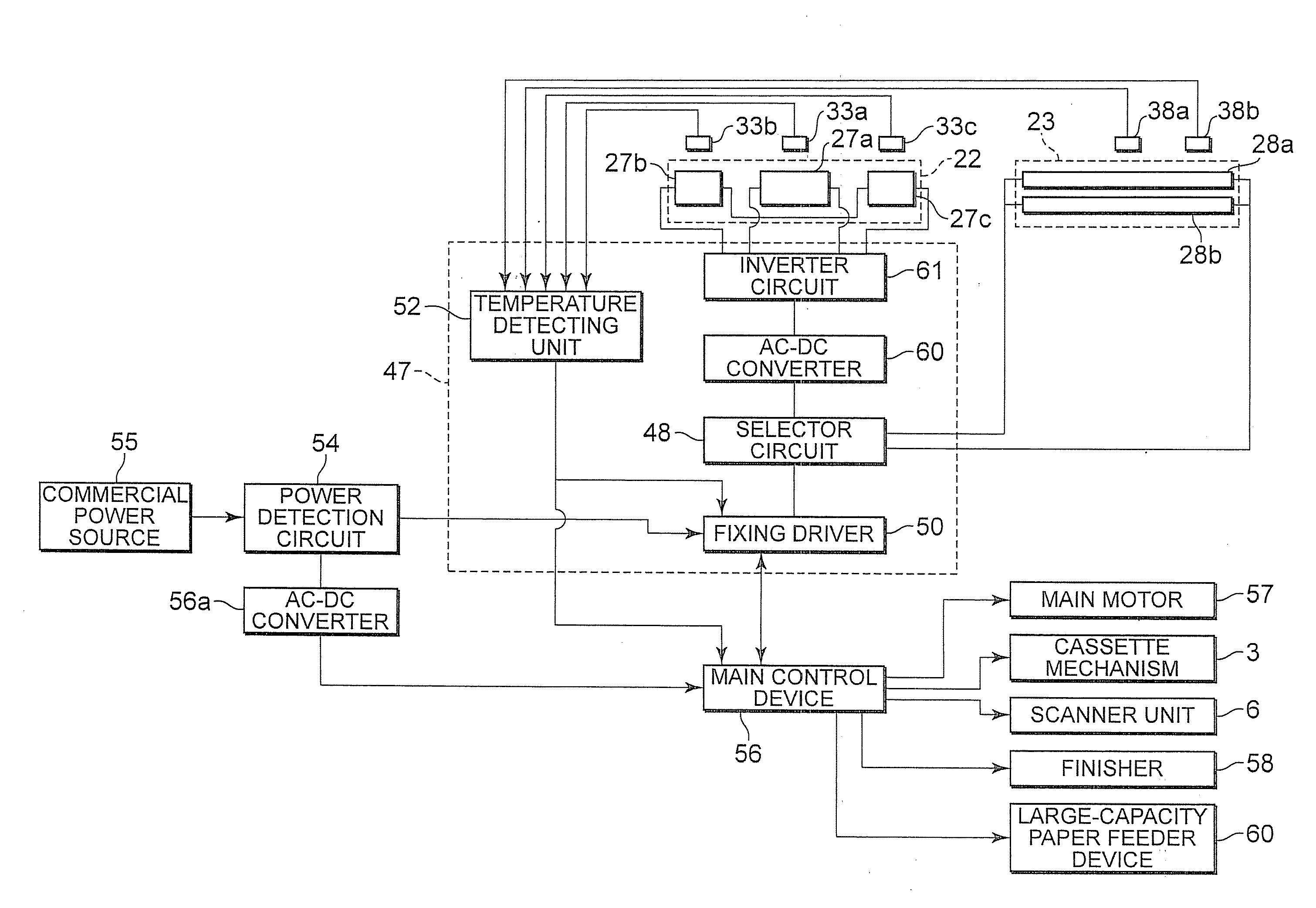

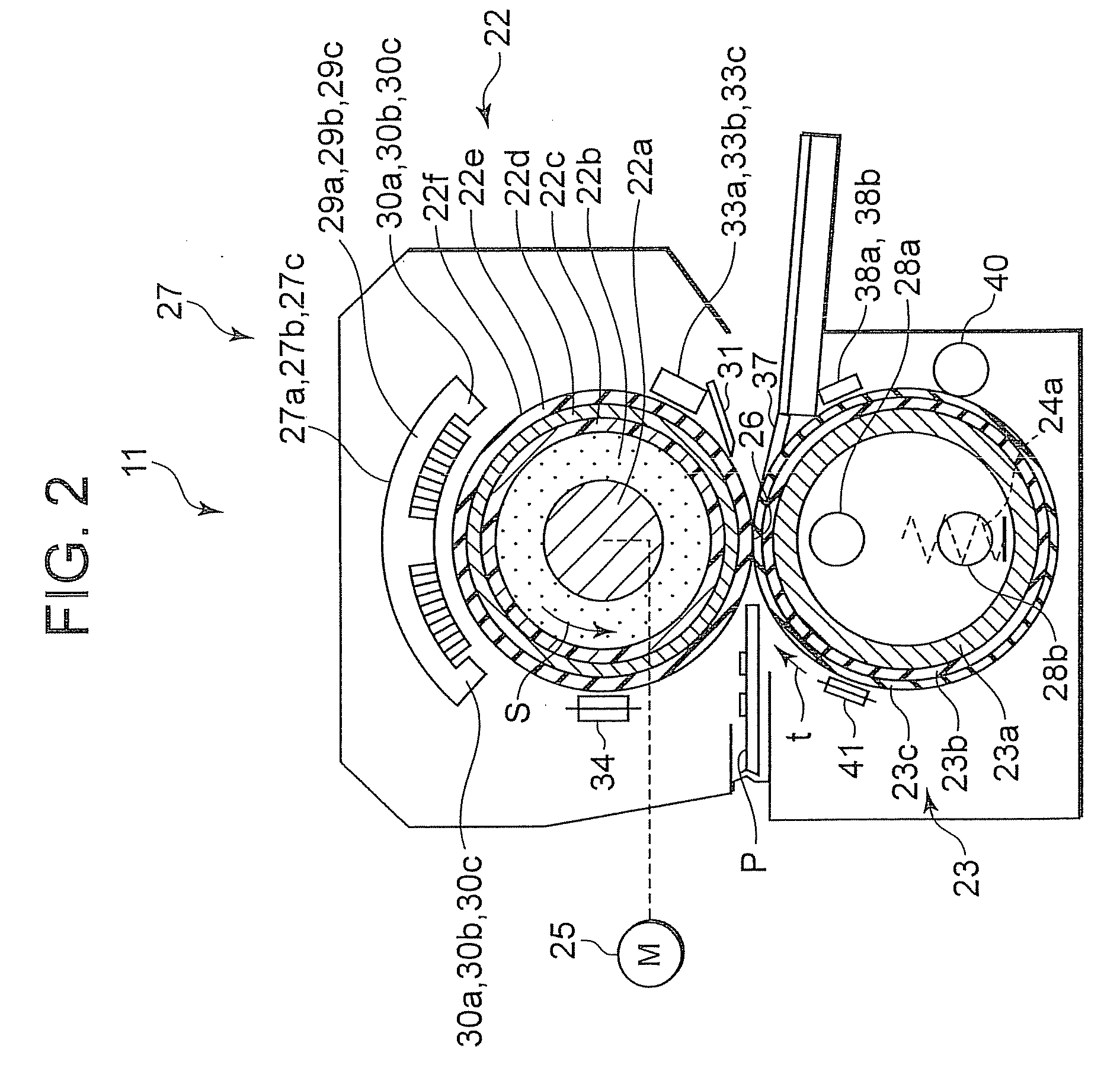

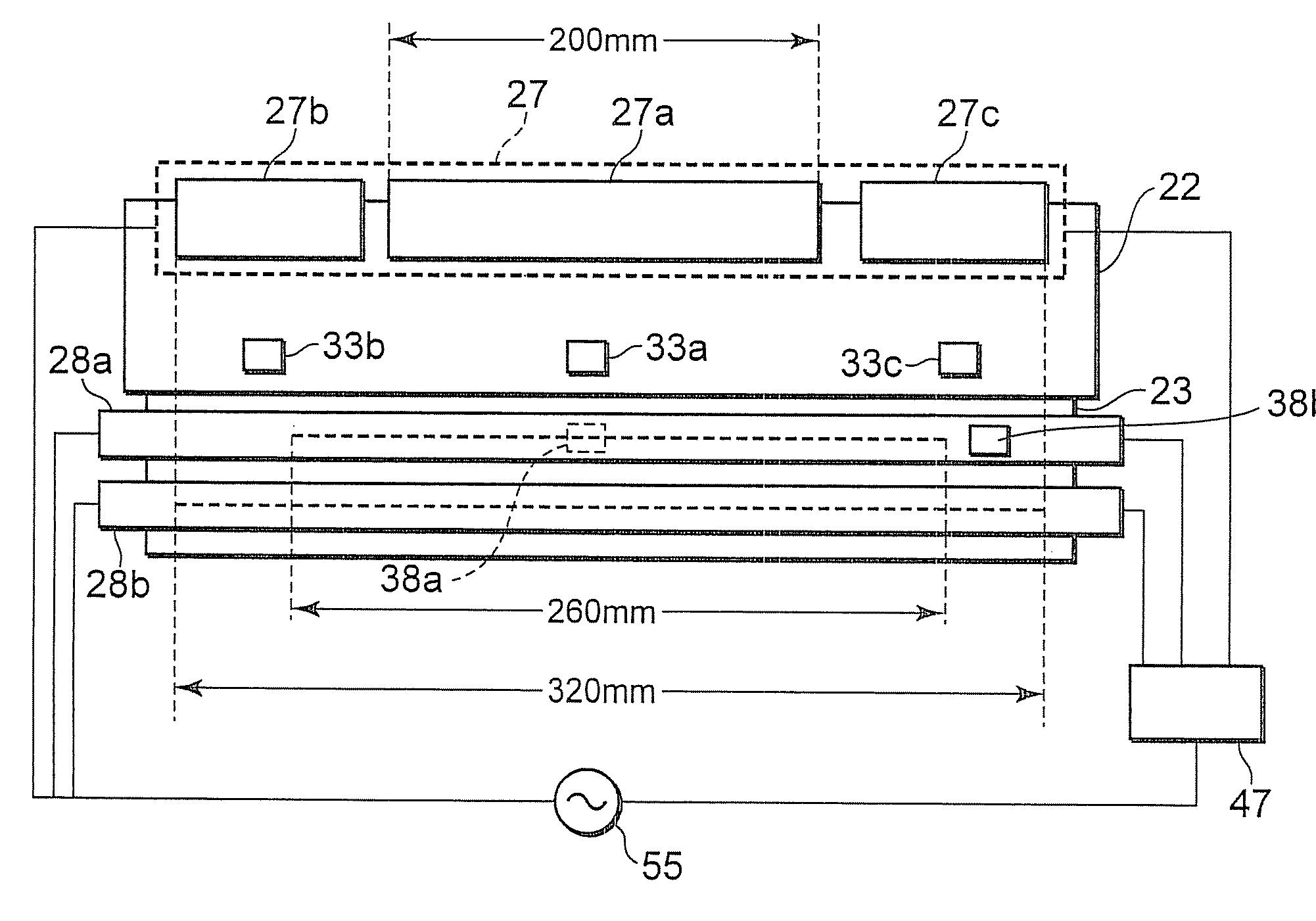

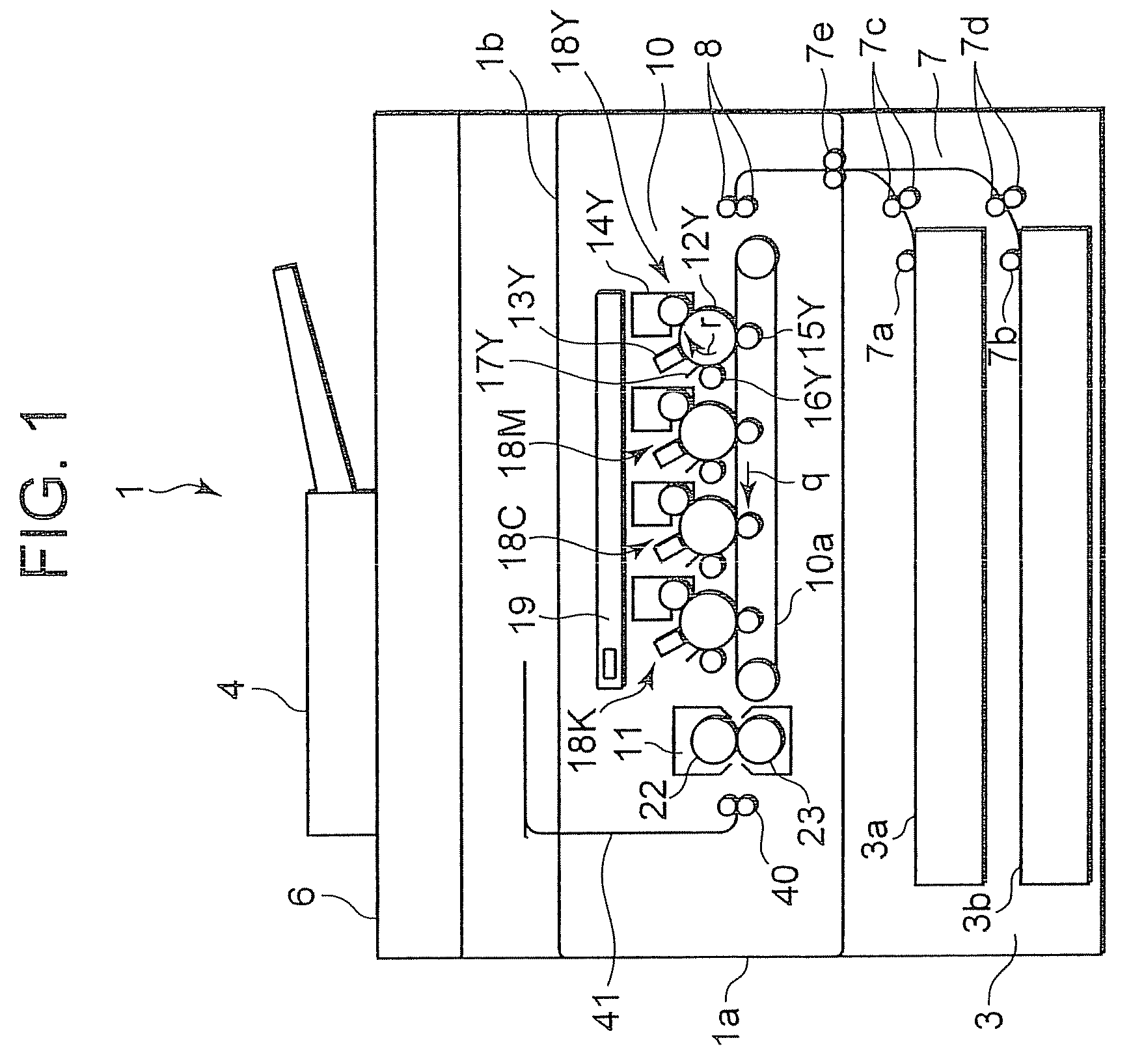

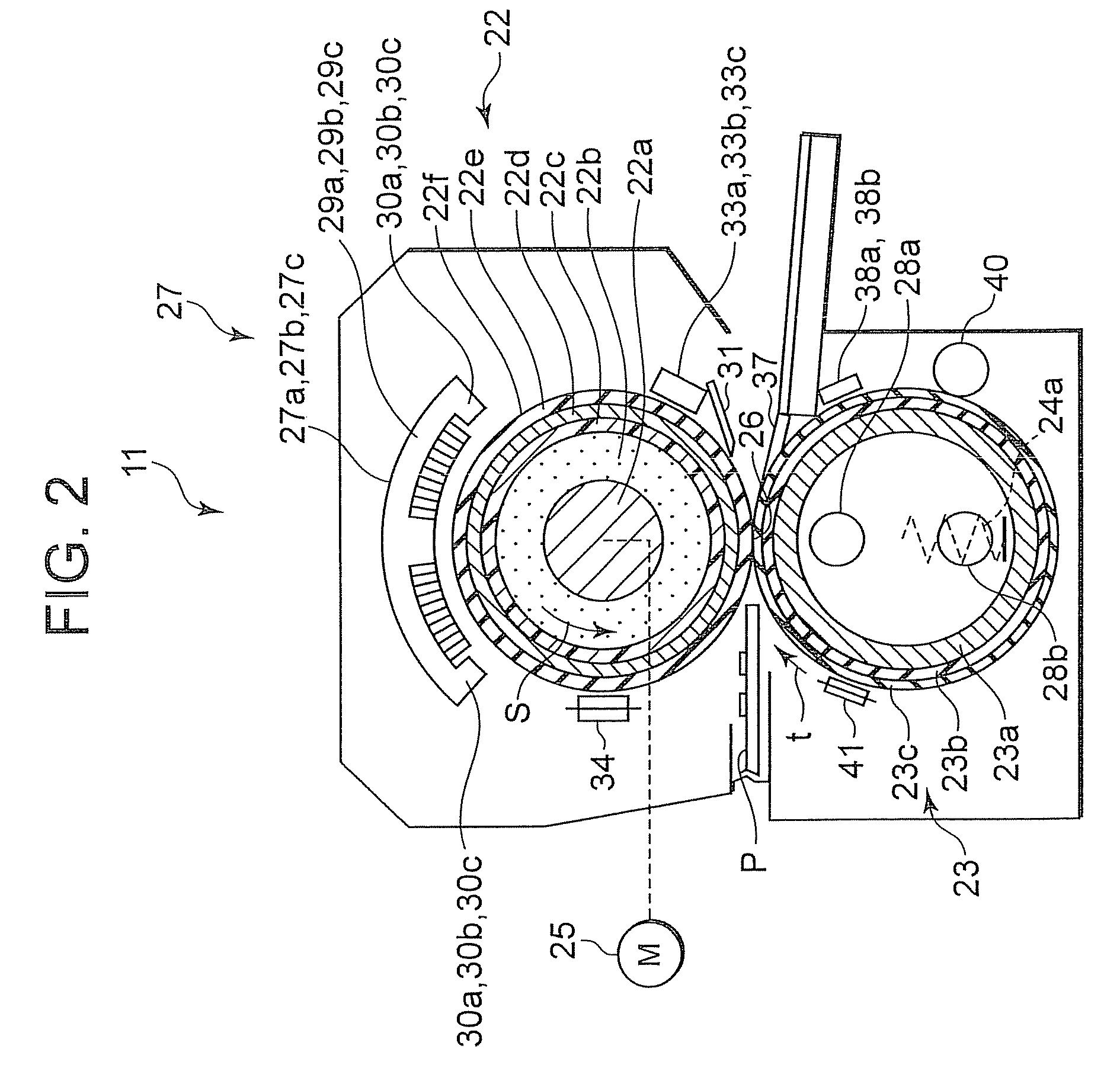

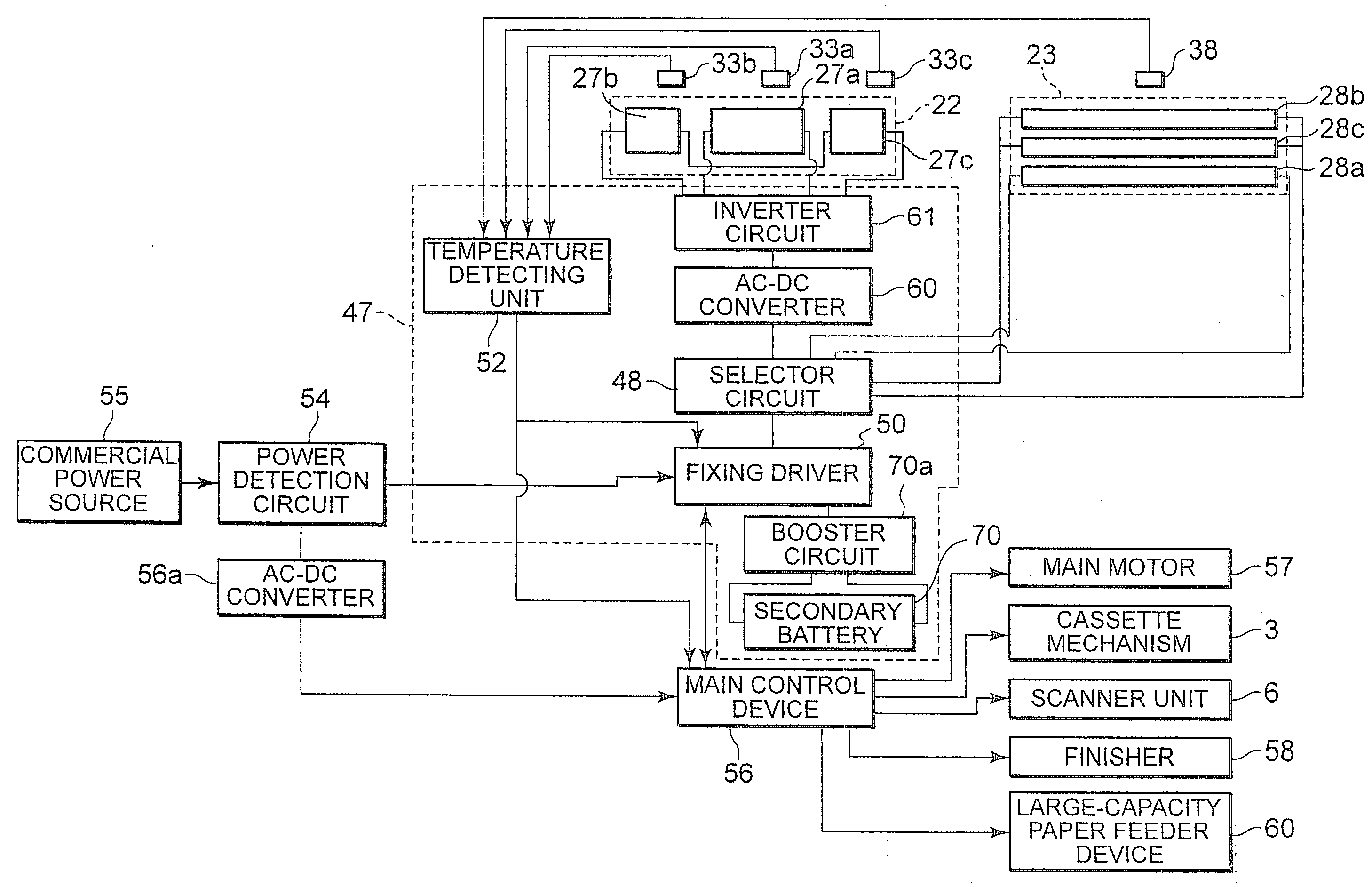

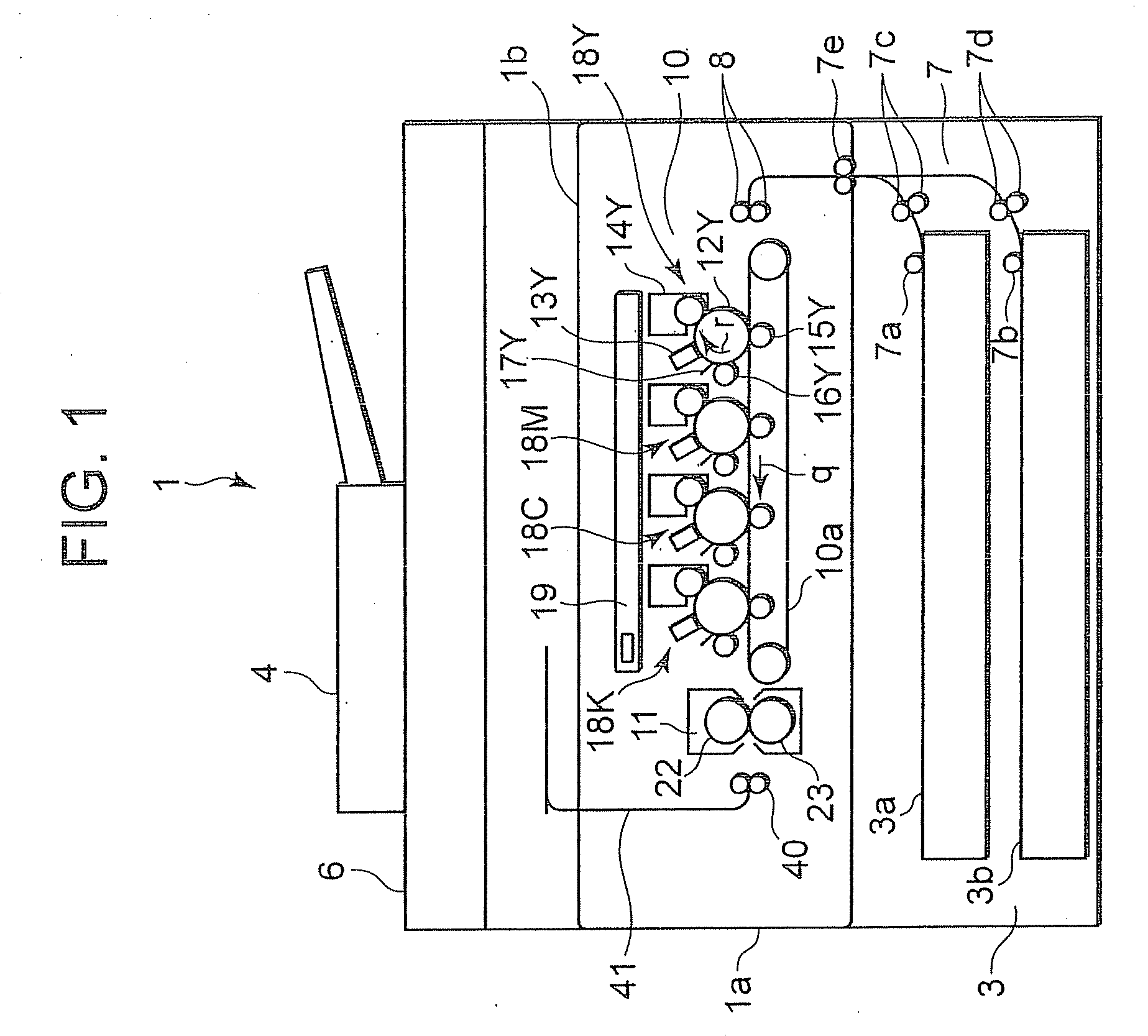

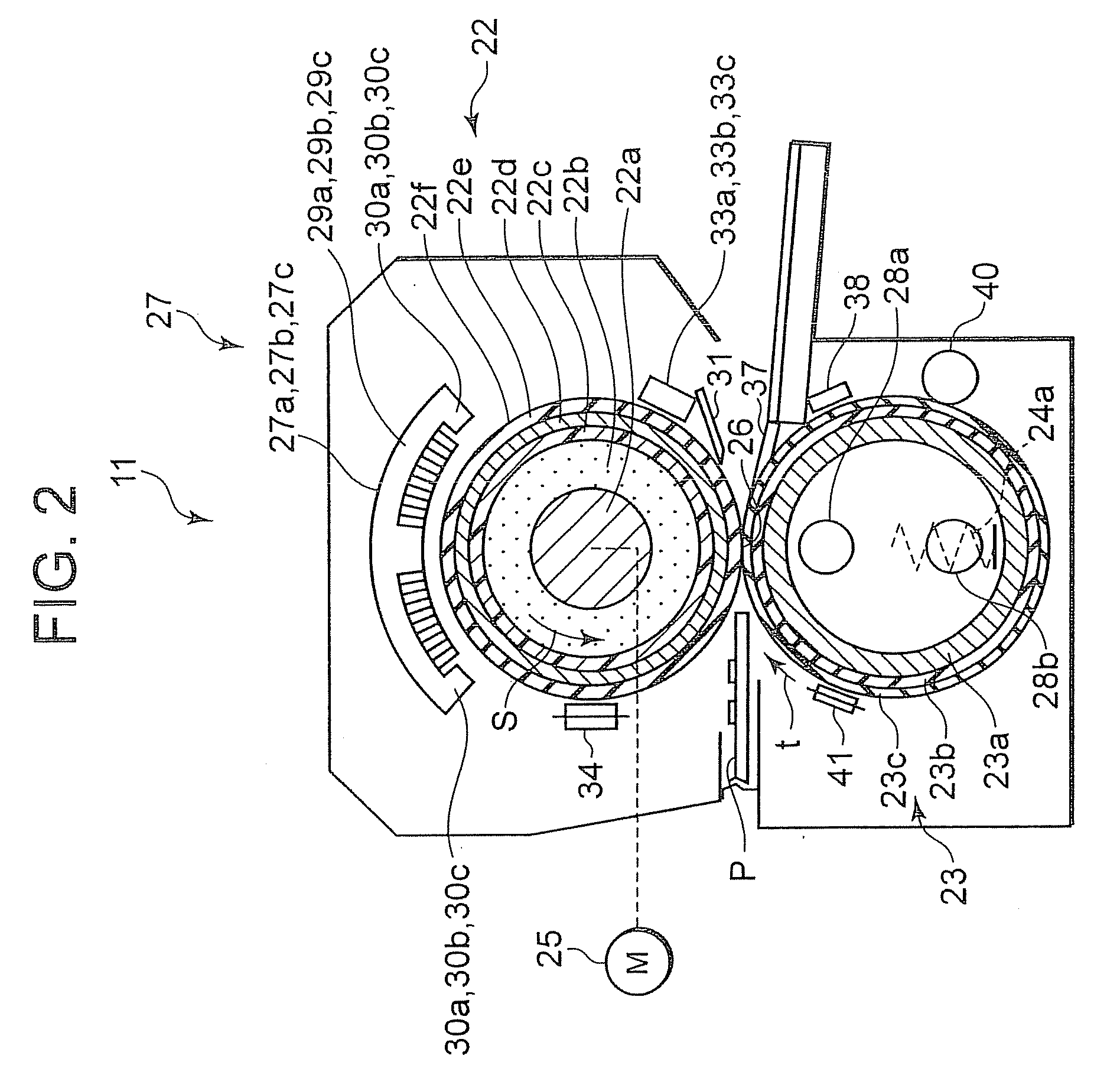

Fixing device for image forming apparatus and control method thereof

InactiveUS20080260408A1Evenly meltedWithout losing convenienceElectrographic process apparatusImage formationEngineering

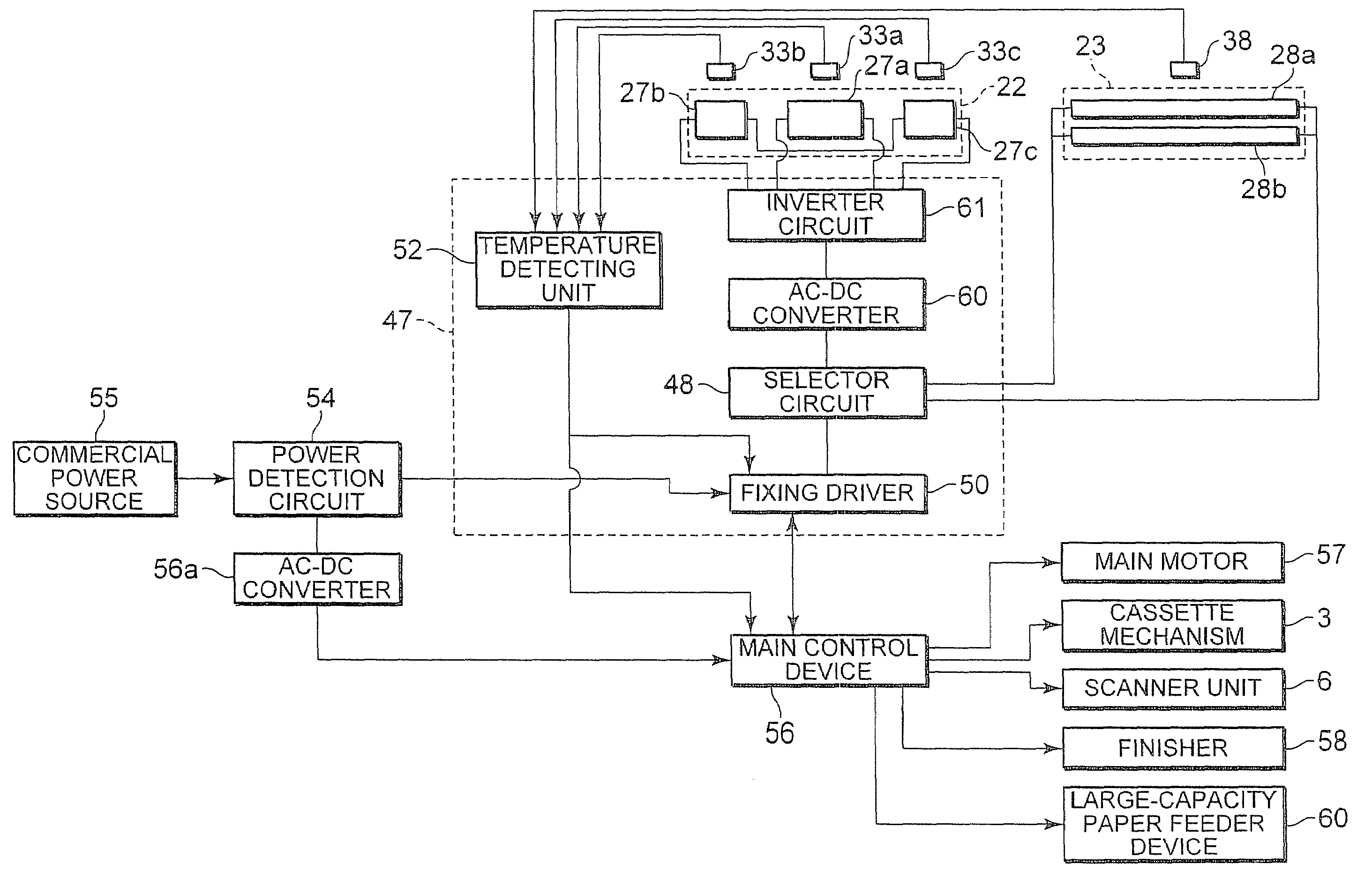

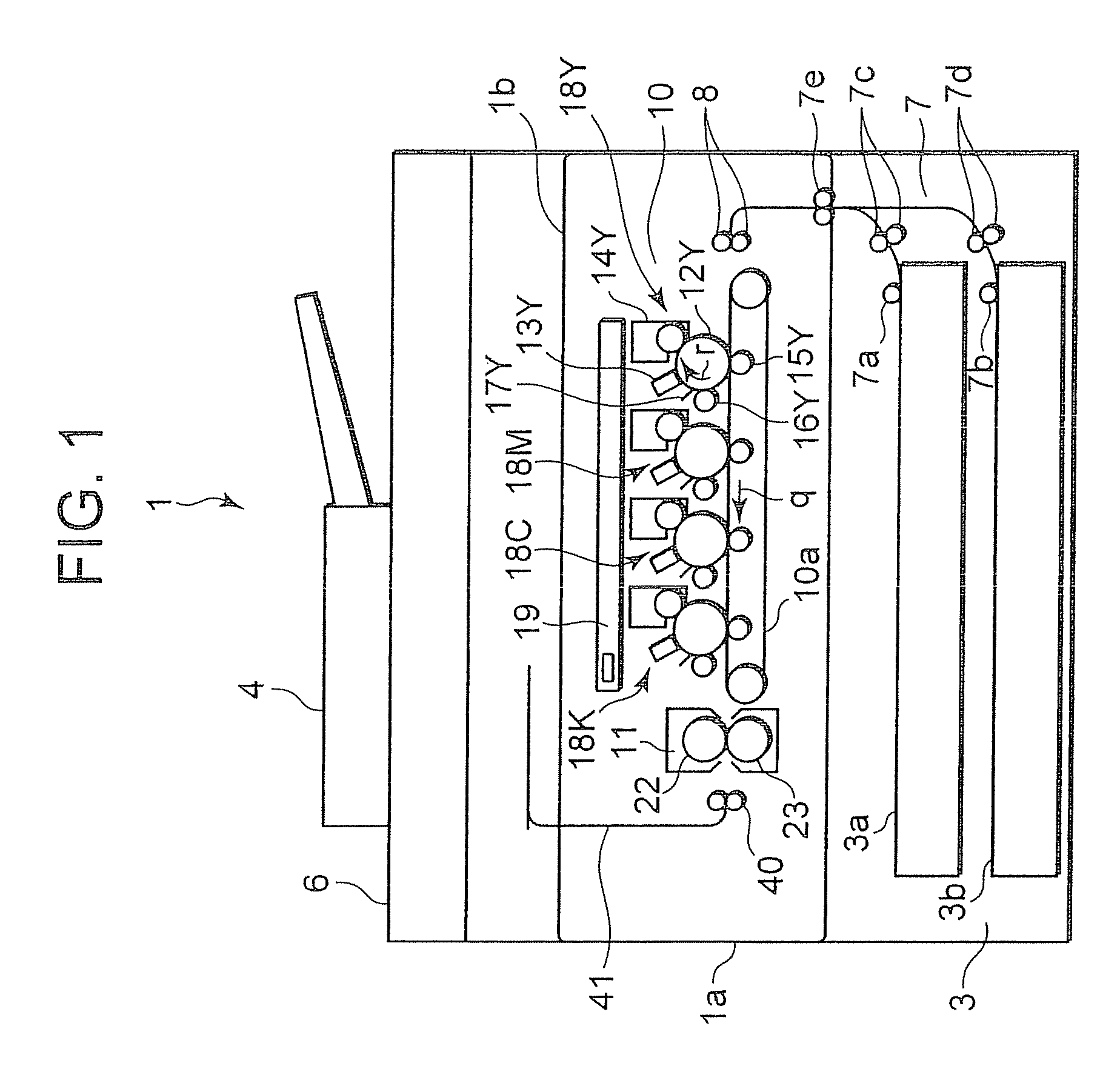

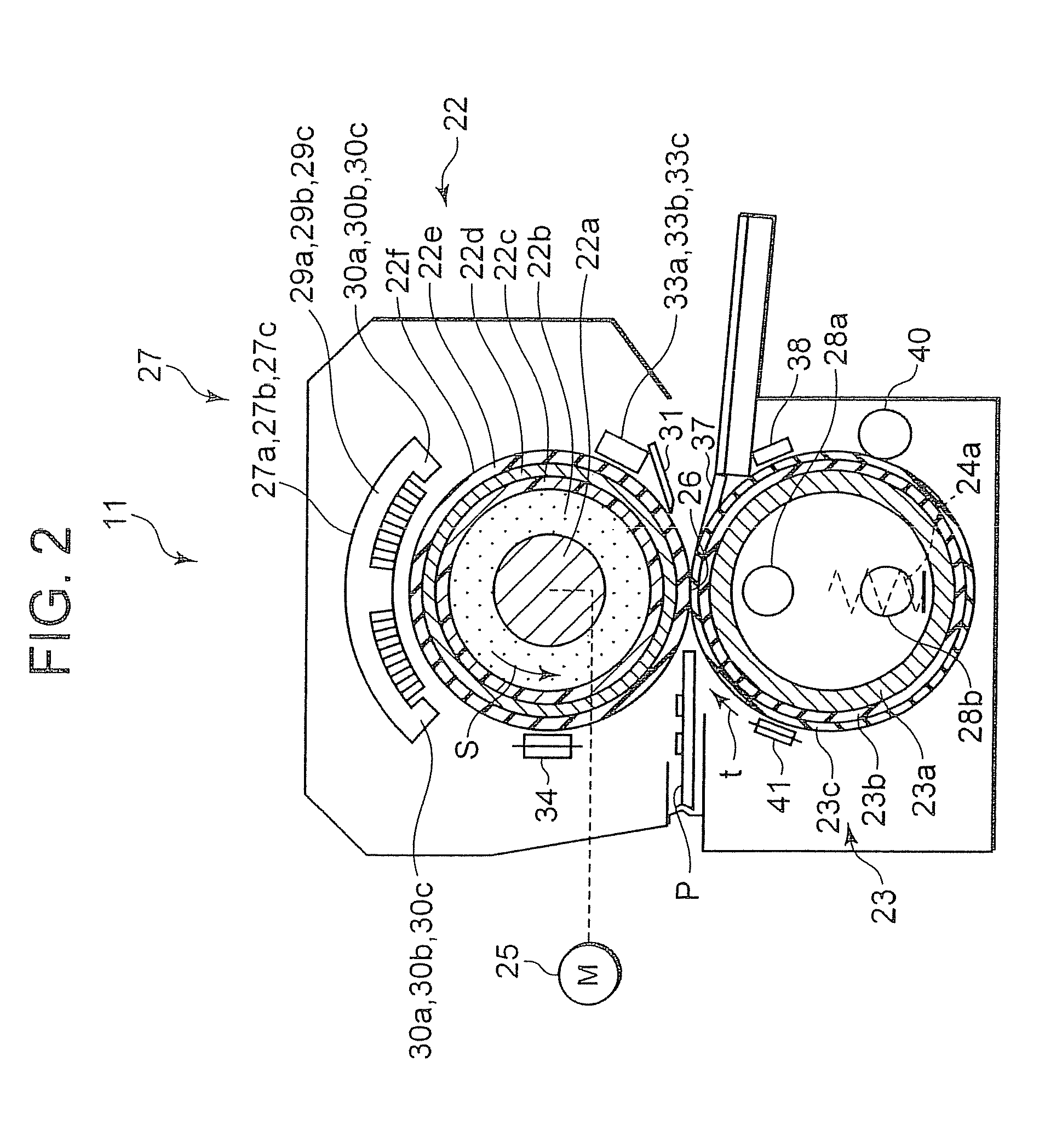

A fixing device of this invention enables variable control of power to be supplied to a heat roller side or a press roller side in accordance with the temperature of the heat roller and the press roller while each mode is carried out. The heating range of a first induction heating coil on the heat roller side and the heating range of a first halogen lamp heater on the press roller side are set differently. In a copy mode, the temperature of the heat roller and the press roller is controlled in detail, and also controlled in accordance with the size of a sheet paper. In a copy standby mode, only the power required for maintaining a set temperature is supplied.

Owner:KK TOSHIBA +1

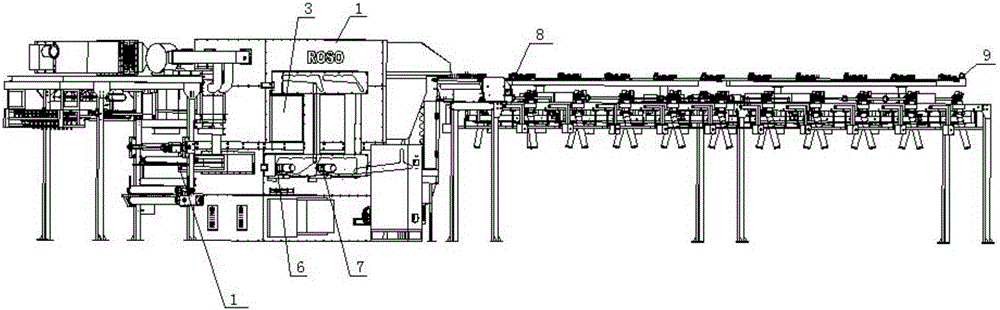

Laser lapping half penetration weld method

InactiveCN103008884AAvoid color differencesReduced processLaser beam welding apparatusColor differenceTreatment costs

The invention discloses a laser lapping half penetration weld method, which is characterized in that a protection film covers a non-penetration surface to obstruct air for welding. Because the protection film covers the non-penetration surface to obstruct air for welding, the exposed non-penetration surface of a stainless steel trolley coach steel structure is reduced and prevented from being oxidized and discolored; the original color of the outer surface of the stainless steel trolley coach steel structure can be kept attractive; the operation of electrochemical corrosion to remove oxidative stain for the exposed non-penetration surface after welding is canceled and reduced; the outer surface of the stainless steel trolley coach steel structure is protected from color difference; working procedures are reduced, the time is saved, the production efficiency is improved, and the product cost is lowered; the chemical preparation discharge and the environment pollution are reduced; and the pollution treatment cost is saved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

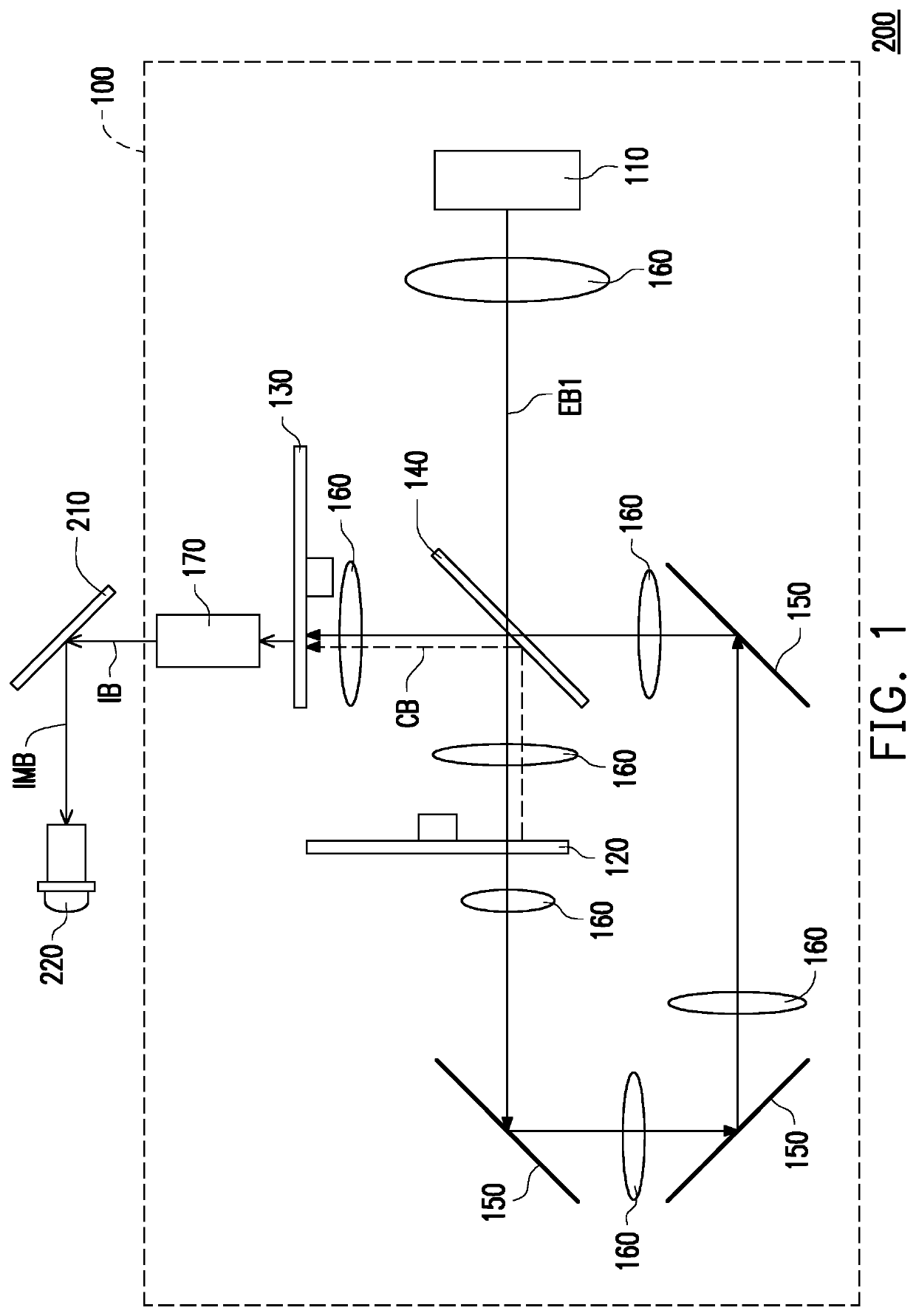

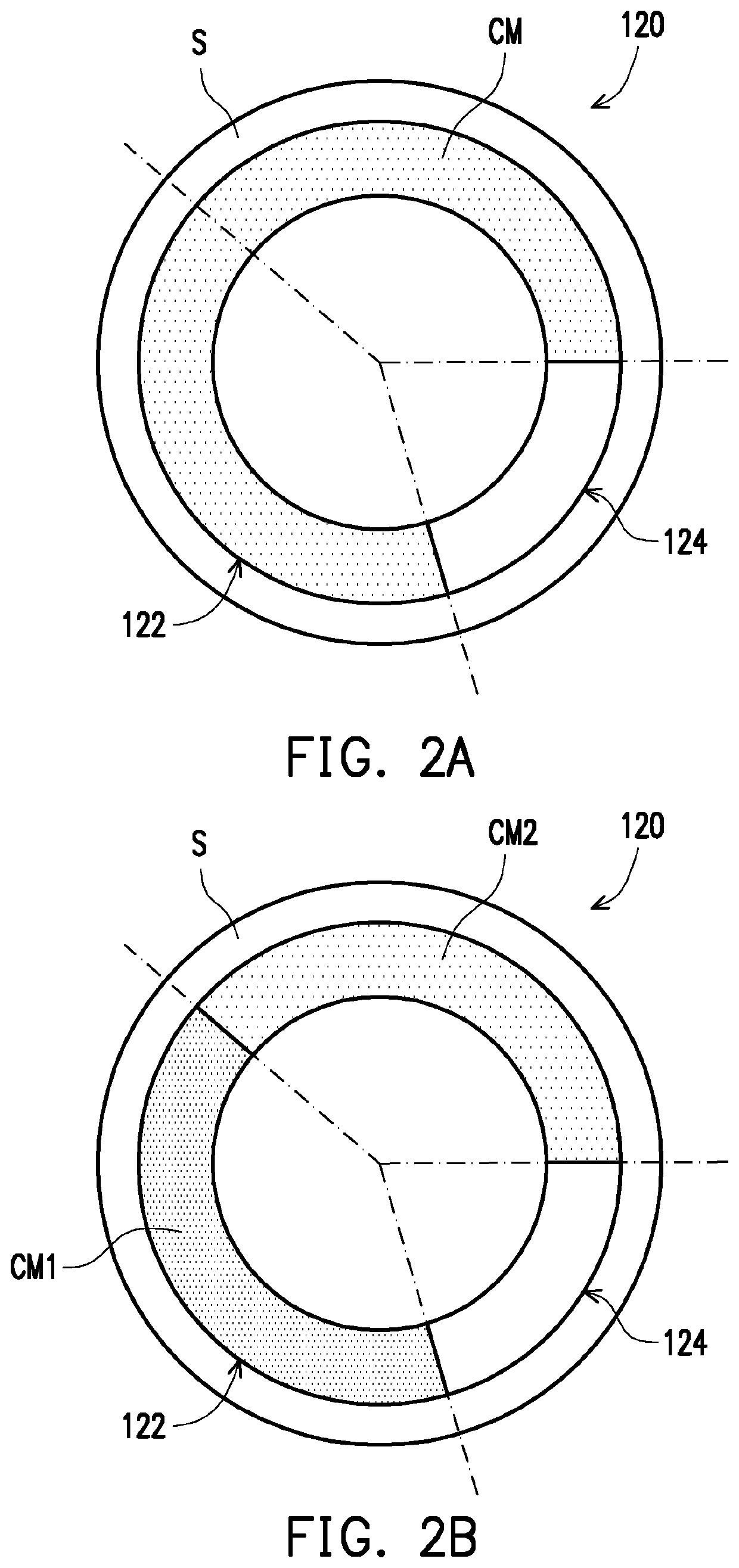

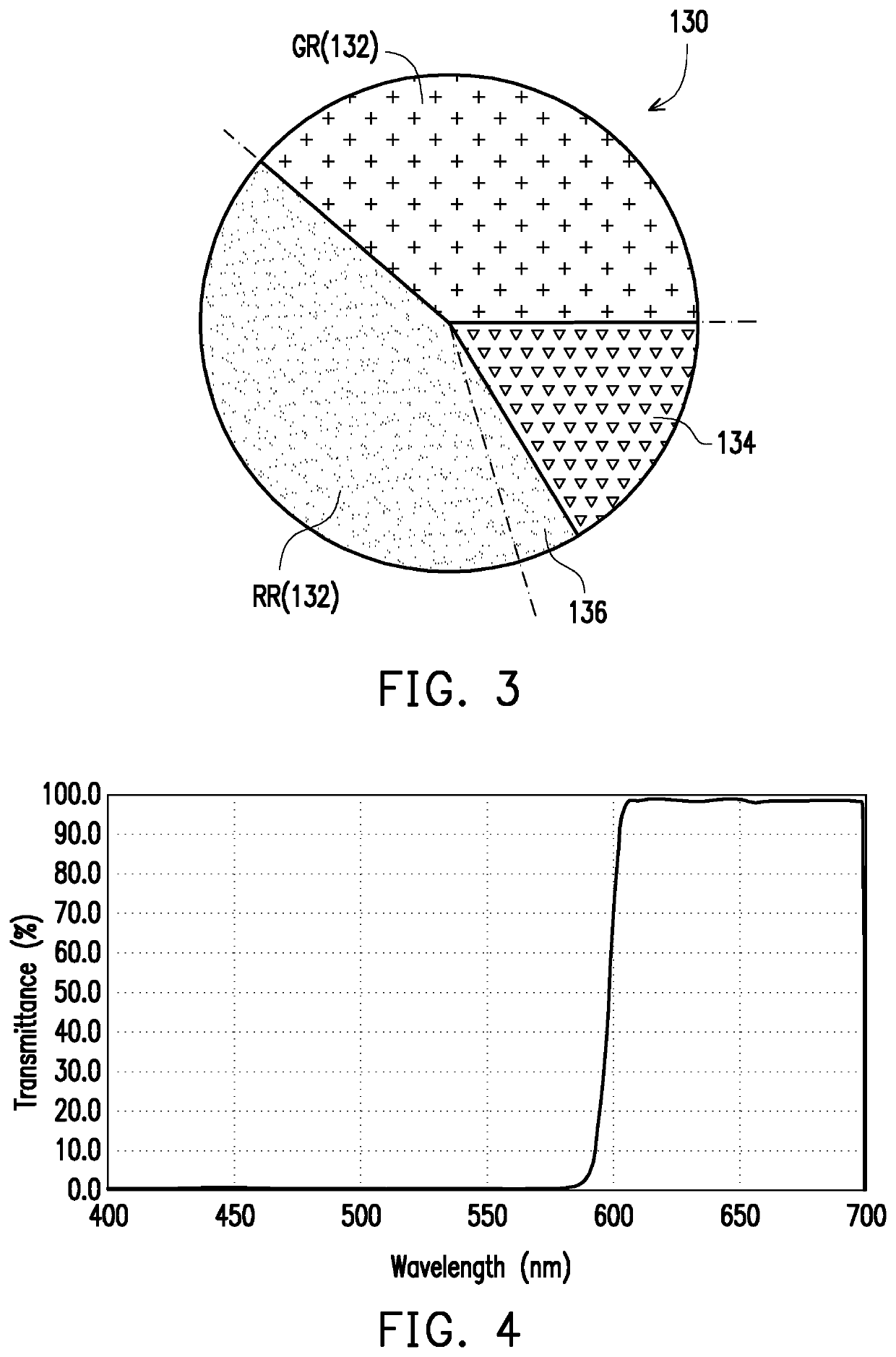

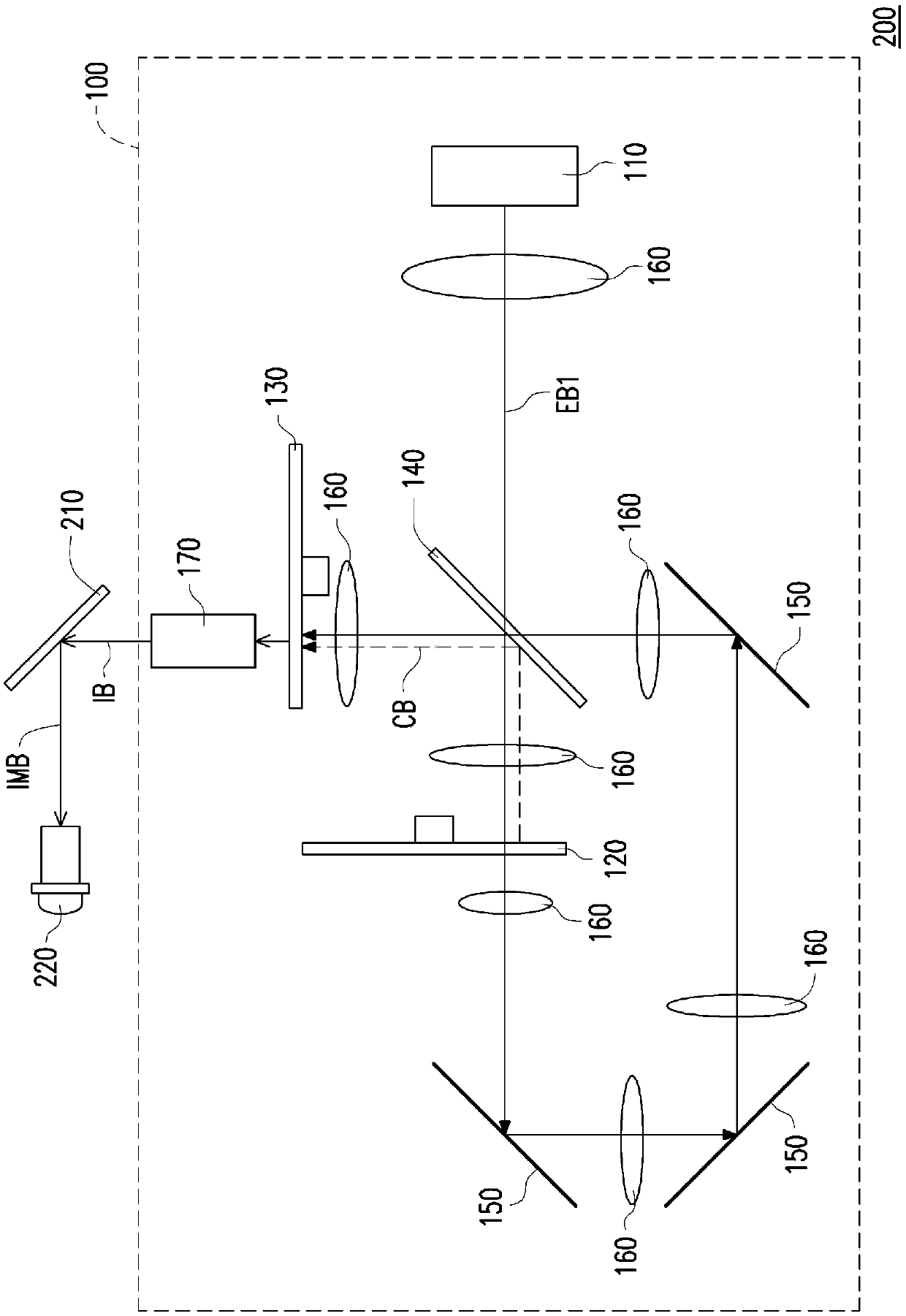

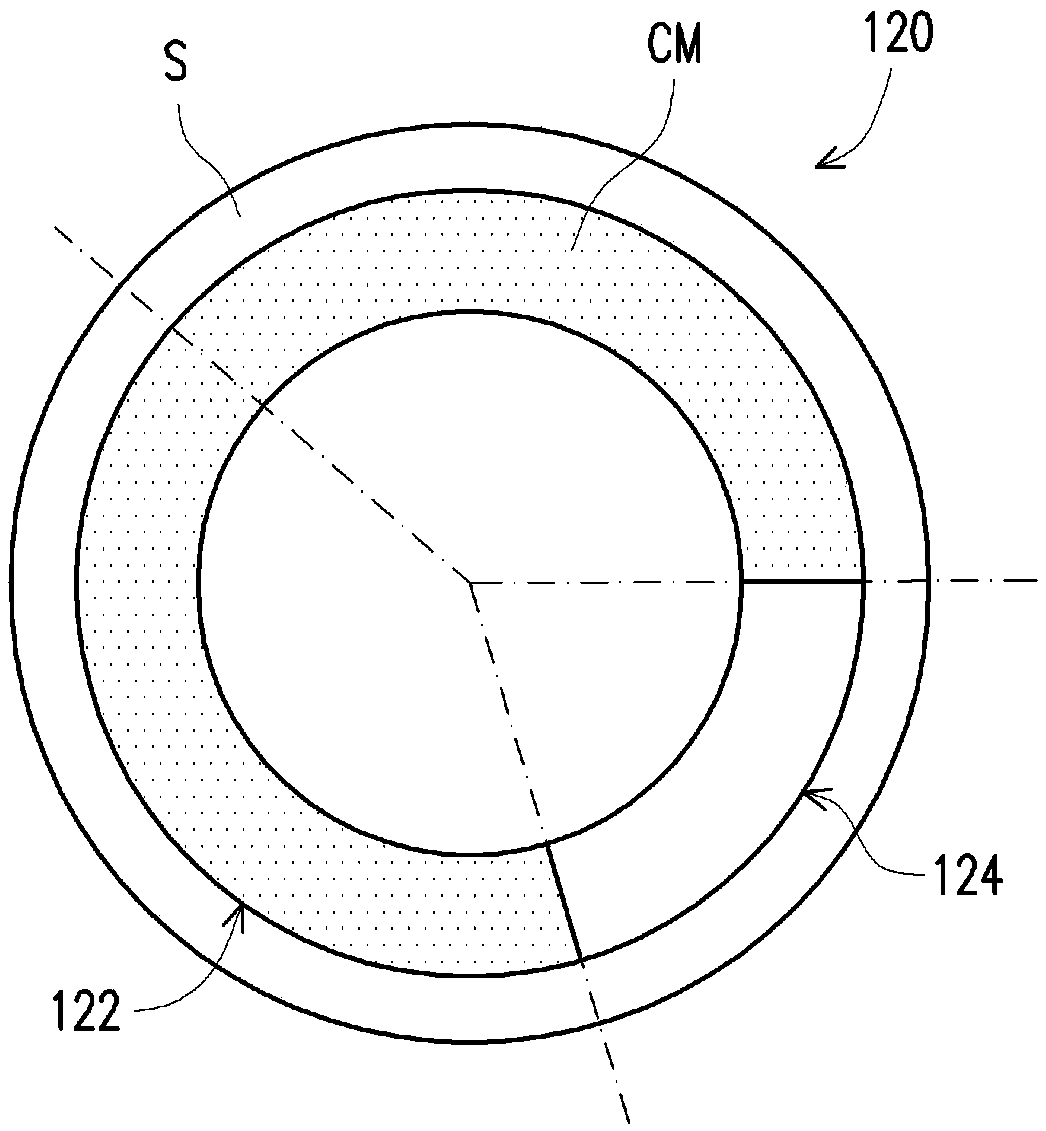

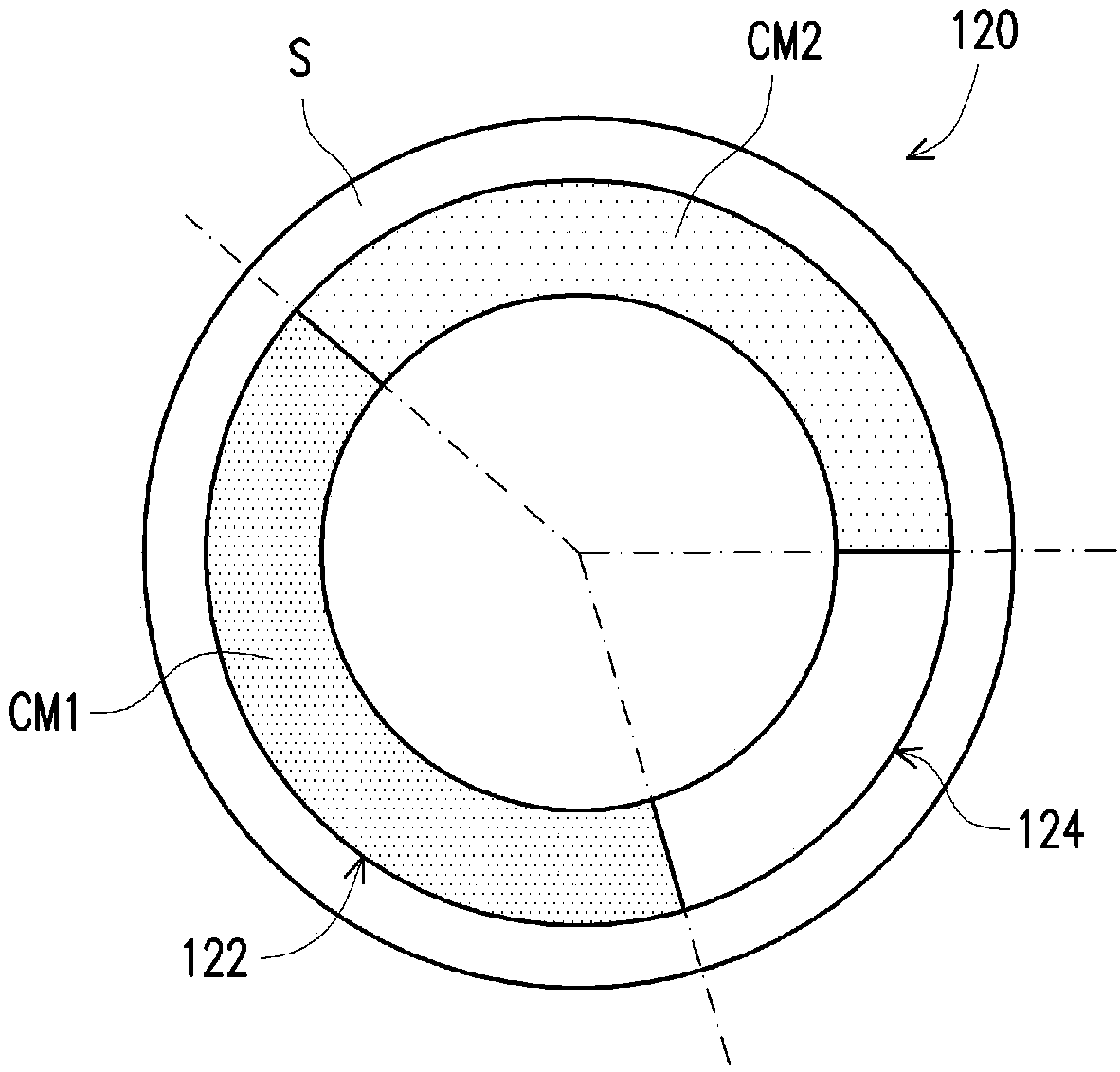

Illumination system and projection apparatus

An illumination system including a first excitation light source, a wavelength conversion wheel, and a filter wheel is provided. The first excitation light source is configured to emit a first excitation beam. The wavelength conversion wheel includes a wavelength conversion region and a first optical region. The wavelength conversion region and the first optical region alternately enter a transmission path of the first excitation beam. The first excitation beam is converted into a conversion beam by the wavelength conversion region when the wavelength conversion region enters the transmission path of the first excitation beam. The filter wheel includes a first region, a second region, and a blocking region. An angle covered by the second region in a circumferential direction is smaller than an angle covered by the first optical region. A projection apparatus is also provided.

Owner:CORETRONIC

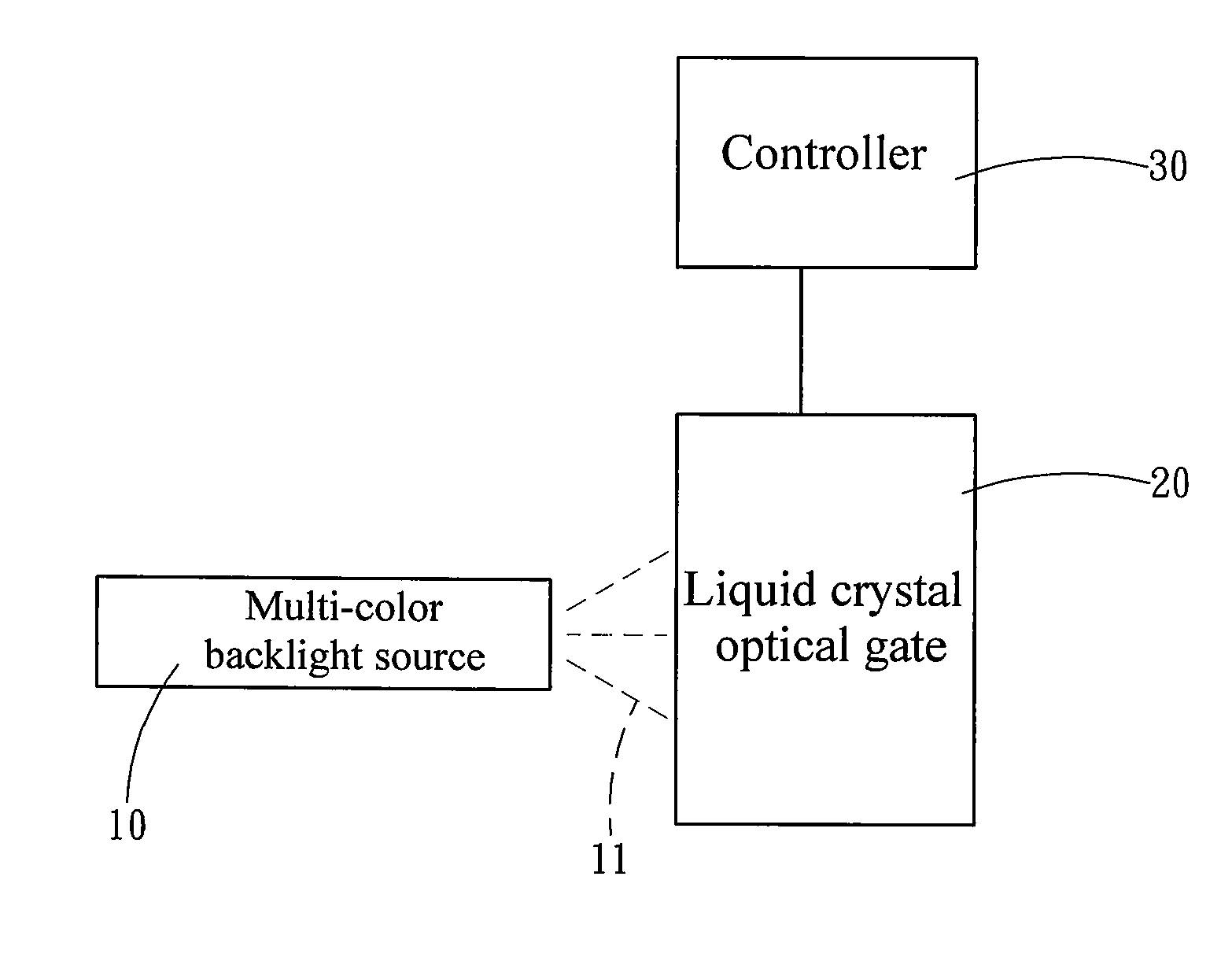

Color sequence offset modulation method and device

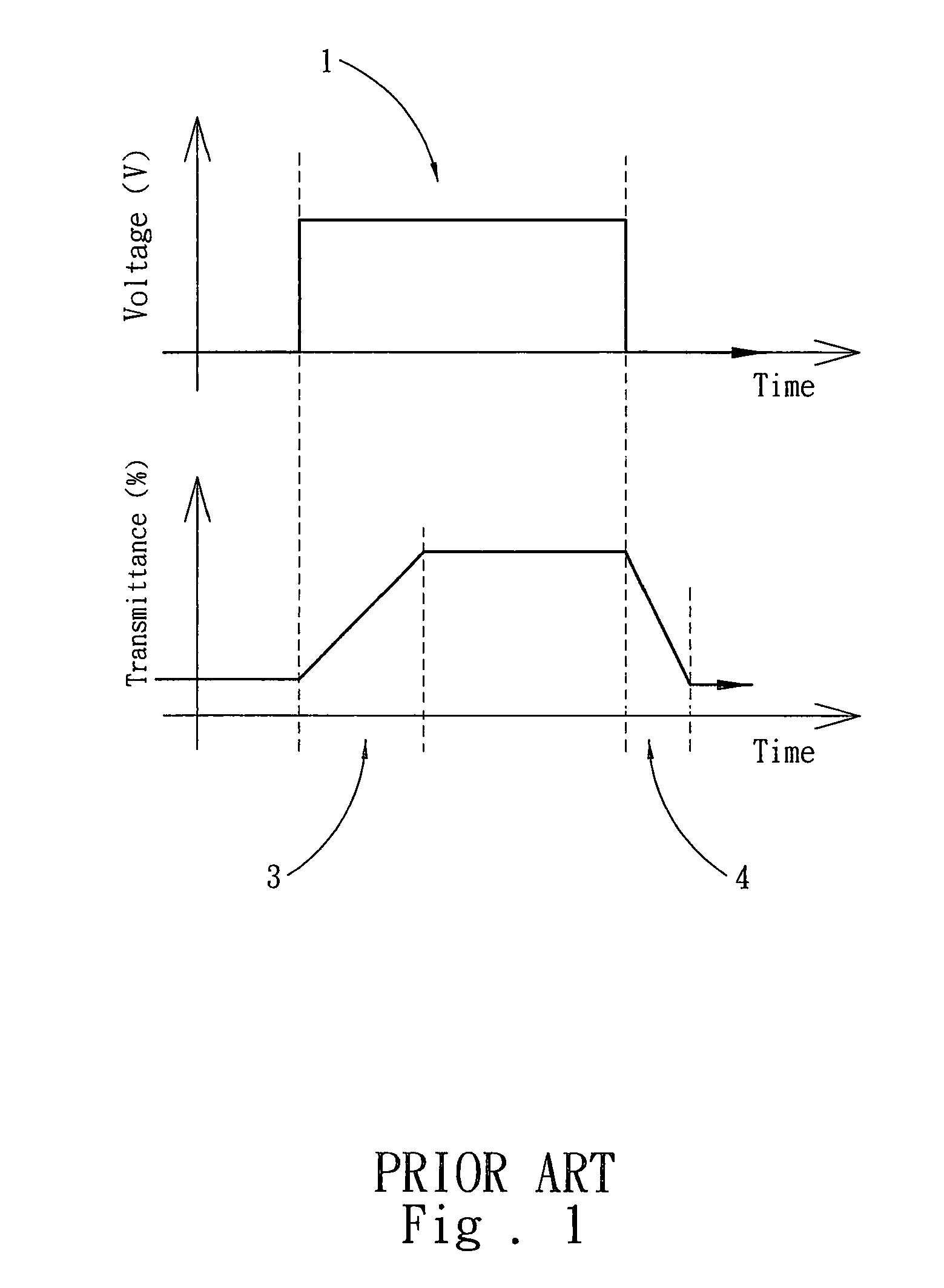

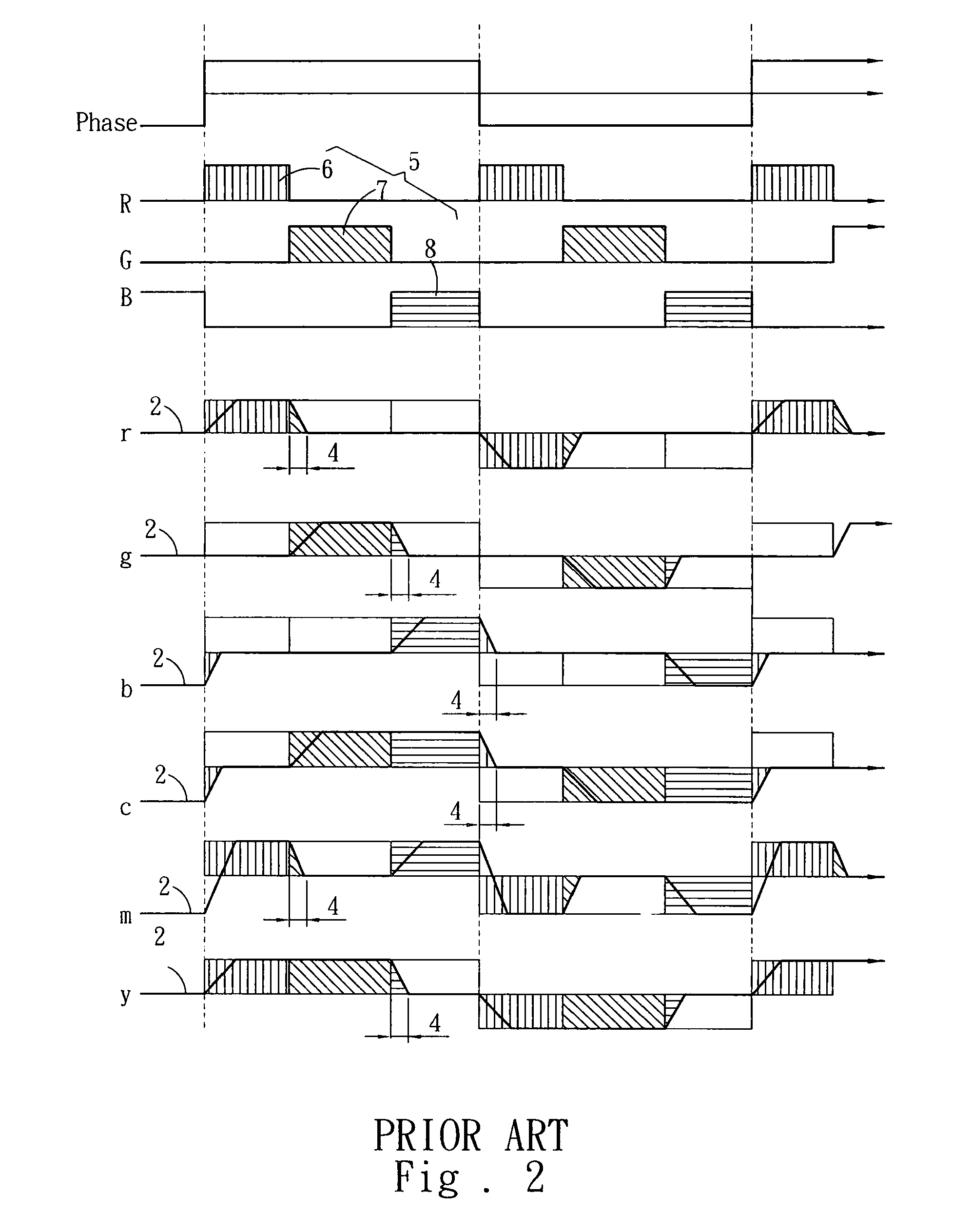

InactiveUS20100117945A1Avoid color deviationAvoid color differencesStatic indicating devicesDelayed responseDark interval

The present invention discloses a color sequence offset modulation method and device, which modulates the colored backlights of a multi-color backlight source to have a dark interval in the time points of shifting the colored backlights and makes the dark interval coincide with the close delay interval caused by the delayed response of liquid crystal, whereby the latter colored backlight will not mix with the former colored backlight during the close delay interval, wherefore the present invention can avoid the color deviation caused by color mixing and can present the designed colors correctly.

Owner:POWERTIP TECH

Thermal transfer printing production technology for paint-free plate

InactiveCN103144151ADynamicCtiveWood veneer joiningWood layered productsThermal printingWater temperature

The invention discloses a thermal transfer printing production technology for a paint-free plate. The thermal transfer printing production technology comprises the following steps that raw wood is put in a steaming vat to be steamed at a temperature of 100 DEG C for one week, and oil in the raw wood is steamed out; the raw wood is fragmented to form strip-shaped plates which are 20 to 100mm in width, 10 to 50mm in thickness and unlimited in length; side surfaces of the plates are combed, so that the plates are easy to splice; the side surfaces of the plates, which are used for being spliced, are pasted with glue; the plates are spliced according to required length; the spliced plates are cold-pressed at a temperature of 10 DEG C to 50 DEG C for 0.5 to 26 hours, so as to enable the plates spliced together to form a whole plate; and the procedures of single rolling, single rolling coloring, thermal printing, coloring and the like are conducted. The heat transfer printing production technology for the paint-free plate, which is disclosed by the invention, is simple, is easy to operate and is low in cost, the produced paint-less plate is reliable in quality and has stereoscopic aesthetic feeling, and the service life of the paint-less plate can be prolonged, so the greenness is realized and the environment is protected.

Owner:SHANGHAI TIANRUI NEW ENVIRONMENTAL PROTECTION MATERIAL

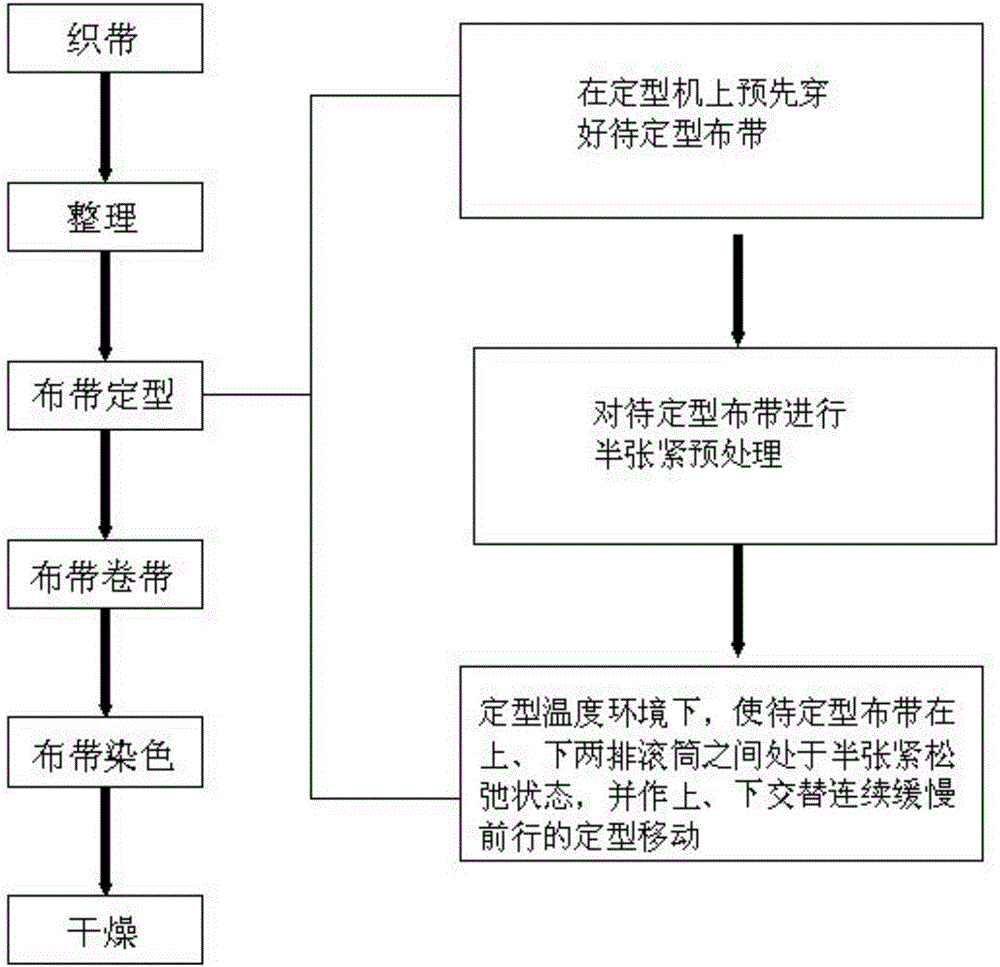

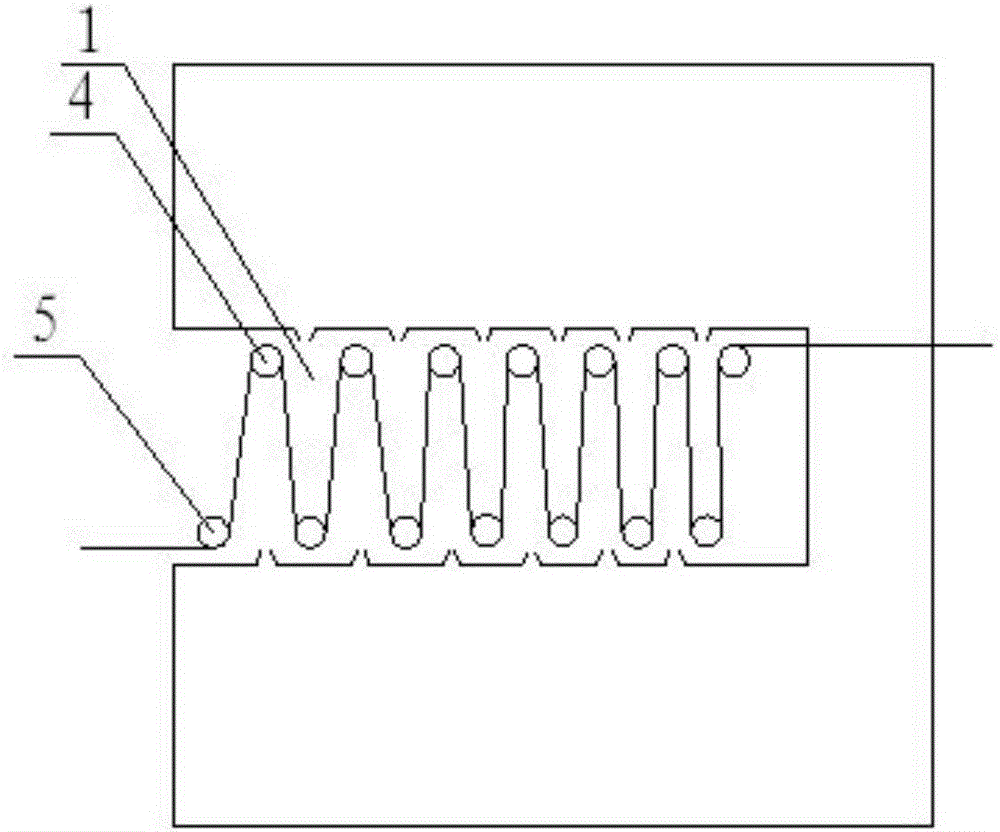

Production technology of zipper cloth tape

InactiveCN105220388AAvoid color differencesTraining step improvementsHeating/cooling textile fabricsElectric machineryEngineering

The invention discloses a production technology of a zipper cloth tape. The production technology comprises a cloth tape setting process, wherein the cloth tape setting process comprises the following steps: penetrating a to-be-set cloth tape on a setting machine in advance, carrying out semi-tensioning pretreatment on the to-be-set cloth tape, starting the setting machine, continuously feeding the to-be-set cloth tape into a setting chamber of the setting machine in a semi-tensioning state by using a tension constant control device driven by a first motor; enabling the to-be-set cloth tape to be in a semi-tensioning relaxed state between upper and lower rows of rollers in the setting chamber, and carrying out up-and-down alternately continuous and slow forward setting movement to a tape outlet direction of the setting chamber, so as to obtain the set cloth tape with the shrinking percentage of 1%-7%; and controlling the rotating speeds of the motors, and enabling the set cloth tape to reach the required shrinking percentage. According to the production technology, the cloth tape is shrunk in set in advance, so that the shrinkage amount is reduced in subsequent dyeing process, and further cloth tape indentation is prevented; the color difference of a zipper among the upper layer, the middle layer and the lower layer in the dyeing process is avoided; and the cloth tape dyeing uniformity is improved.

Owner:CHENGDU ROCK SOLID AUTOMATION TECH

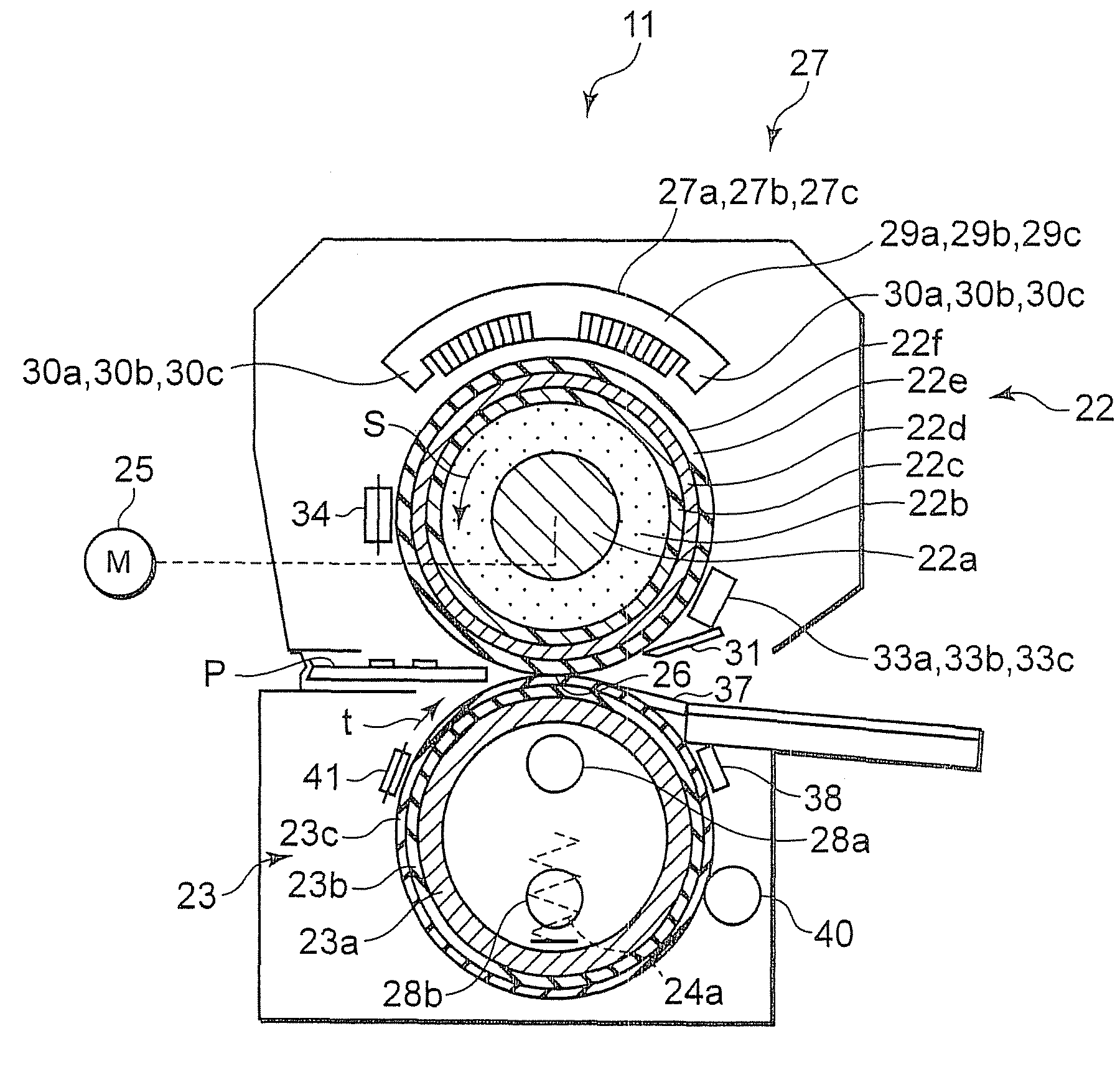

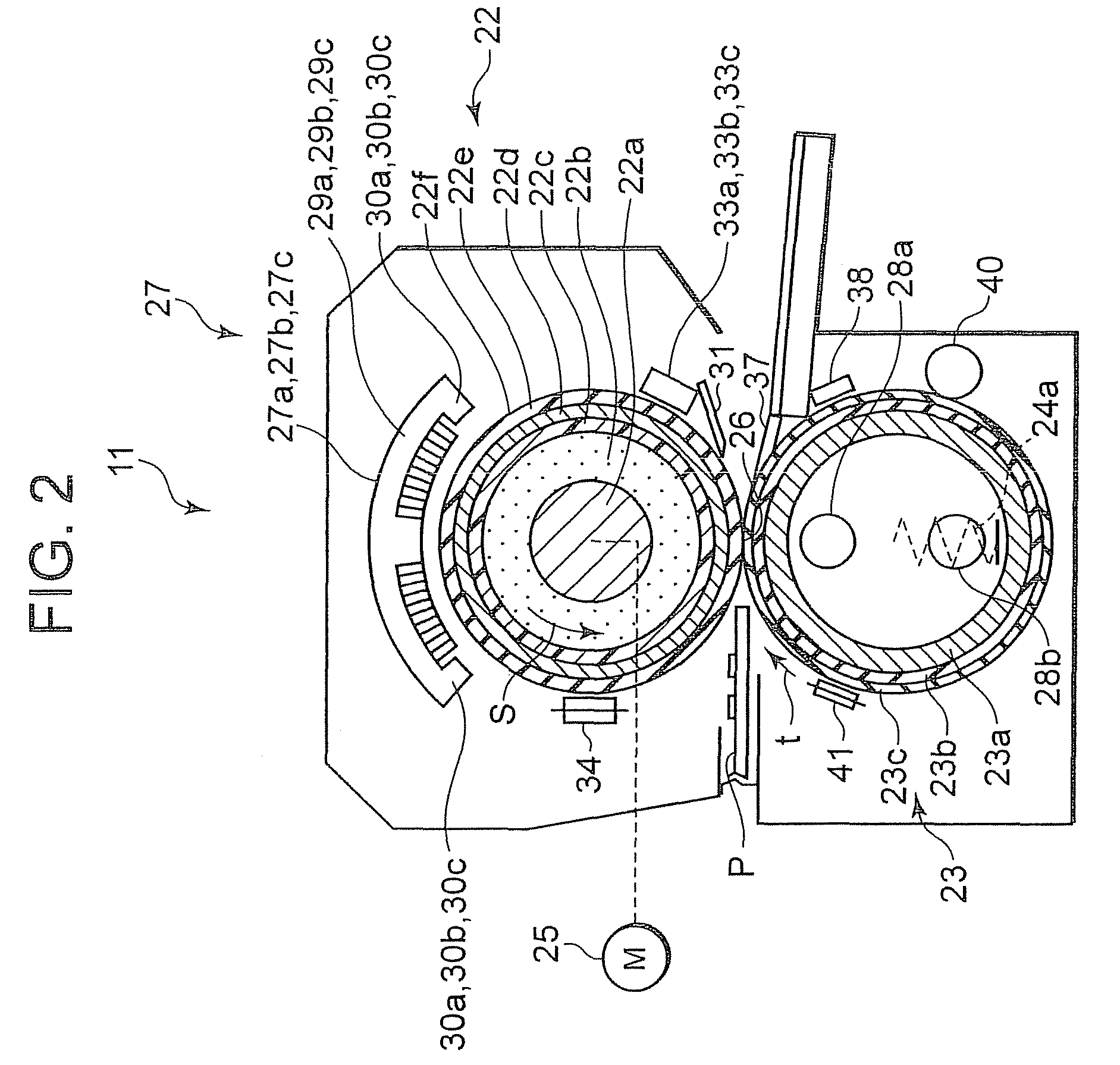

Fixing device for image forming apparatus and control method thereof

InactiveUS7792450B2Evenly meltedNot lose convenienceElectrographic process apparatusImage formationEngineering

Owner:KK TOSHIBA +1

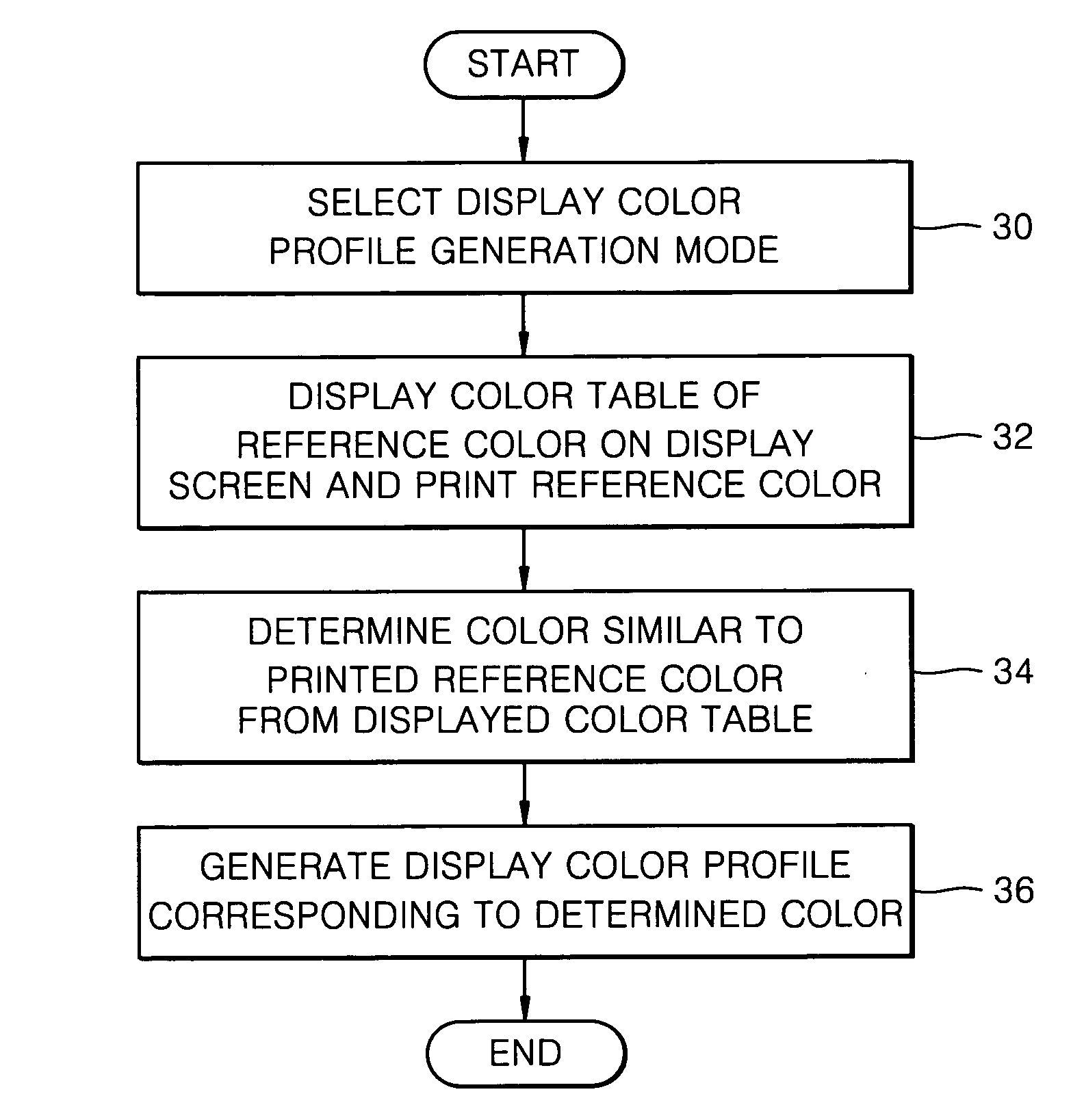

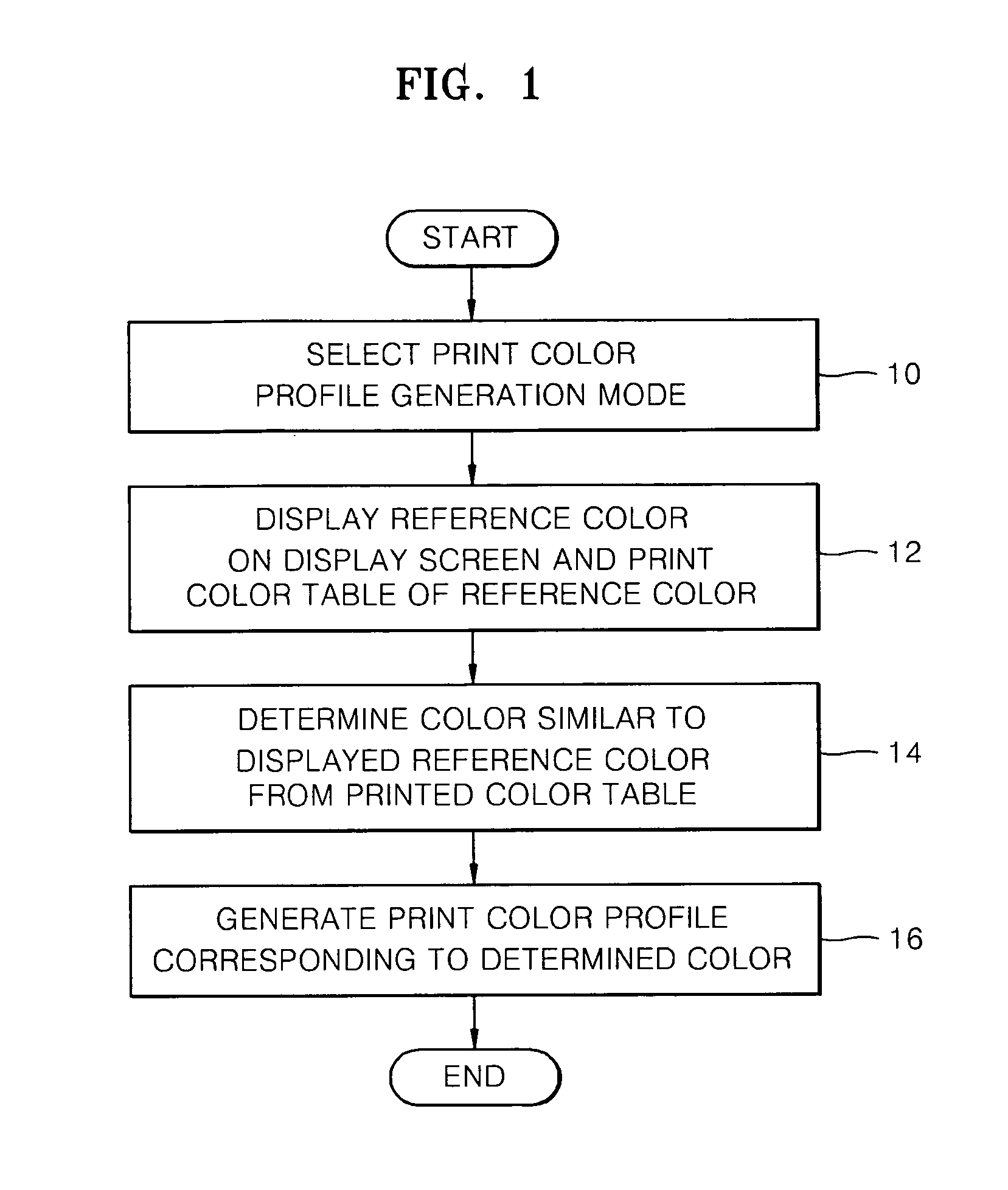

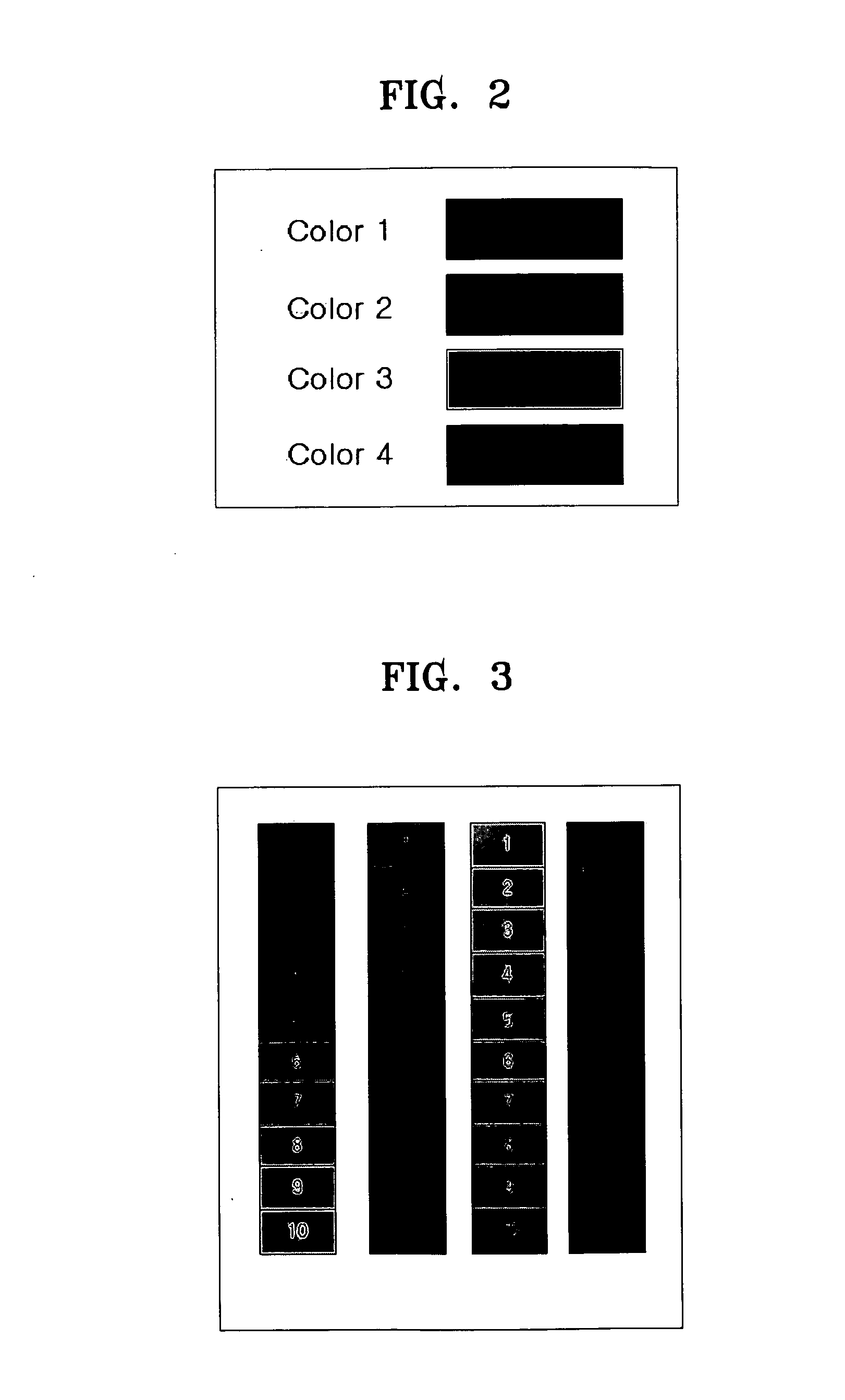

Color profile generation method and apparatus

InactiveUS20070182754A1Avoid color differencesDigitally marking record carriersDigital computer detailsImage formationColor table

A color profile generation method and apparatus are provided, in which at least one of a reference color and a color table of the reference color on a display screen of an image forming device is displayed and at least one of the reference color and the color table that is not displayed on the display screen is printed, a similar color is determined using the reference color and the color table, and a color profile is generated corresponding to the determined color. Accordingly, color of an image displayed on a display screen of an image forming device are matched with colors of an image printed on a printing medium.

Owner:S PRINTING SOLUTION CO LTD

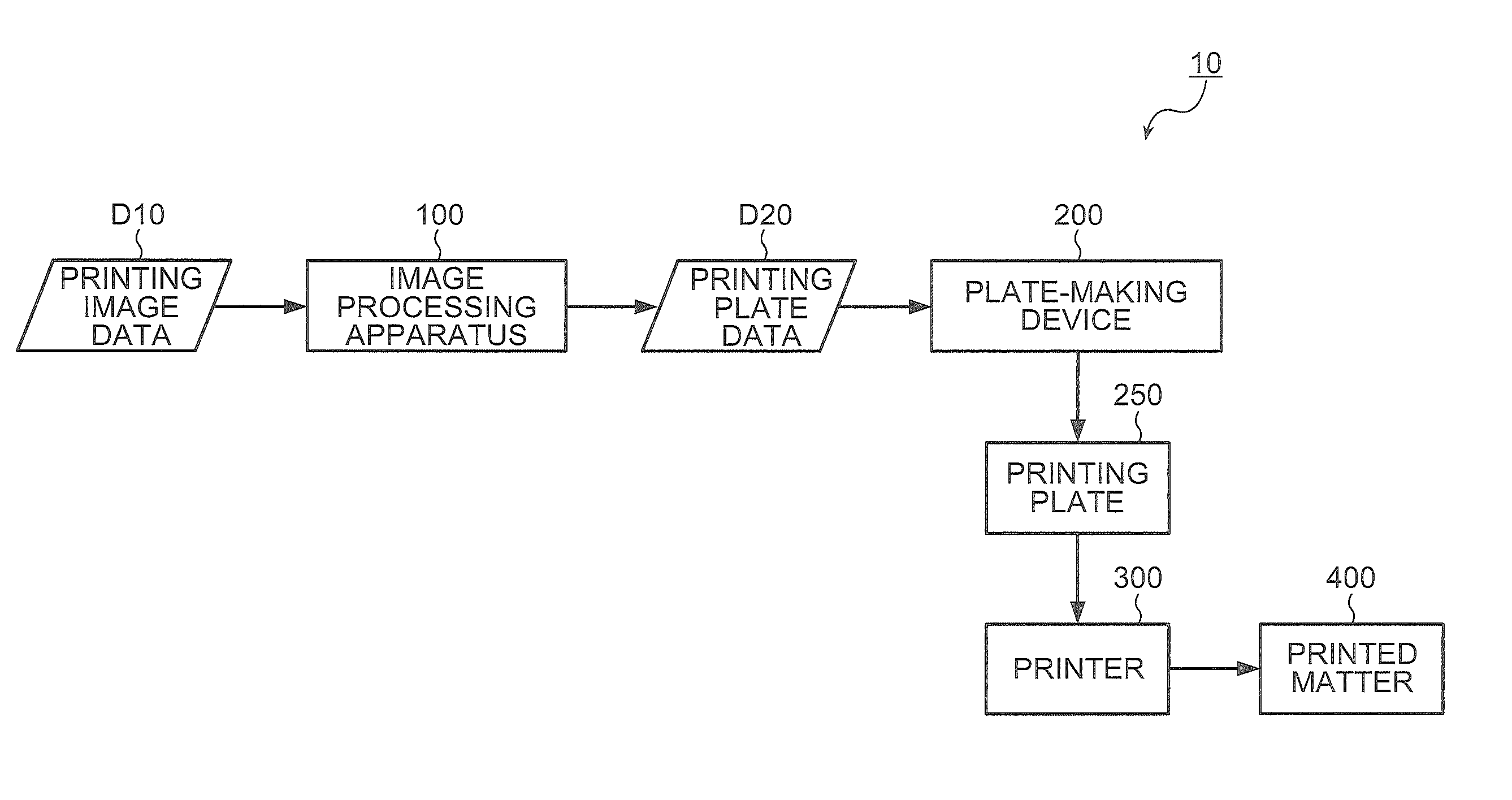

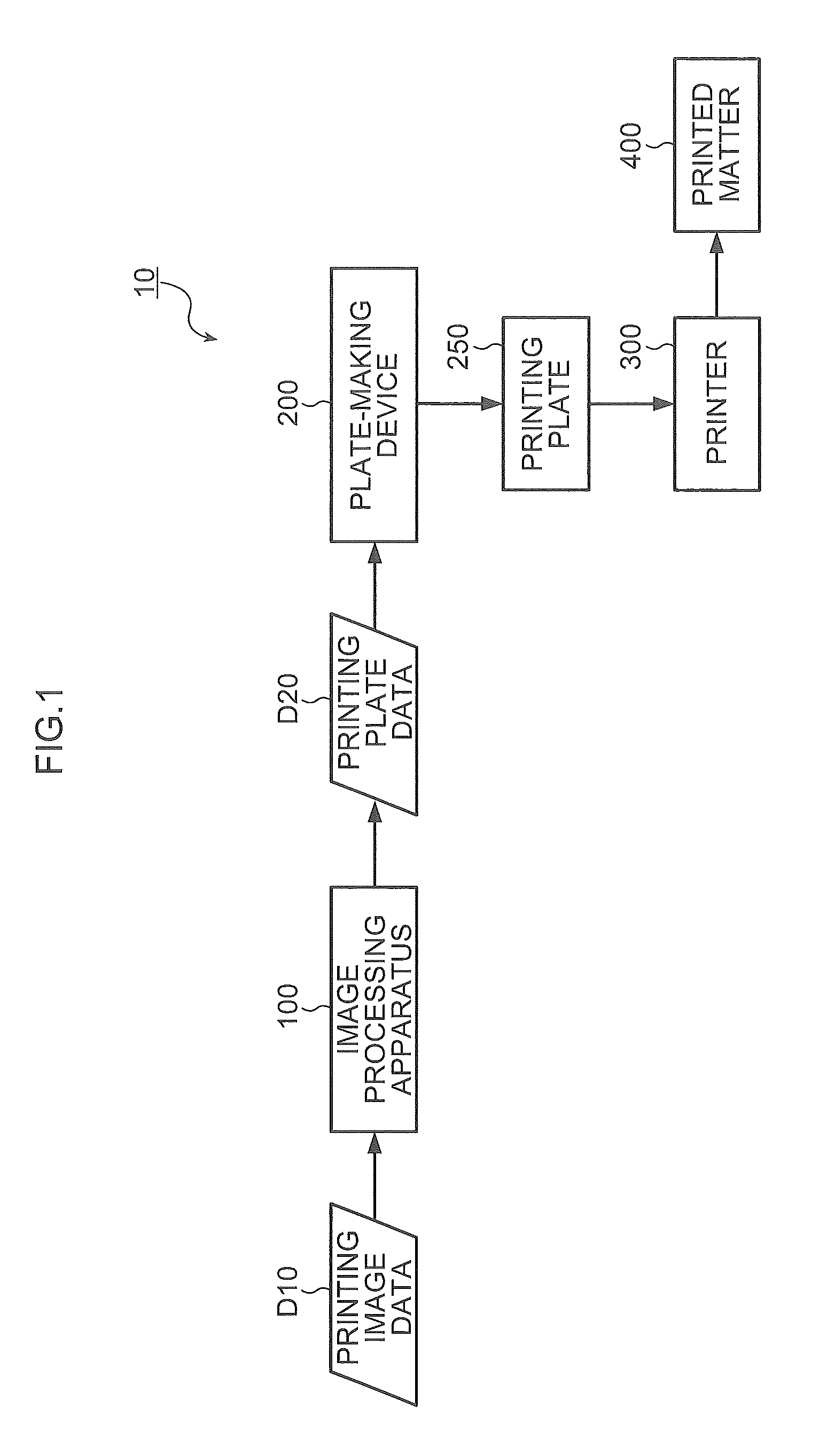

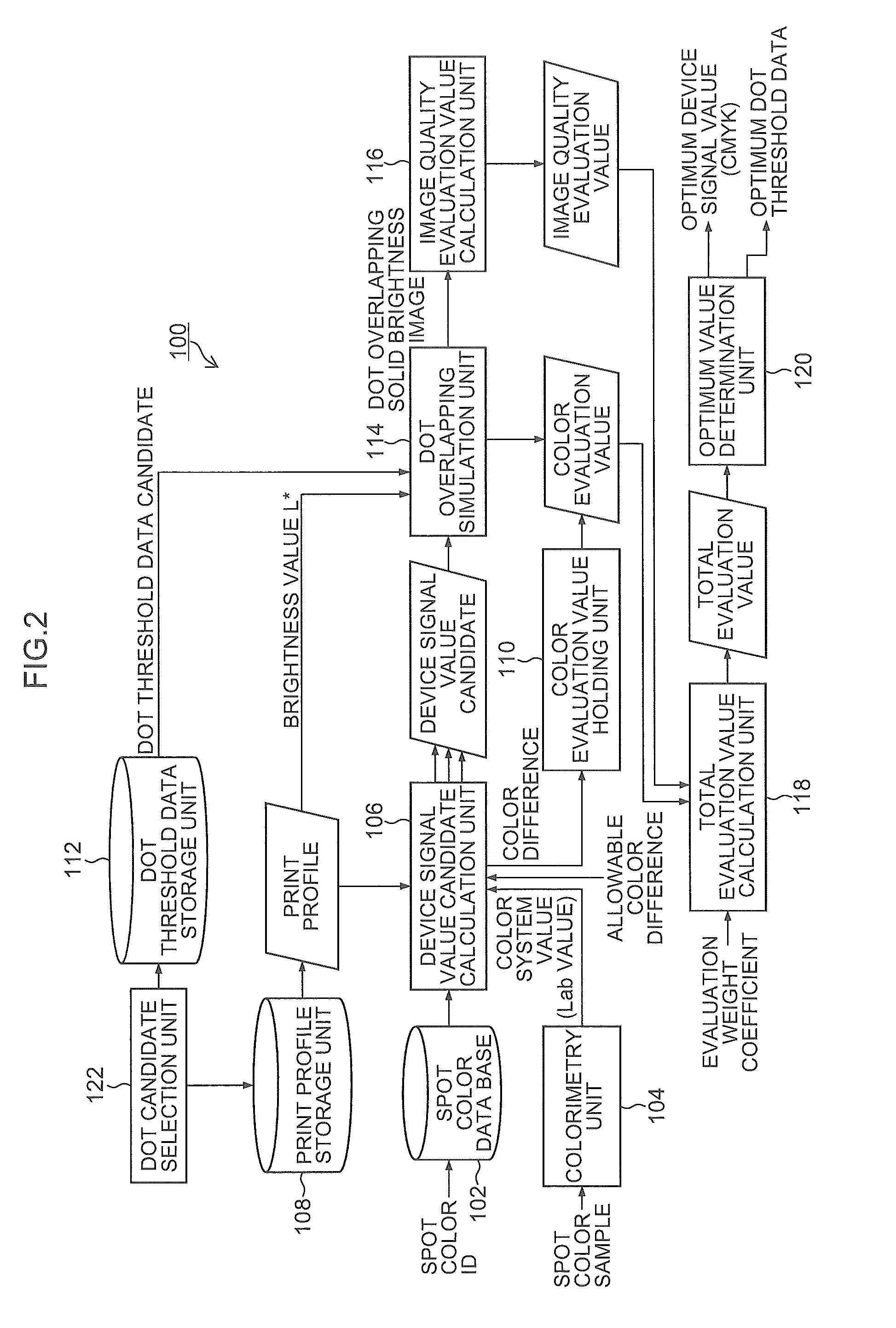

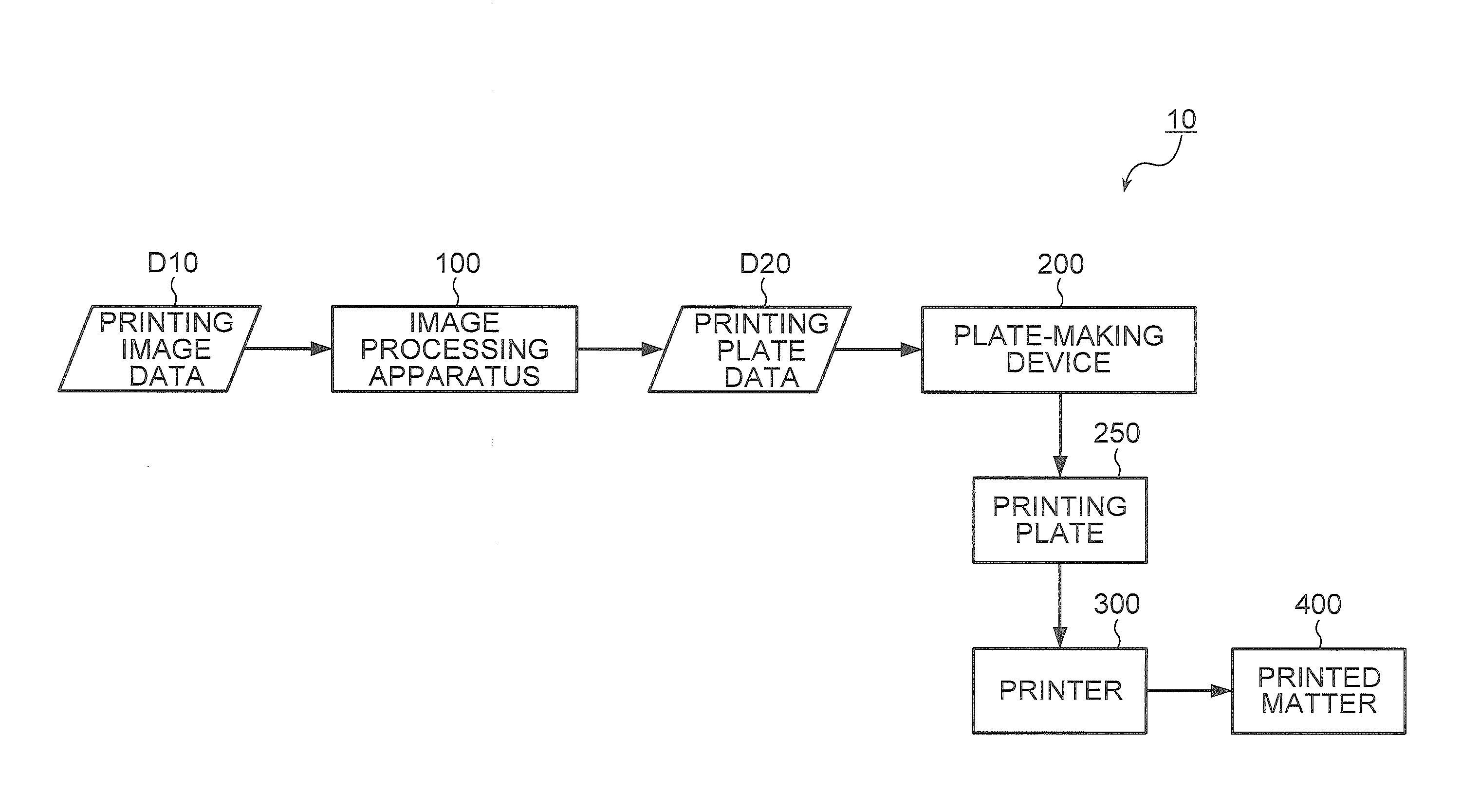

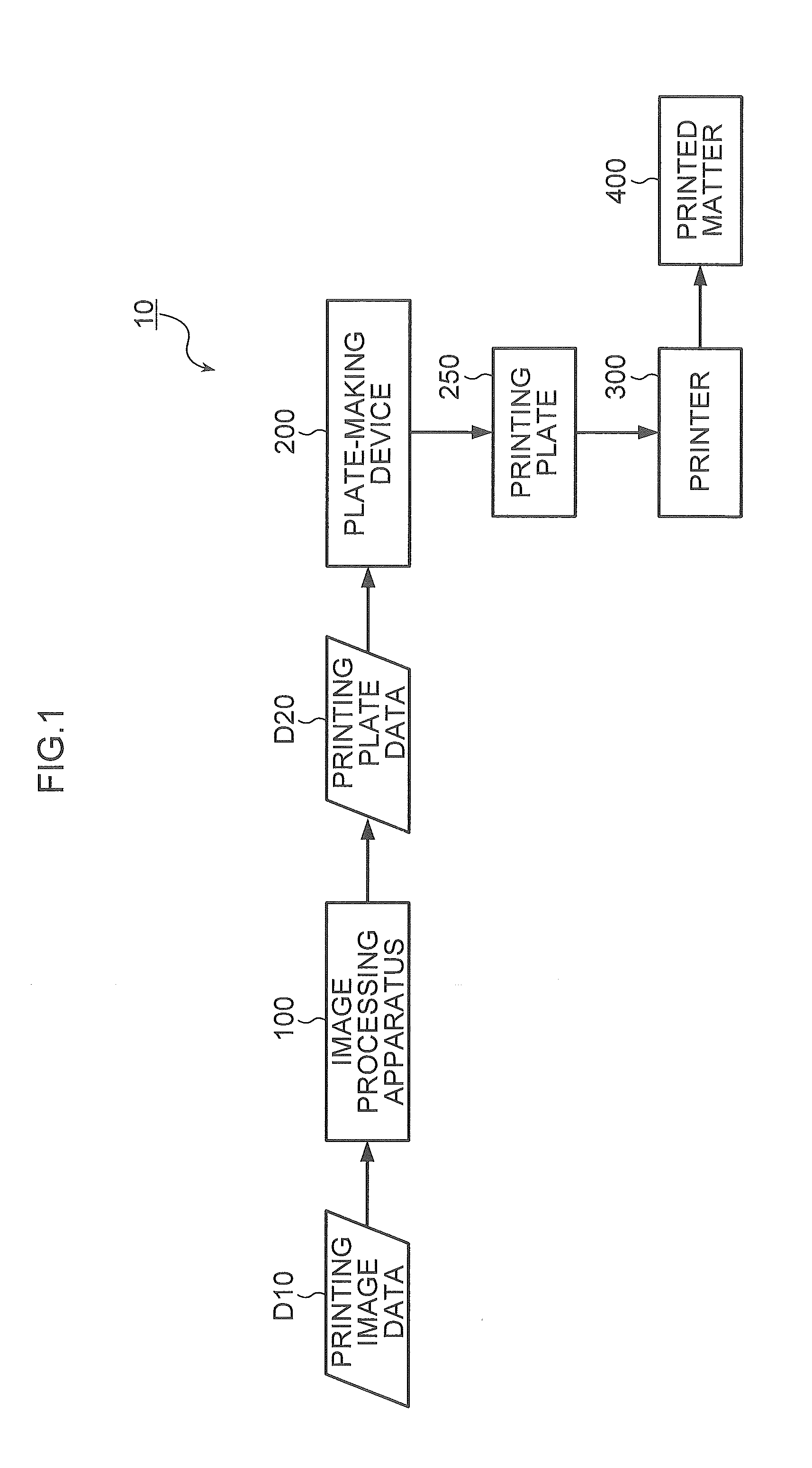

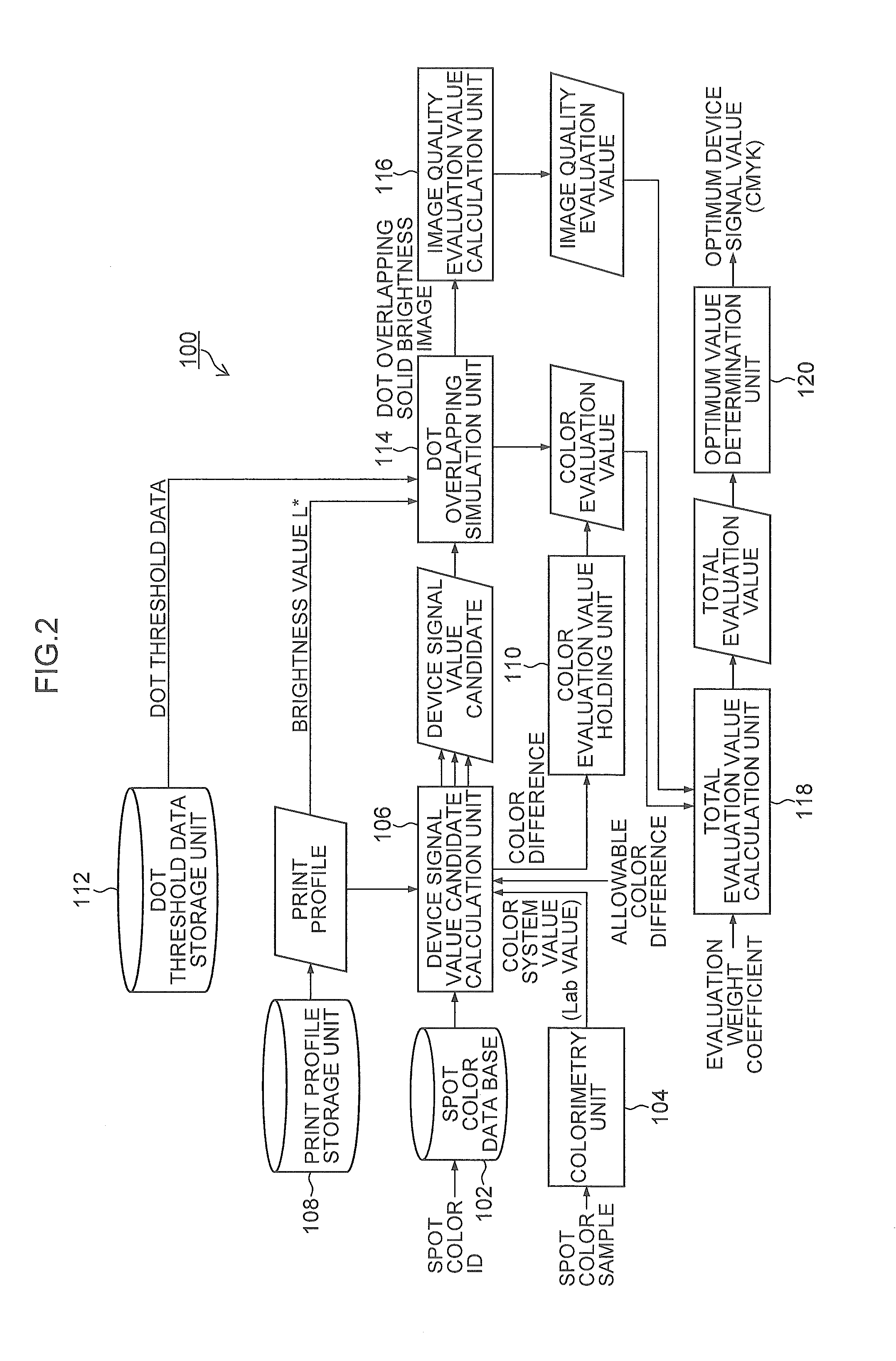

Color separation apparatus, color separation method, and non-transitory computer-readable medium

ActiveUS9055264B2Easy to implementInhibition formationPictoral communicationAlgorithmComputer graphics (images)

A color separation apparatus comprising: a target value acquisition device; a dot threshold data candidate selection device; a print profile acquisition device which acquires a print profile showing correspondence between device signal values and color system values in the printer for each of the candidates of dot threshold data; and a color separation device which allows the printer to calculate candidates of the device signal values on the basis of the target values of colors acquired by the target value acquisition device and the print profile, and determines dot threshold data for reproducing colors corresponding to the target values on the basis of the candidates of dot threshold data and the print profile from among the candidates of dot threshold data, as well as determines device signal values for reproducing colors corresponding to the target values from among the candidates of device signal values.

Owner:FUJIFILM CORP

Fixing device for image forming apparatus and control method thereof

InactiveUS7580649B2Evenly meltedWithout losing convenienceElectrographic process apparatusImage formationMechanical engineering

A fixing device of this invention enables variable control of power to be supplied to a heat roller side or a press roller side in accordance with the temperature of the heat roller and the press roller while each mode is carried out. The heating range of a first induction heating coil on the heat roller side and the heating range of a first halogen lamp heater on the press roller side are set differently. In a copy mode, the temperature of the heat roller and the press roller is controlled in detail, and also controlled in accordance with the size of a sheet paper. In a copy standby mode, only the power required for maintaining a set temperature is supplied.

Owner:KK TOSHIBA +1

Production technology for indigo cotton yarn

The invention discloses a production technology for indigo cotton yarn. The production technology comprises the steps of blowing, carding, first drawing, second drawing, third drawing, roving, spinning and post processing, and specifically comprises the steps that firstly, indigo dye coating is molten to be prepared into a leuco body for use; secondly, preprocessed cotton is put into the indigo dye coating, the temperature is increased to 35 DEG C at a speed of 3 DEG C / min, temperature keeping is conducted for 30 min, the temperature is increased to 120 DEG C at a speed of 2 DEG C / min, dyeing continues to be conducted for 20 min, the temperature is decreased to 40 DEG C at a speed of 3 DEG C / min, and the cotton is taken out; thirdly, blowing, carding, first drawing, second drawing, third drawing, roving and spinning are conducted on the dyed cotton so that the cotton can be spun into cotton yarn for use; fourthly, post processing is conducted on the dyed cotton yarn, and post processing comprises drafty oxidation for 5 min, soaping and stoving, soap washing liquor is formed by adopting anhydrous sodium carbonate of 2 g / L and standard soap flakes of 5 g / L, the temperature is 60 DEG C, time is 20 min, and soap boiling, washing and stoving are conducted on the oxidized fabric.

Owner:源兴纺织(深圳)有限公司

Fixing device for image forming apparatus and control method thereof

InactiveUS20080260407A1Evenly meltedNot lose convenienceElectrographic process apparatusImage formationEngineering

Owner:KK TOSHIBA +1

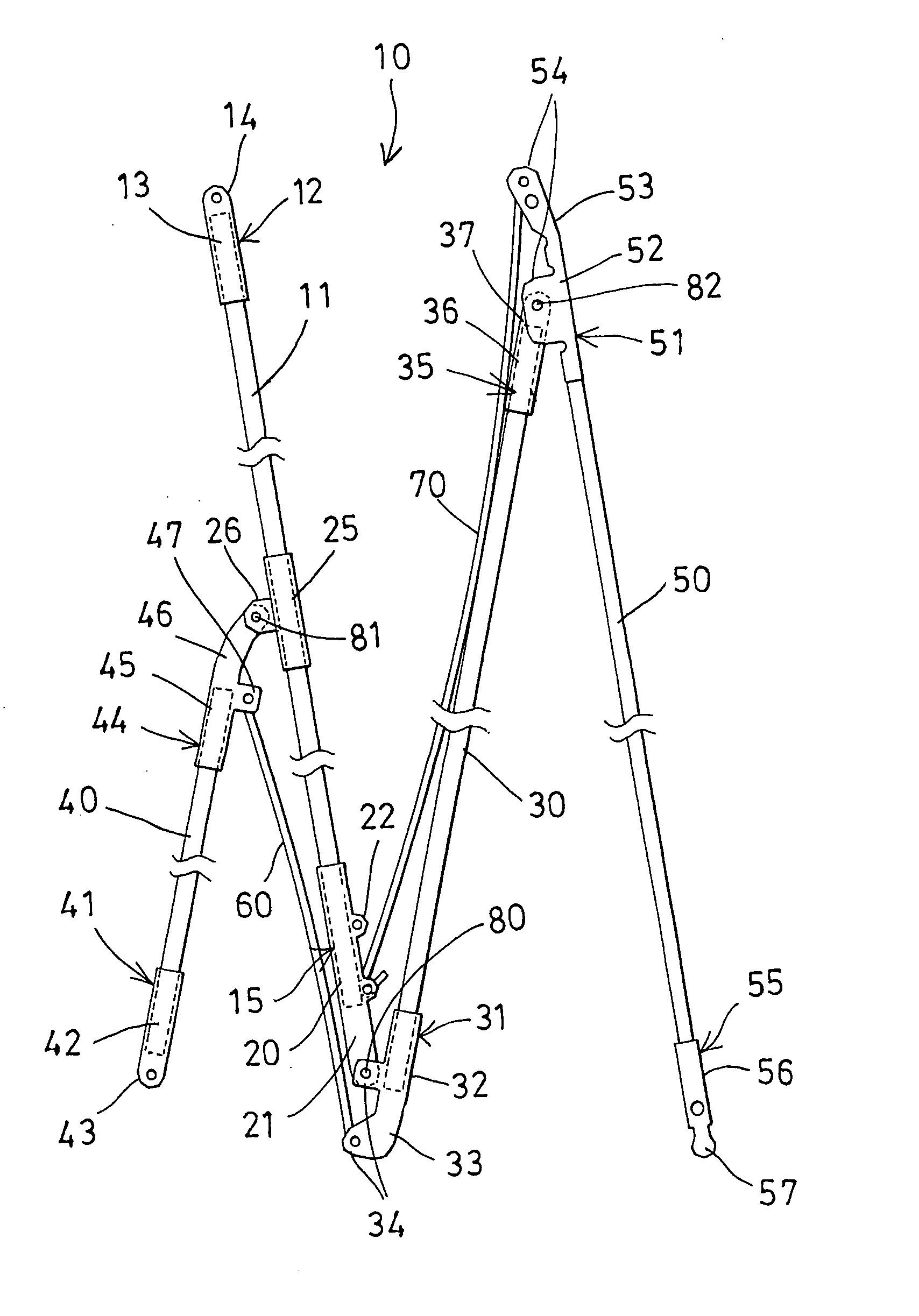

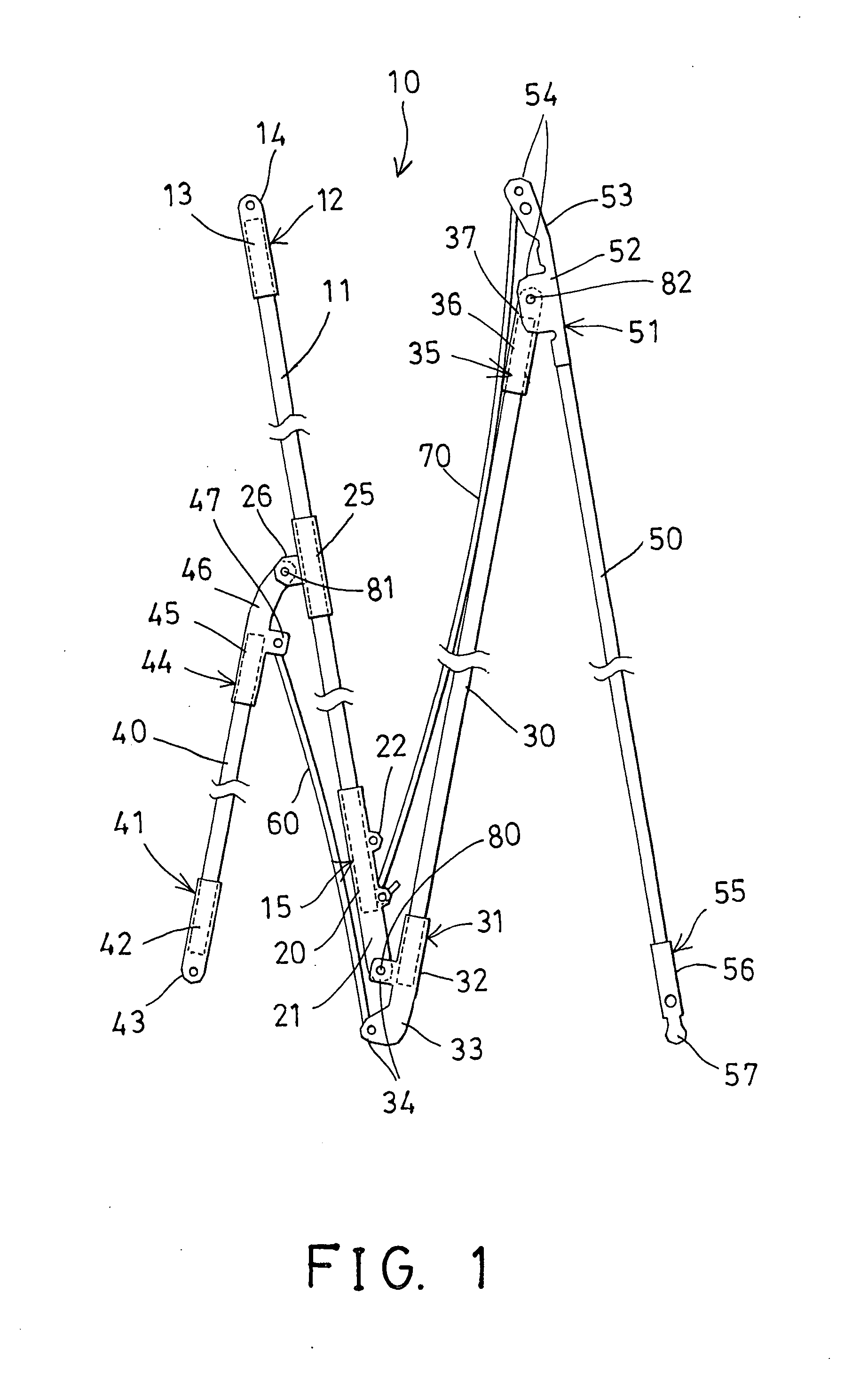

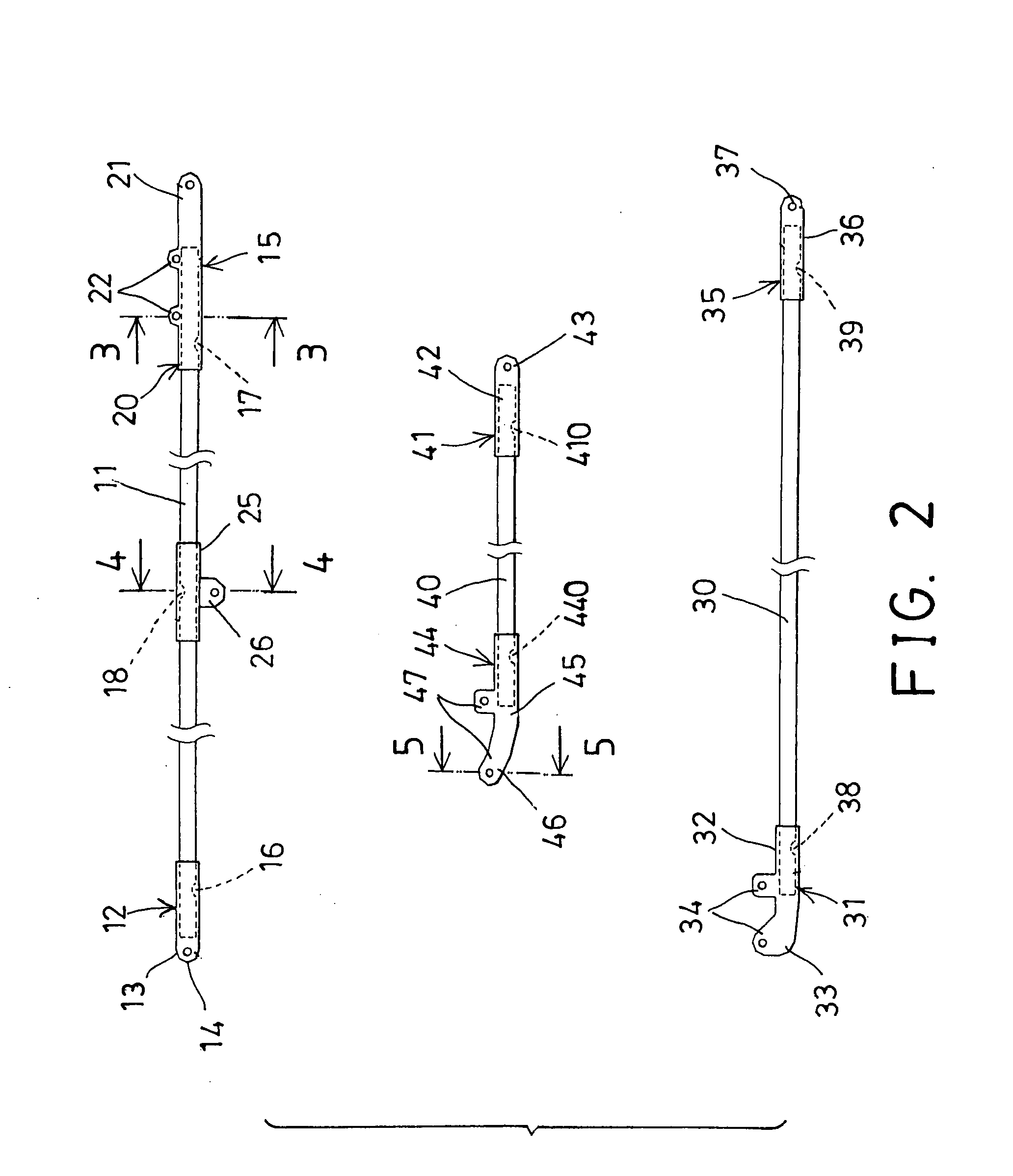

Umbrella having protected stave assembly

InactiveUS20070204894A1Avoid damageAvoid color differencesWalking sticksUmbrellasEngineeringMechanical engineering

A strut device for an umbrella includes an upper stave, a main stave having an inner end portion pivotally coupled to an outer end portion of the upper stave, a lower stave having an outer end portion pivotally coupled to the upper stave with a stave support, and an outer stave having an inner end portion pivotally coupled to the outer end portion of the main stave, the staves are made of a fiber reinforcing material, a number of couplers are attached onto the end portions of the staves and each has a metal member engaged onto the end portions of the staves, and an outer covering attached onto the metal member for covering and protecting the metal member and for preventing the couplers from scraping or damaging the canopy.

Owner:HUANG LU TSAI

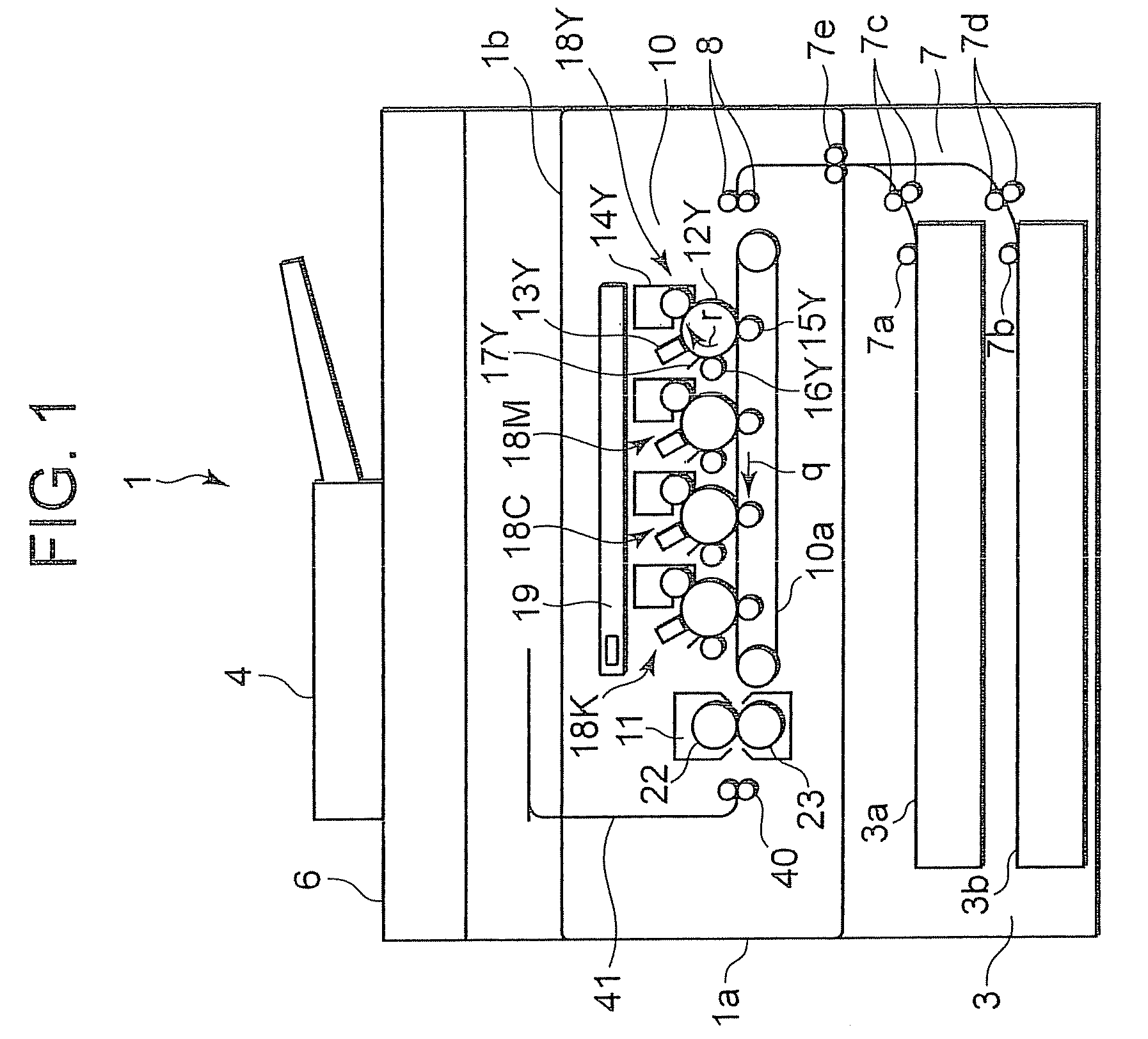

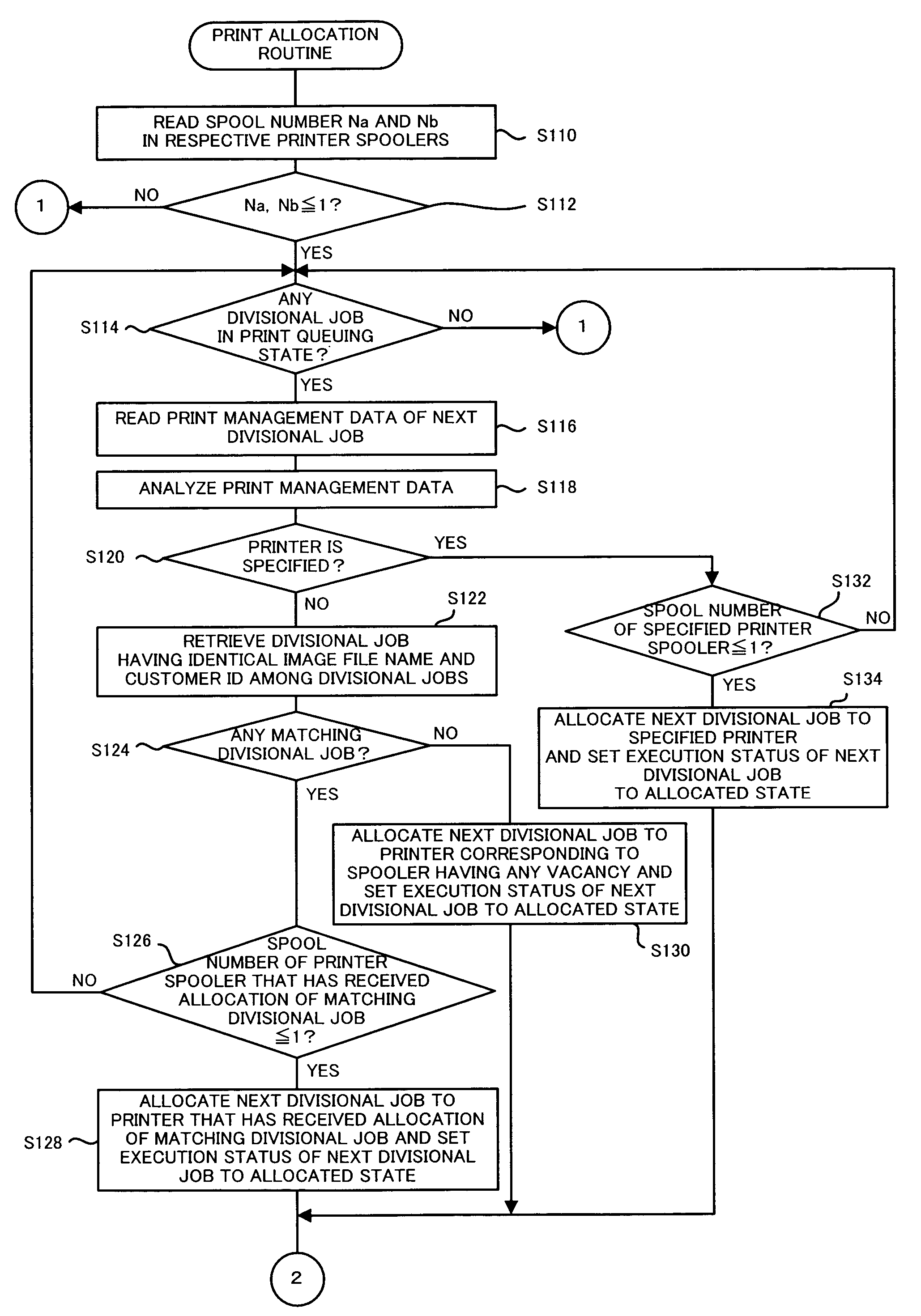

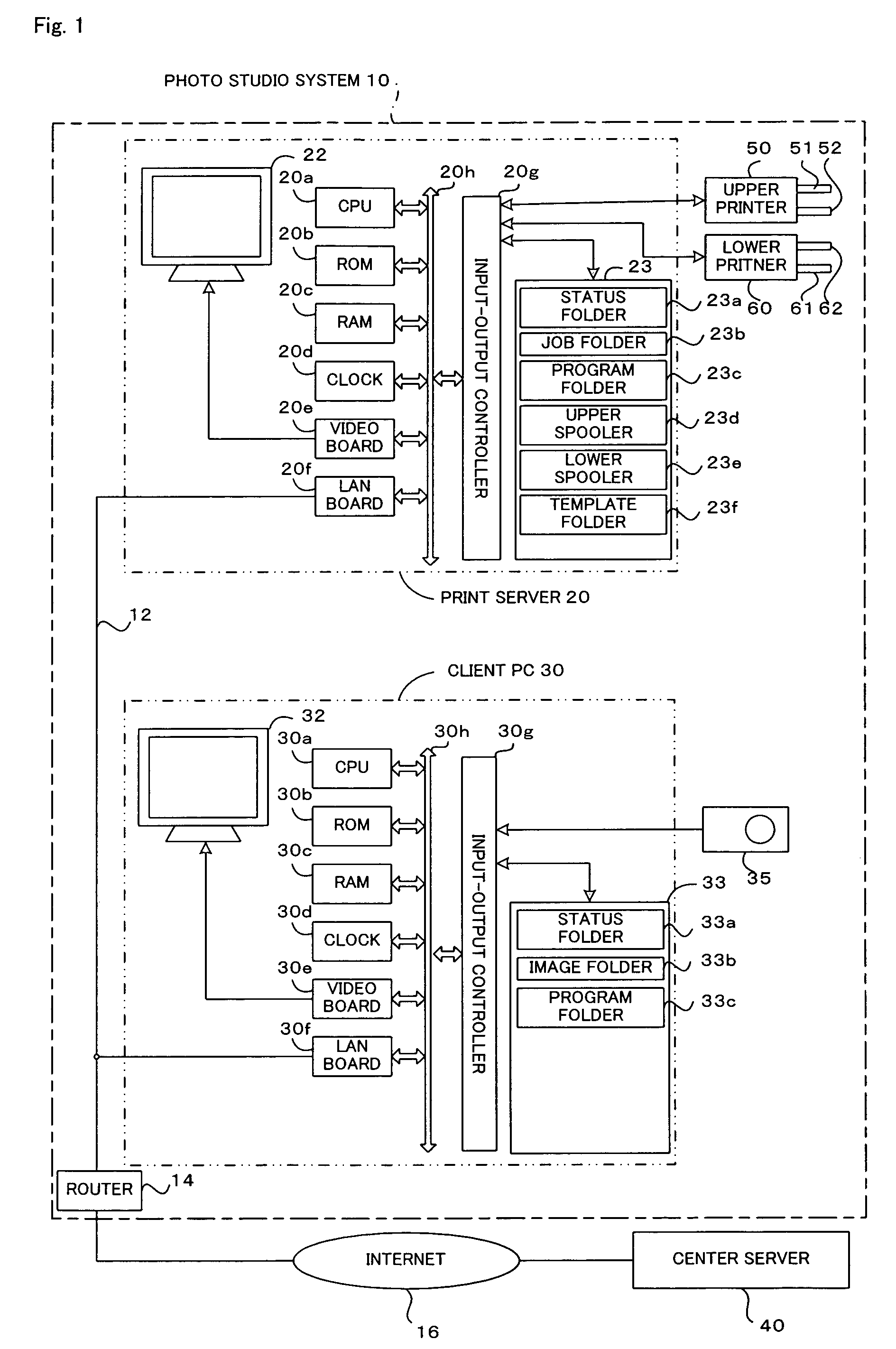

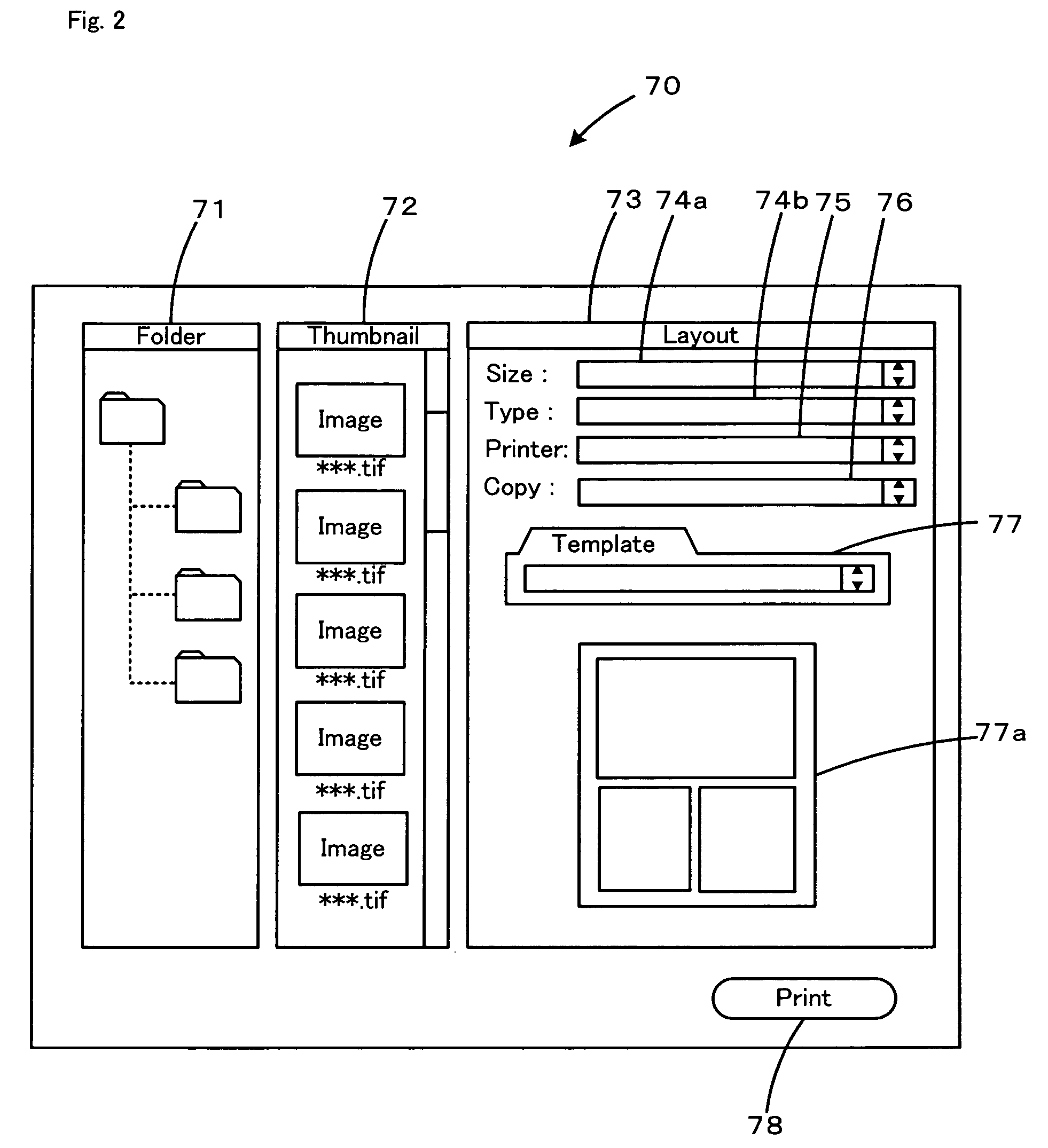

Print management system and print management method

InactiveUS7706027B2Less sense of dissatisfactionEffective distributionTelevision system detailsProgram initiation/switchingDatabaseManagement system

Each print job received from a client computer 30 is divided into minimum printing units as divisional jobs, which are stored in a job folder 23b. When either of an upper spooler 23d and a lower spooler 23e has any vacancy for next allocation, one divisional job is allocated to a printer corresponding to the spooler having the vacancy. The name of the printer that has received allocation of the divisional job is written into the job folder 23b. When any allocated divisional job having an identical image file name and an identical customer ID with those of a current object divisional job is present in the job folder 23b, the current object divisional job is allocated to the printer, to which the allocated divisional job has been allocated. This arrangement allocates multiple divisional jobs for printing an identical image demanded from an identical customer to the same printer, thus ensuring substantially equal quality of resulting printed images.

Owner:SEIKO EPSON CORP

A method and device for inter-image color correction

ActiveCN102542548BAvoid color differencesThe correction effect is stableImage enhancementColor correctionLinear relationship

The invention discloses a method for correcting color between images. The method comprises the steps of inputting two images including a first image and a second image having a common public area; determining the linear relationship on a color channel between the first image and the second image by respectively acquiring the color average value of the color channel in the common area of the first image and the second image; and correcting the color value of pixels on the full image of the first image or the second image according to the linear relationship. The invention also discloses a device for correcting color between images. The method and the device provided by the invention can solve the consistency problem of illumination and color tone in panoramic image generation, image registration and image fusion, and can be specifically used in picture processing software of PC (personal computer) terminal, mobile phone and tablet PC, with the advantages of stable correction effect and wide application.

Owner:WONDERSHARE TECH CO LTD

Fixing device for image forming apparatus to control power of heating source

InactiveUS7623802B2Evenly meltedWithout losing convenienceElectrographic process apparatusControl powerImage formation

Owner:KK TOSHIBA +1

Lighting system and projection device

A lighting system comprises a first excitation light source, a wavelength conversion wheel and a filter wheel, wherein the first excitation light source is used for emitting a first excitation light beam; the wavelength conversion wheel comprises a wavelength conversion area and a first optical area; the wavelength conversion area and the first optical area cut into the transmission path of the first excitation light beam in turn; when the wavelength conversion area cuts into the transmission path of the first excitation light beam, the first excitation light beam is converted into a conversion light beam by the wavelength conversion area, and when the first optical area cuts into the transmission path of the first excitation light beam, the first excitation light beam is outputted from the first optical area; the filter wheel is arranged on a transmission path of the converted light beam and the first excitation light beam from the wavelength conversion wheel; the filter wheel comprises a first area, a second area and a blocking area; and the angle covered by the second area in the circumferential direction is smaller than the angle covered by the first optical area. A projectiondevice is also provided. The projection device using the lighting system avoids color differences in a simple manner.

Owner:CORETRONIC

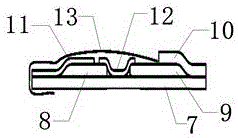

Transparent touch panel

ActiveCN103425319AImprove performanceIncrease contact areaInput/output processes for data processingTouch panelRandom grid

A transparent touch panel comprises a first transparent covering layer, an induction layer and a second transparent covering layer which are sequentially connected. The induction layer comprises a first substrate, a first imprinting adhesive layer, a first conducting layer, a tackifying layer, a second substrate, a second imprinting adhesive layer and a second conducting layer which are sequentially connected; the first imprinting adhesive layer is provided with a first network-cable-shaped groove to form into first grids; the first conducting layer comprises conducting materials which are arranged inside the groove and a first lead electrode which is connected with the conducting materials; the second imprinting adhesive layer is provided with a second network-cable-shaped groove to form into second grids; first grids are regular grids and second grids are random grids; the first network-cable-shaped groove and the edge line of the first network-cable-shaped groove are curved lines or fold lines which enables the contact areas between the conducting materials and the groove edges to be enlarged; the second conducting layer comprises the conducting materials which are arranged inside the groove and a second lead electrode which is connected with the conducting materials. The transparent touch panel can maintain good performance due to the fact that the friction force is increased due to the contact area between the conducting materials and the groove is enlarged.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

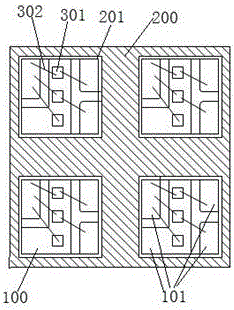

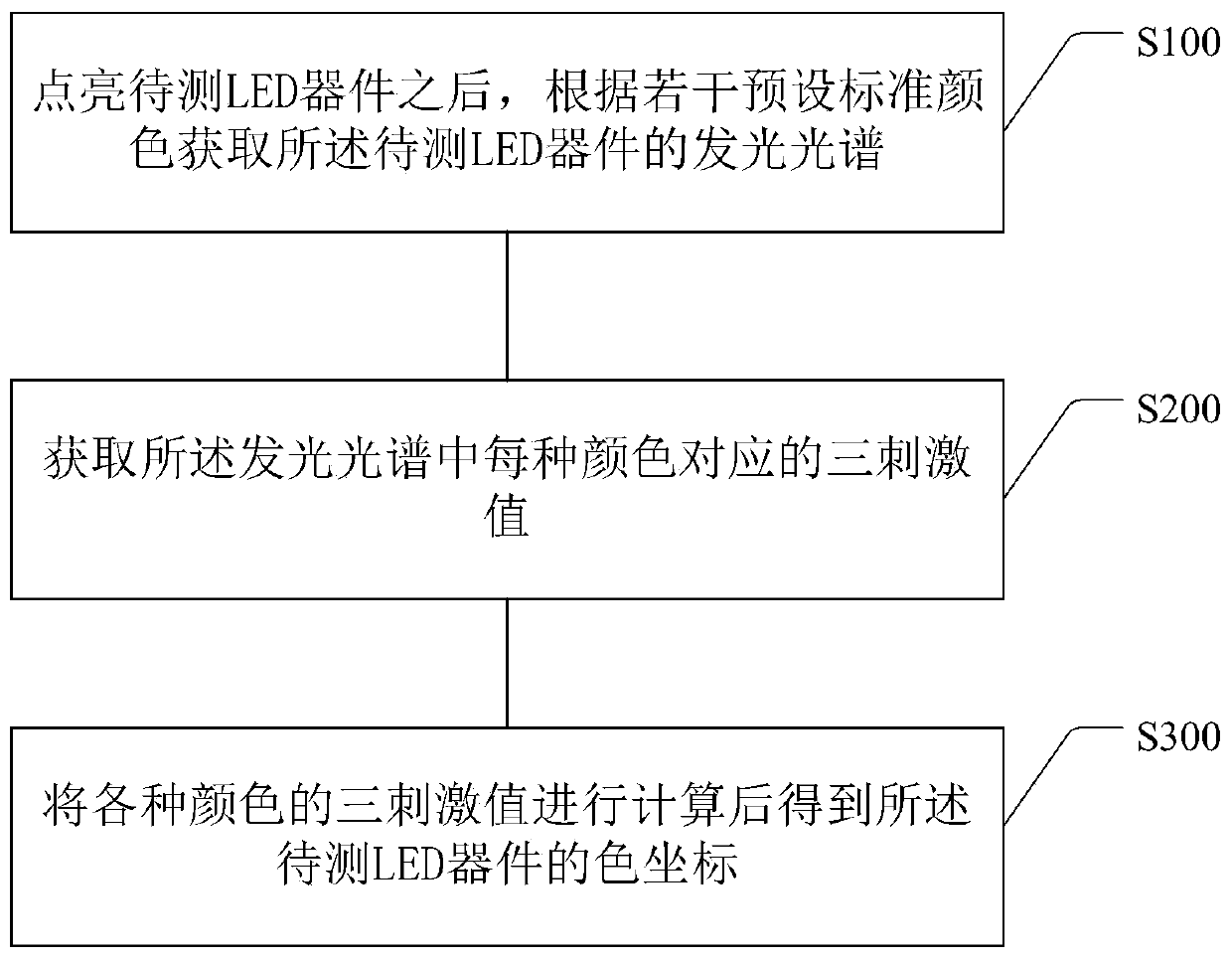

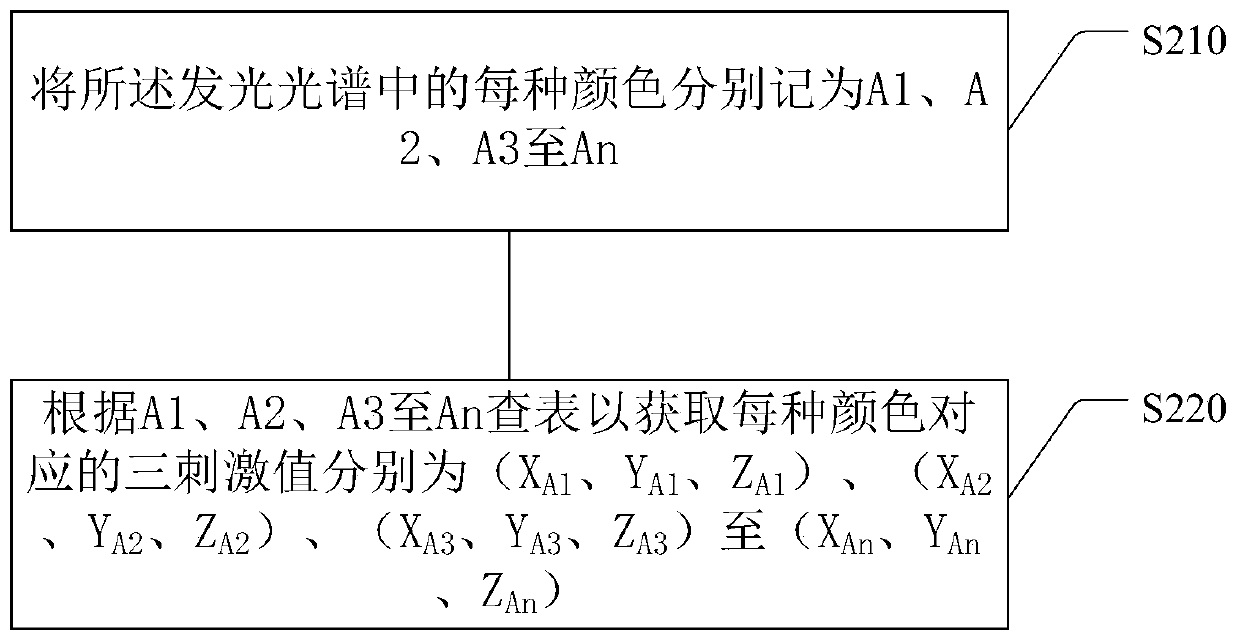

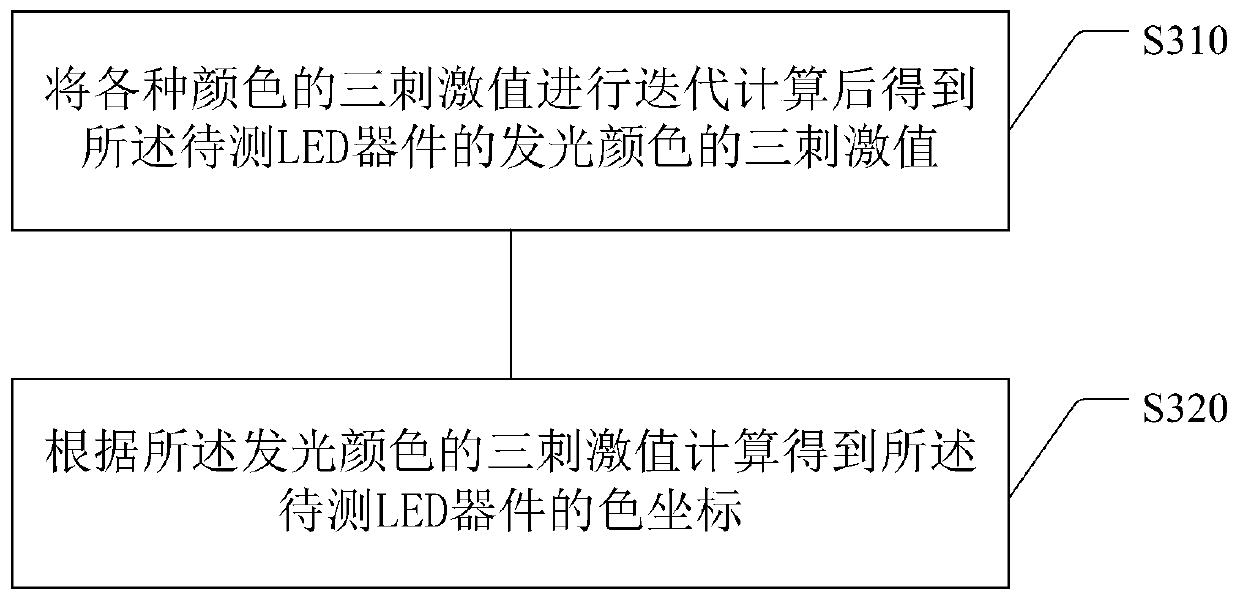

Color separation method and system of LED device

ActiveCN111122125AImprove accuracySolve the problem of inaccurate color coordinatesTesting optical propertiesMaterials scienceColor difference

The invention discloses a color separation method and system for an LED device, and the method comprises the steps: obtaining a luminescence spectrum of a to-be-detected LED device according to a plurality of preset standard colors after the to-be-detected LED device is lightened; obtaining a tristimulus value corresponding to each color in the luminescence spectrum; and calculating the tristimulus values of various colors to obtain color coordinates of the to-be-detected LED device. According to the method, the problem that the obtained color coordinates of the LED device are inaccurate can be solved, color differences of products of the same batch in use are avoided, and the accuracy of color coordinate calculation is improved.

Owner:SHENZHEN RUNLITE TECH

Color separation apparatus, color separation method, and non-transitory computer readable medium

ActiveUS9083921B2Easy to implementInhibition formationPictoral communicationComputer graphics (images)Continuous tone

A color separation apparatus comprising: a target value acquisition device; a dot threshold data acquisition device which acquires dot threshold data including information on a threshold for each of the dots for converting the continuous-tone image data into binary image data for each of the color materials; a print profile acquisition device which acquires a print profile showing correspondence between a device signal value and a value of a color system in the printer; and a color separation device which allows the printer to calculate candidates of the device signal value on the basis of the target values of colors acquired by the target value acquisition device and the print profile, and determines a device signal value for reproducing colors corresponding to the target values from among the candidates of the device signal value on the basis of the dot threshold data and the print profile.

Owner:FUJIFILM CORP

Colored polymer cement underwater paint

The invention belongs to the field of underwater paint, and specifically relates to colored polymer cement underwater paint, which consists of powder materials and liquid materials. The powder materials comprise 1-4 parts of inert inorganic powder materials, 0.001-0.01 part of pigment, 0.5-1 part of aqueous solution containing 10%-20% of polymer emulsion, 1-7 parts of cement and 0.002-0.01 part of dispersing agent, and the liquid materials comprise 0.5-0.9 part of polymer emulsion, 0.1-0.5 part of water and 0.01-0.003 part of defoaming agent. According to the colored polymer cement underwater paint, the pigment is attached to the surface of the inorganic powder materials to form a color powder material; the surface of the color powder material is coated with one layer of insoluble polymer films, so that the paint only shows the color of the powder materials; the colored polymer cement underwater paint has the advantages that the agitation can be implemented manually on the spot and the shelling-out color is uniform; the color difference of common double-component paint brought about due to different dosing proportions is overcome; and the colorization of the polymer cement underwater paint is achieved really.

Owner:浙江鲁班建筑防水有限公司

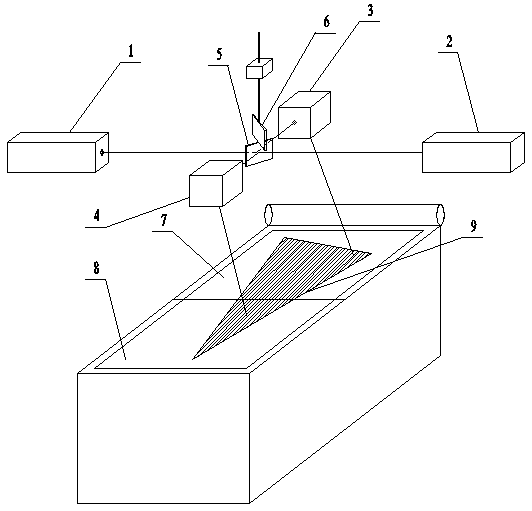

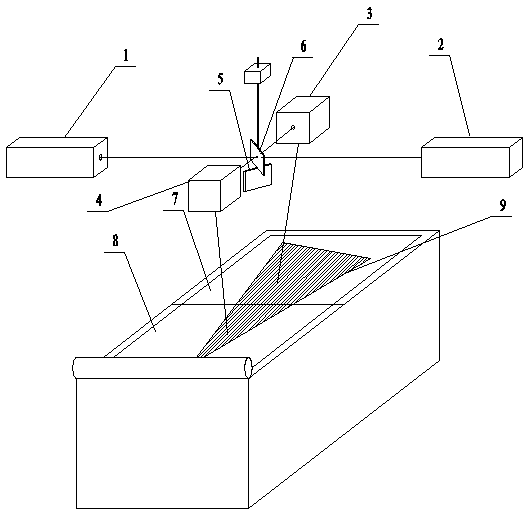

Scanning system, method and three-dimensional object manufacturing equipment for manufacturing three-dimensional objects

ActiveCN106041083BAvoid color differencesImprove sintering qualityAdditive manufacturing apparatusIncreasing energy efficiencyComputer moduleOptoelectronics

A scanning system, method, and three-dimensional object manufacturing equipment for manufacturing a three-dimensional object, the scanning system includes a first laser, a second laser, an optical path adjustment unit, and a control unit, and the control unit includes: a first scanning control module for receiving When the scan instruction is reached, the laser light emitted by the first laser is scanned and sintered in the first area under the adjustment of the optical path adjustment unit, and at the same time, the laser light emitted by the second laser is scanned and sintered in the second area under the adjustment of the optical path adjustment unit; and The second scanning control module is used to scan and sinter the second area with the laser light emitted by the first laser under the adjustment of the optical path adjustment unit after the preset number of layers is scanned and sintered, and at the same time, the second area is scanned and sintered. The laser light emitted by the second laser scans and sinters the first area under the adjustment of the optical path adjustment unit. The invention enables a certain corresponding area to scan and sinter by switching different lasers, thereby improving the sintering quality of three-dimensional object parts.

Owner:HUNAN FARSOON HIGH TECH CO LTD

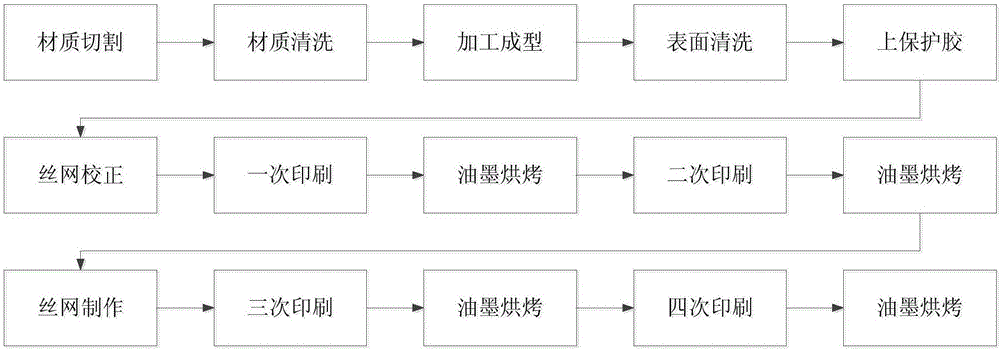

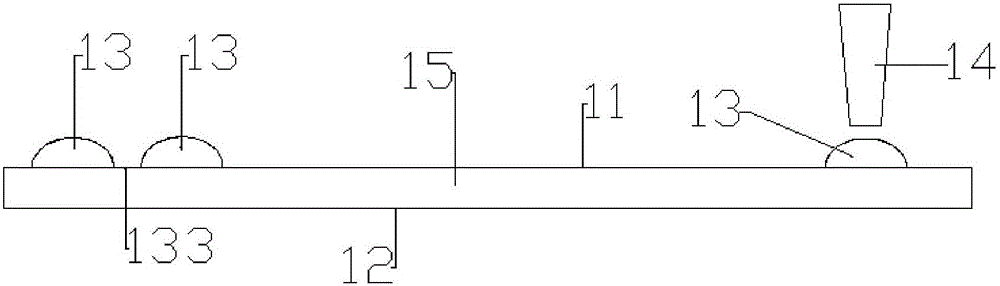

A kind of protection device and manufacturing method

ActiveCN103809695BAvoid color differencesAvoid the problem of material deformation and discolorationDigital data processing detailsInput/output processes for data processingCooking & bakingEngineering

The invention discloses a protection device and a manufacturing method thereof, and belongs to the technical field of touch screen protection. The protection device comprises a transparent protective layer structure, a protection gap and a bulge part; the protective layer structure is arranged between a housing and a touch screen; the protection gap is arranged between the protective layer structure and the touch screen or between the protective layer structure and the housing; the bulge part is arranged on one side, facing the housing or the touch screen, of the protective layer structure through 3D printing; at least one group of bulges of the bulge part are perpendicular to the protective layer structure; the bulge part is used for forming the protection gap; the bulge part is used for enabling an outline projected on the protective layer structure to form a preset pattern. The protection device and the manufacturing method, which adopt the technical scheme, have the benefits that the color difference problem and the material discoloration and deformation problem due to baking are avoided, and the protection gap between the protection device and the touch screen / the housing is limited effectively.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Mycotoxin test paper

InactiveCN106248926AAvoid color differencesUniform flow rateBiological material analysisMycotoxinEngineering

The invention discloses a piece of mycotoxin test paper, and belongs to the field of test paper. The mycotoxin test paper comprises a base body arranged at the bottom. A test pad is arranged in the middle on the base body and is in an annular shape. An anti-overflowing pad is arranged on one side of the test pad. A sample soaking pad is arranged on the other side of the test pad. The edge of the upper end of the test pad coats the upper surfaces of the anti-overflowing pad and the sample soaking pad. The upper surface of the anti-overflowing pad is coated with a developing membrane. The upper surface of the sample soaking pad is coated with a sample absorption strip which is connected with an induction region. The mycotoxin test paper has the advantages that use is convenient, the test paper is rapid and sensitive, no complex pretreatment needs to be performed on samples, whether samples contain ochratoxin or not can be detected rapidly, the test sensitivity is high, and the test limit can reach 1.4 ng / mL.

Owner:成都测迪森生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com