Encapsulation module for surface mounted RGB-LED (Red, Green, Blue-Light Emitting Diode) and manufacturing method thereof

A technology of RGB-LED and manufacturing method, which is applied in the direction of identification devices, instruments, semiconductor devices, etc., can solve the problems of low mechanical strength of products, high production difficulty, low production efficiency of SMD RGB LEDs, etc., to improve the resistance to external mechanical strength. Ability, low maintenance cost, not easy to be corroded by water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

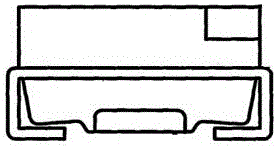

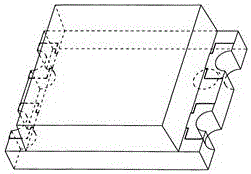

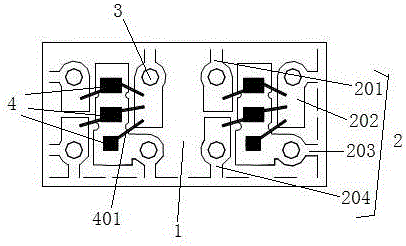

[0058] see image 3 - Fig. 8 is a 1*2 surface mount RGB LED packaging module provided by the present invention. The packaging module has two light emitting units. In actual production, such as Figure 4 and Figure 7 As shown, an isolation frame 9 may also be provided around the light emitting units to reduce the influence between the light emitting units. Preferably, as Figure 5 As shown, on the reverse side of the substrate 1, an identification area 101 may be provided in the middle of each light-emitting unit to facilitate subsequent testing and packaging equipment to identify the front and back sides of the packaging module. Such as Figure 6 and Figure 7 As shown, a protective layer 8 can also be provided on the light-emitting unit. The protective layer 8 is preferably a translucent epoxy resin adhesive layer with a diffusing agent. The setting of the protective layer 8 can prevent the entry of water vapor and prevent components from subject to mechanical damage....

Embodiment 2

[0060] see Figure 9-Figure 1 1. It is a 1*3 surface-mounted RGB LED package module provided by the present invention, and the package module has three light-emitting units. The structure of the light-emitting unit is the same as that of the light-emitting unit in Embodiment 1. Such as Figure 11a and Figure 11b As shown, 24 light-emitting units are arranged on the substrate 1, distributed in 4 rows and 6 columns. Such as Figure 11b As shown, the cutting line 7 divides the substrate 1 into eight packaging modules, and the plating circuit 6 is also arranged on the cutting line 7 . All the plating circuits 6 in this embodiment are arranged on the front side of the substrate 1 . All the upper pads 2 are connected to the nearby electroplating circuit 6 at the position of the cutting line 7 through the electroplating circuit 6. When cutting the substrate 1, all the electroplating circuits 6 at the position of the cutting line 7 are cut off. The disks 2 are thus independent o...

Embodiment 3

[0062] Figure 12-Figure 14 Another 1*3 surface-mounted RGB LED package module provided by the present invention has three light-emitting units on all package modules, but the arrangement of the light-emitting units is different from that in Embodiment 2. In this embodiment, the three light emitting units are arranged in an inverted "L" shape, and the present invention does not limit the arrangement of the light emitting units. Such as Figure 14 As shown, the electroplating circuit of this embodiment is arranged on the front of the substrate 1, and the position of the cutting line 7 also has the electroplating circuit 6, and all the upper pads 2 are electrically connected to the electroplating circuit 6 at the position of the cutting line 7. For the specific connection method, This embodiment is not limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com