Transparent touch panel

A touch panel, transparent technology, applied in the input/output process of instruments, electrical digital data processing, data processing, etc., can solve the problem of affecting the performance of conductive films, poor adhesion of conductive layers, and unstable adhesion of metal grids And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

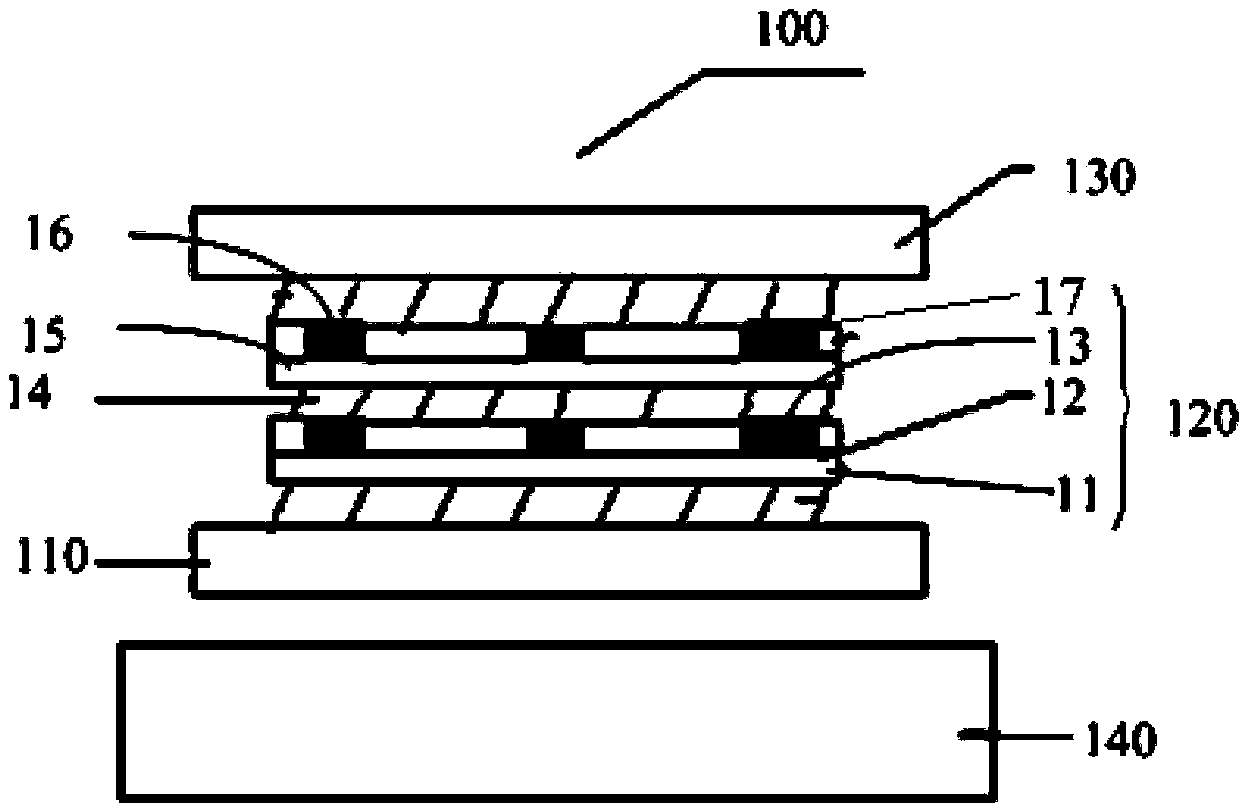

[0052] Such as figure 1 A cross-sectional view of the transparent touch panel 100 shown, the transparent touch panel 100 includes a first transparent cover layer 110 , a sensing layer 120 and a second transparent cover layer 130 from top to bottom.

[0053] The first transparent cover layer 110 is used to connect the display 140 .

[0054] The sensing layer 120 is bonded on the first transparent covering layer 110 by an adhesive. The sensing layer 120 includes a first substrate 11 , a first embossed adhesive layer 12 , a first conductive layer 13 , an adhesion-promoting layer 14 , a second substrate 15 , a second embossed adhesive layer 16 and a second conductive layer 17 connected in sequence.

[0055] The first base 11 is made of PET material, the thickness of the base 11 is 188 μm, and it is transparent.

[0056] The first embossed adhesive layer 12 is disposed on the first substrate 11 . The first embossed adhesive layer 12 is made of UV embossed adhesive material, and ...

Embodiment 2

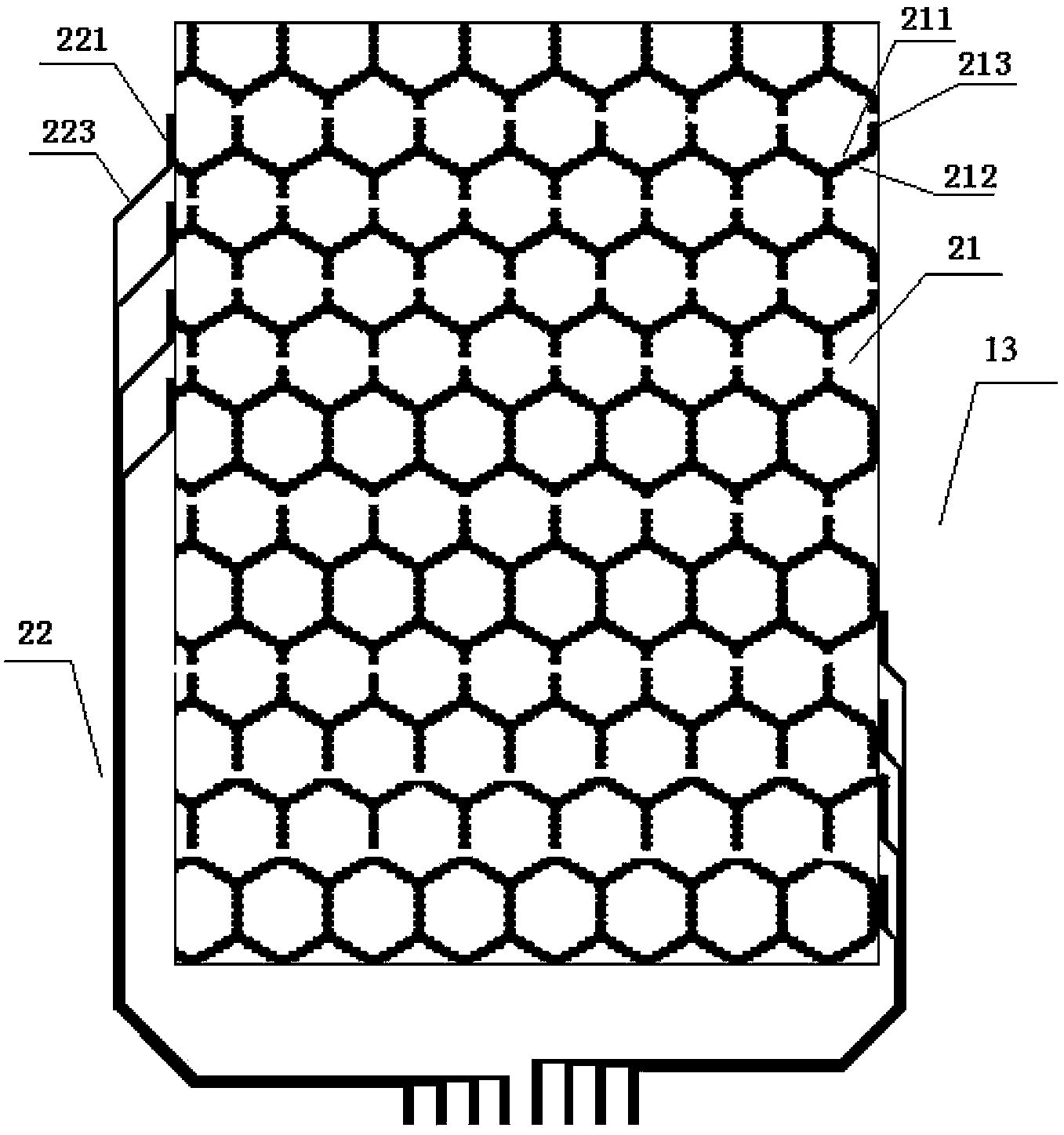

[0071] Such as Figure 4 Shown is a cross-sectional view of the transparent touch panel 200 of this embodiment. The transparent touch panel 200 includes a first transparent cover layer 210 , a sensing layer 220 and a second transparent cover layer 230 from bottom to top.

[0072] The first transparent covering layer 210 is used for connecting the display 240 .

[0073] The sensing layer 220 is glued on the first transparent covering layer 210 . The sensing layer 220 includes a first conductive layer 43 , a first embossed adhesive layer 42 , a base layer 41 , a second embossed adhesive layer 44 and a second conductive layer 45 which are sequentially connected.

[0074] The base layer 41 is arranged in the middle of the two conductive layers. The material of the base 41 is PET, and the thickness of the base 41 is 188 μm.

[0075] The first embossed rubber layer 42 is disposed on the lower surface of the base 41 , and the first network-shaped groove is formed by embossing the ...

Embodiment 3

[0084] Such as Figure 6 Shown is a schematic cross-sectional view of the transparent touch panel 300 of this embodiment, which includes a first transparent covering layer 310 , a sensing layer 320 and a second transparent covering layer 330 from bottom to top.

[0085] The first transparent cover layer 310 is used to connect with the display 340 .

[0086] The sensing layer 320 is connected with the first transparent covering layer 310 and the second transparent covering layer 330 through an adhesive. The sensing layer 320 includes a substrate 71 , a first conductive layer 72 , an isolation layer 73 and a second conductive layer 74 connected in sequence.

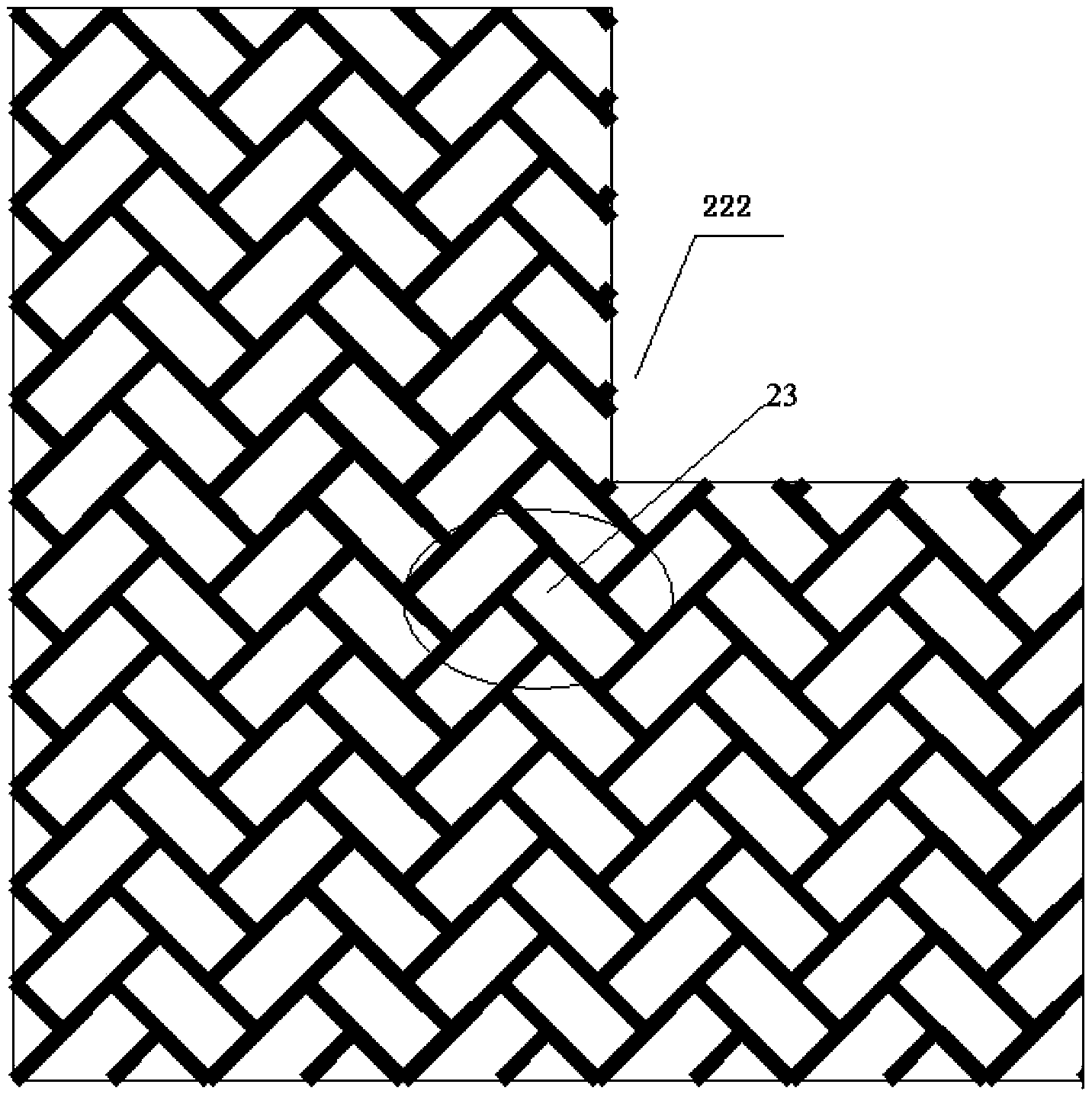

[0087] The material of the base 71 is PET, and the thickness of the base 71 is 188 μm, which is transparent. On the substrate 71 , a first network linear groove is formed by embossing, the depth of the groove is 3 μm, and the width is 2.2 μm. The first grid formed by the first network linear groove is a regular grid.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com